Method for manufacturing transparent alumina ceramic and application thereof

A technology of alumina ceramics and a manufacturing method, applied in dental preparations, pharmaceutical formulations, medical science and other directions, can solve the problems of uneven distribution of MgO, reduce the light transmittance of alumina ceramics, etc., and achieve good grain growth and grain growth. inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

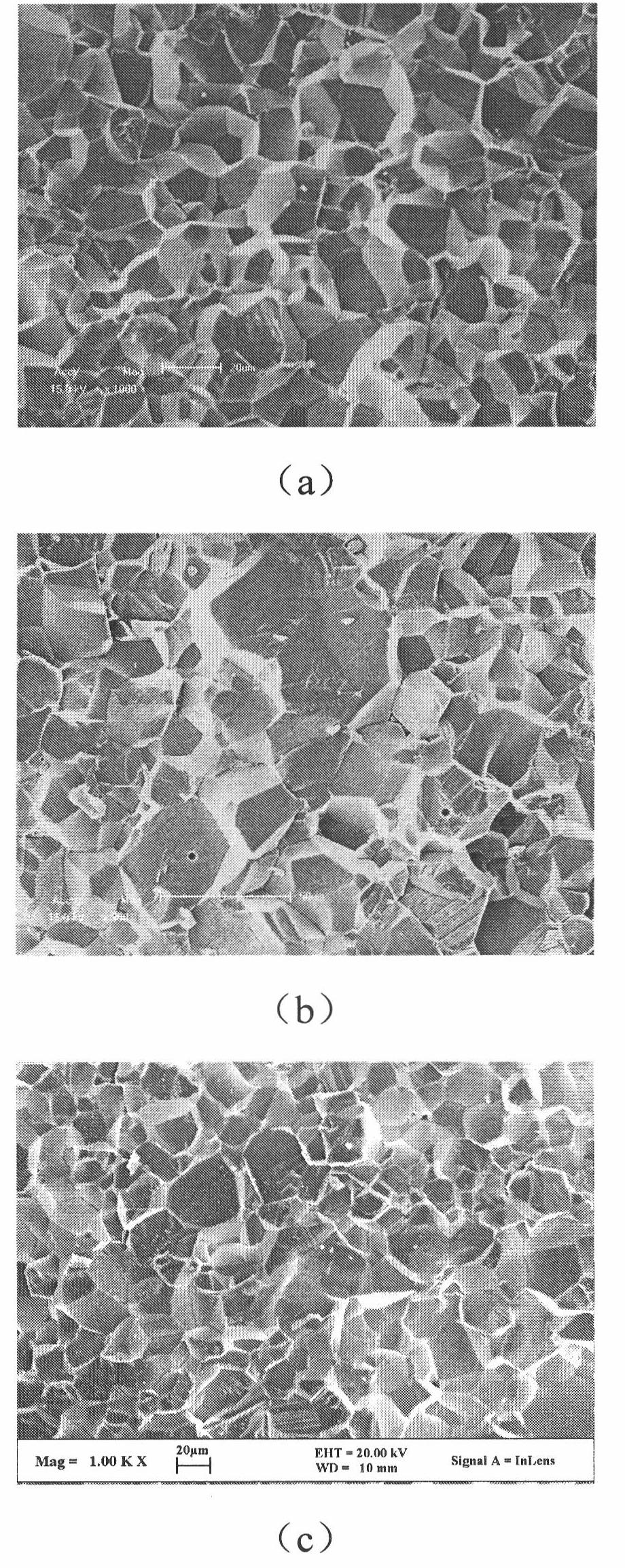

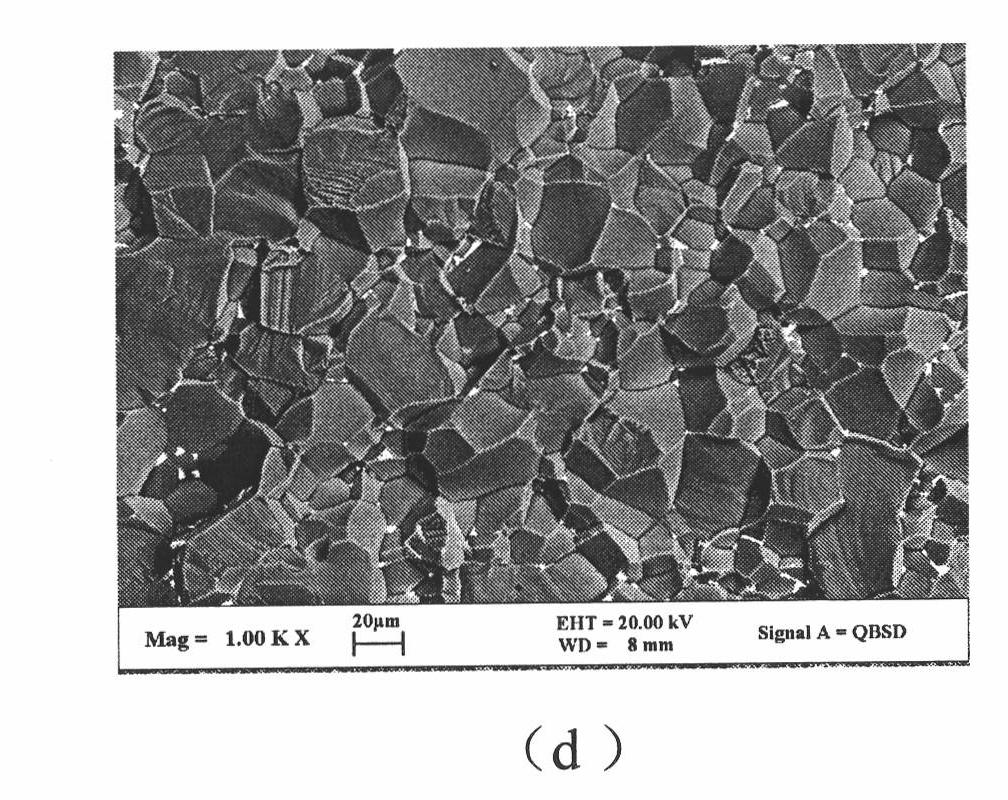

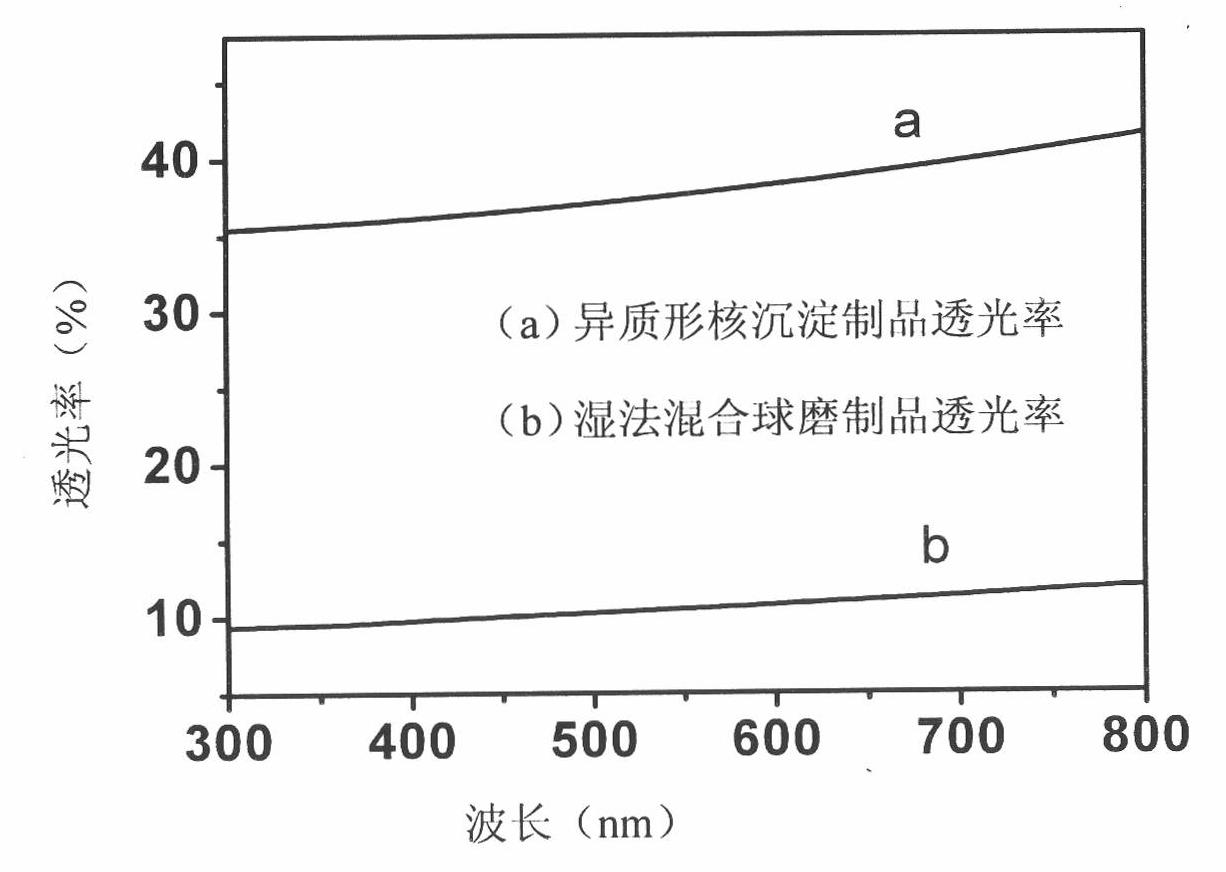

[0028] Using α-Al with an average particle size of 0.35μm and a purity of 99.98% 2 o 3 . 100g alumina powder and 0.09gLa 2 (CO 3 ) 3 ·8H 2 O, 0.22gZr(NO 3 ) 4 Dissolve in ethanol, add 1.5wt% PEG-400 as a dispersant, and ultrasonically vibrate until uniformly dispersed. Then, under the condition