Patents

Literature

93 results about "Alumina matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective conversion of oxygenate to propylene using moving bed technology and a hydrothermally stabilized dual-function catalyst

ActiveUS20060106270A1Improve economyAvoid severe deactivationMolecular sieve catalystCatalystsMolecular sieveFixed bed

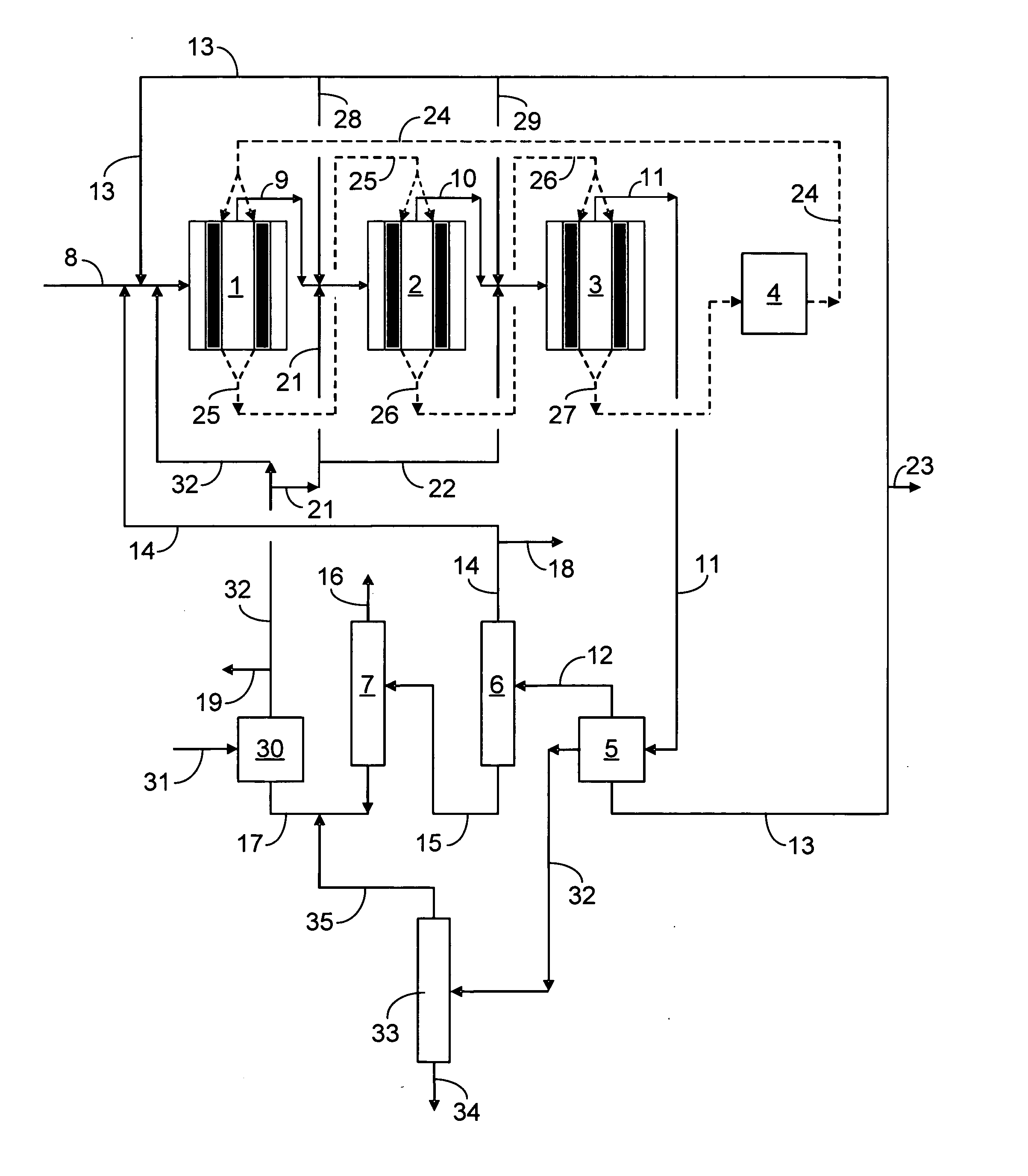

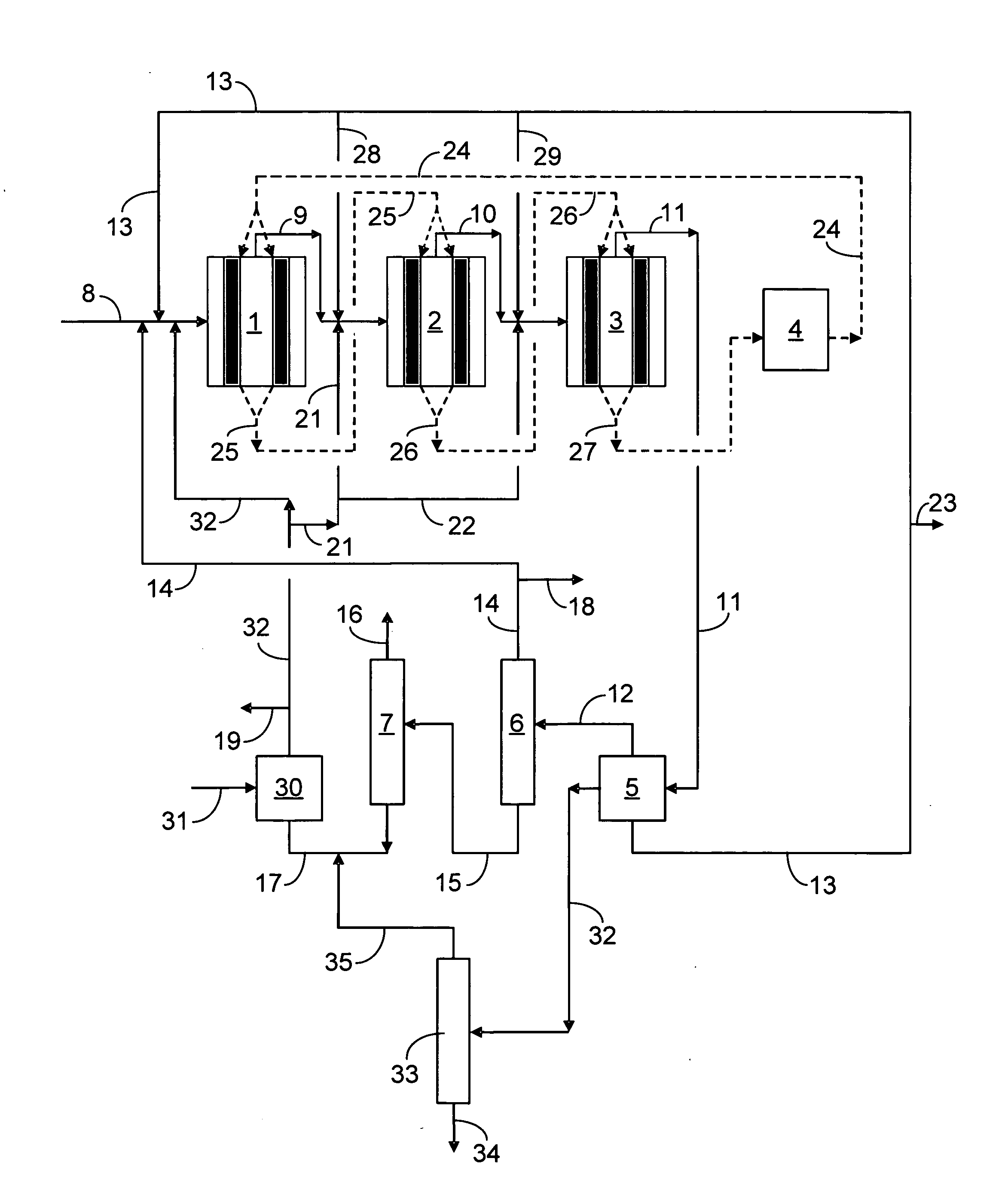

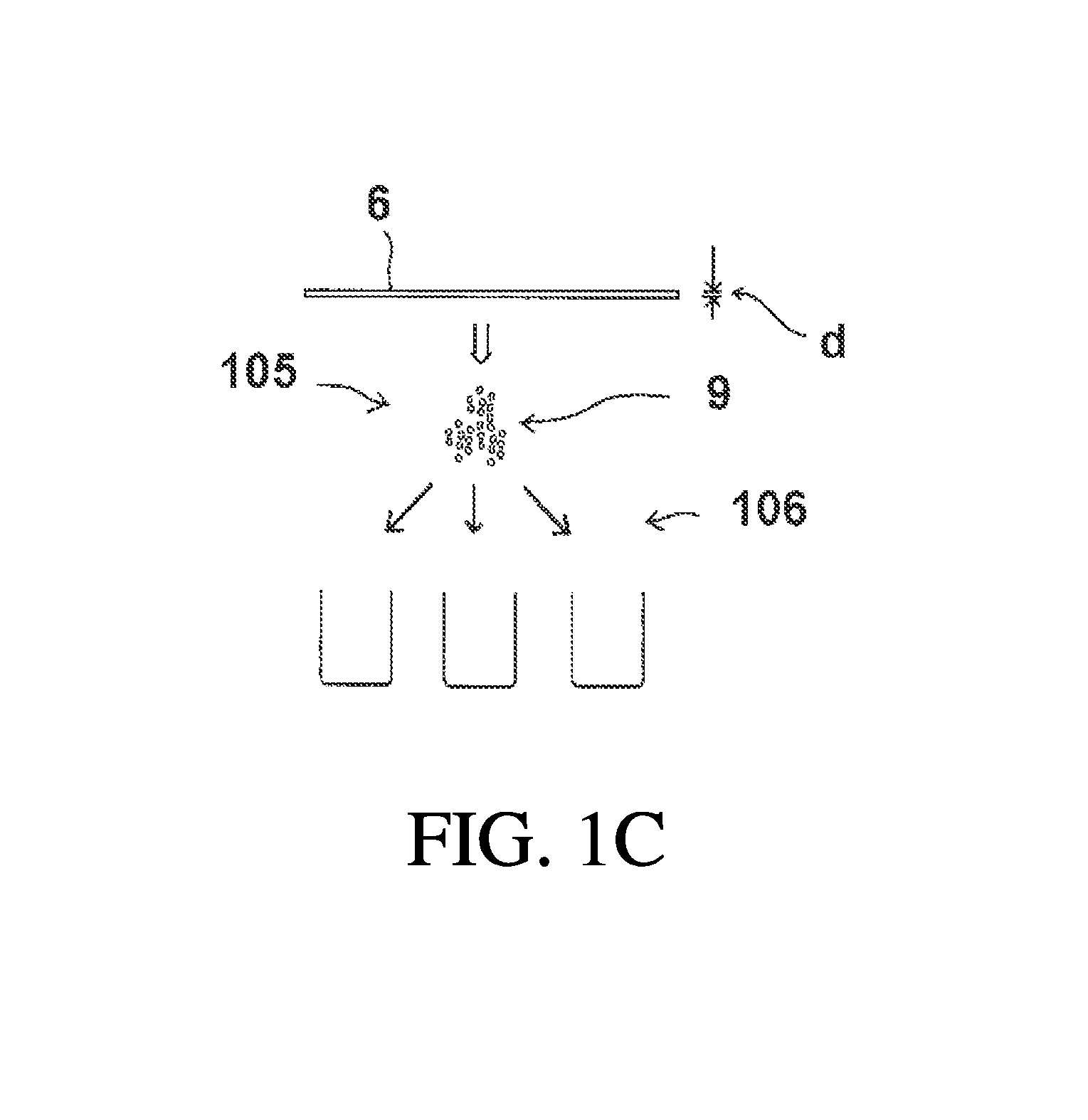

The average propylene cycle selectivity of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the hydrocarbon synthesis portion of the OTP flow scheme in lieu of the fixed bed technology of the prior art; 2) a hydrothermally stabilized and dual-functional catalyst system comprising a molecular sieve having dual-function capability dispersed in a phosphorus-modified alumina matrix containing labile phosphorus and / or aluminum anions; and 3) a catalyst on-stream cycle time of 400 hours or less. These provisions stabilize the catalyst against hydrothermal deactivation and hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield near or at essentially start-of-cycle levels.

Owner:UOP LLC

Method for producing zirconia-reinforced alumina grains, in particular abrasive grains, and grains produced by such method

ActiveUS20130283705A1Cost effective productionImprove material performanceMaterial nanotechnologyPigmenting treatmentThin layerMaterials science

Method for producing zirconia-reinforced Al2O3 grains, including at least the following steps: inductively melting a starting mixture to form a eutectic melt made of alumina and zirconia; applying the eutectic melt as a thin layer material, the thin layer material being quenched; and removing the thin layer material. In this manner abrasive grains can be formed directly or the thin layer material can be classified when it is broken into abrasive grains, the grains are polycrystalline without amorphous glass phases as an alumina matrix having zirconia precipitations, and at least some of the zirconia precipitations can be formed in the nanoscale range.

Owner:VSM VEREINIGTE SCHMIRGEL- UND MASCHINEN-FABRIKEN

Zeolitic catalyst, substrate based on a silica-alumina matrix and zeolite, and hydrocracking process for hydrocarbon feedstocks

ActiveUS20070209968A1High activityIncreasing the mesoporosity of the YMolecular sieve catalystsHydrocarbon oil crackingSilicon dioxideHydrocarbon

The invention relates to a catalyst including at least one hydro-dehydrogenating element chosen from the group formed by the group VIB and group VIII elements of the periodic table and a substrate based on a silica-alumina matrix with a reduced content of macropores containing a quantity greater than 5% by weight and less than or equal to 95% by weight of silica (SiO2) and based on at least one zeolite. The invention also relates to a substrate based on a silica-alumina matrix with a reduced content of macropores containing a quantity greater than 5% by weight and less than or equal to 95% by weight of silica (SiO2) and based on at least one zeolite. The invention also relates to hydrocracking and / or hydroconversion processes and hydrotreating processes utilising a catalyst according to the invention.

Owner:INST FR DU PETROLE

Process for the production of phenylalkanes that use a zeolitic catalyst that is based on silica-alumina

InactiveUS20060224030A1Higher catalytic performance levelResistant to deactivationMolecular sieve catalystsMolecular sieve catalystAlkyl transferArame

An alkylating process for the production of at least one of 2-, 3-, 4-, 5-, and 6-phenylalkanes by alkylation of an aromatic compound with a feedstock containing at least one olefin comprising at least 9 carbon atoms per molecule, in the presence of a catalyst comprising at least one substrate based on at least a zeolite and a non-zeolitic silica-alumina matrix with a low content of macropores, whereby said matrix contains an amount of more than 5% by weight and less than or equal to 95% by weight of silica (SiO2), whereby said process is carried out at a temperature of between 30 and 400° C., a pressure of between 0.1 and 10 MPa, an hourly volumetric flow rate of 0.50 to 200 h−1, and an aromatic compound / olefin molar ratio of between 1:1 and 50:1.

