Patents

Literature

47results about How to "Low thermal shock resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of large-size graphite electrode

The invention relates to a production method of a large-size graphite electrode which comprises the components in percentage by weight: 76-79 percent of calcined petroleum coke, 21-24 percent of medium-high temperature modified asphalt and the balance of filling material with the diameter of 0.075-2 mm, wherein the calcined petroleum coke comprises the following components in percentage by weight: not more than 4 percent of granules with the diameter of more than 12 mm, 6-10 percent of granules with the diameter of 8-13 mm, 13-17 percent of granules with the diameter of 4-8 mm, 9-13 percent of granules with the diameter of 2-4 mm and 30-32 percent of powder with the diameter of not more than 0.075 mm according to the particle size distribution; and the coking value of the modified asphalt is over 55 percent and the softening point is 95-100 DEG C. After the raw materials are mixed according to the proportion, the large-size graphite electrode is produced by adopting a conventional process, wherein the mixing temperature is 160-165 DEG C and the thicker lumpiness during the die-filling is less than 40 mm. A huge-size electrode with the diameter of over 960 mm can be produced by adopting the production method of the large-size graphite electrode; meanwhile, the electrode has low resistivity and good conduction property and can bear strong current, thereby enabling the unit consumption and the electricity consumption to be greatly lowered and saving the production cost.

Owner:JIEXIU JUYUAN & COALY

Ceramic side sealing plate for twin-roll thin-strip continuous casting and preparation method thereof

The invention discloses a ceramic side sealing plate for twin-roll thin-strip continuous casting. The ceramic side sealing plate is characterized by comprising the following chemical components in percentage by mass: 40-75% of hexagonal boron nitride powder, 10-45% of Si3N4 powder, 10-30% of zirconia-mullite powder, 3-15% of TiN powder and 0.5-10% of additive, wherein the additive is one or a combination of several of Y2O3, industrial Al2O3, MgO and light magnesium carbonate. The side sealing plate has high temperature resistance, high strength, thermal shock resistance and low heat conductivity by developing the novel formula of the novel side sealing plate and adjusting a preparation method of the novel side sealing plate.

Owner:武汉钢铁有限公司

Petalite heat-resistant ceramic wok and preparation process thereof

ActiveCN108101525AIncrease productionImprove control effectCooking-vessel materialsCrack resistanceTalc

The invention relates to a petalite heat-resistant ceramic wok. The petalite heat-resistant ceramic wok is prepared by firing the following raw materials in parts by weight: 45 to 65 parts of petalite, 15 to 40 parts of spodumene, 12 to 20 parts of quartz, 15 to 20 parts of kaolin, 6 to 9 parts of talc, 5 to 8 parts of microcrystalline ceramic powder, 1 to 3 parts of halloysite nanotubes, 0.5 to 1part of nanometer tungsten carbide powder, 0.5 to 1 part of nanometer technetium oxide powder, 0.3 to 0.5 part of polyacrylamide. The petalite heat-resistant ceramic wok utilizes the cheaper petaliteas a main raw material, and the prepared petalite heat-resistant ceramic wok has good thermal shock resistance, good crack resistance, good wear resistance and good thermal conductivity.

Owner:JIANGXI JINGSHANG IND CO LTD

Light high-strength unburned brick

InactiveCN101172832ALow thermal conductivityGood thermal insulation performanceSodium silicateAluminium

The invention discloses an unfired brick with light weight and high intensity. The invention contains the components in quality percent as below: 40 to 60 percent of corundum hollow ball, 30 to 45 percent of high bauxite, 8 to 15 percent of high alumina cement and 18 to 22 percent of adscititious modified sodium silicate binder. The figuration bricks and the abnormal bricks with required size are made by adopting the vibration moulding method and being dried with 110 DEG C, wherein, the cubage thickness of the samples is 1.1 to 1.5 g / cm3, the normal temperature pressure compressive strength is more than or equal to 15Mpa, and the using temperature is 1500 DEG C. The unfired brick with light weight and high intensity can be widely used in varied heat engineering devices which are needed to be heat insulated and heat preserved. The invention has the advantages of large strength, high refractability and good heat preserving as well as heat insulating capacities, thereby being able to greatly reduce the energy consumption. Moreover, the invention having convenient preparation and simple technique is useful for the cost saving.

Owner:ZHEJIANG UNIV

Boron nitride ceramic side seal plate for continuous thin-strip casting and manufacturing method of side seal plate

The invention discloses a boron nitride ceramic side seal plate for continuous thin-strip casting. The boron nitride ceramic side seal plate is characterized by comprising the following chemical components by mass percent: 20%-75% of hexagonal boron nitride, 10%-55% of aluminum nitride powder, 5%-40% of magnesium aluminate spinel, 5%-20% of mullite and 0.5%-15% of an additive, wherein the additive is selected from one or combination of several of MgAlON, AlON, CaAl4O7, CaZrO3 and CaTiO3. The boron nitride ceramic side seal plate manufactured by adopting novel ceramic formula and preparation method is relatively high in density, fire-resistant degree and rupture strength, so that the side seal plate is fully ensured to be not softened in a use process. Meanwhile, the side seal plate is low in heat conduction rate and good in thermal shock resistance, so that the side seal plate can well resist the thermal shock of molten steel in the use process and the service life of the side seal plate is prolonged.

Owner:武汉钢铁有限公司

Preparation method of forsterite refractory brick prepared from nickel-iron slag

The invention discloses a preparation method of a forsterite refractory brick prepared from nickel-iron slag. The nickel-iron slag is used as a raw material, and fine magnesite powder is added; the generation amount of a liquid phase in a firing process is controlled by regulating and controlling the mass ratios of all components, so that the volume density and the compression strength of the refractory brick are improved, and the sintering temperature is reduced; the mass ratios of all the components are controlled to meet the following conditions that the mass ratio of MgO to SiO2 is 0.98 to 1.67, the mass ratio of MgO to FeO is 5.87 to 7.71, the mass ratio of MgO to Al2O3 is 11.23 to 17.6, the mass ratio of Al2O3 to SiO2 is 0.087 to 0.095, and the sum of MgO and CaO to the sum of SiO2 and Al2O3 is 0.95 to 1.59; meanwhile, the preparation method comprises the following steps: additionally adding water and a binding agent, uniformly mixing, and carrying out compression moulding and drying treatment; after treatment, roasting at the temperature of 1200 to 1350 DEG C for 2 to 3.5 hours; adopting an oxidizing atmosphere in the firing process, thus obtaining the forsterite refractory brick. The preparation method disclosed by the invention has the advantages of high resource utilization rate, environment friendliness, simple process, low production cost and the like; the forsterite refractory brick prepared from the nickel-iron slag has the advantages of high compression strength, high volume density, low porosity and good thermal shock resistance.

Owner:CENT SOUTH UNIV

Sealing gasket covered with carbon-fiber covering yarn and preparation method of sealing gasket

The invention discloses a sealing gasket covered with carbon-fiber covering yarn. The sealing gasket comprises two mixed padding layers, a reinforcing fiber layer and a carbon-fiber covering yarn layer, wherein the reinforcing fiber layer is located between the two mixed padding layers, and the carbon-fiber covering yarn layer is arranged at the outer side of the sealing gasket in a covering manner. The sealing gasket is made of polytetrafluoroethylene, nitrile rubber, graphite, natural rubber, coke powder, vermiculite powder, barite powder, aramid fibers and glass fibers, and therefore the sealing gasket has the beneficial effects of being quite low in friction coefficient, quite good in high temperature stability and heat shock resistance, quite high in strength and heat conductivity coefficient, low in expansion coefficient, quite high in electrical resistivity, resistant to corrosion and capable of allowing microwaves or infrared rays to permeate and the like, the natural rubber is quite high in elasticity, and therefore the sealing gasket is quite good in elasticity and plasticity; the periphery of the sealing gasket is covered with the carbon-fiber covering yarn layer, and therefore the sealing gasket has the beneficial effects of being quite high in acid resistance, alkali resistance, corrosion resistance and abrasion resistance; and in addition, the sealing gasket is subjected to vulcanization treatment, so that the sealing gasket is durable and not prone to aging.

