Arc-shaped semi-closed gas protective hood for pipeline welding and welding method

A gas shielding, arc-shaped technology, applied in welding protection devices, welding equipment, welding accessories, etc., can solve the problems of unreasonable gas channel design, uneven distribution of shielding gas, blue surface of welding joints, etc. Protection time, labor cost saving, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

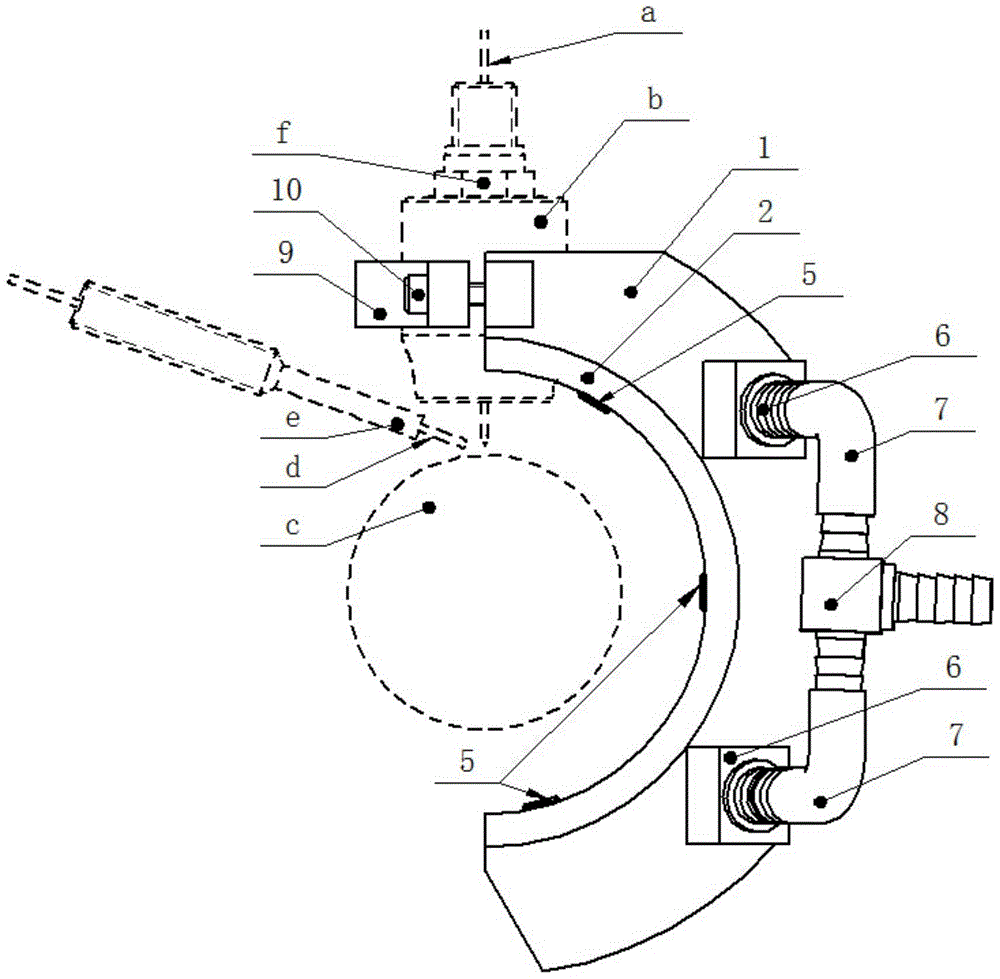

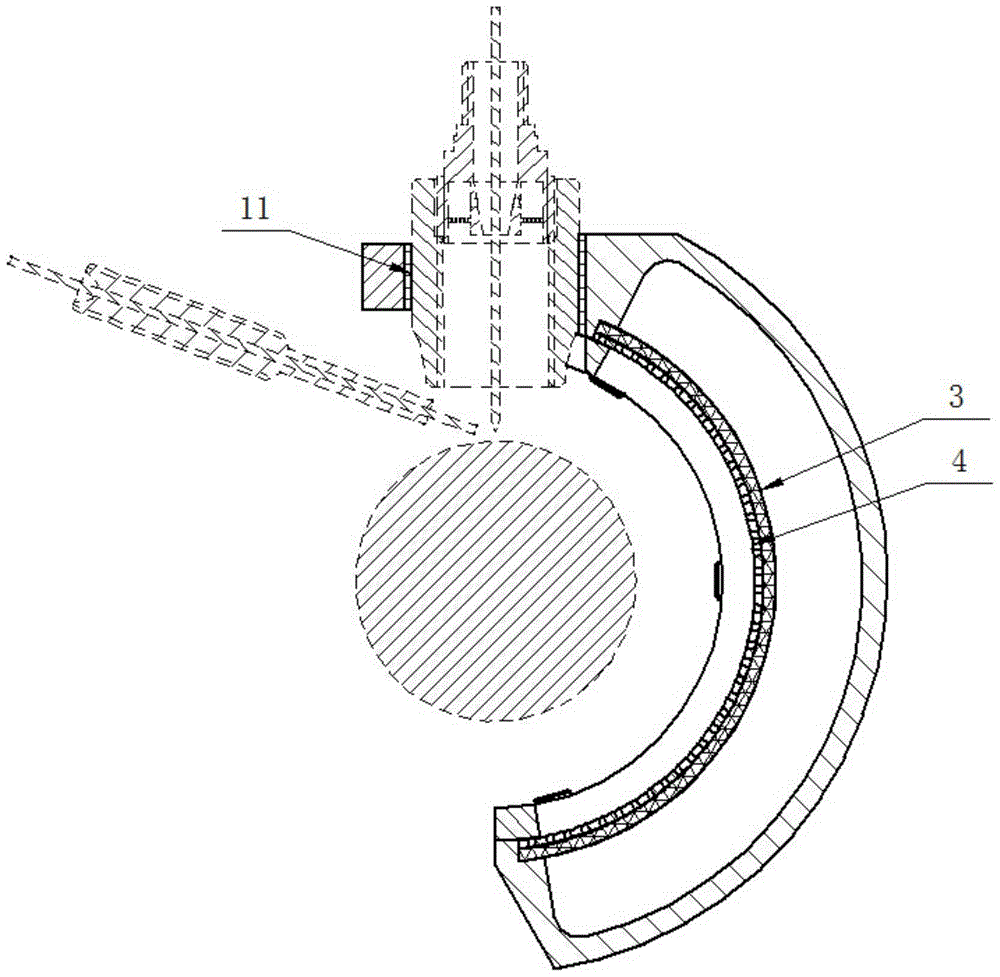

[0058] The arc-shaped semi-sealed gas protection drag cover for welding of the present embodiment is as figure 1 with figure 2 shown. Such as figure 1 The dotted line shows the gas protection form of the open welding track head during the automatic welding of medium and small diameter