Patents

Literature

59results about How to "Good expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foam glass produced by lens glass waste material and its preparing method

InactiveCN1587148AWell mixedUniform structureSolid waste disposalHeat conductingVolumetric Mass Density

The present invention produces foamed glass with the leftover from producing glasses lens in 96.1-98.6 wt%, boric acid 1.0-3.0 wt%, Sb2O3 as assistant 0.2-0.4 wt% and common carbon black as foaming agent 0.2-0.5 wt%, and through ball milling to form compounded material, grinding to finer than 80 micron, spreading in refractory steel mold, covering with isolating refractory steel plate and forming in common technological process to obtain the foamed glass with homogeneous structure. The foamed glass has density of 130 kg / cu m, water absorption less than 0.5 vol%, compression strength and folding strength higher than 0.6 MPa and heat conducting coefficient of 0.046-0.052 w / (m.k). It is one excellent kind of heat insulating material, and may be used widely in petroleum industry, tunnel engineering, outer building wall, etc.

Owner:BEIJING UNIV OF TECH

Sealing gasket covered with carbon-fiber covering yarn and preparation method of sealing gasket

The invention discloses a sealing gasket covered with carbon-fiber covering yarn. The sealing gasket comprises two mixed padding layers, a reinforcing fiber layer and a carbon-fiber covering yarn layer, wherein the reinforcing fiber layer is located between the two mixed padding layers, and the carbon-fiber covering yarn layer is arranged at the outer side of the sealing gasket in a covering manner. The sealing gasket is made of polytetrafluoroethylene, nitrile rubber, graphite, natural rubber, coke powder, vermiculite powder, barite powder, aramid fibers and glass fibers, and therefore the sealing gasket has the beneficial effects of being quite low in friction coefficient, quite good in high temperature stability and heat shock resistance, quite high in strength and heat conductivity coefficient, low in expansion coefficient, quite high in electrical resistivity, resistant to corrosion and capable of allowing microwaves or infrared rays to permeate and the like, the natural rubber is quite high in elasticity, and therefore the sealing gasket is quite good in elasticity and plasticity; the periphery of the sealing gasket is covered with the carbon-fiber covering yarn layer, and therefore the sealing gasket has the beneficial effects of being quite high in acid resistance, alkali resistance, corrosion resistance and abrasion resistance; and in addition, the sealing gasket is subjected to vulcanization treatment, so that the sealing gasket is durable and not prone to aging.

Owner:DONGTAI HUAYANG GLASS FIBER

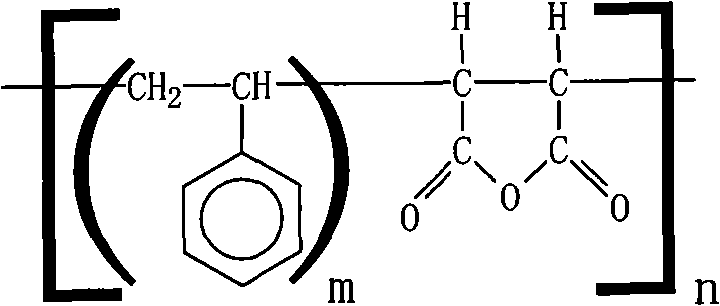

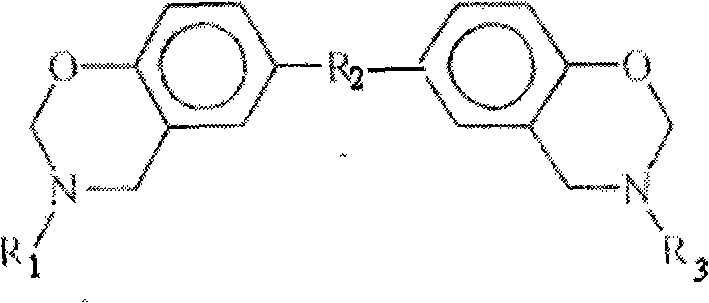

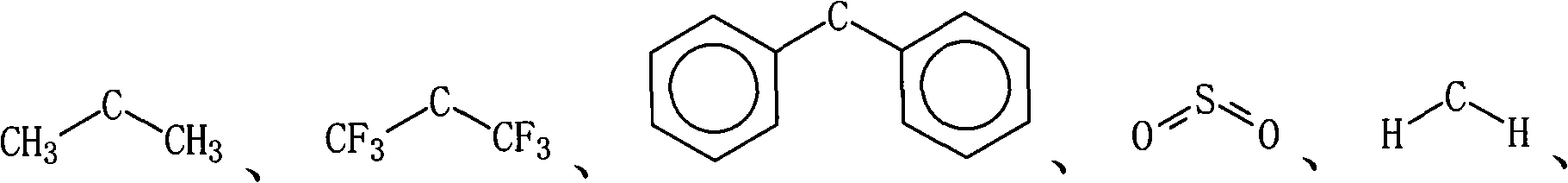

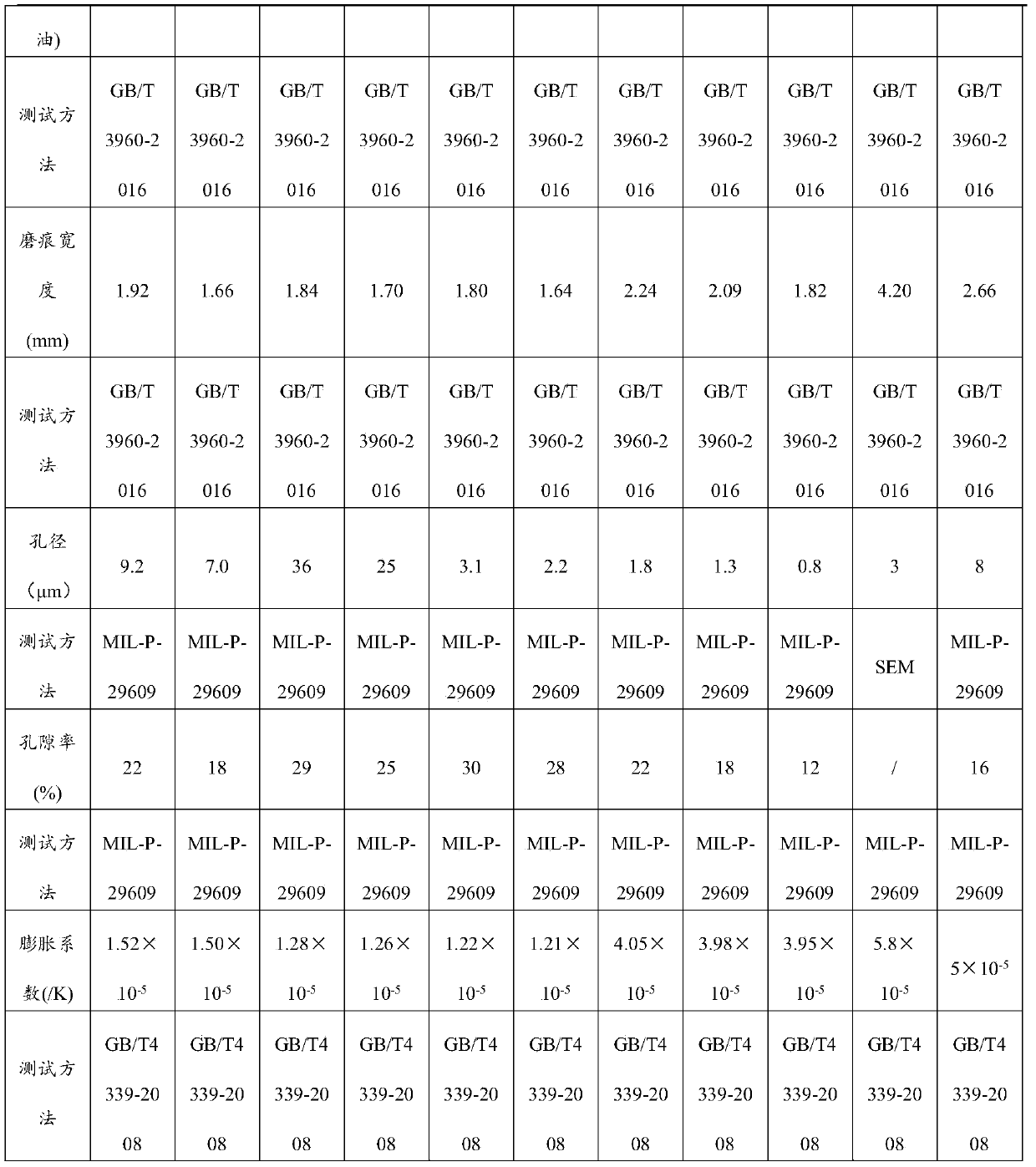

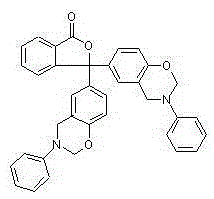

Electronic material composition

ActiveCN102134377ALow dielectric constantSmall dissipation factorMetal layered productsNitrogenCopper foil

The invention relates to a halogen-free electronic material composition which has the characteristics of low dielectric constant and small dissipation factor. The halogen-free electronic material composition comprises (a) styrene-maleic anhydride copolymer, (b) polybenzoxazine, (c) flame retardant and (d) additives. The electronic material composition can be used as a material of a high-frequency copper foil substrate.

Owner:TAIWAN POWDER TECH CO LTD

Ancient green crackled glaze for ceramic decorations and preparation method of ancient green crackled glaze

The invention provides ancient green crackled glaze for ceramic decorations and a preparation method of the ancient green crackled glaze. The ancient green crackled glaze comprises the following components: 50-70 percent of nepheline orthoclase, 10-15 percent of talc, 10-15 percent of CaCO3, 3-8 percent of MgCO3, 4-8 percent of kaolin and 0.5-1.0 percent of CuCO3. The preparation method comprises the following steps of: weighing all the components, then sufficiently mixing the components, adding the mixture to a grinder, adding water which accounts for 50-60 percent of the dry powder, grinding for 5-12 hours, testing the granularity, and screening the ground mixture by using a 350-mesh screen, wherein residues are about 1-3g; and then blending the concentration of the ground glaze to true specific gravity at 42-45 DEG C, spraying or soaking the glaze onto a ceramic product, airing, then feeding the ceramic product into a kiln, carrying out glaze firing at 1185-1200 DEG C for 9-10 hours, finally naturally cooling and discharging the finished product from the kiln. The prepared ancient green crackled glaze is fine and soft in glaze surface, rich in texture and ancient in color and luster.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

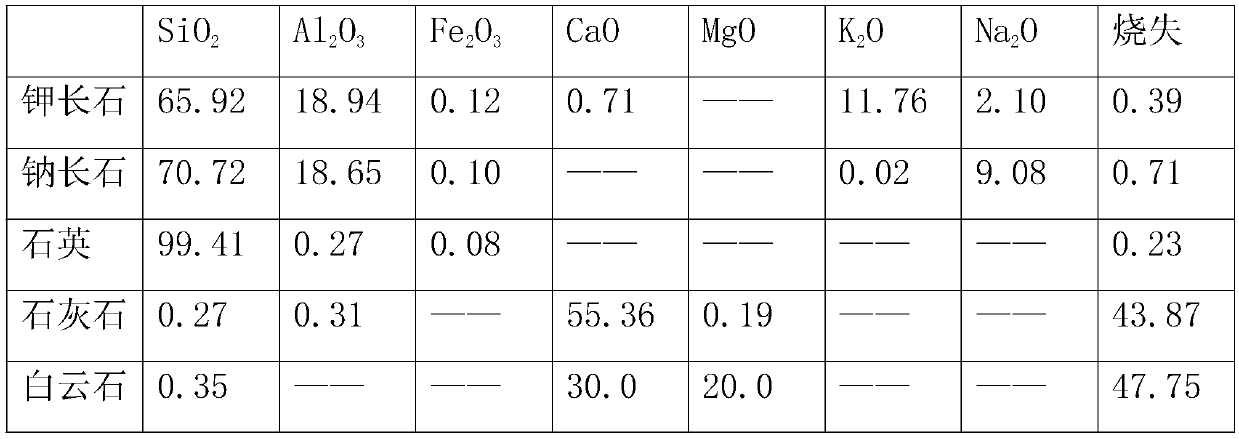

High-strength medium-temperature crackle glaze ceramic product and manufacturing method thereof

The invention provides a high-strength medium-temperature crackle glaze ceramic product which comprises a body material and glaze, and the body material comprises the following raw materials: kaolin, quartz, potassium feldspar, clay, talc and ceramic micro-powder; and the glaze is prepared from the following raw materials: potassium feldspar, albite, kaolin, dolomite, quartz, barium carbonate, zinc oxide, copper oxide, aluminum oxide, heavy calcium carbonate and plant ash. The manufacturing method of the high-strength medium-temperature cracked glaze ceramic product comprises the following steps: respectively mixing a body material and a glaze material, adding water, performing wet milling by using a ball mill, and sieving to obtain body material slurry and glaze slurry; preparing blank biscuit firing from the blank slurry; glazing; and sintering. The ceramic product prepared by medium-temperature firing is short in firing time and low in temperature, so that the energy consumption is low, the rate of finished products is high, and the production cost is reduced; and meanwhile, the glaze surface is very special in cracking, uniform and clear in lines, and full of the glaze surface, thereby giving a special aesthetic feeling to people.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