Owner:INST FR DU PETROLE

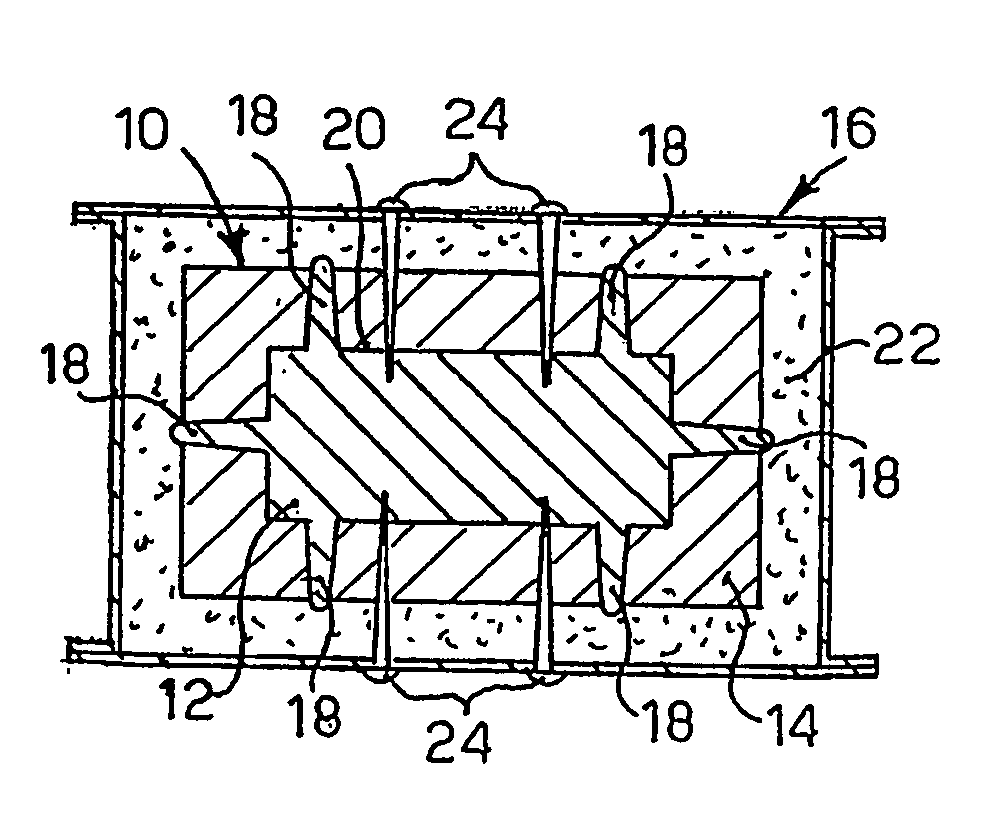

Strain tolerant aggregate material

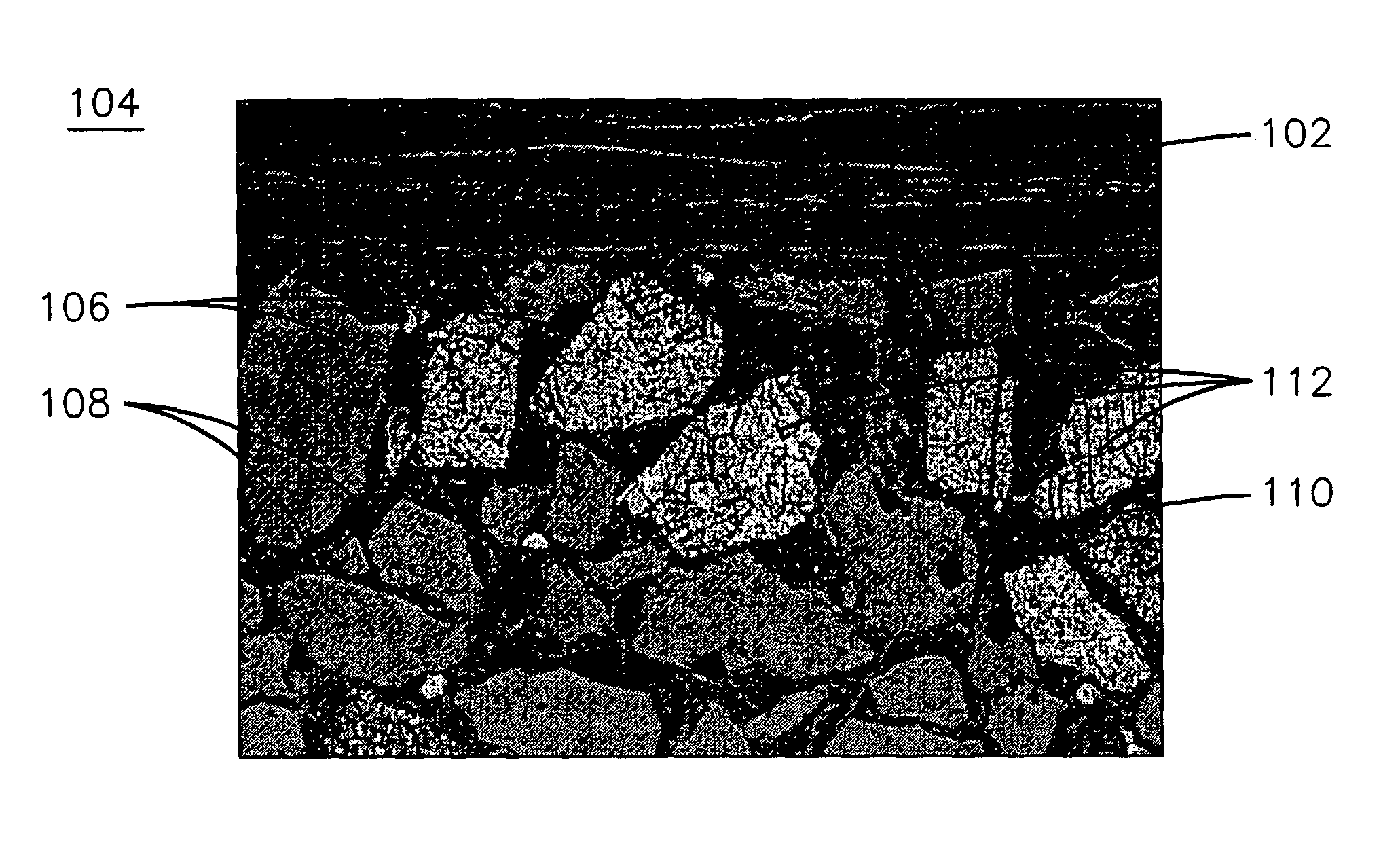

A material (100) formed of a sintered aggregation of ceria particles (106), mullite particles (108) and an alumina matrix material (110). Differential thermal expansion of the ceria and mullite particles generates thermal stress sufficient to create micro-cracking of the ceria particles. The ratio of ceria to mullite may be selected to achieve a desired coefficient of thermal expansion for matching the thermal growth of a mating CMC material (102). The micro cracks provide the material with a desired degree of strain tolerance useful in high temperature applications such as a solid core gas turbine vane (20).

Owner:SIEMENS ENERGY INC

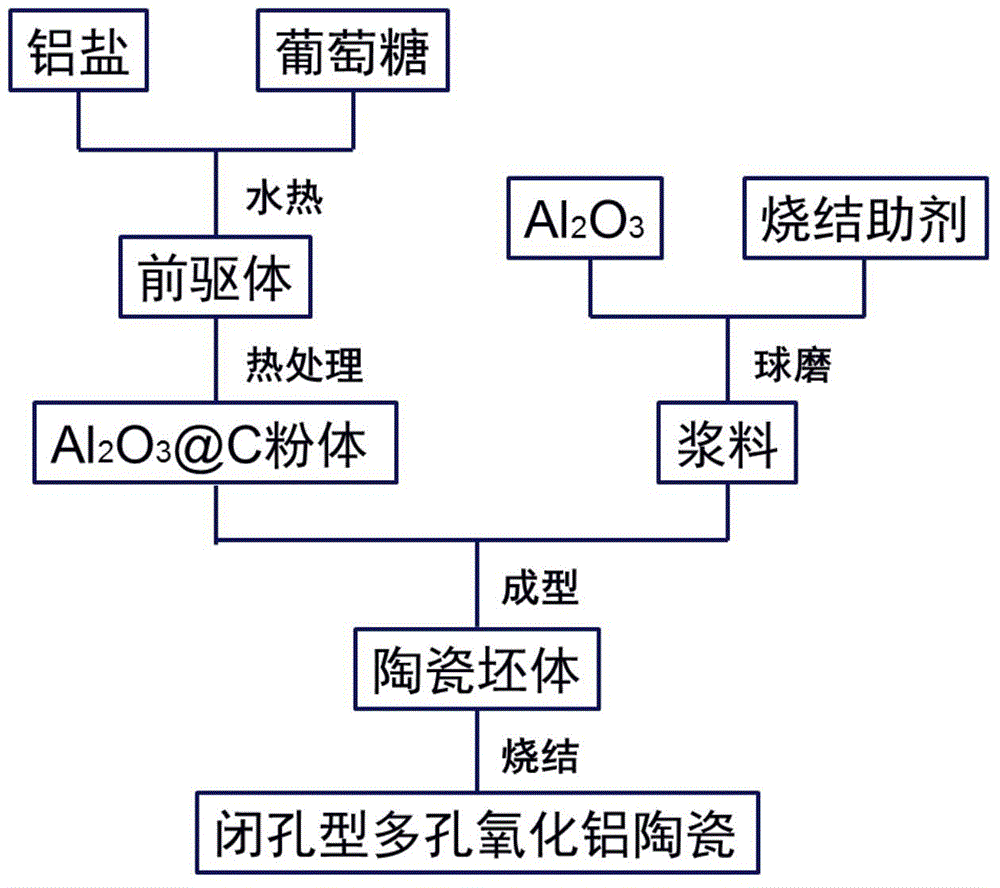

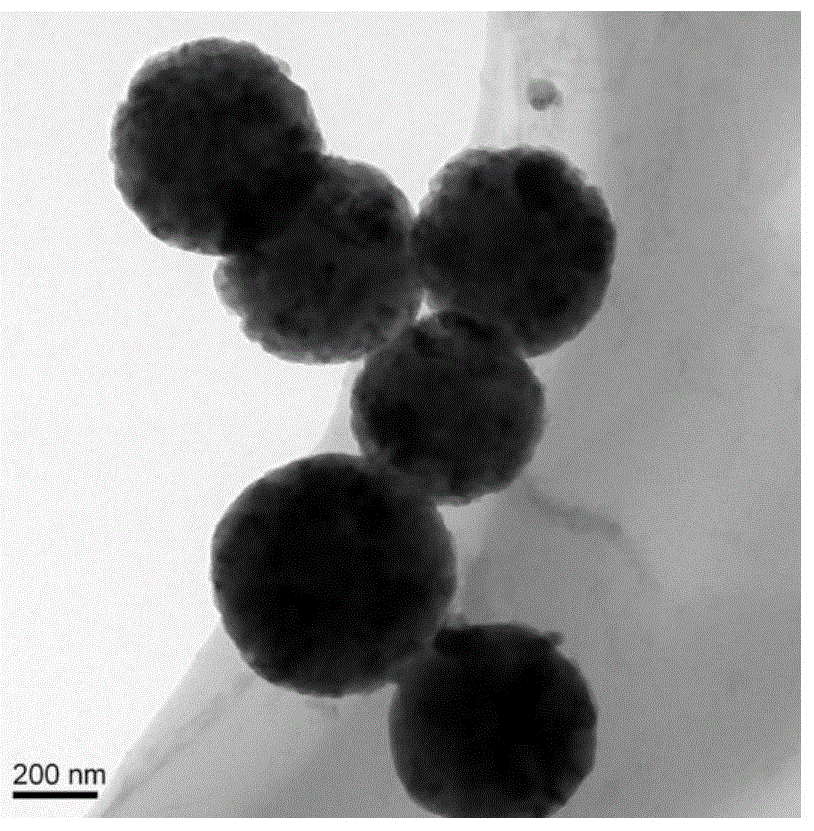

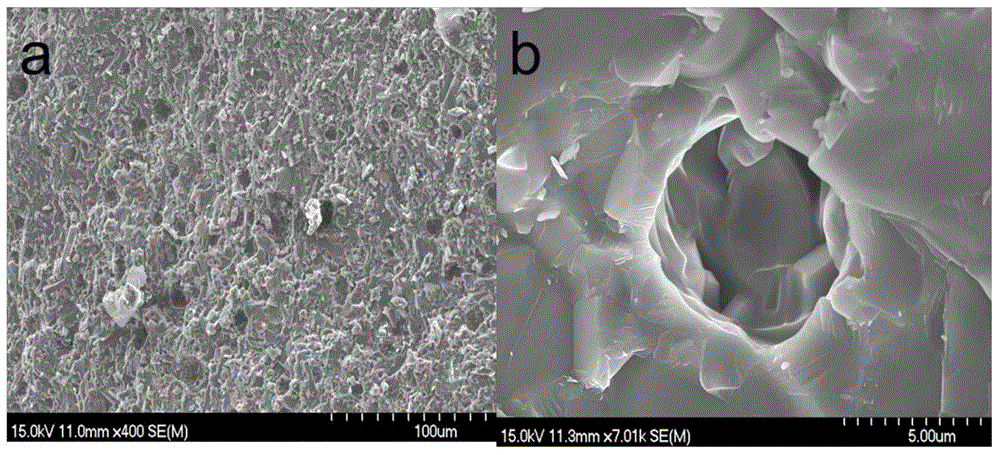

Method for preparing closed-pore porous heat-insulating alumina ceramic

The invention relates to a method for preparing a closed-pore porous heat-insulating alumina ceramic. According to the method, a powder which is prepared by adopting a hydrothermal synthesis method and is in a core-shell structure is added into alumina slurry as a pore forming agent to prepare an alumina ceramic, in the process of sintering an alumina ceramic blank, the carbon sphere as a core is removed under oxidization, the alumina layer as a shell and the alumina substrate are sintered compactly to form a magnesium-aluminium spinel together with a sintering additive, and the magnesium-aluminium spinel is pined into the grain boundary. Closed pores are introduced into the prepared alumina ceramic successfully, the rate of closed pores of the alumina ceramic is up to10-60%, and the rate of open pores is less than 5%. The thermal conductivity of the alumina ceramic is 0.1W / (m.K), and the usage temperature is over 1,400 DEG C. The method provided by the invention can be used for overcoming the defects that the existing process for preparing the porous ceramic by foaming is complex, too many additives are added, and the product is easy to powderize.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Self-reacting alumina-base composite ceramic mold core for fine casting and preparation method thereof

InactiveCN101386546ALow thermal shock resistanceImprove thermal shock resistanceFoundry mouldsFoundry coresComposite ceramicMullite

The invention provides a self-reaction alumina-based composite ceramic core for precision casting, and a preparation method thereof. The composite ceramic core consists of alundum powder, in-situ synthesized aluminum titanate, MgTi2O5 and mullite. The composite ceramic core is prepared from the following raw materials in weight percentage: 70 to 85 percent of alundum powder with different particle sizes, 0 to 2 percent of magnesium oxide powder, 8 to 20 percent of titanium dioxide powder and 6 to 10 percent of kyanite powder, and carbon powder accounting for 1 to 3 percent of the gross mass of the four raw materials is added as an easy-breakdown agent. The method prepares the composite ceramic core through the following steps of mixing, dry-pressing, shaping and firing the raw materials at high temperature. As other raw materials are added to an alumina matrix of the invention, the prepared composite ceramic core has the advantages of good high-temperature chemical stability and thermal stability, low thermal expansion coefficient and small shrinkage factor after sintering, and meets the requirements of a ceramic core for precision casting on room temperature and high temperature strength.

Owner:SOUTH CHINA UNIV OF TECH

Alumina particles with dispersed noble metal, process for producing the same and exhaust gas purifying catalyst employing the same

InactiveUS20020045543A1Increased durabilityGood dispersionDispersed particle separationCatalyst activation/preparationMaterials scienceAlumina matrix

Disclosed are alumina particles with a dispersed noble metal. The alumina particles are hollow-structured alumina particles which comprise alumina as a major component of the matrix, and in which at least one noble metal is dispersed in the alumina matrix and / or on the surface of the alumina particles with a dispersion degree of 10% or more when being measured by the CO adsorption method. The noble metal dispersion degree is so high that the alumina particles are suitable for making a catalyst. The resulting catalyst exhibits the purifying performance, which hardly differs before and after a high temperature durability test, and is extremely good in terms of the durability.