circuit pipes in the nuclear island of the nuclear power site. In the figure, a tungsten electrode, b ceramic nozzle, c workpiece to be welded, d welding wire, e wire feed nozzle , f air screen, b The installation space around the ceramic nozzle is very limited.

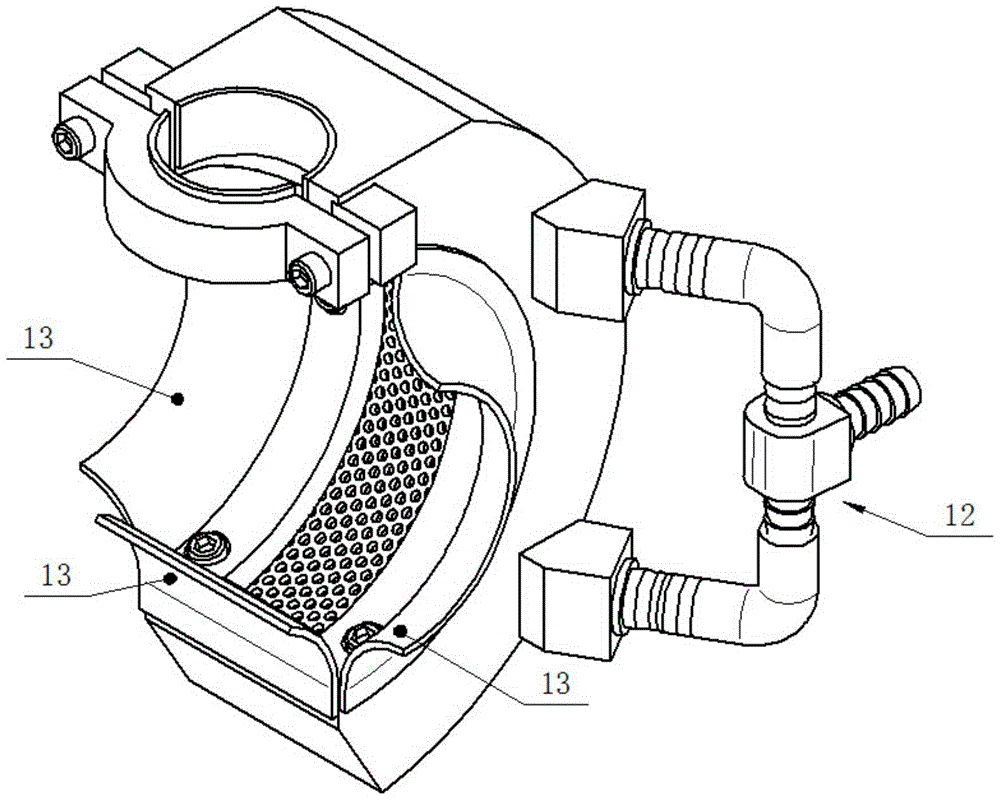

[0059] The width of the air outlet of the gas protection tow cover and the width of the arc cavity in the arc housing 1 are 16 mm, the arc of the arc cavity is 150 degrees, the arc of the arc housing 1 and the arc pressure ring 2 is 180 °, the arc The diameter of the evenly distributed through holes on the shaped baffle 4 is Φ1.3mm, the axial interval is 1.7mm, the radial interval range is 4°, five layers of stainless steel wire mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com