Patents

Literature

133 results about "Diethyltoluene diamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

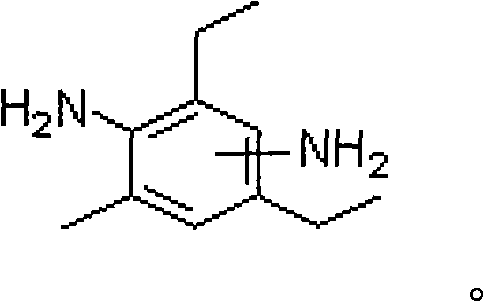

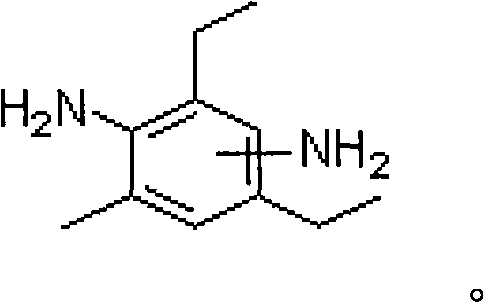

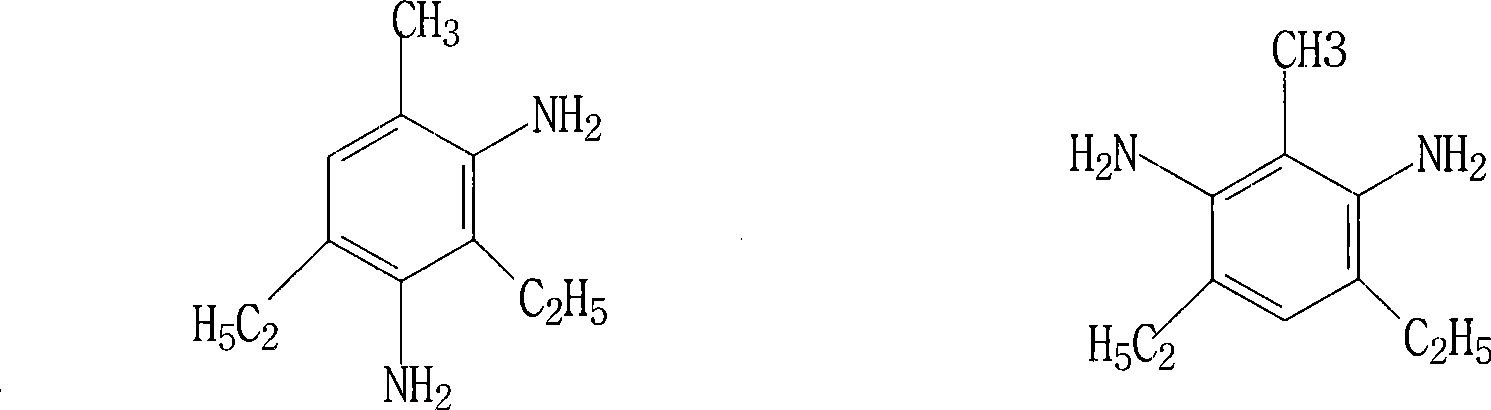

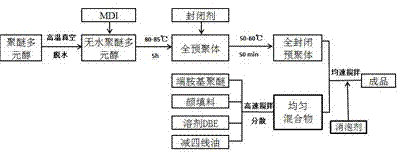

This diethyl toluene diamine is equivalent to Ethancure 100 and Lonza DETDA 80, DETDA is a polyurethane elastomer chain extender is very effective; also can be used as polyurethane and epoxy resin curing agent, epoxy resin, antioxidant, industrial oil and lubricants etc..

Epoxy resin composition as well as bonding sheet and copper-clad plate made from same

InactiveCN101880441AImprove heat resistanceEnhance heat resistance polarityFilm/foil adhesivesSynthetic resin layered productsEpoxyHeat resistance

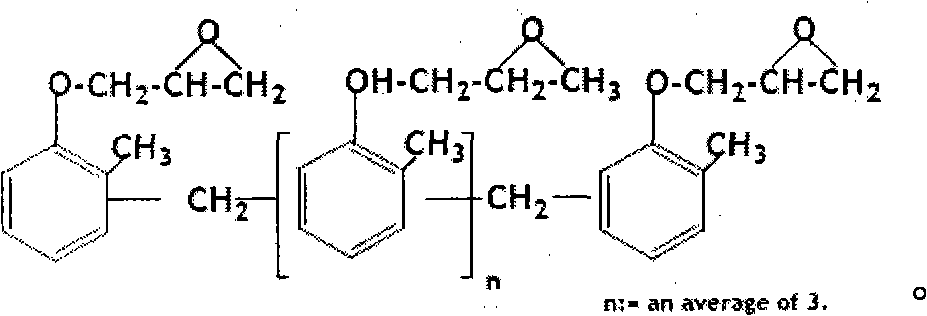

The invention relates to an epoxy resin composition as well as a bonding sheet and a copper-clad plate made from the same. The epoxy resin composition comprises bromine flame-retardant epoxy resin, a curing agent, an imidazole curing accelerating agent and a solvent, wherein the curing agent at least contains diethylmethylbenzenediamine. The bonding sheet made from the resin composition comprises a reinforcing material and a matrix soaked on the reinforcing material, the matrix is the epoxy resin composition. The copper-cladding foil laminating plate made from the resin composition comprises a laminating plate and a copper foil laminated on one side or two sides of the laminating plate, the laminating plate comprises a plurality of mutually bonded bonding sheets, and the bonding sheet is manufactured by adopting the epoxy resin composition. The epoxy resin composition manufactured by adopting o-cresol epoxy resin can effectively improve the heat-resisting property of the product; the compound curing agent containing the diethylmethylbenzenediamine as a liquid amine epoxy resin curing agent is adopted to further strengthen the heat resistance; and the bonding sheet and the copper-cladding plate made from the epoxy resin composition have high heat resistance and are suitable for lead-free solder welding.

Owner:GUANGDONG SHENGYI SCI TECH

Synthesis method of diethyl toluene diamine

InactiveCN101417953AGood dispersionEasy to separateAmino preparation from aminesChemical recyclingSynthesis methodsFiltration

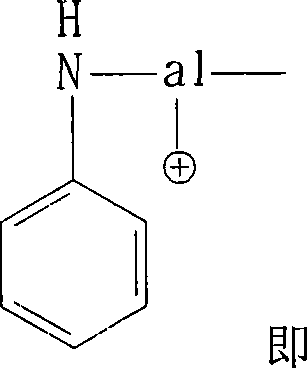

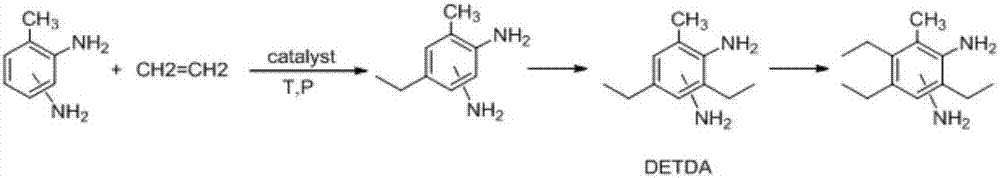

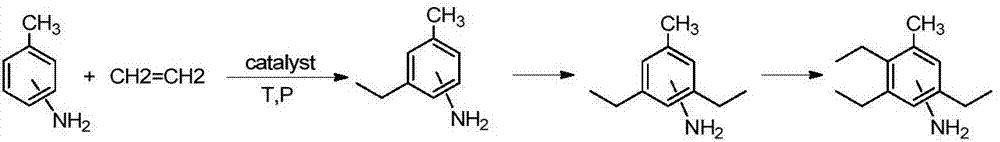

The invention discloses a method for preparing diethyltoluenediamine, which comprises the following steps: diaminotoluene and catalyst are added to a reactor; an 'aromatic amine-aluminum' catalyst system is formed after temperature rising and stirring, and ethylene is pumped into the reactor to purge the hydrogen produced by the reaction; high pressure ethylene gas is pumped in, and after complete alkylation, diphenyl ether or phenoxy biphenyl are added to dilute the reactants; the mixture is filtered, the materials at the bottom of the reactor are recycled, the filtrate is distilled, and diethyltoluenediamine is obtained. The method has the advantages that, aluminum, zinc, aluminum chloride and organic aluminum are used as the catalyst, so activity is increased, reaction pressure is lowered and reaction time is reduced; diphenyl ether or phenoxy biphenyl is added before filtration, so material viscosity can be lowered to facilitate filtration and separation, simultaneously, the 'aromatic amine-aluminum' catalyst system is not damaged; the catalyst can be recycled, so operation steps are reduced, catalyst cost is greatly lowered and environment protection is benefited.

Owner:杭州崇舜化学有限公司

Polyurea external corrosion prevention paint for pipe line and its manufacturing method

ActiveCN1912033AExtended service lifeIncreased shear strengthAnti-corrosive paintsPolyurea/polyurethane coatingsPolyethylene oxideShock resistance

The invention relates to a pipeline polyurea outer anticorrosive coating and the making method thereof, making heated prepolymerization reaction on dibenzo-methane diisocyanate, carbodiimide diisocyanate, polyether binary alcohol and polyether trihydric alcohol to prepare prepolymer solution A, and making end amino polyethylene oxide ether, dimethyl sulfur-based toluene diamine, diethyl diamine, iso-propyl titanate solution, polyacrylate, carbon black, titanium dioxide and lightweight calcium carbonate into solution B, and as using, respectively heating the solutions A and B to 65 deg.C and then mixing them, then quickly spraying and curing to form a coat. And it has excellent constructional performance, and high curing speed, and the formed coat has excellent shearing performance, cathode peeling resistance, wearability, shock resistance and corrosion resistance. And it can be used in pipeline outer anticorrosive engineering, able to resist corrosion of corrosive media to pipelines and prolong pipeline service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

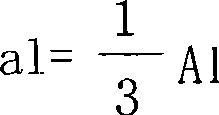

High-solid-content environment-friendly single component polyurea paint and preparation method thereof

ActiveCN107286834ANo generationOmit production stepsPolyurea/polyurethane coatingsPolyamideDiethyltoluene diamine

The invention discloses high-solid-content environment-friendly single component polyurea paint and a preparation method thereof. The paint is prepared from polyether polyol, diphenylmethane diisocyanate, a sealing agent, amine terminated polyether, amine terminated polyether, amine terminated polyether, a chain extender (diethyl methyl benzene diamine), pigment and filler carbon black, polyamide wax powder, fumed silica, coal ash, a toughening agent (vacuum cut distillate oil), a defoaming agent, a solvent (dibasic acid ester) and the like. The paint has the advantage of fundamentally solving the problems that the high cost of the existing single component polyurea paint is unfavorable for promotion and application, storing for a long time is incapable due to short storage period, and the paint is not environment-friendly due to addition of a volatile organic solvent; meanwhile, the vacuum cut distillate oil which is low in cost and is purchased easily is taken as the toughening agent, the comprehensive mechanical properties of the single component polyurea paint are improved, the product effect is good, the product quality is high, and the production cost is decreased, so that a patent product can be popularized and applied energetically; the added solvent is a solvent with a high boiling point, so that the purpose of environmental protection is achieved.

Owner:XINJIANG KENENG WATERPROOF & PROTECTION TECH CO LTD +1

Catalyst for producing diethyltoluene diamine and preparation method and application of catalyst

ActiveCN107999089AHigh activityHigh selectivityAmino preparation from aminesCatalyst activation/preparationAlkyl transferActive component

The invention discloses a supported catalyst for producing diethyltoluene diamine. The supported catalyst for producing diethyltoluene diamine comprises a modified carrier and a supported active component, wherein the modified carrier contains SiO2 and B2O3 obtained by decomposing a soluble silicon-containing compound and a boron-containing compound through drying and roasting after introducing the soluble silicon-containing compound and the boron-containing compound into the carrier. The invention further discloses a preparation method and application of the catalyst. The catalyst disclosed by the invention is suitable for the alkylation of aromatic amines, especially has extremely high activity and selectivity for continuous production of diethyltoluene diamine with toluenediamine alkylation. The catalyst has a simple preparation process, high economy and better application prospects.