Owner:DONGTAI HUAYANG GLASS FIBER

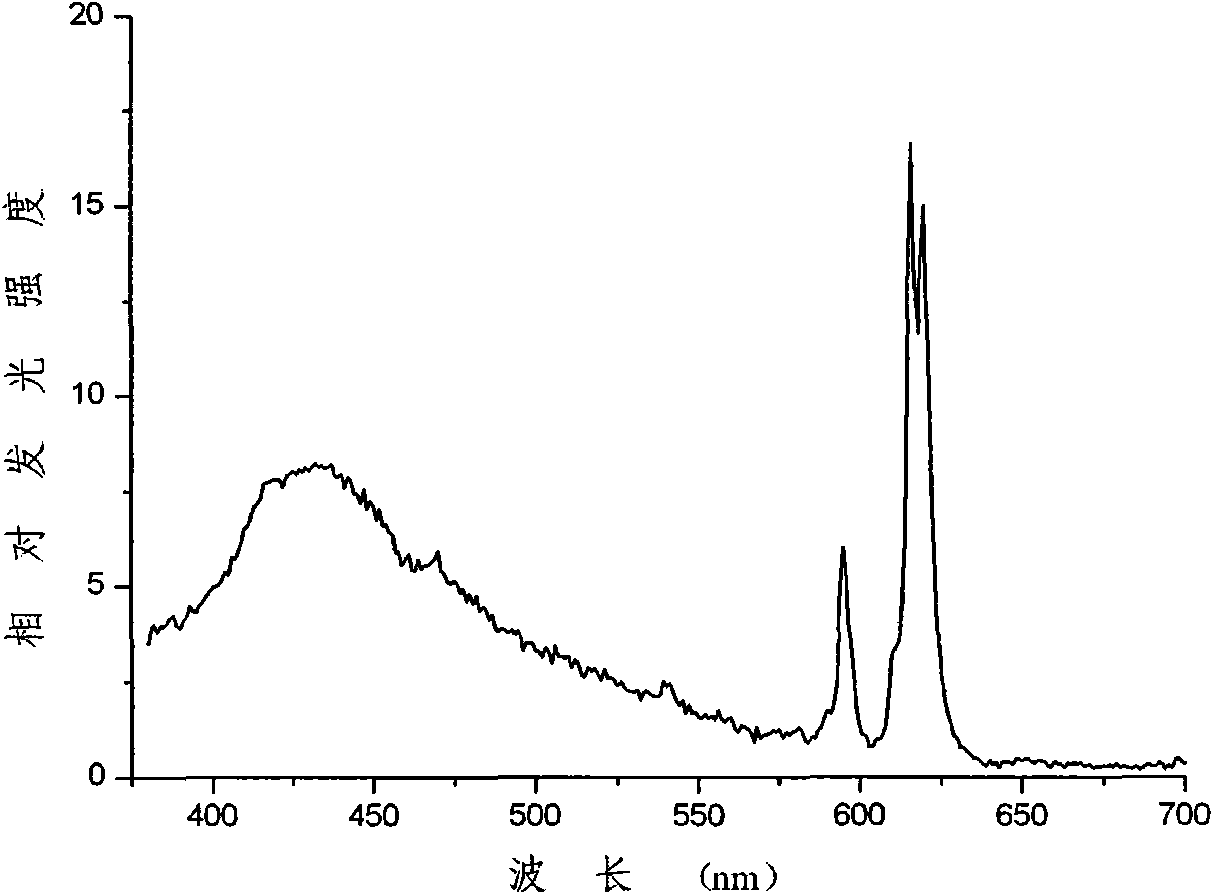

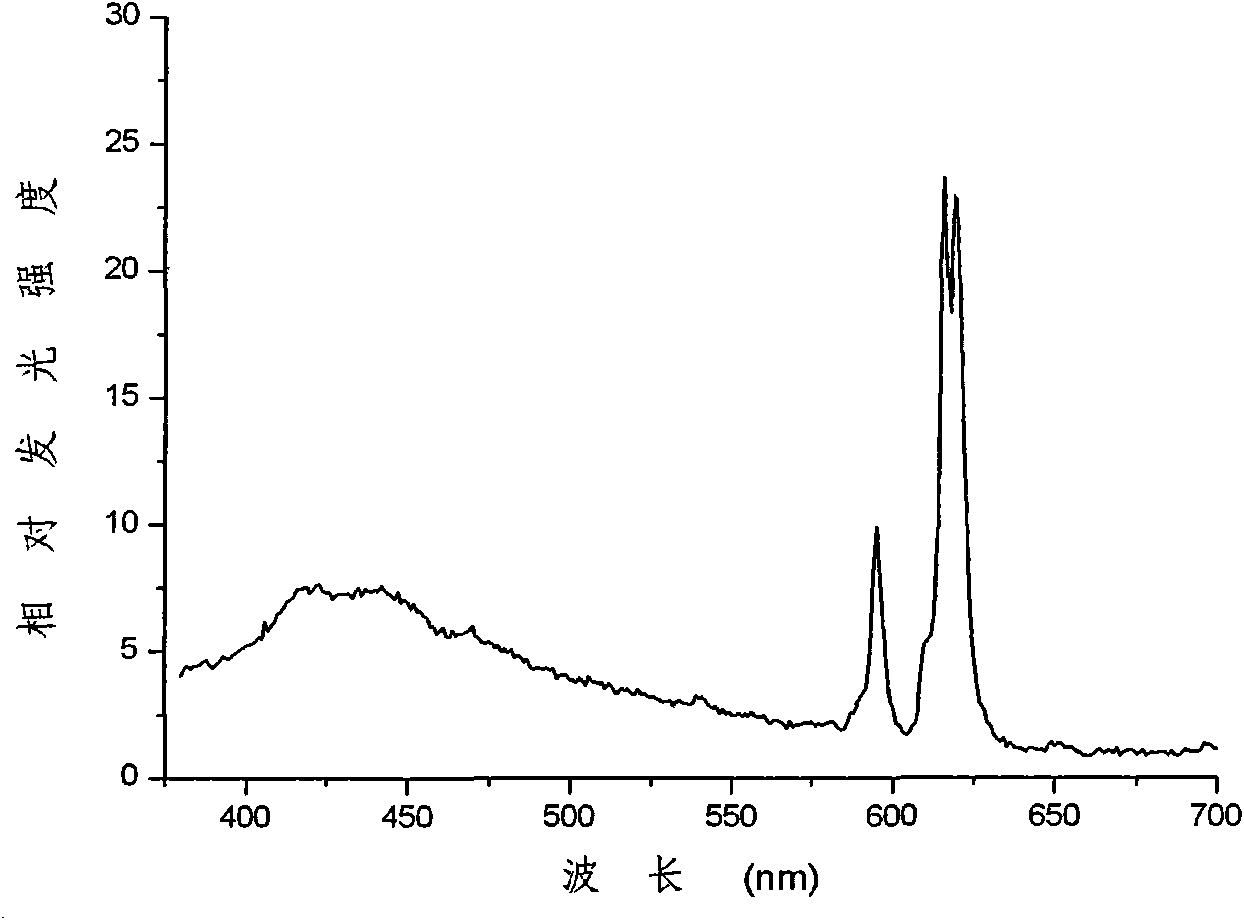

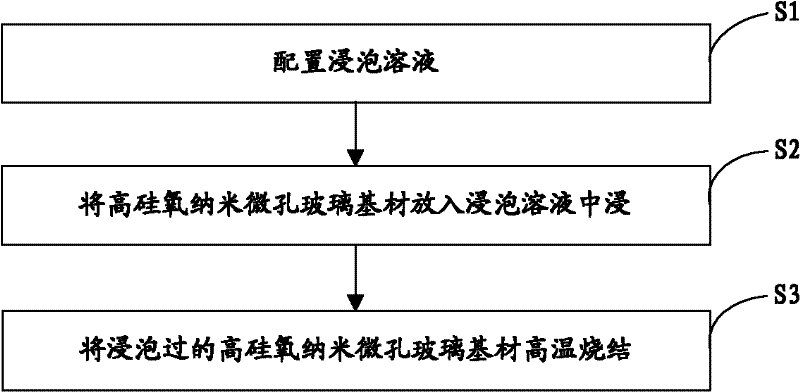

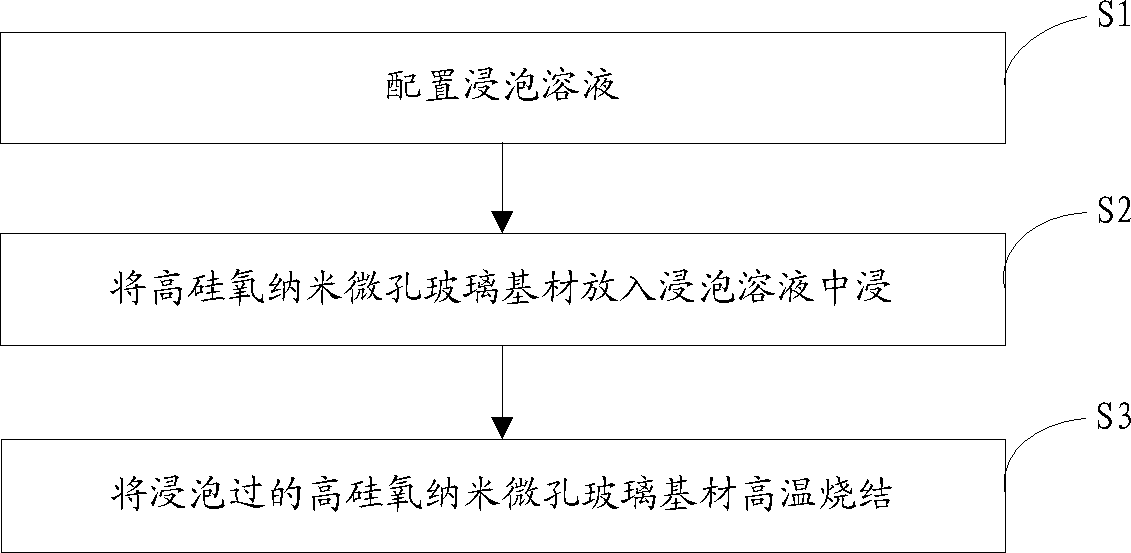

Eu-doped high-silica glass and preparation method thereof

The invention discloses Eu-doped high-silica glass and a preparation method thereof. The Eu-doped high-silica glass is high-silica glass distributed with at least one of Eu3+ and Eu2+. The preparation method comprises the following steps of: preparing a soaking solution containing at least one of Y3+ and Gd3#, and vanadium ions and the Eu3+, a soaking solution containing at least one of the Y3+ and the Gd3#, and the Eu3 + or a soaking solution containing the Eu3+, and then placing high-silica nano microporous glass in the soaking solution for soaking at least 10 minutes; gradually raising the temperature of the soaked high-silica nano microporous glass to 1100-1300 DEG C for sintering 1-5 hours to prepare the Eu-doped high-silica glass. The glass has the advantages of good stability, thermal shock resistance, high excited transmissivity and wide range of application, and can generate blue light, red light or blue and light mixed light for emission under the excitation of ultraviolet light. The preparation method has the advantages of simple process, convenient and reliable operation and stable quality of a product.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

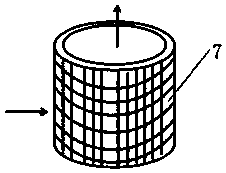

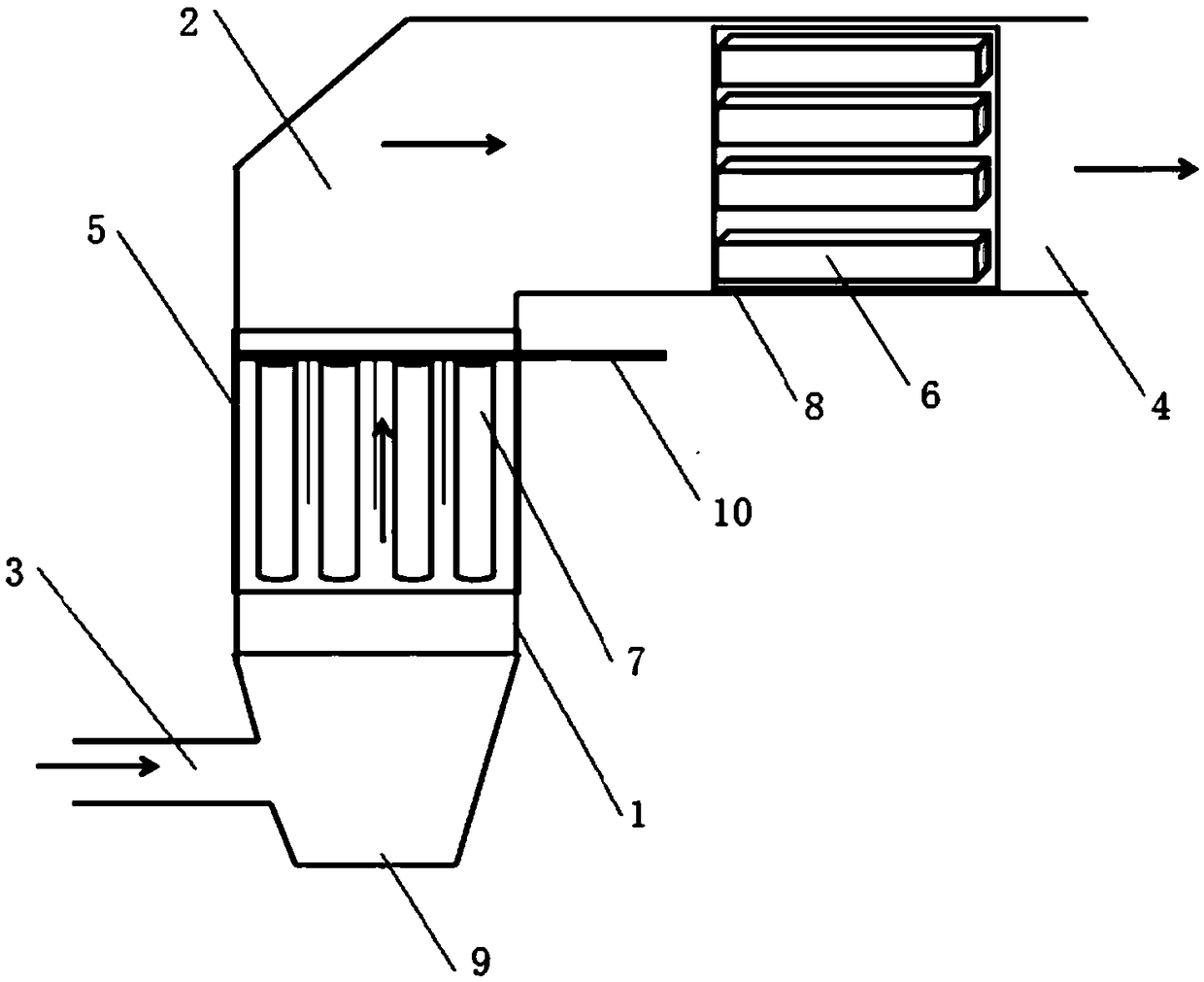

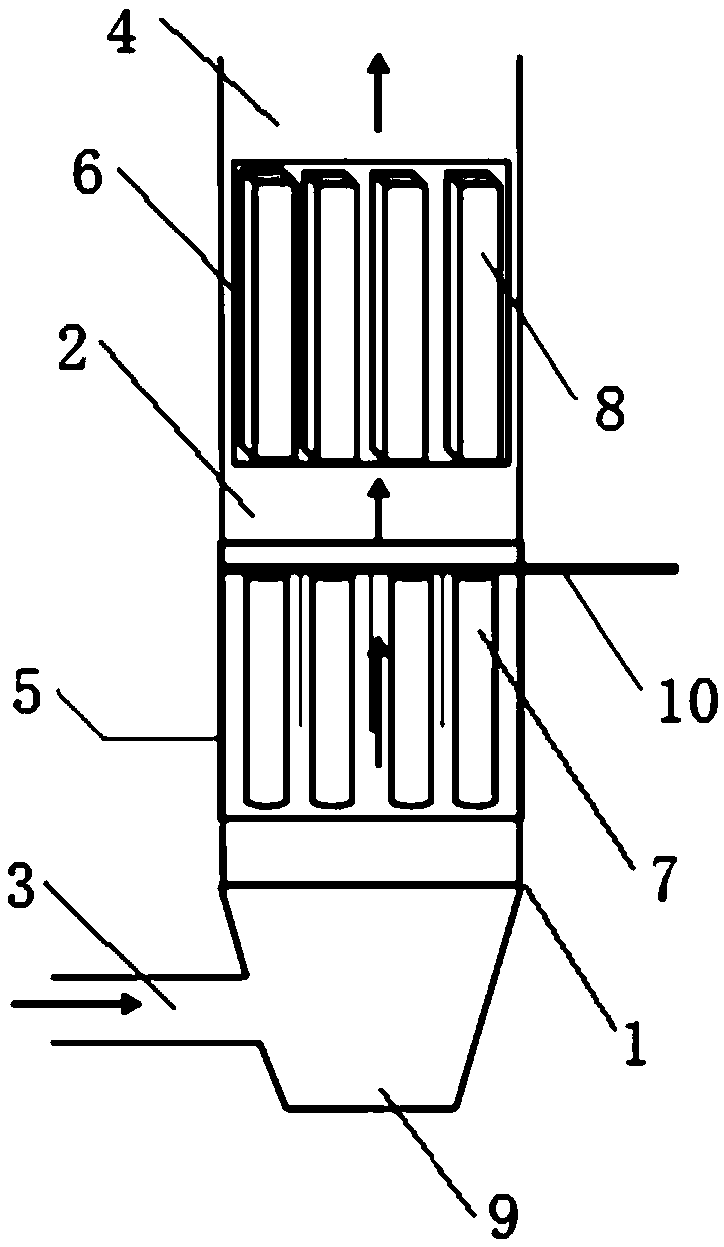

High-temperature flue gas dust removal and denitration integrated device and process thereof

InactiveCN108970396AHigh mechanical strengthLarge filter areaDispersed particle filtrationMetal fiberRare-earth element

The invention discloses a high-temperature flue gas dust removal and denitration integrated device which comprises a machine body, wherein a flue gas passage is formed inside the machine body; a fluegas inlet is formed at the lower part of the machine body; a flue gas outlet is formed at the upper part of the machine body and is conducted with the flue gas passage; a high-temperature dust removerand a SCR (Selective Catalytic Reduction) denitration reactor are sequentially mounted in a detachable mode in the machine body along a direction in which flue gas passes; the high-temperature dust remover comprises a plurality of filter cartridges regularly arranged and a dust purging collection assembly; the top end of each filter cartridge is open, and the bottom end of the filter cartridge issealed; each filter cartridge comprises at least one filter layer made of a metal fiber net; a plurality of ceramic honeycomb bodies regularly arranged are arranged in the SCR denitration reactor; each ceramic honeycomb body comprises a carrier and a catalyst distributed on the carrier; each catalyst is formed by V2O5 or rare earth elements or transition elements; each carrier adopts TiO2 or a molecular sieve or cordierite. The high-temperature dust remover and the SCR denitration reactor are mounted in a detachable mode; the filter cartridges made of the metal fiber nets are adopted; for each filter cartridge, the filtering area is not limited, filter pores are regularly arranged, and a through hole rate is high; the high-temperature flue gas dust removal and denitration integrated device is long in service life and has high-temperature resistance.

