Cover gas blowing device for laser welder head

A laser welding head and shielding gas technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large space for blowing pipe 31, tooling collision, lens failure, etc., so as to increase the welding range and prevent welding. Seam oxidation and damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

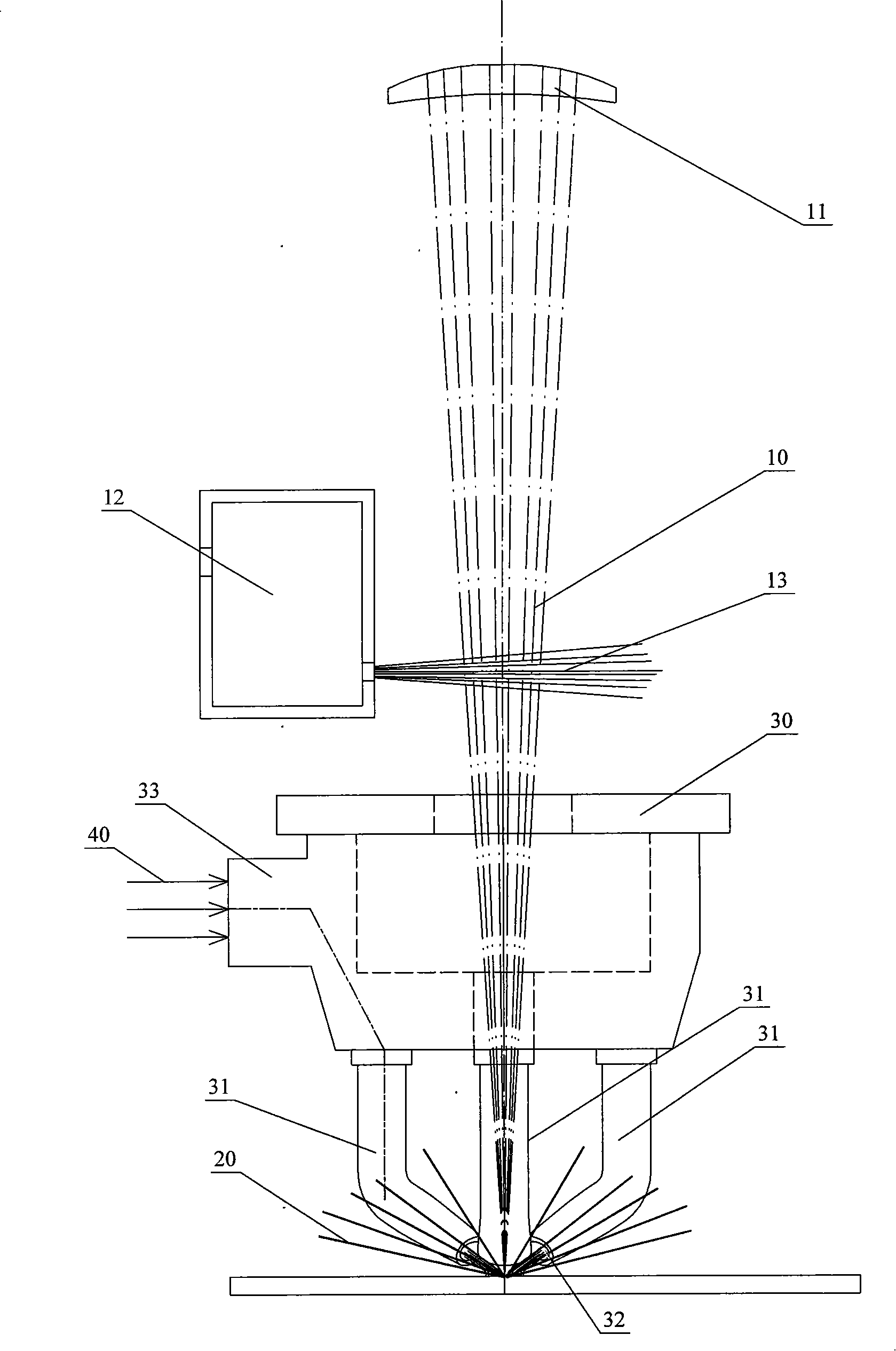

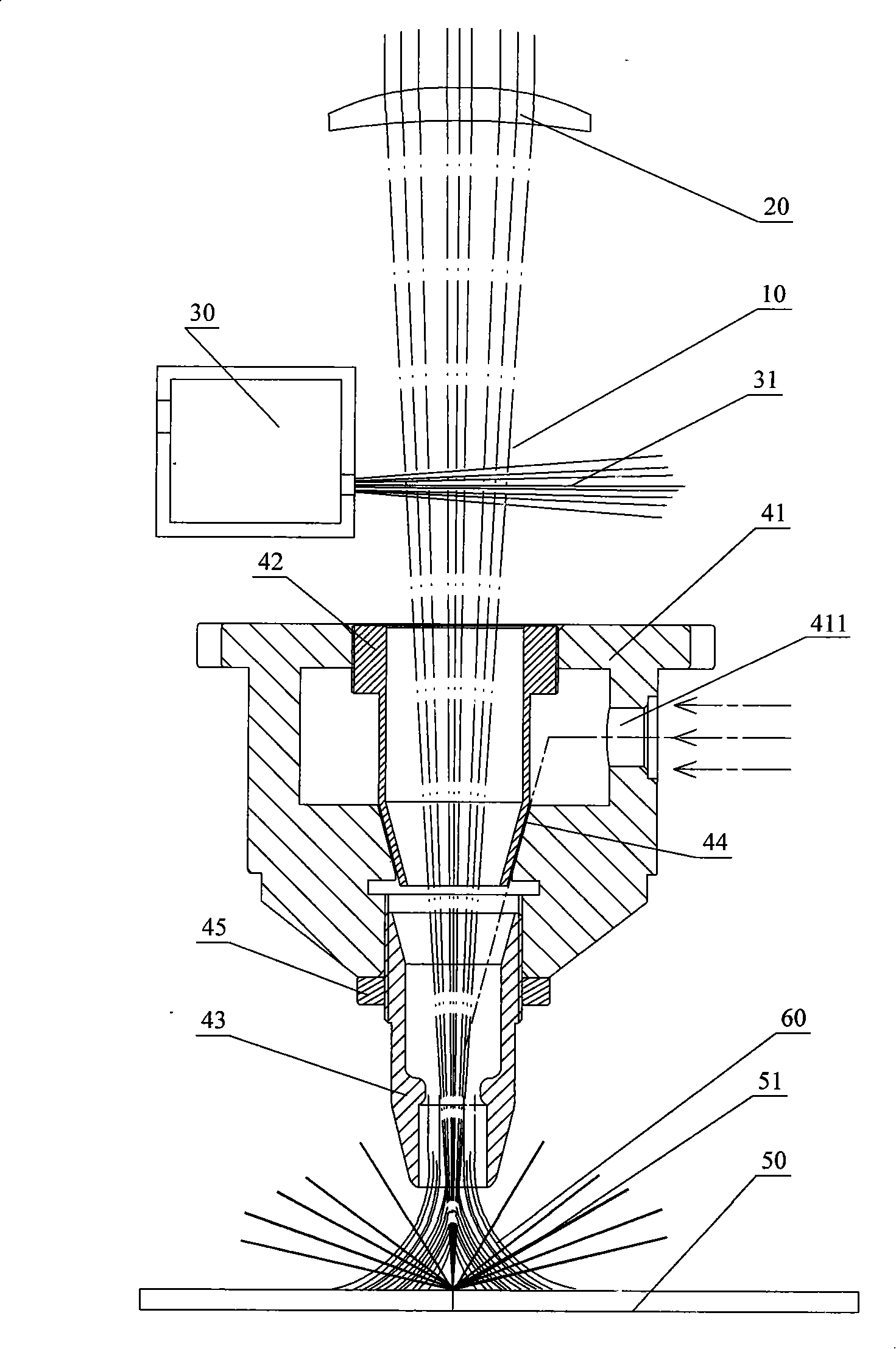

[0015] Such as figure 2 , figure 2 It is a schematic diagram of the work of the laser welding head blowing protective gas device of the present invention. The laser welding head mainly includes: a focusing mirror 20 for reflecting or refracting the laser beam 10, a compressed air cavity 30, and a protective gas blowing device 40, wherein the compressed air cavity 30 is located on the side of the path of the laser beam 10, and the compressed air 31 is blown sideways through the compressed air cavity 30 to prevent the spatter 51 generated during the welding process from continuing to rise and damage the focusing lens 20. After the laser beam 10 passes through the focusing mirror 20 and enters the shielding gas blowing device 40 , the workpiece 50 to be welded is directly welded.