Owner:WANHUA CHEM GRP CO LTD

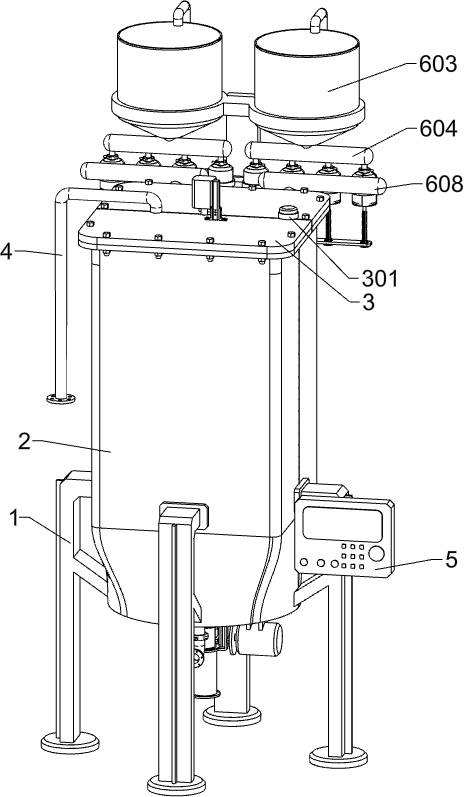

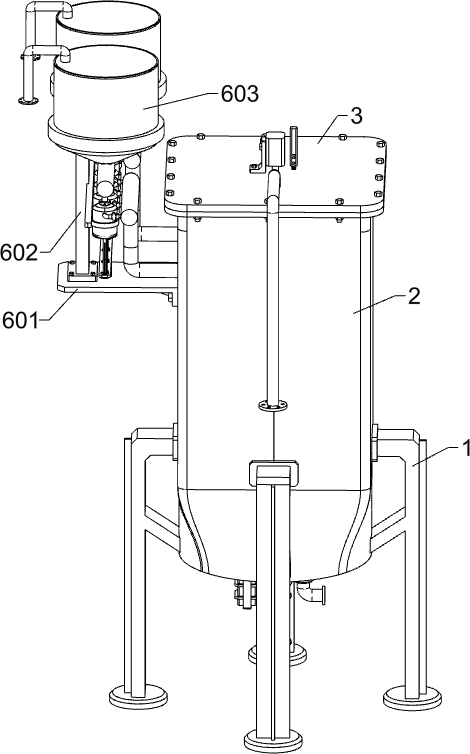

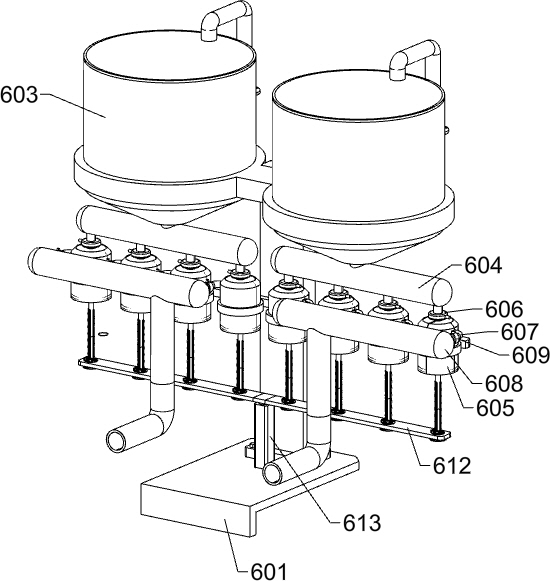

Diethyltoluenediamine production device with accurate material proportioning function

ActiveCN114797636AAvoid stickingQuality improvementAmino compound purification/separationOrganic compound preparationBLENDER/MIXERStructural engineering

The invention aims to provide a diethyltoluenediamine production device with an accurate material proportioning function, and relates to the field of diethyltoluenediamine production devices.The diethyltoluenediamine production device comprises a first supporting frame, a mixing cabin is fixedly connected to the first supporting frame, a quantitative proportioning mechanism is arranged on the first supporting frame, the quantitative proportioning mechanism communicates with the mixing cabin, and the mixing cabin communicates with the quantitative proportioning mechanism; a stirring mechanism is arranged in the mixing cabin, and an inner wall cleaning mechanism is arranged in the mixing cabin. The quantitative proportioning mechanism is arranged, so that the influence of the bottom pressure of the material box on feeding is avoided, and meanwhile, the situation that the production quality of a diethyl toluenediamine product is reduced due to inaccurate proportioning of two liquid materials caused by different feeding amounts of the two liquid materials is avoided; the stirring mechanism is arranged, so that the stirring time of two liquid materials is shortened, and the production efficiency of diethyltoluenediamine is improved; the inner wall cleaning mechanism is arranged, so that the influence of impurities on the inner wall of the mixing cabin on the next preparation of the diethyltoluenediamine is avoided, and the quality of the diethyltoluenediamine is improved.

Owner:东营海瑞宝新材料有限公司

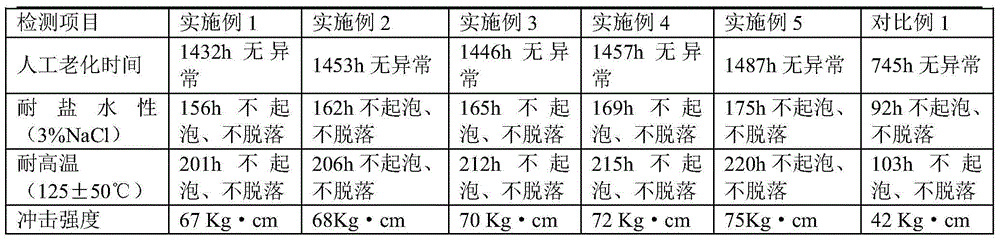

Anticorrosive paint for stainless steel decorating plate and preparation method of anticorrosive paint

InactiveCN104877483AImprove protectionImprove rust resistanceCoatingsPolyvinyl alcoholDiethyltoluene diamine

The invention relates to anticorrosive paint for a stainless steel decorating plate and a preparation method of the anticorrosive paint. The anticorrosive paint comprises the following components in parts by mass: 33-34 parts of white latex, 2-10 parts of iron oxide red, 1-4 parts of chromium oxide green, 0.3-1.5 parts of mica magnesium oxide, 5-15 parts of aluminum triphosphate, 2-8 parts of zinc chromate, 1-7 parts of polyvinyl acetal, 0.8-4 parts of zinc oxide, 6-18 parts of zirconia, 1-5 parts of cobalt naphthenate, 0.5-1.8 parts of polyvinyl siloxane, 0.7-2.2 parts of tripropylene glycol diacrylate, 0.1-0.6 part of diethyl methyl benzene diamine, 1-5 parts of sodium nitrite, 0.3-1.6 parts of phenolic resin and 12-24 parts of purified water. The anticorrosive paint has not only an excellent anticorrosive function, but also the properties of relatively high impact resistance, flexibility, hardness, water resistance and the like.

Owner:SUZHOU DEXIANG DECORATION ENG

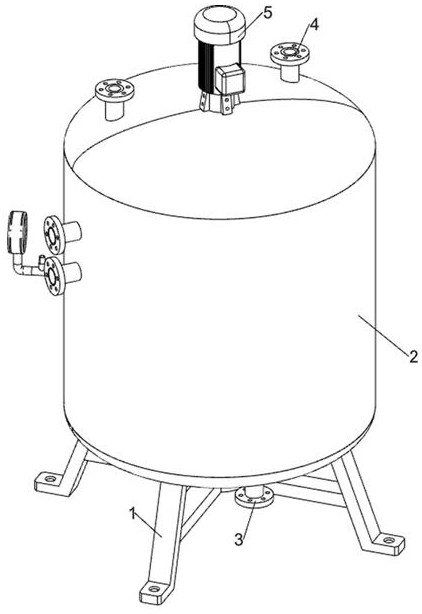

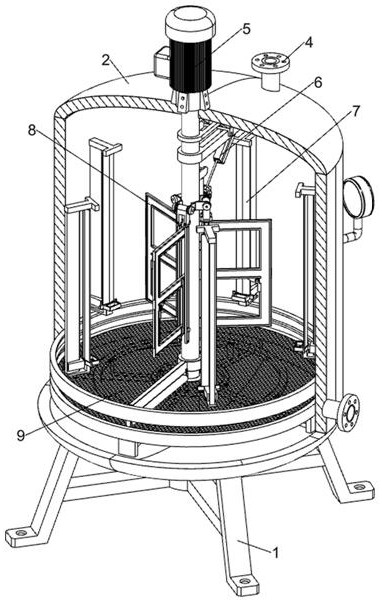

Self-cleaning type diethyltoluenediamine reaction kettle

ActiveCN113559813AStir wellWell mixedOrganic compound preparationRotary stirring mixersChemical reactionPhysical chemistry

The invention relates to the technical field of chemical reaction kettles, in particular to a self-cleaning type diethyltoluenediamine reaction kettle. The technical problem is that a wall plate and a machine head stirring blade of a diethyl toluenediamine reaction kettle are difficult to clean. According to the technical scheme, the self-cleaning type diethyltoluenediamine reaction kettle comprises a bottom supporting frame, a reaction kettle body, a liquid discharge valve, a liquid feeding valve, a stirring machine head assembly, a lifting control system, a wall plate cleaning system, a machine head cleaning system and a fragmentation system; the reaction kettle body is welded to the top of the bottom supporting frame. The inner side of the reaction kettle is automatically cleaned, cleaning liquid is added after the reaction kettle is used, the surfaces of the two sides of each wall plate of the reaction kettle and gaps in the connecting positions of the wall plates and the kettle body are sequentially and automatically cleaned, automatic cleaning of the machine head is achieved, and the surfaces of stirring blades of the machine head are prevented from being wrapped by impurities.

Owner:东营海瑞宝新材料有限公司

Thermal interface material of surface modified graphene-carbon nitride-epoxy resin and preparation method of thermal interface material

ActiveCN109337291AMaintain stabilityAppropriate quality scoreHeat-exchange elementsEpoxyCarbon nitride

The invention relates to a thermal interface material of surface modified graphene-carbon nitride-epoxy resin and a preparation method of the thermal interface material, and solves the problem of lowthermal conductivity caused by poor dispersibility and interface compatibility of an existing graphene composite material. The thermal interface material comprises the following components by mass percentage: 2.5-10% of graphene, 2.5-10% of carbon nitride, 17-24% of diethyltoluenediamine, 65-77% of epoxy resin and the balance of polyvinylpyrrolidone. The invention also provides the preparation method of the thermal interface material. The thermal interface material provided by the invention can be widely applied to the field of preparation of thermally conductive composite materials.

Owner:BEIJING UNIV OF CHEM TECH

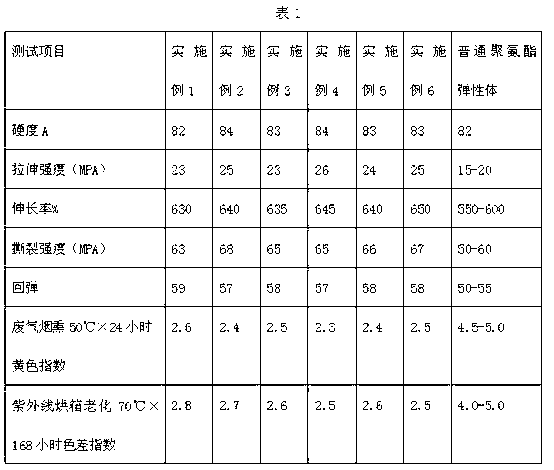

Yellowing-resistant and uvioresistant polyurethane elastomer and preparation method thereof

InactiveCN103275300AOvercome adverse effects on physical and mechanical propertiesPromote absorption and transformationPolymer sciencePropanoic acid

The invention discloses a yellowing-resistant and uvioresistant polyurethane elastomer and a preparation method thereof. The yellowing-resistant and uvioresistant polyurethane elastomer is prepared from a component A and a component B, wherein the component A comprises 60-70% of polyether polyol, 20-35% of toluene diisocyanate and 1-2% of (bi[beta(3-tert-butyl-5-methyl-4-hydroxylphenyl)]propanoyl) as an antioxidant; and the component B comprises 65-80% of polyether polyol, 12-30% of diethyl methyl benzene diamine as a curing agent, 0.05-1% of triethylene diamine dipropylene glycol solution as a catalyst and 1-2% of {2-(2'-hydroxyl-3',5'-bi[1,1-dimethylphenyl])-benzotriazole)-5-chloridized benzotriazole} as an anti-aging agent. The yellowing-resistant and uvioresistant polyurethane elastomer can be used for intensely absorbing ultraviolet rays with the wavelength of 270-400nm and has favorable absorption, conversion, reflection and radiation functions for the ultraviolet rays, so that the ultraviolet ray shielding property and the efficient anti-aging and yellowing resistance of a polyurethane product are improved.