Owner:ZHEJIANG ZHENENG CATALYST TECH CO LTD

High-temperature abradable seal coating and preparation method thereof

InactiveCN108179371ASimple structureEase of mass productionMolten spray coatingWorking temperatureHardness

The invention provides a high-temperature abradable seal coating and a preparation method thereof. The MCrALY alloy powder is sprayed to the surface of a base body through a supersonic flame sprayingdevice to prepare a coating, multiple times of spraying are carried out on the surface of the base body, and the deposition thickness of the single spraying is smaller than or equal to 0.01mm; stressrelief and diffusion treatment are carried out on the sprayed coating with the thickness of 0.5-1.0mm by adopting vacuum heat treatment; and finally spraying is carried out to obtain a sealing coatingwith the thickness larger than or equal to 1.5mm. The sealing coating prepared by the preparation method has the advantages of oxidation resistance, high-temperature low hardness, abrasion resistance, high temperature stability, thermal shock resistance and high bonding strength, the working temperature can reach 1100 DEG C, the abrasion of a turbine rotor blade can be obviously reduced, the abrasion resistance and the reliability of the coating are improved, the service life of the coating is prolonged, the service life of the turbine rotor blade is obviously prolonged, the maintenance costof the engine is remarkably reduced, and the reliability of the engine is improved.

Owner:AECC AVIATION POWER CO LTD

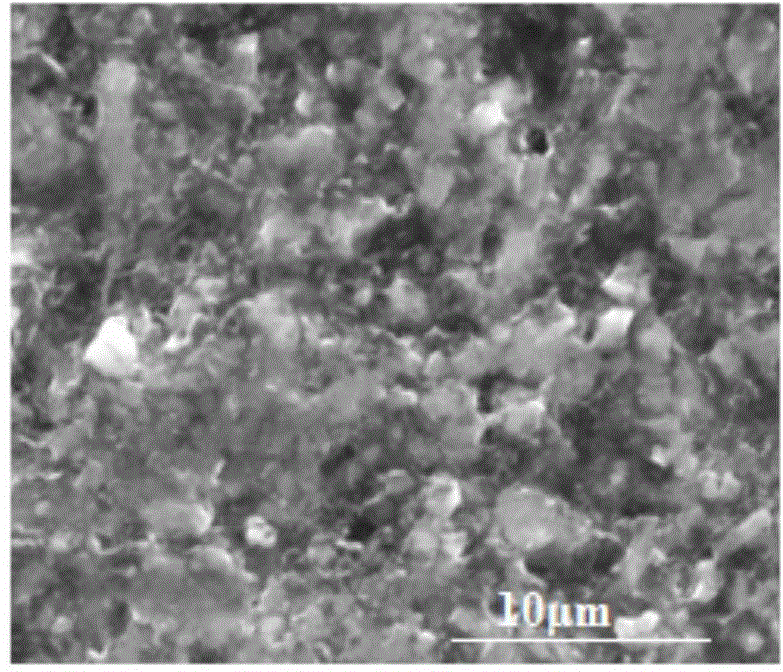

Graphene-based metal abrasion intelligent repair material and preparation method thereof

InactiveCN106635263AGood wear resistanceLow thermal shock resistanceLubricant compositionRevolutions per minuteWater content

The invention relates to a graphene-based metal abrasion intelligent repair material and a preparation method thereof. The repair material provided by the invention consists of the following components according to weight and volume: 5 to 10 g of graphene, 30 to 150 g of serpentine powder, 20 to 40 g of molybdenum powder, 15 to 55 g of rare earth powder, 90 to 210 g of copper powder, 35 to 95 g of nickel powder and 1000 to 2000 ml of 100N base oil. The preparation method comprises the steps of putting the serpentine powder into a plastic ware, rinsing with hot water at the temperature of 80 to 90 DEG C and enabling the water to naturally evaporate; putting the serpentine powder, the molybdenum powder, the rare earth powder, the copper powder and the nickel powder into drying equipment, and drying at the temperature of 110 to 130 DEG C for 100 to 130 minutes, wherein the water content of each of the serpentine powder, the molybdenum powder, the rare earth powder, the copper powder and the nickel powder is less than 2 percent after drying; putting the dried powder into a homogenizer, stirring at the stirring speed of 2000 to 3000 revolutions per minute, adding the base oil after stirring, and continuously stirring for 1 to 10 hours to obtain a colloidal mixture; and putting the colloidal mixture into an ultrasonic dispersing instrument to perform dispersion.

