A collection port water spray cooling device for a high temperature wind tunnel

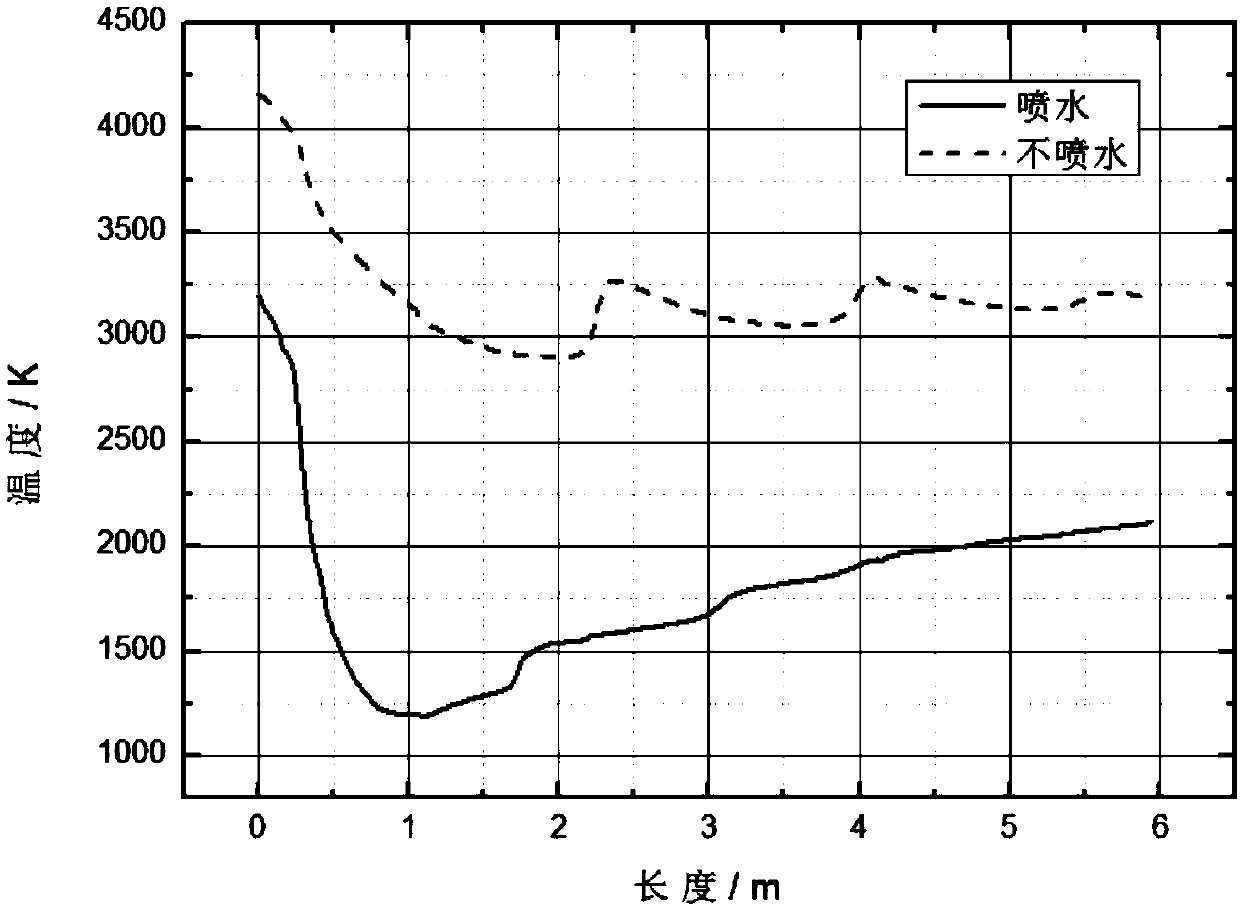

A technology of spraying water to cool down and collecting ports, which can be used in measuring devices, special data processing applications, lighting and heating equipment, etc., and can solve problems such as thermal airflow cooling without obvious shock wave reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

