Anti-scuffing treatment method for surface of water turbine

A treatment method and surface treatment technology, applied in metal material coating process, fusion spraying, coating, etc., to achieve good wear resistance, high hardness, and effective anti-abrasion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

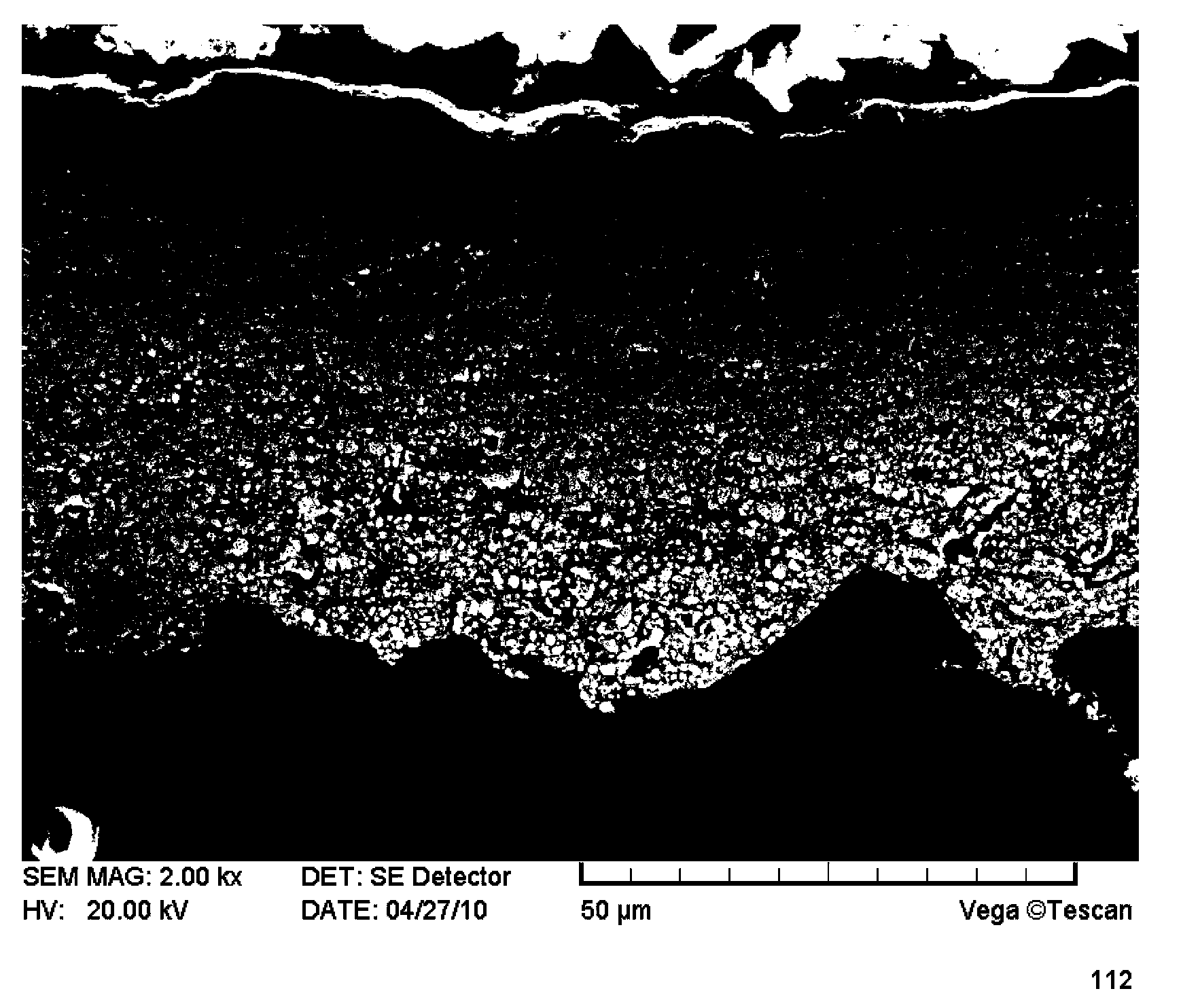

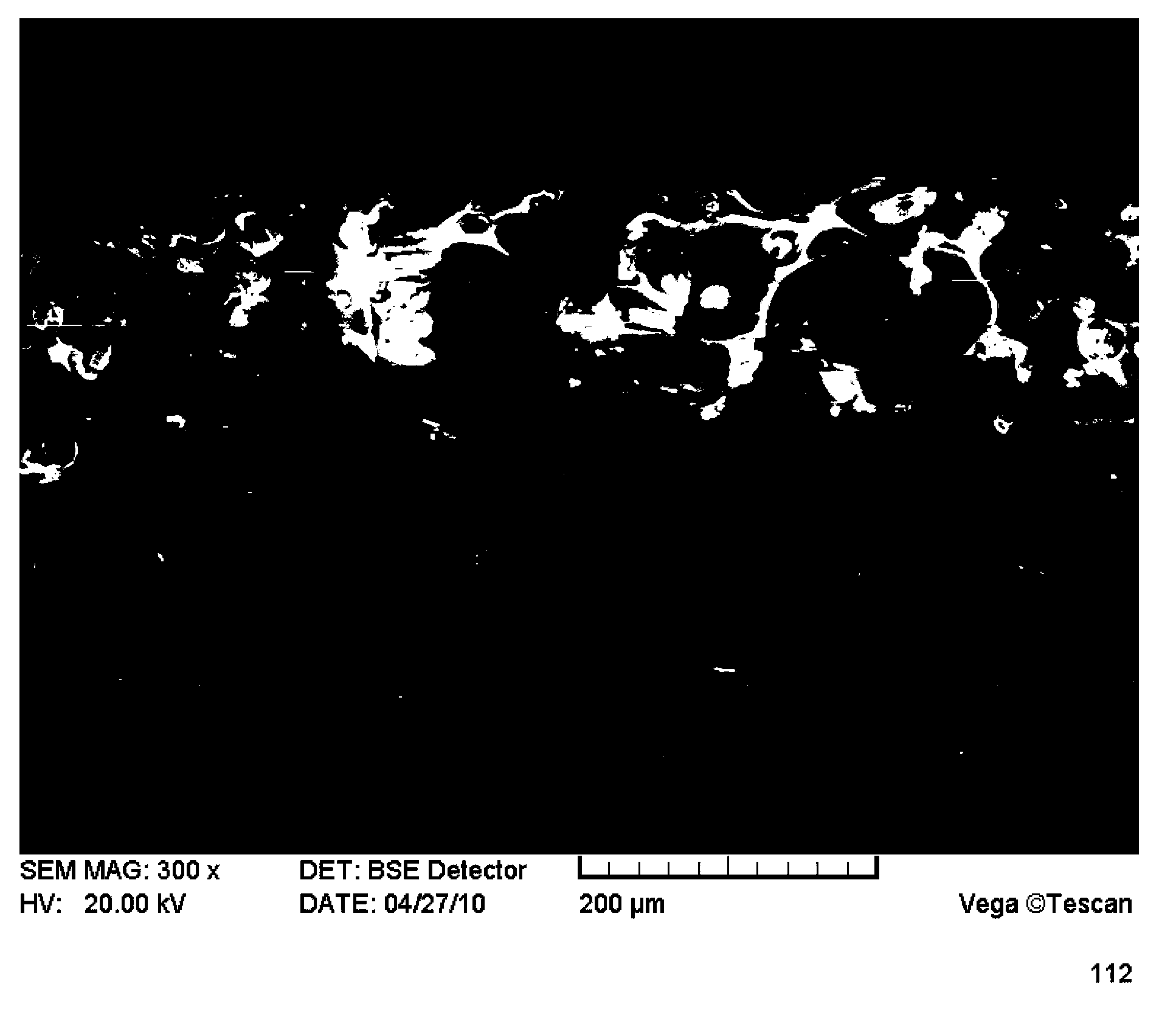

[0063] HVOF technology is to inject the spray material into the flame of high-speed jet combustion in the powder state, and its spray speed can reach 2000 m / s. The material is tightly and evenly attached to the surface of the object to be sprayed, and is physically combined with the substrate.

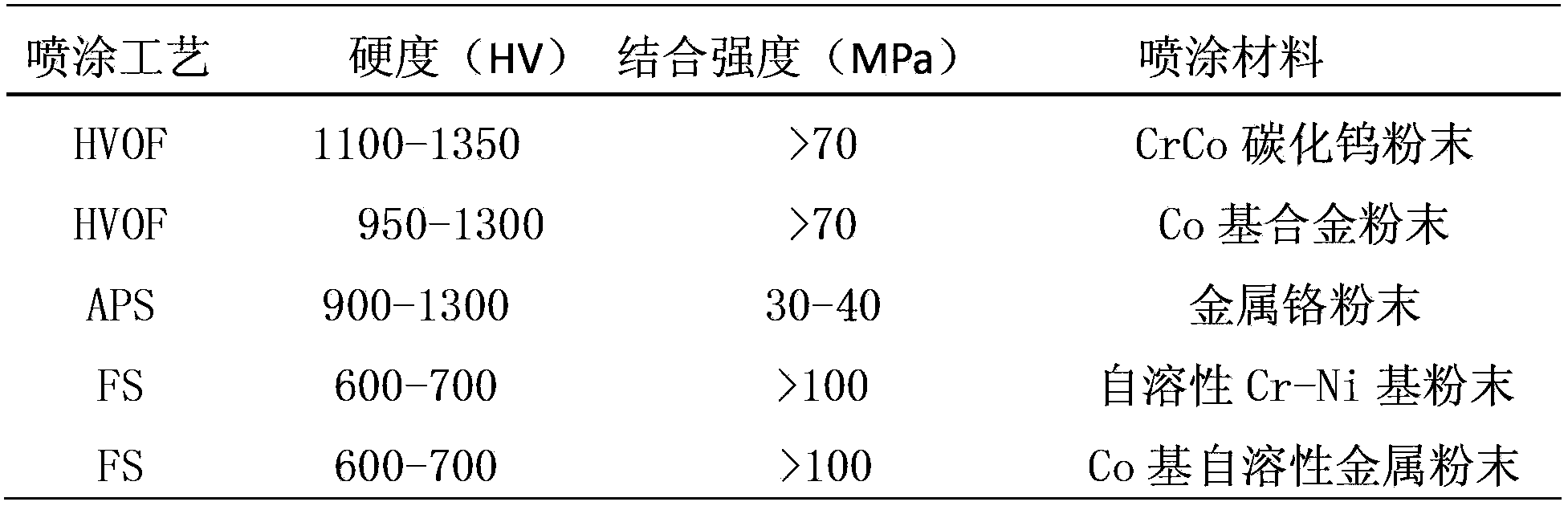

[0064] The characteristics of the High Velocity Oxygen Spraying (HVOF) technology are more favorable for resisting the abrasive damage of the turbine. Therefore, an innovative coating forming process for super-large and complex space-distorted surface parts is used for HVOF spraying, so that the microstructure of the coating is more uniform and dense, the substrate does not undergo any deformation, the bonding strength is greater than 70MPa, and the surface hardness is greater than 1100Hv. The surface wear resistance is more than 70 times higher than 0Cr13Ni4Mo, and its cavitation resistance is equivalent to 0Cr13Ni4Mo. The successful application of this composite coating technology h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com