Owner:TOYOTA CENT RES & DEV LAB INC +1

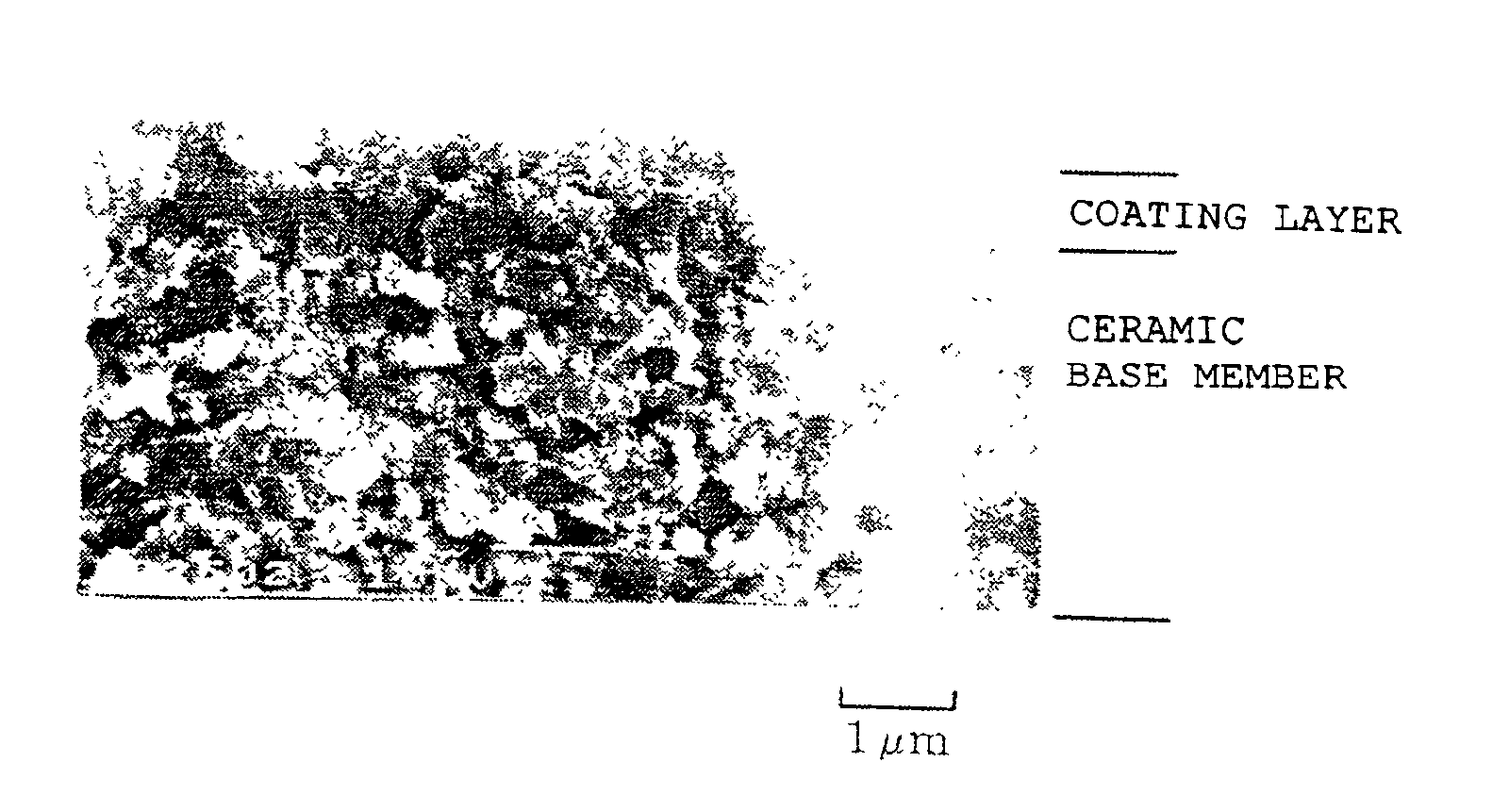

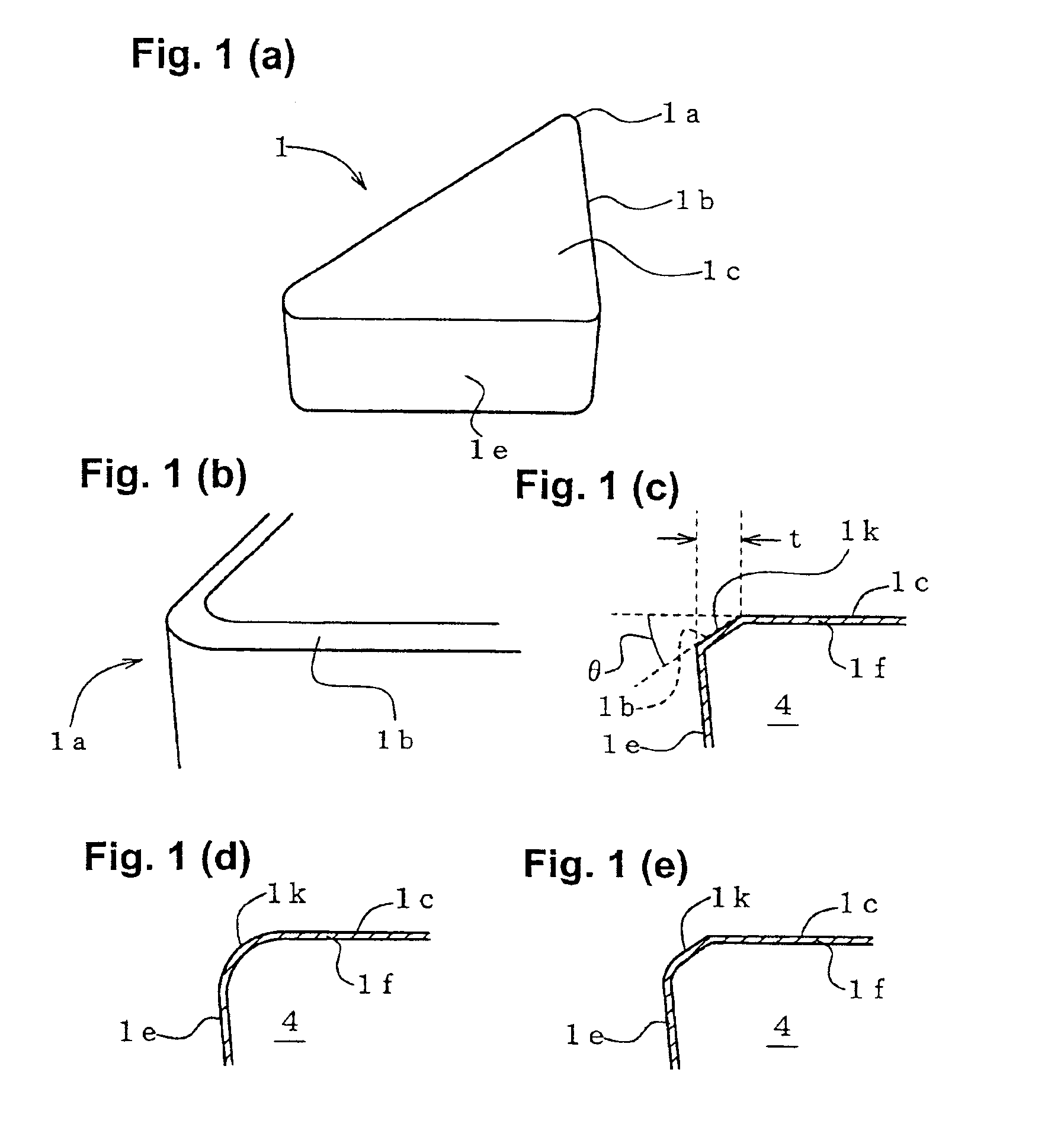

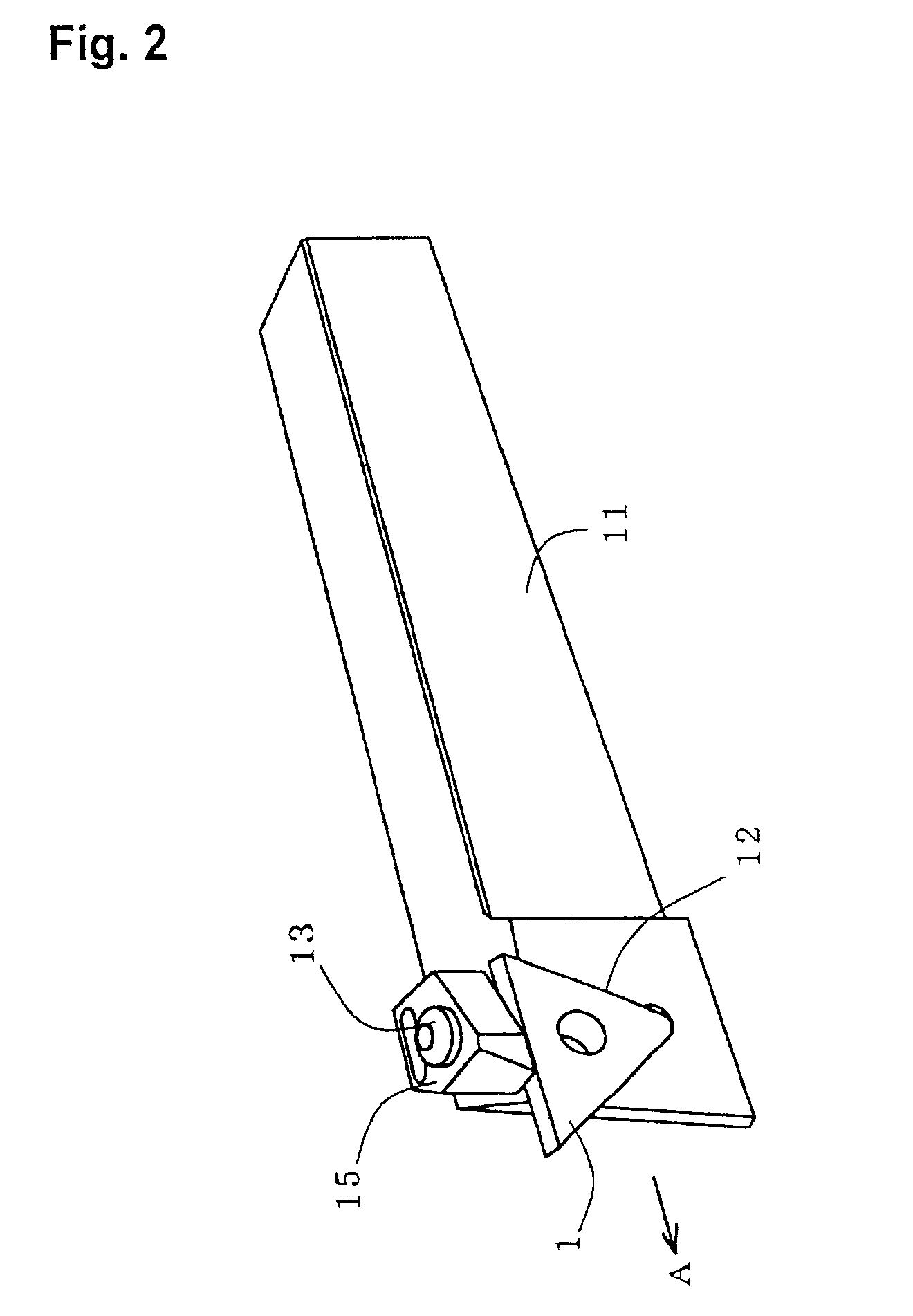

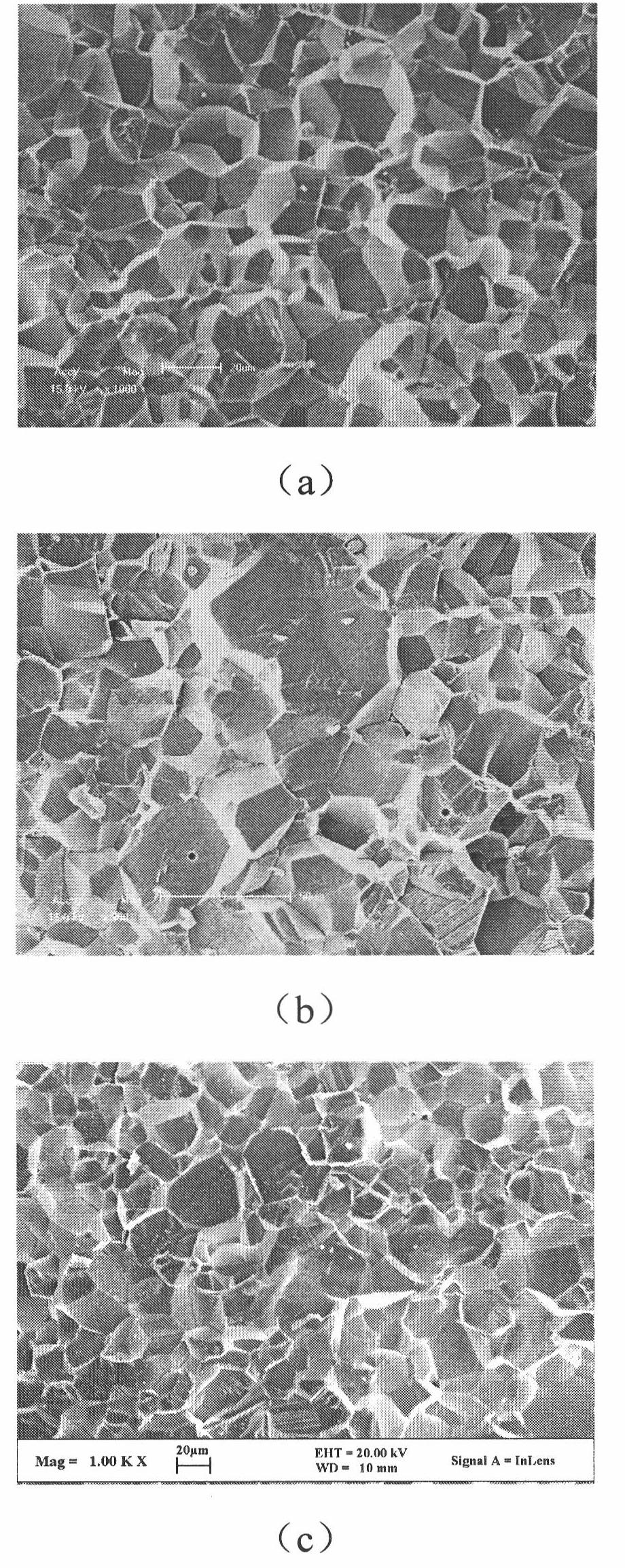

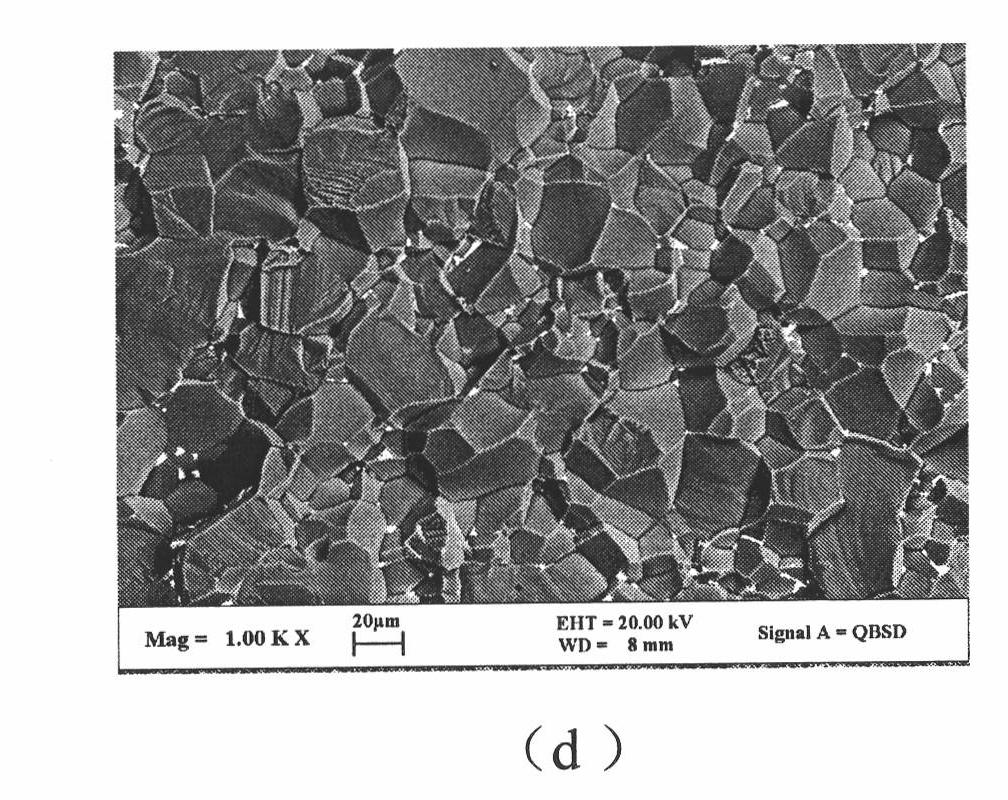

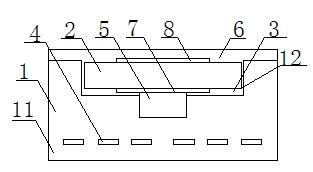

Cutting tool

InactiveUS6939607B2Low costImprove cutting performancePigmenting treatmentCutting insertsBorideComposite ceramic

A ceramic cutting tool including a ceramic base member 4 of a tool main body 1 which is formed of a composite ceramic which contains a hard phase dispersed within an alumina matrix phase. The hard phase contains, as a predominant component, one or more elements selected from hard-phase-forming metal elements M in the form of at least one of a carbide, nitride, or boride, or in the form of a solid solution of at least two selected from the carbide, nitride and boride. The hard-phase-forming metal elements M include Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W and Si. The surface of the ceramic base member 4 is covered with a coating layer 1f, which contains titanium carbonitride or titanium nitride as a predominant component. The coating layer 1f has an average crystal-grain size of 0.1 to 0.5 μm as observed on the surface, and an average thickness of 0.5 to 2 μm. The coating layer 4f is formed by a CVD at a low to medium temperature range of 750 to 900° C. The ceramic cutting tool can be fabricated at low cost and can secure stable cutting performance over a long period even when the tool is used under severe cutting conditions under which large thermal and mechanical loads act on the tool.

Owner:NGK SPARK PLUG CO LTD

Method for manufacturing transparent alumina ceramic and application thereof

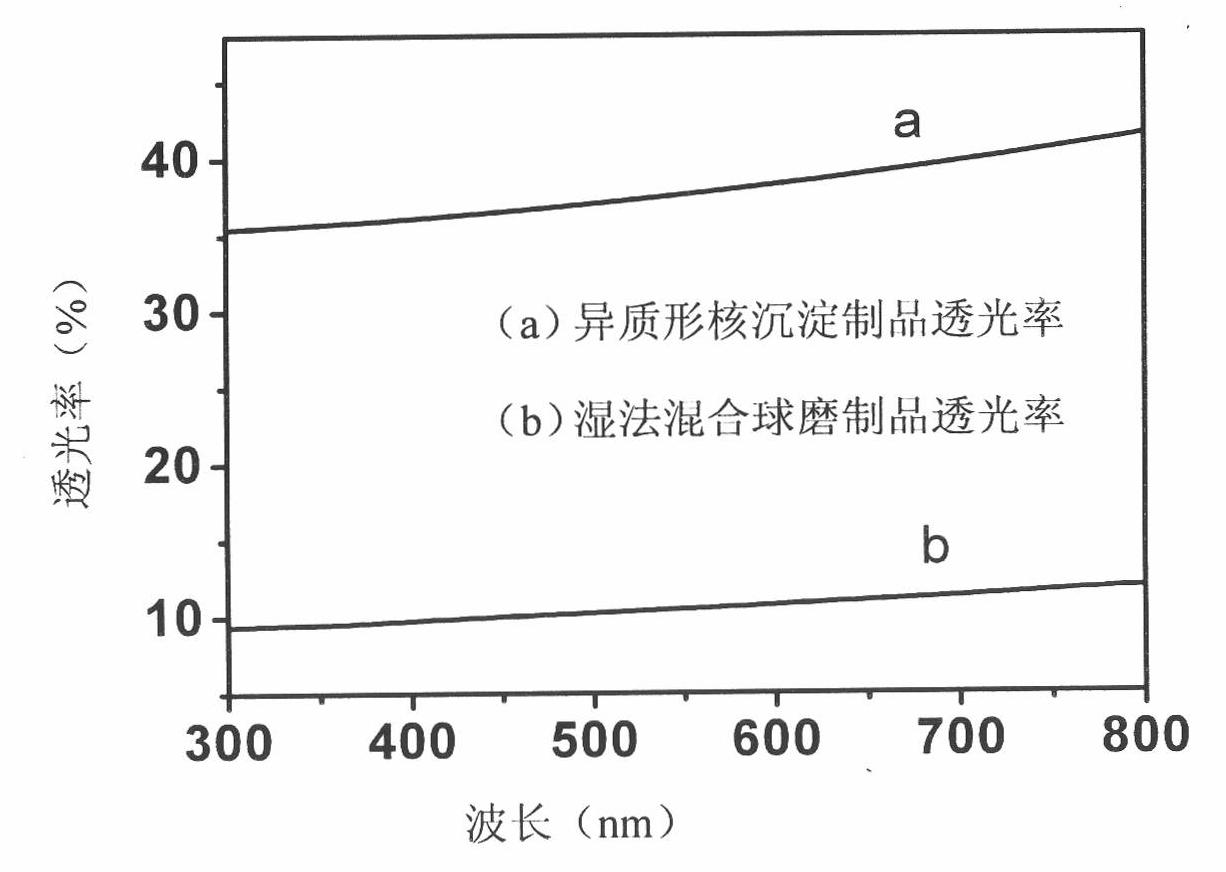

InactiveCN102093038AEnhanced inhibitory effectFine and uniform microstructureImpression capsDentistry preparationsTransmittanceNanoscopic scale

The invention discloses a method for manufacturing transparent alumina ceramic, which belongs to the technical field of high-performance transparent alumina ceramic preparation. In the method, an additive is introduced by adopting a chemical heterogeneous nucleation sedimentation method, so that the additive ions are uniformly coated on the surface of alumina powder by using the alumina powder asa heterogeneous nucleation center to form nano powder with 'shell-nuclear' composite structure; and the obtained nano powder is molded and sintered to prepare the transparent alumina ceramic. The additive is coated on the surface of the alumina powder to form a nano coating, and the additive is finally uniformly dispersed in the alumina matrix on nano scale after sintering so as to achieve the effect of well inhibiting the growth of crystal grains. The method successfully overcomes the defect caused by a wet mixing ball milling method, and finally prepares the transparent alumina ceramic withfiner and more uniform additive microstructure and better light transmission. The linear transmittance of the prepared transparent alumina ceramic is about 35 to 43 percent when the wavelength is 300to 800 nanometers.

