Integratedsoluble bridge plug and preparation method thereof

A soluble bridge plug and soluble bridge technology, applied in drilling equipment, earthwork drilling, wellbore/well components, etc., can solve problems such as affecting production efficiency, difficult to remove bridge plugs, and unsatisfactory effects, achieving structural Simple, simplified structure, fast dissolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of an integrated soluble bridge plug of the present invention comprises the following steps:

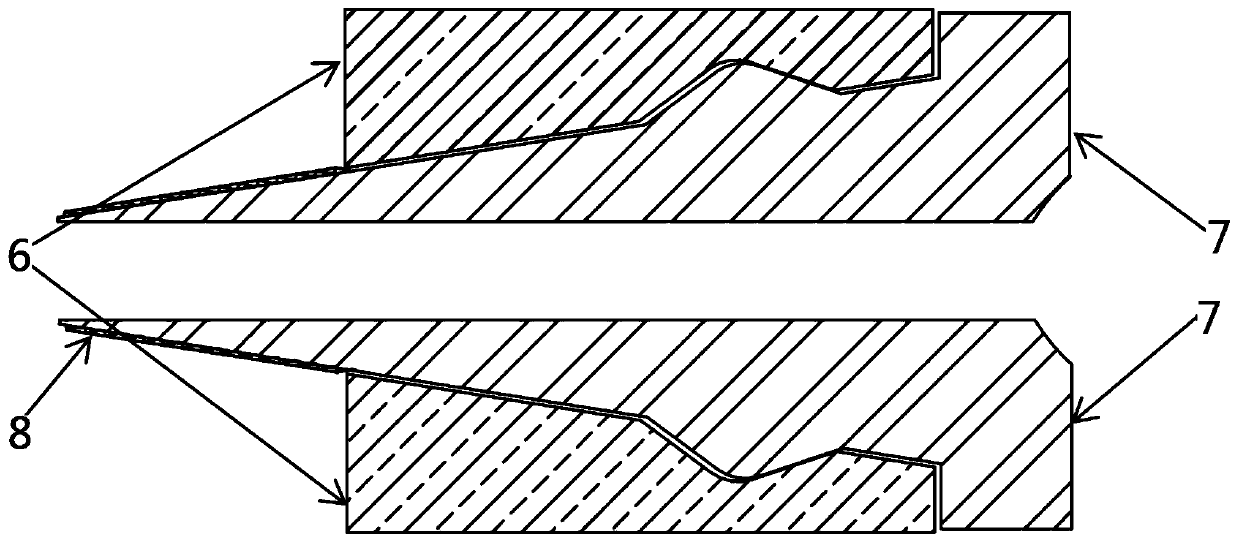

[0054] S1, the vertebral body 7 is organically combined with the rubber 6 as a rubber mold connector through mold vulcanization;

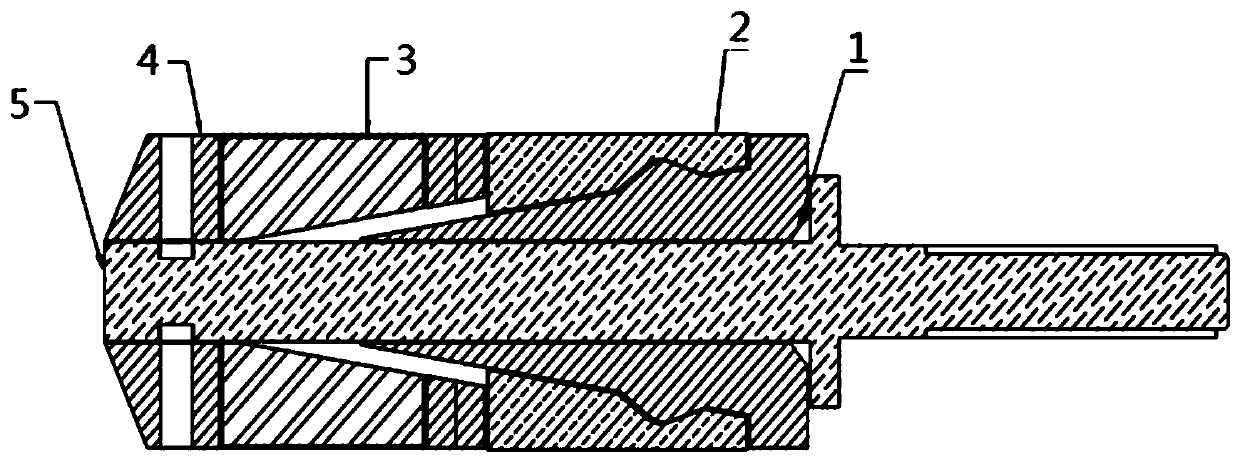

[0055] The rubber 6 is vulcanized to the outside of the vertebral body 7. During the setting process, the rubber 6 expands as the outer diameter of the vertebral body 7 increases, so as to achieve the sealing effect. The ball seat 1 is processed at the tail of the vertebral body 7.