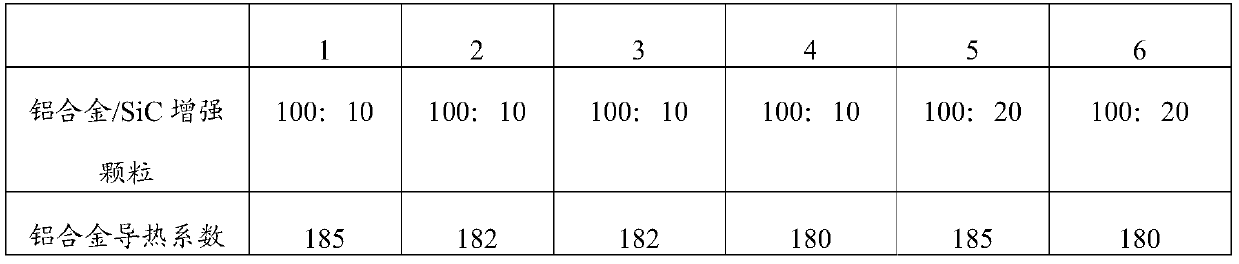

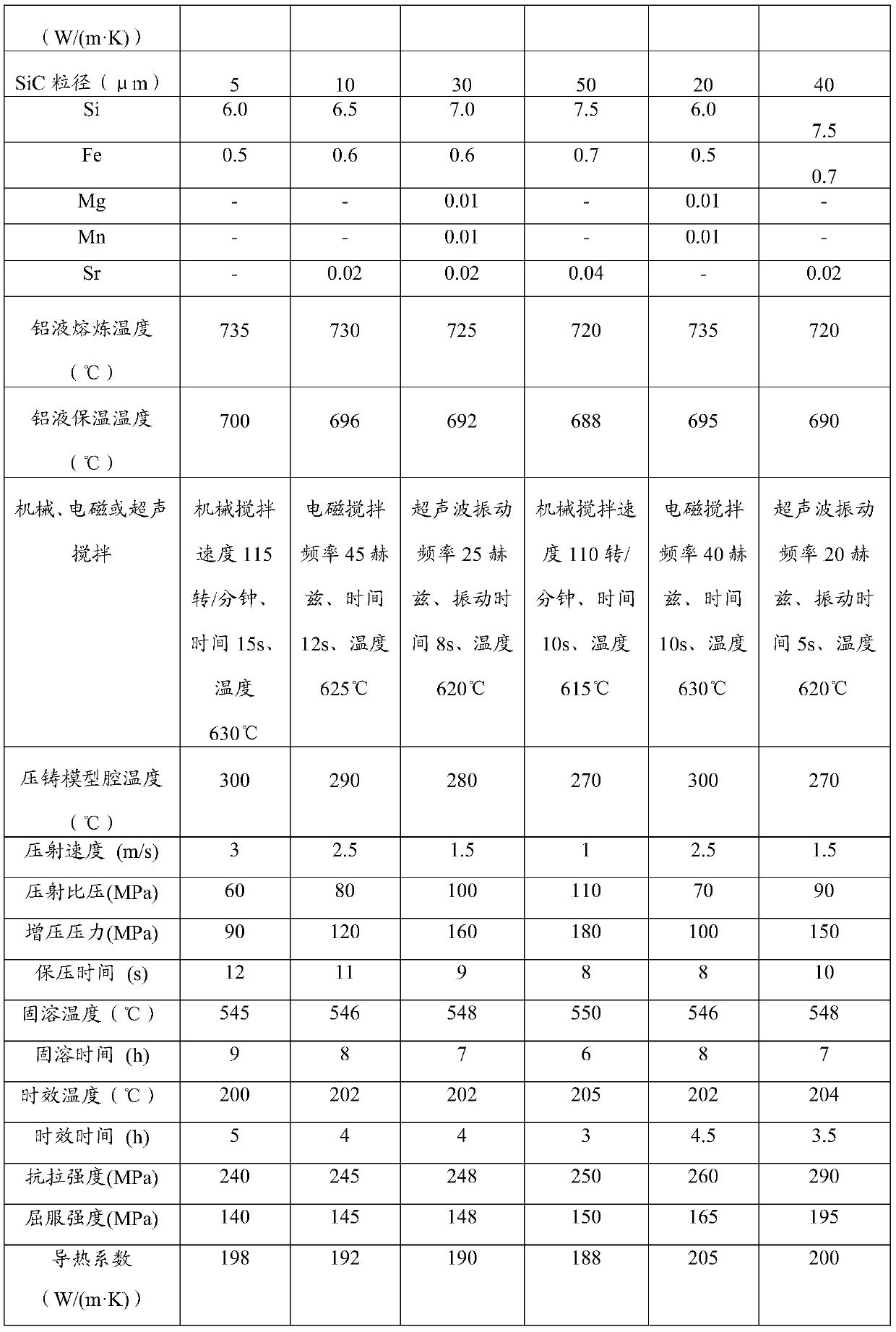

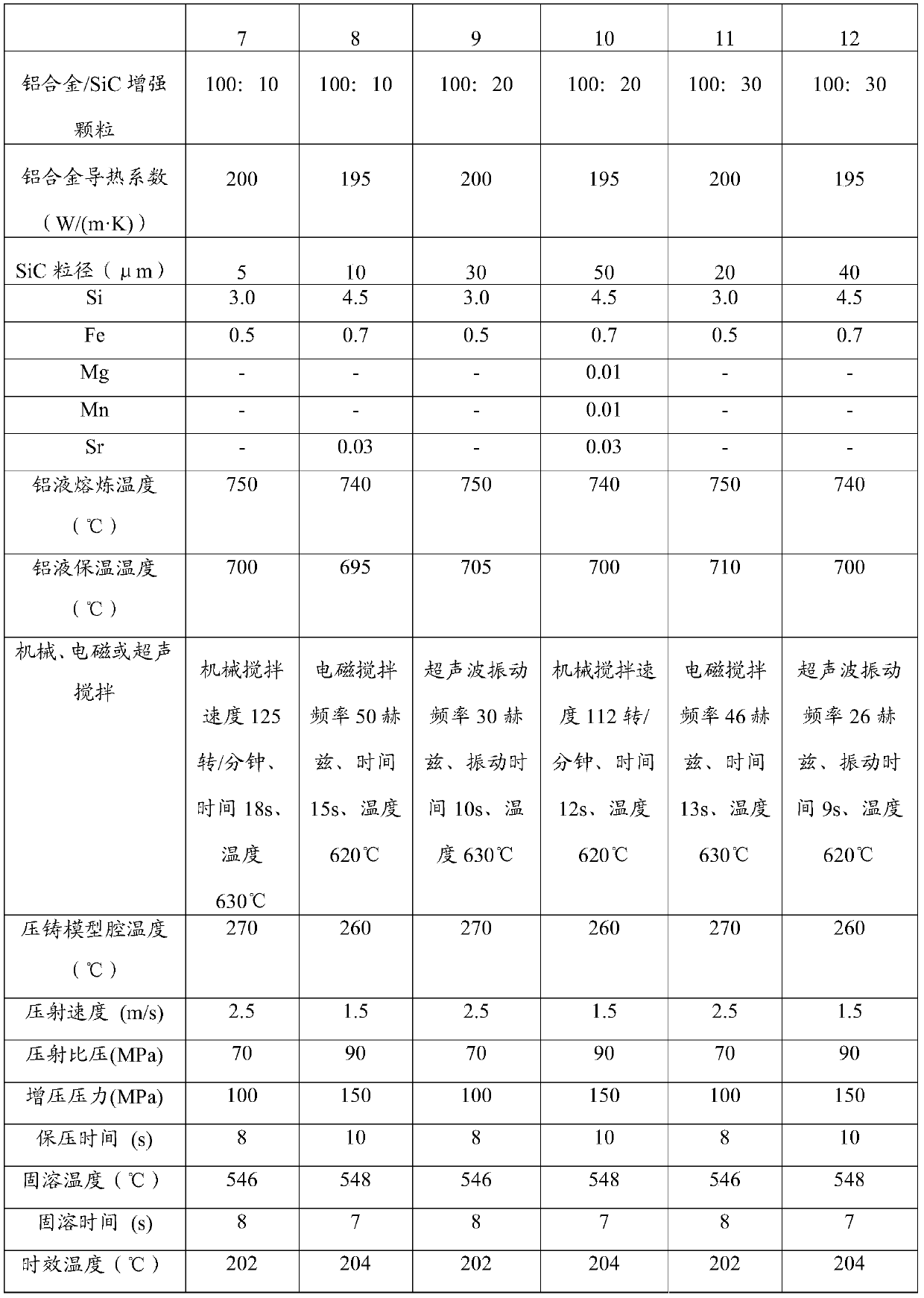

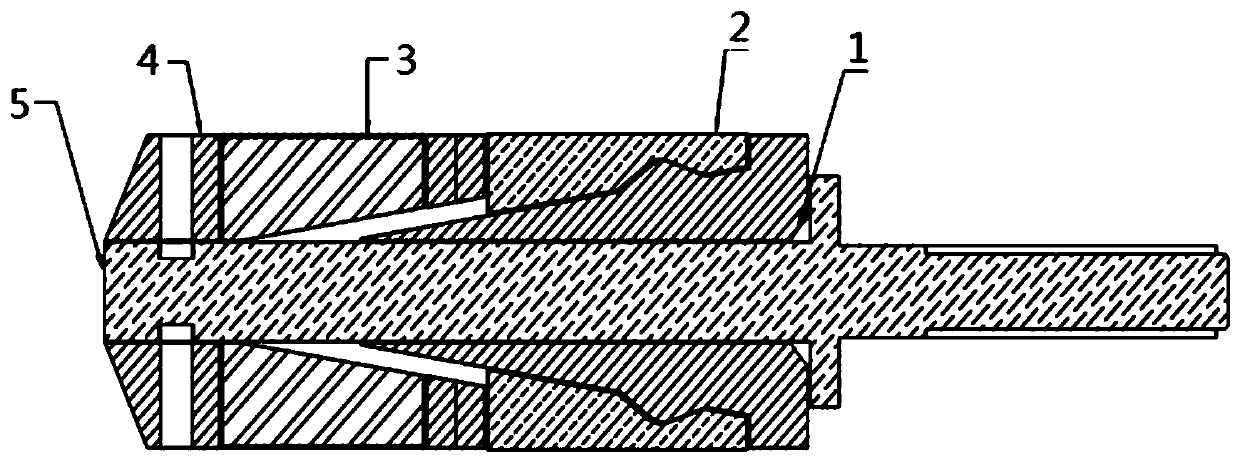

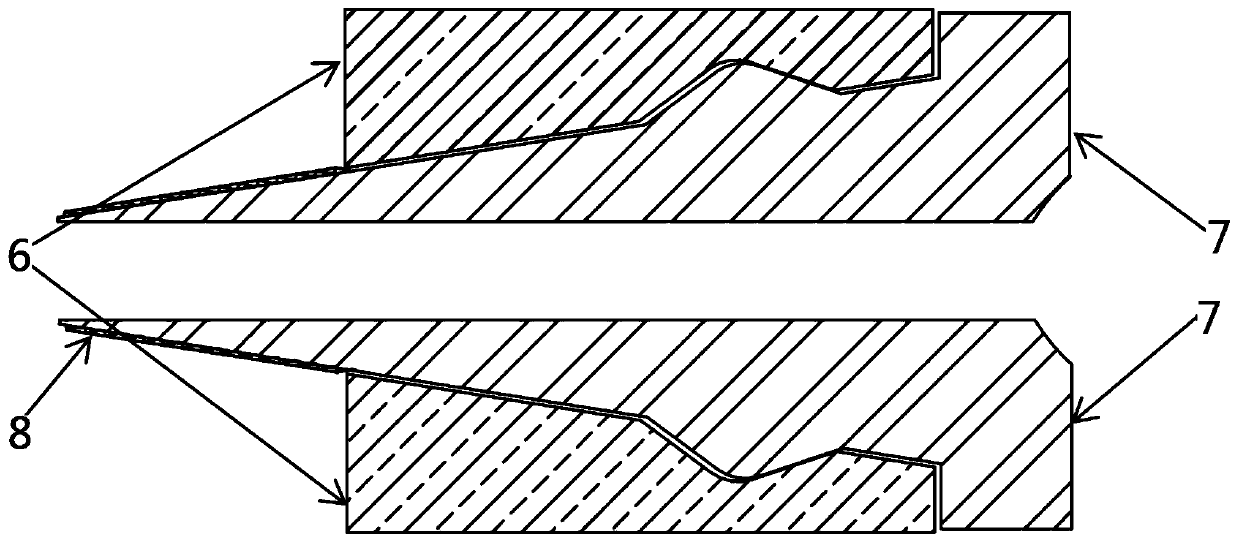

High-thermal-conductivity particle reinforcement Al-based composite and preparing method thereof

The invention relates to the technical field of metal-based composites and particularly relates to a high-thermal-conductivity particle reinforcement Al-based composite and a preparing method thereof.The high-thermal-conductivity particle reinforcement Al-based composite comprises reinforcing particles and aluminum alloy, wherein the reinforcing particles are uniformly distributed in an aluminumalloy base body and form great interface bonding with the base body; and the mass ratio of the aluminum alloy to the reinforcing particles is 100:(1-30). The preparing method has the advantages that the mass ratio of the aluminum alloy to the reinforcing particles is optimized, the quantity of each component in the aluminum alloy is controlled, and the thermal conductivity of the aluminum alloy and the reinforcing particles is controlled; and the obtained Al-based composite has high thermal conductivity and great comprehensive mechanical properties.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Integratedsoluble bridge plug and preparation method thereof

InactiveCN110259413ASimple structureReduce overall outer diameterDrilling rodsSealing/packingVulcanizationSoftware engineering