Owner:TSINGHUA UNIV

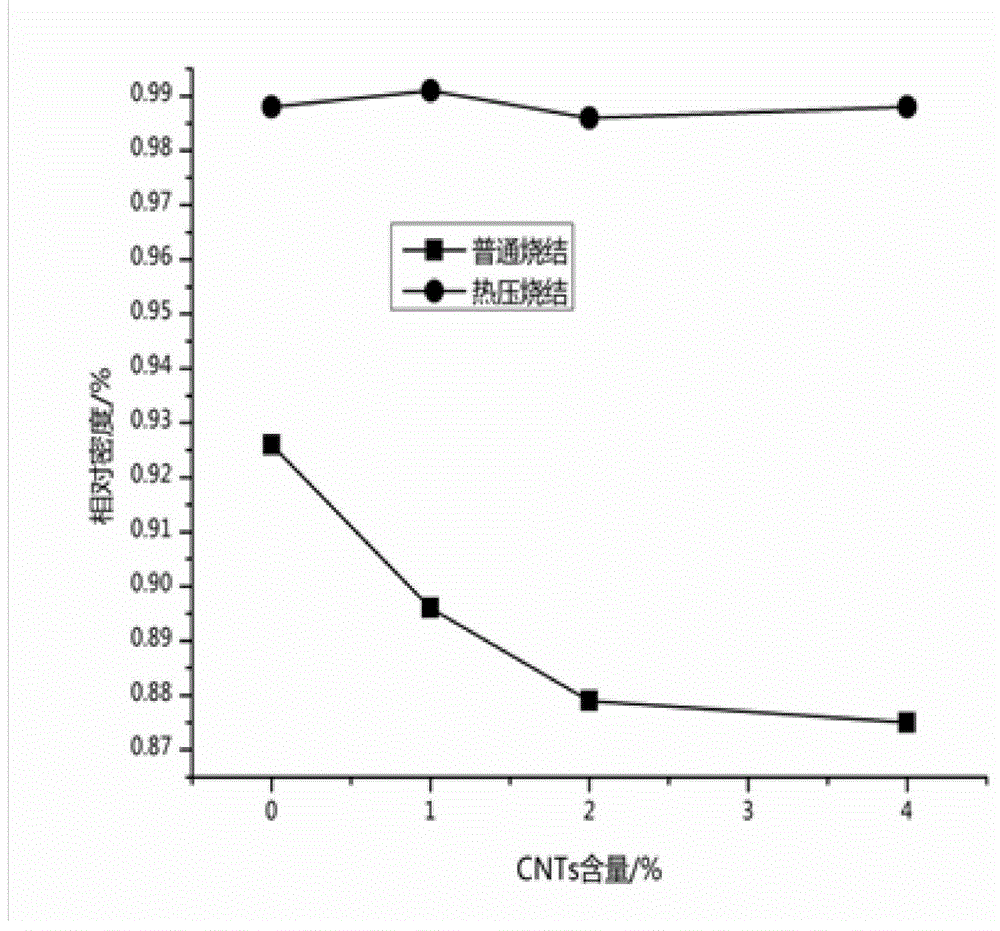

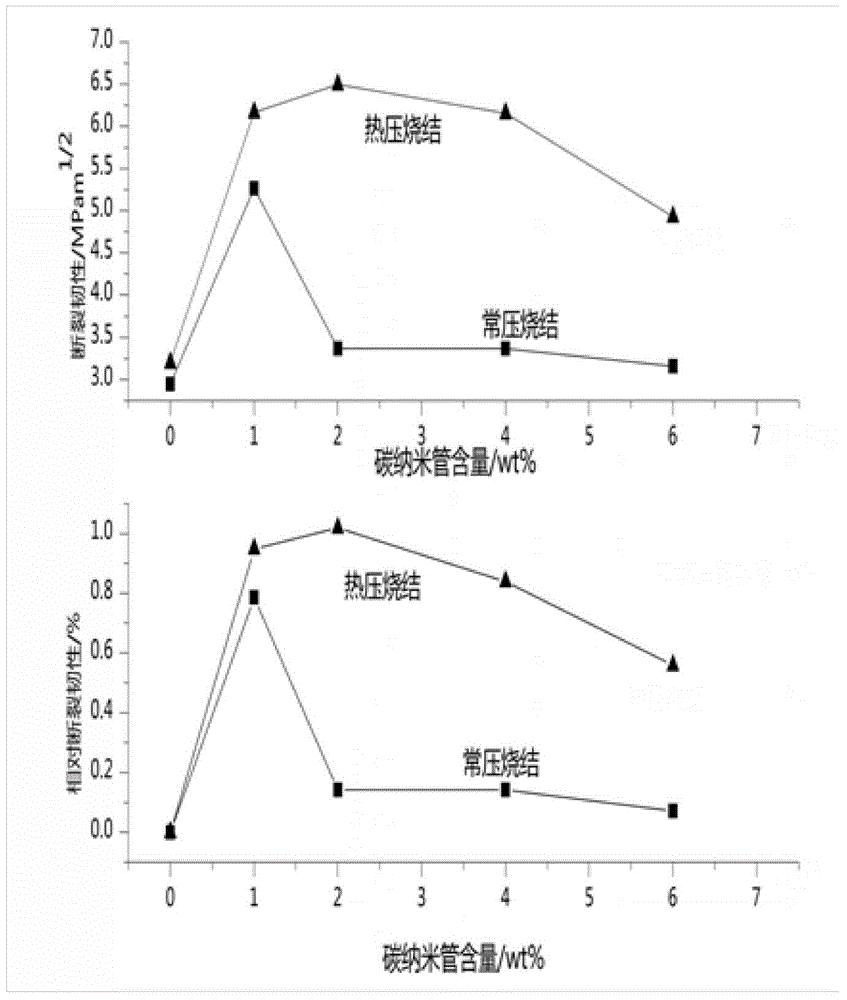

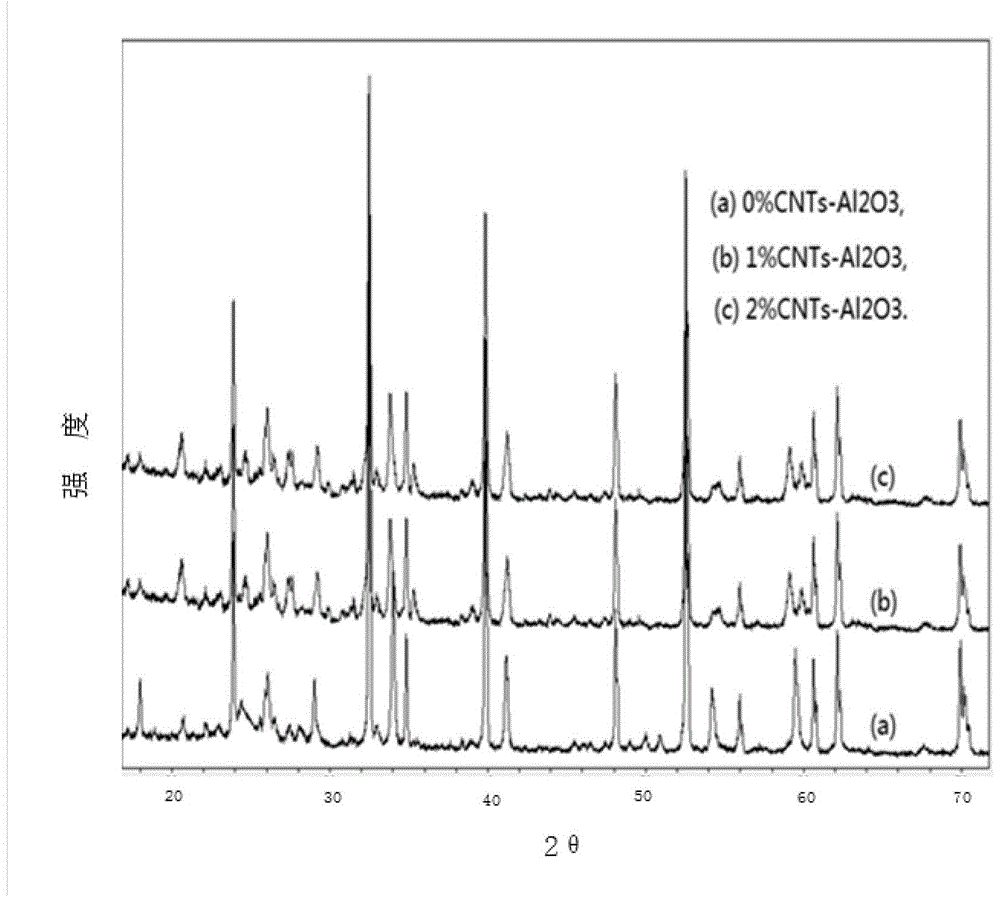

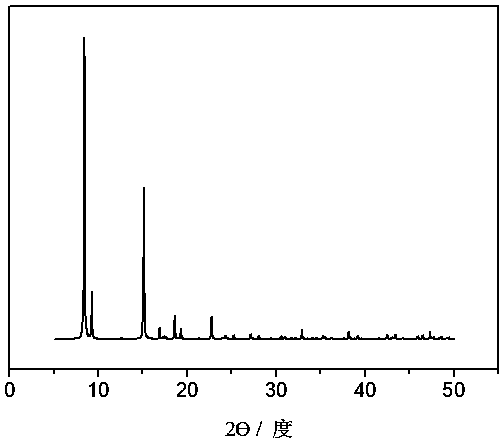

Carbon nano tube-aluminium oxide composite material and preparation method thereof

The invention discloses a carbon nano tube-aluminium oxide composite material. The composite material consists of carbon nano tubes and aluminium oxide, wherein the content of the carbon nano tubes in weight percent is 0.1%-6%. The composite material is prepared by virtue of a hot-pressing sintering technology and the carbon nano tubes are uniformly dispersed in an aluminium oxide matrix material. By hot-pressing sintering, the problem about the compacting sintering of the composite material can be solved; besides, the sintering temperature is lowered remarkably and the sintering time is prolonged. The compactness of the composite material reaches 98.8%, and the fracture toughness of the composite material reaches 6.32MPam1 / 2 which is improved by about 99.2% compared with that of the aluminium oxide material. XRD (X Ray Diffraction) and SEM (Scanning Electron Microscope) results show that under the hot-pressing sintering condition, the composite material forms an intact sintered phase and is high in compactness, transgranular fractures are interlaced with intergranular fractures on the matrix, the carbon nano tubes are uniformly dispersed in the aluminium oxide matrix and no agglomeration phenomenon happen.

Owner:XUCHANG UNIV

Lanthanum oxide-aluminum oxide composite coating prepared by plasma spraying method

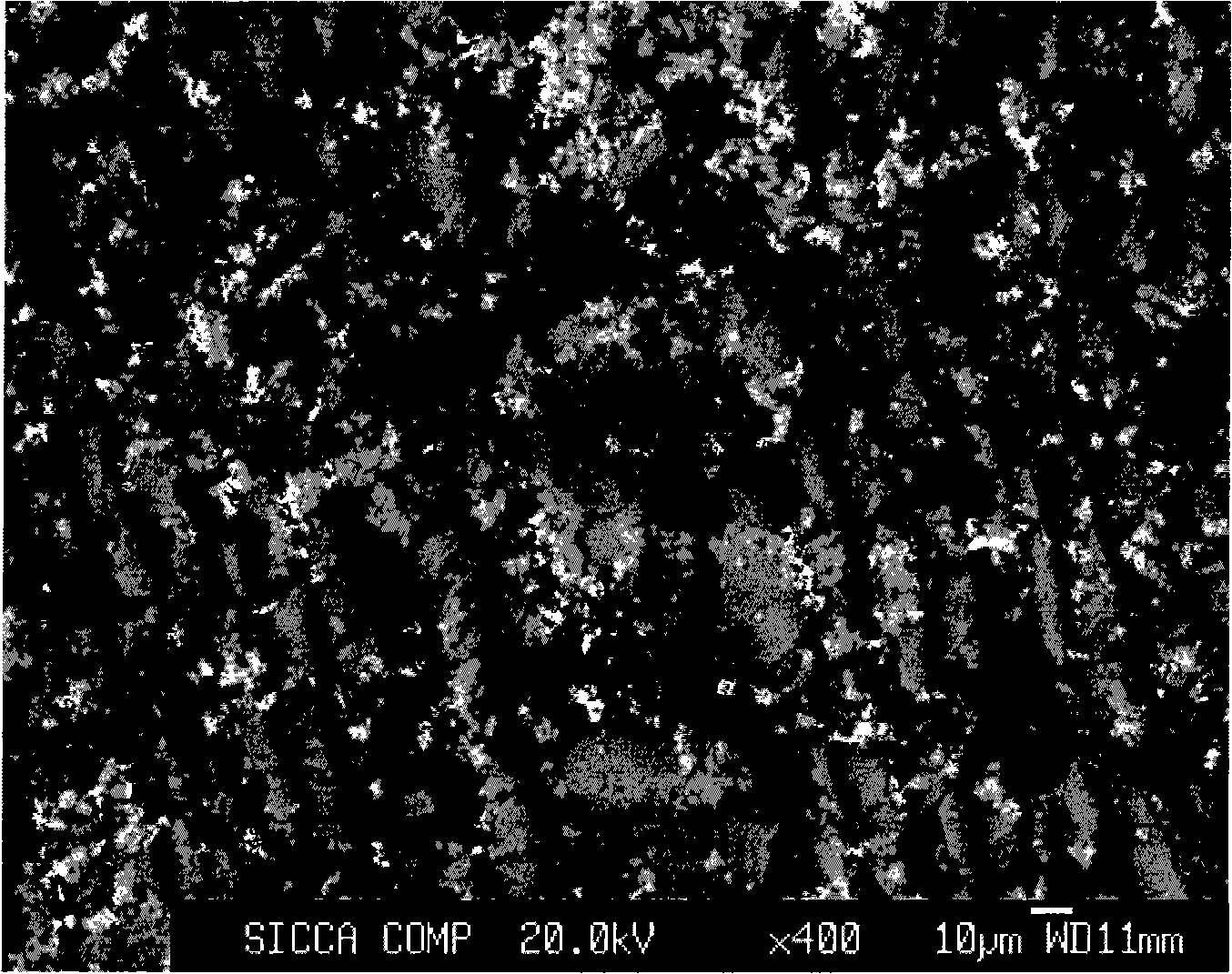

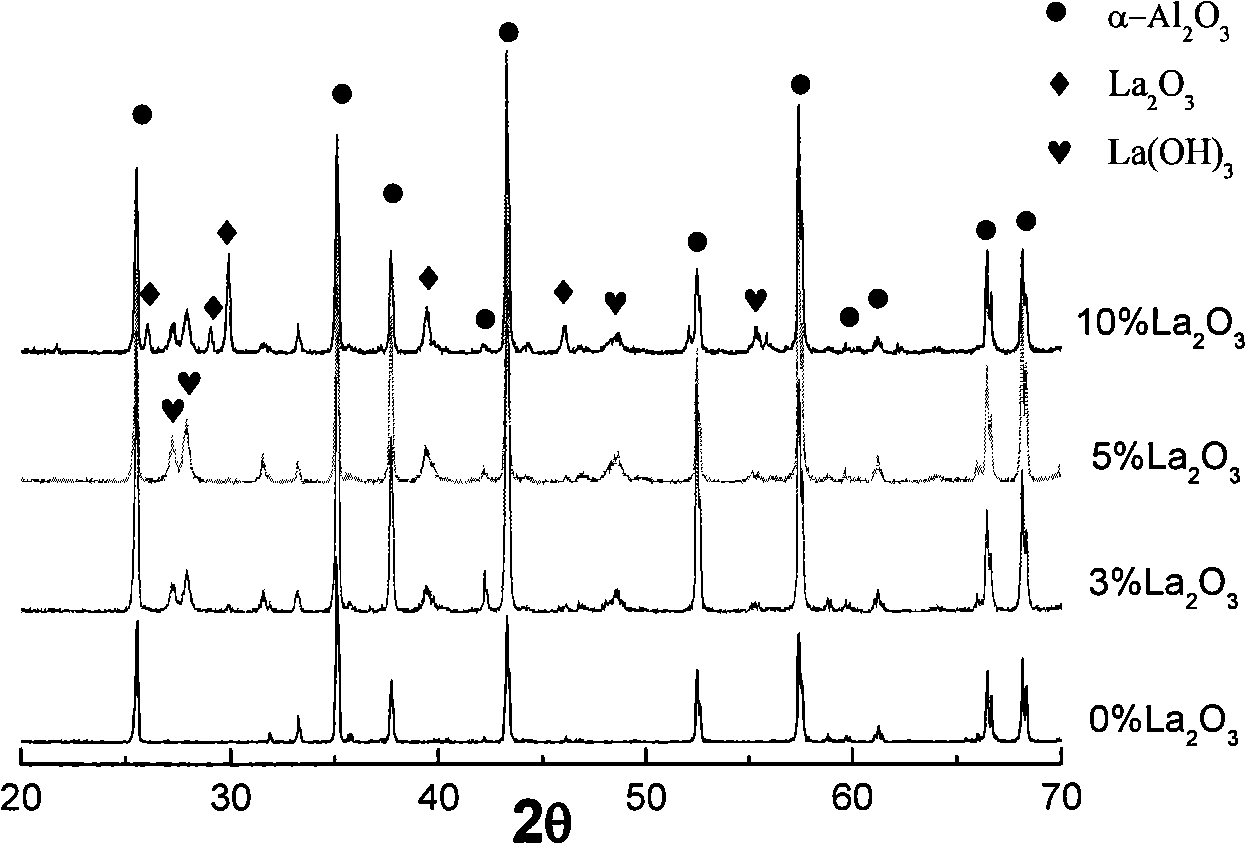

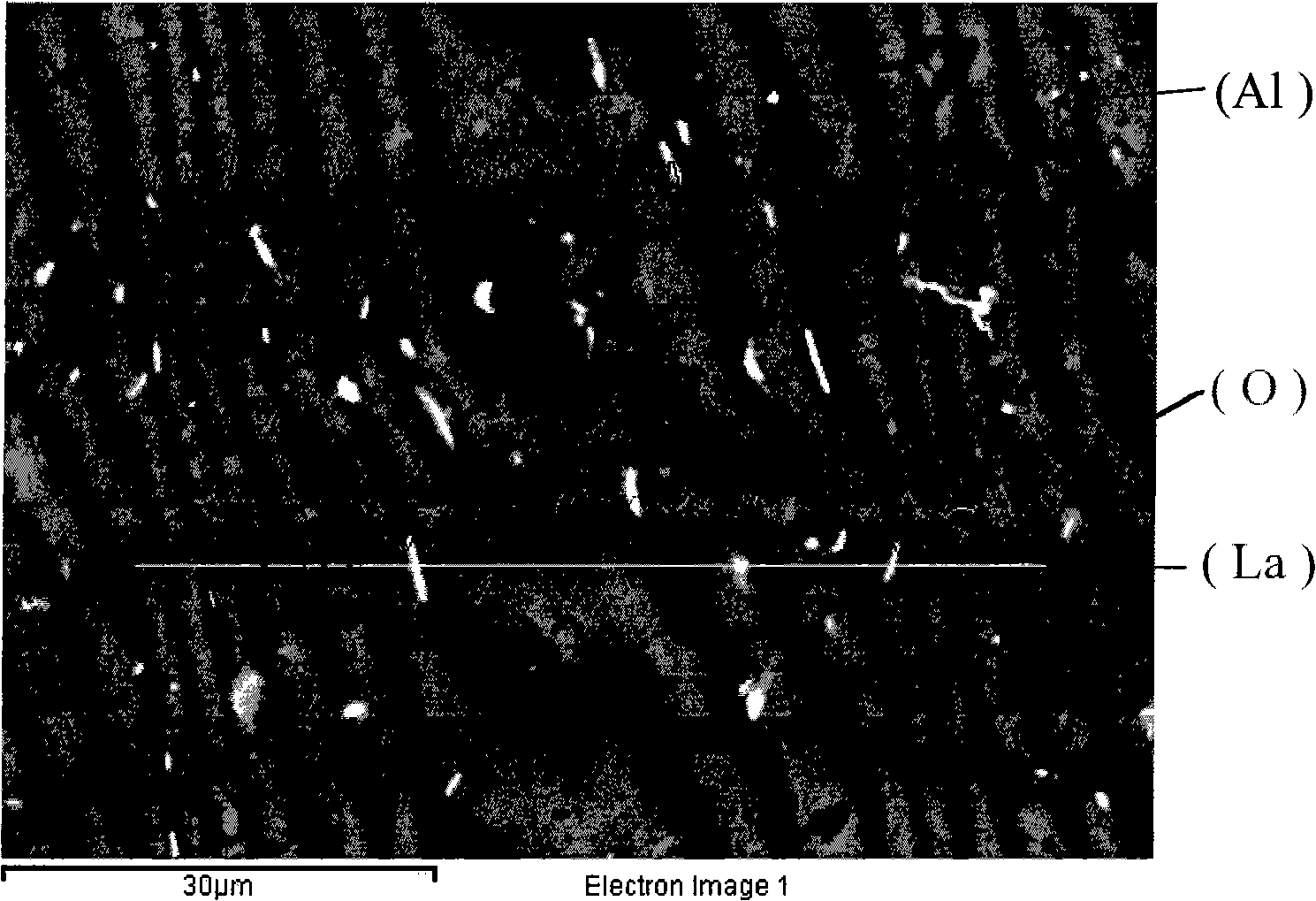

ActiveCN101280405AEvenly dispersedImprove deposition efficiencyMolten spray coatingStructure analysisCeramic coating