Owner:DONGGUAN JINGLUN IND

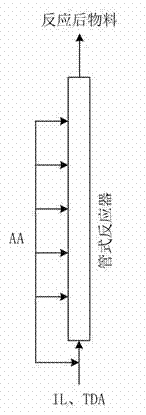

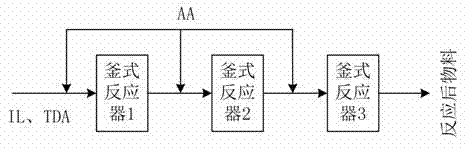

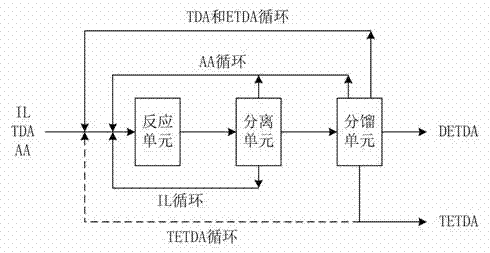

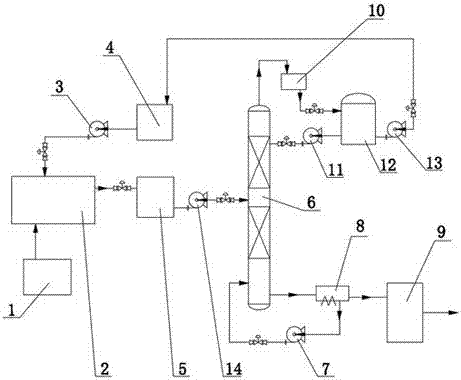

Method for synthesizing diethyltoluenediamine through alkylation of toluenediamine catalyzed by ionic liquid

InactiveCN102807493AReduce security risksFlexible processAmino preparation from aminesHydrogen halidePtru catalyst

The invention discloses a method for synthesizing diethyltoluenediamine through alkylation of toluenediamine catalyzed by ionic liquid. The method is characterized in that toluenediamine and alkylation reagents such as chloroethane and ethylene are used as raw materials, and acidic ionic liquid is used as catalyst; positive ions of the ionic liquid catalyst come from hydrogen halide of amine containing alkyl, or hydrogen halide of phosphorus containing alkyl or halide containing imidazole or a pyridine ring, and negative ions come from one or more metal halides. The method has the advantages of low reaction temperature and reaction pressure, short reaction time, safer process, high toluenediamine conversion rate and high diethyltoluenediamine selectivity. The invention additionally discloses an alkylation device for synthesizing diethyltoluenediamine under the catalytic effect of ionic liquid. The alkylation device at least comprises a reaction unit, a separation unit and a fractionation unit.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

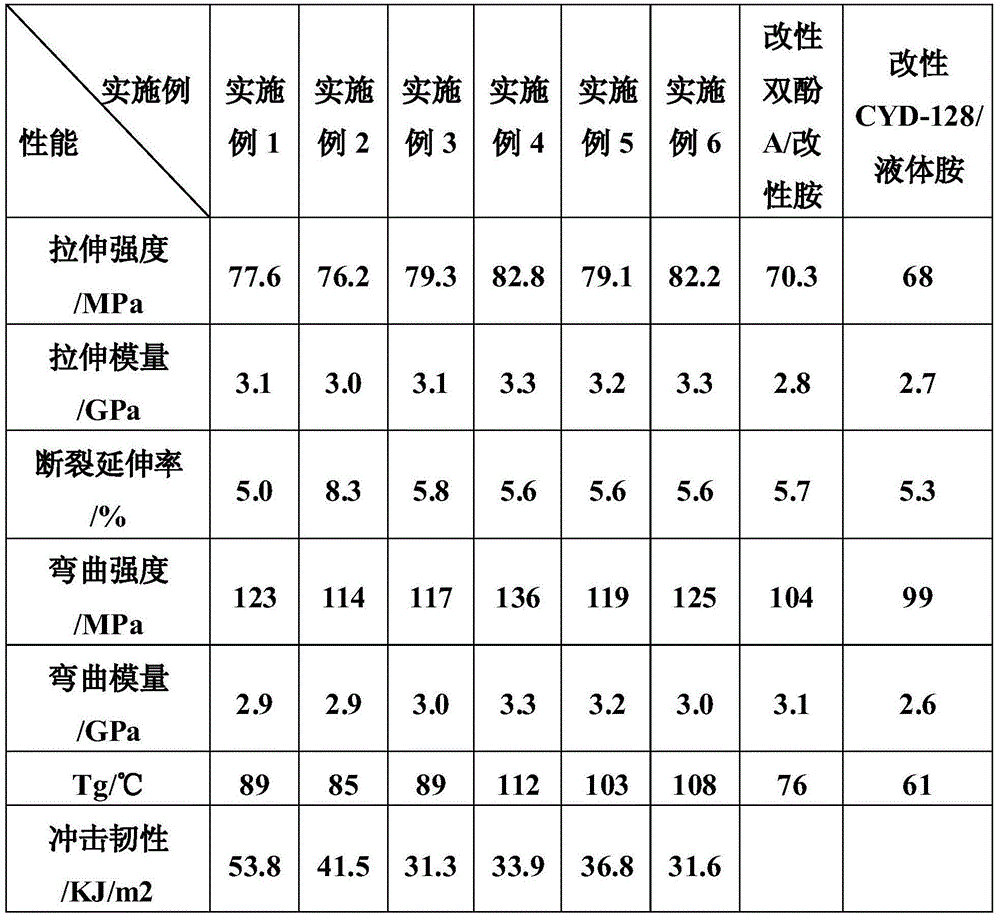

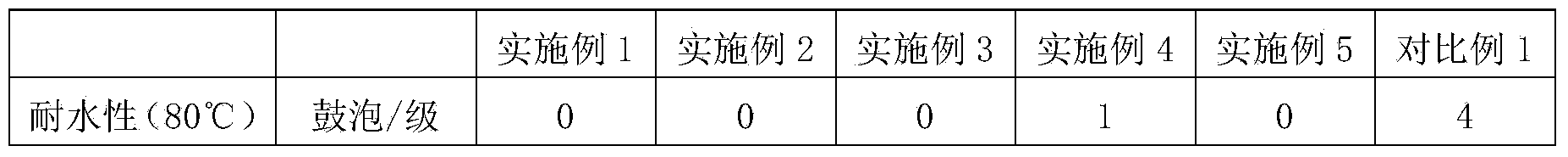

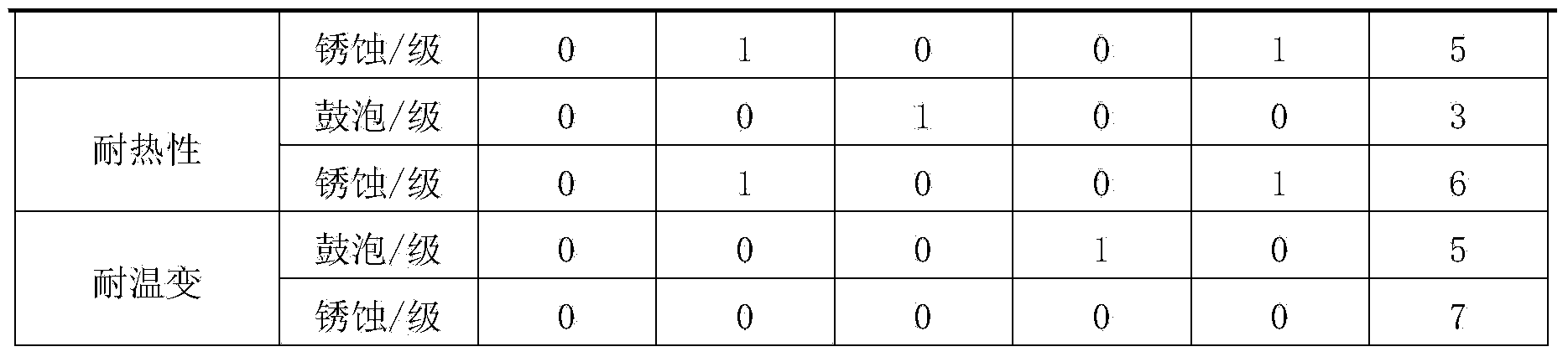

High-toughness epoxy resin composition applied to RTM (resin transfer molding) process and preparation method thereof

The invention provides an epoxy resin composition which is not only applicable to an RTM (resin transfer molding) process, but also is high in toughness and higher in strength. The invention further provides a preparation method of the epoxy resin composition. The preparation method is as follows: under a room temperature, uniformly mixing diethyl toluene diamine with polyether amine D-230 to prepare a component B liquid curing agent with polyether amine D-230 with mass fraction of 20%-90%; then, removing air bubbles in vacuum for component A epoxy resin and component B liquid curing agent at 30 DEG C-40 DEG C; adopting an RTM injector for uniformly mixing the component A with the component B in a mass ratio of 100:(25-50), then injecting to an RTM mould with a mould temperature of 30 DEG C-40 DEG C for curing to obtain the high-toughness epoxy resin composition. The epoxy resin composition disclosed by the invention has an RTM operation process window greater than 138 min at 30 DEG C-45 DEG C, and is suitable for RTM process forming. The epoxy resin composition is low in viscosity, does not need to use a diluent, a defoaming agent, and the like; and a curing product of the epoxy resin composition has high toughness.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Anticorrosive coating for solar water storage tank and preparation method of anticorrosive coating

InactiveCN104371447AImprove corrosion resistanceGood adhesionAnti-corrosive paintsEpoxy resin coatingsMethacrylateAcrylic resin

The invention provides an anticorrosive coating for a solar water storage tank and a preparation method of the anticorrosive coating. The anticorrosive coating comprise the following raw materials: polyvinyl acetate resin, thermosetting acrylic resin, bisphenol A epoxy resin, ethyl 2,4-dimethyl benzoate, silicon sol, iron powder, tetraethoxysilane, methyltriethoxysilane, diethyl toluenediamine, dimethylamino ethyl methacrylate, boron nitride, carbon black, glass flakes, organic acid salts, pigment, xylene and n-butanol. The preparation method comprises the following steps of firstly mixing, stirring and grinding polyvinyl acetate resin, thermosetting acrylic resin, ethyl 2,4-dimethyl benzoate, silicon sol, tetraethoxysilane and xylene; adding bisphenol A epoxy resin, iron powder, methyltriethoxysilane, diethyl toluenediamine, dimethylamino ethyl methacrylate, boron nitride and carbon black, stirring and dehydrating; and then adding the residual components, stirring and grinding. The coating has the advantages of good corrosion resistance, adhesion property, flexibility and impact resistance.

Owner:WUXI SUNOCEAN

Bottle flake recycled polyester elastic wig filaments

InactiveCN109957849AShrinkage stableGuaranteed rigidityElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyethylene terephthalateAntioxidant

The invention discloses bottle piece recycled polyester elastic wig filaments, which are prepared from the following raw materials: waste polyethylene terephthalate (PET) bottle flakes, neopentyl glycol, diethylaminoethanol, 1, 4-butanediol, ethylene glycol, a heat stabilizer, a toughening agent, terpene resin, diethyltoluenediamine, an antioxidant and filler. The artificial wig fiber filaments prepared by the method are excellent in performance, have effects of simulating and super-simulating, can be widely applied to wig preparation, can also be used in the decorative art field, and have thecharacteristics of being easy to fall off, good in air permeability, low in price, convenient to wear, non-toxic and durable. The bottle piece recycled polyester elastic wig filaments are prepared byrecycling the waste PET bottle flakes, thereby greatly reducing the production cost; the bottle piece recycled polyester elastic wig filaments have the advantages of being simple to operate, environmentally-friendly and high in working efficiency, have effective bacteria resistance and bacteriostasis, and are hygroscopic and air-permeable as well as soft and comfortable.