The invention discloses an integrated soluble bridge plug and a preparation method thereof. The integrated soluble bridge plug includes a soluble bridge plug, the soluble bridge plug sleeves a tension rod, a ball seat is arranged between the soluble bridge plug and the tension rod, a lower joint is arranged at one end of the tension rod, a clamping tile is arranged between the lower joint and the soluble bridge plug and sleeves the tension rod, and the soluble bridge plug is of a composite structure and made of rubber and vertebral vulcanization. The integrated soluble bridge plug is small in volume, large in diameter, simple in structure and high in dissolution speed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

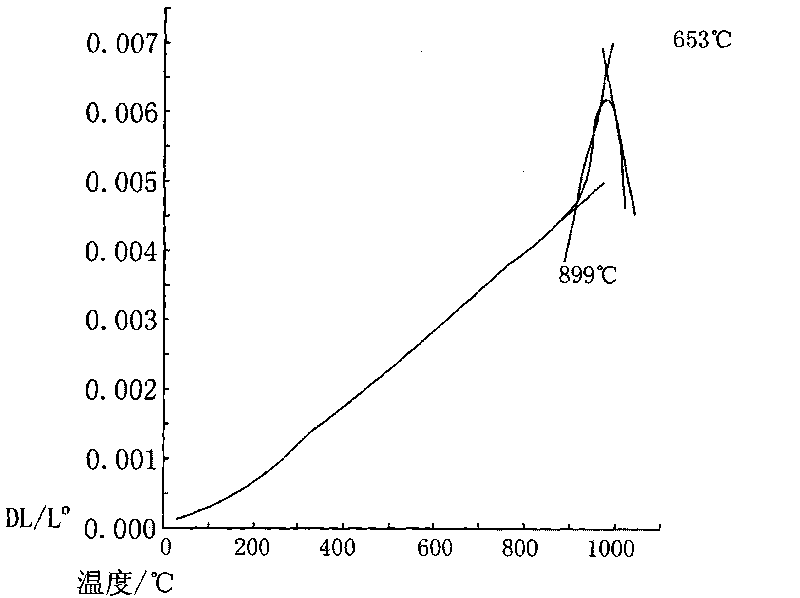

High-thermal-conductivity low-porosity graphite for curved glass hot bending mold and preparation method thereof

The invention discloses high-thermal-conductivity low-porosity graphite for a curved glass hot bending mold. The thermal conductivity is not lower than 94W / (m.K), the porosity is not higher than 20%,the thermal expansion coefficient is not higher than 5.8 * 10<-6> / DEG C, and the average particle size is not higher than 5mu m. The preparation method of the graphite comprises the following steps: preparing petroleum coke powder, crystalline flake graphite powder and modified asphalt powder into modified asphalt coke flake powder, uniformly mixing the modified asphalt coke flake powder with modified mesocarbon microbeads, crushing, standing, carrying out isostatic pressing molding, roasting carbonization, dipping treatment and graphitization treatment to obtain the high-thermal-conductivitylow-porosity graphite. According to the graphite material, the petroleum coke powder is used as a main material, the modified asphalt mesocarbon microbeads and crystalline flake graphite are used as auxiliary materials, aggregate types and proportions are reasonably matched, mirror surface heat conduction, pores and expansion coefficients of the processed graphite material can be improved, the average particle size of the graphite material is not larger than 5 micrometers, and the graphite material can be applied to curved glass hot bending molds.

Owner:HUNAN CHANGYU NEW CARBON MATERIALS

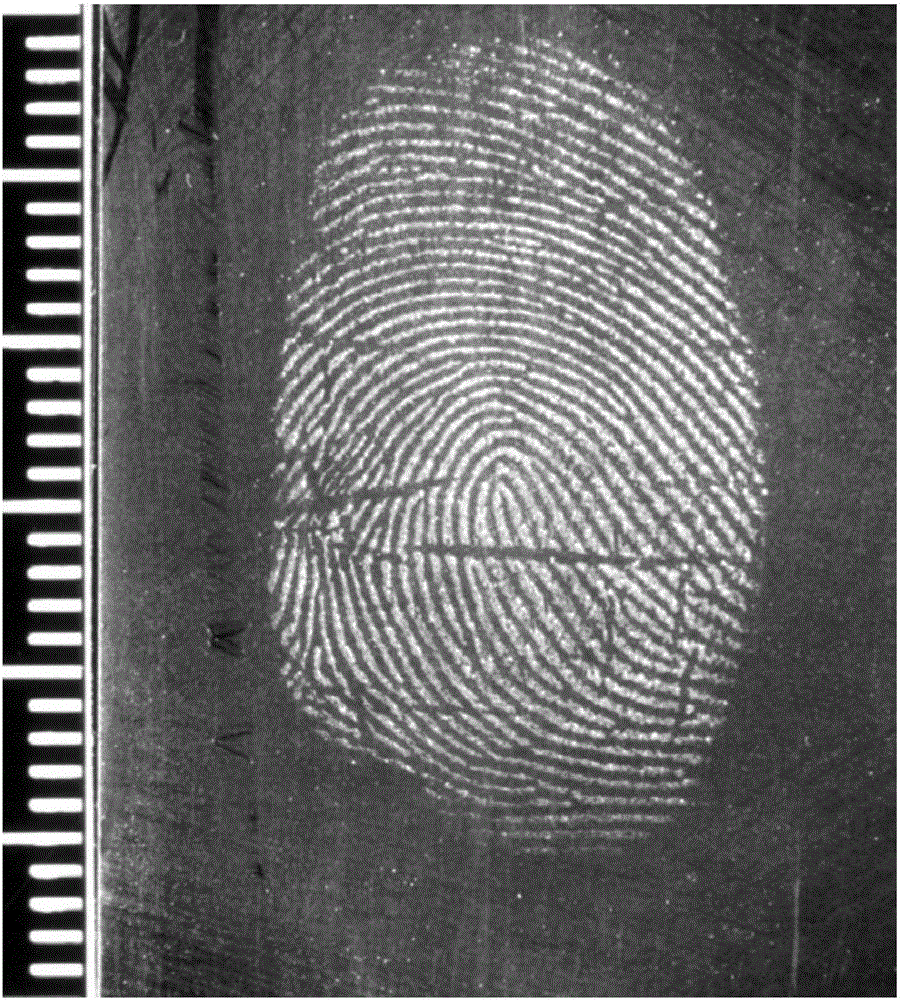

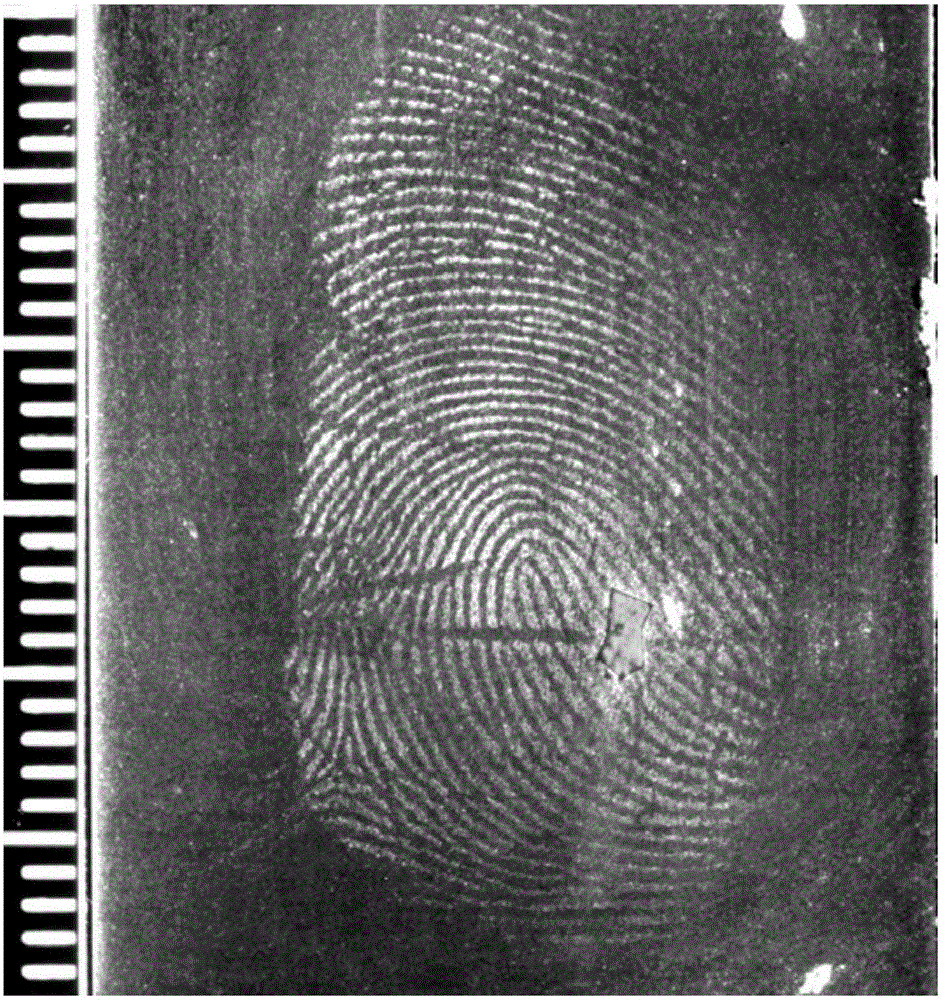

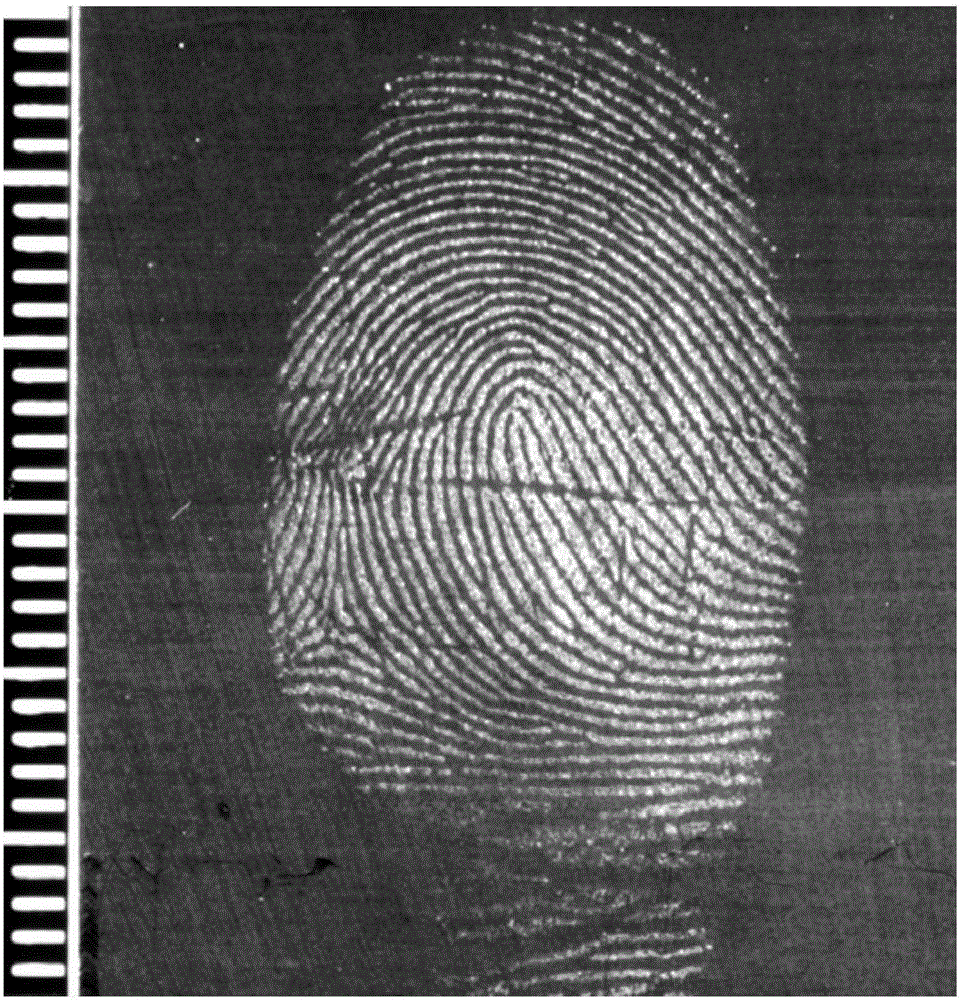

Magnetic fingerprint revealing powder and preparation method and application thereof

ActiveCN105326509AReduce coefficient of frictionIncrease coefficient of frictionDiagnostic recording/measuringSensorsSide effectMaterials science

The invention belongs to the technical field of fingerprint identification and relates to magnetic fingerprint revealing powder and a preparation method and application thereof. The magnetic fingerprint revealing powder is composed of magnetic powder and developing powder, and a chemical formula of the magnetic fingerprint revealing powder is Ma(BN)b, wherein M refers to the magnetic powder selected from at least one of Fe powder, Co power, Ni powder, Fe3O4 or Fe78Si9B13 amorphous powder, B refers to the developing powder, a and b refer to atom percentage contents of corresponding elements, a is larger than or equal to 50 and smaller than or equal to 88.9, b is larger than or equal to 11.1 and smaller than or equal to 50, and the amount of a and b is 100. Compared with the prior art, the magnetic fingerprint revealing powder not only has the advantages of easiness in raw material acquisition, simplicity in preparation, stability in performance, easiness in storage and the like but also has no toxic or side effect on users and has a most prominent advantage that high-precision reveal of fingerprints on the surfaces of various objects in dry or humid environment can be realized. Therefore, the preparation process is simplified on the premise of high revealing precision of the magnetic fingerprint revealing powder, and the magnetic fingerprint revealing powder is widely applicable to various complicated environments and has an extremely high practical application value.