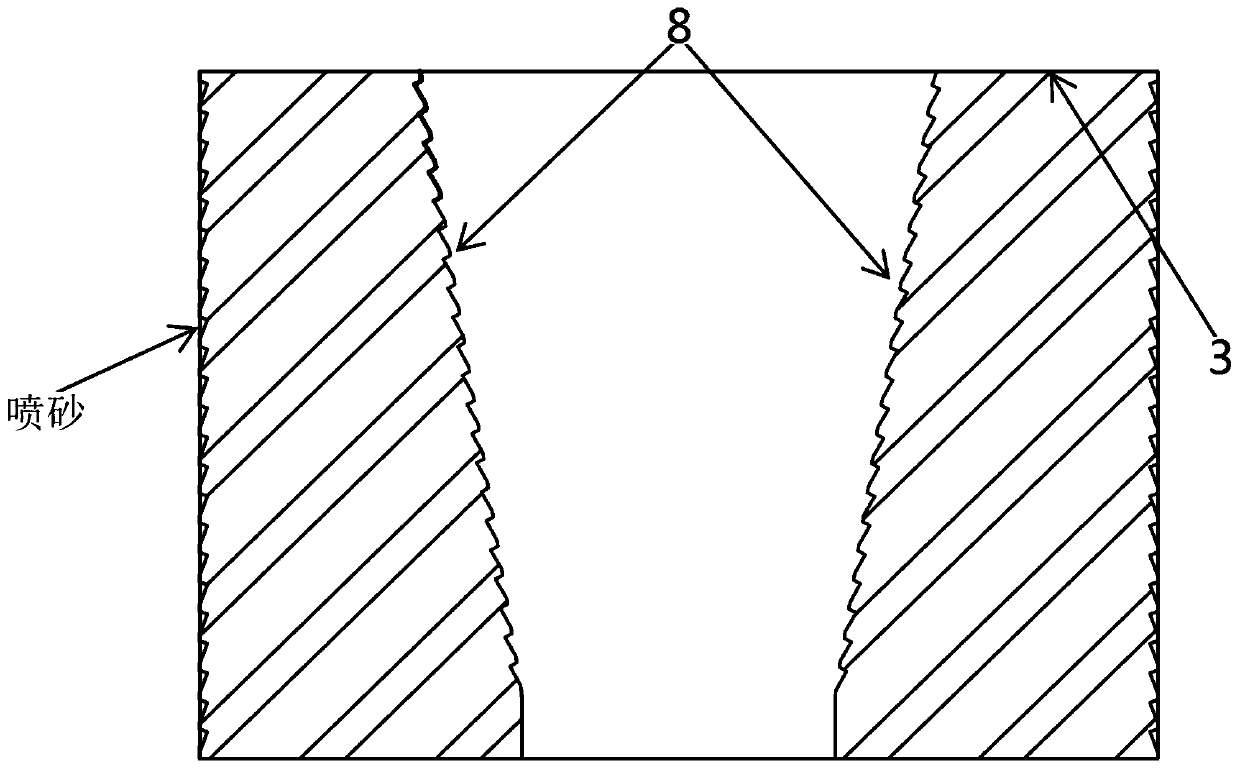

[0056] Put the cone into the vulcanization mold, the rubber is evenly filled outside the cone, the mold is sealed, and the mold is heated through a flat vulcanizer, and pressure is applied to the mold to make the rubber closely fit to the outside of the cone;

[0057] The vertebral body 7 is a soluble metal or a soluble non-metal, and the soluble metal can be magnesium alloy, magnesium-aluminum alloy; the soluble non-metal is: soluble plastic, solu...

Embodiment

[0067] see Figure 7 , put the bridge plug into the well, its working method is as follows: the plug is used as a sealing push cylinder to push the cone forward, and the adapter pulls the lower joint to move backward, so that the slip and the cone rubber compound move to the middle, so that the rubber can be more Well, it is safer to achieve the sealing effect with the inner wall of the casing.

[0068] The present invention provides a new structure soluble bridge plug integrating soluble rubber and soluble vertebral body vulcanization and its manufacturing method. Because of its small volume, it can effectively carry out sealing operation through the pressure deformation zone of the wellbore; at the same time, it reduces the In addition to being able to completely dissolve or degrade in the well after fracturing, it can also degrade within a set time, so the manufactured bridge plug has small volume, strong strength High, adapt to various temperature conditions, and can stil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com