High efficiency LED heat radiating module

A technology of light-emitting diodes and heat dissipation modules, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc. It can solve the problems of unimproved left and right heat dissipation functions of heat dissipation glue, inability to work stably with high-power light-emitting diodes, and reduced service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

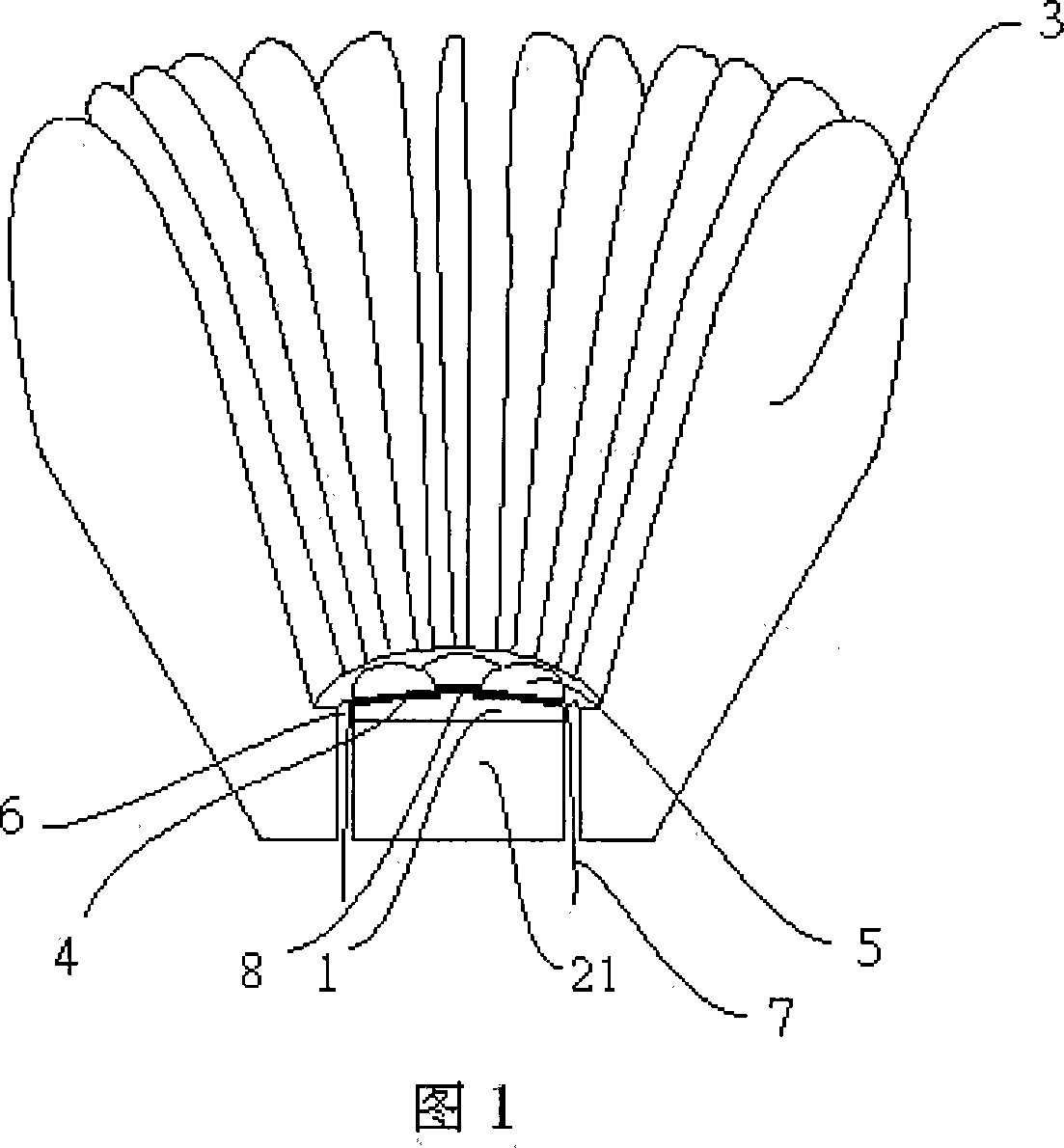

[0024] The method of LED heat dissipation module with high heat dissipation efficiency, as shown in Figure 1, 1. According to the heat dissipation requirements, the heat sink with the front heat dissipation fin 3 is made, and the structure of the heat sink is sunken in the middle; 2. The middle of the heat sink is sunken On the heat-absorbing end face 21, use reinforcing fibers, diamond fine particle powder, insulating inorganic materials and diamond composite materials of polymer binders to directly build up a convex curved surface electrically insulating and heat-conducting layer 8 containing diamond components; the third .The upper part of the electrical insulation and heat conduction layer is made of a metal circuit layer 4 by printing; fourth. There are two circuit channels 6 between the electrical insulation and heat conduction layer and the lower heat sink for the signal and power line 7 to pass through; fifth. A plurality of LED chips 5 are installed and packaged on the...