The invention relates to a lanthanum oxide and aluminum oxide composite coating layer which are prepared by adopting a plasma spraying method and the preparation method thereof, which belongs to the abrasion proof ceramic coating layer field. Aluminum oxide power and lanthanum oxide power are weighed as per the 3 / 97 to 10 / 90 proportion of lanthanum oxide and aluminum oxide and then are mixed by ball milling; composite power is deposited on the cleaned and blasted metal basis material by adopting the plasma spraying process. The microstructure analysis of the lanthanum oxide and aluminum oxide composite coating layer prepared by the invention shows that the lanthanum element is uniformly dispersed on the basal body of the aluminum oxide, compared with the spraying pure Al2O3 coating layer, a plasma spraying Al2O3-La2O3 coating layer has higher deposition efficiency, and the wear resistant of the plasma spraying coating layer is effectively improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Self-toughening substance containing type continuous fiber reinforced thermo-structure composite and preparation method thereof

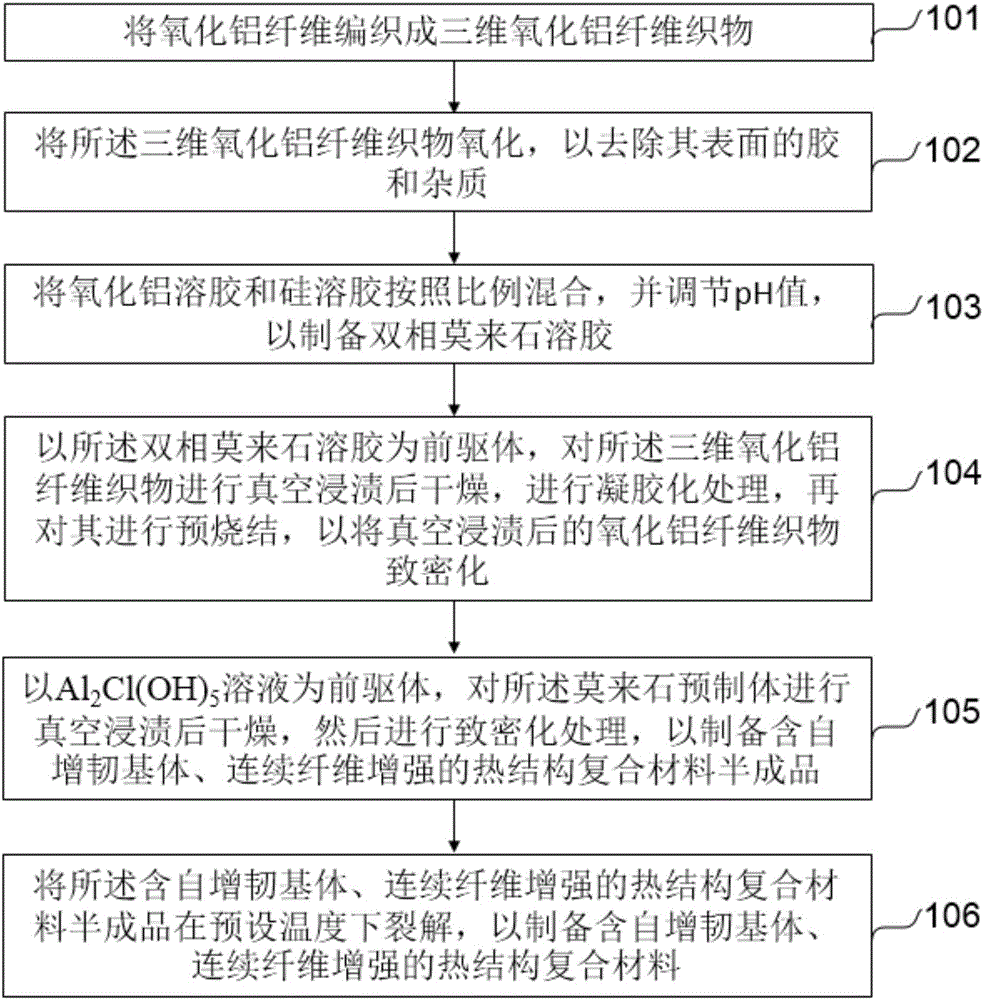

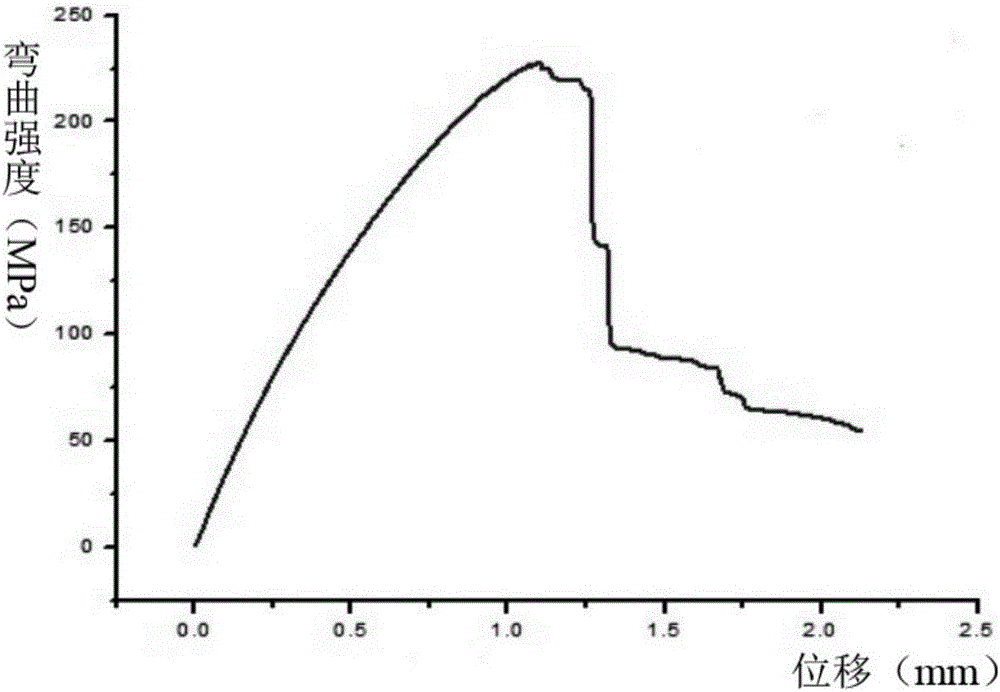

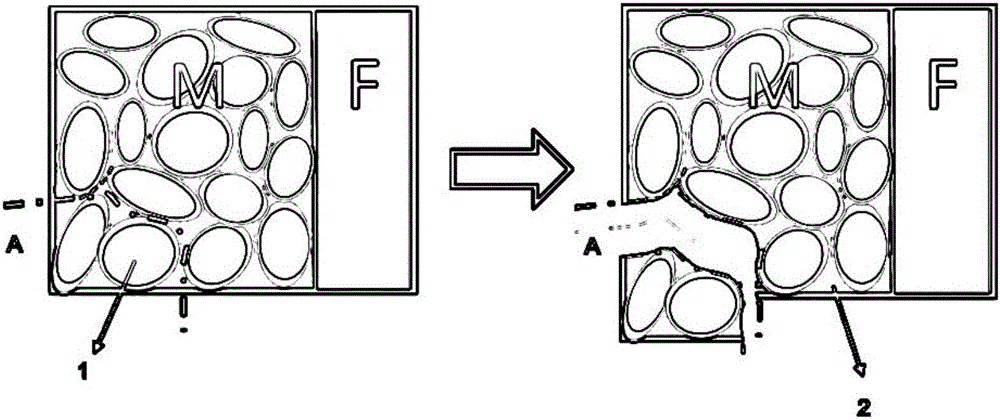

ActiveCN106747555AImprove high temperature stabilityImprove mechanical propertiesCeramicwareMulliteFlexural strength

The invention relates to a self-toughening substance containing type continuous fiber reinforced thermo-structure composite and a preparation method thereof. The self-toughening substance containing type continuous fiber reinforced thermo-structure composite comprises a substrate which consists of a porous mullite framework and an aluminum oxide substrate, and a reinforcement which is a three-dimensional continuous aluminum oxide fiber fabric, wherein the porous mullite framework is prepared from mullite powder which is converted through mullite sol; the aluminum oxide substrate is prepared according to an infiltration pyrolysis method using Al2Cl(OH)5 as a precursor. The self-toughening substance containing type continuous fiber reinforced thermo-structure composite is outstanding in mechanical property, high in bending intensity, high in high-temperature stability, and of great significance on the development of the technical field.

Owner:BEIHANG UNIV

Catalyst for reducing olefin content in mixed material of liquified gas and gasoline

The catalyst for reducing olefin content in mixed material of liquefied gas and gasoline includes cocrystallized RE-ZSM5 / ZSM11 molecular sieve as the active component in 25-75 wt% and alumina matrix for the rest. Its preparation process includes the following steps: 1. adding the aluminum source, inorganic acid, RE salt, water glass and deionized water successively into the reactor under stirring to synthesize the active component cocrystallized RE-ZSM5 / ZSM11 molecular sieve; and 2. mixing the cocrystallized RE-ZSM5 / ZSM11 molecular sieve with alumina and water, extruding the mixture into strip, drying at 60-120 deg.c for 2-4 hr, roasting in air atmosphere at 500-600 deg.c for 4-6 hr, and curing in 100 % water vapor at 400-600 deg.c for 2-10 hr to obtain the catalyst. The catalyst of the present invention has the capacity of obviously lowering olefin content in mixed material of liquefied gas and gasoline and raising the arene content.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

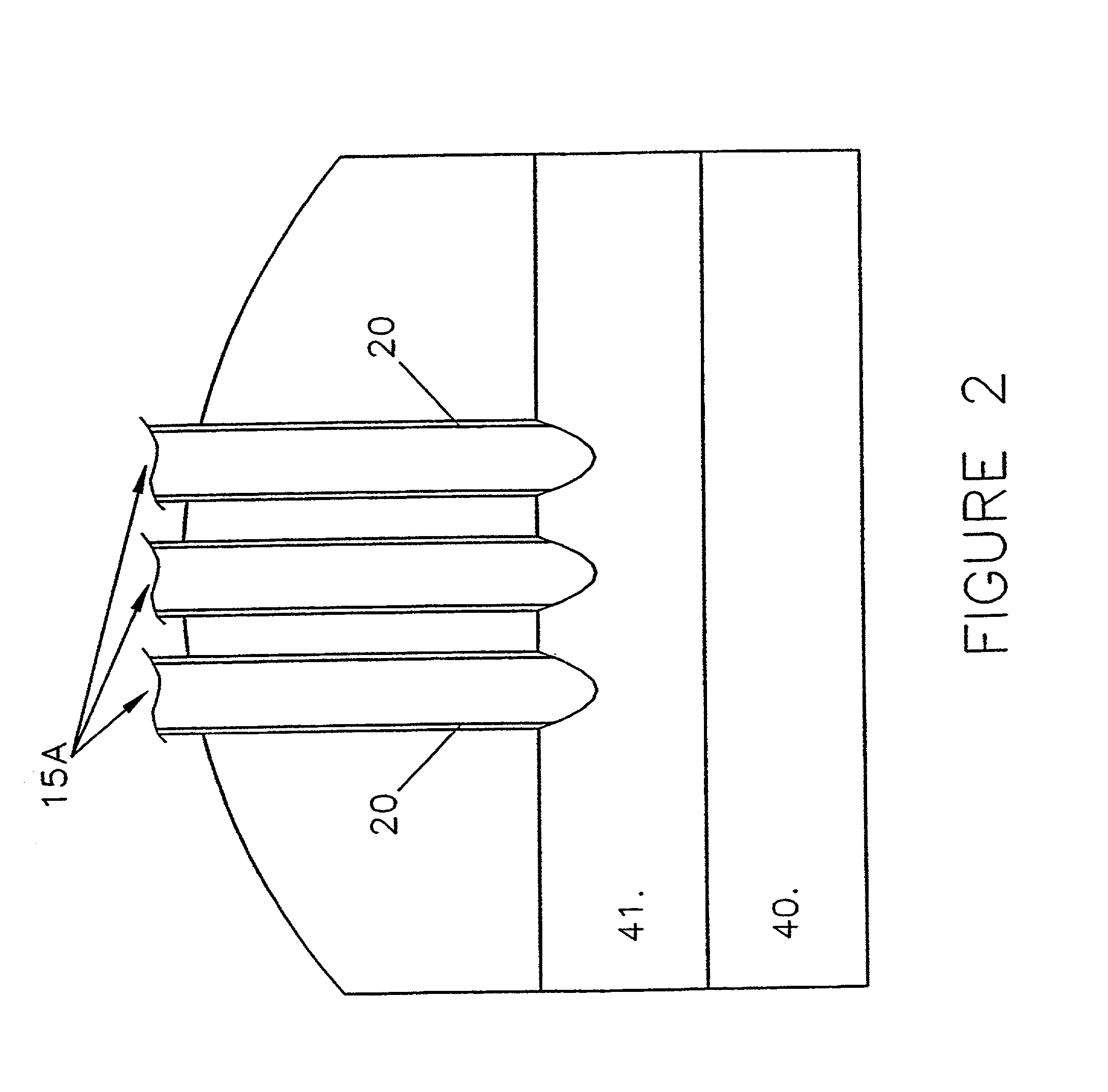

Aluminium-wettable protective coatings for carbon components used in metallurgical processes