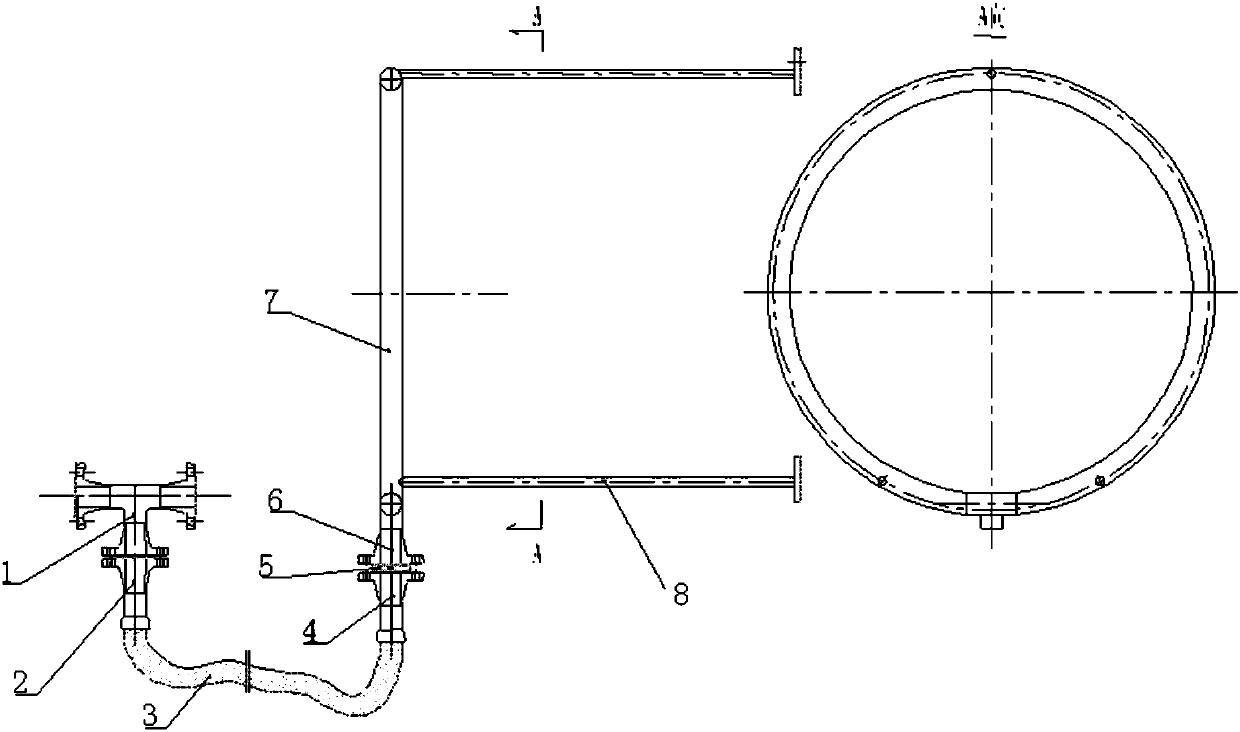

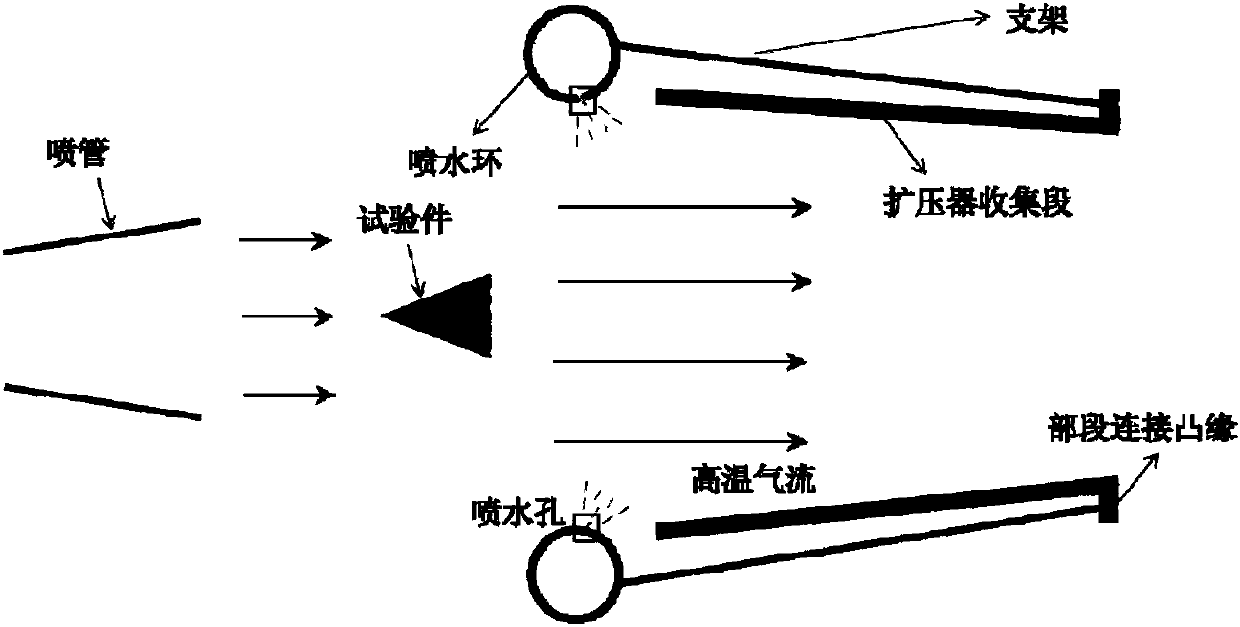

[0095] Such as figure 1 and figure 2 As shown, a high-temperature wind tunnel with water spray cooling device at the collection port, the device includes a water spray ring 7 and a blasting orifice plate 5;

[0096] The water spray ring 7 has water spray holes;

[0097] The blast hole plate 5 is located upstream of the water spray ring 7 .

[0098] The device also includes a bracket 8, which is used to fix the water spray ring 7 on the collection port section of the wind tunnel diffuser.

[0099] The device also includes a water supply pipeline 3, an upper flange 6 and a lower flange 4;

[0100] The water supply pipeline 3 communicates with the water spray ring 7 through the upper flange 6 and the lower flange 4; the high-pressure water source passes into the water spray ring 7 through the water supply pipeline 3, and the water supply pipeline 3 is A blast hole plate 5 is installed at the junction with the water spray ring 7 .

[0101] The water spray ring 7 is an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com