Owner:孙义柱

High-strength high-elasticity polyurethane material for shoe material and preparation method of high-strength high-elasticity polyurethane material

InactiveCN106189191AHigh strengthIncrease elasticityMicroballoon preparationMicrocapsule preparationPolyesterSucrose

The invention discloses a high-strength high-elasticity polyurethane material for a shoe material. The high-strength high-elasticity polyurethane material is prepared from the following raw materials in parts by weight: 70-90 parts of polyester polyol, 30-45 parts of toluene diisocyanate, 10-15 parts of diethyltoluenediamine, 15-25 parts of bamboo charcoal powder, 5-6 parts of chitosan, 1-3 parts of activated carbon, 1-3 parts of sodium alginate, 1-3 parts of gelatin, 10-15 parts of sucrose fatty acid ester, 5-8 parts of a 3% calcium chloride solution, 0.1-0.3 part of honeysuckle flower essential oil, 0.1-0.3 part of radix angelicae sinensis essential oil, 2-4 parts of dibutyltin dilaurate, 3-5 parts of 1,3-propylene glycol, 0.5-2 parts of a blowing agent CFA-A8, 10-20 parts of an acetic acid solution, 0.5-1 part of acetic acid, an appropriate amount of water and an appropriate amount of ethanol. The polyurethane composite has favorable air permeability, and favorable antibacterial and deodorizing efficacies, and has the advantages of high hardness and high elasticity.

Owner:ANHUI BOZHOU XIBAO SHOES & CLOTHES

Method for producing TZ-MPA spray polyurea waterproofing coating

InactiveCN101585994AOvercome the disadvantages of constructionEasy constructionAntifouling/underwater paintsPaints with biocidesVertical planeDiethyltoluene diamine

The invention discloses a method for producing a spray polyurea waterproofing coating. The spray polyurea waterproofing coating is produced from a component A consisting of PPG-2000, MDI and NCO and a component B consisting of amino terminated polyether JEFFAMINE at T-5000, DETDA-diethylmethane diamine, pigment, kaolin (1,250 meshes) and earthware clay in a weight ratio of 1:2, has no catalyst and quick curing, can be sprayed on any curved surface, inclined plane and vertical plane, does not generate sagging phenomenon, is not sensitive to water content and moisture, is not influenced by environmental temperature and moisture in construction, has 100 percent of solid content, does not contain any volatile organic compound (VOC), is environment-friendly, can be sprayed or poured in a volume ratio of 1:1, has the one-time construction thickness range from hundreds of microns to several centimeters, overcomes the disadvantages of the prior multiple construction, uses a whole set of equipment, and has convenient construction and high efficiency.

Owner:曹天志 +2

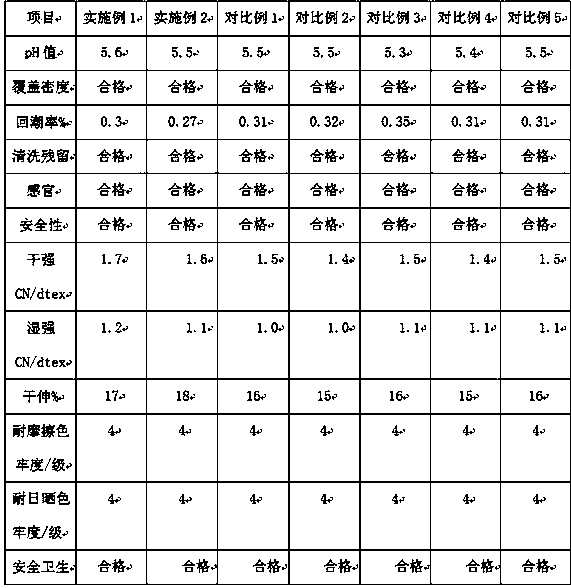

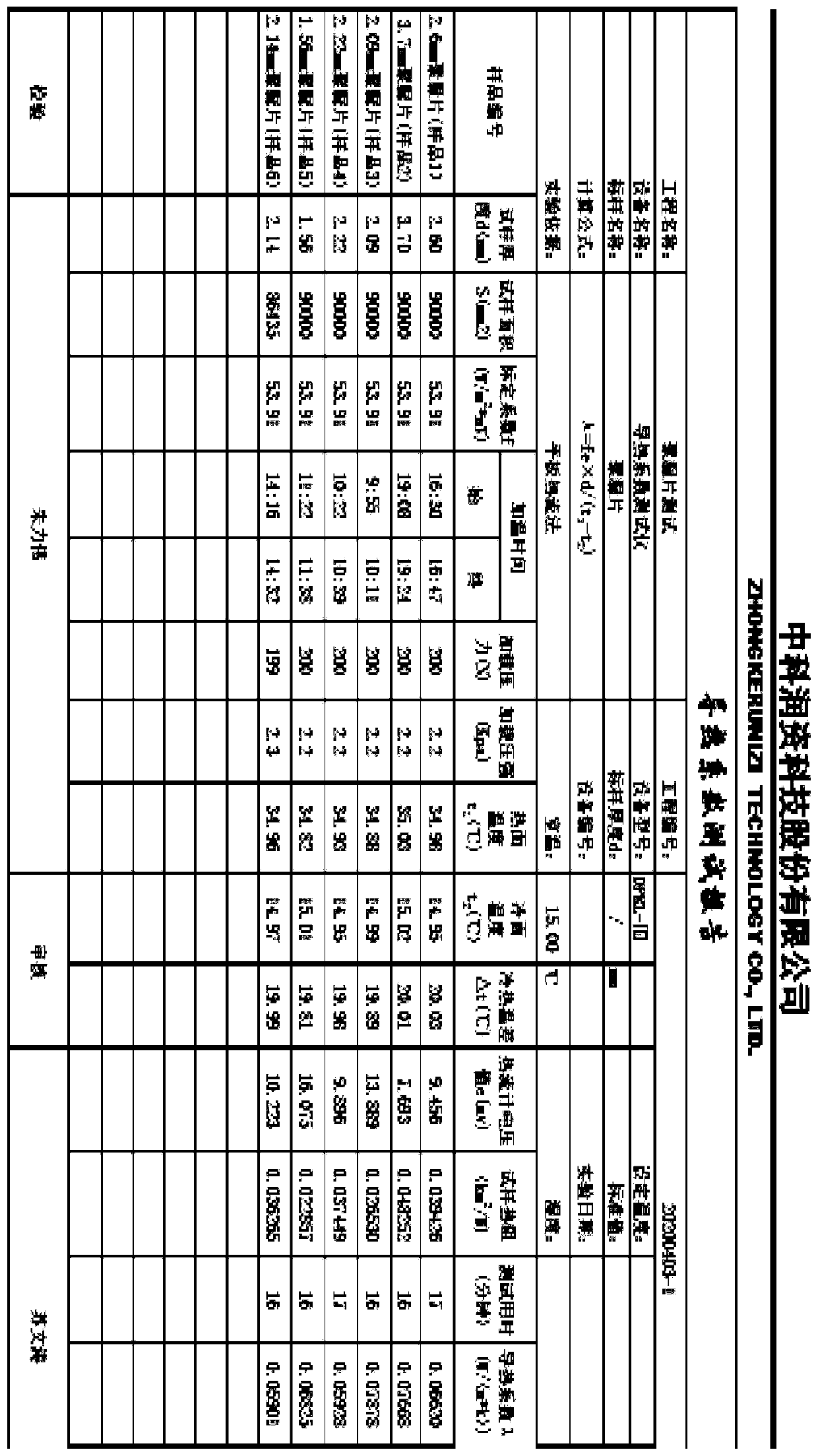

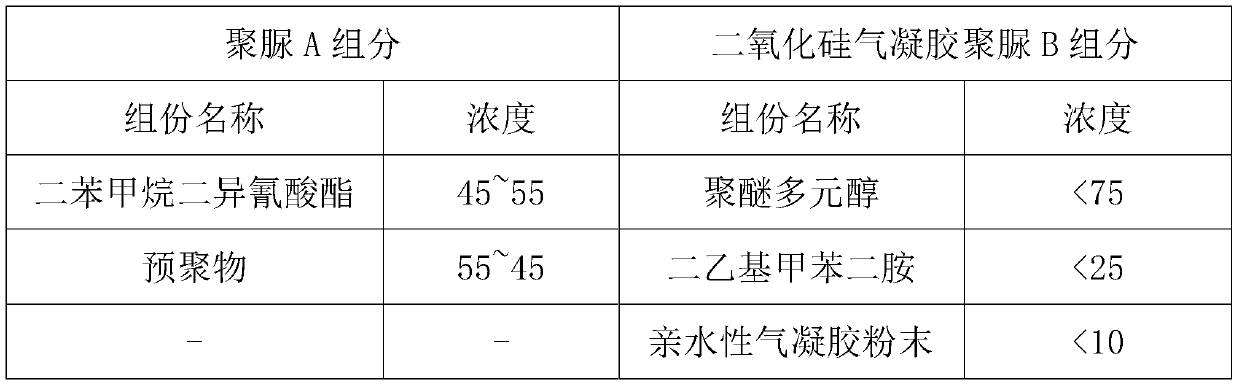

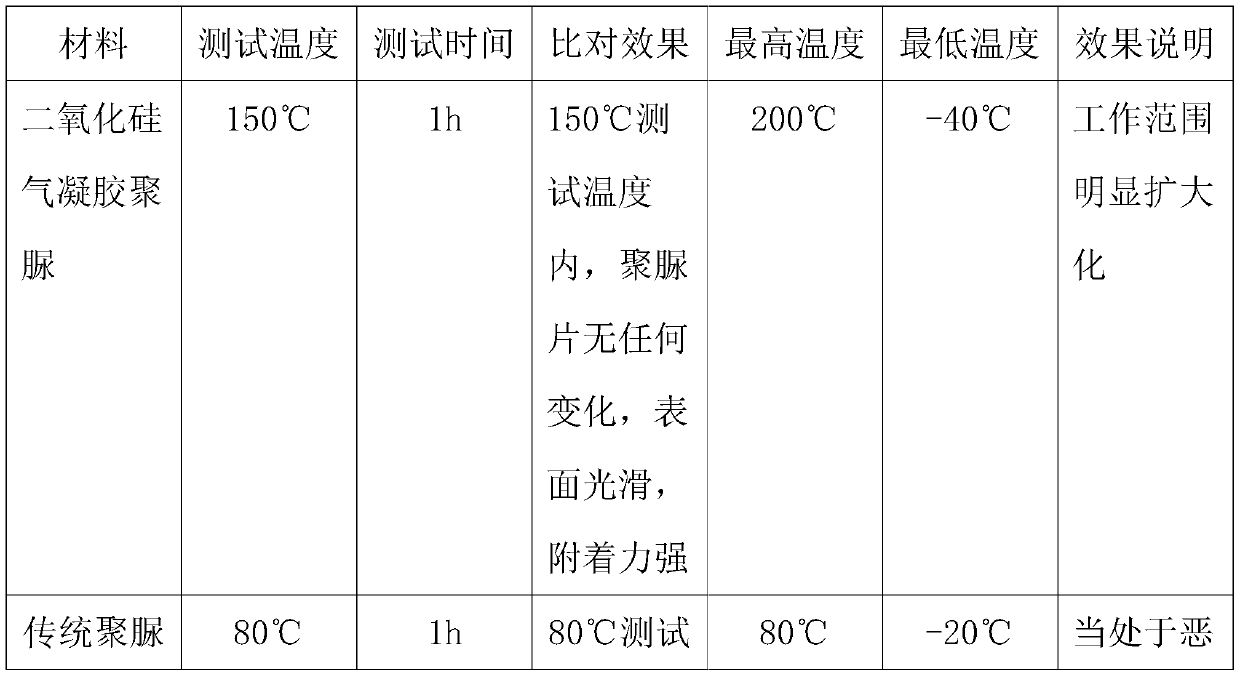

Silicon dioxide aerogel polyurea and preparation method thereof

InactiveCN111518380AWide operating temperature rangeLow thermal conductivityDiphenylmethanePolymer science

The invention relates to the technical field of aerogel application, in particular to silicon dioxide aerogel polyurea and a preparation method thereof. The silicon dioxide aerogel polyurea compositematerial is prepared by mixing a silicon dioxide aerogel polyurea component and a traditional polyurea component, a traditional polyurea component serves as a component A, a silicon dioxide aerogel polyurea component serves as a component B, the mixing ratio of the component A to the component B is 1: 1 or 2: 1, the silicon dioxide aerogel polyurea component is composed of a polyurea component andhydrophilic silicon dioxide powder, and the polyurea component is composed of polyether polyol and diethyltoluenediamine; a traditional polyurea component is composed of diphenylmethane diisocyanateand a prepolymer. The blank in the field of silicon dioxide aerogel polyurea materials is filled up, the working temperature range of traditional polyurea is greatly widened, the weather resistance ofthe material in practical application is enhanced, meanwhile, the heat conductivity coefficient range of the material is adjustable through a special formula system, and the application feasibility of the material in the field of heat preservation is expanded.

