Nitrogen-containing austenitic stainless steel flux-cored wire with high strength and pitting corrosion resistance, and preparation method

A technology of austenitic stainless steel and flux-cored welding wire, which is used in welding equipment, manufacturing tools, welding media, etc., can solve the problem of difficulty in exerting nitrogen-containing austenitic stainless steel, reducing the yield and quality of welding wire, and high sensitivity to welding porosity defects. problems, to achieve the effect of inhibiting the escape of nitrogen elements, optimizing the bonding force, and stabilizing the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

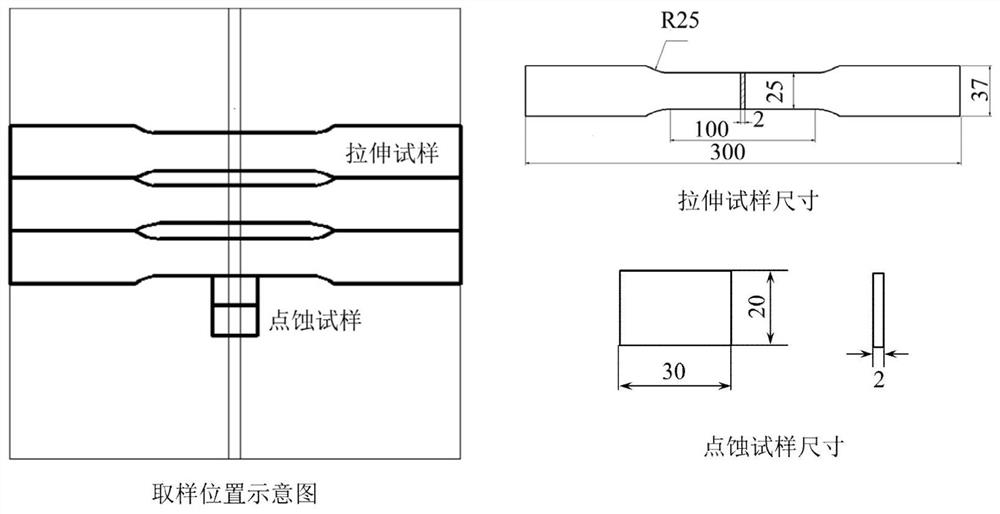

Image

Examples

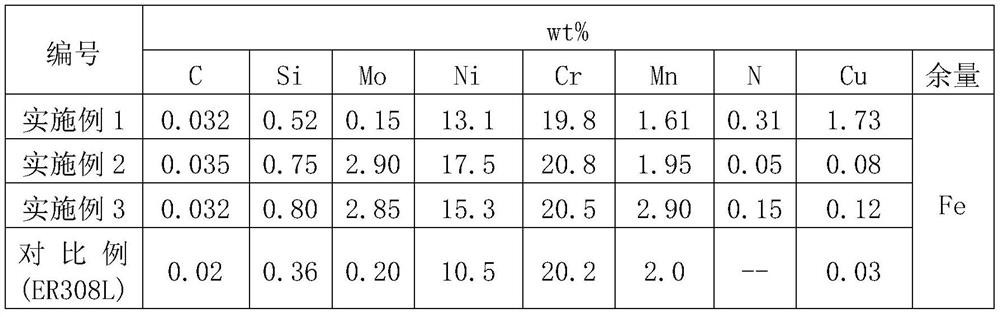

Embodiment 1

[0043] High-strength and pitting-resistant nitrogen-containing austenitic stainless steel flux-cored welding wire is composed of flux core powder and stainless steel strip wrapped around the flux core powder. The flux core powder is composed of alloy components and slag components, as follows:

[0044] The mass percentages of each substance in the slag component to the drug core powder are: sodium titanate and potassium titanate: 7%, zirconia: 5%, ferric oxide: 3%, fluoride: 8.8%, potassium feldspar : 1%, rutile: 12%, bismuth oxide: 10% and aluminum powder 1%.

[0045] The mass percentage of each substance in the alloy component to the drug core powder is: electrolytic manganese: 1.8%, ferrosilicon: 0.7%, chromium powder: 20%, nickel powder: 12.5%, ferromolybdenum: 0.2%, copper powder: 2.0% , chromium nitride: 1.5% mixed with iron powder as the balance;

[0046] The particle size of each substance in the drug core powder is 60-180 mesh.

[0047] The mass percent composition ...

Embodiment 2

[0055] High-strength and pitting-resistant nitrogen-containing austenitic stainless steel flux-cored welding wire is composed of flux core powder and stainless steel strip wrapped around the flux core powder. The flux core powder is composed of alloy components and slag components, as follows:

[0056] The mass percentages of the various substances in the slag components in the drug core powder are: sodium titanate and potassium titanate 6%, zirconia: 2%, ferric oxide: 4%, fluoride: 5.5%, potassium feldspar: 3%, rutile: 12%, bismuth oxide: 1.4% and aluminum powder 2%.

[0057] The mass percentages of the substances in the alloy components in the core powder are: electrolytic manganese: 3.0%, ferrosilicon: 1%, chromium powder: 21%, nickel powder: 15.5%, molybdenum iron: 3.5%, chromium nitride: 0.2 %, copper powder: 0.1% mixed with iron powder as the balance.

[0058] The particle size of each substance in the drug core powder is 60-180 mesh.

[0059] The mass percent composit...

Embodiment 3

[0067] High-strength and pitting-resistant nitrogen-containing austenitic stainless steel flux-cored welding wire is composed of flux core powder and stainless steel strip wrapped around the flux core powder. The flux core powder is composed of alloy components and slag components, as follows:

[0068] The mass percentages of the various substances in the slag components in the drug core powder are: sodium titanate and potassium titanate 6%, zirconia: 2%, ferric oxide: 4%, fluoride: 5.5%, potassium feldspar: 3%, rutile: 12%, bismuth oxide: 1.4% and aluminum powder 2%.

[0069] The mass percentage of each substance in the alloy component to the core powder is: electrolytic manganese: 3%, ferrosilicon: 1%, chromium powder: 21%, nickel powder: 20%, molybdenum iron: 3.5%, copper powder: 0.1% , chromium nitride 5% and iron powder as the balance mixed.

[0070] The particle size of each substance in the drug core powder is 60-180 mesh.

[0071] The mass percent composition of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com