Owner:于贵

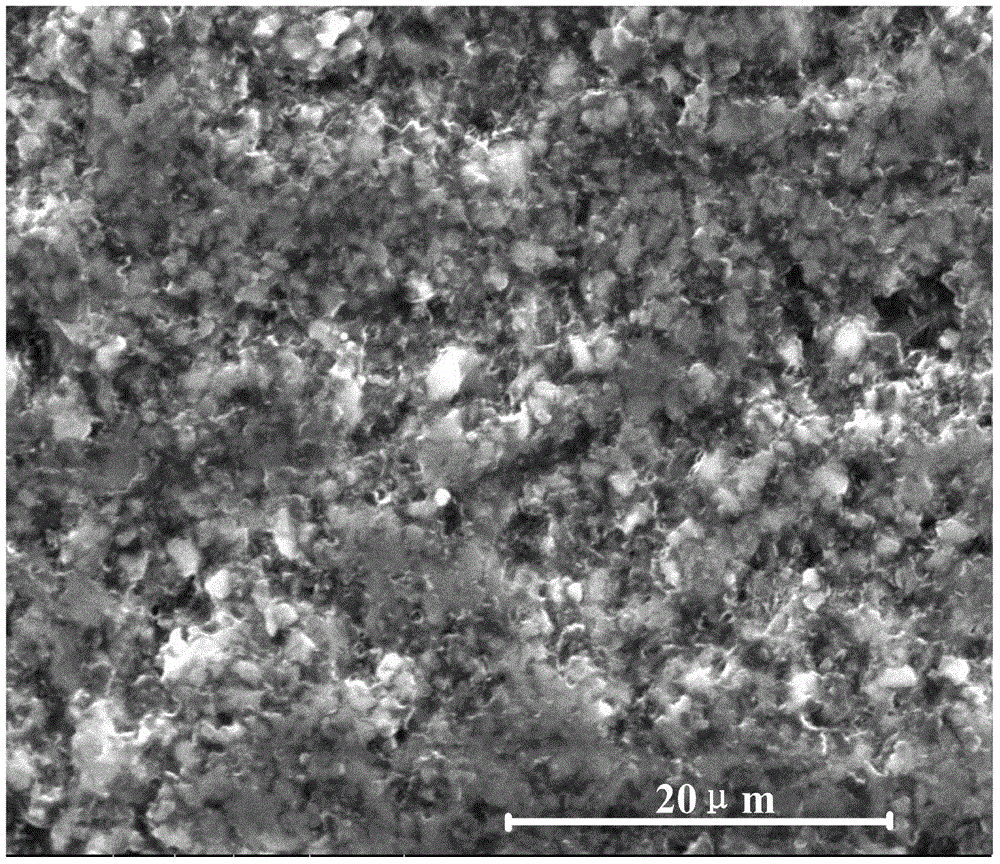

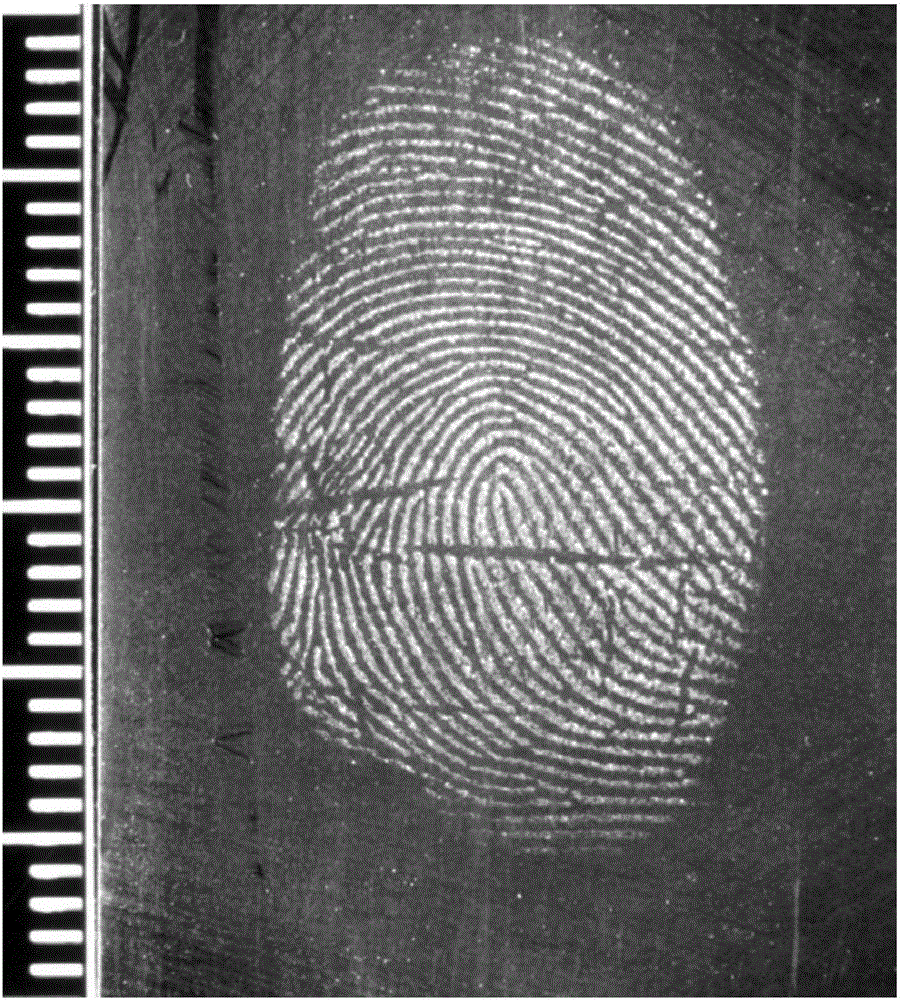

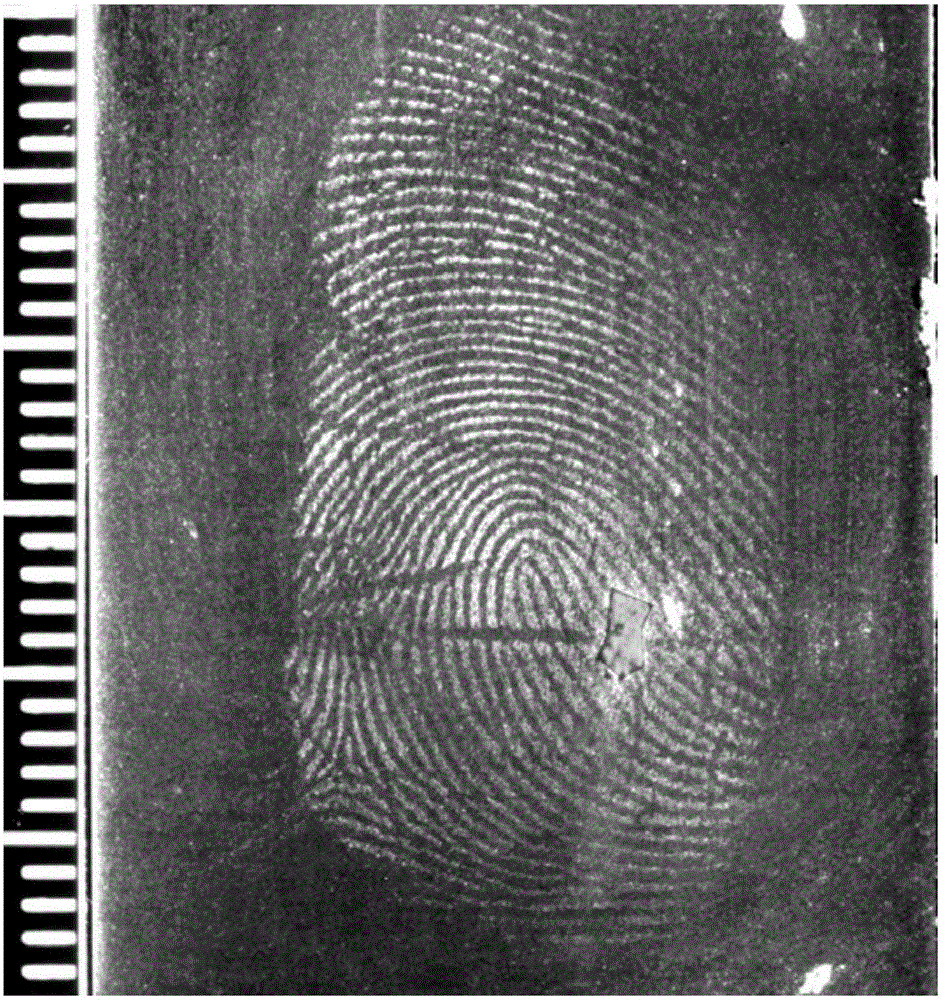

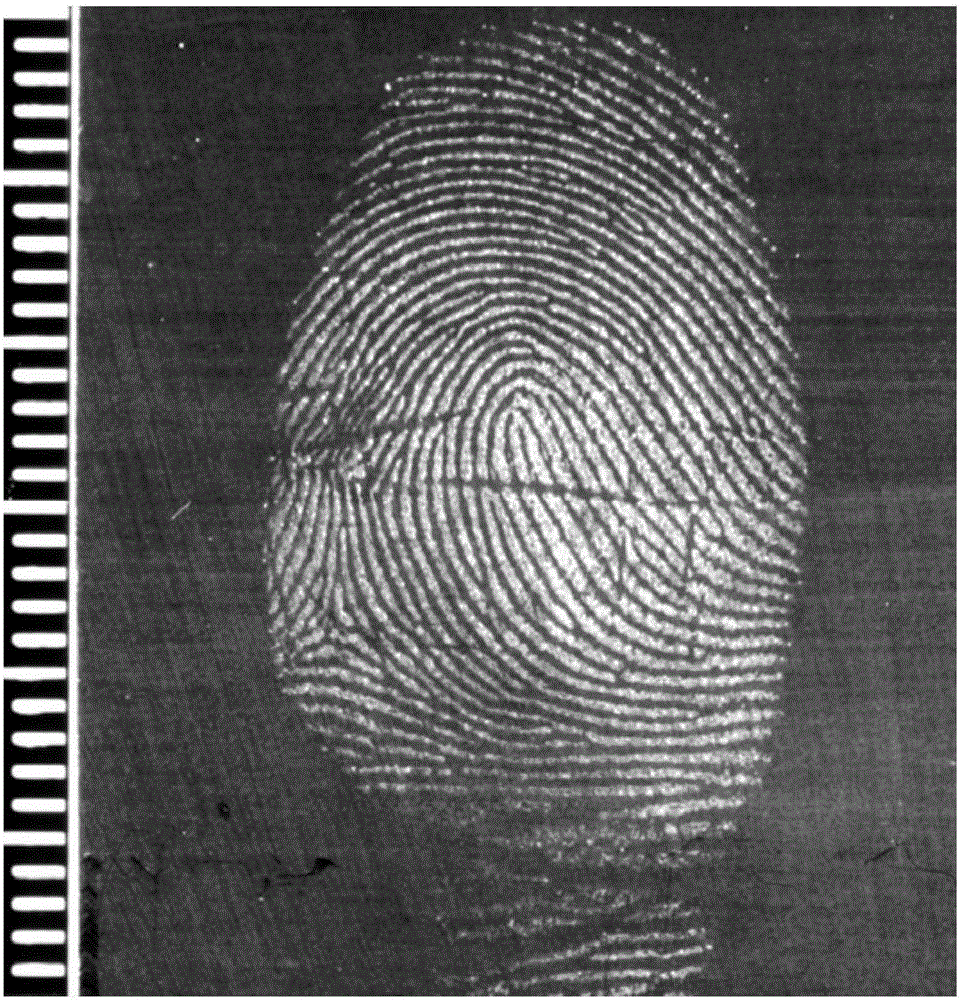

Magnetic fingerprint revealing powder and preparation method and application thereof

ActiveCN105326509AReduce coefficient of frictionIncrease coefficient of frictionDiagnostic recording/measuringSensorsSide effectMaterials science

The invention belongs to the technical field of fingerprint identification and relates to magnetic fingerprint revealing powder and a preparation method and application thereof. The magnetic fingerprint revealing powder is composed of magnetic powder and developing powder, and a chemical formula of the magnetic fingerprint revealing powder is Ma(BN)b, wherein M refers to the magnetic powder selected from at least one of Fe powder, Co power, Ni powder, Fe3O4 or Fe78Si9B13 amorphous powder, B refers to the developing powder, a and b refer to atom percentage contents of corresponding elements, a is larger than or equal to 50 and smaller than or equal to 88.9, b is larger than or equal to 11.1 and smaller than or equal to 50, and the amount of a and b is 100. Compared with the prior art, the magnetic fingerprint revealing powder not only has the advantages of easiness in raw material acquisition, simplicity in preparation, stability in performance, easiness in storage and the like but also has no toxic or side effect on users and has a most prominent advantage that high-precision reveal of fingerprints on the surfaces of various objects in dry or humid environment can be realized. Therefore, the preparation process is simplified on the premise of high revealing precision of the magnetic fingerprint revealing powder, and the magnetic fingerprint revealing powder is widely applicable to various complicated environments and has an extremely high practical application value.

Owner:TONGJI UNIV

Graphene coating for heat-dissipating copper foils and preparation method and application thereof

InactiveCN107916041AIncrease coefficient of frictionReduce coefficient of frictionEpoxy resin coatingsMetal layered productsGraphene coatingMetallurgy

The invention provides graphene coating for heat-dissipating copper foils, comprising graphene slurry, boron nitride slurry, a binder and a thinner, wherein the graphene slurry is made by mixing graphene powder, a surface treating agent and a solvent, and the boron nitride slurry is made by mixing boron nitride powder, a surface treating agent and a solvent. The graphene coating organically combines the graphene slurry and boron nitride slurry with copper foils and can provide great additive action for improving heat conductivity and heat-dissipating property of heat-dissipating insulating copper foils. The invention also provides a preparation method of the graphene coating for heat-dissipating copper foils and a copper foil.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Ceramic product and production method thereof

The invention belongs to the field of ceramic, and more specifically relates to a ceramic product and a production method thereof. The ceramic product comprises the following raw materials in parts by weight: 20-25 parts of bentonite, 5-8 parts of nano calcium carbonate, 10-15 parts of red feldspar, 15-18 parts of kaolin, 15-18 parts of potash feldspar, 10-15 parts of pyrophillite, 10-13 parts of wollastonite, 8-12 parts of blue feldspar, 6-10 parts of quartz, 10-13 parts of spodumene, 1-2 parts of chrome oxide, 3-5 parts of silicon carbide powder, and 2-4 parts of jade powder. The production method comprises the steps of weighing, grinding, filtering, drying, cleaning, glazing and sintering. The ceramic product has the advantages of small expansion coefficient, good toughness, wear resistance, and high intensity..

Owner:崔松伟

Preparation method of nanowire reinforced silicon nitride foamed ceramic composite silicon dioxide aerogel and product thereof

The invention relates to the technical field of thermal insulation materials, and particularly discloses a preparation method of nanowire reinforced silicon nitride foamed ceramic composite silicon dioxide aerogel and a product thereof. Ceramic slurry containing silicon powder, water, a sintering aid and protein powder is cured, formed and dried to prepare a green body; the green body is embedded into silicon nitride powder, and nitrogen sintering is perfromed to obtain nanowire reinforced silicon nitride foamed ceramic; and the nanowire reinforced silicon nitride foamed ceramic is further put into SiO2 sol, vacuum impregnation, gelling, solution replacement and drying are performed to obtain the nanowire reinforced silicon nitride foamed ceramic composite silicon dioxide aerogel. According to the preparation method, the steps of the nanowire reinforced foamed ceramic are simplified, the silicon dioxide aerogel and the ceramic are connected more tightly due to the existence of the nanowire, the aerogel is prevented from falling off, the service life of the material is prolonged, and large-scale production is promoted.

Owner:NAVAL UNIV OF ENG PLA

Thermal barrier coating with good light resistance and thermal shock resistance and manufacturing method for thermal barrier coating

InactiveCN105112839AImproves antioxidant propertiesImprove insulationMolten spray coatingOxidation resistantOxygen vacancy

The invention discloses a thermal barrier coating with good light resistance and thermal shock resistance. After added aluminum powder is roasted and modified at a high temperature, oxidation resistance of a ceramic phase and permeability of matrix metal can be improved; in a spraying process, part of particles are molten insufficiently in plasma jet flow, are slightly weak in deformation degree while hitting against the matrix, and are liable to form a porous structure which is lapped together, thereby improving heat insulation property of the coating; secondly, by virtue of a modification method, Y<3+> and Ce<4+> in a zirconium dioxide crystal lattice substitute Zr<4+>, so that oxygen vacancy and local stress field are generated, phonon scattering in the crystal lattice is increased, and thermal conductivity is obviously reduced; moreover, atomic weight of a solute atom Ce is much larger than that of Y, so that scattering intensity of phonons in a product disclosed by the invention can be remarkably improved, thereby reducing the thermal conductivity; and the prepared coating is high in surface hardness, good in toughness, not liable to crack and layer, has the characteristics of good light resistance, good thermal shock resistance and the like, and has a wider application.

Owner:MAANSHAN LANKE REMFG TECH

Blast-furnace tapping channel castable

The invention particularly relates to a blast-furnace tapping channel castable which resolves the problems that after conventional tapping channel castable construction is completed, air holes are needed to be formed by means of low temperature dissolving to exhaust air, or the tapping channel castable is prone to bursting in high temperature operation, and big fire cannot be directly used for baking. The blast-furnace tapping channel castable comprises the raw materials of, by mass, 40-50 parts of 95 brown aluminum oxide, 2-3 parts of pure calcium aluminate high alumina cement, 20-25 parts of 98 silicon carbide, 5-8 parts of activated aluminum oxide, 4-5 parts of silica powder, 1-2 parts of addition boron carbide, 0.2-0.5 part of metallic aluminum, and 2-6 parts of metallic silicon. The blast-furnace tapping channel castable has the advantages of being low in pure iron consumption and low in comprehensive cost, is directly baked through the big fire and does not burst after the construction is completed, does not affect slag erosion assistant performance, and is good in high temperature antioxidation, resistance to washing out, and thermal shock resistance. The blast-furnace tapping channel castable is energy-saving and environment-friendly, and plays great roles in prolonging service life of tapping channels, guaranteeing safety production of an iron making system, and reducing labor strength of workers.

