Yellowing-resistant and uvioresistant polyurethane elastomer and preparation method thereof

A polyurethane elastomer, anti-ultraviolet technology, applied in the field of polyurethane, can solve the problems of poor physical and mechanical properties of polyurethane elastomer, anti-yellowing, poor anti-ultraviolet, affecting the service life of products, etc., to achieve low cost and improve ultraviolet shielding performance , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

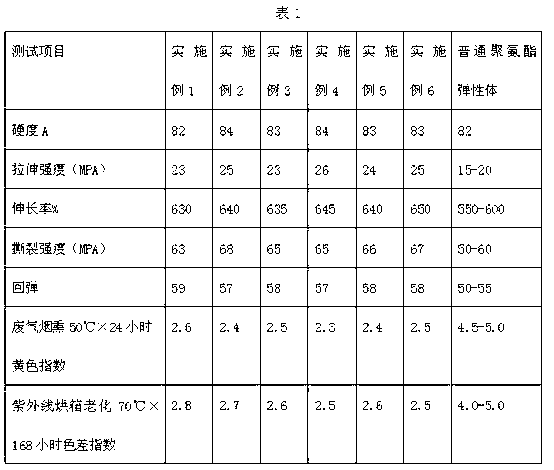

Examples

Embodiment 1

[0054] A kind of preparation method of anti-yellowing, anti-ultraviolet polyurethane elastomer, it comprises following preparation steps:

[0055] Step 1. 70 kg of polyether polyol with a functionality of 2 and a number average molecular weight of 1000, 29 kg of toluene dicyanate, antioxidant (bis[β(3-tert-butyl-5-methyl-4 -Hydroxyphenyl)propionic acid]triethylene glycol ester) 1kg, added to the container in turn, and reacted at 67°C for 2 hours to obtain component A with a mass content of isocyanide of 7.2%;

[0056] Step 2: Add 78 kg of polyether polyol with a functionality of 3 and a number average molecular weight of more than 5000, 20 kg of curing agent diethyltoluenediamine, 1 kg of dipropylene glycol solution of catalyst triethylene diamine, anti-aging agent { 2-(2'-Hydroxy-3',5'-bis[1,1-dimethylphenyl])-benzotriazole)-5-chlorinated benzotriazole} 1kg added to the container in turn , dehydration under the conditions of a temperature of 45°C and a vacuum of -0.095MPa unt...

Embodiment 2

[0059] A kind of preparation method of anti-yellowing, anti-ultraviolet polyurethane elastomer, it comprises following preparation steps:

[0060]Step 1. 65 kg of polyether polyol with a functionality of 2 and a number average molecular weight of 2000, 33 kg of toluene dicyanate, antioxidant (bis[β(3-tert-butyl-5-methyl-4 -Hydroxyphenyl)propionic acid]triethylene glycol ester) 2kg was added to the container in turn, and reacted in the container at 70°C for 3 hours to obtain component A with a mass content of isocyanide of 5.2%;

[0061] Step 2: Add 70 kg of polyether polyol with a functionality of 3 and a number average molecular weight of more than 5000, 28 kg of curing agent diethyltoluenediamine, 0.5 kg of dipropylene glycol solution of catalyst triethylene diamine, anti-aging agent { 2-(2'-Hydroxy-3',5'-bis[1,1-dimethylphenyl])-benzotriazole)-5-chlorinated benzotriazole} 1.5kg was added to the container in turn , dehydration under the conditions of a temperature of 50°C an...

Embodiment 3

[0064] A kind of preparation method of anti-yellowing, anti-ultraviolet polyurethane elastomer, it comprises following preparation steps:

[0065] Step 1. Add 63 kg of polyether polyol with a functionality of 2 and a number average molecular weight of 3000, 35 kg of toluene dicyanate, and an antioxidant (bis[β(3-tert-butyl-5-methyl-4- Hydroxyphenyl) propionate] triethylene glycol ester) 2kg were added to the container in turn, and reacted in the container at 75°C for 2 hours to obtain component A with a mass content of isocyanide of 7.2%;

[0066] Step 2: Add 78 kg of polyether polyol with a functionality of 3 and a number average molecular weight of more than 5000, 20 kg of curing agent diethyltoluenediamine, 1 kg of dipropylene glycol solution of catalyst triethylene diamine, anti-aging agent { 2-(2'-Hydroxy-3',5'-bis[1,1-dimethylphenyl])-benzotriazole)-5-chlorinated benzotriazole} 1kg added to the container in turn , dehydration under the conditions of a temperature of 50°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com