Owner:TONGJI UNIV

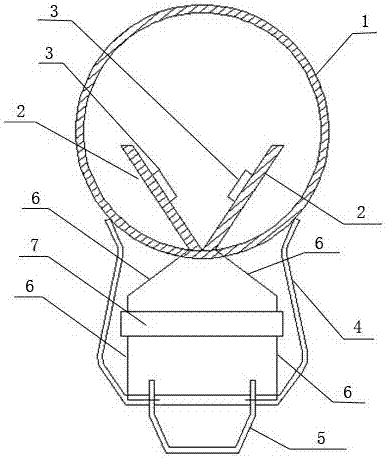

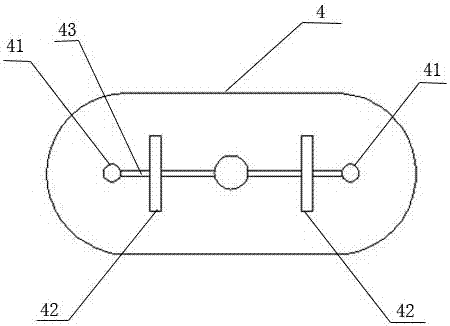

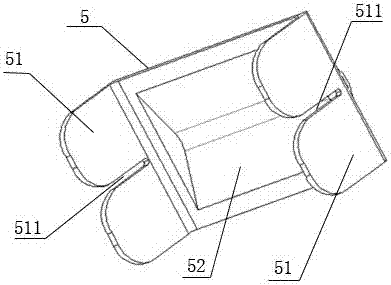

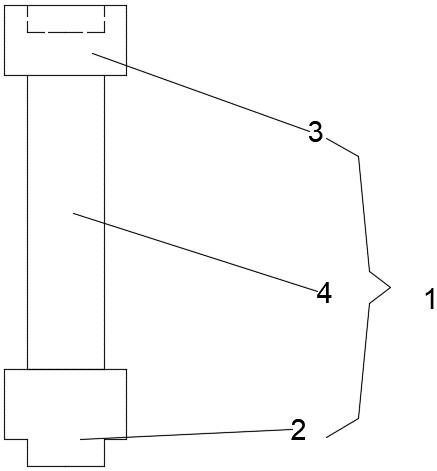

Absorbable biliary duct stent and preparation method thereof

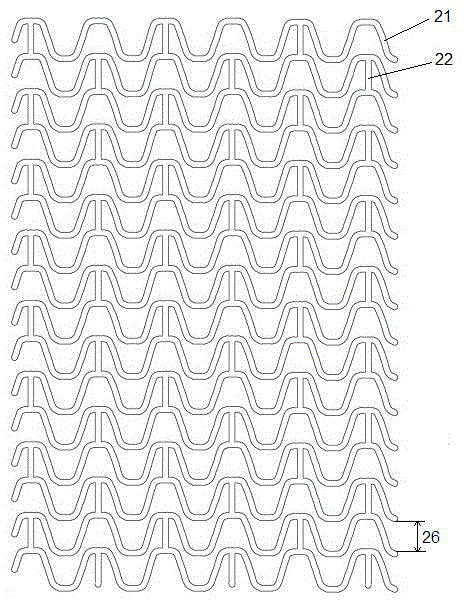

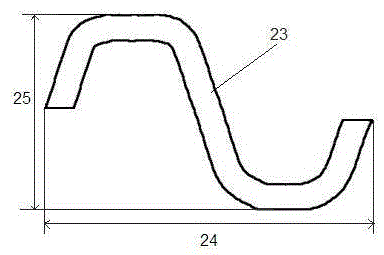

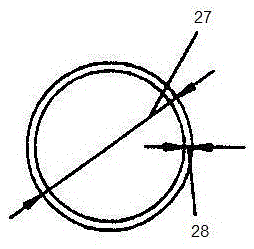

InactiveCN104921855AOvercome deficienciesGood expansion coefficientStentsSurgeryBiliary obstructionsBiliary tract

The invention relates to an absorbable biliary duct stent which comprises a stent body and a medicine layer coating the surface of the stent body. The stent body is provided with a tubular fine metal mesh structure, the fine metal mesh structure comprises a plurality of annular supporting rings and connectors for connecting the annular supporting rings, two adjacent annular supporting rings are connected through one connector, pipes made of absorbable high polymer materials are engraved by laser to form the stent body with the fine metal mesh structure, a plurality of basic units similar to sinusoidal waveforms are connected to form each annular supporting ring, two adjacent connectors are crossly arranged at intervals, the connectors are linear connecting rods axially arranged along the stent, and the medicine layer contains biliary tumor resistant medicines and / or biliary calculus resistant medicines. The invention further provides a preparation method for manufacturing the absorbable biliary duct stent. The biliary duct stent has internal degradability, fine expansion coefficient and radial mechanical support capacity, and the medicine layer coating the surface of the stent can treat benign and malignant biliary hyperplasia stenosis and avoid aggravating biliary obstruction due to biliary hyperplasia restenosis after stent implantation.

Owner:SHANGHAI JUNLIAN MEDICAL EQUIP

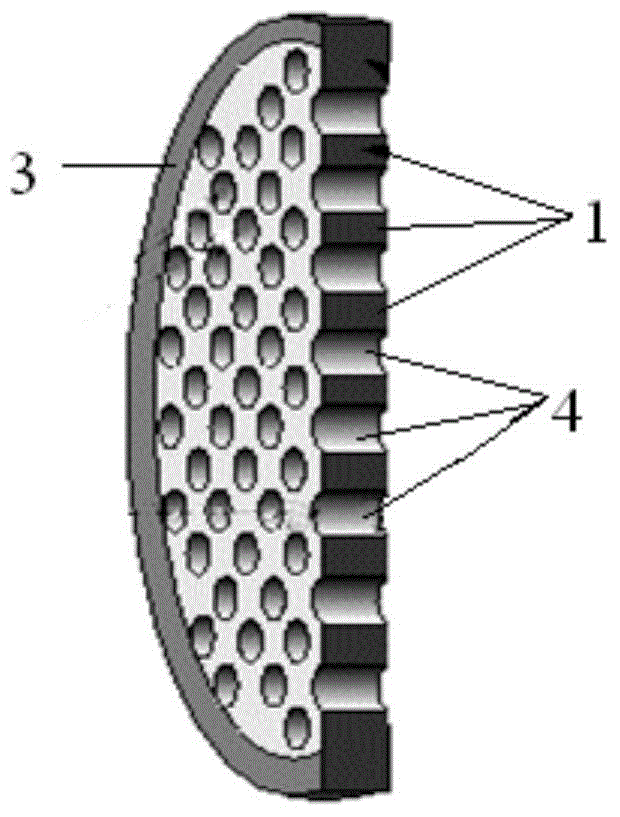

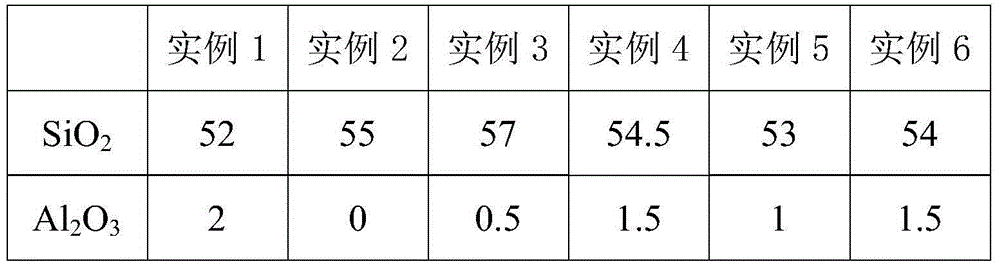

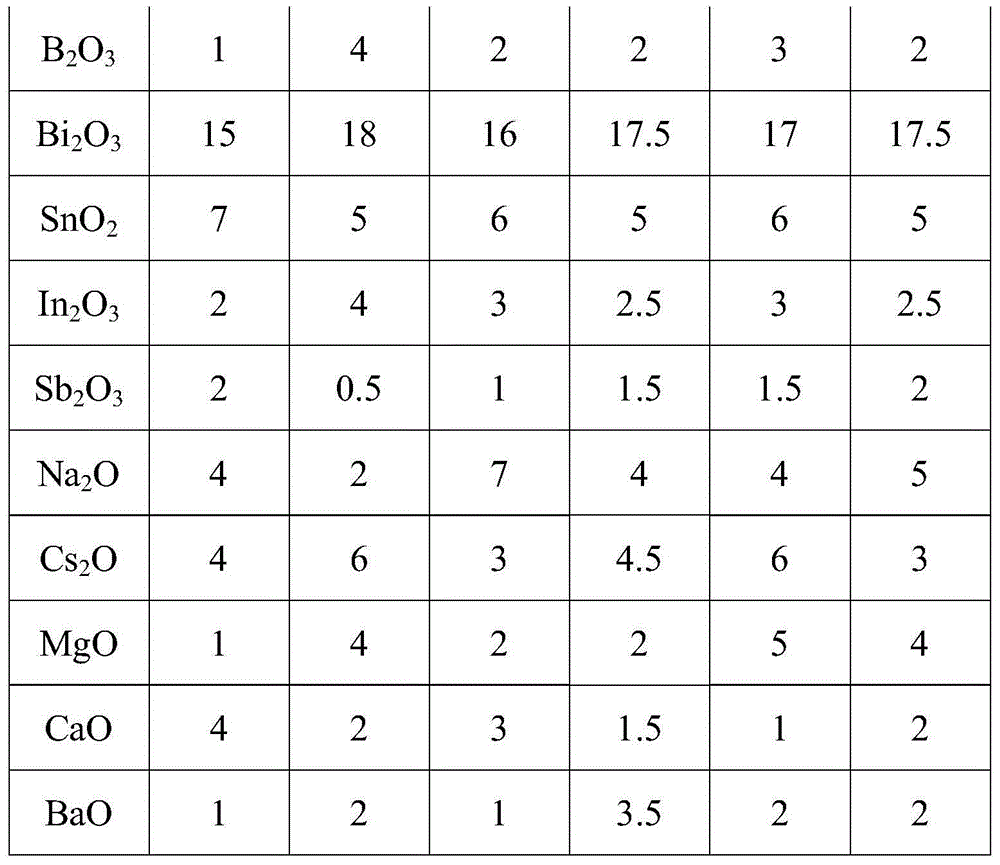

Micro-channel plate cladding glass and preparation method thereof

The invention relates to a micro-channel plate cladding glass, a micro-channel plate, and a preparation method thereof. The micro-channel plate cladding glass comprises the following components in parts by weight: 52 to 57 parts of SiO2, 0 to 2 parts of Al2O3, 1 to 4 parts of B2O3, 15 to 18 parts of Bi2O3, 5 to 7 parts of SnO2, 2 to 4 parts of In2O3, 0.5 to 2 parts of Sb2O3, 8 to 10 parts of Na2O and Cs2O, and 6 to 8 parts of MgO, CaO, and BaO. The micro-channel plate cladding glass and micro-channel plate prepared therefrom have the characteristics of non-toxicity, innocuousness, and environment-friendliness.

Owner:CHINA BUILDING MATERIALS ACAD

Ceramic roller for hot rolling steel billet delivery and its preparation method

The invention relates to a improved ceramic roller with high mechanical strength, strong impact resistance and well resistance to temperature rapid change for but not only the hot rolled steel plate. Wherein, the roller comprises fused quartz particle of 80~90 shares and base binder of 10~20 shares, has rupture strength P more than 45MPa and expansivity less than 0. 8í‡10-6 / deg C, repeats in water of 1000~30Deg for 15 times without cracking, has surface roughness near 1. 6ª– or much less, and rubs with steel plate for 100 times with compression of 10kg / cm2 not to form rub marks and benefit to ensure the quality of steel surface.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Graphene coating for heat-dissipating copper foils and preparation method and application thereof

InactiveCN107916041AIncrease coefficient of frictionReduce coefficient of frictionEpoxy resin coatingsMetal layered productsGraphene coatingMetallurgy

The invention provides graphene coating for heat-dissipating copper foils, comprising graphene slurry, boron nitride slurry, a binder and a thinner, wherein the graphene slurry is made by mixing graphene powder, a surface treating agent and a solvent, and the boron nitride slurry is made by mixing boron nitride powder, a surface treating agent and a solvent. The graphene coating organically combines the graphene slurry and boron nitride slurry with copper foils and can provide great additive action for improving heat conductivity and heat-dissipating property of heat-dissipating insulating copper foils. The invention also provides a preparation method of the graphene coating for heat-dissipating copper foils and a copper foil.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

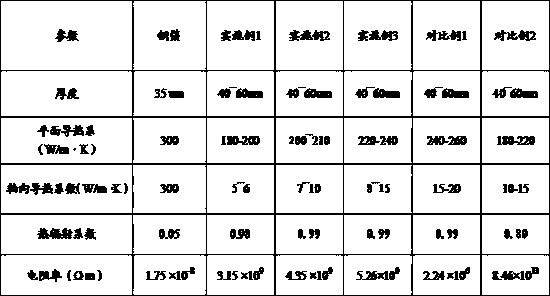

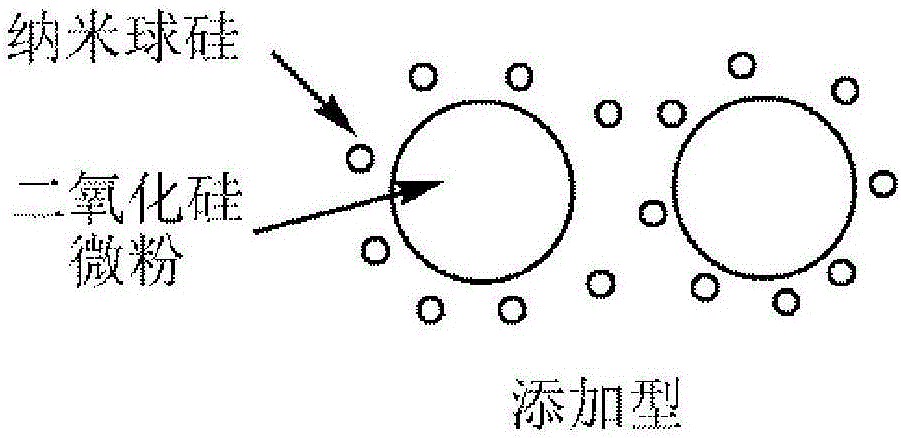

Preparation method of coated filler slurry composition, prepreg comprising slurry composition, laminated board and printed circuit board

ActiveCN106674602AHigh solid contentGood dispersionSynthetic resin layered productsGlass/slag layered productsOrganic solventHeat resistance

The invention provides a preparation method of a coated filler slurry composition, a prepreg comprising the slurry composition, a laminated board and a printed circuit board. The preparation method comprises the following steps: mixing master batch filler with an organic solvent and a dispersant, mechanically stirring and uniformly dispersing the mixture, and further dispersing the mixed liquid through dispersing equipment to prepare prefabricated slurry; adding a catalyst into the prefabricated slurry, uniformly mixing the mixture, and marking the mixture as a liquid A; dissolving a coating agent in an organic solvent to prepare a solution, and marking the solution as a liquid B; adding the liquid B into the liquid A while stirring, and performing a reaction to obtain a reaction mixed solution; and storing the reaction mixed solution at normal temperature for 1-30 days to obtain the coated filler slurry composition. The coated filler slurry composition prepared by the invention can improve the dispersibility and flowability of the integral slurry composition and improve the resin flowability in a high filler filling state. The copper coated laminated board manufactured by the slurry composition has relatively good heat resistance and low coefficient of thermal expansion and good comprehensive performance.