Owner:孝义市和中兴矿产有限公司

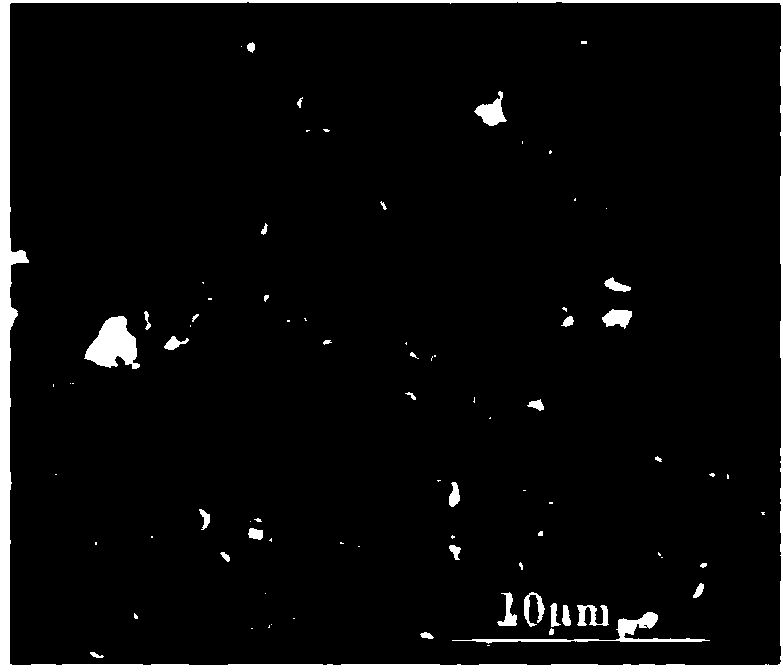

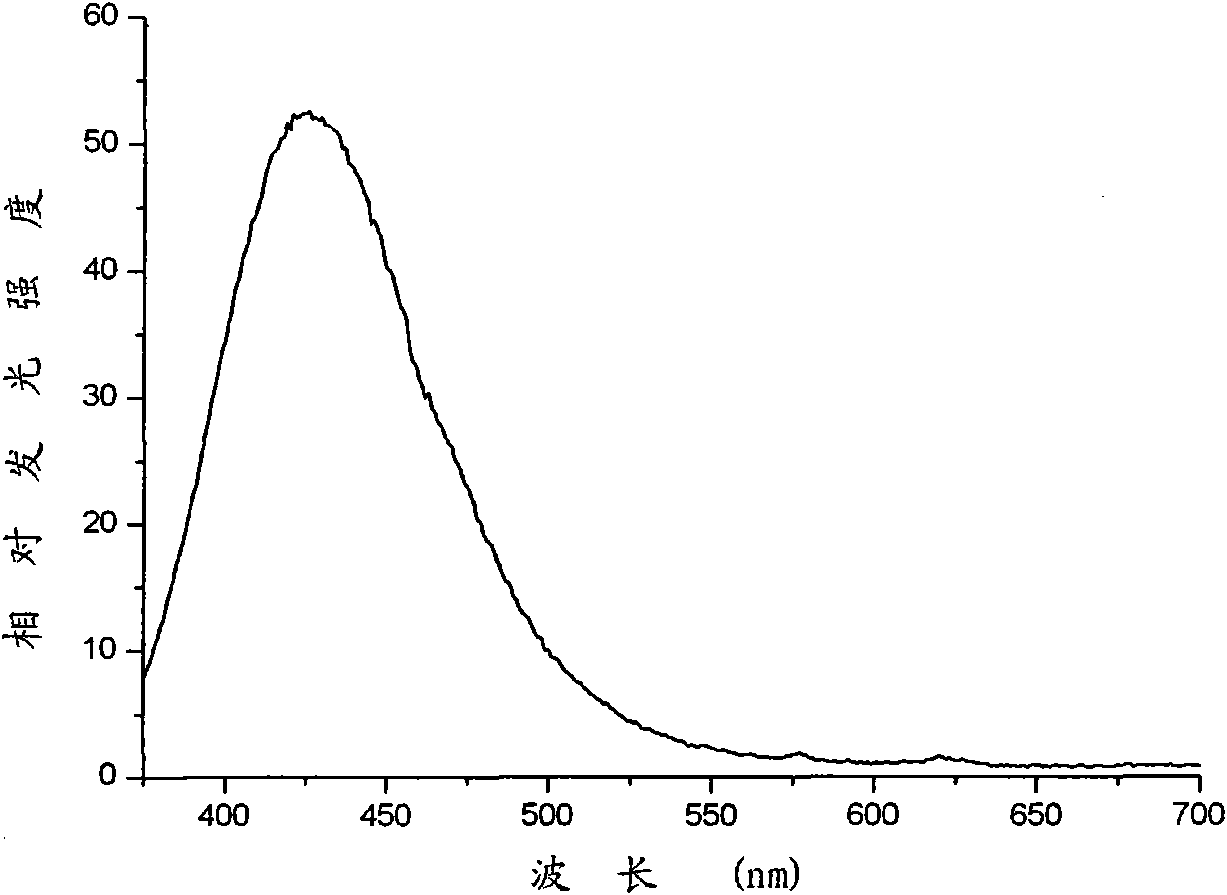

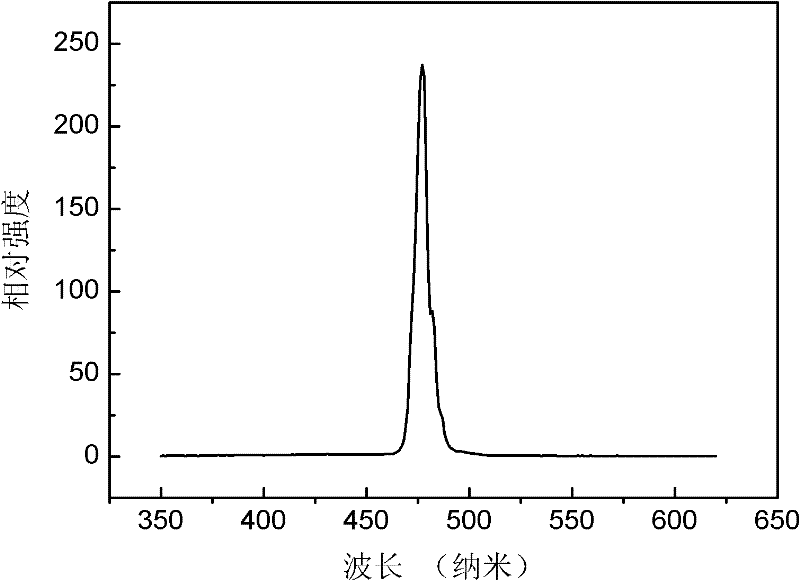

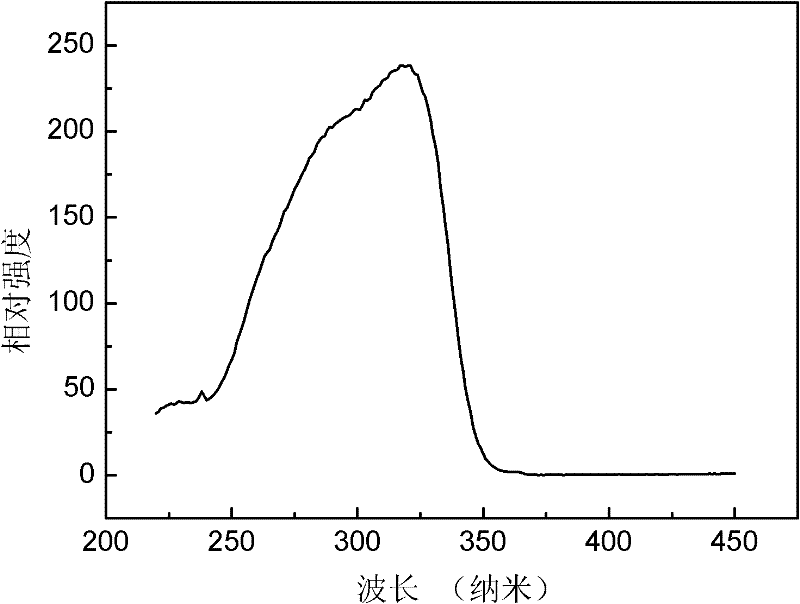

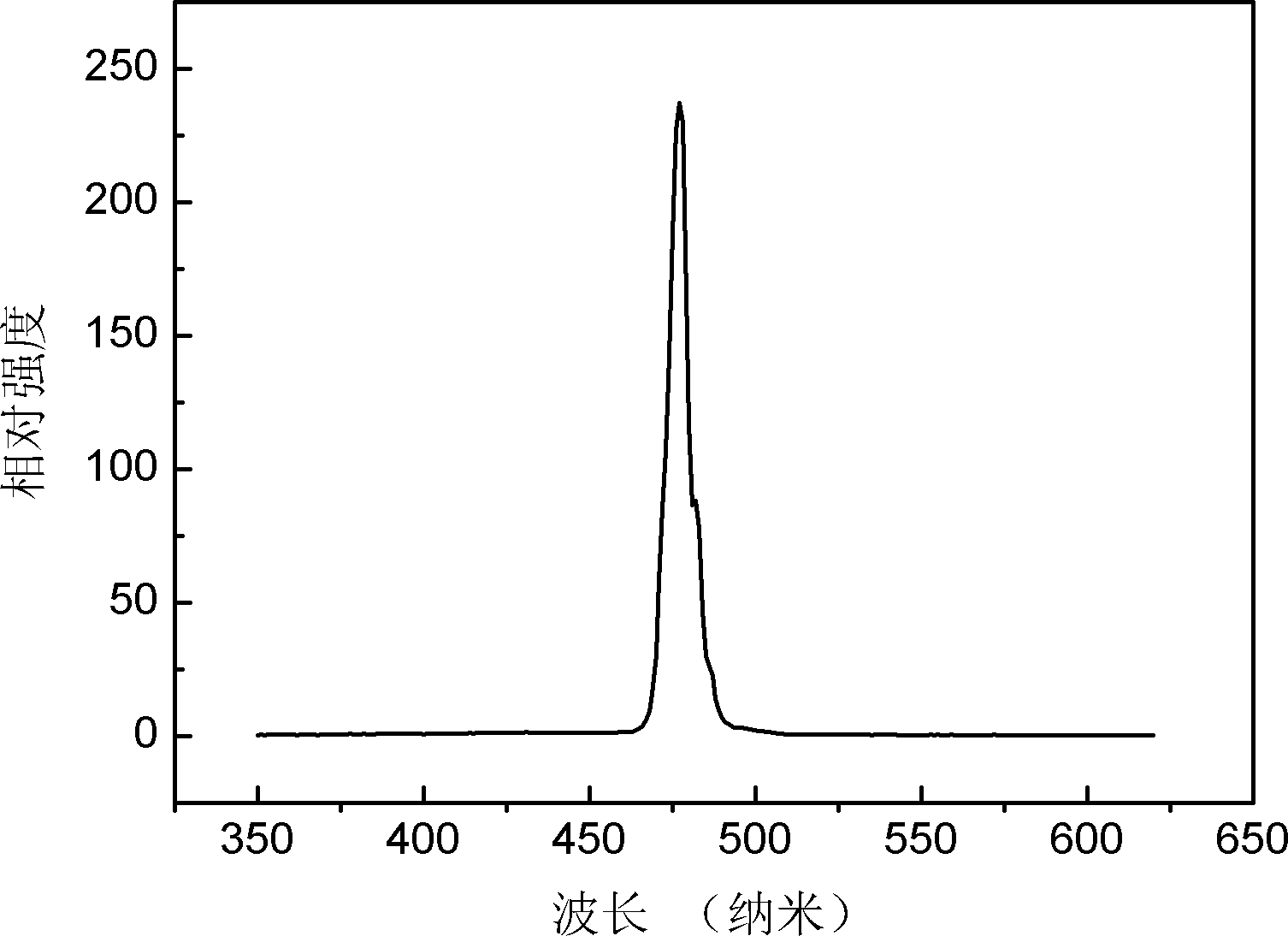

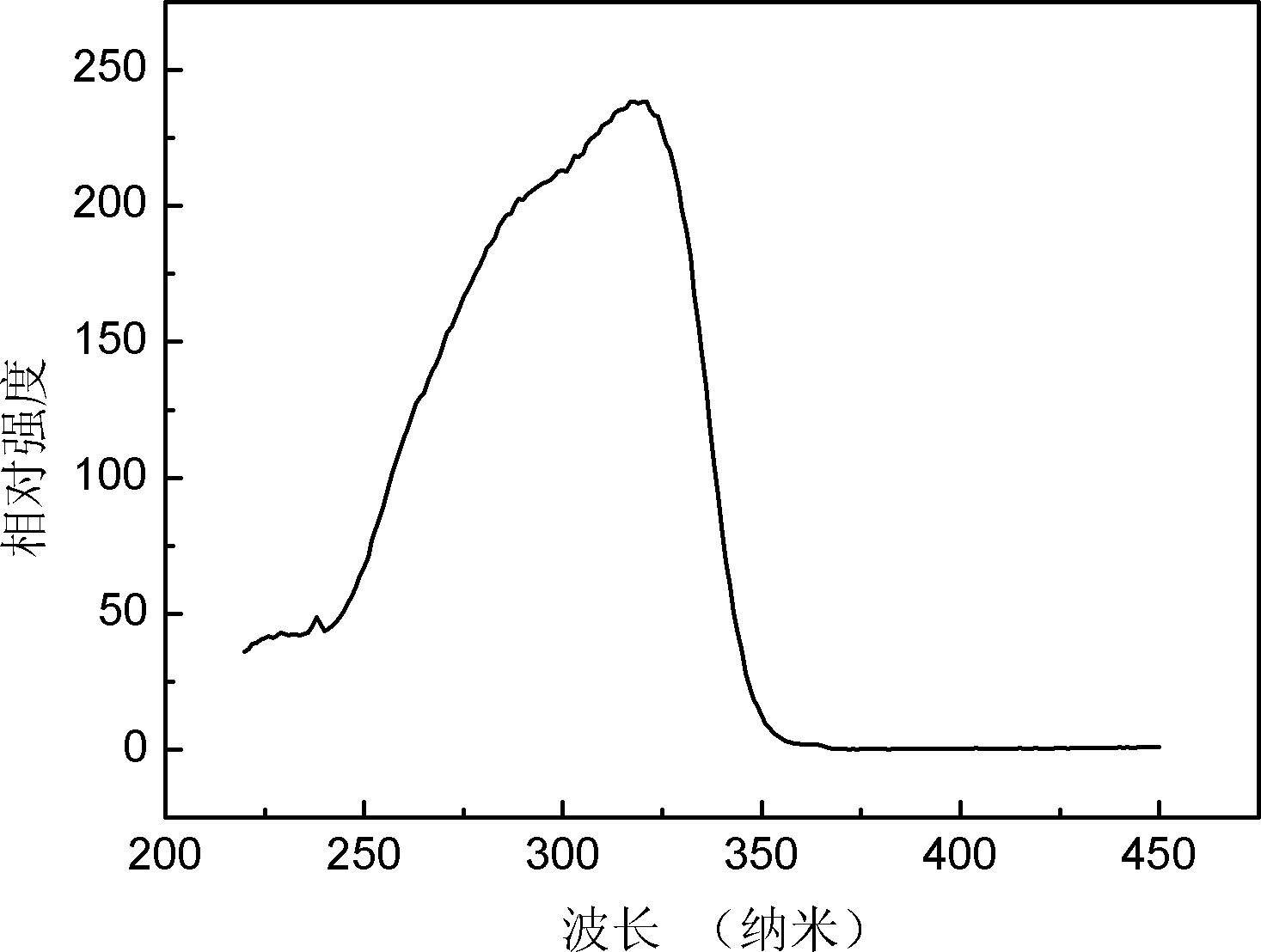

High-silica blue luminescent glass and preparation method thereof

InactiveCN102476918AImprove luminous efficiencyHigh mechanical strengthUltraviolet lightsHost material

The invention belongs to the field of a luminescent material and discloses high-silica blue luminescent glass and a preparation method thereof. The high-silica blue luminescent glass comprises a high-silica nano micropore glass substrate and Re[1-x]TmxVO4 nano luminescent minicrystals which are uniformly distributed in the micropores of the high-silica nano micropore glass substrate, wherein Re is at least one of Y, La and Gd, and x ranges from 1*10<-4> to 0.05. According to the invention, the high-silica nano micropore glass is used as a luminescent ion substrate, and the Re[1-x]TmxVO4 nano luminescent minicrystals are distributed in the micropores of the luminescent ion substrate; and the high-silica nano micropore glass substrate has good ultraviolet light permeable property, which is extremely beneficial to absorption of luminescent particles on excitation wavelengths, thereby improving the luminescence efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of high-temperature resistant and anti-abrasion-and-corrosion gradient coating used for circulating fluidized bed boiler

InactiveCN106399912ASolve unresolvable defectsReduce coefficient of frictionMolten spray coatingAlcoholPower flow

The invention discloses a preparation method of a high-temperature resistant and anti-abrasion-and-corrosion gradient coating used for a circulating fluidized bed boiler. The preparation method includes the steps that firstly, sand blasting roughening is performed on the surface of a circulating fluidized bed boiler part; secondly, the surface subjected to sand blasting roughening is washed with acetone and ethyl alcohol successively and is dried; thirdly, a NiCrBSi intermediate coating is sprayed on the roughened and cleaned surface in a plasma spraying manner, then Cr3C2-NiCr-BN-Si3N4 particles are sprayed in a plasma spraying manner, and the conditions of a plasma spraying process includes that the main gas pressure is 0.7-1.0 MPa, the auxiliary gas pressure is 0.6-0.9 MPa, the main air flow is 1300-1800 l / h, the auxiliary air flow is 900-1100 l / h, the arc current is 450-600 A, the arc voltage is 85-100 V, the powder feeding gas pressure is 0.2-0.4 MPa, the powder feeding gas flow is 280-400 l / h, the spraying distance is 100-150 mm, the spraying speed is 2-3 kg / h, and the coating thickness is 1-2.5 mm. The coating can be resistant to high temperature corrosion and high temperature abrasion and corrosion when used for the circulating fluidized bed boiler, and the coating is firm and cannot fall.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

Method for strengthening performance of complex-phase refractory material by pre-calcining-sintering microwave two-step method

ActiveCN112456969ARealize efficient value-added utilizationSolve the puzzle of the way outCeramic materials productionClaywaresMagnesium chlorateMicrowave sintering

The invention discloses a method for strengthening the performance of a complex-phase refractory material by a pre-calcination sintering microwave two-step method. The method comprises the following steps of: step 1, mixing ferronickel slag, magnesite clinker and chromium trioxide, carrying out ball milling to obtain a mixture, adding a magnesium chloride solution into the mixture, carrying out compression molding to obtain green pellets, and drying the green pellets, putting the dried green pellets into a microwave reactor, and pre-calcining the green pellets for 5-40 minutes at the temperature of 1100-1250 DEG C to obtain a pre-calcined blank; and 2, further performing microwave sintering on the pre-calcined blank obtained in the step 1 so as to obtain the complex-phase refractory material, the temperature of the microwave sintering ranging from 1,300 DEG C to 1,350 DEG C, and the temperature time of the microwave sintering is shorter than or equal to 20 min. With the method adopted,the high-performance complex-phase refractory material with the compressive strength of 183.4 to 206.6 MPa, the refractoriness of 1845 to 1873 DEG C, the volume density of 3.16 to 3.61 g / cm <3> and the apparent porosity of 1.2 to 1.7 percent is obtained. The method has the advantages of high resource utilization rate, high product additional value, low production cost, environmental friendliness,simple process and the like.