Owner:中科润资科技股份有限公司

Preparation method of mesoporous activated carbon

The invention discloses a preparation method of mesoporous activated carbon. The preparation method includes: soaking sawdust in treating liquid, rising temperature to 50-60 DEG C, and stirring for 10-20 minutes; rising temperature to 100-120 DEG C under a vacuum condition, allowing standing for 40-50 minutes, and lowering temperature to room temperature; adding diethyltoluenediamine, and mixing well to obtain a first material; rising temperature of the first material to 600-650 DEG C under a condition of nitrogen protection, and maintaining for 150-200 minutes; lowering temperature to room temperature to obtain a carbonized material; soaking the carbonized material in a diethylamine water solution, rising temperature to 30-40 DEG C, and maintaining the temperature for 100-120 minutes; filtering, using deionized water to wash until pH does not change, and drying to obtain the mesoporous activated carbon. The mesoporous activated carbon obtained by the preparation method has good performance, and applicability is improved.

Owner:江苏富汇通环保科技有限公司

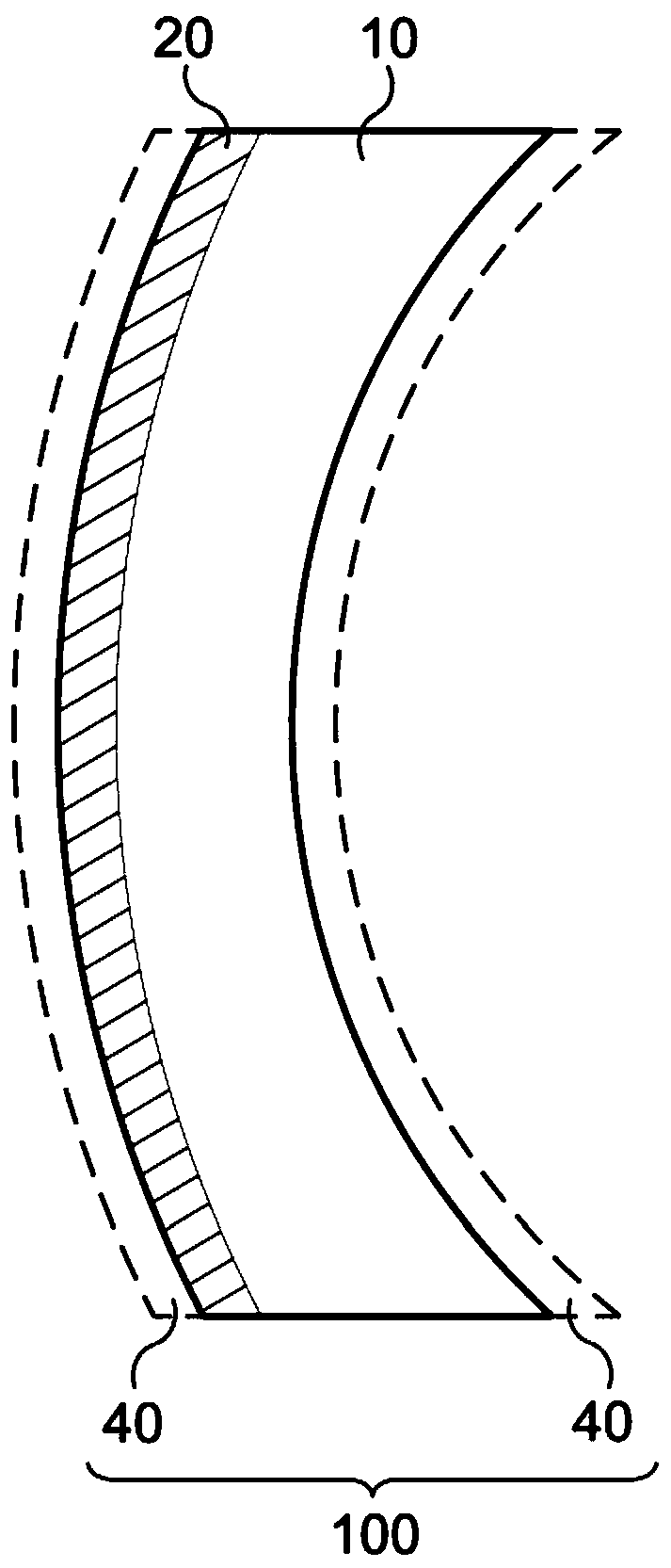

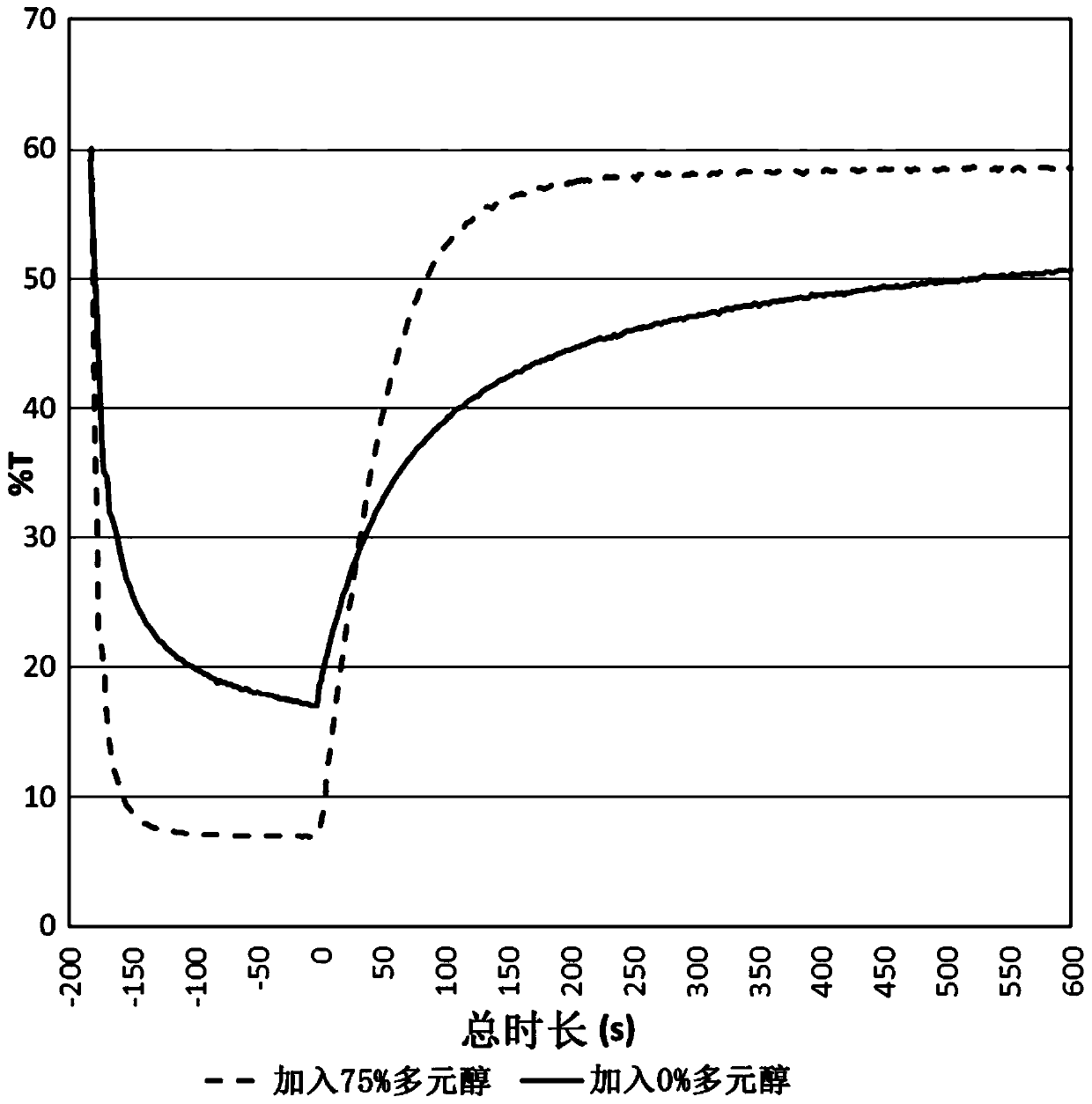

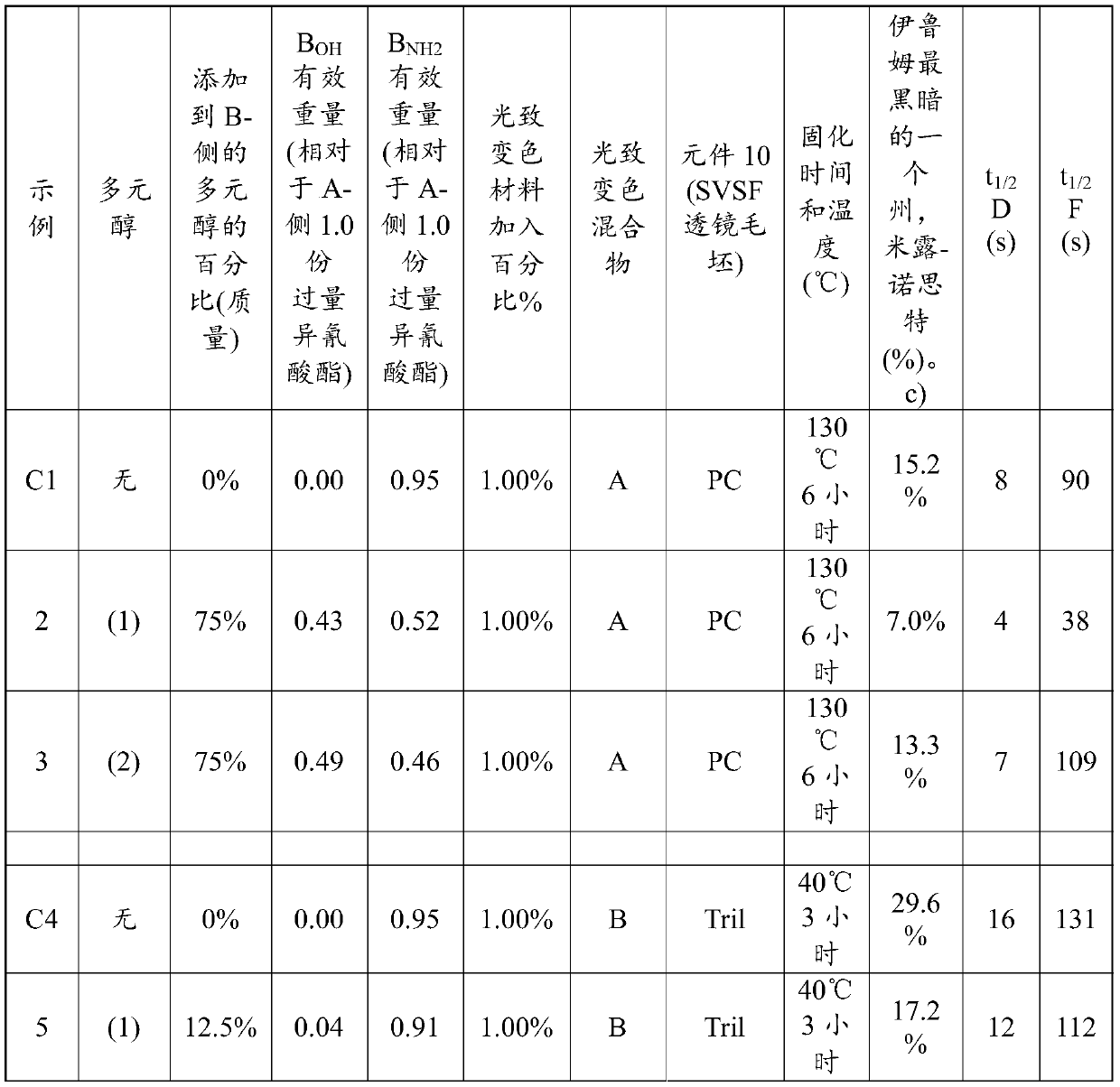

Optical articles comprising photochromic poly(urea-urethane)

A process for producing a photochromic eyewear lens. In one embodiment at least a layer of modified photochromic poly(urea-urethane) is formed by combining photochromic material and the reaction product of a polyurethane pre-polymer and a mixture of diethyltoluene diamine and one or more polyols, plus catalyst. The mixture comprises both NH2 and OH reactive groups, with at least 0.04 equivalent weights of OH reactive species available for reaction with each 1.0 equivalent weight of excess NCO reactive species available in the pre-polymer. The lens comprising the modified photochromic poly(urea-urethane) can exhibit faster fade-back rates and better photochromic performance than lenses with non-modified poly(urea-urethane).