Owner:联瑞新材(连云港)有限公司

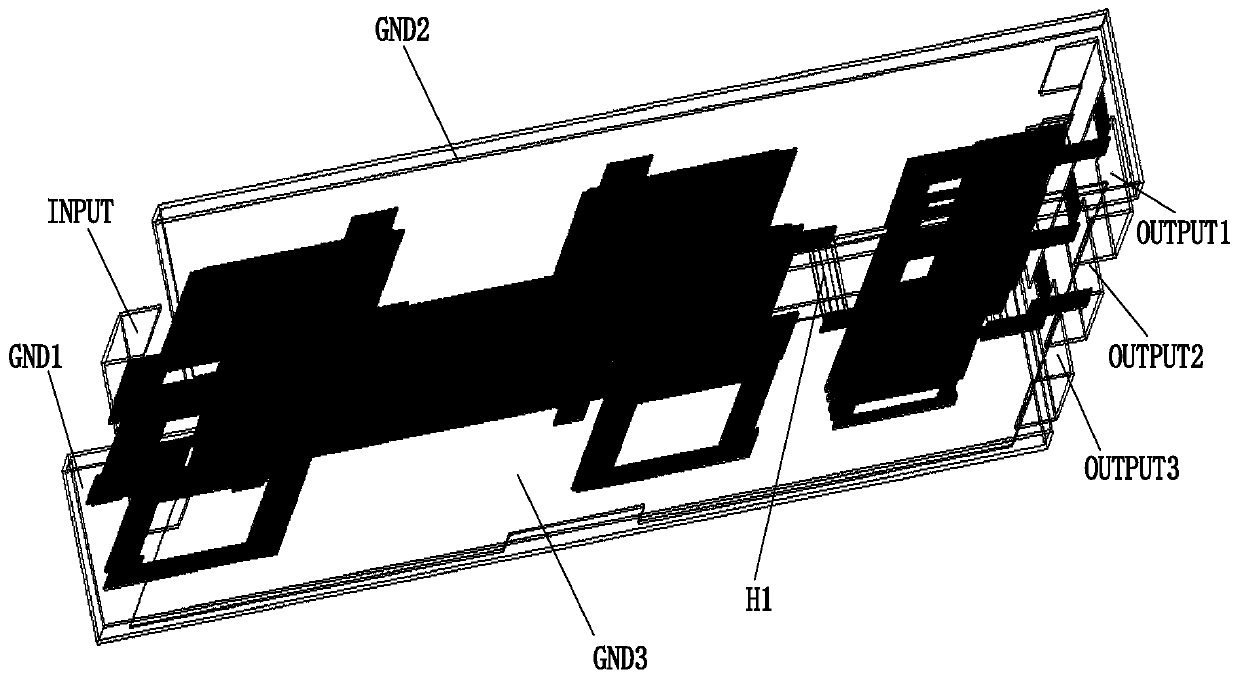

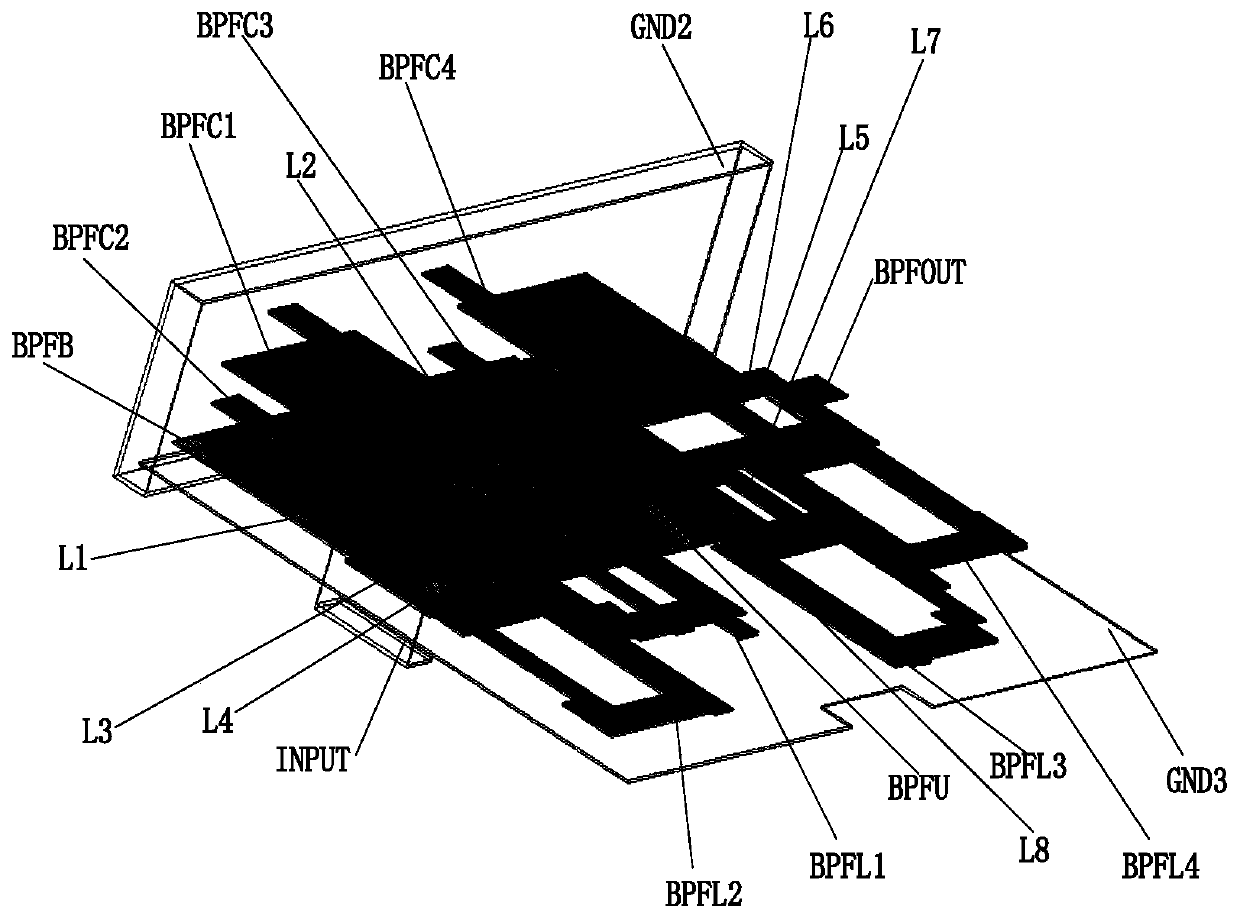

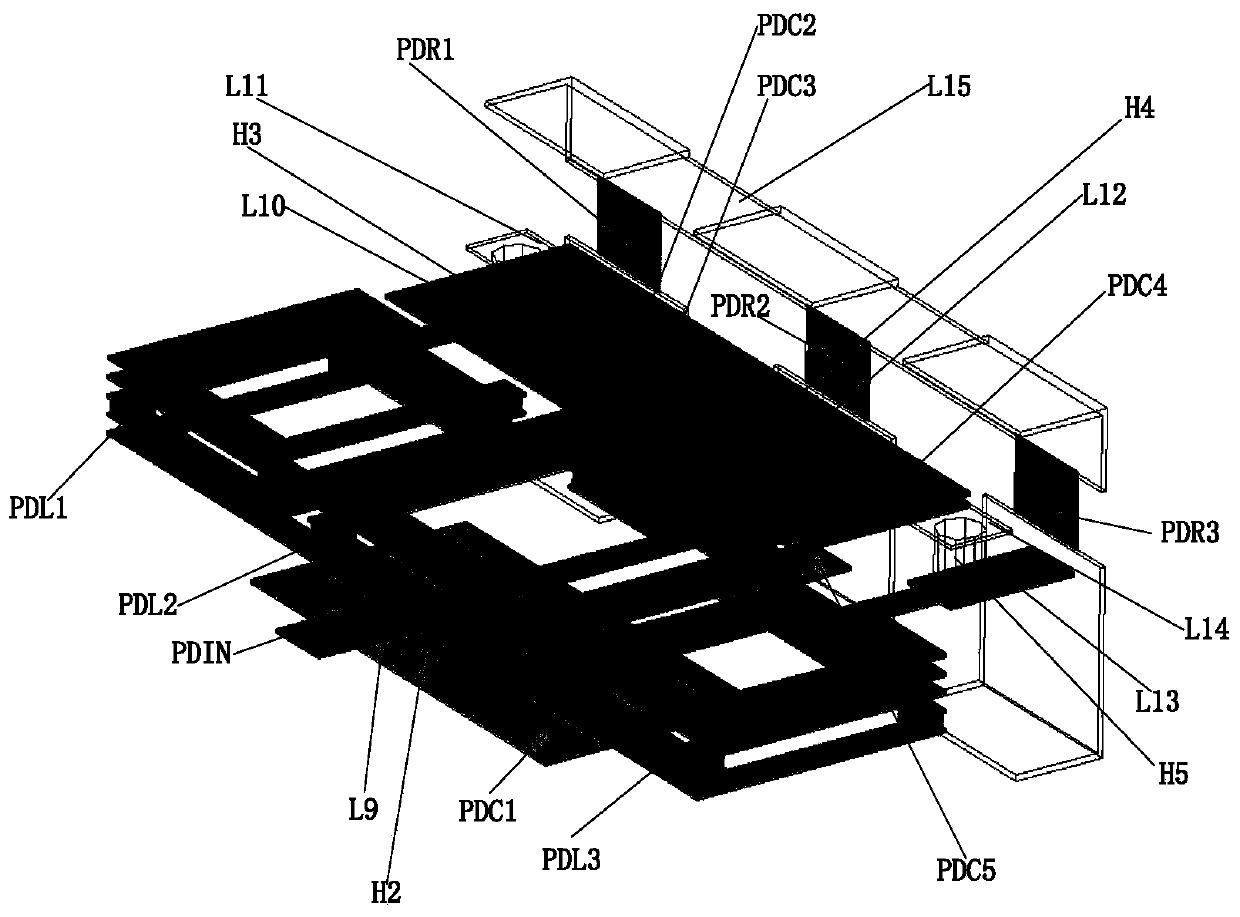

LTCC-based novel semi-lumped one-to-three filter power divider

The invention discloses an LTCC-based novel semi-lumped one-to-three filter power divider, and belongs to the technical field of microwave. The filter power divider comprises a semi-lumped bandpass filter and a same-phase three-path power divider, and the novel filter power divider is successfully achieved by abutting of an output end of the bandpasss filter and an input end of the same-phase power divider. The bandpass filter employs a semi-lumped structure, and the same-phase power divider is a one-to-three equal power divider. Three-dimensional integration is achieved by a low-temperature cofiring ceramic (LTCC) process, and the filter power divider has the advantages of good port isolation degree, low insertion loss, good return loss, small size, favorable electrical performance, highintegration, high finished rate, low expansion coefficient and the like and has favorable application prospect in the field of a communication system radio-frequency front-end circuit and a radar system which are relatively high in miniaturization requirement.

