Device and method for additional welding seam compensation shielding gas

A technology of compensating gas and shielding gas, which is applied in the direction of welding connection, welding equipment, welding accessories, etc., can solve the problems of improving welding efficiency, affecting the quality of weld seam, taking care of one thing and losing another, etc., so as to improve welding quality, adjust settings conveniently, feature and Outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

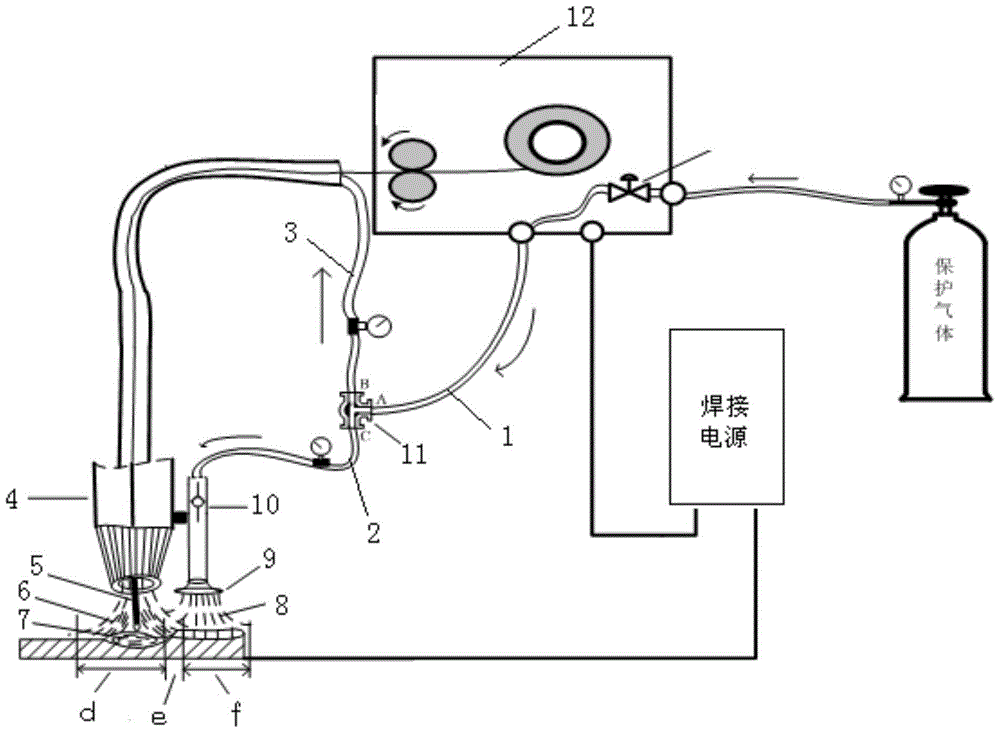

[0026] as the picture shows. The device for supplementing welding seam compensation shielding gas in the present invention includes a gas cylinder, a wire feeding mechanism 12 for welding wire 5, a gas supply pipeline for welding torch nozzle 4, and a compensation gas nozzle 9;

[0027] The air supply pipeline includes an air supply main pipe 1, a B branch pipe 3, a C branch pipe 2 and a three-way valve 11;

[0028] One end of the air supply main pipe 1 is connected to the A end of the three-way valve 11; one end of the B branch pipe 3 is connected to the B end of the three-way valve 11, and the other end is connected to the welding torch nozzle 4; one end of the C branch pipe 2 is connected to the C end of the three-way valve 11 , and the other end is connected to the compensation gas nozzle 9.

[0029] The compensation gas nozzle 9 is fixedly or detachably connected to the welding torch; the compensation gas nozzle 9 is located on the back side of the gas shield of the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com