Owner:YOUNGER MFG

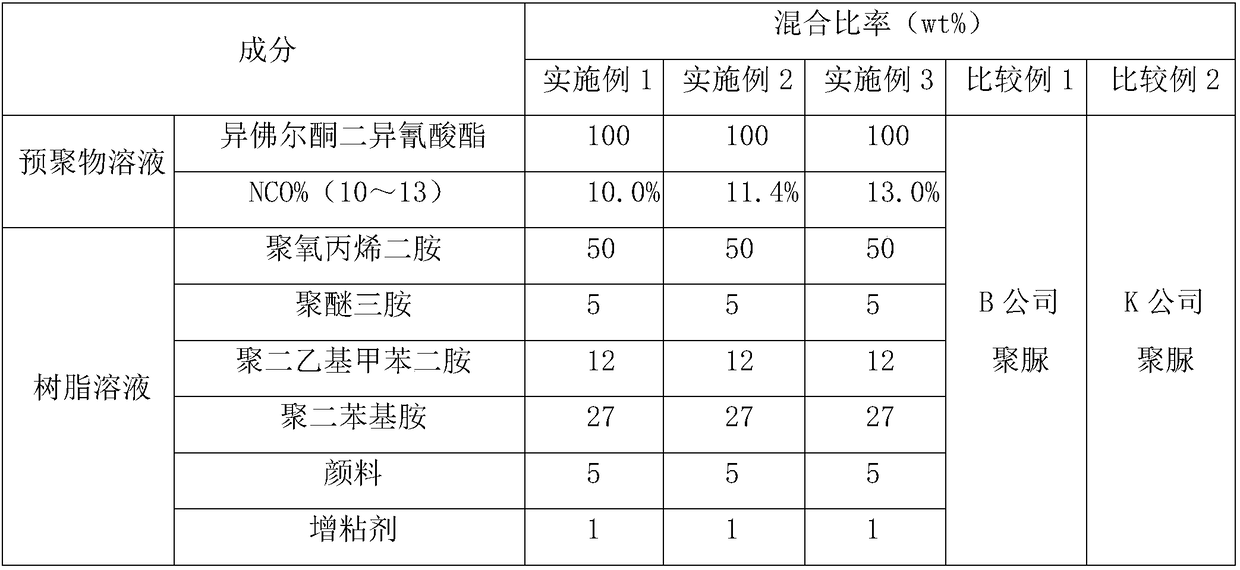

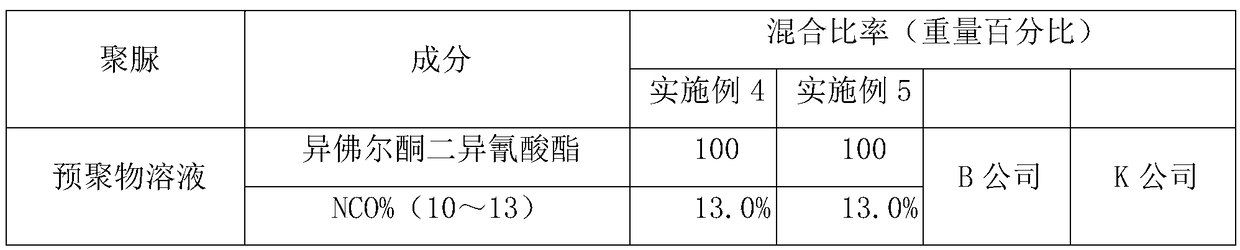

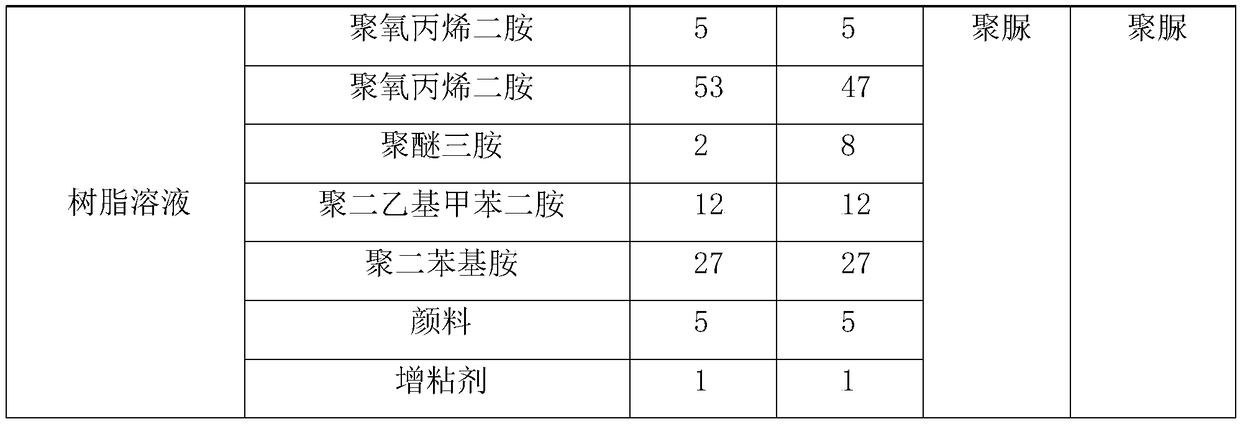

Aliphatic compound polyurea coating agent for rust prevention and water resistance

InactiveCN109207037AGood chemical resistanceExcellent abrasion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsDiethyltoluene diamineEthylamine

The invention discloses an aliphatic compound polyurea coating agent for rust prevention and water resistance, wherein the aliphatic compound polyurea coating agent comprises a prepolymer solution anda resin solution, and the prepolymer solution and the resin solution are mixed in a ratio of 1:1 for use; the prepolymer solution consists of 100 wt% of isophorone diisocyanate or 100 wt% of hexamethylene diisocyanate, and isophorone diisocyanate or hexamethylene diisocyanate contains 10%-13% of NCO; the resin solution contains 50 wt%-53 wt% of polyoxypropylene diamine, 4 wt%-7 wt% of polyether ethylamine with the molecular weight of 5000, 12 wt%-14 wt% of polydiethyltoluene diamine, 25 wt%-29 wt% of polydiphenylenediamine, 1 wt%-2 wt% of a tackifier and 4 wt%-5 wt% of a pigment. The aliphatic compound polyurea coating agent not only can completely avoid yellowing phenomenon, but also has slow curing time; when coating, the aliphatic compound polyurea coating agent has good self-levelingproperty, no embossing caused by dust or fine dust, and no change in physical properties of a coating film, so the aliphatic compound polyurea coating agent can completely eliminate cracks and greatlyimproves the rust prevention performance and water resistance.

Owner:上海沐皿新材料科技有限公司

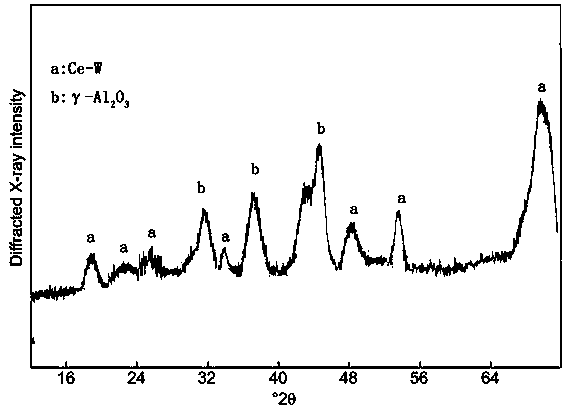

Diethyltoluenediamine synthesized alumina matrix catalyst loaded with active metal components and application

ActiveCN108620059AExtended service lifeHigh reaction yieldAmino preparation from aminesCatalyst activation/preparationReactive siteActive site

The invention relates to a diethyltoluenediamine synthesized alumina matrix catalyst loaded with active metal components and application and belongs to the technical field of fine chemical industry. Aiming at the problems of high reaction impurity content and easy catalyst deactivation of the catalyst in the catalytic synthesis process of the diethyltoluenediamine, the invention provides a catalyst based on a tabular alumina carrier, Ce and W as active sites, and the catalytic reaction process has the advantages of high reaction activity, low impurity content and long catalyst service life.

Owner:东营海瑞宝新材料有限公司

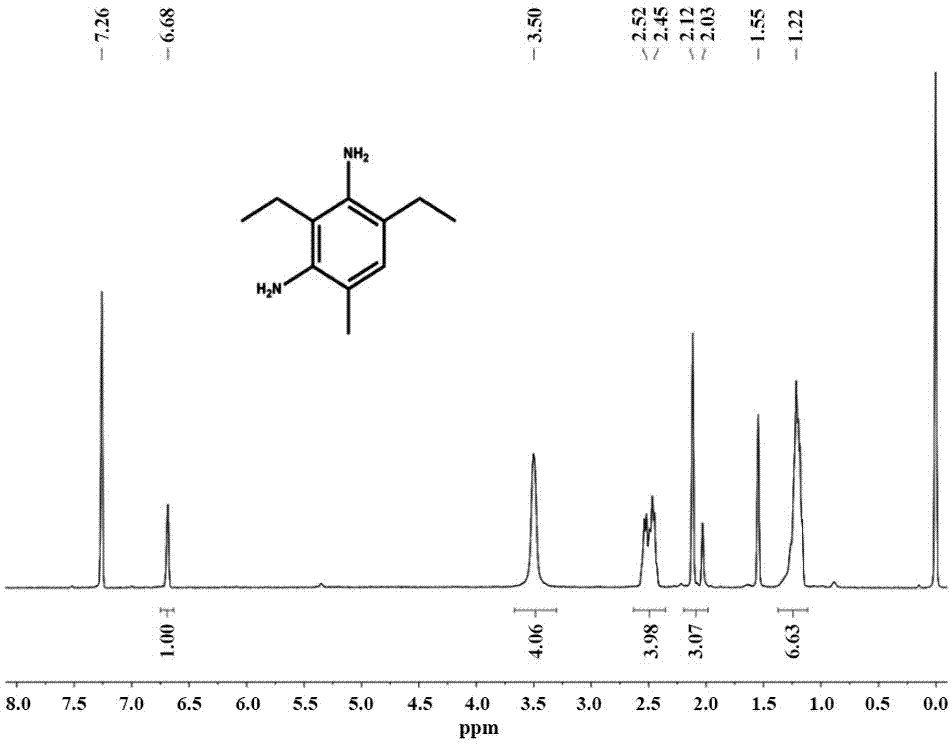

Synthesis method of diethyltoluenediamine

ActiveCN106946714AMild reaction conditionsEasy to controlAmino preparation from aminesHeterogenous catalyst chemical elementsSynthesis methodsDistillation

The invention relates to a synthesis method of diethyltoluenediamine (DETDA). According to the synthesis method, sol-gel method is adopted to prepare catalyst CeO2-CuO / ZnO / Al2O3; feeding is carried out at a toluenediamine (TDA) : ethylene : the catalyst metal atom molar ratio of 1.1:2.2:0.05; H2 is introduced into the high pressure reaction kettle for reduction and activation of the catalyst, TDA is added, full stirring is carried out, and ethylene gas is added to replace H2; the temperature is increased to 220 to 230 DEG C via temperature programming, reaction pressure is maintained to be 3.0MPa, and reaction is carried out for 3h; an appropriate amount of water is added into the high pressure reaction kettle, and reduced pressure distillation is carried out so as to obtain DETDA. The DETDA selectivity and the yield of the synthesis method are 85.2% and 93.7% respectively, the purity is 99.1%, the quality is capable of satisfying requirements of the national quality standards, and the synthesis method is green and clean, and is friendly to the environment.

