Self-cleaning type diethyltoluenediamine reaction kettle

A technology of diethyltoluenediamine and reactors, applied in chemical/physical/physical chemical fixed reactors, detailed information of chemical/physical/physical chemical reactors, preparation of amino compounds, etc., can solve problems affecting purity, Difficult to stir impeller cleaning and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

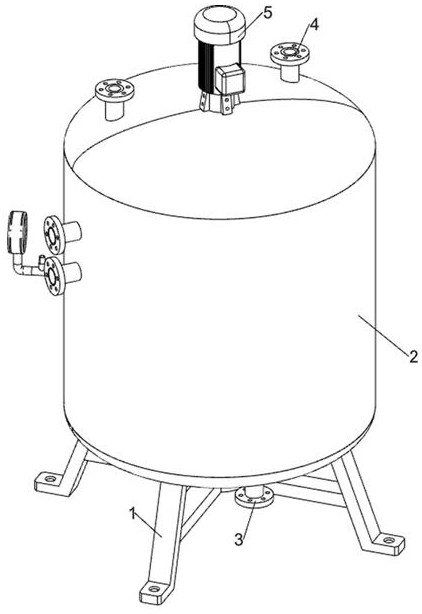

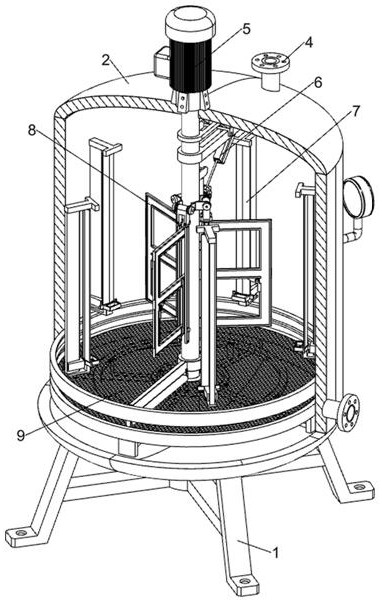

[0036] according to Figure 1-2 As shown, a self-cleaning diethyltoluene diamine reactor includes a bottom support frame 1, a reactor body 2, a liquid outlet valve 3, a liquid inlet valve 4, a mixer head assembly 5, a lifting control system 6, a wall Plate cleaning system 7, machine head cleaning system 8 and crushing system 9; the top of the bottom support frame 1 is welded with the reactor body 2; the middle and front side of the bottom of the reactor body 2 is equipped with a liquid outlet valve 3; the top of the reactor body 2 is left behind A liquid inlet valve 4 is installed on the side and the right rear side; a mixer head assembly 5 is installed in the middle of the reactor body 2; a lifting control system 6 is installed on the front side of the mixer head assembly 5; five Wall plate cleaning system 7; three machine head cleaning systems 8 are equidistantly installed on the outer ring surface of the lower part of the mixer head assembly 5;

[0037] During the normal p...

Embodiment 2

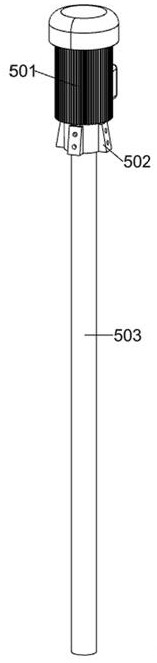

[0039] On the basis of Example 1, according to Figure 2-3 As shown, the mixer head assembly 5 includes a power motor 501, a motor holder 502 and a head shaft 503; the top middle of the reactor body 2 is connected with a motor holder 502 by bolts; the top bolt of the motor holder 502 is connected with a power motor 501; The bottom of the output shaft at the bottom of the power motor 501 is affixed to the machine head shaft 503; the outer upper part and bottom of the machine head shaft 503 are rotatably connected to the reactor body 2; the front side of the machine head shaft 503 is equipped with a lift control system 6; Three head cleaning systems 8 are equidistantly installed on the outer ring surface of the lower part of the head shaft 503 ; the bottom of the head shaft 503 is connected to the crushing system 9 .

[0040] Control and connect the power supply of the power motor 501, and then the power motor 501 drives the machine head shaft 503 to rotate, and the machine head...

Embodiment 3

[0042] On the basis of Example 2, according to Figure 2-5 As shown, the lifting control system 6 includes a connecting frame plate 601, a first connecting shaft seat 602, a bottom support plate 603, an electric push rod 604, a second connecting shaft seat 605, a control sliding sleeve 606, a third connecting shaft seat 607, The elastic telescopic rod 608 and the upward movement traction assembly; the upper part of the outer surface of the head shaft rod 503 is fixedly sleeved with the connecting frame plate 601; The front side of the bottom of 601 is fixedly connected with the first connecting shaft seat 602; the bottom front side of the connecting frame plate 601 is fixedly connected with the bottom supporting plate 603; the lower side of the first connecting shaft seat 602 is connected with the electric push rod 604; The bottom of the telescopic end is fixedly connected with the second connection shaft seat 605; the front part of the third connection shaft seat 607 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com