Titanium oxide and alumina composite ceramic insulation structure and preparation method for same

A technology of alumina ceramics and composite ceramics, used in insulators, insulators, electrical components, etc., can solve problems such as poor reliability and unstable material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

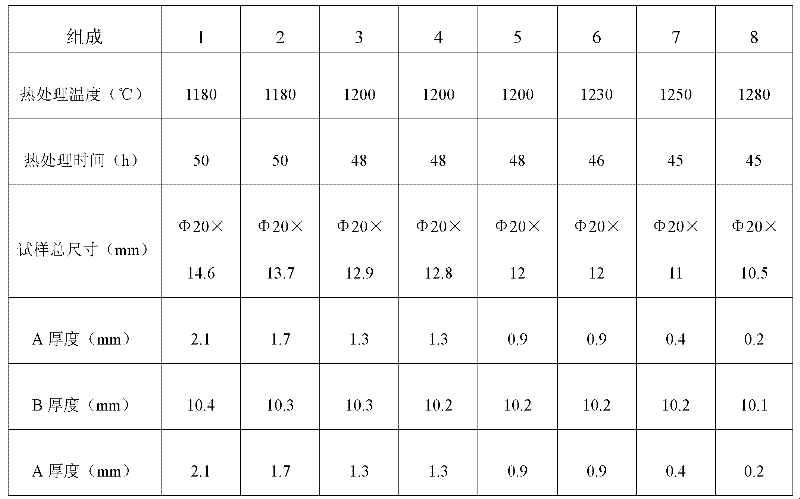

[0025] Such as figure 1 As shown, a composite ceramic insulating structure with variable dielectric constant or resistivity includes a columnar alumina ceramic substrate B, which can be 75, 85 or 95Al 2 o 3 The porcelain body is connected with an alumina-based composite ceramic layer A doped with titanium oxide at its two ends through co-firing technology, and the mass fraction of titanium oxide in the composite ceramic layer A is 0.5-20%. The diameter of the composite ceramic layer A is equal to the diameter of the columnar alumina ceramic substrate B.

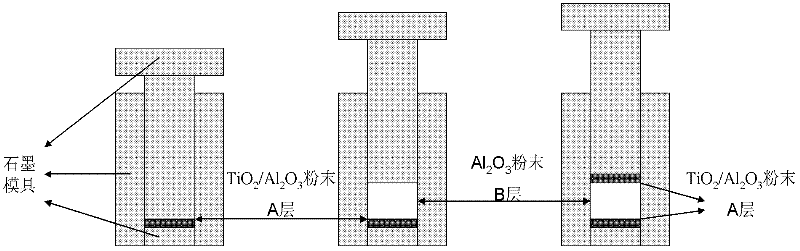

[0026] A method for preparing a composite ceramic insulating structure with variable dielectric constant or resistivity, comprising the steps of:

[0027] Step 1: prepare alumina-based powder mixed with titanium oxide, and take 0.5-20% titanium oxide and Al according to the mass fraction 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com