Owner:ANYANG INST OF TECH

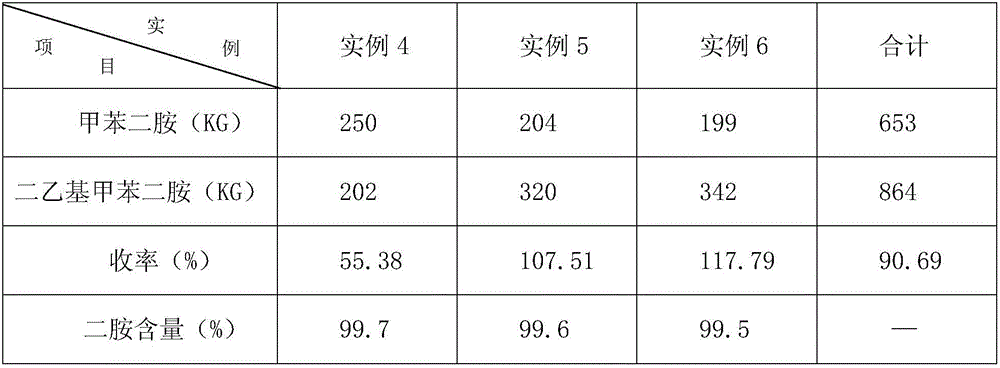

Method for synthesizing diethyltoluenediamine

ActiveCN106083605AReduce the number of timesReduce security risksAmino preparation from aminesAlkyl transferOrganic solvent

The invention discloses a method for synthesizing diethyltoluenediamine. An arylamine-aluminum catalyst system is formed with diaminotoluene under certain conditions, then, an alkylation reaction with ethylene is carried out in an autoclave, a reaction product directly enters a distillation still for distillation after the reaction ends, a front cut fraction and a remaining catalyst system directly return to the autoclave, then, the raw material diaminotoluene is put into the autoclave and is subjected to an alkylation reaction with ethylene directly, and the arylamine-aluminum catalyst system can be reused through one-time preparation. Meanwhile, a straight distillation technology is adopted, so that the consumption of organic solvents is avoided, the purity of the product can be higher, and the production process is more environmentally friendly. According to the synthesis method, the catalyst system is reused repeatedly, and the process is free of solvents and neutralizing and washing processes, so that the production cost is reduced, the production efficiency is increased, and process flows are simpler, safer and more environmentally friendly.

Owner:山东崇舜新材料科技有限公司

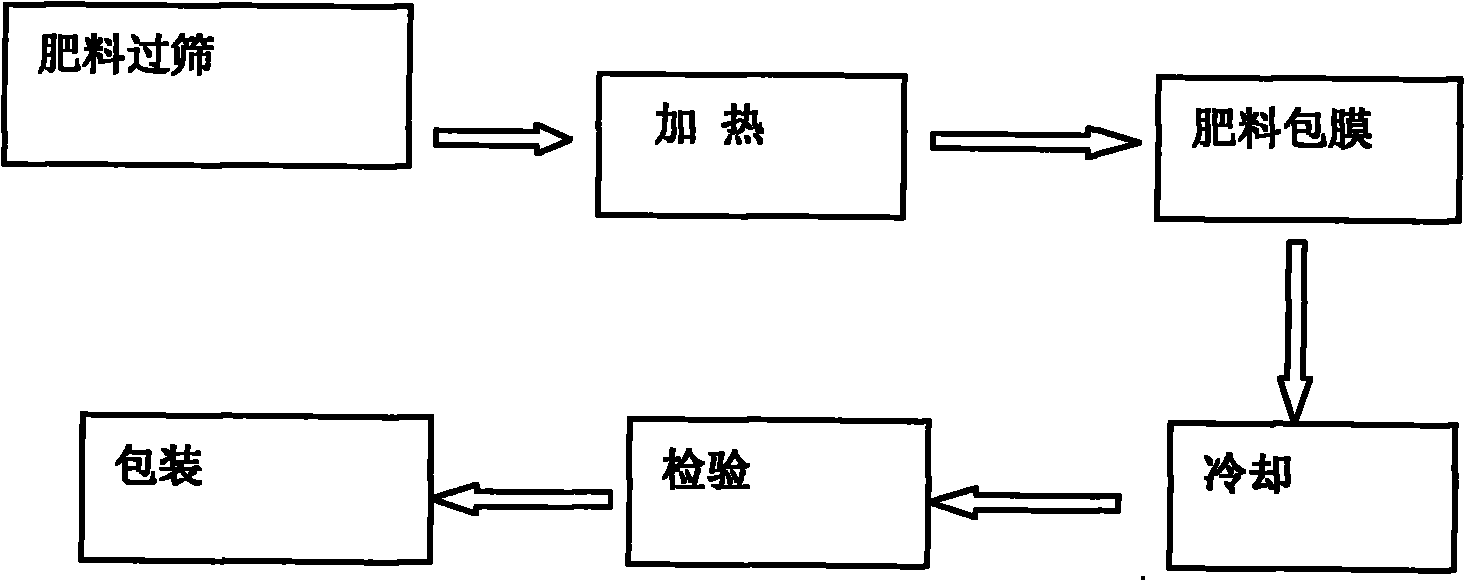

Coating film and production method of coated controlled-release fertilizer

InactiveCN103524699ALittle investmentHigh input-output ratioLayered/coated fertilisersFertilizer mixturesPolyesterControlled release

The invention relates to a coating film. The coating film contains materials A and B, wherein the material A mainly contains the following components in parts by weight: 20-30 parts of polyester polyol, 40-50 parts of soybean oil polyol, 20-30 parts of castor oil and 5-10 parts of diethyl methyl benzene diamine; and the material B is polyaryl polymethylene isocyanate.

Owner:蔡小伶

Coating method for inside of woven bag

The invention discloses a coating method of a woven bag. The coating method comprises the following steps of: firstly weaving warps and wefts made of fiber materials into a barrel-shaped fiber weaving layer on a circular weaving machine; then spraying paint prepared on site on the inner side of the weaving layer to form lining, wherein the paint comprises the following components in parts by weight: 16-20 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyving akohol, 30-45 parts of isocyanate, 20-35 parts of polyether glycol and 10-20 parts of diethyl methyl benzene diamine; and drying and obtaining a woven bag product with internal spraying.

Owner:湖南安福环保科技股份有限公司

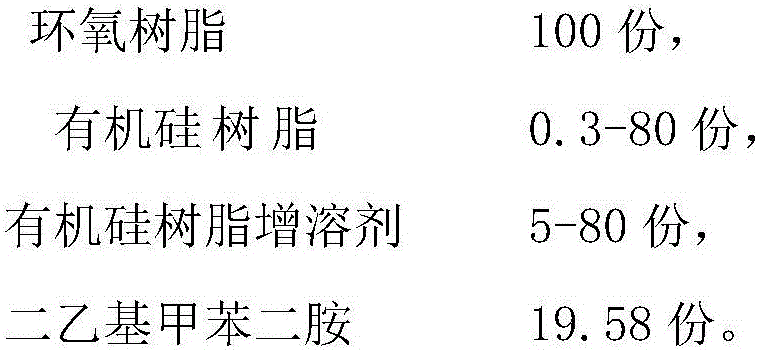

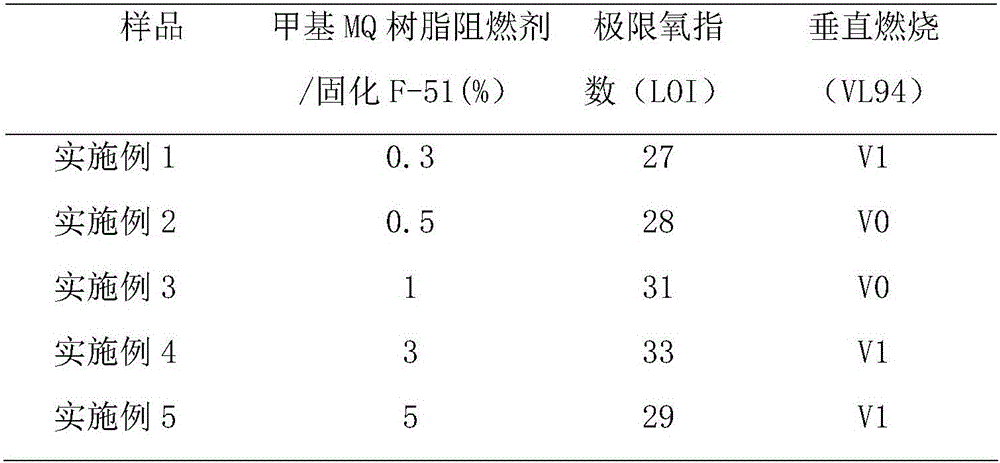

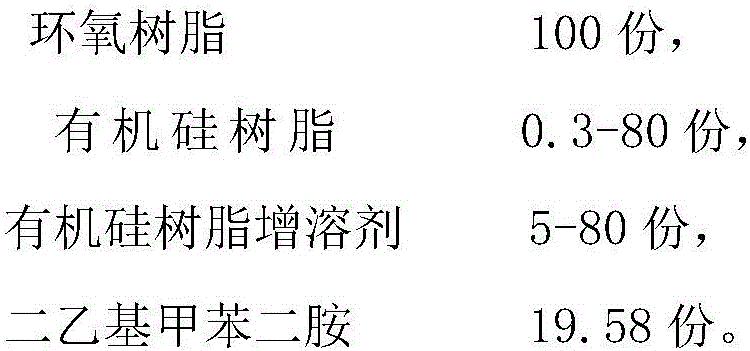

Organic silicon resin modified epoxide resin composition

The invention discloses an organic silicon resin modified epoxide resin composition. The composition is mainly composed, by weight, 100 parts of epoxy resin, 0.3-80 parts of organic silicon resin, 5-80 parts of organic silicon resin solubilizer and 19.58 parts of diethyl methyl benzene diamine. The composition contains the organic silicon resin with a double-layer dense spherical structure, the organic silicon resin can be completely compatible with epoxy resin and evenly dispersed in epoxy resin under the action of the organic silicon resin solubilizer, in this way, the flame retardant property of a blend system is improved greatly, and flame retardant effect is improved.

Owner:SICHUAN UNIV

Antistatic polyurethane elastomer

InactiveCN103724593AGood physical and mechanical propertiesImprove antistatic performanceDiethyltoluene diamineAmmonium nitrate

The invention discloses an antistatic polyurethane elastomer. The antistatic polyurethane elastomer comprises the following components in part(s) by mass: 1-2 part(s) of ethyltrimethoxysilane, 50 parts of epoxy propane-type polyether polyol, 0.5 part of N,N-bis[3-(dimethylamino)propyl]-N',N'-dimethyl-1,3-propanediamine, 1 part of sodium oleoyl amino acid, 0.3 part of an inhibitor, 2 parts of dimethyl octadecyl hydroxyethyl ammonium nitrate, 15 parts of toluene di-cyanate ester, 5 parts of triethylene glycol bis-[3-(3-tert-butyl-4-hydroxy-5-methyl phenyl)propionate], 31 parts of polyether polyol and 5 parts of diethyltoluenediamine. The antistatic polyurethane elastomer has good physical and mechanical properties and is high in antistatic capability.