Owner:NANJING UNIV OF SCI & TECH

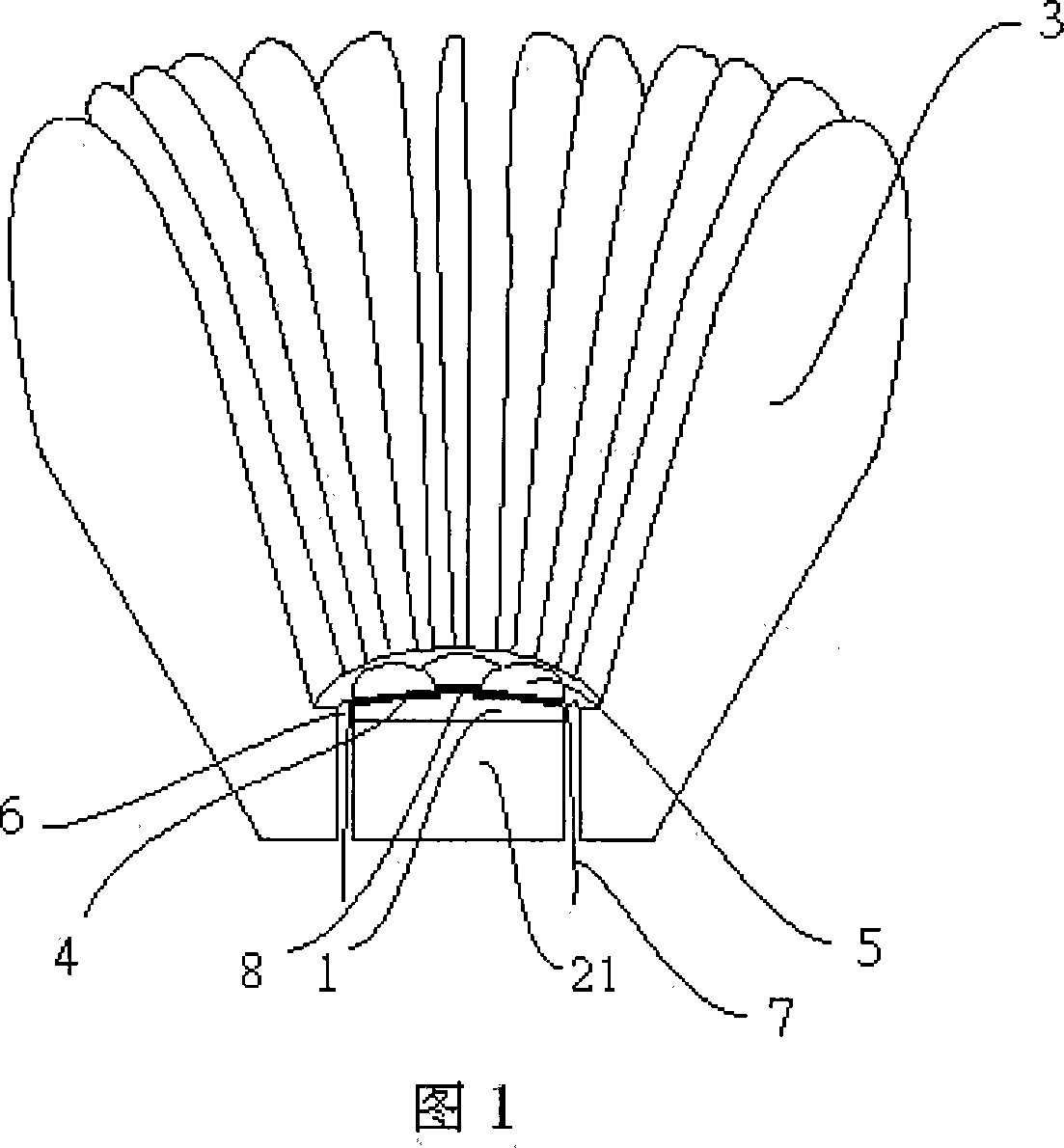

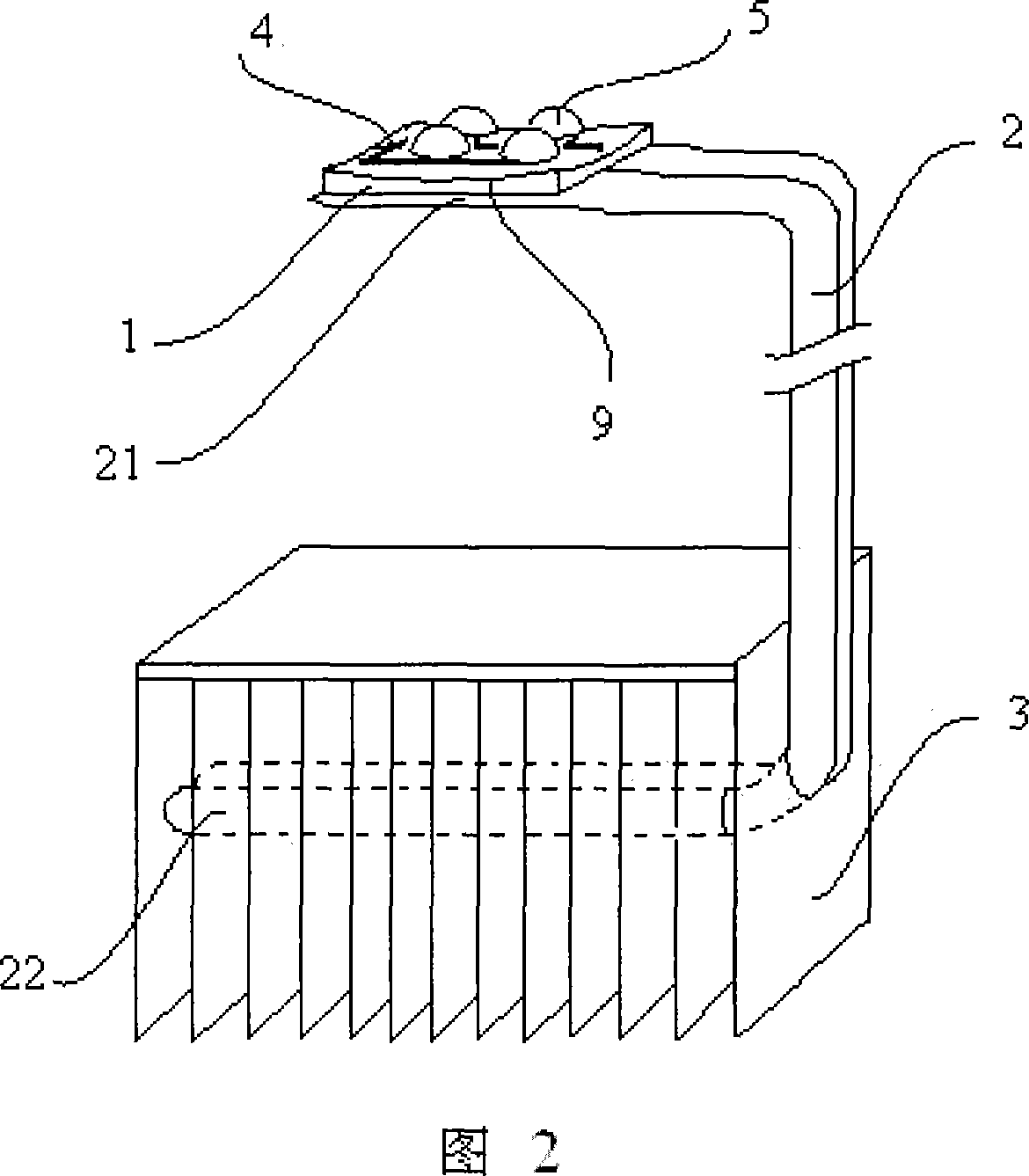

High efficiency LED heat radiating module

InactiveCN101118883AThe joint surface is completeImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesElectricityHeat conducting

The present invention relates to a LED heat emission pattern assembly with high efficiency, and the heat emission pattern assembly directly makes an electric insulation heat conducting layer with diamond element on the heat absorbing end face of the radiator. The metal circuit layer can be provided with one or a plurality of LED components. The pattern assembly structure of the heat emission glue is not used, the present invention solves the problems of heat emission, blocking and piling to keep that the LED works in a normal temperature.

Owner:陈鸿文

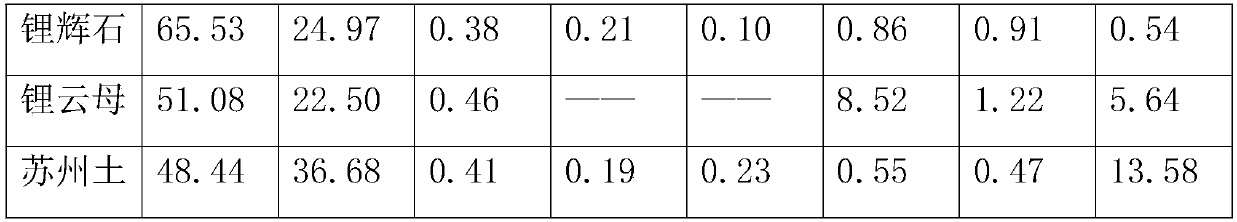

Lead-free transparent frit for preparing ceramics

The invention discloses lead-free transparent frit for preparing ceramics, and particularly relates to the field of ceramic preparation. The lead-free transparent frit comprises main ingredients and accessory ingredients, wherein the main ingredients mainly comprise SiO2, B2O2, Al2O3, ZnO, Li2O, Na2O, MgO, K2O and CaO, and the accessory ingredients mainly comprise SrO, Bi2O3, Re, nitrate, titaniumpowder and vanadium pentoxide. Firing is conducted by using a lithium-containing compound or mineral spodumene and Suzhou soil as raw materials, a chemical substances formed through firing replaces PbO in lead-containing glaze, and the minimum eutectic mixture is formed together, and therefore, lead oxide is replaced. A low glaze firing temperature and a wide firing range are ensued, the glaze glossiness can be ensured, and matching of the expansion coefficient can be ensured. Li2O is an oxide with a strong melting function, the expansion coefficient of the glaze can be significantly reduced,and the durability is improved; when the Li2O is added into the frit, the lead-free transparent frit which is high in elasticity and high in glossiness can be obtained at a low glaze firing temperature, B2O2 can obviously reduce the melting temperature and the viscosity of the frit, and the B2O2 can be used as a strong fluxing agent.

Owner:江西省千陶新型材料有限公司

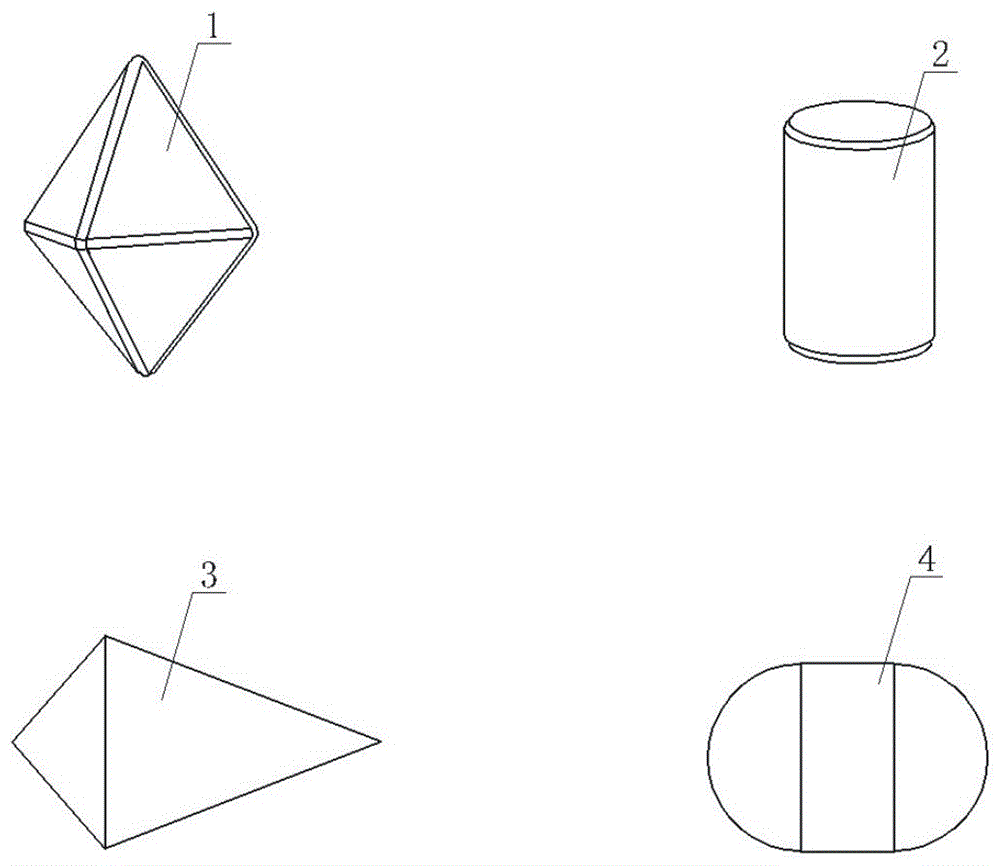

Ceramic grinding segment for cement grinder and preparation method of ceramic grinding segment

The invention discloses a ceramic grinding segment for a cement grinder and a preparation method of the ceramic grinding segment. The ceramic grinding segment is prepared from the following components in percentage by weight: 92 to 95% of alumina, 0.5 to 2% of tungsten carbide, 0.8 to 3% of calcium carbonate, 1 to 1.2% of magnesium carbonate, 0.5 to 2% of titanium nitride, 1 to 3% of silicon dioxide, and 0.8 to 1% of zirconia, wherein the ceramic grinding segment for the cement grinder is in a shape of a cylinder, a spherical column combination, a spindle or a frustum of a square pyramid which is symmetrical up and down. The preparation method of the ceramic grinding segment is characterized by carrying out press forming and then high temperature sintering, and comprises the processes of material preparation, ball milling, spray granulation, silo aging, profiling, high temperature sintering, powder removing and polishing, drying of a finished product and the like. The density of the finished product is only half of a steel material, so as to be capable of effectively saving electricity and energy and reduce carbon emission. The finished product further has high hardness, good abrasion resistance, low material consumption, good economy, high temperature resistance, capability of working at high strength for a long time, good toughness, difficult breaking and collapse while being impacted, excellent practicality, good binding force and easier forming.

