Diethyltoluenediamine synthesized alumina matrix catalyst loaded with active metal components and application

A technology of diethyltoluene diamine and active metals, which is applied in the field of diethyltoluene diamine synthesis of alumina matrix catalysts, can solve the problems of low impurity content, catalyst service life, catalyst deactivation, and high reaction impurity content. Achieve high reaction yield and catalyst service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

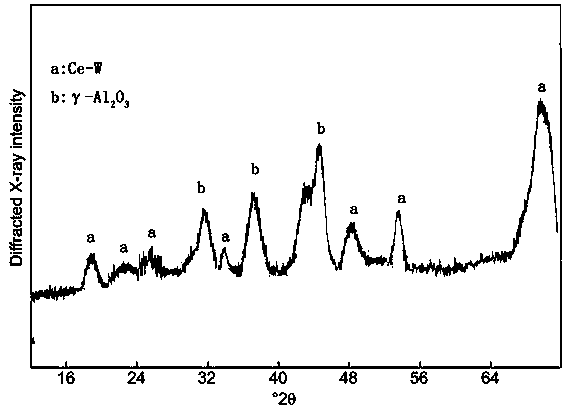

[0030] The preparation of the synthetic catalyst of embodiment 1 diethyltoluenediamine

[0031] Step 1, preparation of carrier: Al 2 o 3 Slowly add to 72 ℃ NaOH aqueous solution, the concentration of NaOH aqueous solution is 5.4mol / L, NaOH and Al 2 o 3 The molar ratio is 1.0:1. After the addition is complete, the solution is heated to 98 ° C and kept for 1 h to obtain NaAlO 2 solution; the NaAlO 2 After the solution was diluted 5 times with water, CO was slowly introduced into the diluted solution. 2 Response, CO per min 2 The volume ratio of the blown volume to the mixed liquid is 5:1, CO 2 Gas source pressure is 0.1MPa, CO 2 The bubbling time is 40min, CO 2 During the bubbling process, the temperature of the mixed liquid was controlled at 28 ° C. After the completion of the introduction, it was kept for 24 hours, and then the generated solid was filtered out, washed with deionized water, and dried in vacuum to obtain flaky Al(OH) 3 carrier;

[0032] Step 2, the loa...

Embodiment 2 2

[0033] The preparation of the synthetic catalyst of embodiment 2 diethyltoluenediamine

[0034] Step 1, preparation of carrier: Al 2 o 3 Slowly add to 76 ℃ NaOH aqueous solution, the concentration of NaOH aqueous solution is 6.0mol / L, NaOH and Al 2 o 3 The molar ratio is 1.5:1. After the addition is complete, the solution is heated to 100°C, and the reaction is kept for 2h to obtain NaAlO 2 solution; the NaAlO 2After the solution was diluted 6 times with water, CO was slowly introduced into the diluted solution 2 Response, CO per min 2 The volume ratio of the blown volume to the mixed liquid is 8:1, CO 2 Air source pressure is 0.15MPa, CO 2 The bubbling time is 55min, CO 2 During the bubbling process, the temperature of the mixed solution was controlled at 32 ° C. After the completion of the introduction, it was kept for 48 hours, and then the generated solid was filtered out, washed with deionized water, and dried in vacuum to obtain flaky Al(OH) 3 carrier;

[0035]...

Embodiment 3 2

[0036] The preparation of the synthetic catalyst of embodiment 3 diethyltoluenediamine

[0037] Step 1, preparation of carrier: Al 2 o 3 Slowly add to 75 ℃ NaOH aqueous solution, the concentration of NaOH aqueous solution is 5.6mol / L, NaOH and Al 2 o 3 The molar ratio is 1.2:1. After the addition is complete, the solution is heated to 99°C and kept for 1.5h to obtain NaAlO 2 solution; the NaAlO 2 After the solution was diluted 5.5 times with water, CO was slowly introduced into the diluted solution 2 Response, CO per min 2 The volume ratio of the blown volume to the mixed liquid is 7:1, CO 2 Gas source pressure is 0.12MPa, CO 2 The bubbling time is 50min, CO 2 During the bubbling process, the temperature of the mixed liquid was controlled at 30°C. After the completion of the feeding, keep it for 30h, then filter out the generated solid, wash it with deionized water, and dry it in vacuum to obtain flaky Al(OH) 3 carrier;

[0038] Step 2, the loading of the active cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com