Embodiment 2

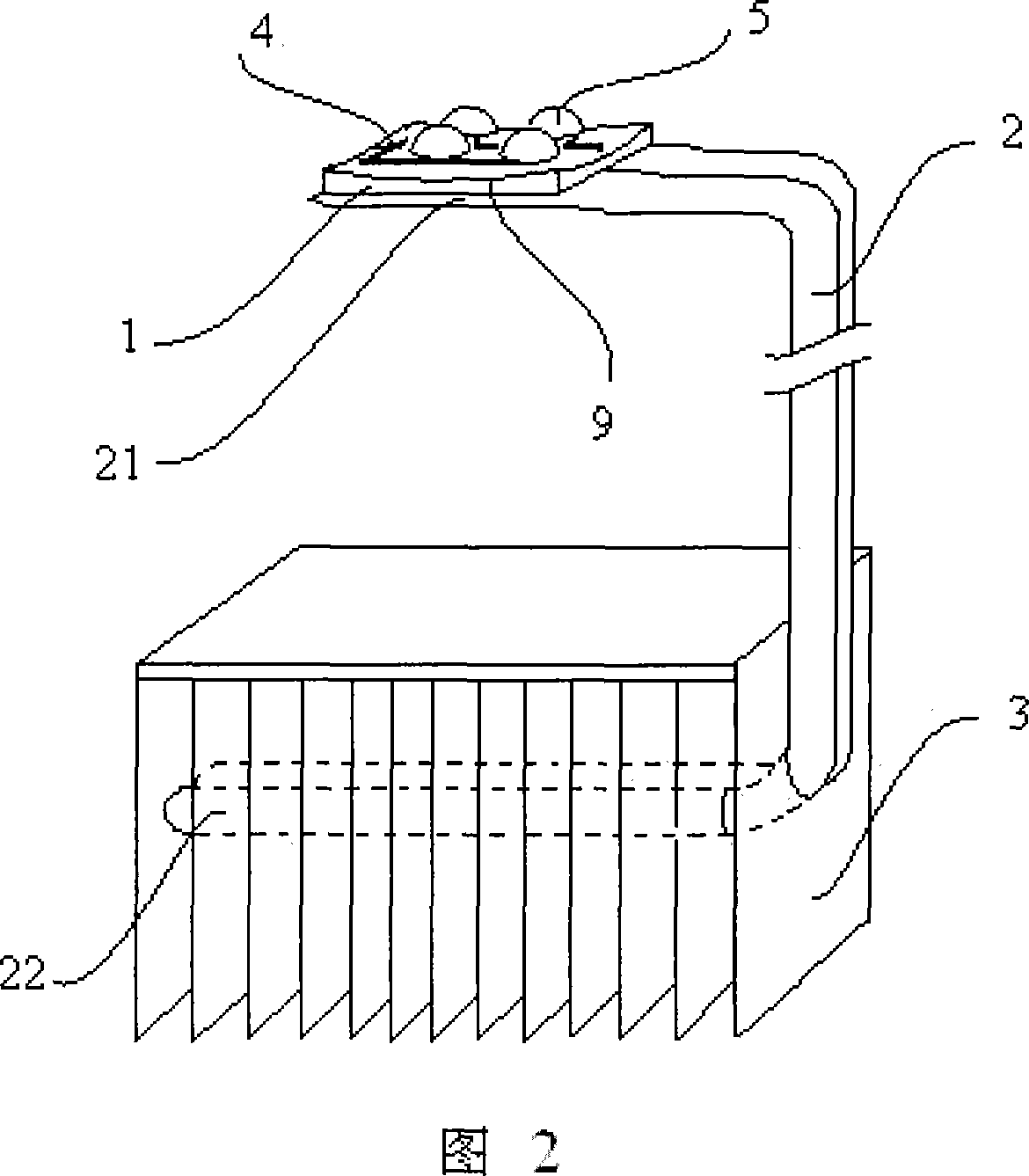

[0026] The method of LED heat dissipation module with high heat dissipation efficiency is shown in Figure 2. First, the heat sink is designed and manufactured according to heat dissipation requirements. Structure; second. on the end face 21 of the heat pipe that is flattened at the front end, use a diamond composite material to directly build up a concave curved surface electrical insulation and heat conduction layer 9 containing diamond components; third. the upper part of the electrical insulation and heat conduction layer, Fabricate the metal circuit layer 4 by etching; fourthly, install and package a plurality of LED chips 5 on the metal circuit layer 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com