Patents

Literature

57results about How to "Stable welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

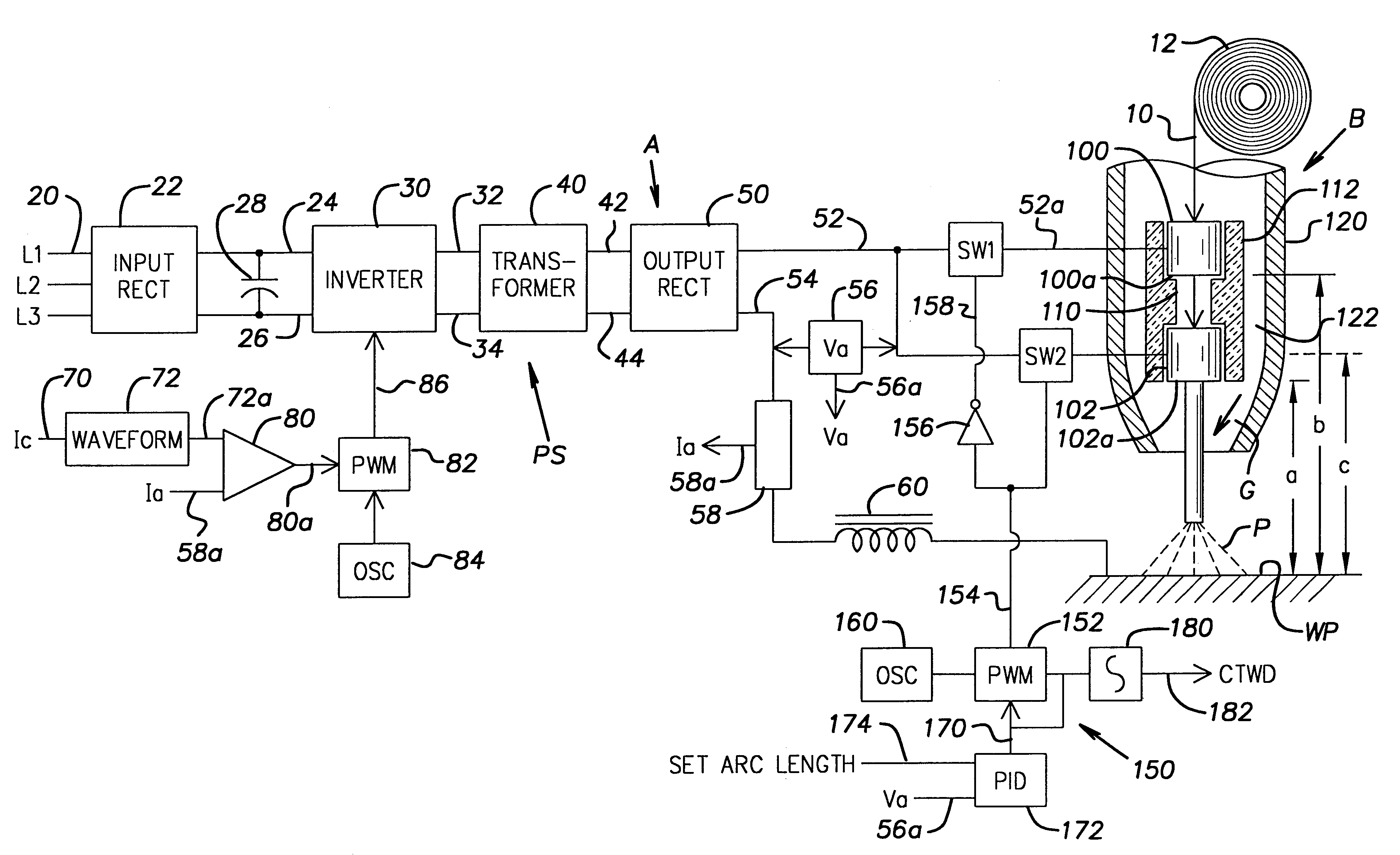

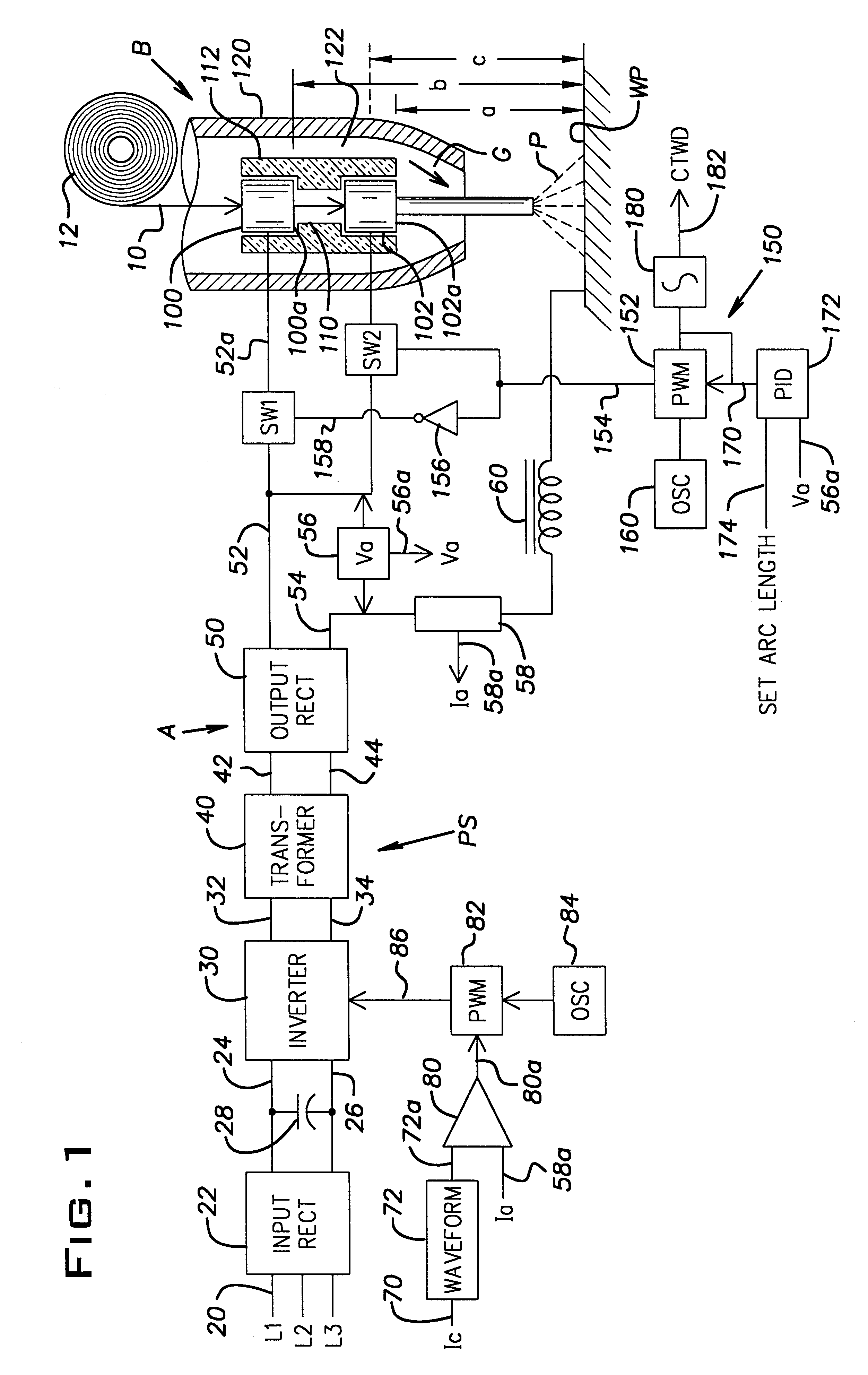

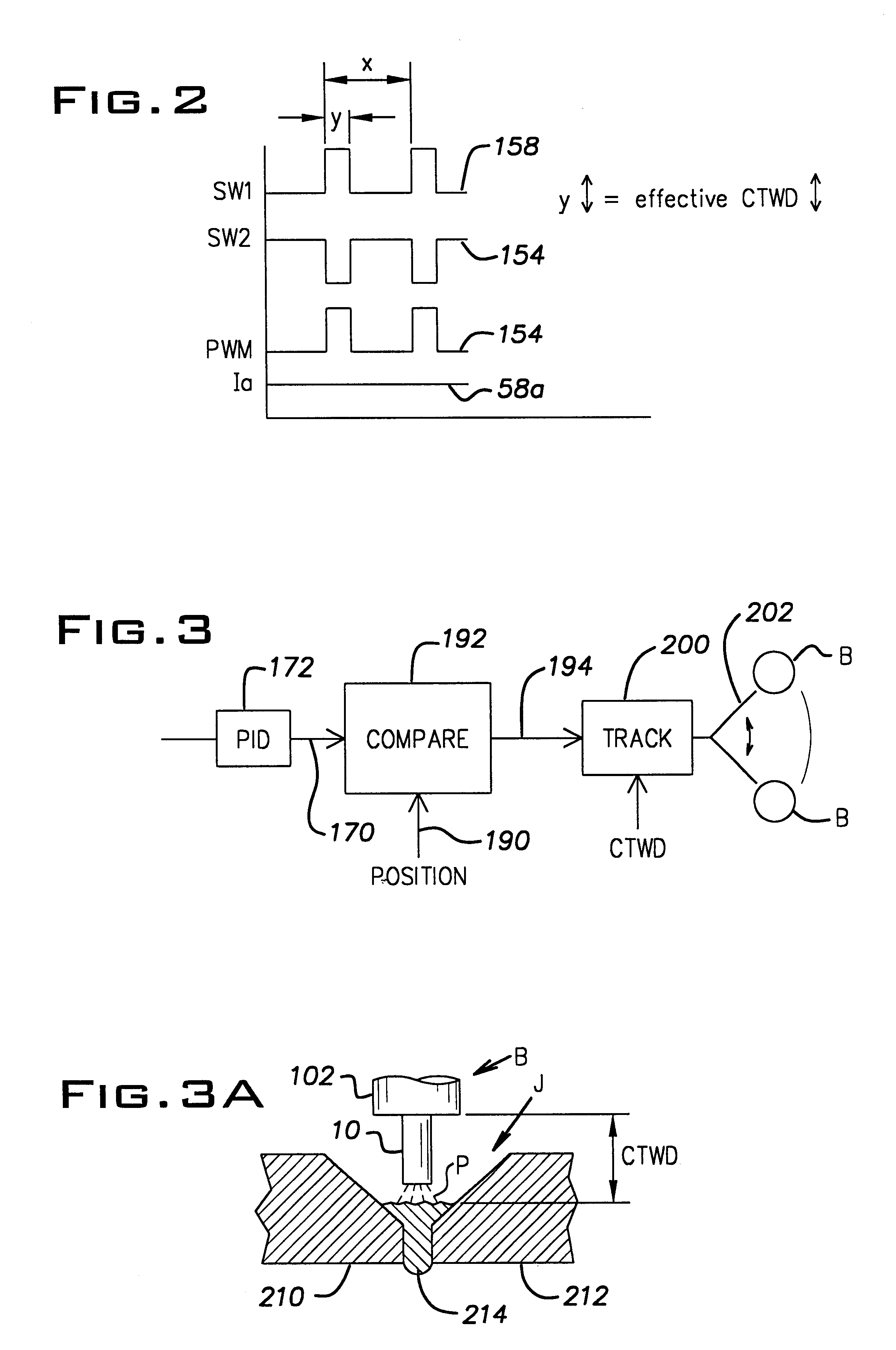

Arc welder and torch for same

InactiveUS6259059B1Increase currentStable welding processSupport devices with shieldingElectrode accessoriesElectric arcEngineering

