High-temperature-resistant coated sucker rod

A sucker rod, high temperature resistance technology, applied in drill pipe, inorganic chemistry, molybdenum compound and other directions, can solve the problems of poor sucker rod resistance to high temperature, not meeting the needs of oil production, etc., to improve adhesion performance, convenient Takeover and disassembly, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

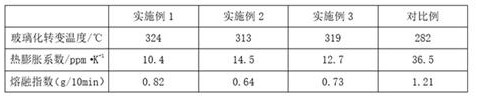

Embodiment 1

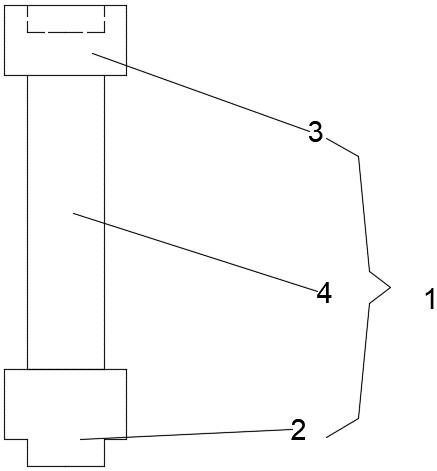

[0041] A high temperature resistant coated sucker rod, the sucker rod is composed of at least one sucker rod unit section 1; the sucker rod unit section 1 includes a raised port 2, a concave port 3 and a cylindrical rod 4, the The protruding port 2 and the concave port 3 are respectively fixedly arranged at both ends of the cylindrical rod 4; the protruding port 2 and the concave port 3 can be fitted with each other; a plurality of the sucker rod unit sections 1 can respectively pass through The protruding port 2 and the concave port 3 are connected end to end.

[0042] The protruding port 2 and the concave port 3 are connected by thread or buckle.

[0043] The sucker rod unit section 1 is made of anti-corrosion metal material.

[0044] The outer surface of the sucker rod unit section 1 is provided with a high temperature resistant layer.

[0045] The high temperature resistant layer is prepared from modified polyimide.

[0046] The modified polyimide is prepared by modifyi...

Embodiment 2

[0069] A high temperature resistant coated sucker rod, the sucker rod is composed of at least one sucker rod unit section 1; the sucker rod unit section 1 includes a raised port 2, a concave port 3 and a cylindrical rod 4, the The protruding port 2 and the concave port 3 are respectively fixedly arranged at both ends of the cylindrical rod 4; the protruding port 2 and the concave port 3 can be fitted with each other; a plurality of the sucker rod unit sections 1 can respectively pass through The protruding port 2 and the concave port 3 are connected end to end.

[0070] The protruding port 2 and the concave port 3 are connected by threads.

[0071] The sucker rod unit section 1 is made of anti-corrosion metal material.

[0072] The outer surface of the sucker rod unit section 1 is provided with a high temperature resistant layer.

[0073] The high temperature resistant layer is prepared from modified polyimide.

[0074] The modified polyimide is prepared by modifying polyim...

Embodiment 3

[0097] A high temperature resistant coated sucker rod, the sucker rod is composed of at least one sucker rod unit section 1; the sucker rod unit section 1 includes a raised port 2, a concave port 3 and a cylindrical rod 4, the The protruding port 2 and the concave port 3 are respectively fixedly arranged at both ends of the cylindrical rod 4; the protruding port 2 and the concave port 3 can be fitted with each other; a plurality of the sucker rod unit sections 1 can respectively pass through The protruding port 2 and the concave port 3 are connected end to end.

[0098] The protruding port 2 and the concave port 3 are connected by thread or buckle.

[0099] The sucker rod unit section 1 is made of anti-corrosion metal material.

[0100] The outer surface of the sucker rod unit section 1 is provided with a high temperature resistant layer.

[0101] The high temperature resistant layer is prepared from modified polyimide.

[0102] The modified polyimide is prepared by modifyi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com