Owner:CENT SOUTH UNIV

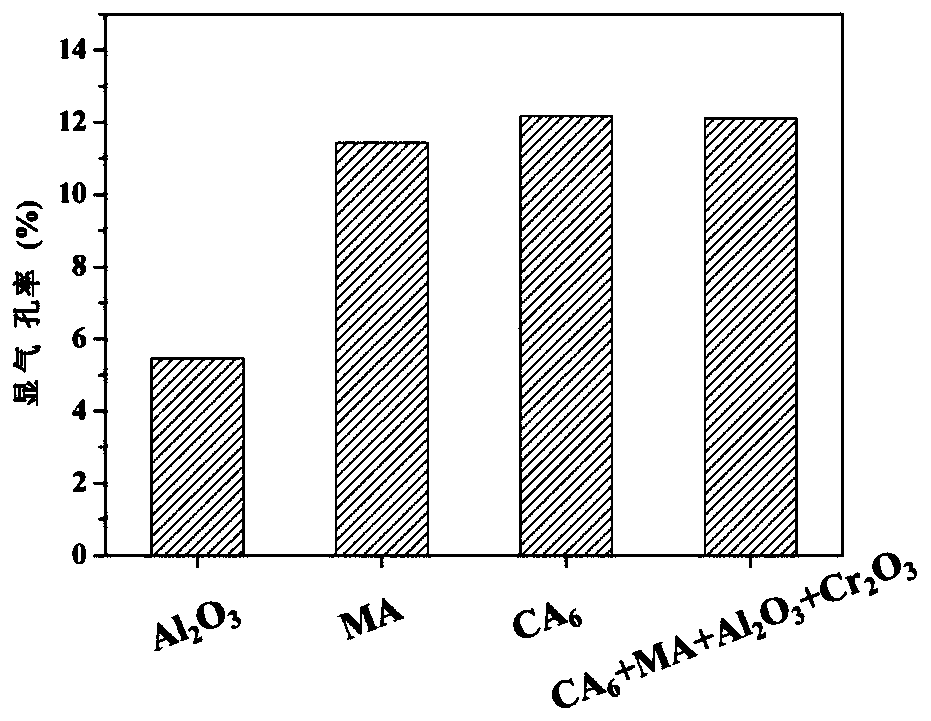

CA6-MA-Cr2O3-Al2O3 ladle lining castable and preparation method thereof

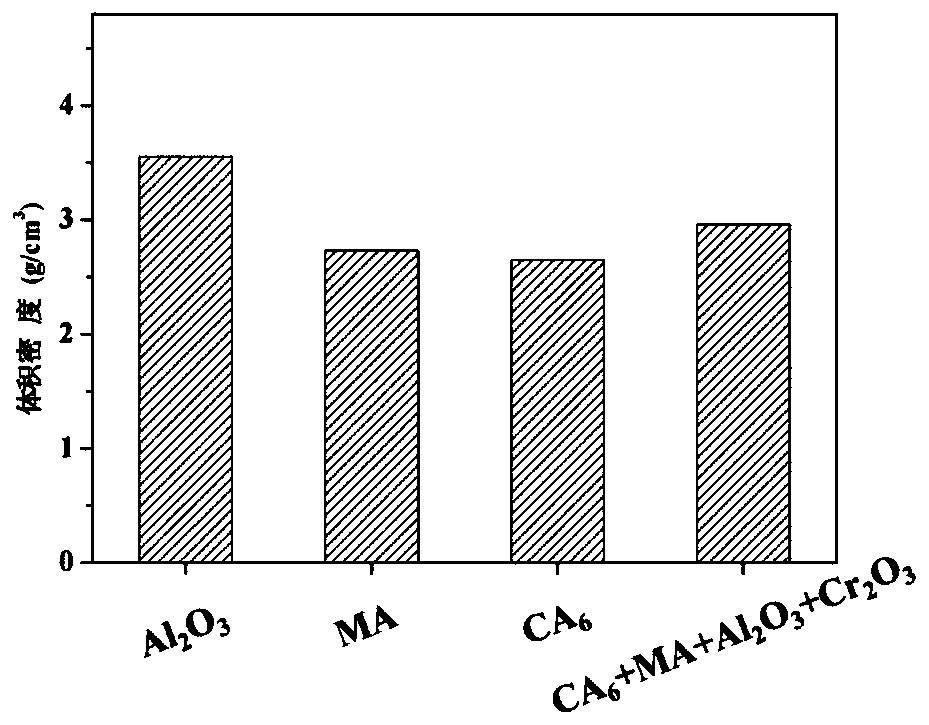

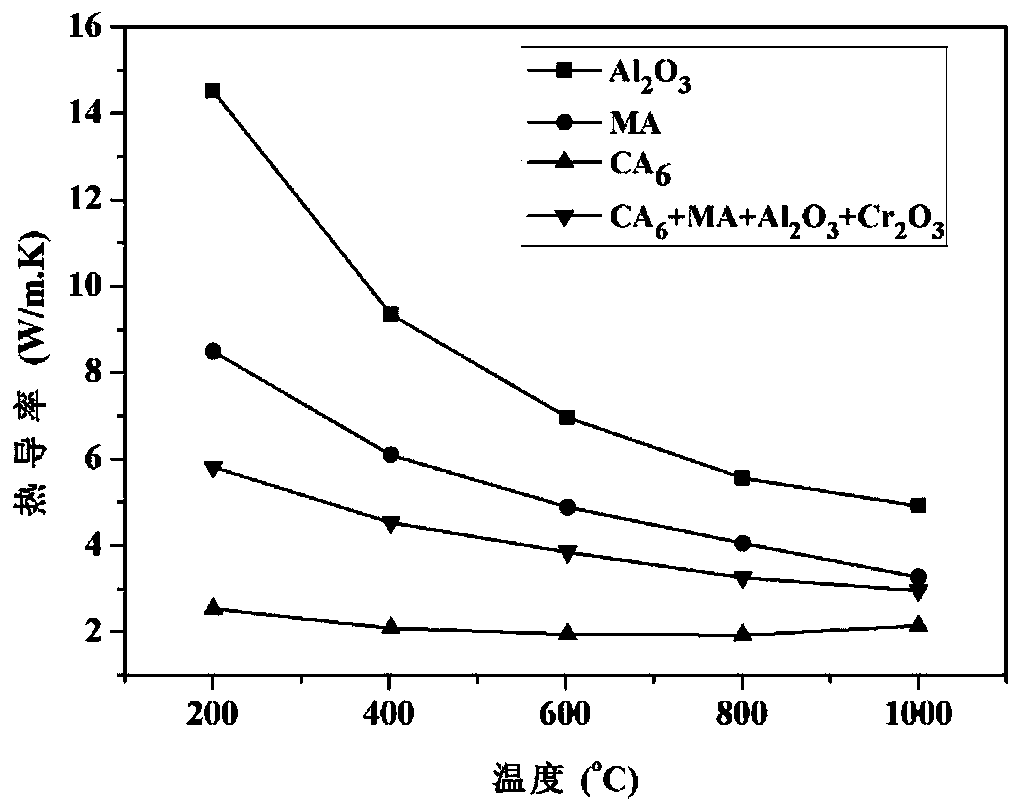

The invention relates to a CA6-MA-Cr2O3-Al2O3 ladle lining castable and a preparation method thereof. According to the technical scheme, 65-75wt% of CA6-MA-Cr2O3-Al2O3 particles, 5-8wt% of alpha-Al2O3micro powder, 3-6wt% of calcium aluminate cement, 7-10wt% of magnesium aluminate spinel fine powder and 8-12wt% of platy corundum fine powder are taken as raw materials, a polycarboxylate water reducing agent and water are added, and stirring, forming, demoulding and baking are carried out to prepare the CA6-MA-Cr2O3-Al2O3 ladle lining castable. The preparation method of the CA6-MA-Cr2O3-Al2O3 particles comprises the following steps of: mixing 60-70wt% of CA6, 4-8wt% of chromium oxide, 10-20wt% of MA and 10-15wt% of aluminum oxide, and ball milling, adding water, granulating, drying, calcining at 1650-1750 DEG C, crushing and screening to obtain the CA6-MA-Cr2O3-Al2O3 particles with three particle size levels respectively. The product prepared by the method has the advantages of high strength, low thermal conductivity, good thermal shock stability, excellent erosion resistance, energy conservation and environmental protection.