of constant magnetic stirring, add ammonia water (0.04mol / L) dropwise at a rate of 2mL / min to form the precipitation of additive ions, strictly control the dropping speed, and finally adjust the pH The value is 8.1, keep the magnetic stirring for 1.5h, so that the precipitation reaction is uniform and sufficient.

[0029] The obtained suspension is filtered, washed (alcohol-washed), dried, and the obtained powder is dry-pressed and isostatic-pressed to form a rough body after granulation. min, the sintering temperature is 1150°C, and the temperature is kept for 2h. Then adopt vacuum sintering, the sintering temperature is 1750 ℃, and the time is 3h. The sintered ceramic sheet...

Embodiment 2

[0032] Using α-Al with an average particle size of 0.4μm and a purity of 99.99% 2 o 3 . 100g alumina powder and 0.18gCe(NO3) 3 ·6H 2 O, 0.09gThCl 4 Dissolve in ethanol, add 0.10wt% isopropanol as a dispersant, and ultrasonically vibrate until uniformly dispersed. Then the homogeneously dispersed suspension was slowly added dropwise with sodium acetate (0.05mol / L) at a rate of 5mL / min under the condition of constant magnetic stirring to form the precipitation of additive ions, and the speed of dropping was strictly controlled, and finally Adjust the pH value to 8.9, and keep magnetic stirring for 2 hours, so that the precipitation reaction in the period is uniform and sufficient.

[0033] The obtained suspension was filtered, washed (alcohol-washed), and dried. The obtained powder was injection molded and thermally degreased for 40 hours to obtain a green body. First, it was pre-sintered by pressureless sintering. The temperature is 1200°C and the temperature is kept for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com