Owner:LINCOLN GLOBAL INC

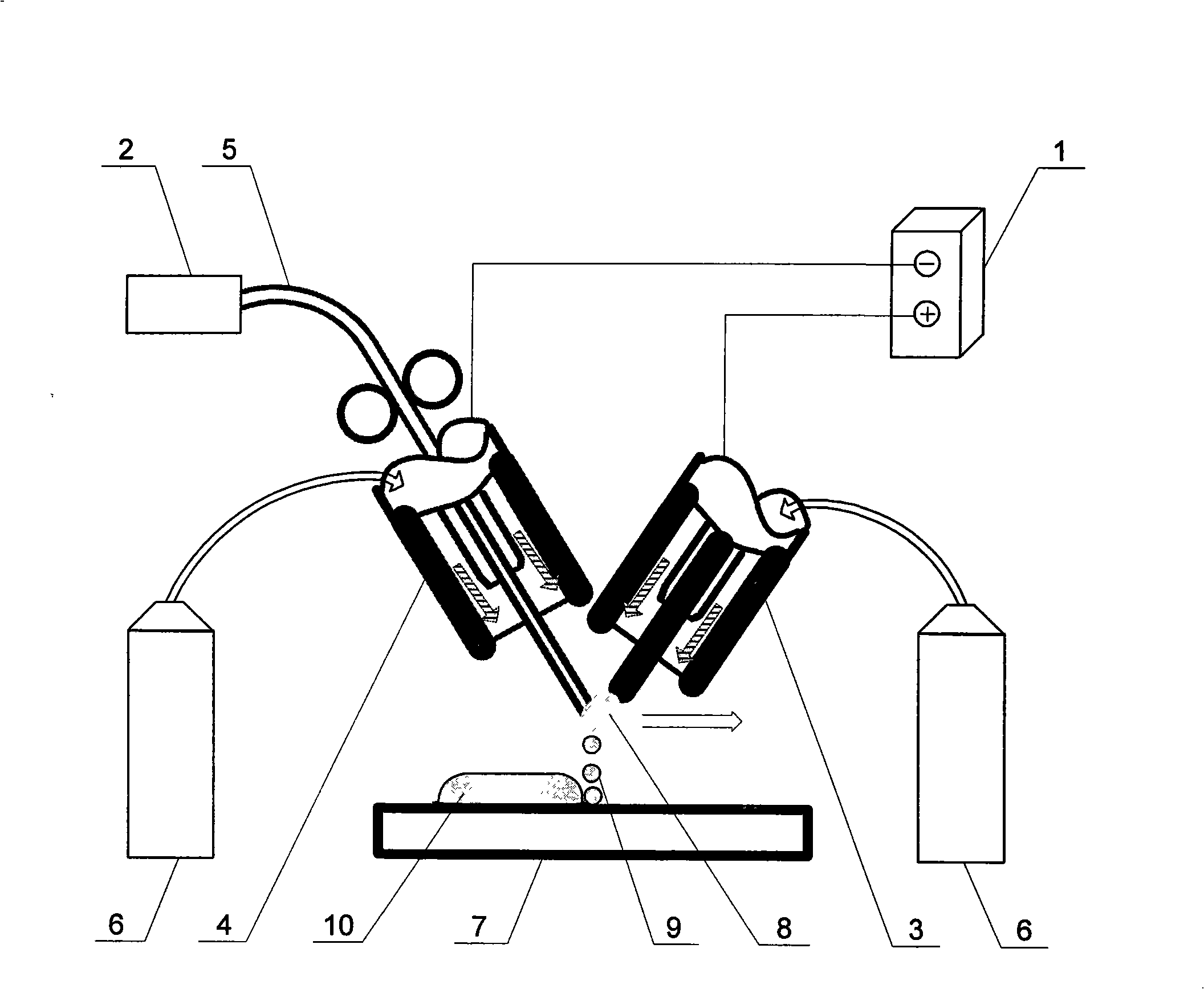

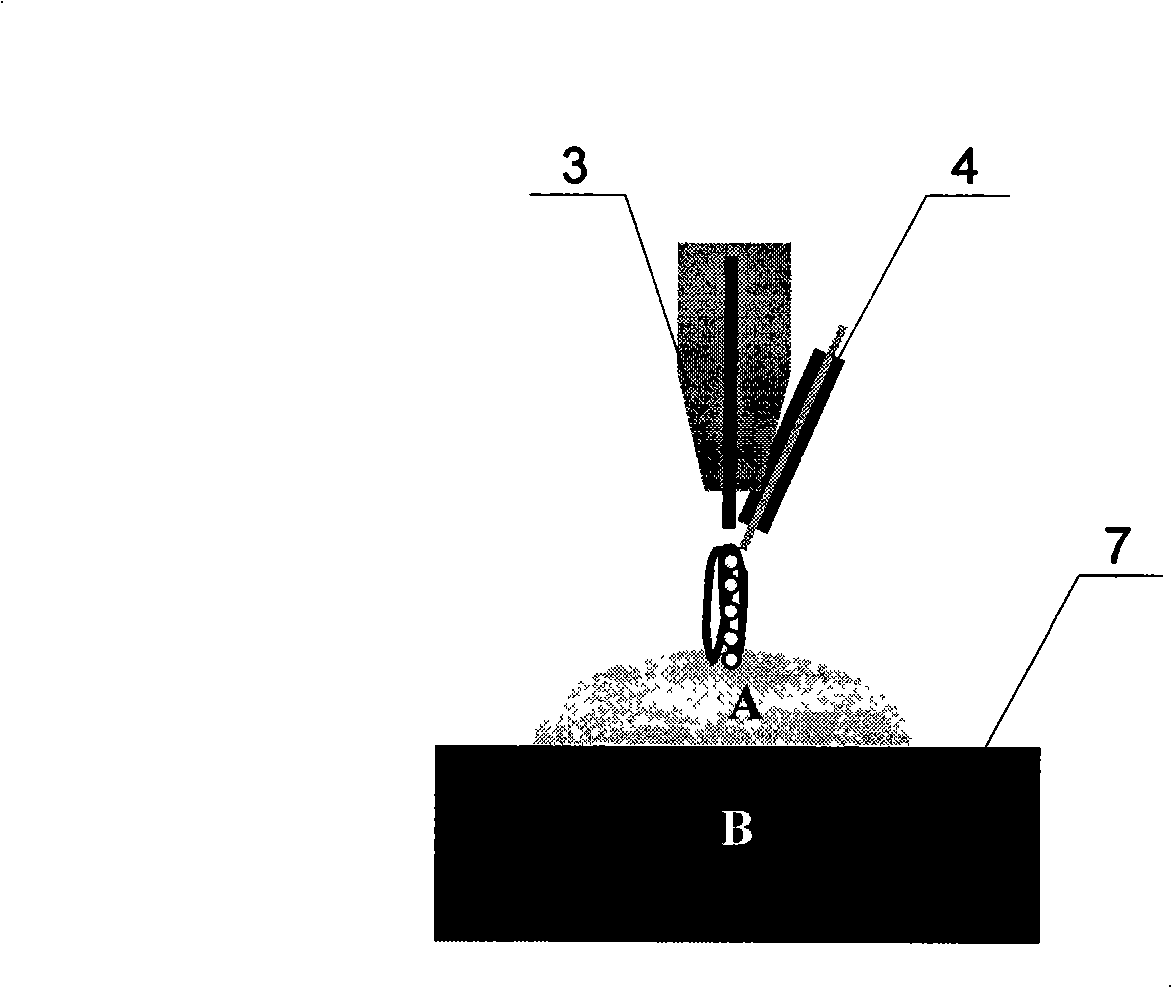

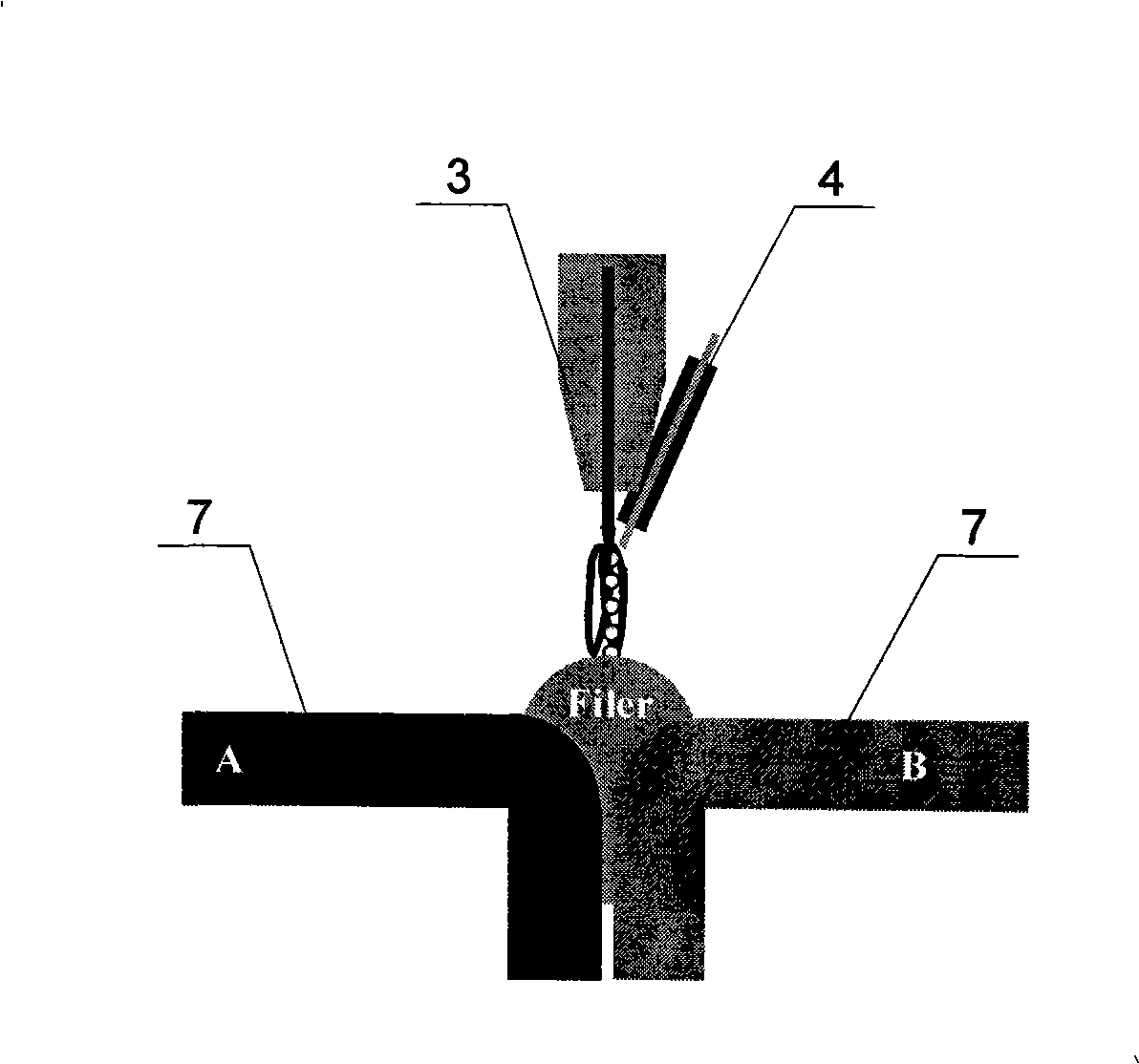

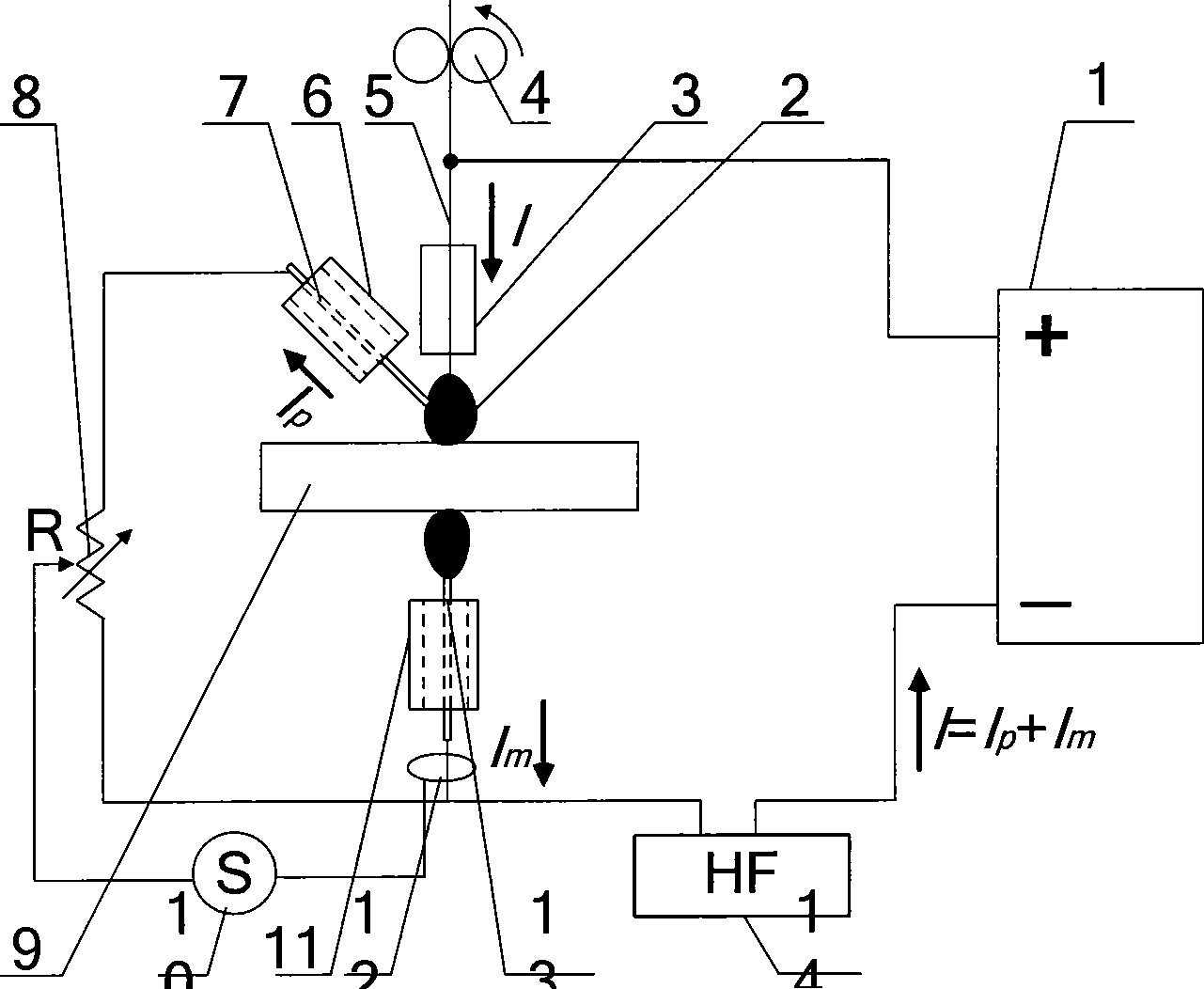

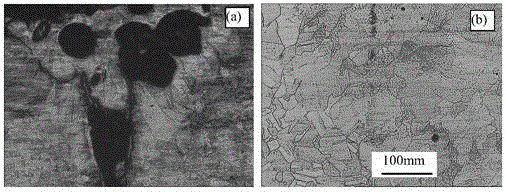

Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

The invention relates to an indirect arc welding device between tungsten electrode and melting electrode and a welding method thereof, belonging to the technical field of material welding device and welding method, which is used to solve the problems in the prior arc welding devices, such as high hot input, low weld joint deposited ratio and high dilution ratio. The two ends of the welding wire are respectively connected with a wire feeder and a melting electrode welding torch, and exposed outside of the conductive mouth of the melting electrode welding torch. The welding wire is connected with a power supply, and the tungsten electrode welding torch and the melting electrode welding torch are connected respectively with the positive and negative electrodes of GTAW, and the axial point of the two welding torches is on the top of the weldment to be welded, and two protection gas cylinders are connected respectively with the protection gas inlets. Based on the device to weld in a certain welding process, turning on the arc generating switch, and using arc only generated between the tungsten electrode and melting electrode to quickly heat to melt the welding wire, and the droplet of the melted welding wire with heat heats the device indirectly and welds. The welding method has the advantages that the weld joint deposited ratio is increased up to 50g / min and the dilution ratio is controlled within 5%.