Owner:WUHAN UNIV OF SCI & TECH

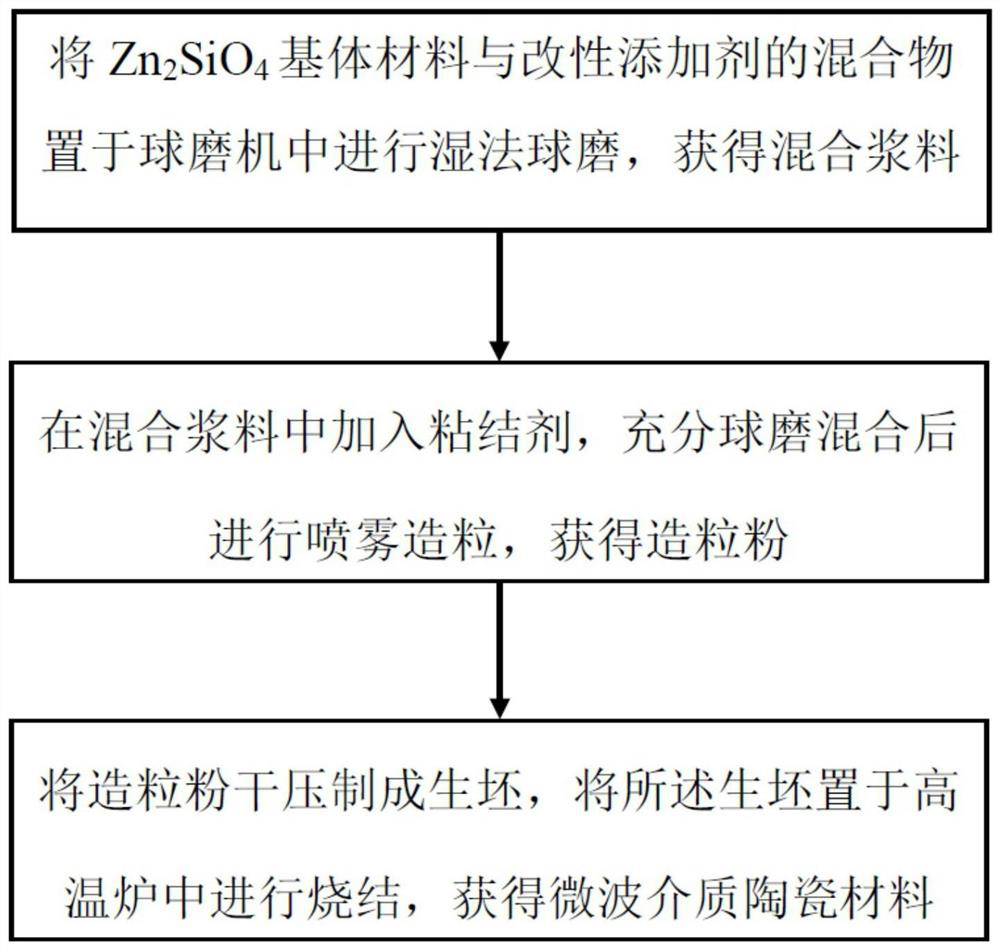

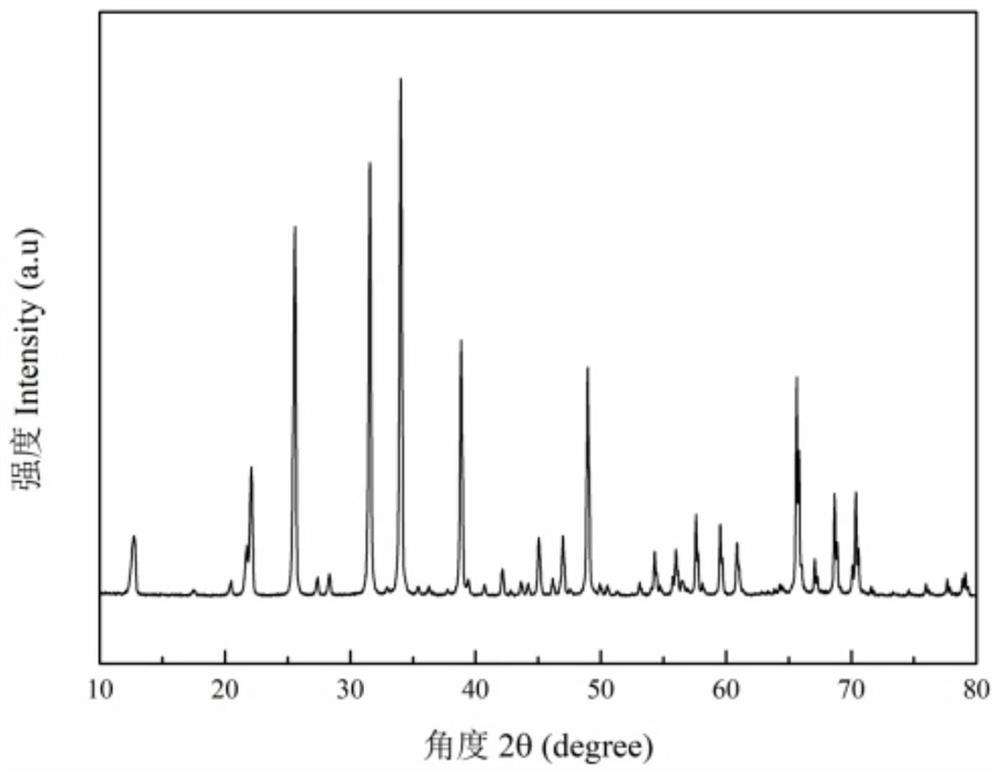

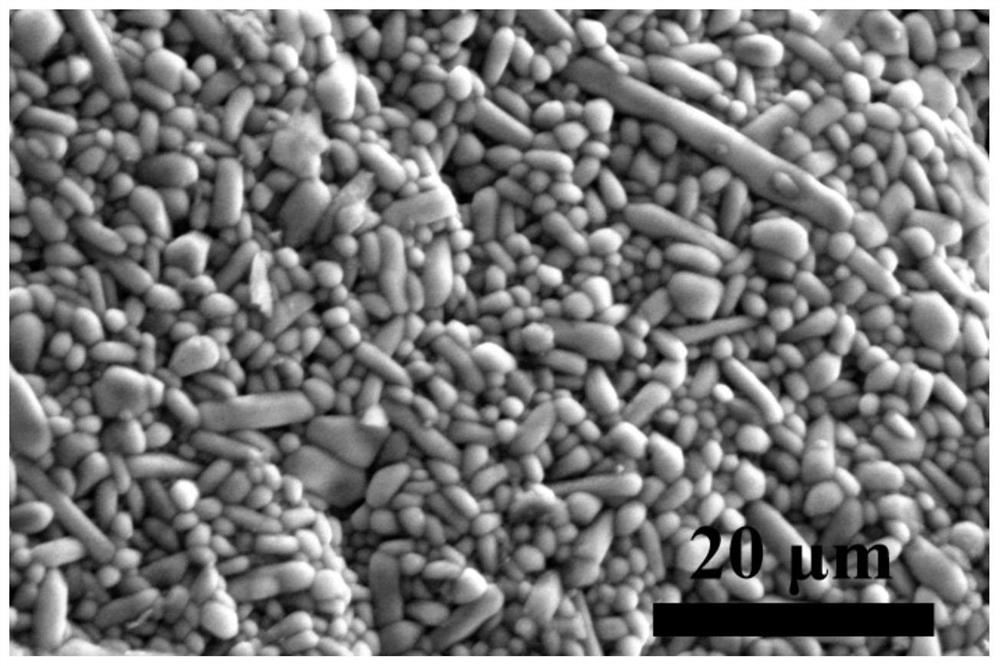

Microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material. The microwave dielectric ceramic material comprises the following components in percentage by mass: 82-90% of a base material and 10-18% of a modified additive, wherein the matrix material is Zn2SiO4, the modified additive comprises a first additive TiO2, one or two of second additives Al2O3 and Co2O3, one or two of third additives MgO and SiO2, and a fourth additive MnCO3. The microwave dielectric ceramic material provided by the invention has the excellent properties of low dielectric constant, high quality factor, high thermal shock resistance and near-zero temperature coefficient of resonance frequency, is relatively low in sintering temperature, and can adapt to the application of various devices and the use requirements of the devices in a cross-regional climatic environment. In addition, the preparation method of the microwave dielectric ceramic material provided by the invention has the characteristics of simple and convenient process and easiness in batch production.