Owner:CHANGSHU YONGLI CHEM

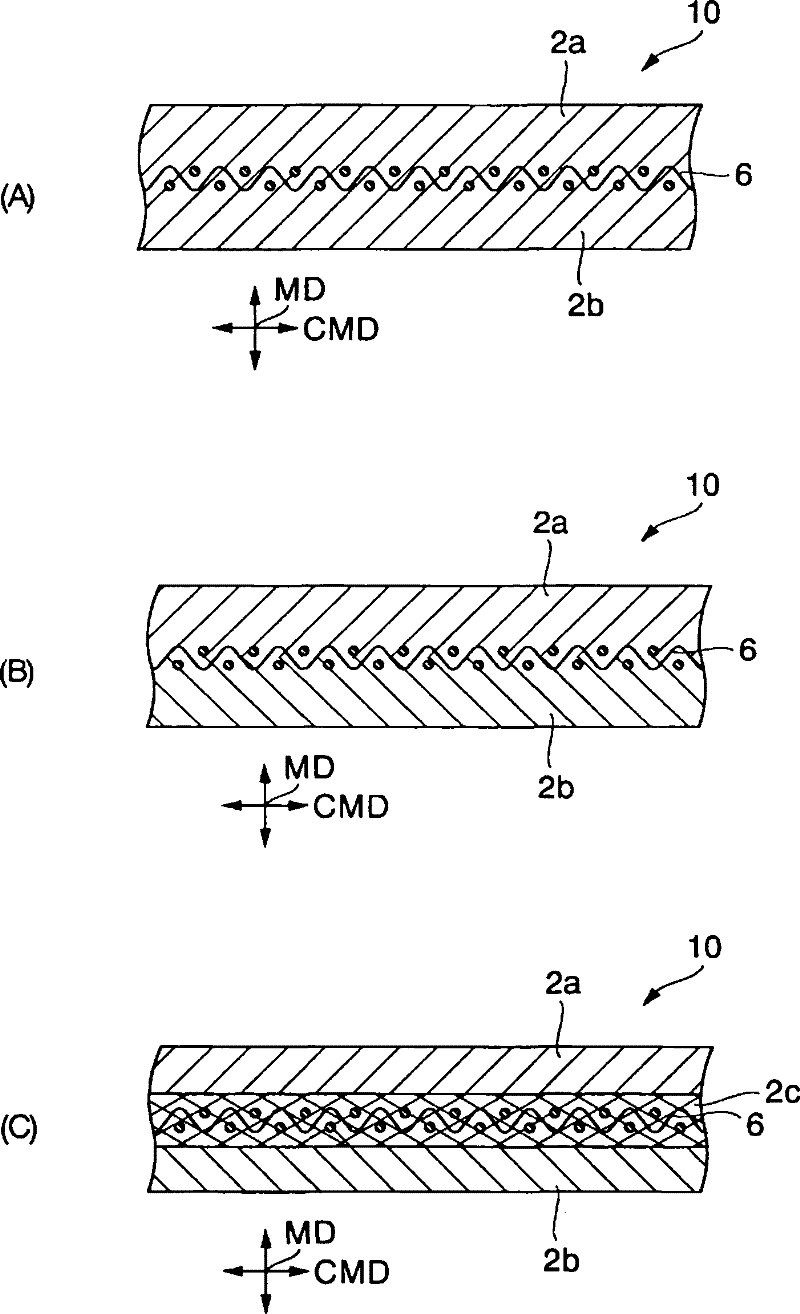

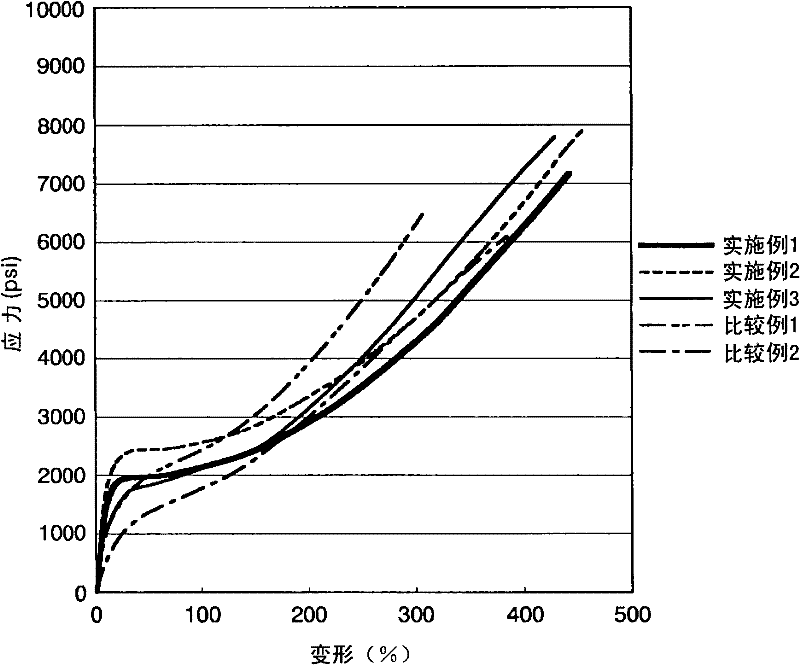

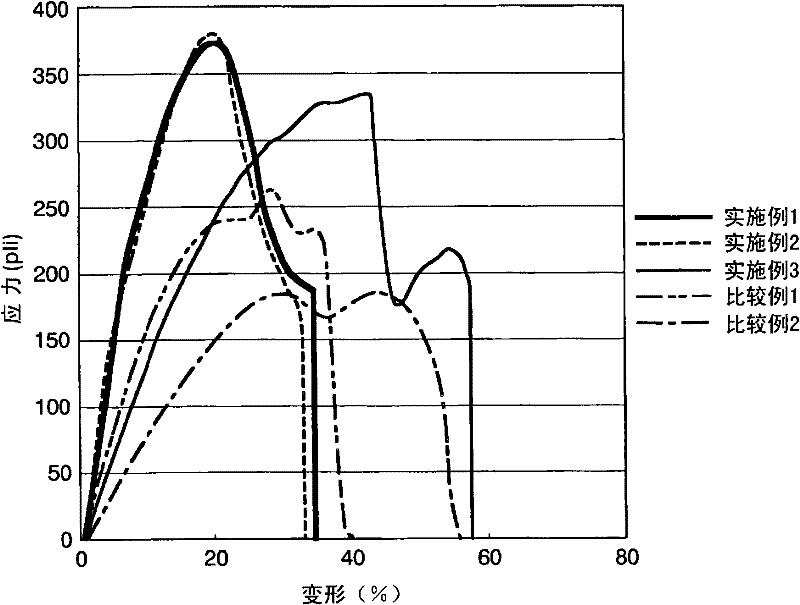

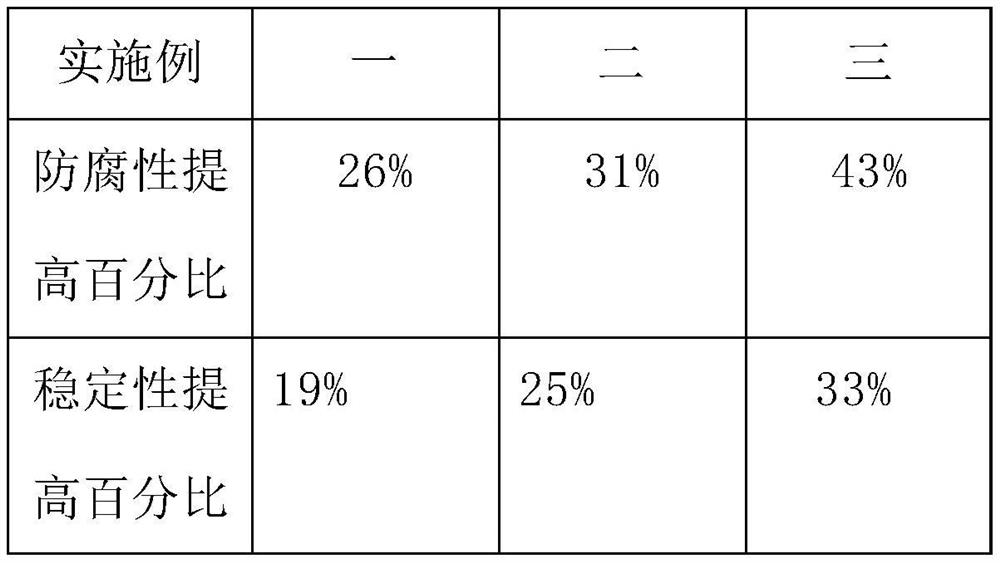

Shoe press belt for paper making

ActiveCN101720370BImprove wear resistanceIncreased durabilitySynthetic resin layered productsPress sectionFiberCarbamate

Disclosed is a shoe press belt (10) which comprises a reinforcing fibrous base material (6) embedded in a polyurethane layer, and has an outer circumference layer (2a, 21) and an inner circumference layer (2b, 22) each formed with a polyurethane. The polyurethane layer comprises a polyurethane which is produced by curing a composition comprising a mixture of an urethane prepolymer (A) and a curing agent (B). The urethane prepolymer (A) is produced by reacting an isocyanate compound (a) containing 55 to 100 mol% of a p-phenylene-diisocyanate compound with polytetramethylene glycol (b) and has an isocyanate group at its terminal. The curing agent (B) is selected from the group consisting of 1,4-butanediol, hydroquinone bis-sshydroxyethyl ether, 3,5-diethyltoluenediamine and 3,5-dimethylthiotoluenediamine. The belt (10) has excellent cracking resistance, bending fatigue resistance and wear resistance.

Owner:ICHIKAWA ELECTRIC CO LTD

Novel busbar and manufacturing method thereof

InactiveCN109251655AImprove thermal conductivityInhibitionFireproof paintsPolyurea/polyurethane coatingsEpoxyBusbar

The invention discloses a novel busbar, and belongs to the technical field of wiring system. The novel busbar comprises a busbar main body; the surface of the busbar main body is successively providedwith an internal flame retardant layer, a heat absorbing layer, and an external flame retardant layer; the paint of the external flame retardant layer comprises, by weight, 65 to 80 parts of toluenediisocyanate, 45 to 55 parts of a polyether glycol, 10 to 12 parts of polydimethylsiloxane, 8 to 10 parts of epoxy resin, 2 to 4 parts of a metal oxide, 3 to 6 parts of graphene, 3 to 5 parts of ammonium polyphosphate, 1 to 2 parts of melamine, 4 to 6 parts of pentaerythritol, 2 to 3 parts of diethyl toluenediamine, 2 to 4 parts of trimethylol propane, and 3 to 4 parts of dibutyltin dilaurate. Thepaint flame resistance is improved obviously, generation of smoke is inhibited, and the mechanical properties are improved greatly.

Owner:镇江朝阳机电科技有限公司

Pipeline anticorrosion polyurea spraying elastomer

InactiveCN112210278AImprove continuityImprove integrityAnti-corrosive paintsPolyurea/polyurethane coatingsPhosphorous acidAlkane

The invention discloses a pipeline anticorrosion polyurea spraying elastomer. The polyurethane elastomer comprises the following raw material in parts by weight: 10 parts of polyether polyol, 12 partsof a viscosity reducer, 35 parts of a flame retardant, 24 parts of mixed aromatic polyisocyanate, 35 parts of amino-terminated polyether, 45 parts of an amine chain extender, 65 parts of an antioxidant, 35 parts of leveling agent, 45 parts of isocyanate, 15 parts of an amino-terminated alkylene oxide compound, 20 parts of diethyl toluenediamine, 10 parts of diamino, 25 parts of methylthiochlorobenzene, 35 parts of dimethylthiotoluenediamine, 20 parts of dialkyl diamine, 35 parts of dialkyl methyl diamine, 20 parts of phosphite triester, 65 parts of fumed silica, 70 parts of fluorocarbon resinand 65 parts of urea. The pipeline anticorrosion polyurea spraying elastomer has the advantages of simple preparation, less material configuration, low production equipment requirement, simple production process, convenient popularization and application, and strong practicability.

Owner:常州市大使涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com