Owner:HARBIN INST OF TECH

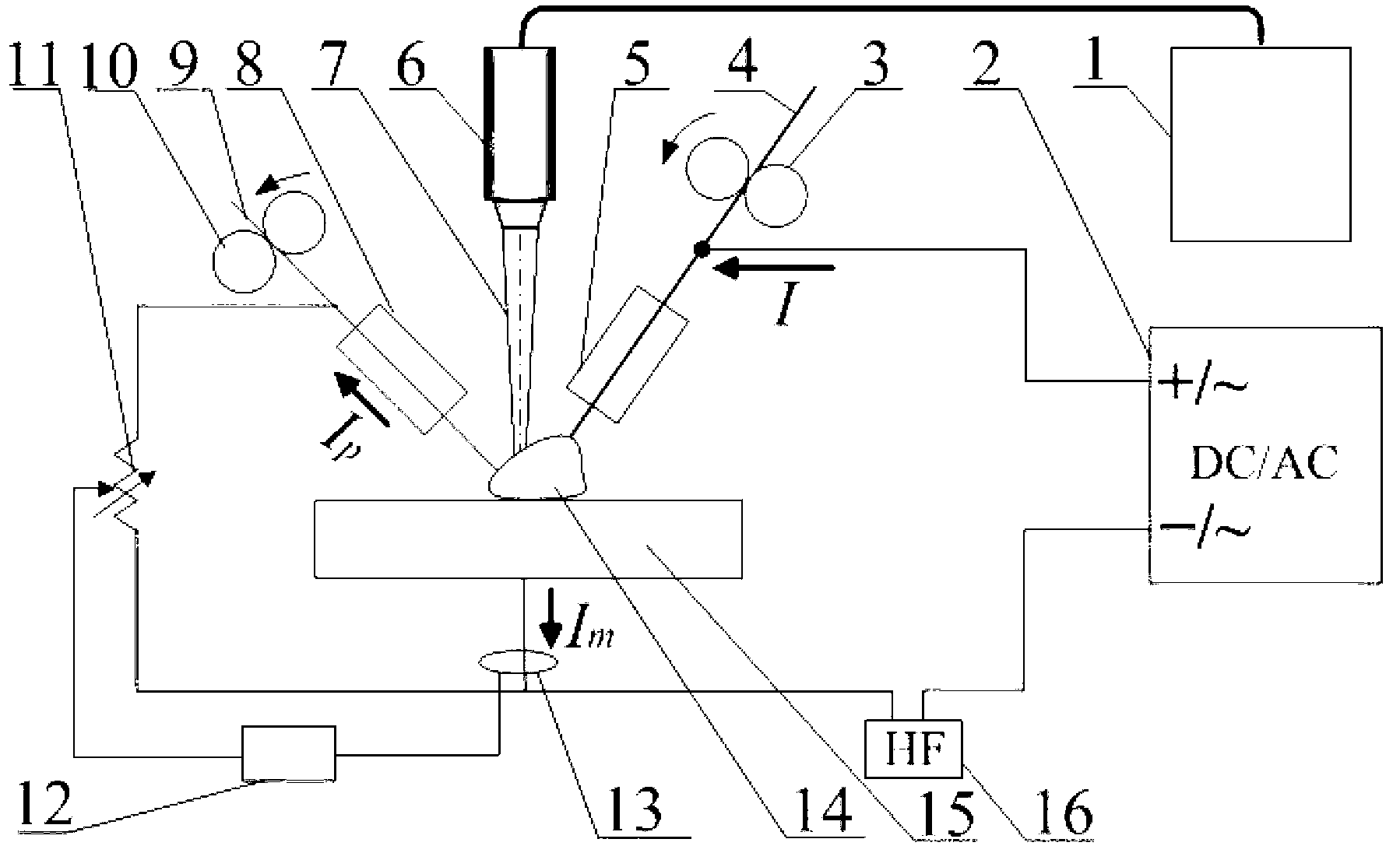

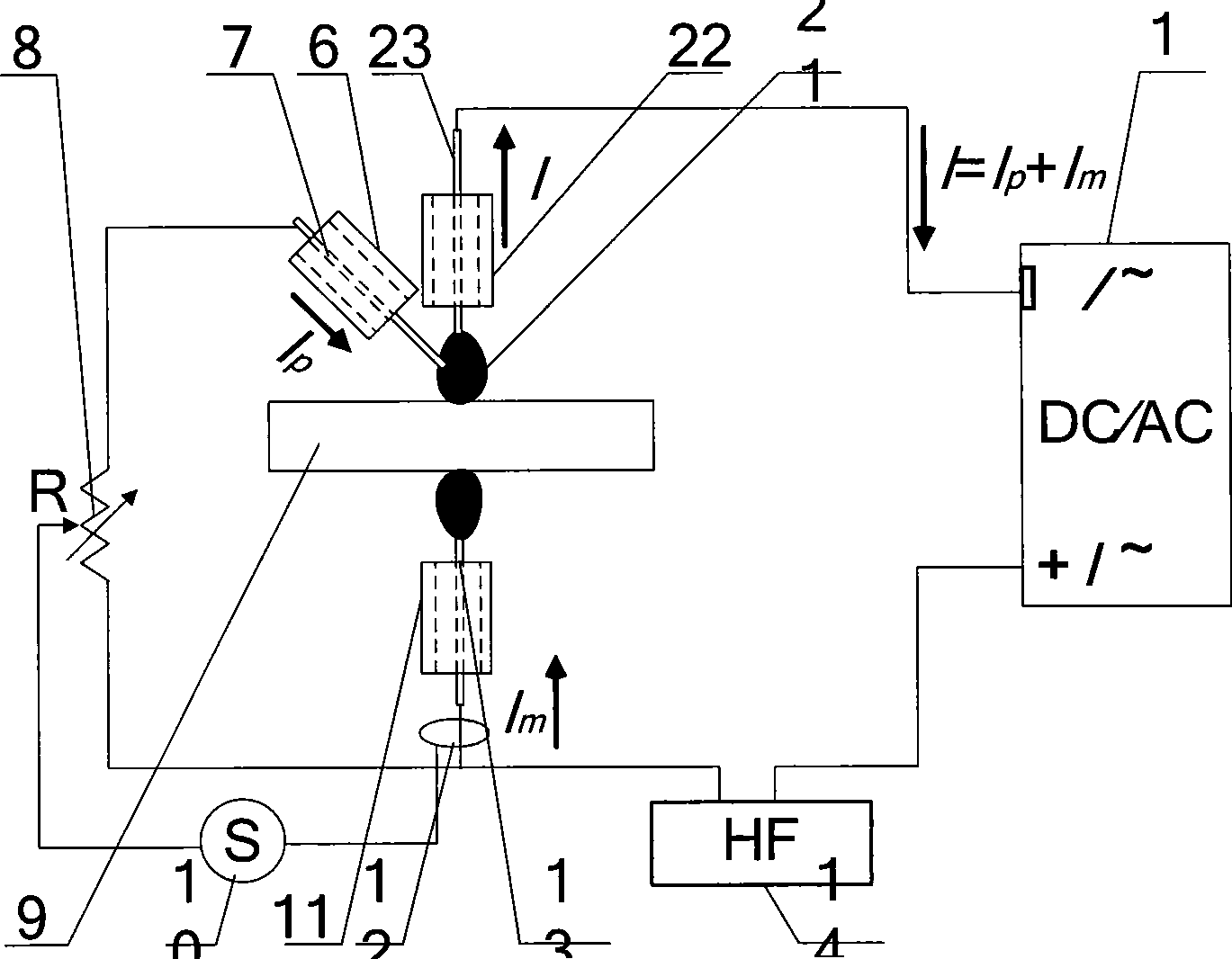

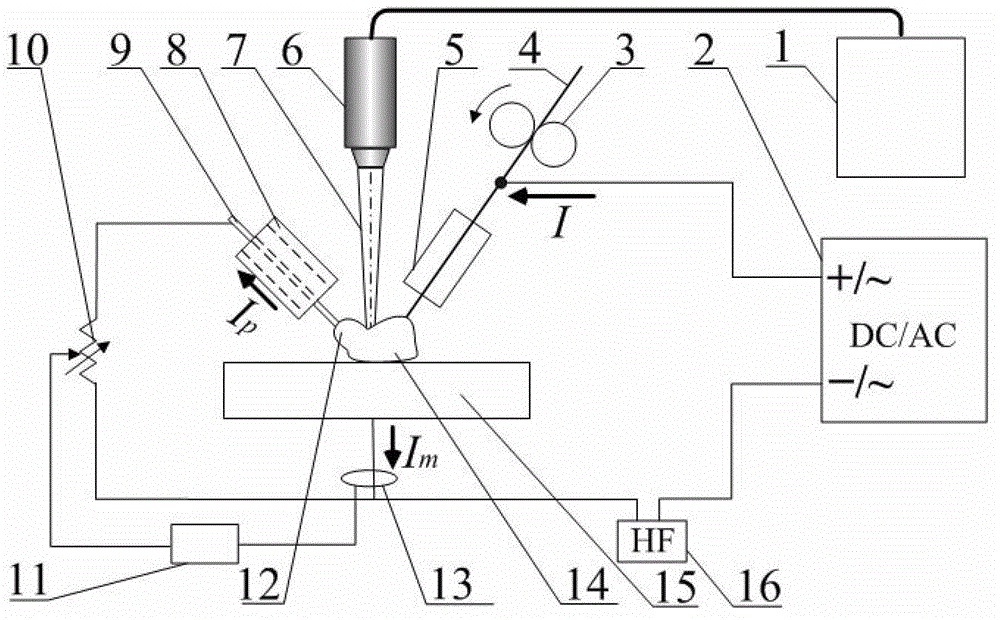

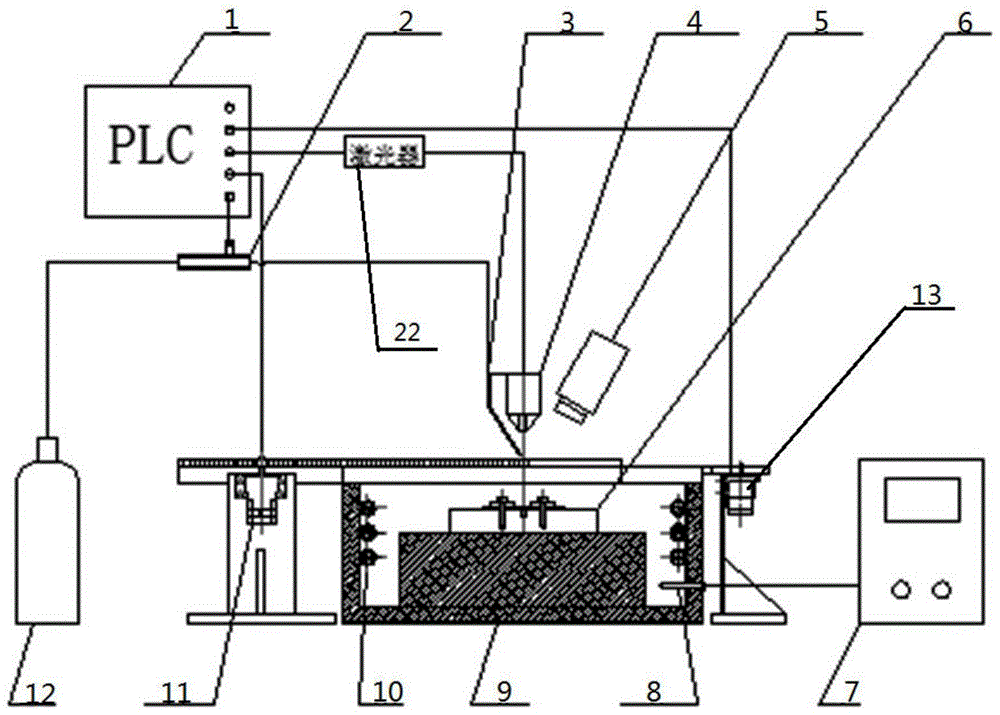

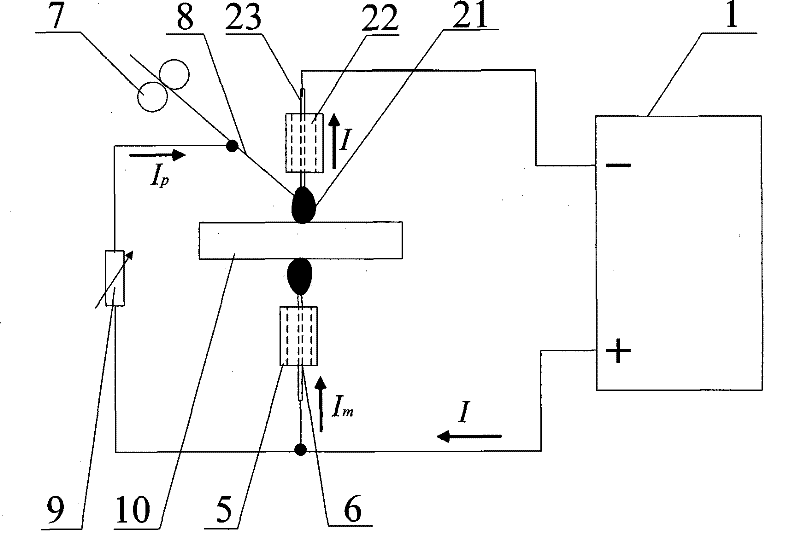

Laser-arc composite welding device based on heat input control and welding method

ActiveCN103071935ALow heat inputReduce thermal deformationLaser beam welding apparatusHeat-affected zoneInput control

The invention provides a laser-arc composite welding device based on heat input control and a welding method. The laser-arc composite welding device based on the heat input control comprises a laser device, a laser head, an arc-welding power supply, a main consumable-electrode welding gun and a wire feeding mechanism and also comprises a bypass welding gun and a rheostat, wherein the laser head is connected with the laser device, the laser head is arranged above a workpiece, the main consumable-electrode welding gun and the bypass welding gun are symmetrically placed at both sides of a laser beam formed by the laser head, the main consumable-electrode welding gun is connected with the positive pole of the arc-welding power supply, the electrifying end of the workpiece is connected with the negative pole of the arc-welding power supply, and the bypass welding gun is connected with the negative pole of the arc-welding power supply by the rheostat. According to the laser-arc composite welding device based on the heat input control and the welding method, the welding heat input of a composite laser-arc heat source can be controlled, the heat affected zone and the welding deformation are reduced, and the metallurgical performance and the microstructure of a welding seam are improved. The laser-arc composite welding device based on the heat input control and the welding method not only are suitable for the fusion welding of homogeneous metal but also are suitable for the braze (fusion) welding of dissimilar metal, such as aluminum or steel and magnesium or steel.