Owner:无锡市高宇晟新材料科技有限公司

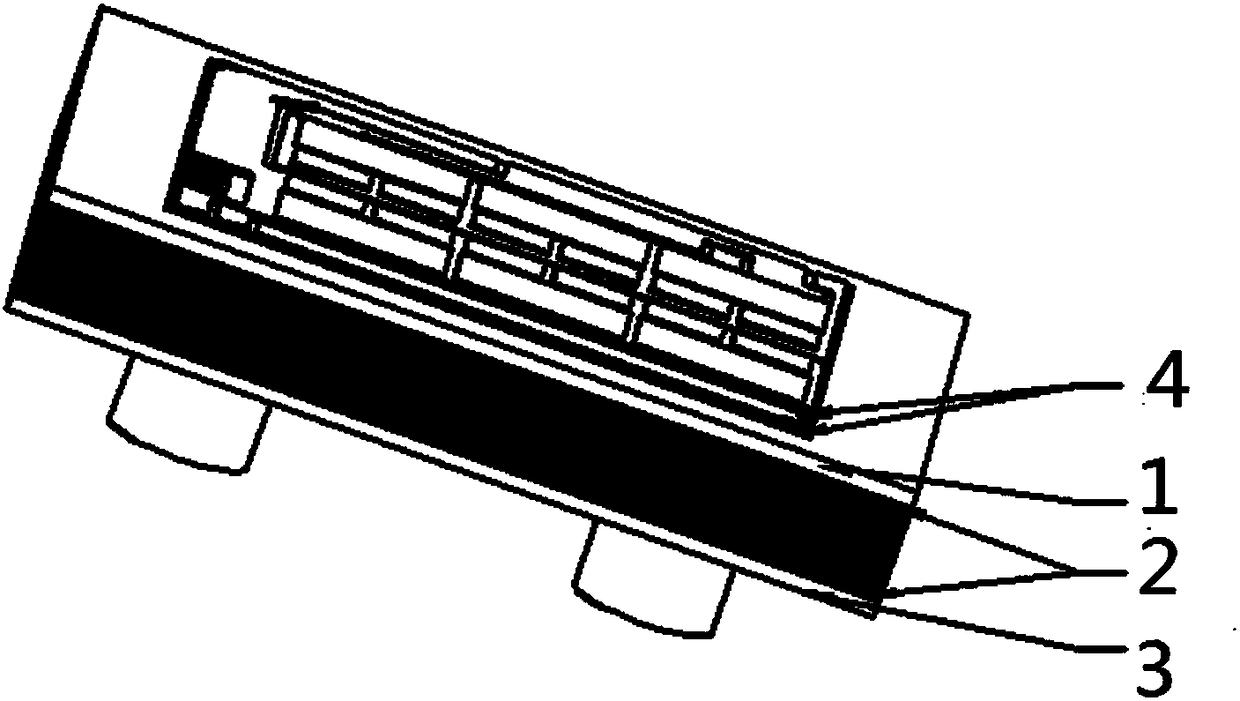

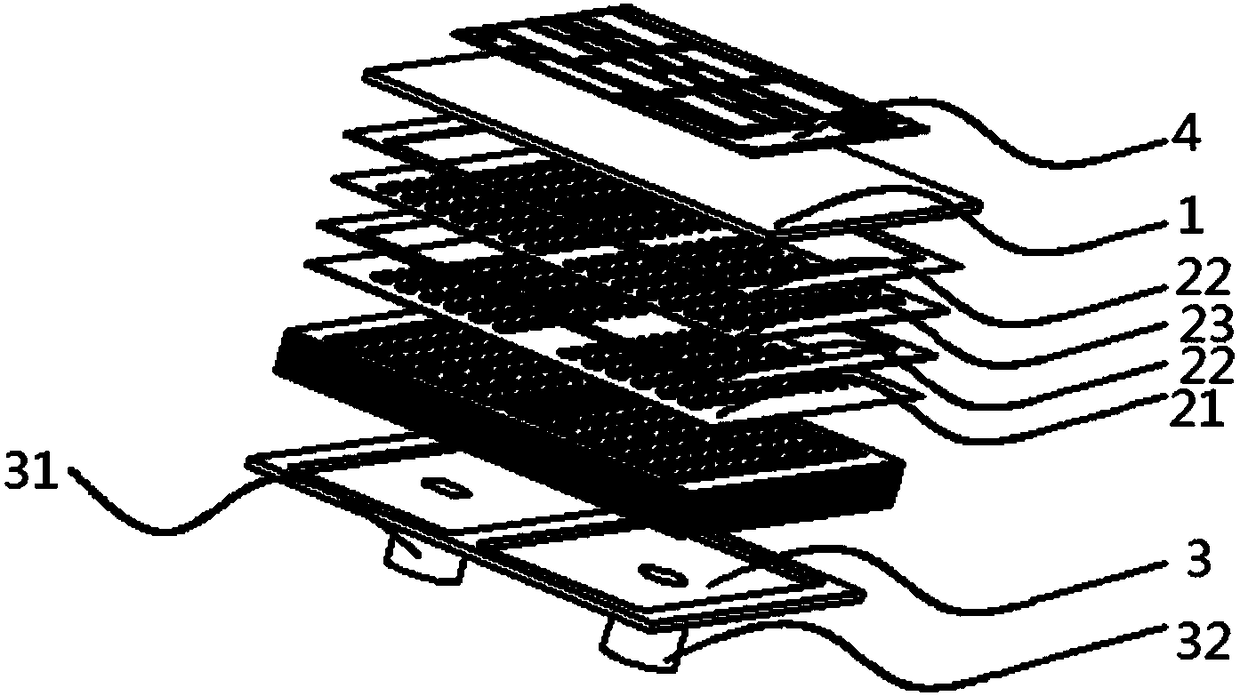

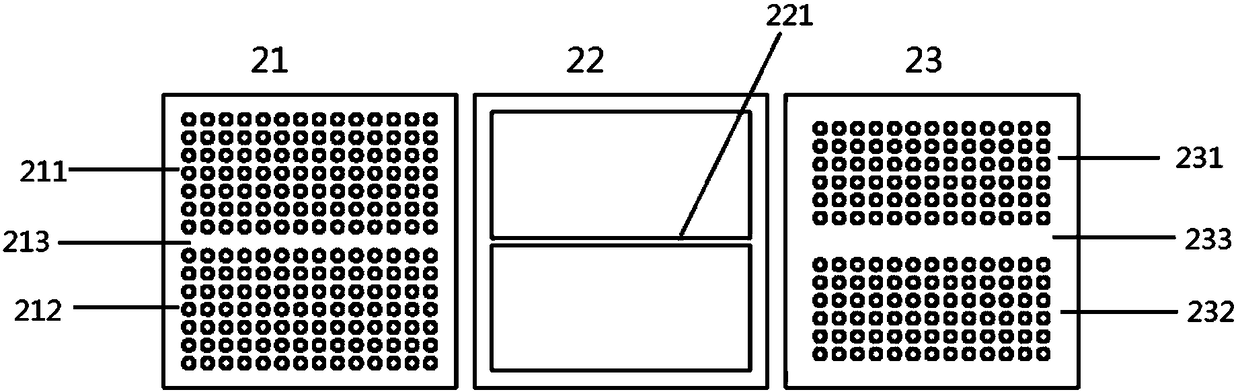

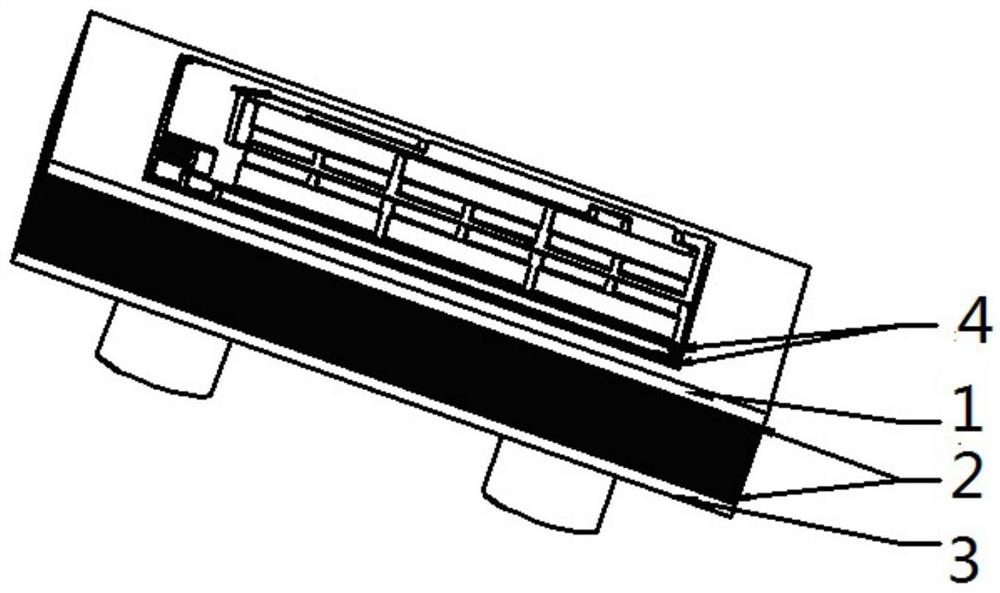

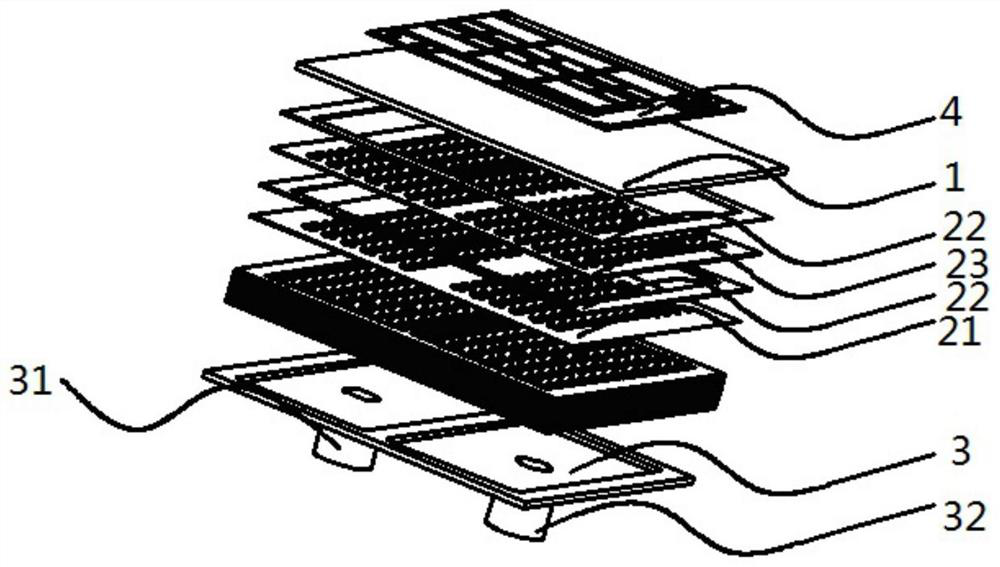

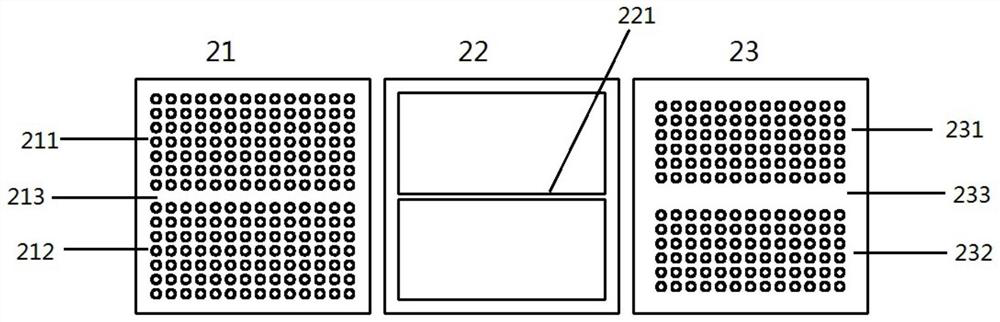

A chip heat sink, a preparation method thereof, and a DBC substrate assembly

ActiveCN109216303ALow thermal shock resistanceAnti-cold and heat shock performance guaranteeSemiconductor/solid-state device detailsSolid-state devicesDBcAlloy

The invention relates to the field of chip heat sink, in particular to a chip heat sink, a preparation method thereof and a DBC substrate assembly. The chip heat sink comprises an upper end cover, a co-fired laminated heat dissipation structure and a lower end cover, wherein the lower end cover is provided with a coolant inlet and a coolant outlet; the material of the co-fired laminated heat dissipation structure is oxygen-free copper; and the material of the upper end cover and the lower end cover is oxygen-free copper and / or copper-containing alloy. Also disclosed are a method for manufacturing a chip heat sink and a DBC substrate assembly including the chip heat sink of any structure described above. The chip heat sink of the invention has good cold and heat shock resistance, heat conductivity and seal property of the chip heat sink, the cost of the chip heat sink of the invention is low, and the preparation process is easy to operate and realize.

Owner:BYD CO LTD

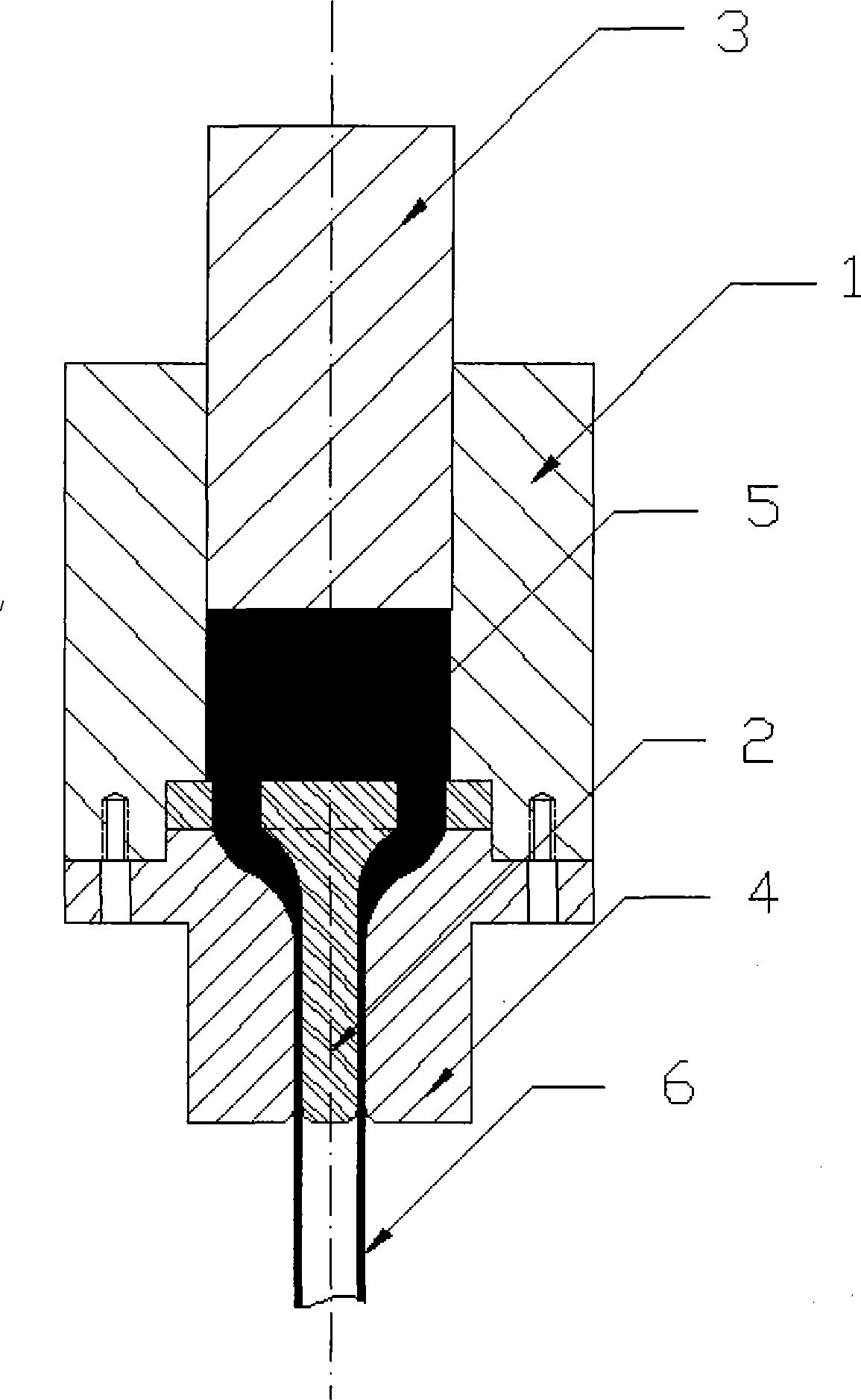

Preparation method of silicon carbide ceramic tubular product

InactiveCN101580390BExcellent extrusion formabilityControllable tube shapeThermal dilatationShock resistance

The invention belongs to the technical fields of a silicon carbide ceramic material and a preparation method thereof, in particular relates to a preparation method of a silicon carbide ceramic tubular product with high strength, high thermal conduction, low expansion, high thermal-shock resistance performance and controllable external dimensions. The silicon carbide ceramic tubes have even texture and uniform tubular wall thickness; the thickness of each tubular wall can be controlled from 0.5 mm to 20 mm, each tubular outer diameter can be from 5 mm to 100 mm, the silicon carbide ceramic tube with the longest length is limited by a sintering furnace, and each tubular wall can be in a compact structure or a micropore structure. The silicon carbide ceramic tubular product uses organic resin and SiC powder as main raw materials and utilizes an extrusion molding technology to prepare a tubular precast blank which is compacted and equalized at a high temperature, pyrolysed to forma final product after reaction, infiltration and sintering. The silicon carbide ceramic tubular product has the fundamental characteristics of SiC ceramics, such as high strength, low thermal expansion coefficient, high thermal conduction, chemical corrosion resistance, oxidation resistance, good high temperature stability, strong thermal-shock resistance performance, and the like. The preparation method has simple technology, convenient operation, no complicated equipment and low manufacture cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Manufacturing method of high-purity tantalum oxide body crucible

The invention discloses a manufacturing method of a high-purity tantalum oxide body crucible. The technical scheme of the manufacturing method is as follows: carrying out proportioning on high-puritytantalum oxide powder, and carrying out granulation, pressing, drying, high-temperature sintering, annealing, polishing and finishing. The method has the advantages of reasonable process and low manufacturing cost, and the obtained product has the advantages of high strength, good purity, low water absorption, good thermal shock resistance, small deformation, almost no defects of cracking and thelike, long service period and high durability.

Owner:JIUJIANG TANBRE

High-silica blue luminescent glass and preparation method thereof

InactiveCN102476918BImprove luminous efficiencyHigh mechanical strengthUltraviolet lightsHost material

The invention belongs to the field of a luminescent material and discloses high-silica blue luminescent glass and a preparation method thereof. The high-silica blue luminescent glass comprises a high-silica nano micropore glass substrate and Re[1-x]TmxVO4 nano luminescent minicrystals which are uniformly distributed in the micropores of the high-silica nano micropore glass substrate, wherein Re is at least one of Y, La and Gd, and x ranges from 1*10<-4> to 0.05. According to the invention, the high-silica nano micropore glass is used as a luminescent ion substrate, and the Re[1-x]TmxVO4 nano luminescent minicrystals are distributed in the micropores of the luminescent ion substrate; and the high-silica nano micropore glass substrate has good ultraviolet light permeable property, which is extremely beneficial to absorption of luminescent particles on excitation wavelengths, thereby improving the luminescence efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of chip radiator and its preparation method and dbc substrate assembly

ActiveCN109216303BLow thermal shock resistanceAnti-cold and heat shock performance guaranteeSemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal conductivity

The invention relates to the field of chip radiators, in particular to a chip radiator, a preparation method thereof, and a DBC substrate assembly. The chip radiator includes: an upper end cover, a co-fired laminated heat dissipation structure and a lower end cover sequentially laminated. The lower end cover is provided with a cooling liquid inlet and a cooling liquid outlet. The material of the co-fired laminated heat dissipation structure is Oxygen-free copper, the material of the upper end cap and the lower end cap is oxygen-free copper and / or an alloy containing copper. It also relates to a preparation method of a chip radiator and a DBC substrate assembly, the substrate assembly includes the chip radiator with any structure above. The heat sink of the present invention has good cold and heat shock resistance, thermal conductivity, and sealing performance of the chip heat sink, and the cost of the chip heat sink of the present invention is low, and the preparation process is easy to operate and realize.

Owner:BYD CO LTD

Production method of large-size graphite electrode

The invention relates to a production method of a large-size graphite electrode which comprises the components in percentage by weight: 76-79 percent of calcined petroleum coke, 21-24 percent of medium-high temperature modified asphalt and the balance of filling material with the diameter of 0.075-2 mm, wherein the calcined petroleum coke comprises the following components in percentage by weight: not more than 4 percent of granules with the diameter of more than 12 mm, 6-10 percent of granules with the diameter of 8-13 mm, 13-17 percent of granules with the diameter of 4-8 mm, 9-13 percent of granules with the diameter of 2-4 mm and 30-32 percent of powder with the diameter of not more than 0.075 mm according to the particle size distribution; and the coking value of the modified asphalt is over 55 percent and the softening point is 95-100 DEG C. After the raw materials are mixed according to the proportion, the large-size graphite electrode is produced by adopting a conventional process, wherein the mixing temperature is 160-165 DEG C and the thicker lumpiness during the die-filling is less than 40 mm. A huge-size electrode with the diameter of over 960 mm can be produced by adopting the production method of the large-size graphite electrode; meanwhile, the electrode has low resistivity and good conduction property and can bear strong current, thereby enabling the unit consumption and the electricity consumption to be greatly lowered and saving the production cost.

Owner:JIEXIU JUYUAN & COALY

A two-step microwave precalcination-sintering method for strengthening the performance of composite refractory materials

ActiveCN112456969BReduced corrosion resistanceImprove fire resistanceCeramic materials productionClaywaresChromium trioxideRefractory

Owner:CENT SOUTH UNIV

Boron nitride ceramic side seal plate for thin strip continuous casting and preparation method thereof

Owner:武汉钢铁有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com