Owner:山东天汇科技有限公司 +1

Ceramic product and production method thereof

The invention belongs to the field of ceramic, and more specifically relates to a ceramic product and a production method thereof. The ceramic product comprises the following raw materials in parts by weight: 20-25 parts of bentonite, 5-8 parts of nano calcium carbonate, 10-15 parts of red feldspar, 15-18 parts of kaolin, 15-18 parts of potash feldspar, 10-15 parts of pyrophillite, 10-13 parts of wollastonite, 8-12 parts of blue feldspar, 6-10 parts of quartz, 10-13 parts of spodumene, 1-2 parts of chrome oxide, 3-5 parts of silicon carbide powder, and 2-4 parts of jade powder. The production method comprises the steps of weighing, grinding, filtering, drying, cleaning, glazing and sintering. The ceramic product has the advantages of small expansion coefficient, good toughness, wear resistance, and high intensity..

Owner:崔松伟

Carbon fiber coated seal gasket and manufacturing method thereof

InactiveCN106084730AReduce coefficient of frictionImprove high temperature stabilityEngine sealsMicrowaveCarbon fibers

The invention discloses a carbon fiber coated seal gasket. The seal gasket comprises a carbon fiber layer on the periphery, mixed material layers in the middle and a reinforced fiber layer between the mixed material layers. By adopting hexagonal system boron nitride, the seal gasket is low in friction coefficient, high in high-temperature stability, heat shock resistance and strength, large in heat conductivity coefficient, small in dilatation coefficient, large in specific resistance, resistant to corrosion and capable of transmitting microwaves or infrared rays and has high elasticity and plasticity as rubber is high in elasticity. The periphery of the seal gasket is coated with the carbon fiber layer, and the seal gasket is high in acid and alkali resistance, corrosion resistance and abrasion resistance and is not prone to ageing and durable as the seal gasket is sulfidized.

Owner:DONGTAI HUAYANG GLASS FIBER

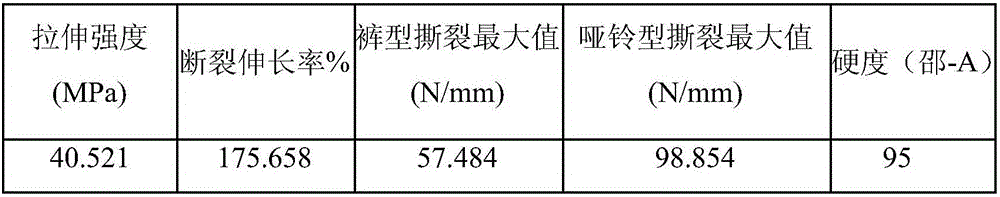

Polyurethane elastomer antifreezing faucet and preparation method thereof

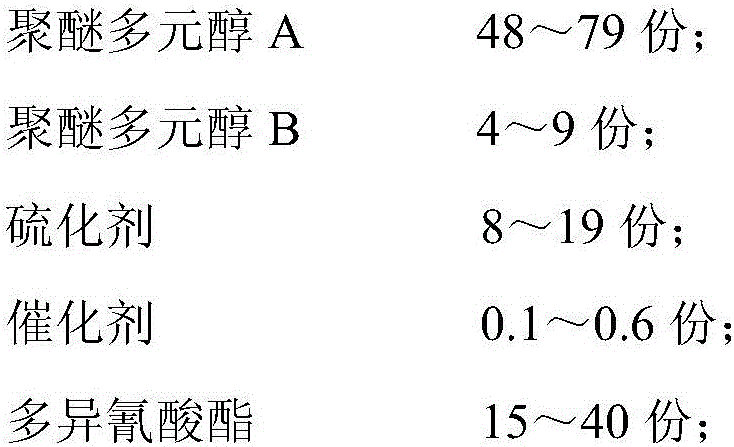

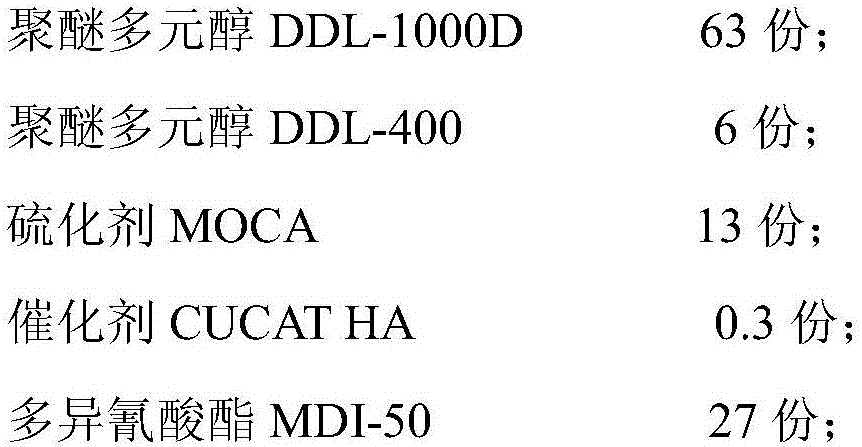

InactiveCN106220814AImprove low temperature resistanceImprove water resistanceValve housingsPolyurethane elastomerPolyol

The invention belongs to the technical field of polyurethane products, and particularly relates to a polyurethane elastomer antifreezing faucet and a preparation method thereof. The antifreezing faucet is formed by combining a copper valve core, an iron handle, a faucet casing and fixing screw nuts, wherein the faucet casing and the fixing screw nuts are prepared from the following raw materials in parts by weight: 48 to 79 parts of polyether polyol A, 4 to 9 parts of polyether polyol B, 8 to 19 parts of vulcanizing agents, 0.1 to 0.6 part of catalysts and 15 to 40 parts of polyisocyanates, wherein the polyether polyol A uses polyether polyol with the functionality degree being 1.5 to 2.5 and the molecular weight being 500 to 1500; the polyether polyol B uses polyether polyol with the functionality degree being 1.5 to 2.5 and the molecular weight being 300 to 500. The antifreezing faucet has good low temperature resistant performance, good water resistance performance, good expansion coefficient and good wear resistant performance; the preparation method is simple and is easy to implement.

Owner:ZIBO DEXIN LIANBANG CHEM IND

Health-care UV-lamp

InactiveCN1599000AGood expansion coefficientAchieve health goalsElectric discharge tubesElectric discharge lampsUltravioletMaterials science

The invention relates to a health care ultraviolet lamp, adopts combined rotatory reflector glass shell. The wall of the glass shell is coated by vaporization with highly pure aluminum film and there is arc tube and ballast filament in the glass shell. The weight compositions of the chemical feedstock of the glass shell is as follows: between 68% and 71.9% of SiO2, between 7.29% and 10% of Na2O, between 5.0% and 9.0% of K2O, between 3.51% and 4% of B2O3, between 3.0% and 3.79% of ZnO and between 5.0% and 8.0% of PbO and the summation of the percentage of every materials is a hundred percent.

Owner:于首成

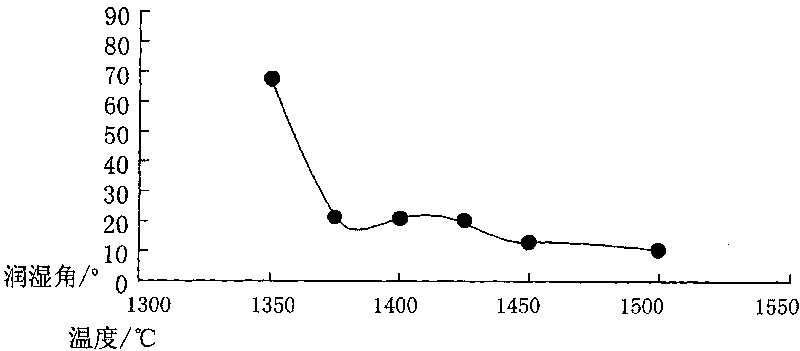

Al2O3-Dy2O3-SiO2 ternary system rare-earth sealing material and preparation method of glass sealing ring thereof

The invention relates to an Al2O3-Dy2O3-SiO2 ternary system rare-earth sealing material and a preparation method of a glass sealing ring thereof, which is designed aiming at the technical problem that the rare-earth sealing material is not good enough in the sealing process of the traditional ceramal halide lamp arc tube. The Al2O3-Dy2O3-SiO2 ternary system rare-earth sealing material puts emphasis on comprising the following components in percentage by weight: 15-25% of Al2O3, 55-65% of Dy2O3 and 20-25% of SiO2. The glass manufacture process flow of the Al2O3-Dy2O3-SiO2 ternary system rare-earth sealing material comprises the following steps of: weighing according to the weight ratio of materials; mixing the materials; melting at high temperature; keeping the temperature; adding to a liquid nitrogen box; and obtaining ternary system rare-earth glass. The manufacture process flow of the glass sealing ring comprises the following steps of: crushing the ternary system rare-earth glass by air flows; sifting; granulating; compressing for forming; roasting; degassing in vacuum; and obtaining the ternary system rare-earth glass sealing ring. The Al2O3-Dy2O3-SiO2 ternary system rare-earth sealing material and the process are suitable for a ceramal halide lamp arc tube, a ceramal halide lamp and the manufacture of rare-earth sealing materials, welding materials and glass rings of the ceramal halide lamp arc tube.

Owner:NINGBO YAMAO OPTOELECTRONICS CO LTD

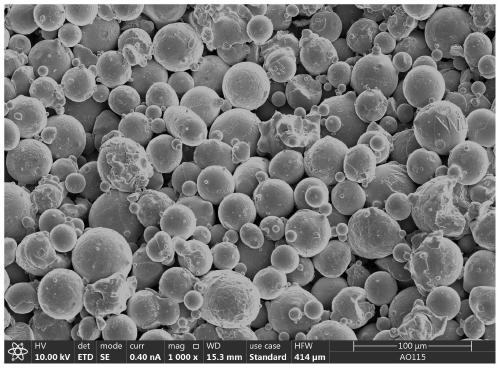

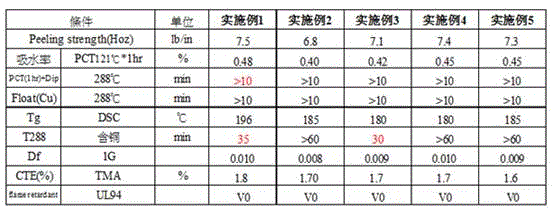

Porous high-entropy alloy material and preparation method and application thereof

ActiveCN111085685AHigh tensile strengthHigh porosityTransportation and packagingMetal-working apparatusHigh entropy alloysRolling-element bearing

The invention provides a porous high-entropy alloy material and a preparation method and application thereof, and belongs to the technical field of high-entropy alloy preparation. The provided preparation method comprises the following steps that AlCoCrAgNi high-entropy alloy spherical powder is provided, and the particle size of the AlCoCrAgNi high-entropy alloy spherical powder is 25-380 microns; and the AlCoCrAgNi high-entropy alloy spherical powder is sequentially subjected to pre-pressing treatment and sintering to obtain the porous high-entropy alloy material. The prepared porous high-entropy alloy material has the advantages of being high in tensile strength, high in porosity, low in friction coefficient, and good in matching performance between the expansion coefficient and a bearing; and meanwhile, the prepared porous high-entropy alloy material, as a bearing retainer, can be used for a heavy machinery rolling bearing, and solve the problems that in the prior art, an oil bearing retainer is low in bearing capacity, and poor in the matching performance between the expansion coefficient and a steel bearing.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

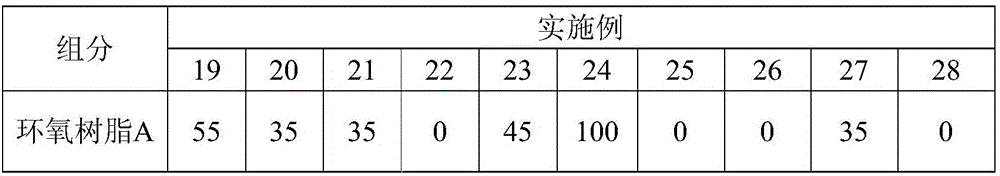

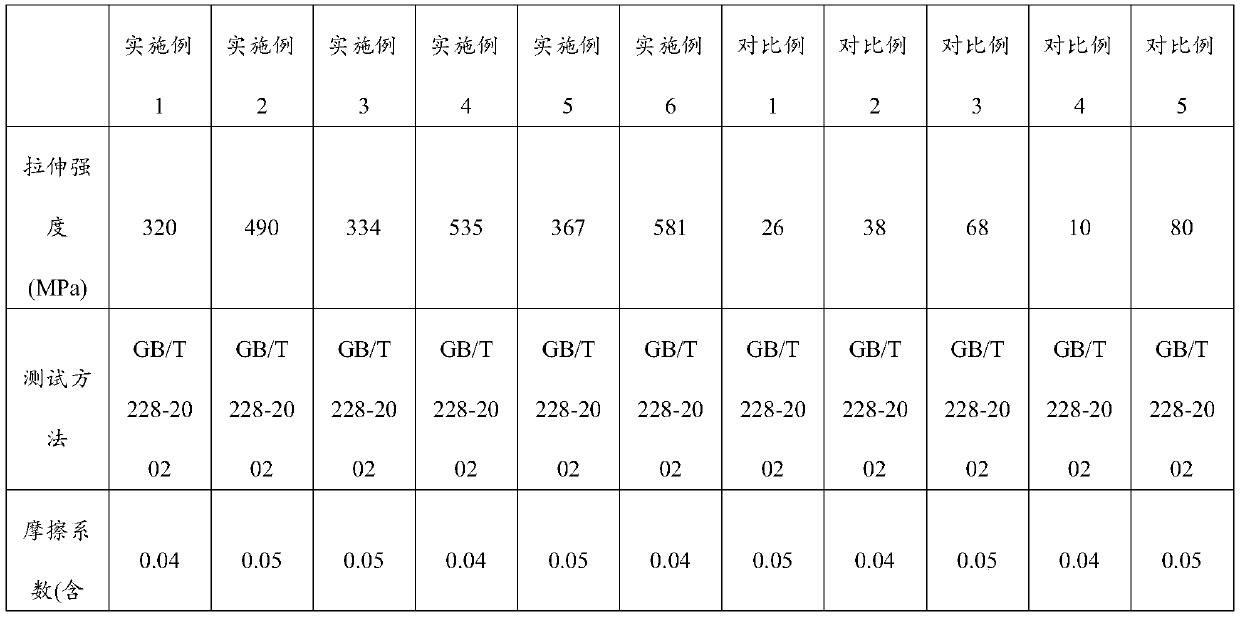

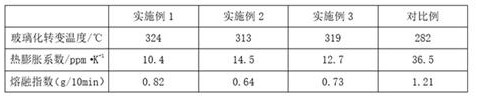

A kind of halogen-free low expansion epoxy resin composition

ActiveCN103554833BSmall expansion coefficientReduce the expansion coefficient of the resin and have a good expansion coefficientSynthetic resin layered productsMetal layered productsEpoxyHalogen

The invention discloses a halogen-free low-expansion epoxy resin composition. The resin composition comprises a multifunctional epoxy resin, a phosphorus-containing epoxy resin, a benzoxazine resin, a phosphorus-containing curing agent, an inorganic filler, Curing accelerators and solvents. The resin with good rigidity and toughness contained in the composition, as well as the inorganic filler endow the composition with a low expansion coefficient and excellent heat resistance. The laminate prepared from the above composition is a halogen-free compound, and the flame retardant grade is UL94 -V0 level.