Owner:哈尔滨哈船特装科技发展有限公司

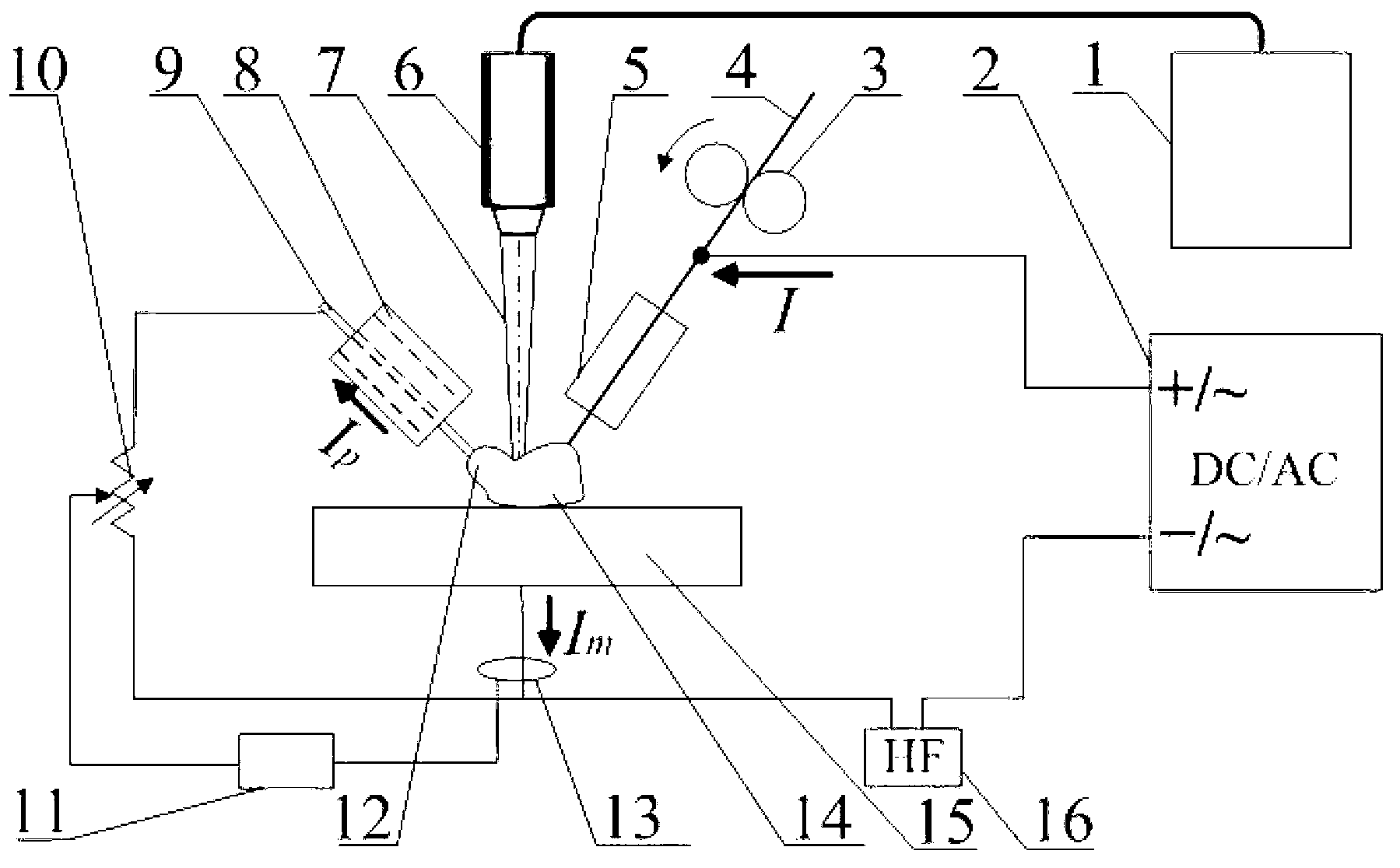

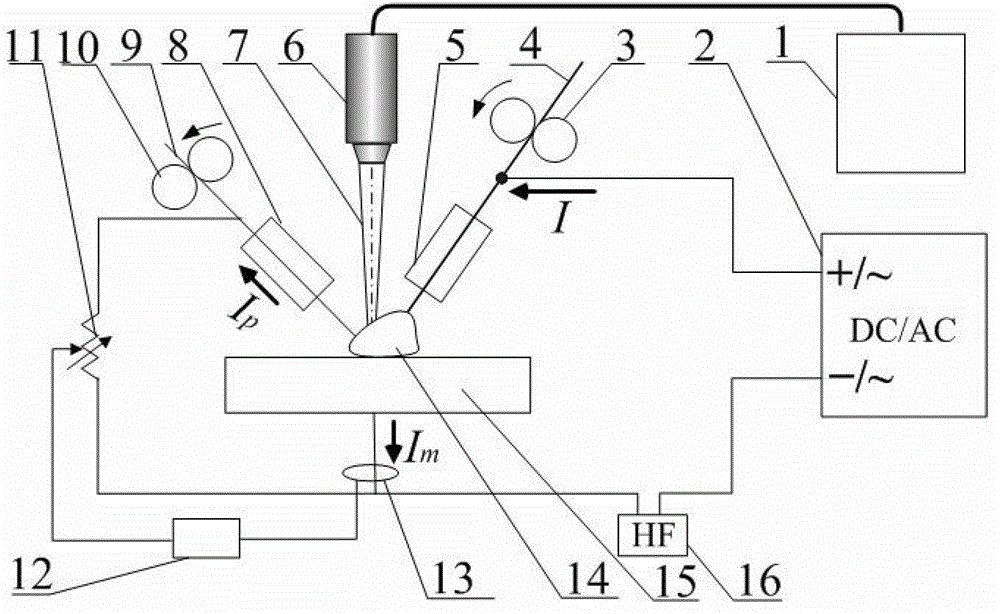

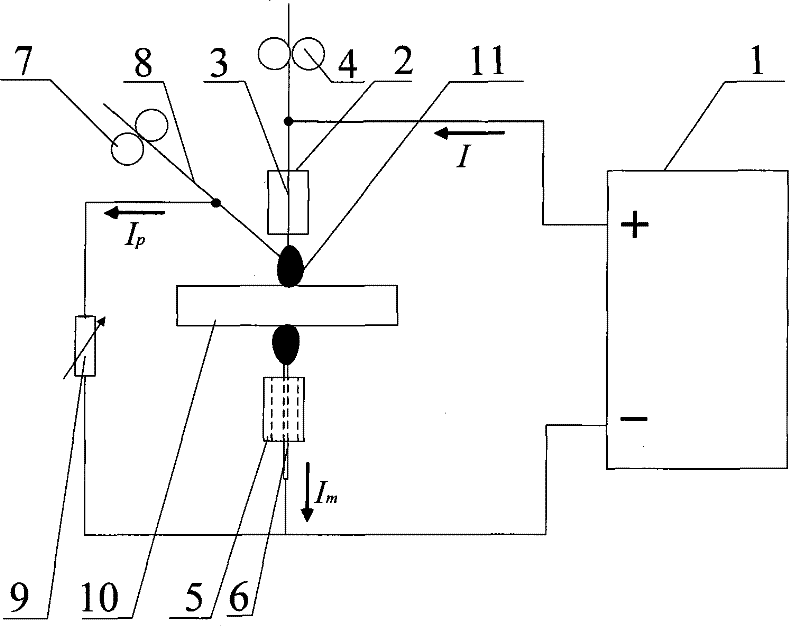

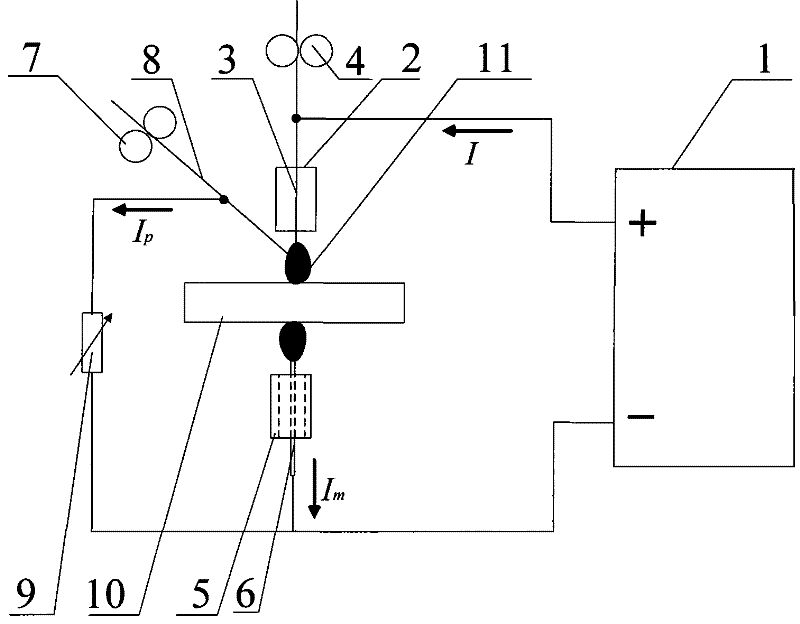

Bypass shunt double-sided arc welding device and welding method

InactiveCN101530943AImprove carrying capacityAchieve high deposition rateArc welding apparatusElectrode erosionWelding power supply

The invention relates to a bypass shunt double-sided arc welding device and a welding method, which is characterized in that the device comprises a welding source, a main welding gun, an auxiliary welding gun, a bypass welding gun, an arc striker, a current sensor, a bypass resistor and a control system, etc. the main welding gun and the auxiliary welding gun are symmetrically arranged at both sides of a workpiece and are connected with two poles of the welding source; the bypass welding gun is argon tungsten-arc welding gun and is applied to one side of the main welding gun as a bypass to shunt partial welding current flowing through mother plates; therefore, the main welding gun can be connected with big current, reduce heat input acting on the mother plates while realizing high deposition efficiency and improve welding quality, while the auxiliary welding gun on the back of a molten pool is only connected with partial current, which is conductive to reducing electrode erosion and improving bearing capacity of the molten pool. As tungsten electrode electronic work function of the bypass welding gun is far lower than that of a metal workpiece, by the method, limit of welding wire shunt can be overcome and bypass current can be conveniently adjusted so as to ensure heat and force acting on the arc and molten pool are at ideal levels, therefore, the welding method is efficient and controllable.