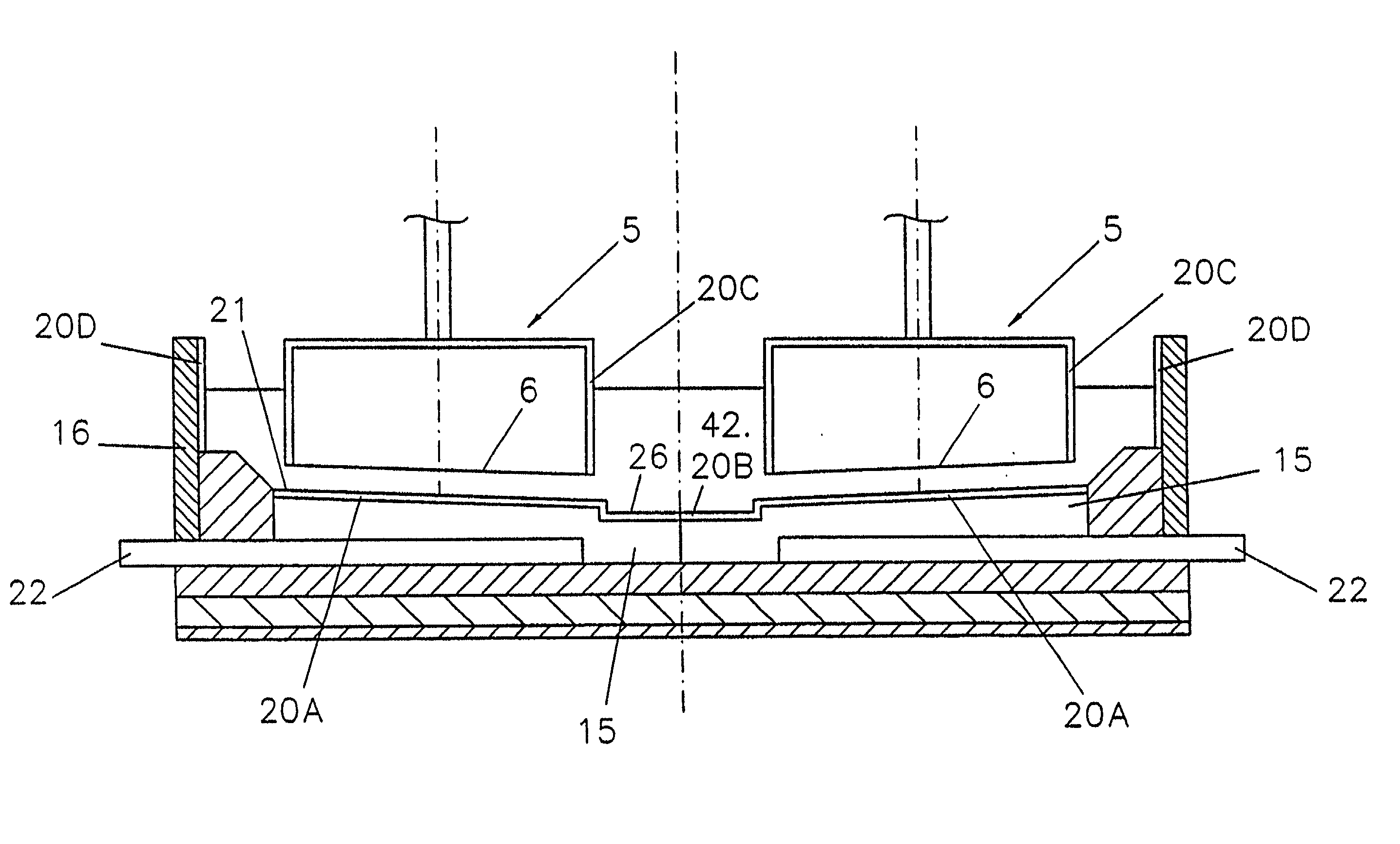

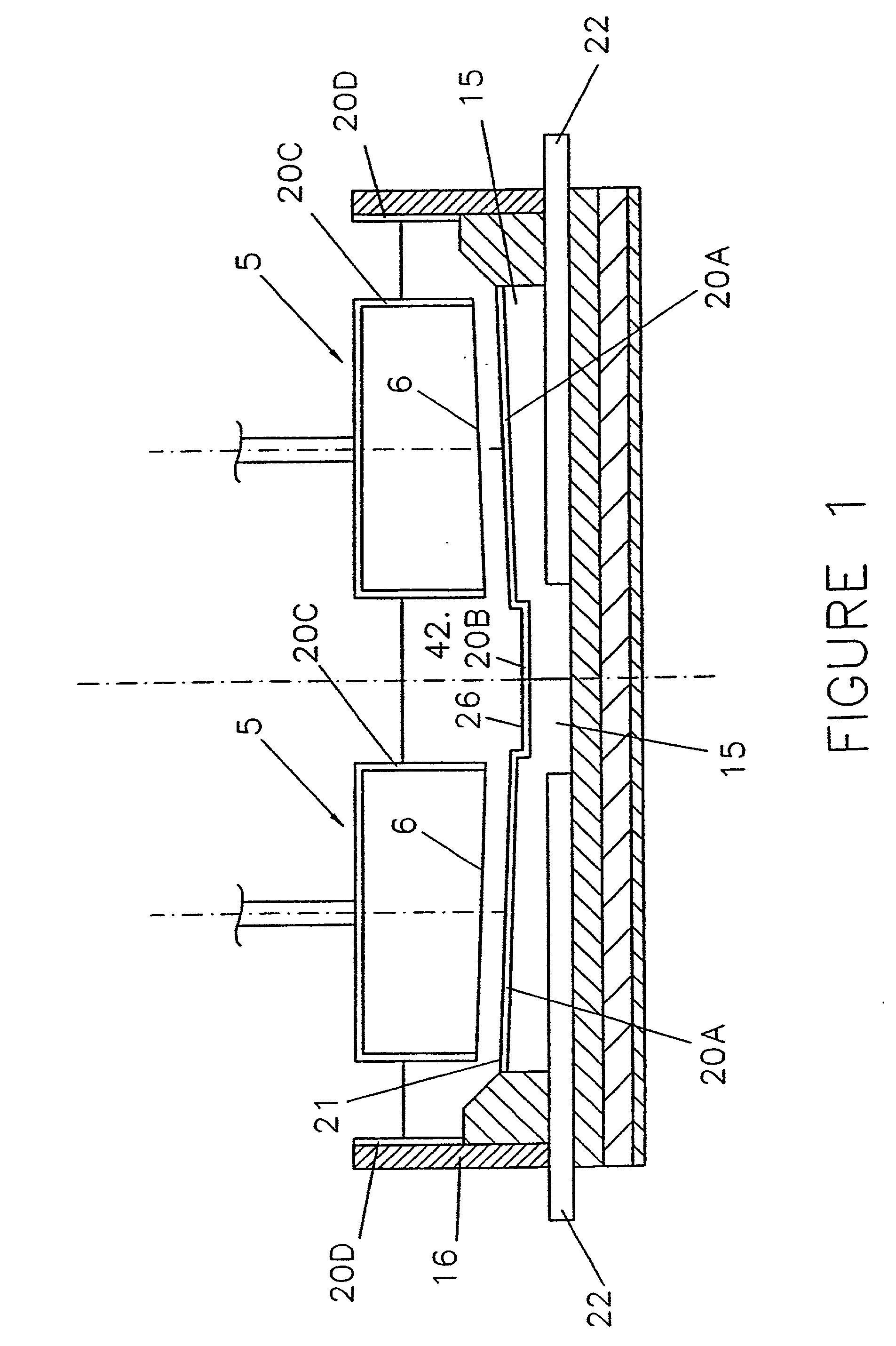

An aluminium-wettable protective coating on a substrate, for use at elevated temperature in an oxidising and / or corrosive gaseous and / or molten environment is disclosed. The coating (20A, 20B, 20C, 20D) is applied to protect the substrate (5, 15, 16) from liquid and / or gaseous attack. The coating comprises particles of at least one metal oxide and / or at least one partly oxidised metal in a dried and / or cured colloidal carrier and / or organic binder. The metal oxide and / or partly oxide metal is reactable with molten aluminium when exposed thereto to form an alumina matrix containing metal of said particles and aluminium. The coated substrate (5, 15, 16) may be used in an aluminium electrowinning cell an arc furnace for the recycling of steel or an apparatus for the purification of a molten metal such as aluminium, magnesium, iron or steel.

Owner:MOLTECH INVENT

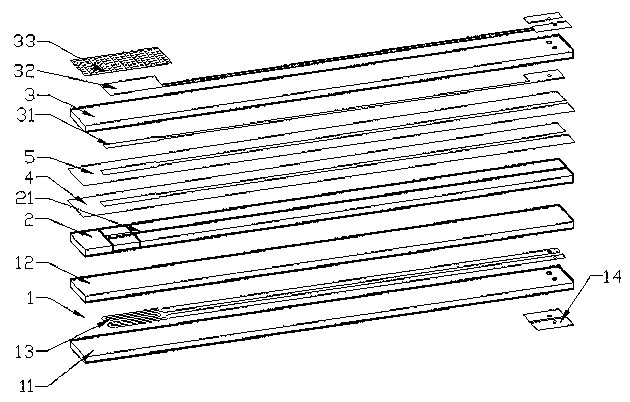

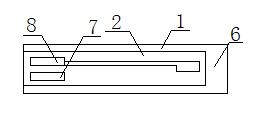

Chip type oxygen sensor

InactiveCN103018283AImprove thermal conductivityImprove thermal efficiencyMaterial analysis by electric/magnetic meansOxygen sensorUltimate tensile strength

The invention discloses a chip type oxygen sensor, which has high heating efficiency, fast response speed and higher strength. The chip type oxygen sensor comprises three parts, namely, a ceramic heater (1), an alumina substrate (2) and a zirconium oxide substrate (3), which are sequentially arrange from bottom to top; a reference air channel (21) is arrange on the alumina substrate; an inner working electrode (31) and an inner working electrode (32) are pasted on the upper surface and lower surface of the zirconium oxide substrate (3) respectively; the outer working electrode (32) is printed with a porous protective layer (33); an alumina printing layer (4) and a zirconium oxide printing layer (5) are printed between the alumina substrate (2) and the zirconium oxide substrate (3); the alumina printing layer (4) is printed on the upper side surface of the alumina substrate (2); and the zirconium oxide printing layer (5) is printed on the lower side surface of the zirconium oxide substrate (3). The chip type oxygen sensor can be applied in the technical field of automobile engine exhaust testing.

Owner:ZHUHAI LUCKYMAN TECH CO LTD

Inert processing of oxide ceramic matrix composites and oxidation sensitive ceramic materials and intermediate structures and articles incorporating same

Owner:COI CERAMICS

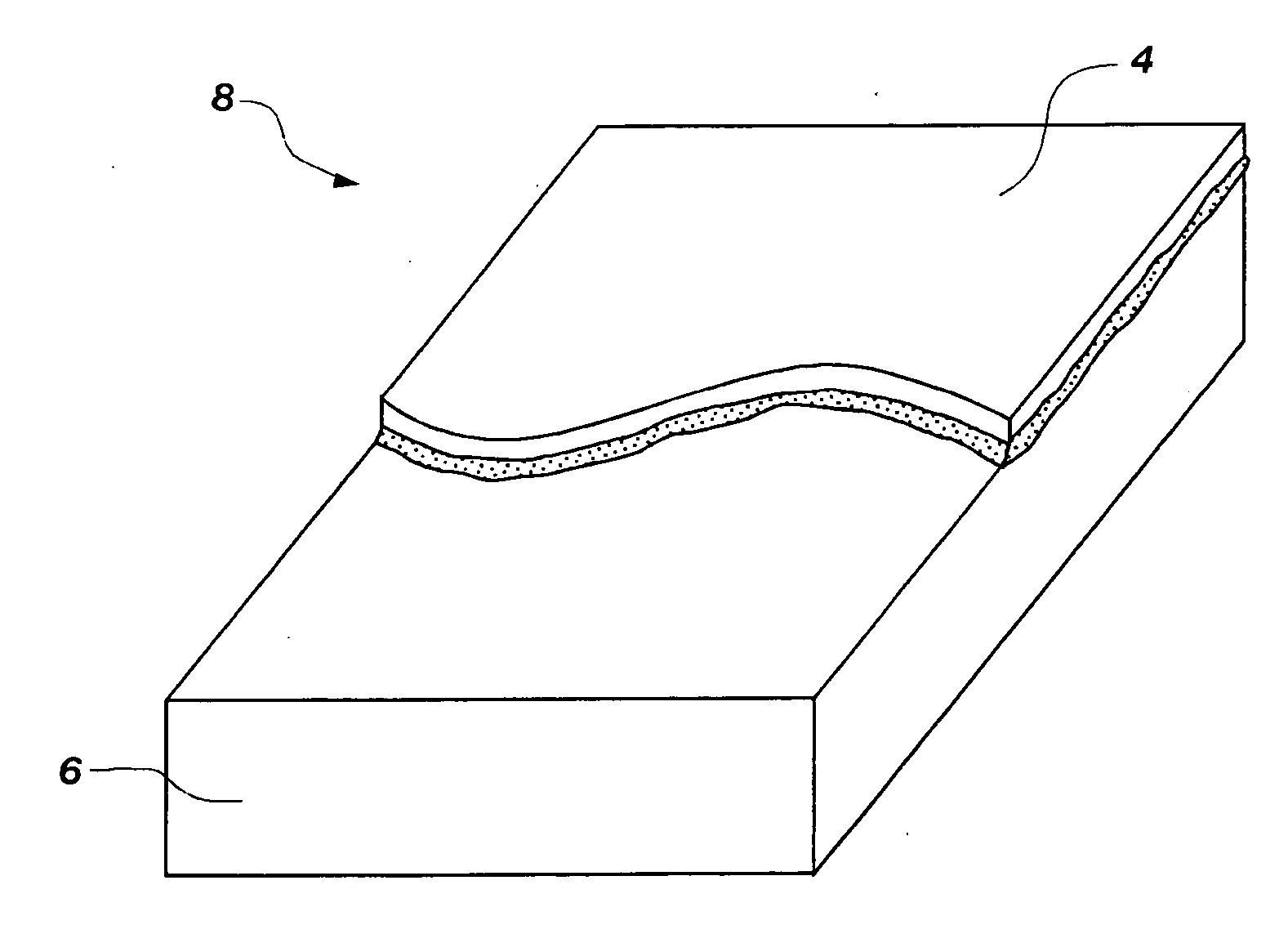

Method to produce an element subject to wear, and element subject to wear thus obtained

ActiveUS20070128462A1Maintain good propertiesLow costSemiconductor/solid-state device detailsSolid-state devicesMolten metalAlumina matrix

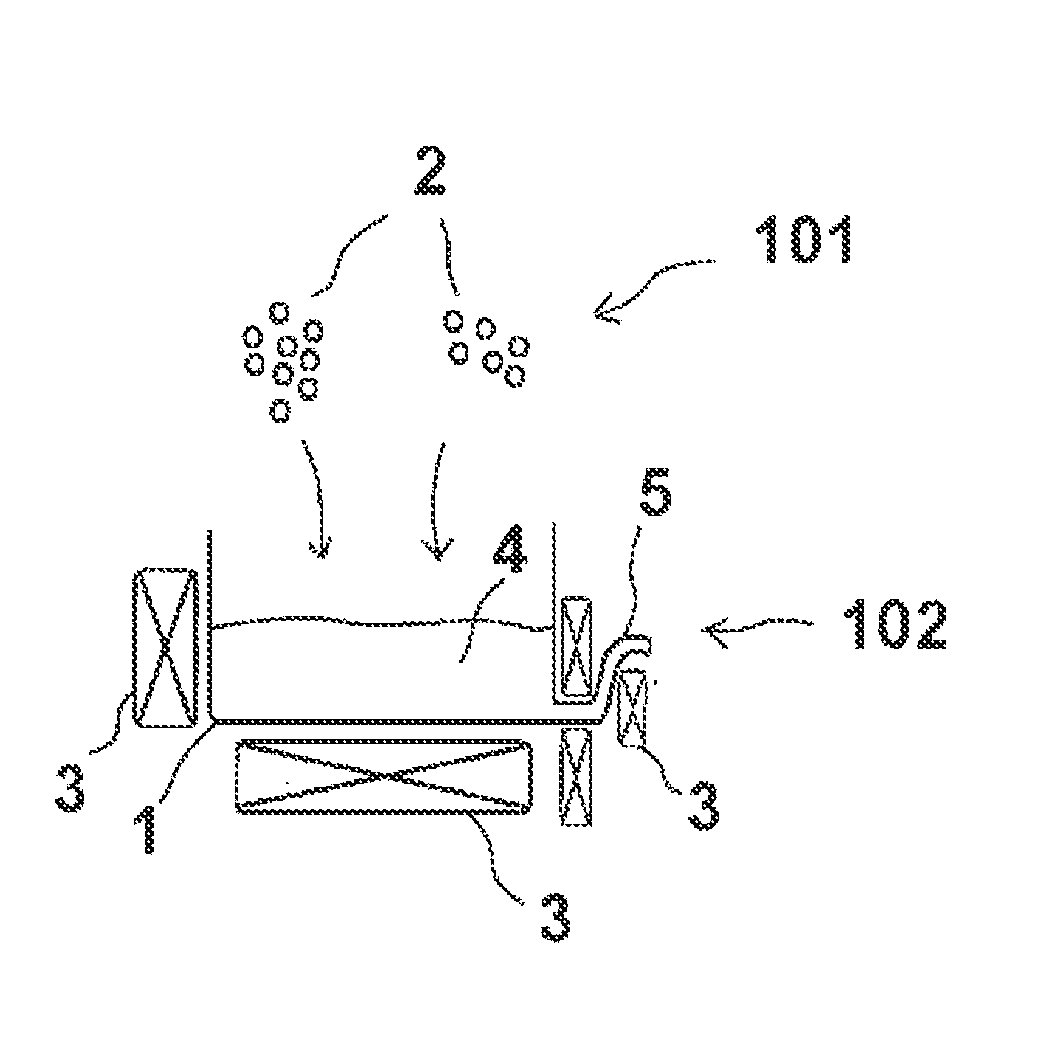

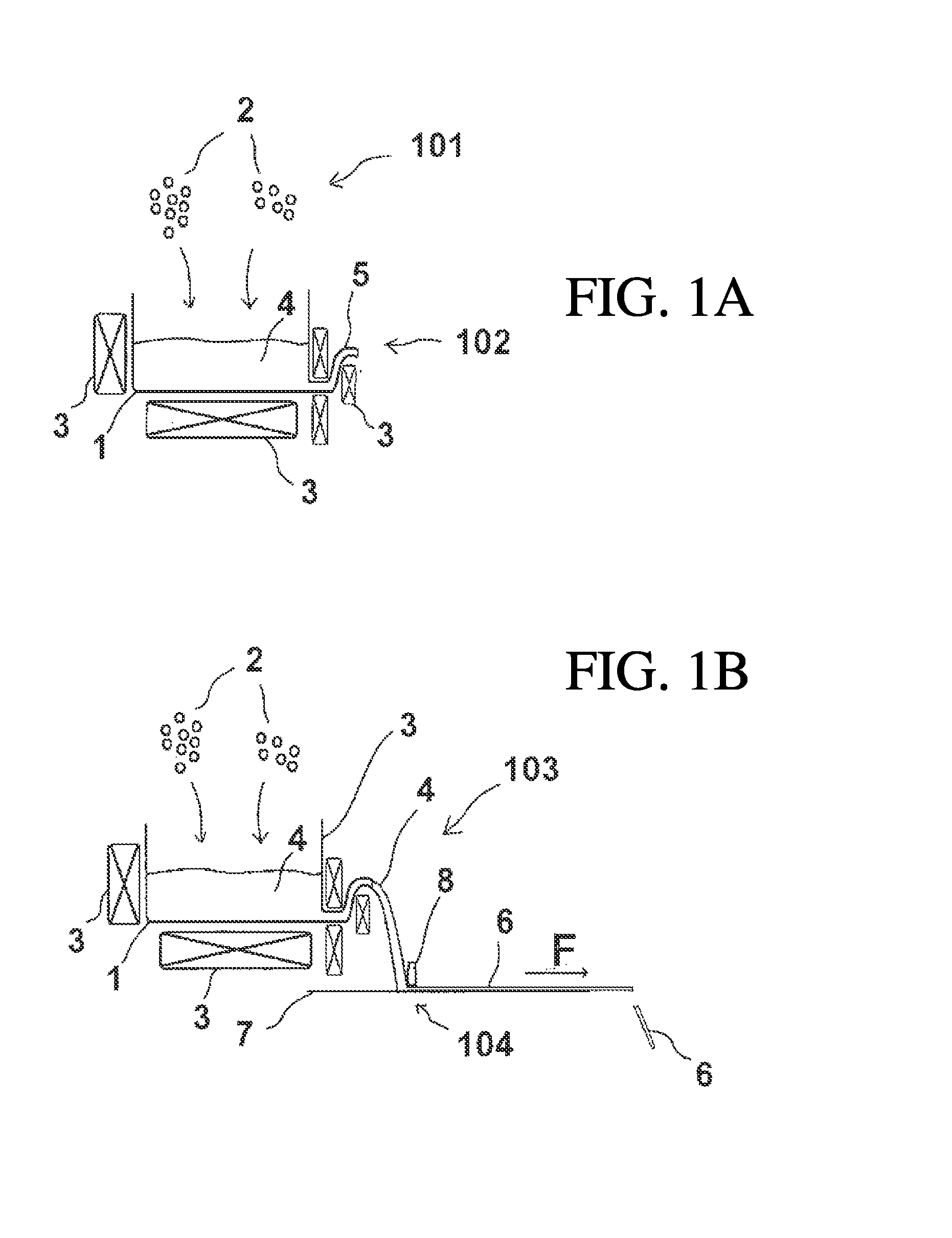

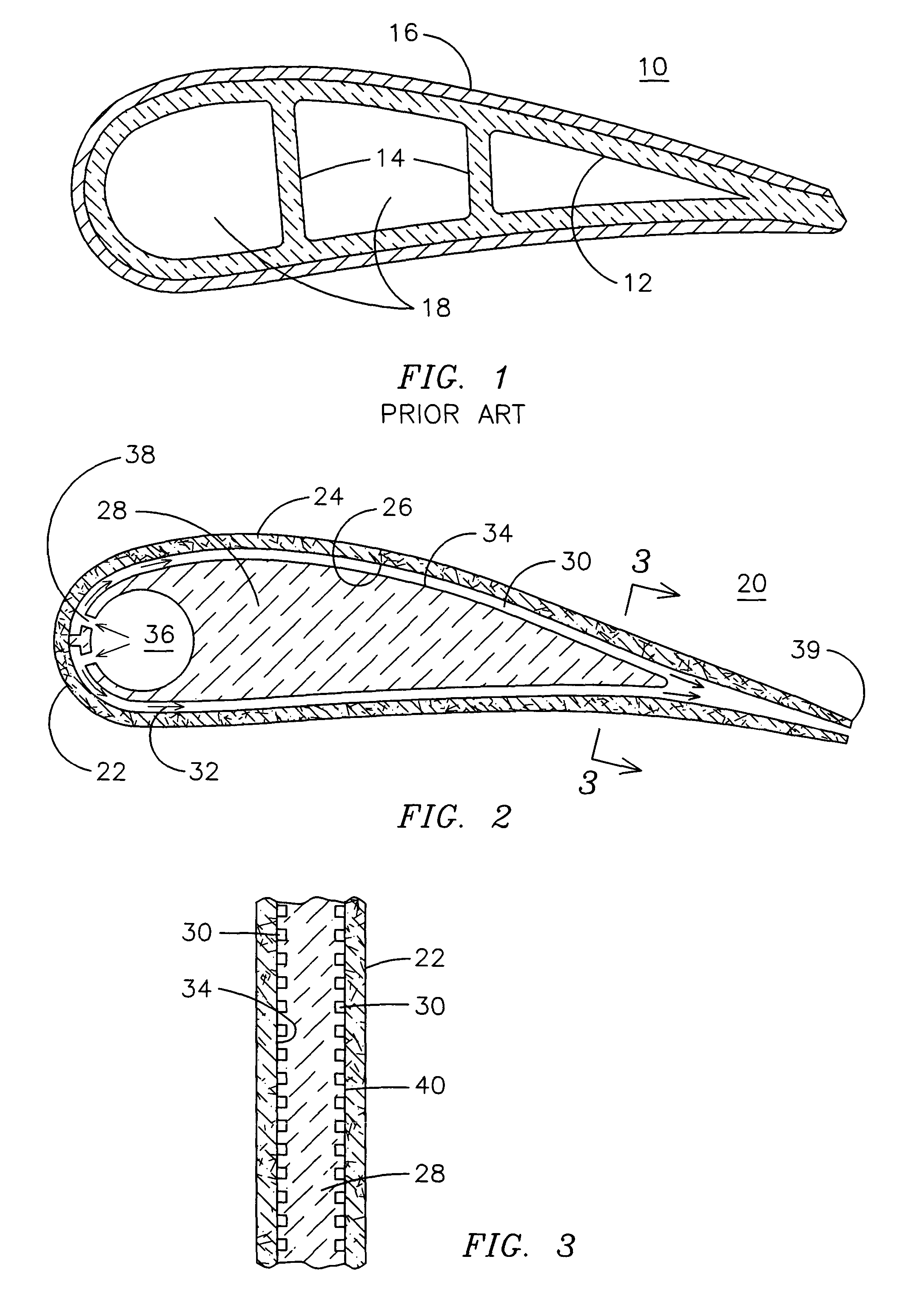

Method to produce an element (10) subject to wear, such as a mechanical member, an abrasion or crushing tool or suchlike, comprising a metal matrix (14) and at least a core (12) of ceramic material. The method comprises a preliminary step wherein the core (12) is prepared by mixing at least a first component with a base of aluminum oxide in the form of a (a-Al2O3) with a second component comprising a eutectic compound with a base of a-Al2O3 and ZrO2, a second step wherein the core (12) is arranged in a mold, so as to define a free volume inside the mold, and a third step wherein a molten metal material is cast into the mold, to occupy the free volume so as to anchor to the core (12) and thus form a single body.