Owner:ITEQ DONGGUAN

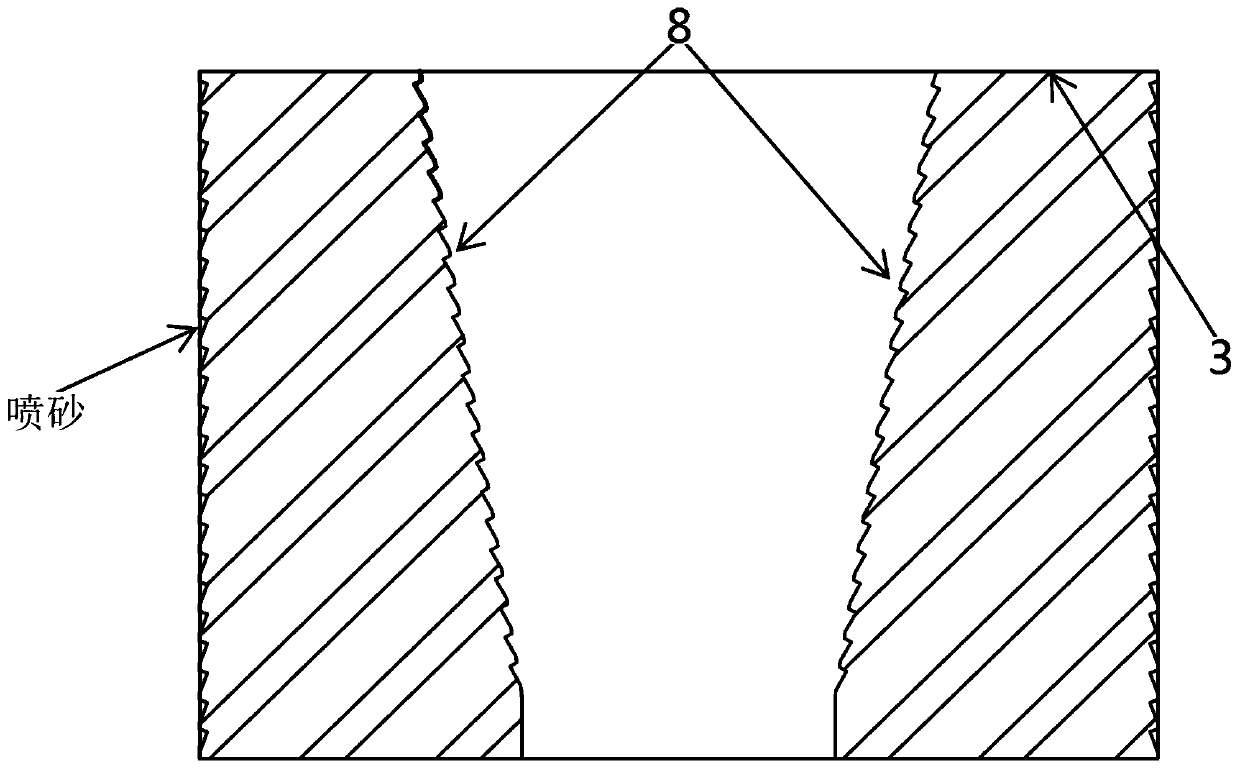

Preparation method of high-temperature resistant and anti-abrasion-and-corrosion gradient coating used for circulating fluidized bed boiler

InactiveCN106399912ASolve unresolvable defectsReduce coefficient of frictionMolten spray coatingAlcoholPower flow

The invention discloses a preparation method of a high-temperature resistant and anti-abrasion-and-corrosion gradient coating used for a circulating fluidized bed boiler. The preparation method includes the steps that firstly, sand blasting roughening is performed on the surface of a circulating fluidized bed boiler part; secondly, the surface subjected to sand blasting roughening is washed with acetone and ethyl alcohol successively and is dried; thirdly, a NiCrBSi intermediate coating is sprayed on the roughened and cleaned surface in a plasma spraying manner, then Cr3C2-NiCr-BN-Si3N4 particles are sprayed in a plasma spraying manner, and the conditions of a plasma spraying process includes that the main gas pressure is 0.7-1.0 MPa, the auxiliary gas pressure is 0.6-0.9 MPa, the main air flow is 1300-1800 l / h, the auxiliary air flow is 900-1100 l / h, the arc current is 450-600 A, the arc voltage is 85-100 V, the powder feeding gas pressure is 0.2-0.4 MPa, the powder feeding gas flow is 280-400 l / h, the spraying distance is 100-150 mm, the spraying speed is 2-3 kg / h, and the coating thickness is 1-2.5 mm. The coating can be resistant to high temperature corrosion and high temperature abrasion and corrosion when used for the circulating fluidized bed boiler, and the coating is firm and cannot fall.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

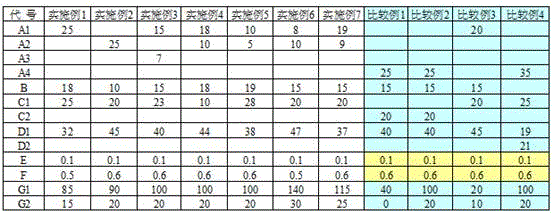

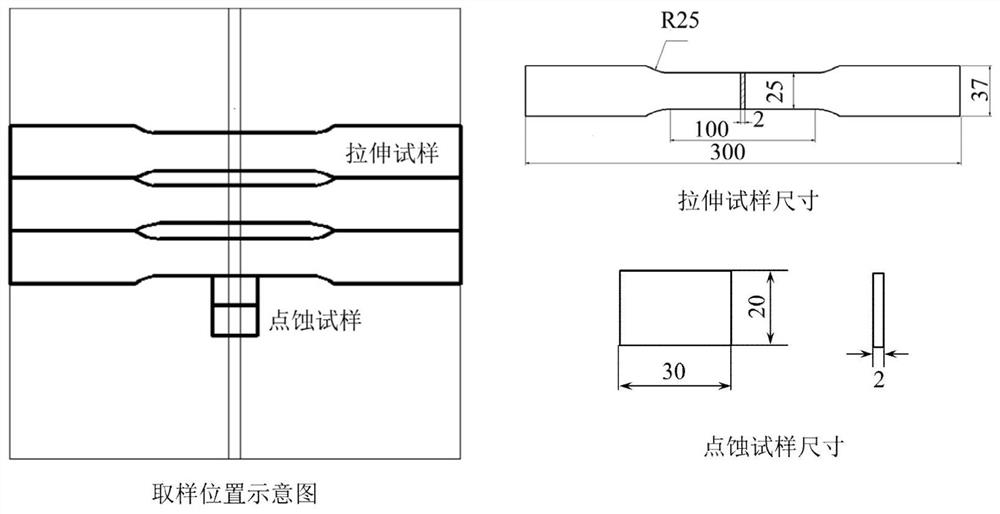

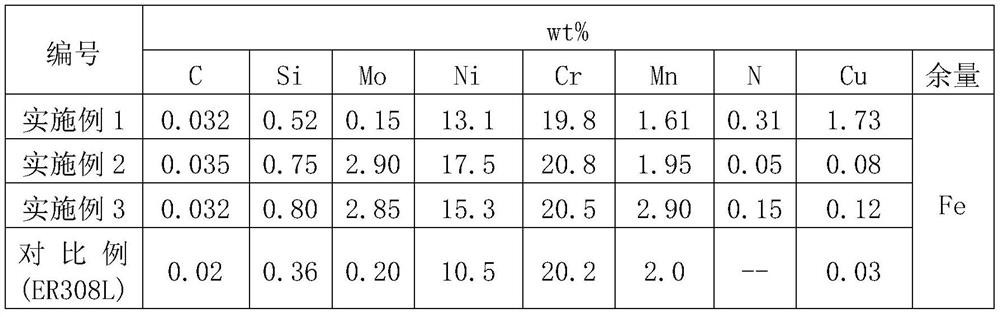

Nitrogen-containing austenitic stainless steel flux-cored wire with high strength and pitting corrosion resistance, and preparation method

ActiveCN113001057APrevent weld oxidationInhibit the escape of nitrogenWelding/cutting media/materialsProcess efficiency improvementAustenitic stainless steelFerrosilicon

The invention discloses a nitrogen-containing austenitic stainless steel flux-cored wire with high strength and pitting corrosion resistance. The flux-cored wire is composed of flux-cored powder and a stainless steel band wrapping the flux-cored powder, and is characterized in that the flux-cored powder is composed of alloy components and slag system components, and the alloy components of the flux-cored powder comprise, by mass, 1.5wt%-3wt% of electrolytic manganese, 0.5wt%-1wt% of silicon iron, 20wt%-22 wt% of chromium powder, 12.5wt%-20wt% of nickel powder, 0.2wt%-3.5 wt% of ferromolybdenum, 0.1wt%-2.0 wt% of copper powder, 0.1wt%-5wt% of chromium nitride and the balance iron powder and inevitable impurities. According to the flux-cored wire, the design scheme of multi-element composite slag system coupling protection is adopted, and escape of the nitrogen element in the welding process of nitrogen-containing austenitic stainless steel is inhibited while the weldability is not affected and the welding process difficulty is not increased.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

led mirror headlight

ActiveCN105135281BPlay the role of card connectionInvolved ingeniouslyElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringAluminum substrate

Owner:JIANGSU SHUSHI LIGHTING CO LTD

Preparing method of high-temperature-resistant anti-abrasion gradient coating of circulating fluidized bed boiler

InactiveCN106282901ASmall expansion coefficientHigh strengthMolten spray coatingAbrasive blastingAlcohol

The invention discloses a preparing method of a high-temperature-resistant anti-abrasion gradient coating of a circulating fluidized bed boiler. The preparing method includes the steps that (1), sandblasting coarsening is carried out on the surface of a component of the circulating fluidized bed boiler; (2), the sandblasting coarsened surface is sequentially washed with acetone and ethyl alcohol and dried; (3), plasma spray is carried out on the coarsened and cleaned surface to obtain a NiCrBSi middle coating, and then Cr3C2-NiCr-BN particles are sprayed in a plasma mode; according to the plasma spray technological conditions, the main pressure force is 0.7-1.0 MPa, the auxiliary pressure force is 0.6-0.9 MPa, the main airflow rate is 1300-1800 l / h, the auxiliary airflow rate is 900-1100 l / h, the arc current is 450-600 A, the arc voltage is 85-100 V, the powder conveying air pressure is 0.2-0.4 MPa, the powder conveying airflow rate is 280-400 l / h, the spray distance is 100-150 mm, the spray speed is 2-3 kg / h, and the thickness of the coating is 1-2.5 mm. The coating is capable of resisting high-temperature corrosion and abrasion when used in the circulating fluidized bed boiler and is firm without falling.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

High-temperature-resistant coated sucker rod

ActiveCN112227965AImprove compactnessEasy to takeDrilling rodsMolybdeum compoundsEngineeringSucker rod

The invention relates to the field of sucker rods, in particular to a high-temperature-resistant coated sucker rod. The sucker rod is composed of at least one sucker rod unit section. Each sucker rodunit section comprises a convex port, a concave port and a cylindrical rod, wherein the convex port and the concave port are fixedly arranged at the two ends of the cylindrical rod correspondingly. Ahigh-temperature-resistant layer is arranged on the outer surface of each sucker rod unit section. The high-temperature-resistant layers are prepared from modified polyimide. The problem that the surface of the sucker rod is hot in long-time work is solved. The high-temperature-resistant coated sucker rod has the following advantages that (1) the sucker rod is composed of the at least one sucker rod unit section, and pipe connecting and dismounting are convenient; and (2) the high-temperature-resistant layers are arranged, high temperature can be isolated outside the sucker rod, and the situation that the sucker rod deforms or influences the oil pumping quality due to accumulation of a large amount of heat during use is avoided.

Owner:DONGYING JINYILAI PETROLEUM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com