Owner:HARBIN ENG UNIV

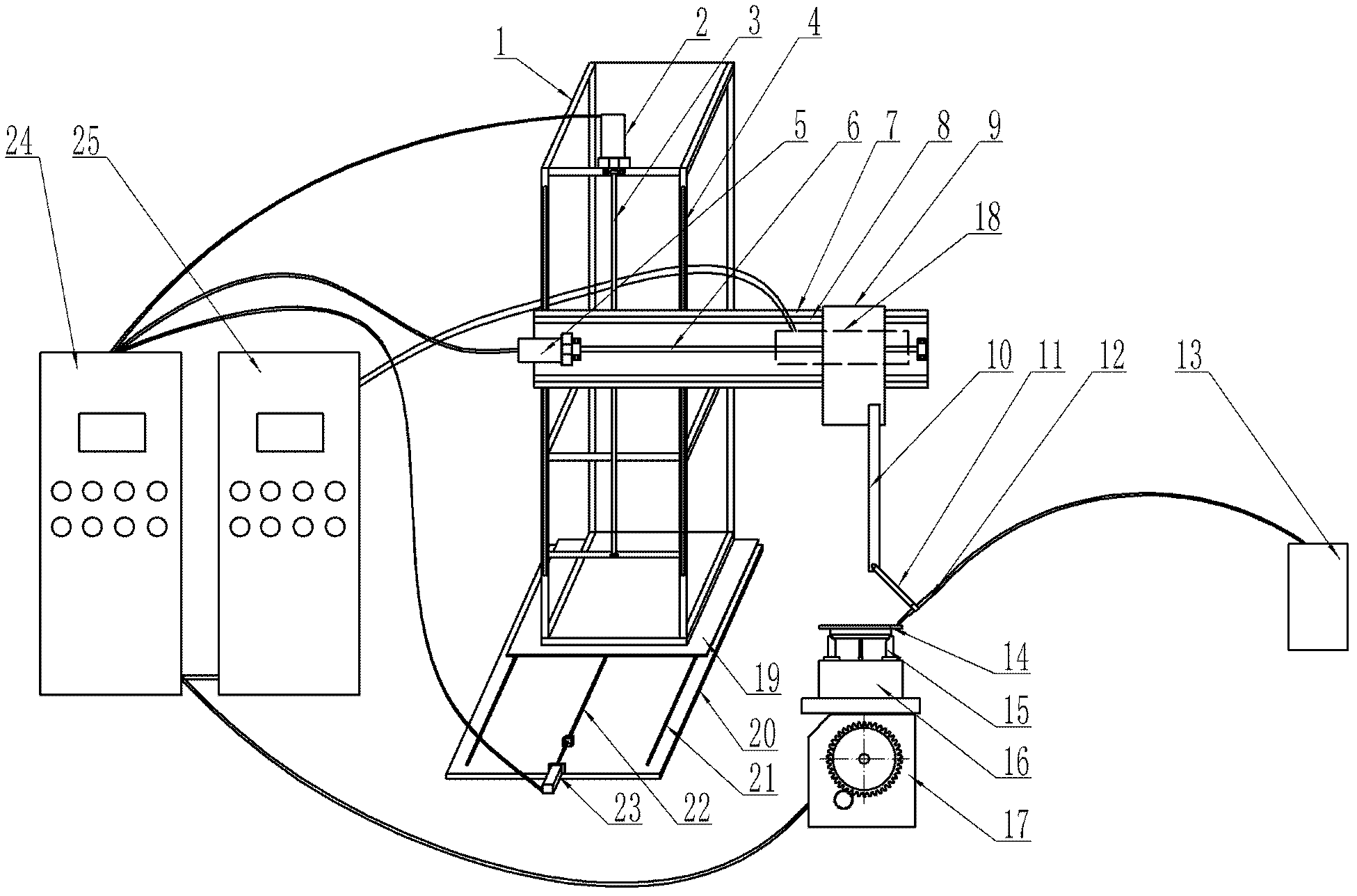

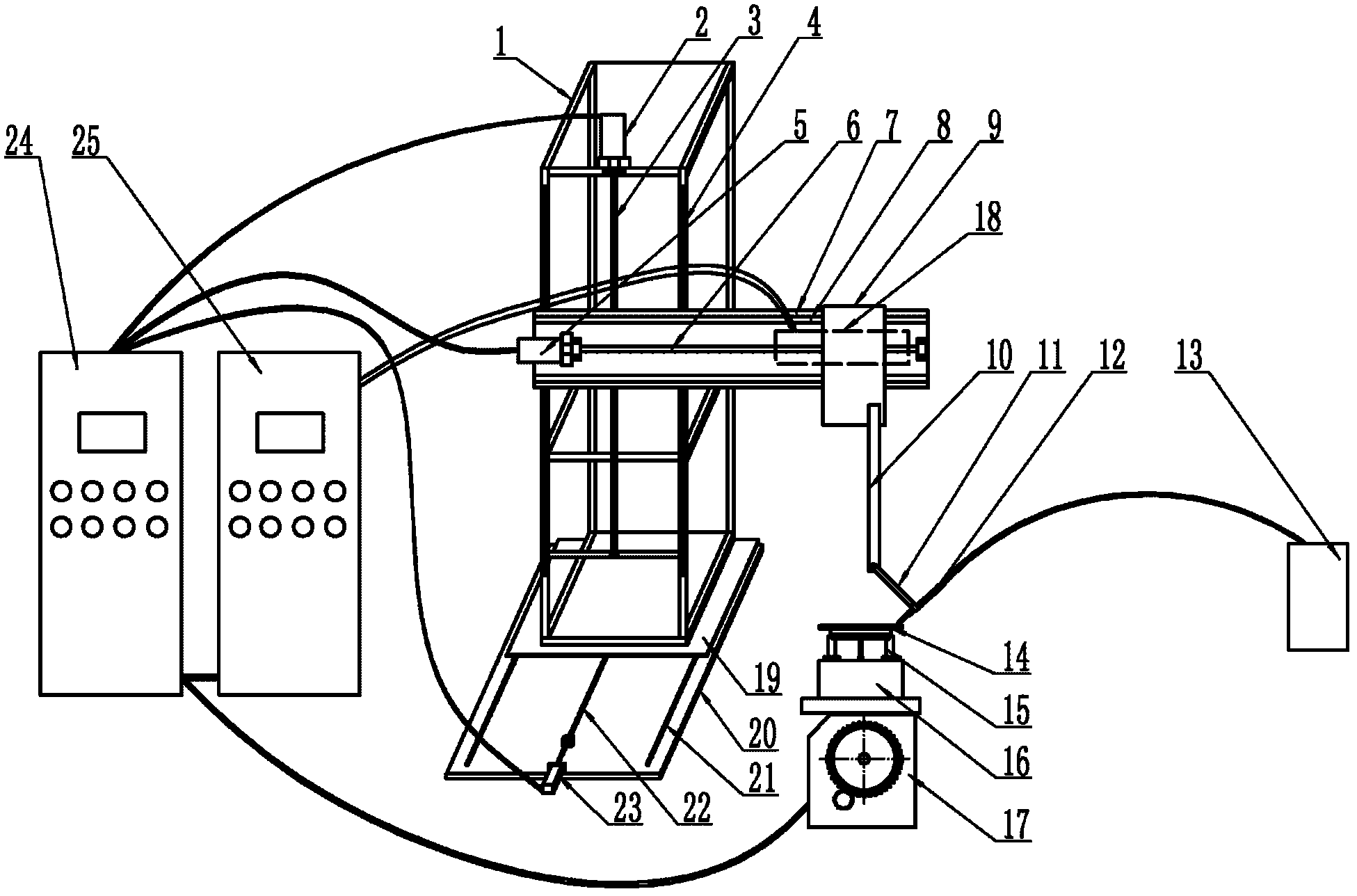

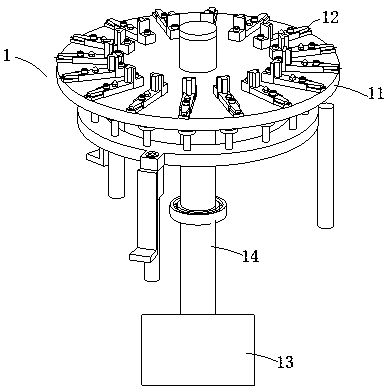

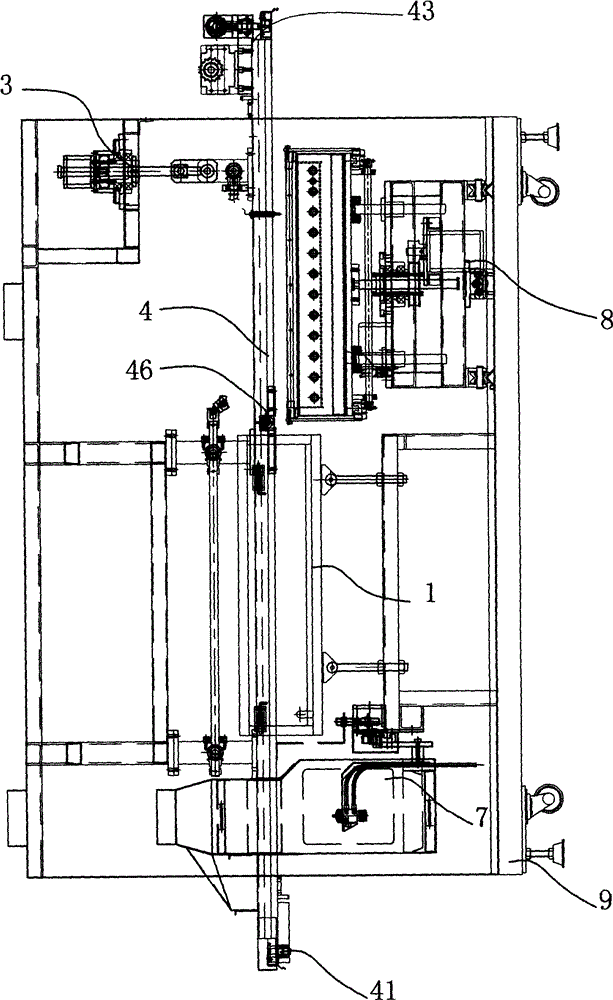

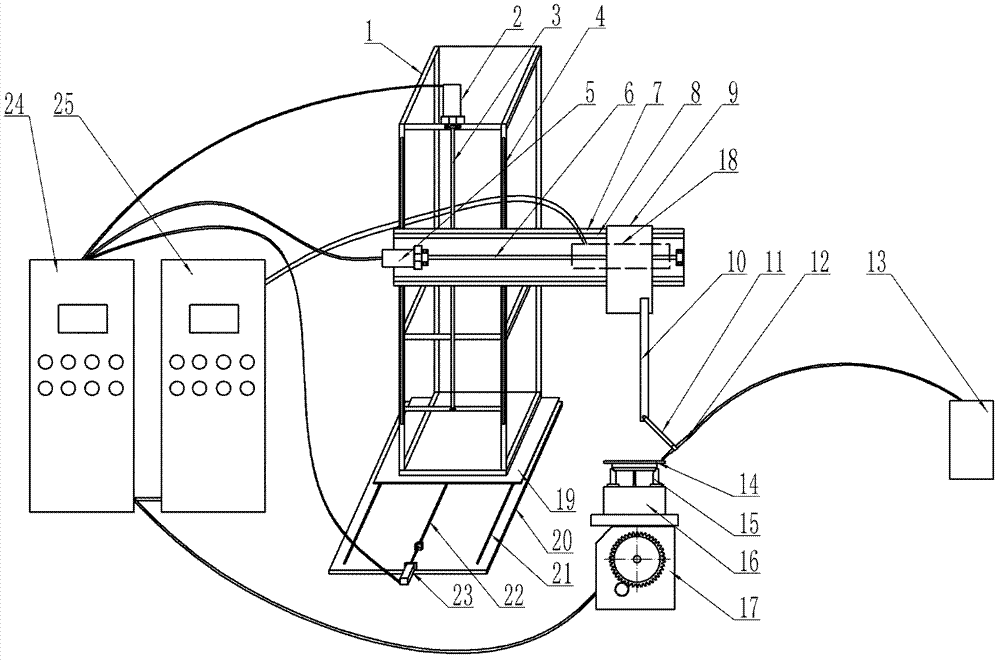

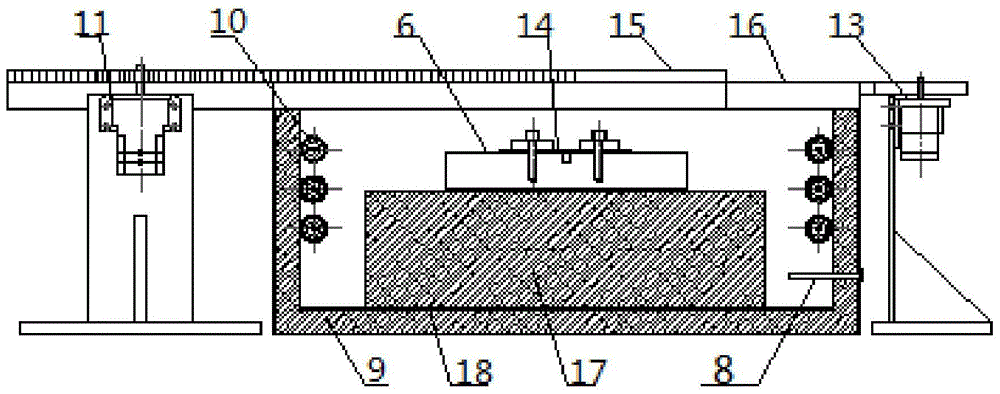

Full-automatic build-up welding machine

InactiveCN102350565APrecise Positioning WeldingImprove wear resistanceArc welding apparatusEngineeringTechnical performance

The invention relates to a full-automatic build-up welding machine. The full-automatic build-up welding machine provided by the invention mainly is used for solving the technical problem that the existing surfacing machine cannot finish the one-off integral soldering for three surfaces with a cyclic structure on the same workpiece clamping device. The technical scheme of the build-up welding machine has the main points that a moving framework (1) capable of longitudinally horizontal moving, a horizontal bracket (7) capable of perpendicularly moving and a horizontal sliding bracket (9) capable of transversely horizontal moving along the horizontal bracket (7) form a bracket capable of moving in three directions; a soldering gun bracket (10) is arranged on the horizontal sliding bracket (9); a soldering gun (12) connected with a soldering machine (13) is sheathed on a soldering gun holding device (11); and a positioning changing machine (17) is arranged at a position corresponding to the soldering gun (12). The full-automatic build-up welding machine provided by the invention can continuously weld multiple surfaces of a workpiece once, thereby greatly improving the production efficiency and effectively improving the technical performances of a product. The full-automatic build-up welding machine provided by the invention can be widely applied to various welding processes required to welding the multiple surfaces of the workpiece.

Owner:湘潭大唐焊接材料有限公司

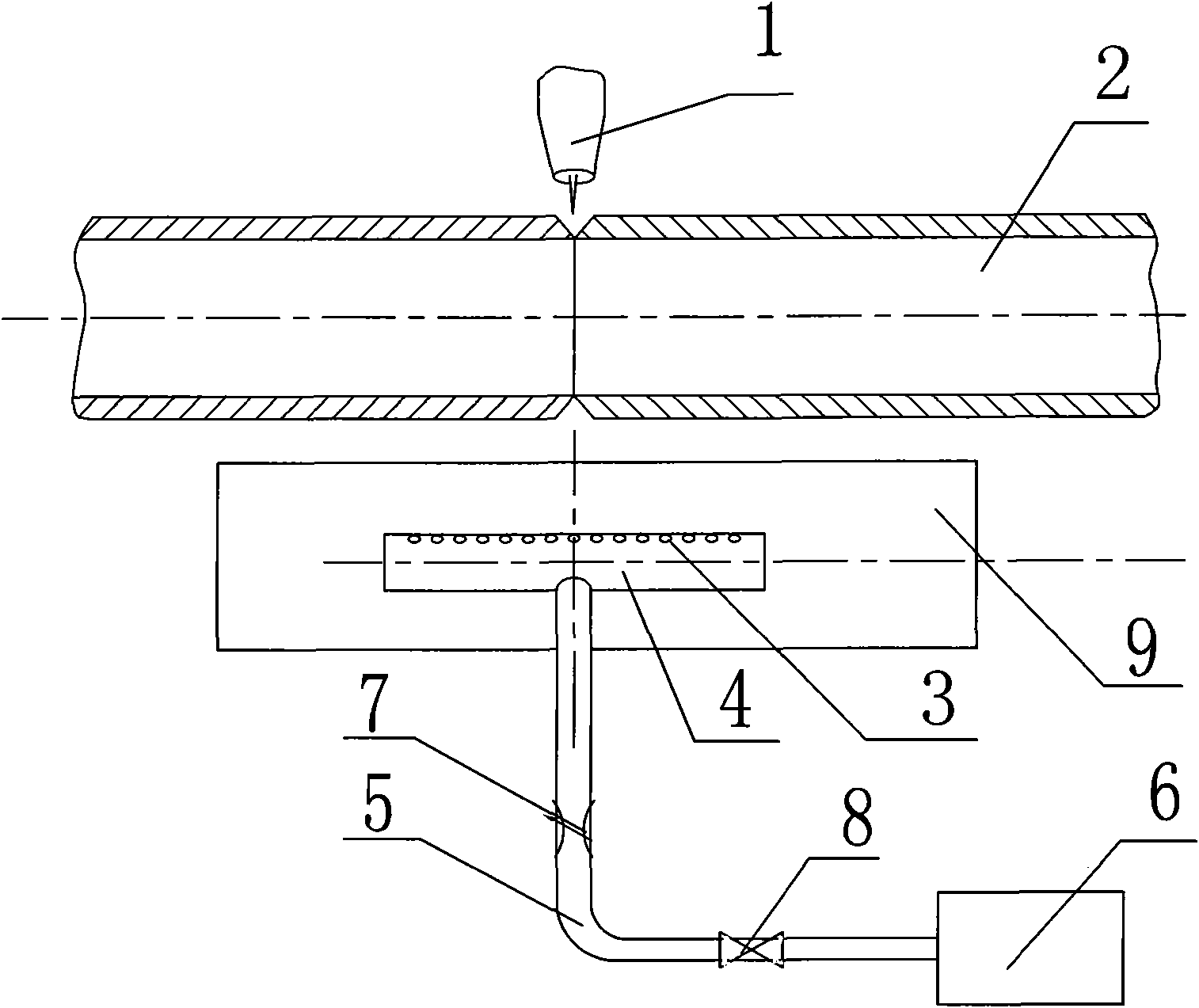

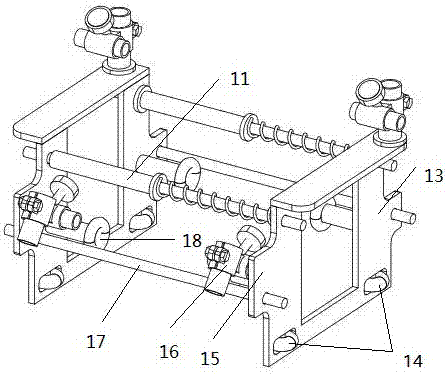

Device and method for water-cooling hot wire argon tungsten-arc welding of austenitic stainless steel tube