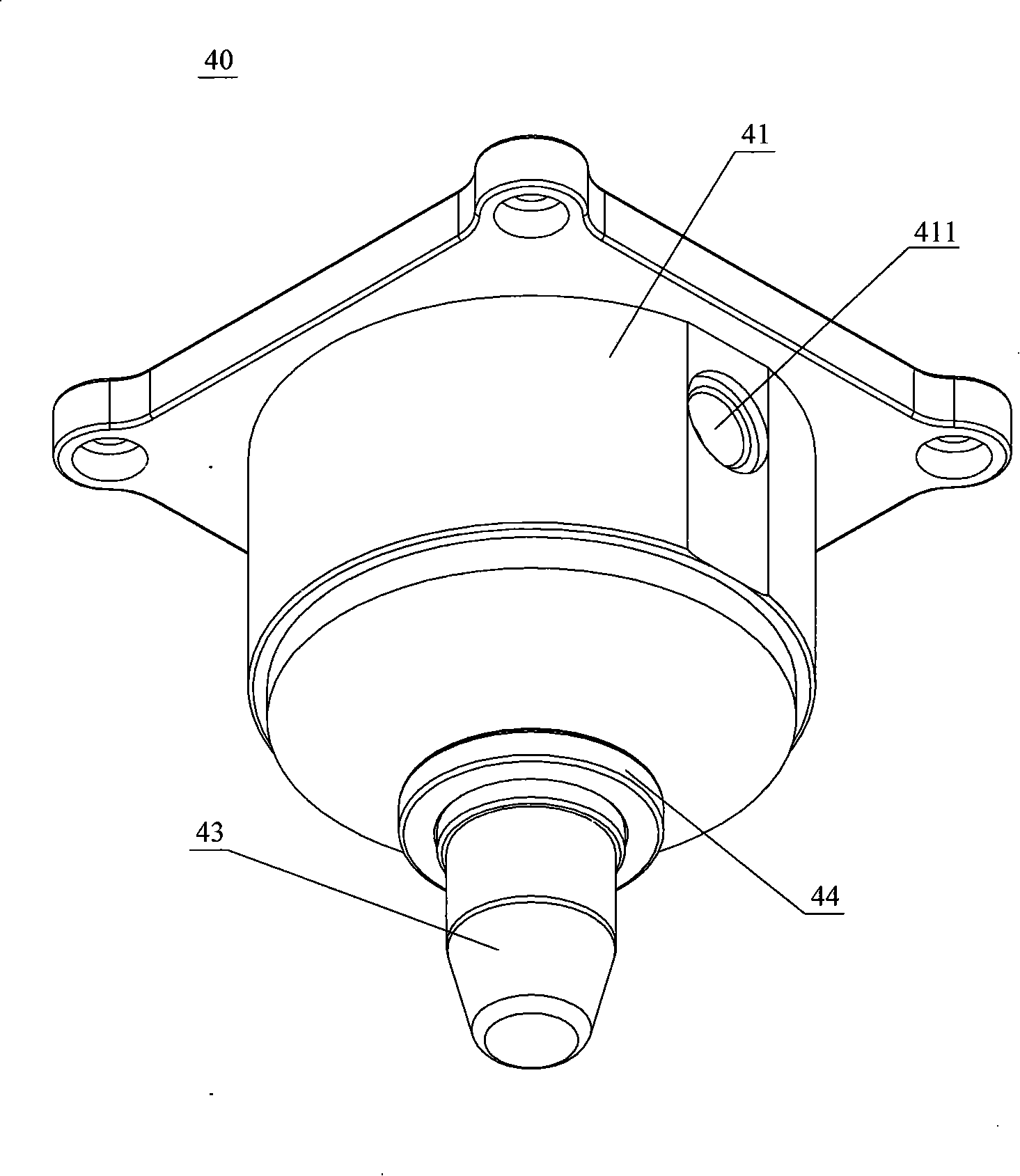

[0016] Such as Figure 2 to Figure 5 , is a schematic structural view of the shielding gas blowing device of the present invention, the shielding gas blowing device 40 is used to spray shielding ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com