Electronic material composition

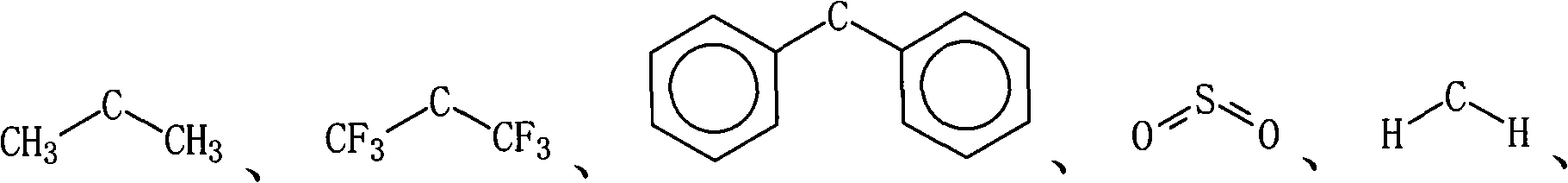

A technology of electronic materials and components, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of use restrictions, halogen residues, high chlorine content of materials, etc., and achieve small dissipation factor and dielectric constant Low, dimensional stability and good expansion coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

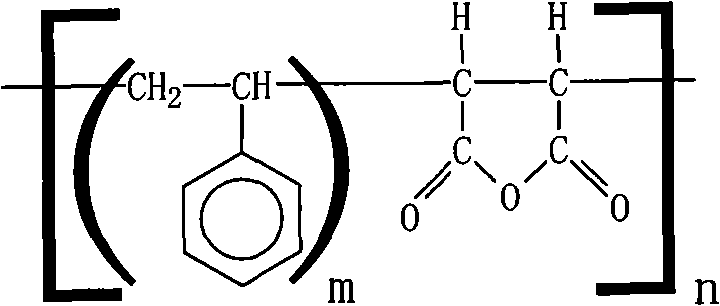

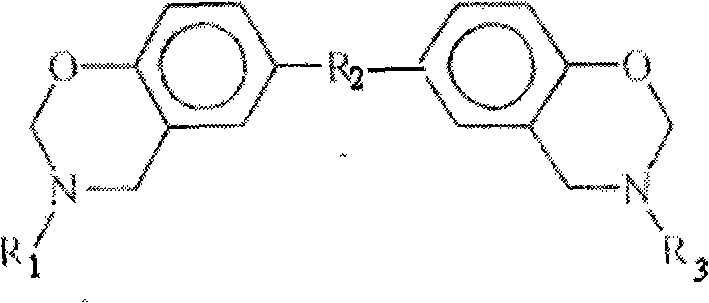

[0064] 100 parts by weight of oxo-nitrobenzocyclohexane, 50 parts by weight of styrene-maleic anhydride copolymer (SMA-3000), 40 parts by weight of silicon dioxide, 25 parts by weight of polymethylphosphonic acid 1,3-phenylene ester, 0.33 parts by weight of 2-methylimidazole and 70 parts by weight of methyl ethyl ketone were added into the stirrer.

Embodiment 2

[0066] With 100 parts by weight of oxoazinobenzocyclohexane, 10 parts by weight of styrene-maleic anhydride copolymer (SMA-3000), 40 parts by weight of silicon dioxide, 25 parts by weight of melamine pyrophosphate, 0.69 parts by weight of 2-methylimidazole and 70 parts by weight of methyl ethyl ketone were added into the stirrer.

Embodiment 3

[0068] With 100 parts by weight of oxoazinobenzocyclohexane, 45 parts by weight of styrene-maleic anhydride copolymer (SMA-3000), 40 parts by weight of aluminum hydroxide, 25 parts by weight of phosphazene flame retardant, 0.96 parts by weight of 2-methylimidazole and 70 parts by weight of methyl ethyl ketone were added into the stirrer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com