ActiveCN102009250ASlow altitude changeStable welding processWelding accessoriesAustenitic stainless steelTungsten

The invention relates to a device and a method for a water-cooling hot wire argon tungsten-arc welding of an austenitic stainless steel tube. If the sensitization and tendency of generating hot cracks are controlled only by reducing welding current and welding voltage and reducing welding hot input, the welding efficiency is reduced, and the welding characteristic of high-efficiency mechanical hot wire argon tungsten-arc welding cannot be fully played. In the method for the water-cooling hot wire argon tungsten-arc welding of the austenitic stainless steel tube, the prewelding preparation is performed first, namely the height and position of a welding gun are adjusted, an austenitic stainless steel straight tube is subjected to butt joint, and the water supply position of cooling water is adjusted; the welding gun and wires of welding equipment are protected by the same gas course; and when welding priming coats and the tube rotate to the position of 270 degrees, a cooling water valve is opened, and a welding joint is subjected to spray cooling by a spraying device until all priming coats, filling layers and covering layers are welded completely. The device and the method are used for the argon arc welding of the austenitic stainless steel tube.

Owner:HARBIN BOILER

Gas protective welding flux cored wire for welding heat resistant steel

ActiveCN102489901ALow diffusible hydrogen contentImprove performanceWelding/cutting media/materialsSoldering mediaFerrosiliconMolten slag

The invention belongs to a gas protective welding flux cored wire for welding heat resistant steel. The gas protective welding flux cored wire comprises low-carbon steel metal skin and a flux core, wherein the low-carbon steel metal skin comprises the following components in percentage by weight: 0.01 to 0.1 percent of C, 0.1 to 0.4 percent of Mn, 0.01 to 0.03 percent of Si, 0.005 to 0.015 percent of S, 0.005 to 0.015 percent of P and the balance of iron; the flux core accounts for 14 to 25 percent of the total weight of the welding wire and comprises the following components in percentage by weight: 1.2 to 3.0 percent of medium-carbon ferromanganese, 0.20 to 2.0 percent of ferrosilicon powder, 0.05 to 0.5 percent of magnesium powder, 1.5 to 2.0 percent of metal chromium powder, 0.2 to 2.0 percent of ferromolybdenum powder, 0.05 to 0.2 percent of electrically fused magnesia, 0.01 to 0.3 percent of fluoride and 7 to 15 percent of iron powder; and the components are mixed uniformly, the mixture is coiled on a thin steel strip made of low-carbon steel to form strips, and the strips are drawn to form wires. The gas protective welding flux cored wire has the characteristics of no molten slag on deposited metal after welding, capability of performing continuous multi-layer welding without slag removal, high welding process property, stable electric arcs, small splatter, attractive appearance of weld joints and the like, the welding efficiency is improved by 20 to 40 percent, and vertical downward welding can be realized by short circuiting transfer.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

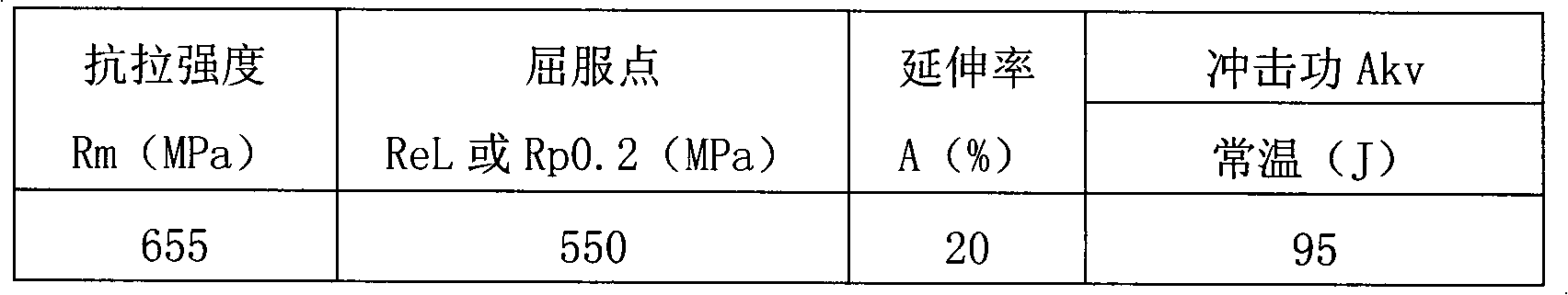

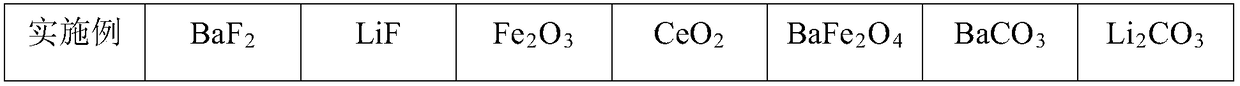

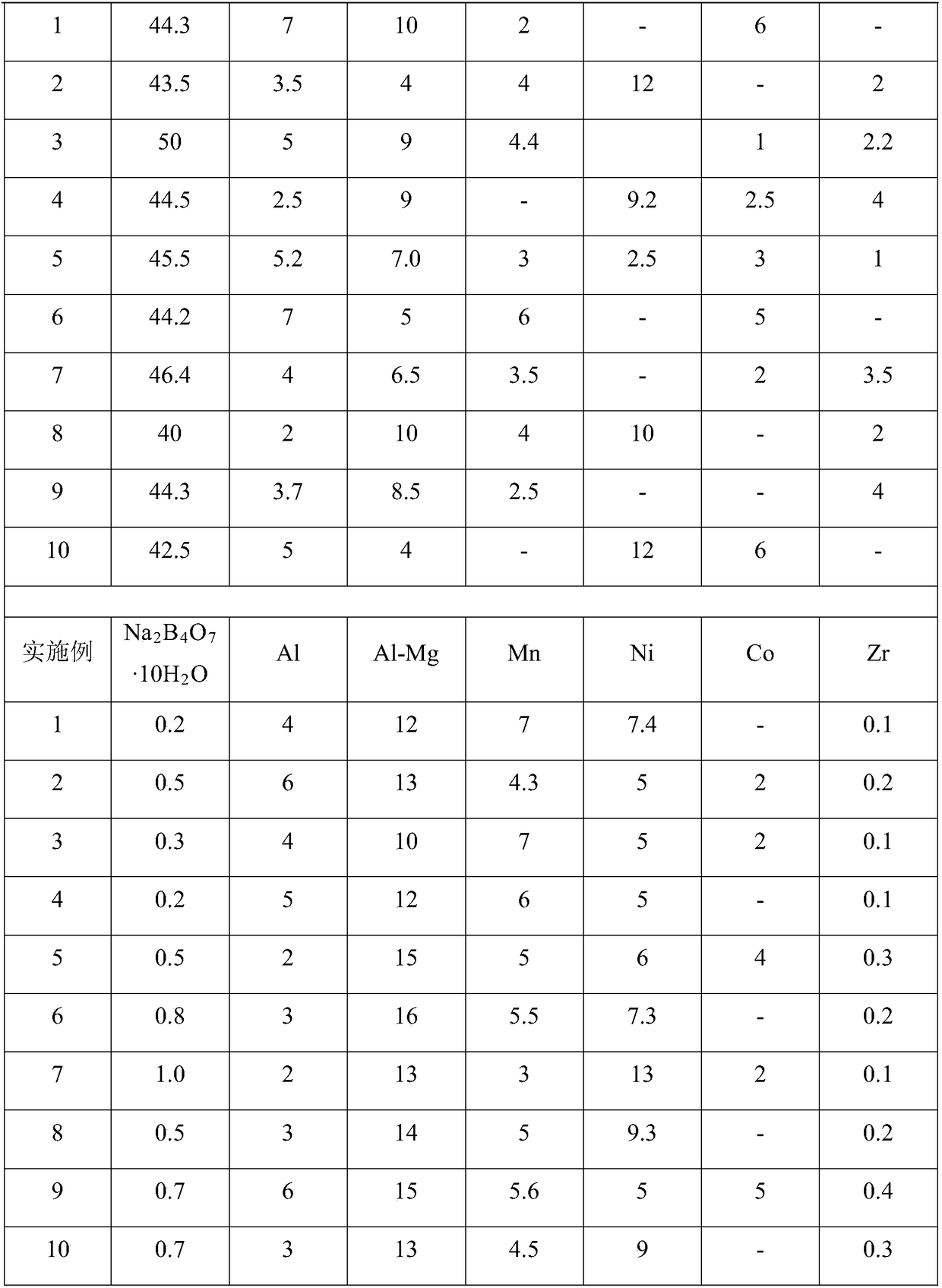

Low-hydrogen high-tenacity self-protection flux-cored wire and preparation method thereof

InactiveCN108544137AIncreased diffusible hydrogen contentPrevent intrusionWelding/cutting media/materialsSoldering mediaManganeseConductor Coil

The invention discloses a low-hydrogen high-tenacity self-protection flux-cored wire and a preparation method thereof and belongs to the field of metal welding materials. The low-hydrogen high-tenacity self-protection flux-cored wire is composed of low-carbon steel steel strip and a flux core, wherein the flux core is composed of the following components in percentage by mass: 45-55% of fluoride,10-20% of oxide, 2-8% of carbonate, 0.2-1.0% of sodium borate, 2-6% of metallic aluminium, 10-16% of aluminium magnesium alloy, 3-7% of metallic manganese, 5-13% of metallic nickel, 0-5% of metallic cobalt and 0.1-0.4% of metallic zirconium, and the sum of the mass percent of the components is 100%. The preparation method comprises the following steps: mixing fluoride, oxide, carbonate and sodiumborate to obtain a mixture, carrying out sintering pretreatment on the mixture, then, adding other raw materials, uniformly mixing to obtain flux core powder, adding the flux core powder in the steelstrip, and carrying out reducing, straightening, disc winding and packaging to obtain the finished product of the welding wire.

