Method for improving recovery rate of nitric acid in glucurolactone production

A technology for improving the recovery rate of glucuronolactone, which is applied in the field of improving the recovery rate of nitric acid in the production of glucuronolactone, can solve problems such as nitrogen oxide gas pollution, achieve simplified processes, reduce production costs, reduce equipment investment costs and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]

[0027] Specific examples of the present invention are provided below, but should not be limited to the following examples:

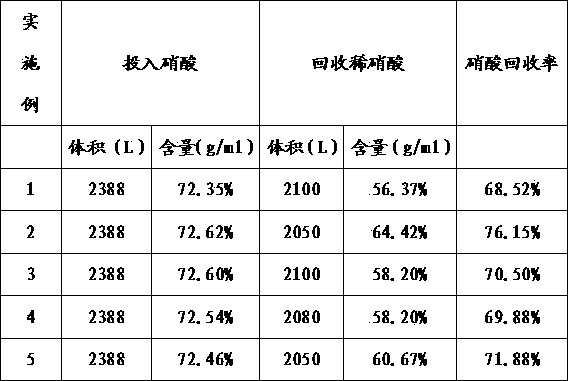

[0028] Example of recovery of nitric acid from nitrogen oxide gas in the production process of glucuronolactone:

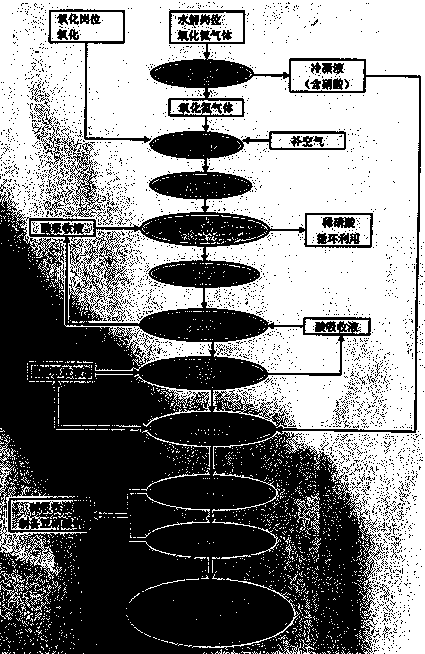

[0029] according to figure 1 The process shown is carried out.

[0030] (1) The nitrogen oxide gas produced by the hydrolysis reaction in the production process of glucuronide is washed by a circulating scrubber, and the temperature of the circulating scrubbing water is controlled between 20-50 °C, and the high-temperature water in the nitrogen oxide gas produced by the hydrolysis reaction is The steam is condensed into the circulating scrubbing water;

[0031] (2) The nitrogen oxide gas produced by the hydrolysis reaction after the cycle scrubbing is mixed with the nitrogen oxide gas produced by the oxidation reaction and passed into the air, and input into the conversion tower, so that the NO in the nitrogen oxide gas and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com