Owner:F A R - FONDERIE ACCIAIERIE ROIALE

Metal-organic framework MIL-160 film, preparation method and application

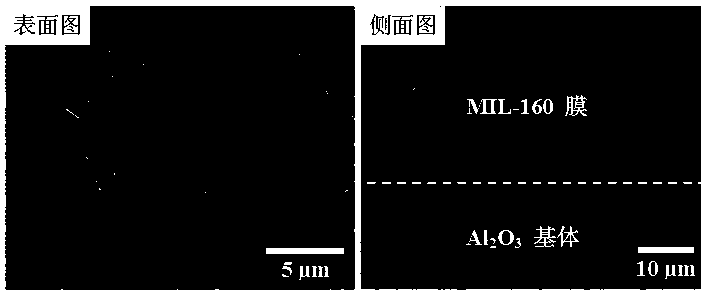

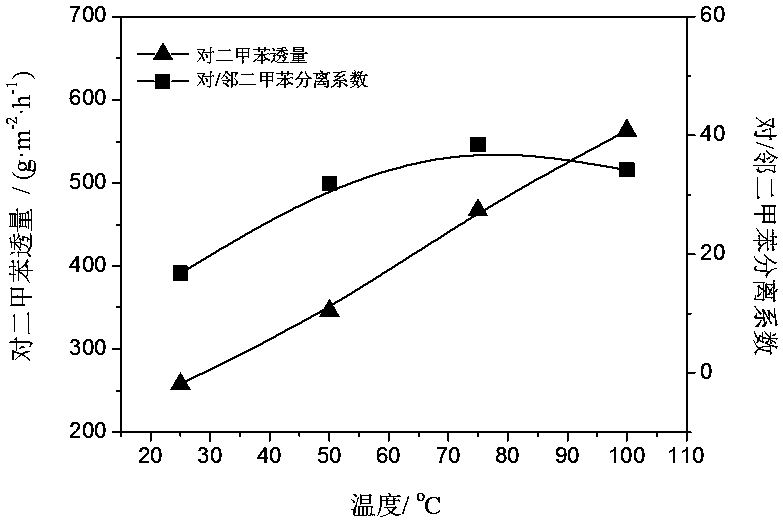

ActiveCN108889132AImprove selective separation performanceAchieve separationDistillationMembrane purification/separationPorous substrateKinetic diameter

The invention discloses a metal-organic framework MIL-160 film, a preparation method and an application, and belongs to the technical field of preparation of functional film separating materials. Themetal-organic framework MIL-160 film has excellent chemical stability and hydrothermal stability, the hole diameter of the film is about 0.6 nanometer, and the size of the hole diameter is equal to that of the dynamics diameter of a xylene homologue. According to the method, a porous aluminum oxide substrate is functionally modified through dopamine, polydopamine is modified on the surface of theporous substrate, MIL-160 particle 'capturing' and 'adsorbing' capacity of the surface of the porous substrate is enhanced, so that nucleating and growing of the MIL-160 film on the surface of the substrate are facilitated, and the uniform and compact MIL-160 film is prepared and has high separation performance. The MIL-160 film prepared by the method is used for separation of xylene geometric isomers, the xylene permeation flux of the film is 258-563g*m<-2>*h<-1>, and the p-xylene / o-xylene separation coefficient of the film is 16.8-38.5 at the pervaporation temperature of 25-100 DEG C.

Owner:EAST CHINA NORMAL UNIVERSITY

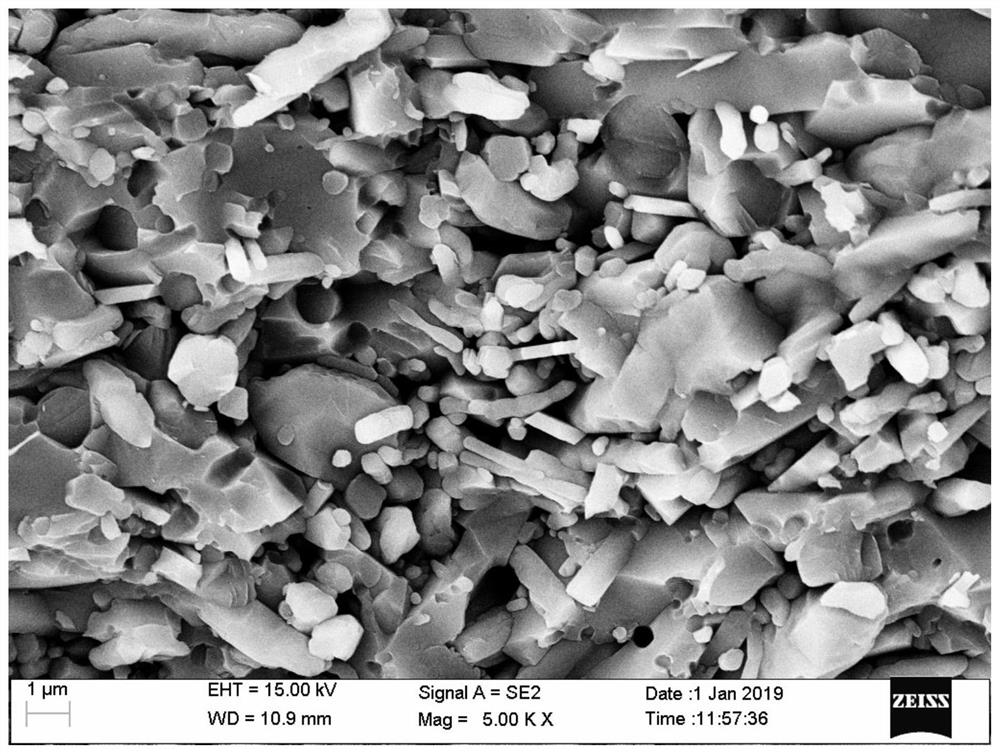

Silicon carbide whisker-toughened aluminum oxide composite ceramic material for bulletproof armor and preparation method thereof

InactiveCN111995413AAchieve microstructureImprove fracture toughnessArmour platesOxide ceramicComposite ceramic

The invention relates to the field of composite materials for bulletproof armor, in particular to a silicon carbide whisker-toughened aluminum oxide composite ceramic material for bulletproof armor and a preparation method thereof. The composite ceramic material is composed of silicon carbide whiskers with a volume fraction of 5%-80% and aluminum oxide. Microscopically, the silicon carbide whiskers are preferentially arranged in an aluminum oxide matrix along a group of parallel planes. The preparation method of the composite ceramic material comprises the following steps: carrying out freezecasting and vacuum freeze drying treatment on water-based slurry containing the silicon carbide whiskers and the aluminum oxide powder to obtain a porous green body with an oriented lamellar structure, and sequentially carrying out pressure forming, organic matter removal and sintering densification treatment on the green body to obtain the aluminum oxide composite ceramic material toughened by the silicon carbide whiskers. The fracture toughness, impact toughness and repeated impact resistance of the composite ceramic material are remarkably improved compared with single silicon carbide ceramic and single aluminum oxide ceramic; and the composite ceramic material is expected to be applied to the field of bulletproof armor to effectively improve the protection capacity and durability of the bulletproof armor.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Catalyst containing MCM-22 zeolite

ActiveCN1647855AIncrease acidityExtended operating cycleMolecular sieve catalystsCrystalline aluminosilicate zeolitesHalogenDiethyl benzene

The present invention is a kind of catalyst containing MCM-22 zeolite 30-90 wt%, halogen counting in simple substance 0.1-2 wt% and alumina matrix in the balanced amount. The catalyst is used in liquid phase benzene alkylating reaction, and compared with available technology, the catalyst has raised ethyl benzene selectivity, lowered diethyl benzene and triethyl benzene selectivity, and 7.3-10.0 % raised ethyl benzene STY.

Owner:CHINA PETROLEUM & CHEM CORP +1

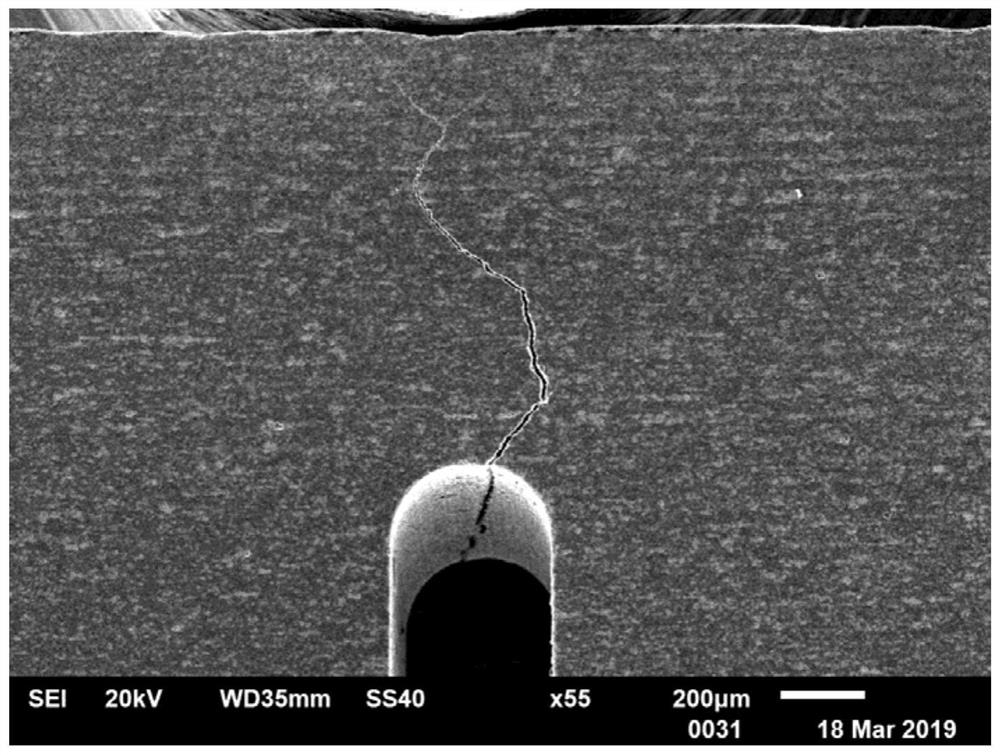

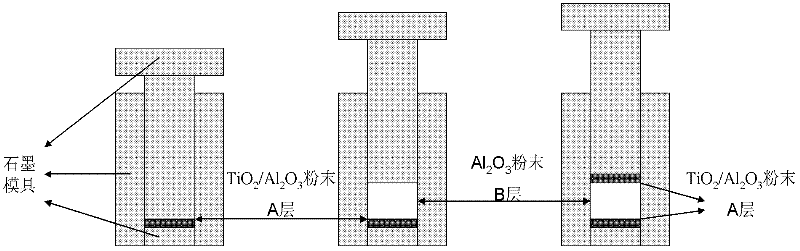

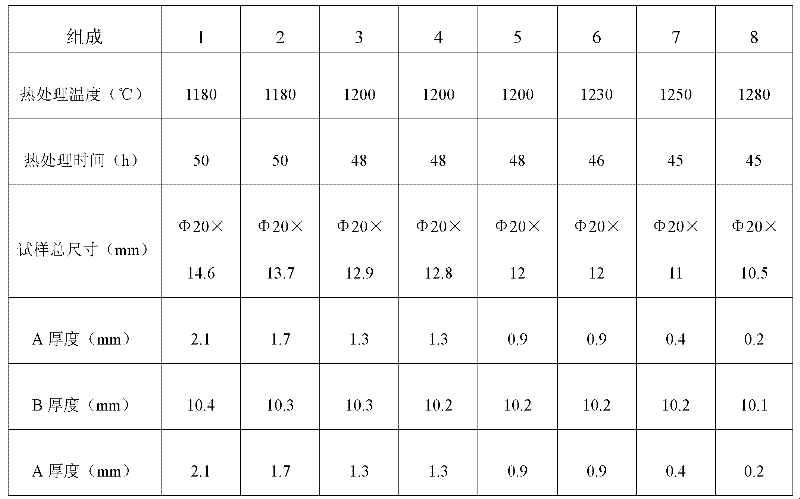

Titanium oxide and alumina composite ceramic insulation structure and preparation method for same

InactiveCN102496429AImprove mechanical propertiesImprove stabilityInsulating bodiesComposite ceramicAlumina composite

Disclosed are a titanium oxide and alumina composite ceramic insulation structure and a preparation method for the same. The insulation structure comprises an alumina ceramic matrix, and composite ceramic layers are connected to two ends of the alumina ceramic matrix by means of co-firing technology and are made of alumina-matrix composite ceramics mixed with 0.5-20% of titanium oxide by weight. The preparation method includes the steps of (1) mixing and ball-milling 0.5-20% of titanium oxide by weight with 80%-99.5% of A12O3 (bauxite) ceramic powder by weight, and preparing alumina-matrix powder mixed with titanium oxide by means of drying; (2) sequentially adding the powder, the A12O3 ceramic powder and the powder into a graphite mould prior to compacting respectively so that a green body is prepared; (3) obtaining the titanium oxide and alumina composite ceramic insulation structure by means of vacuum hot-pressing sintering; and (4) performing heat treatment for the fired insulation structure so as to obtain the insulation structure with variable dielectric constants or resistivity. The insulation structure prepared by the method is obviously variable in dielectric constants, so that the vacuum surface flashover performance can be remarkably improved.

Owner:XI AN JIAOTONG UNIV

Preparation method for metal salt/gamma-Al2O3 heat accumulating type catalyst carrier

The invention provides a preparation method for a metal salt / gamma-Al2O3 heat accumulating type catalyst carrier. The preparation method comprises the following steps of: preparing macropore gamma-Al2O3 by adopting aluminum nitrate an aluminum source and modified polystyrene microballoon spheres as a template agent; and soaking the metal to a pore channel of the macropore gamma-Al2O3, thereby finally obtaining the heat accumulating type gamma-Al2O3. According to the obtained metal salt / gamma-Al2O3 heat accumulating type catalyst carrier disclosed by the invention, the metal salt is uniformly and sufficiently distributed in a porous netted structure alumina matrix; a phase-change heat accumulating material is divided into a plurality of micro heat accumulating type units by the alumina pore channel; and the micro heat accumulating units are further used for preventing the molten phase-change material from flowing outwards due to tension action of a capillary tube while improving heat absorption and heat release, thereby not affecting the performances of the catalytic material due to changes of the micro heat accumulating type units as well as the heat accumulation and the heat release.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of metal polishing solution with alumina matrix

ActiveCN103952084AGood suspensionNot easy to precipitatePolishing compositions with abrasivesSlurrySolid content

The invention discloses a preparation method of a metal polishing solution with an alumina matrix. The preparation method is characterized by comprising the following steps: (1) raw material selection, (2) calcining, (3) specific surface testing, (4) grinding, (5) emptying, (6) solid content testing, (7) burdening and (8) detection. The preparation method has the beneficial effects that the cutting output is increased by selecting flaky alumina, the degree of finish is increased by adding nitric acid, and the slurry has better suspension property and is not easy to precipitate by adding dispal.

Owner:DEMETER SUZHOU ELECTRONICS ENVIRONMENTAL MATERIALS CO LTD

Zirconia coating saggar used for sintering of electronic components and preparation method thereof

InactiveCN109279878AImprove structural strengthImprove thermal shock performanceCharge supportsZirconia coatingYttrium

The invention discloses a zirconia coating saggar used for sintering of electronic components. The saggar includes an alumina matrix and a zirconia coating. The alumina matrix includes, by weight, thefollowing components: 10%-30% of fused white corundum with a coarse particle size of 0.2-0.5 mm, 10%-30% of fused mullite with a particle size of 0.1-0.2 mm, 10%-30% of fused mullite fine powder with200 meshes, 10%-20% of highly pure alumina micro-powder, and 0.1%-1% of an organic bonding agent. The zirconia coating includes, by weight, the following components: 10%-30% of yttrium oxide stabilized zirconia powder with 80 meshes, 10%-30% of calcium oxide stabilized zirconia powder with 150 meshes, 10%-30% of yttrium oxide stabilized zirconia powder with 150 meshes, and 10%-30% of yttrium oxide stabilized zirconia powder with 325 meshes. The invention also relates to a preparation method of the zirconia coating saggar used for the sintering of the electronic components; and equipment for spraying a zirconia coating adopts the most advanced atmospheric plasma spraying equipment in the country, so that the prepared zirconia coating is dense and peeling off-resistant, and the service lifeof the coating is prolonged.