Owner:SHENYANG AEROSPACE UNIVERSITY

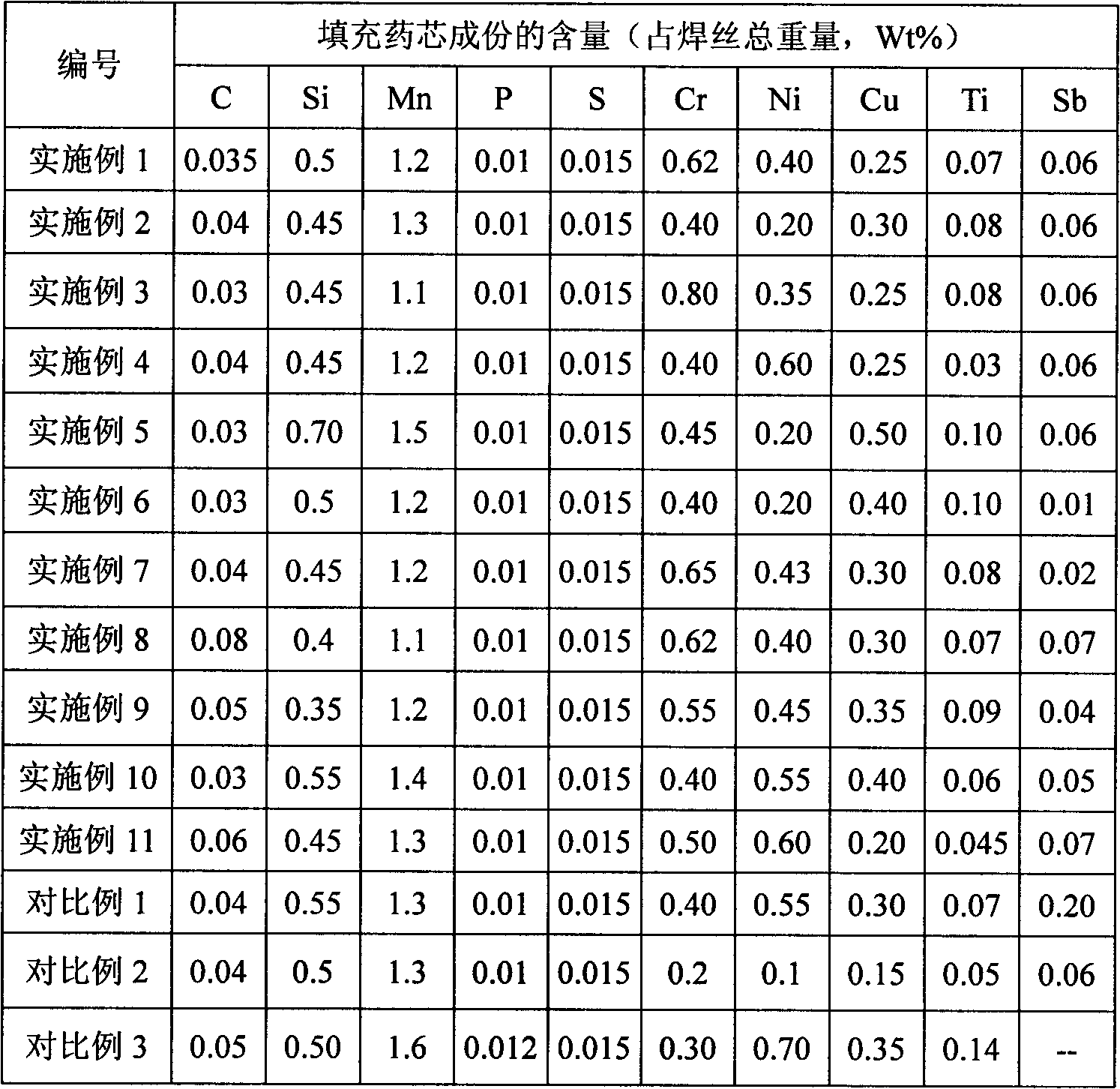

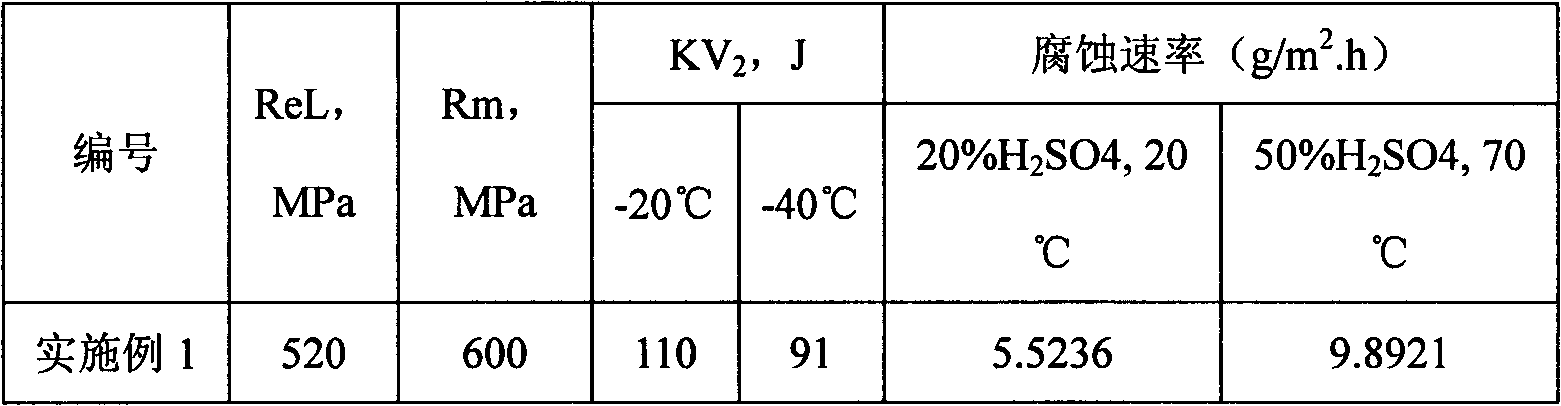

Corrosion-resistant flux-cored welding wire used for gas shielded welding

InactiveCN102825401AGood mechanical propertiesCorrosiveArc welding apparatusWelding/cutting media/materialsAlloyMechanical property

The invention discloses a corrosion-resistant flux-cored welding wire used for gas shielded welding; the flux-cored welding wire is characterized in that the chemical components and content of the alloy powder in percentage by total weight of the wire are as follows: 0.03%-0.08% of C, 0.3%-0.7% of Si, 1.1%-1.5% of Mn, less than or equal to 0.015% of S, less than or equal to 0.02% of P, 0.2%-0.5% of Cu, 0.4%-0.8% of Cr, 0.2%-0.6% of Ni, 0.03%-0.1% of Ti, 0.02%-0.10% of Sb, and the balance of iron and unavoidable impurity; and meanwhile, the ratio of Cu and Sb elements is controlled to be within the range of 4.0-8.0. The wire deposited metal and the welded have excellent mechanical property, the deposited metal has the tensile strength of more than 550MPa and has the impact toughness of more than 60J at (-40) DEG C. The gas shielded welding wire has the combination property of air-corrosion resistance and sulphuric acid dew point corrosion resistance, and meanwhile, the wire is wide in welding parameter adjustment range, stable in welding process and attractive in the formed welding line, so that the wire is beneficial to the all-position welding.

Owner:ANGANG STEEL CO LTD

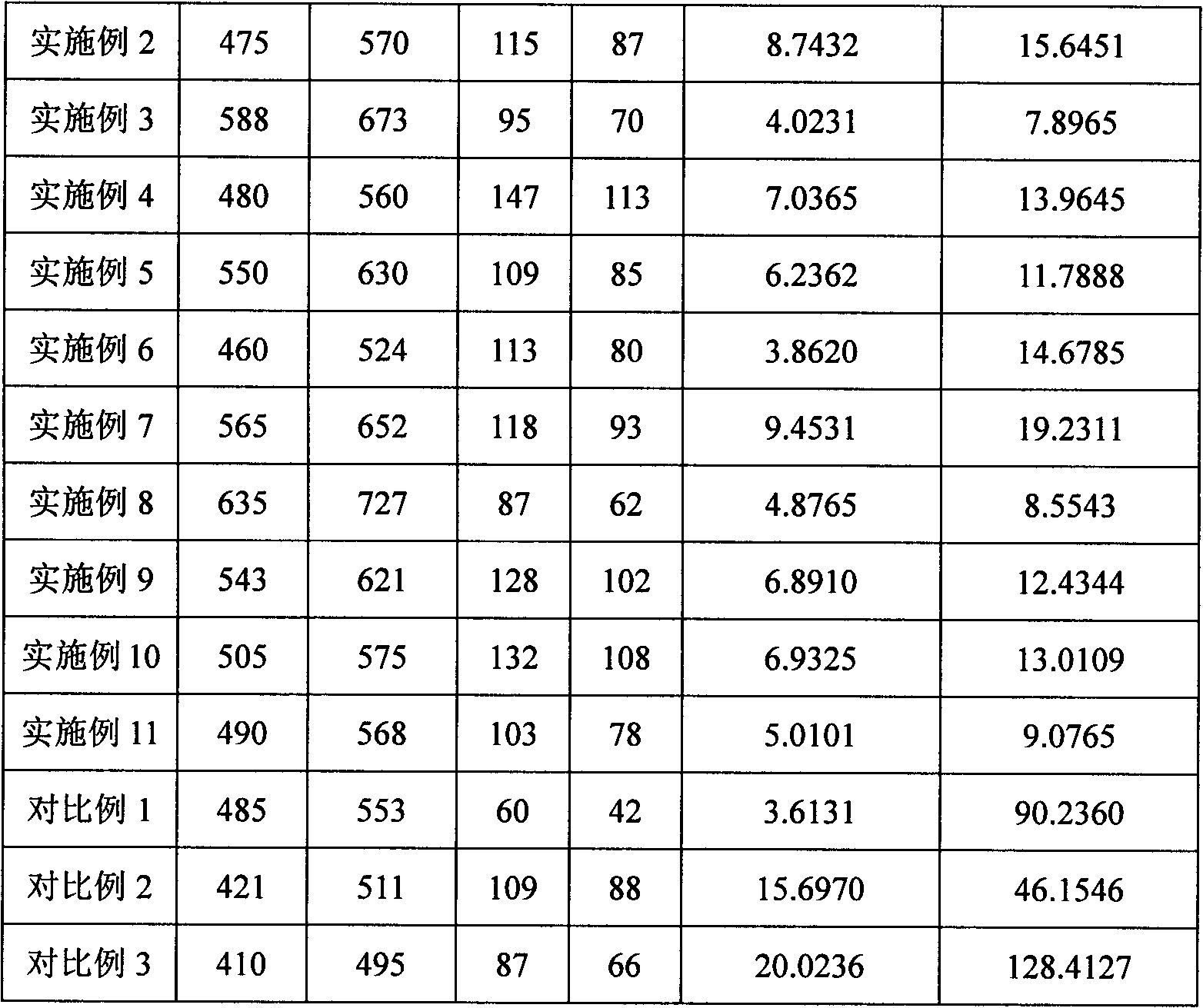

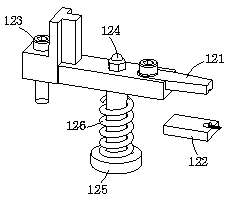

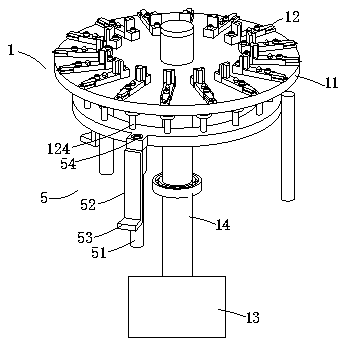

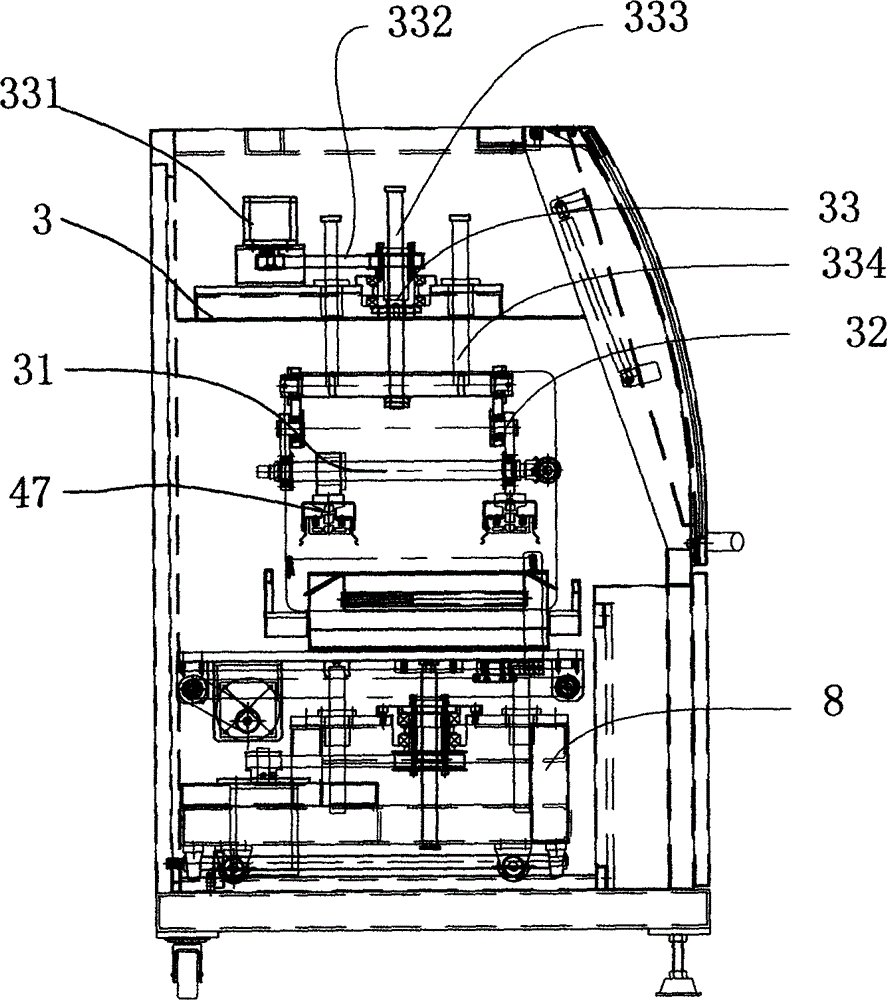

LED lamp strip assembling device

PendingCN107588339AStable welding processImprove welding efficiencyElectric lightingSemiconductor devices for light sourcesEngineeringLED lamp

The invention relates to an LED lamp strip assembling device which comprises a lamp strip assembling turntable device. An LED lamp feeding device, an LED lamp direction testing device, an LED lamp turning device, a poor LED lamp screening device, a pin cutting device, a soldering flux dipping device, a color-ring resistor feeding device, an LED lamp welding device and a resistance measuring deviceare distributed on the circumference of the lamp strip assembling turntable device, it is ensured that a welding process is stably performed and is a lamp clamping cycle process, each lamp clamp performs cyclic work orderly due to the fact that multiple lamp clamps are arranged on a turntable, the LED lamp strip welding efficiency is improved, and the welding precision is also high.