Owner:宜兴市锦泰耐火材料有限公司

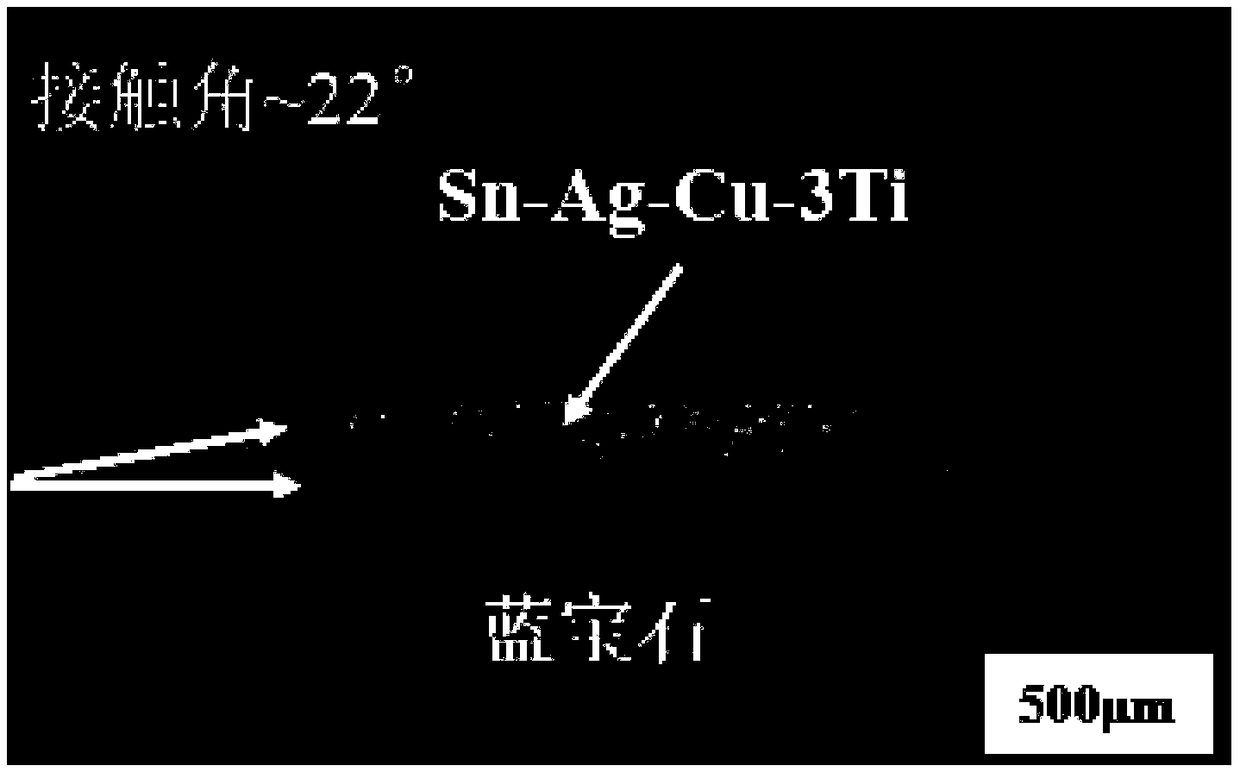

Single crystal alumina low-temperature brazing method

ActiveCN108907385AReduce residual stressImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaSingle crystalFiller metal

The invention discloses a single crystal alumina low-temperature brazing method, and belongs to the technical field of ceramic material connection. According to the method, low-temperature brazing connection of single crystal alumina is achieved through the characteristics that the melting point of tin is low and activity of titanium is high, and thermal damage during the brazing process is reduced; and thermal stress generated during the brazing process is effectively released through the characteristic that tin is soft, and residual stress of interface connection parts of single crystal alumina and brazing filler metal is reduced. The method is achieved through the following steps of: firstly preparing Sn-Ag-Cu-Ti alloy powder; carrying out ultrasonic cleaning on a single crystal aluminamatrix through acetone, and drying the single crystal alumina matrix; then, spraying the Sn-Ag-Cu-Ti alloy powder on the surface of the polished single crystal alumina matrix; then, placing another polished single crystal alumina matrix on the alloy powder; and finally, putting the entire single crystal alumina / brazing filler metal / single crystal alumina sandwich structure into a quartz tube, carrying out vacuumizing till the vacuum degree is 5* 10 (<->4) Pa or below, moving the quartz tube into a tube furnace, heating for 30 min at the temperature of 450 DEG C to 650 DEG C, taking out the quartz tube in a vacuumized state, and cooling the quartz tube to the room temperature.

Owner:HUAQIAO UNIVERSITY

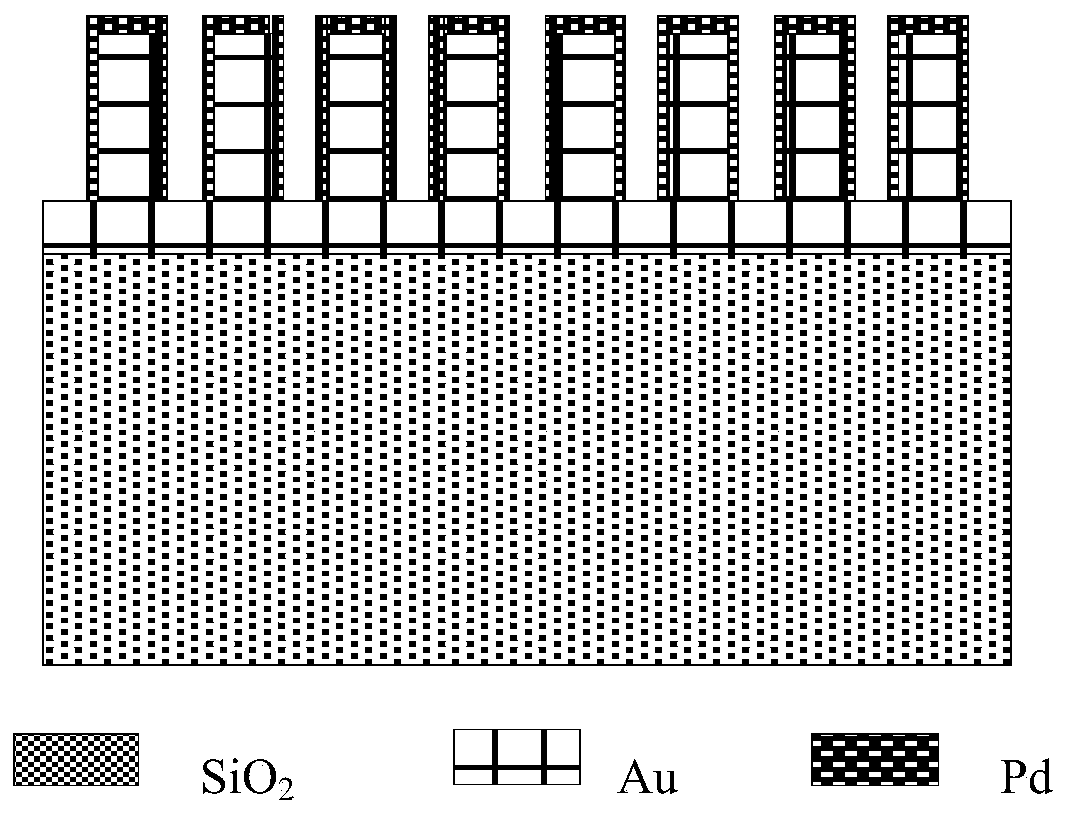

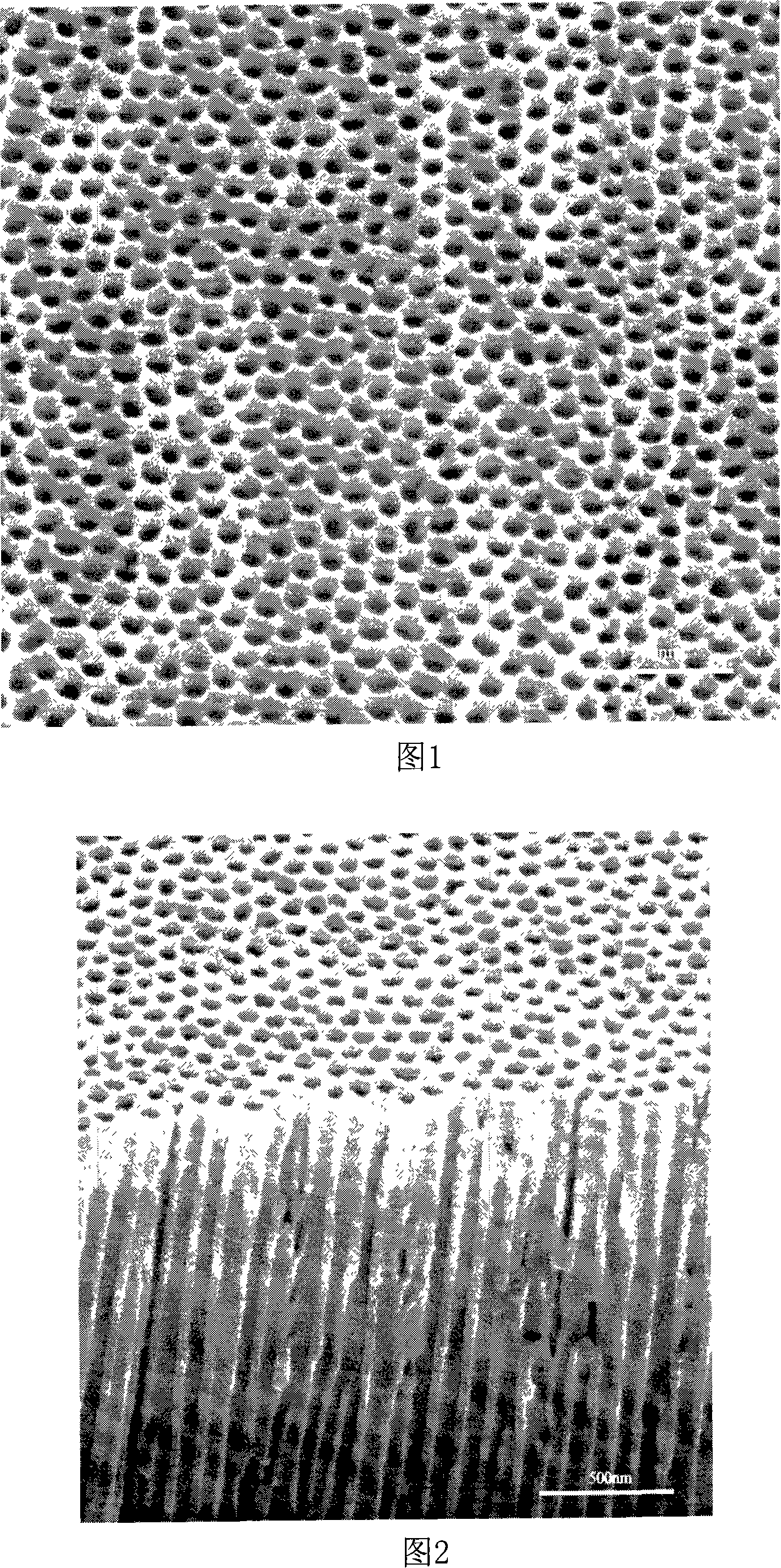

Optical fiber hydrogen sensor based on core/shell nano periodic linear array plasma metamaterial

ActiveCN111208059AVolume changeChange the refractive indexMaterial nanotechnologyPhase-affecting property measurementsEtchingComposite film

The invention relates to an optical fiber hydrogen sensor based on a core / shell nano periodic linear array plasma metamaterial. The sensor comprises an optical fiber and a gold core / palladium shell nanowire array patterned on an end surface of the optical fiber. The preparation method comprises steps that gold and aluminum are deposited on the end surface of the optical fiber, a porous aluminum oxide structure is formed through the anodic oxidation process, the diameter of a hole is corroded and enlarged, gold is filled, a gold nanowire is formed, an aluminum oxide gold nanowire composite filmis formed by the gold nanowire and the aluminum oxide structure, and palladium is plated around the gold nanowire or on an end surface of the gold nanowire to form a gold-palladium composite structure; a layer of periodically ordered polystyrene nano microsphere film is transferred on a surface of the palladium-plated aluminum oxide gold nanowire composite film, the gold-palladium composite nanowire structure which is not masked by the polystyrene nano microspheres is removed through ion etching, and the polystyrene nano microspheres are removed, and lastly, the alumina matrix is removed. Themethod is advantaged in that an optical fiber sensor is manufactured through the electrochemical technology, the method is simple and low in cost, and the optical fiber sensor has high sensitivity and high safety.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

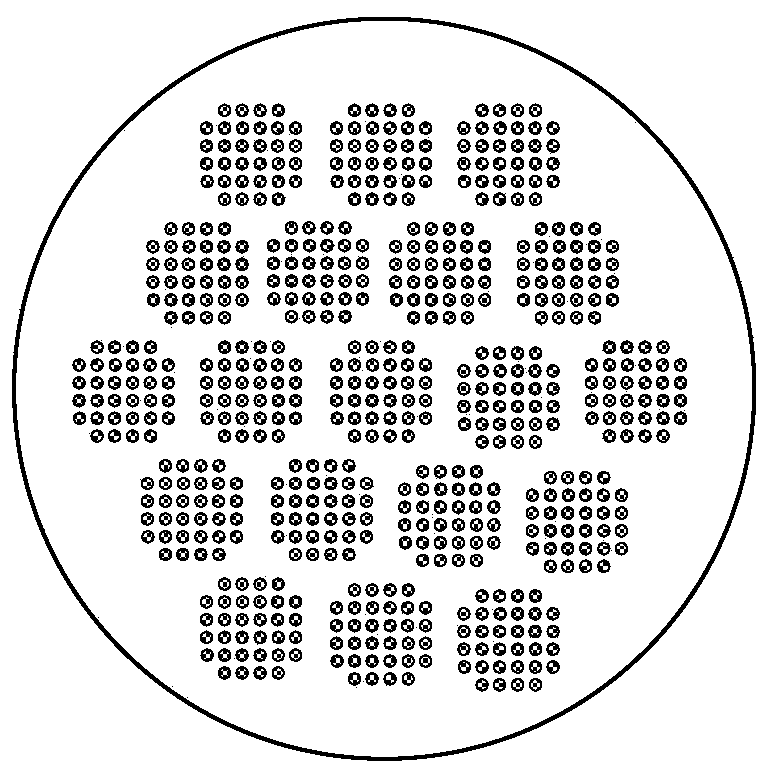

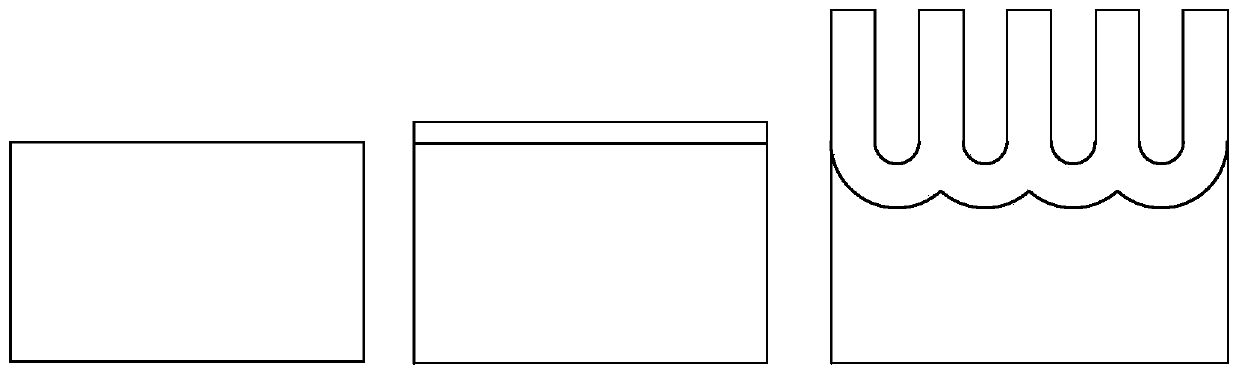

Large area electron field emission nano structure array and its preparation method

InactiveCN101150028AImprove electrical contact performanceGood mechanical propertiesDischarge tube/lamp detailsCold cathode manufactureElectrochemical anodizationField electron emission

This invention discloses a new type of large area electronic field emission nano-structured array and its preparation method, in which, the structure includes: Alumina nano-conical cones of pinpoint structure are distributed uniformly on a matrix vertically and are coated with a layer of electronic field emission material and holes of the matrix are filled with conductive electrode materials. The preparation method includes: carrying out electrochemical anode oxidation process to an Al foil or Al adhered on the matrix to get a matrix with Almina film and nm holes at the surface, corroding the film with a corroding solution reacting with Almina to get the large area serial Almina nm conical array, filling the holes of the matrix with conductive electrode material and then coaring a layer of field emission material on the array to get a new type of large area electronic field emission nm-structured array.

Owner:SUN YAT SEN UNIV

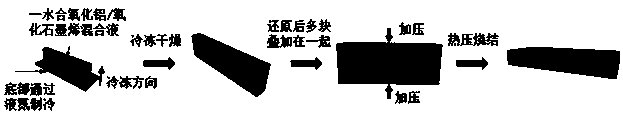

Preparation method of oriented graphene/alumina composite ceramic

InactiveCN110143810AImprove fracture toughnessImprove bending strengthFlexural strengthAlumina composite

The invention discloses a preparation method of an oriented graphene / alumina composite ceramic. The method comprises the following steps: 1, preparing alumina monohydrate / graphene composite sponge; and 2, preparing an oriented graphene / alumina composite material. According to the method disclosed by the invention, water-soluble alumina monohydrate is introduced into an alumina ceramic phase, and orientation of graphene in an alumina matrix is realized by oriented freezing and oriented pressurizing in hot pressed sintering, so that a shell-like structure is obtained. The structure is capable ofendowing alumina ceramics with excellent breaking tenacity, bending strength and other mechanical properties, and enabling the alumina ceramics to achieve excellent electrical and thermal conductivity and obvious electrical and thermal anisotropic properties in an oriented direction. The process is simple, the cost is low, and an excellent alumina ceramic-based composite material with integrationof structure and function can be obtained.

Owner:HARBIN INST OF TECH

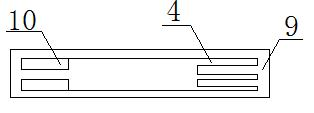

Inlaid plate-shaped oxygen sensor and preparation method thereof

InactiveCN102636527AQuick responseImprove high temperature insulation performanceMaterial electrochemical variablesEnergy consumptionZirconium dioxide

The invention relates to the technical field of a zirconium dioxide oxygen sensor for an automobile electric injection engine, in particular to an inlaid plate-shaped oxygen sensor and a preparation method thereof. The inlaid plate-shaped oxygen sensor comprises a ceramic heater, a zirconia sensitive element, a glass glaze sealing layer, a heating circuit, a reference gas channel, an alumina base body and a groove, wherein the zirconia sensitive element is arranged in the ceramic heater; the ceramic heater is connected with the zirconia sensitive element through the glass glaze sealing layer; the ceramic heater consists of the alumina base body and the groove; the groove is arranged on the upper surface of the alumina base body, and the heating circuit is arranged on the lower surface; and the reference gas channel is arranged between the zirconia sensitive element and the groove. The inlaid plate-shaped oxygen sensor provided by the invention improves the high-temperature insulation performance of the product, has fast response to electric signal, reduces the energy consumption and production cost, has long service life and is easy to popularize.

Owner:CHANGZHOU LAMBDA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com