Owner:江西省五洲同芯实业有限公司

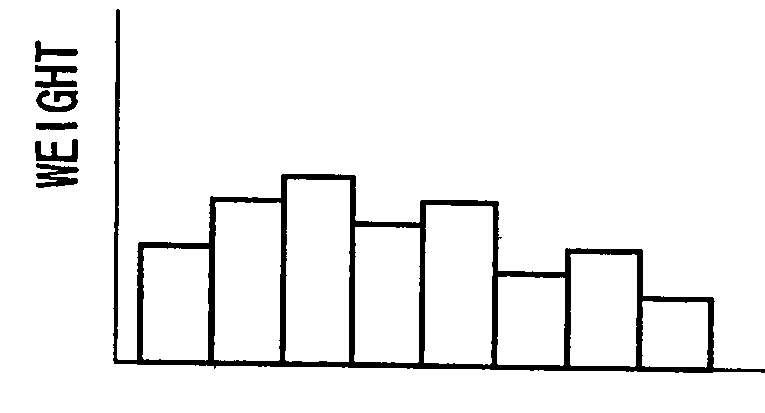

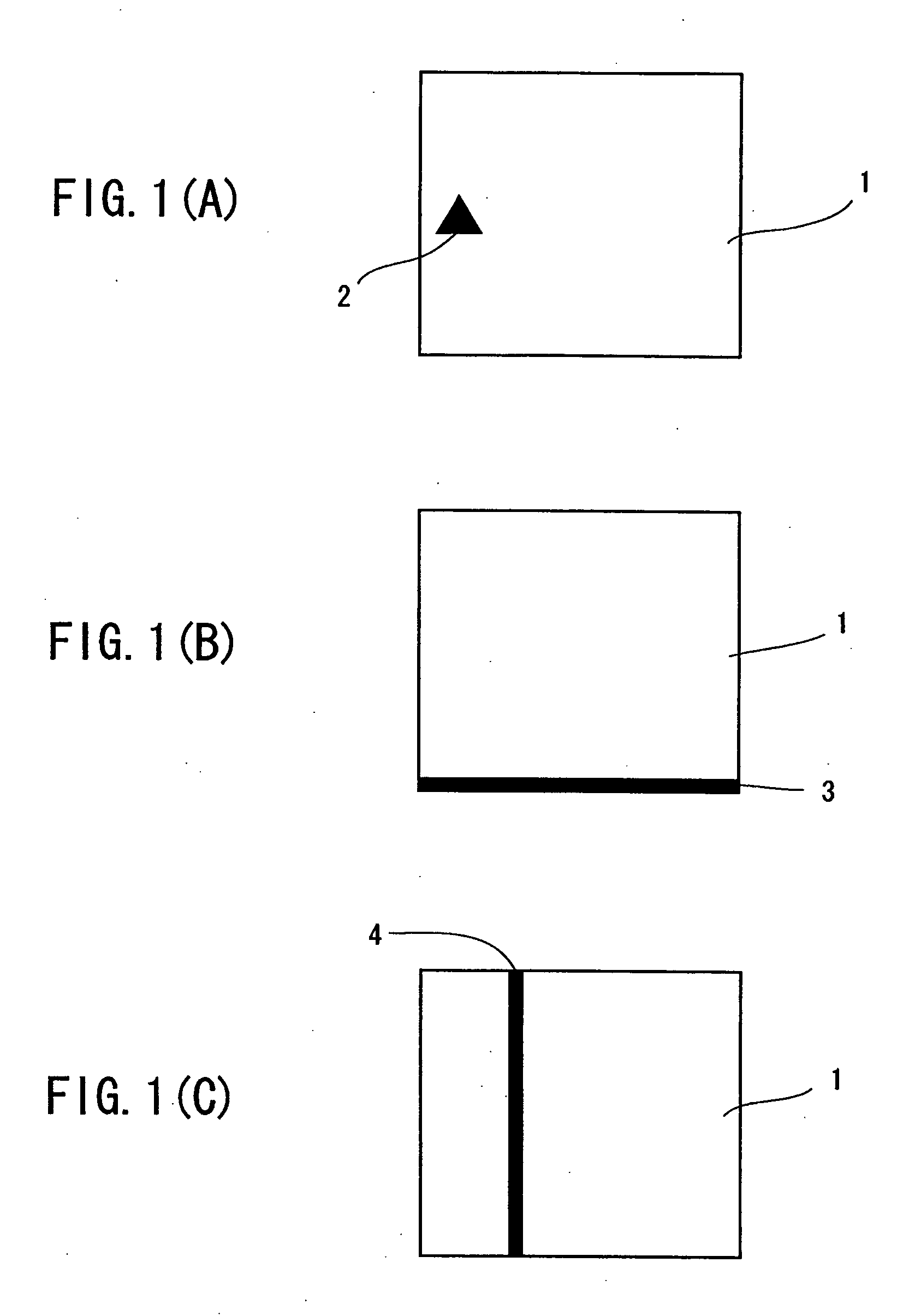

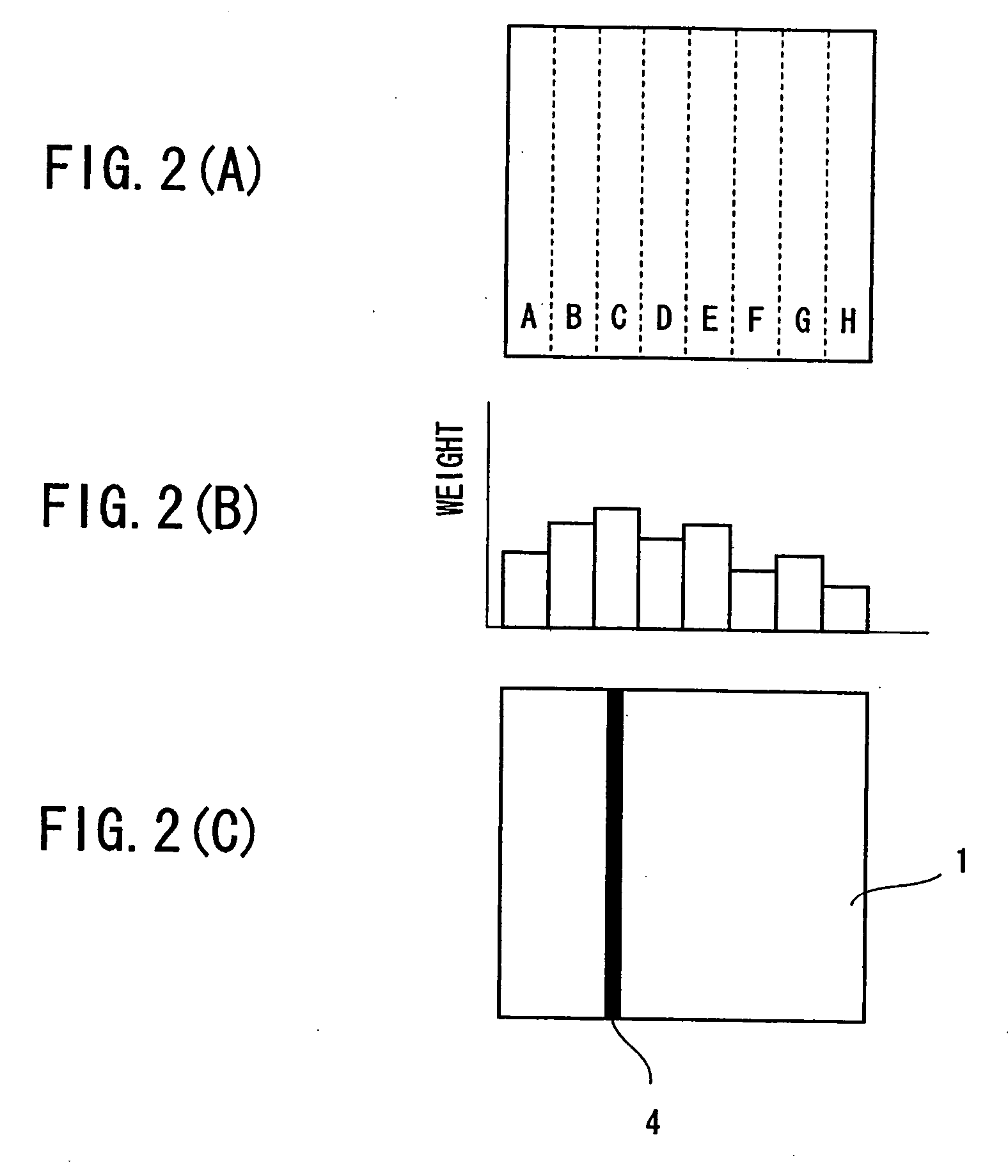

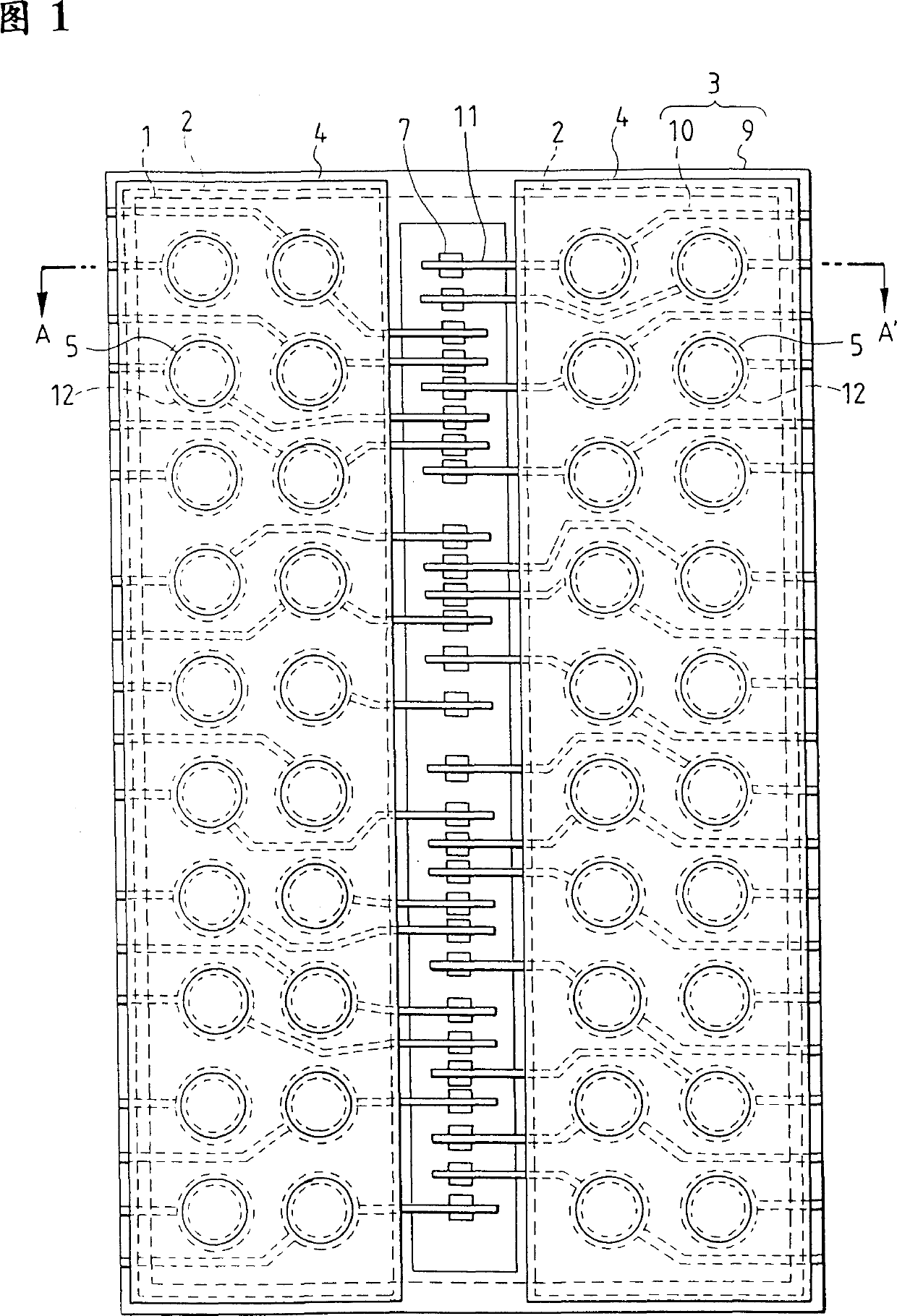

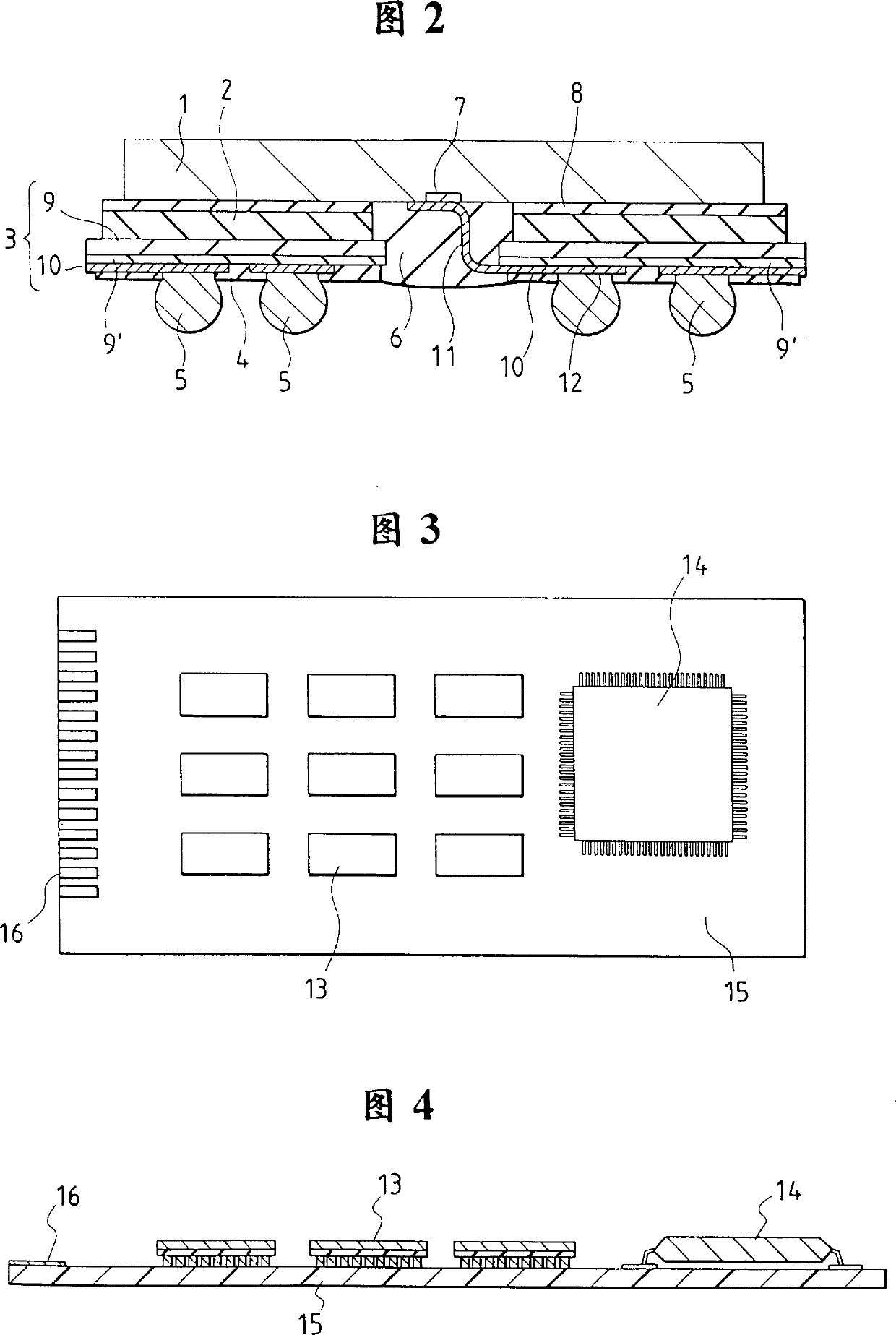

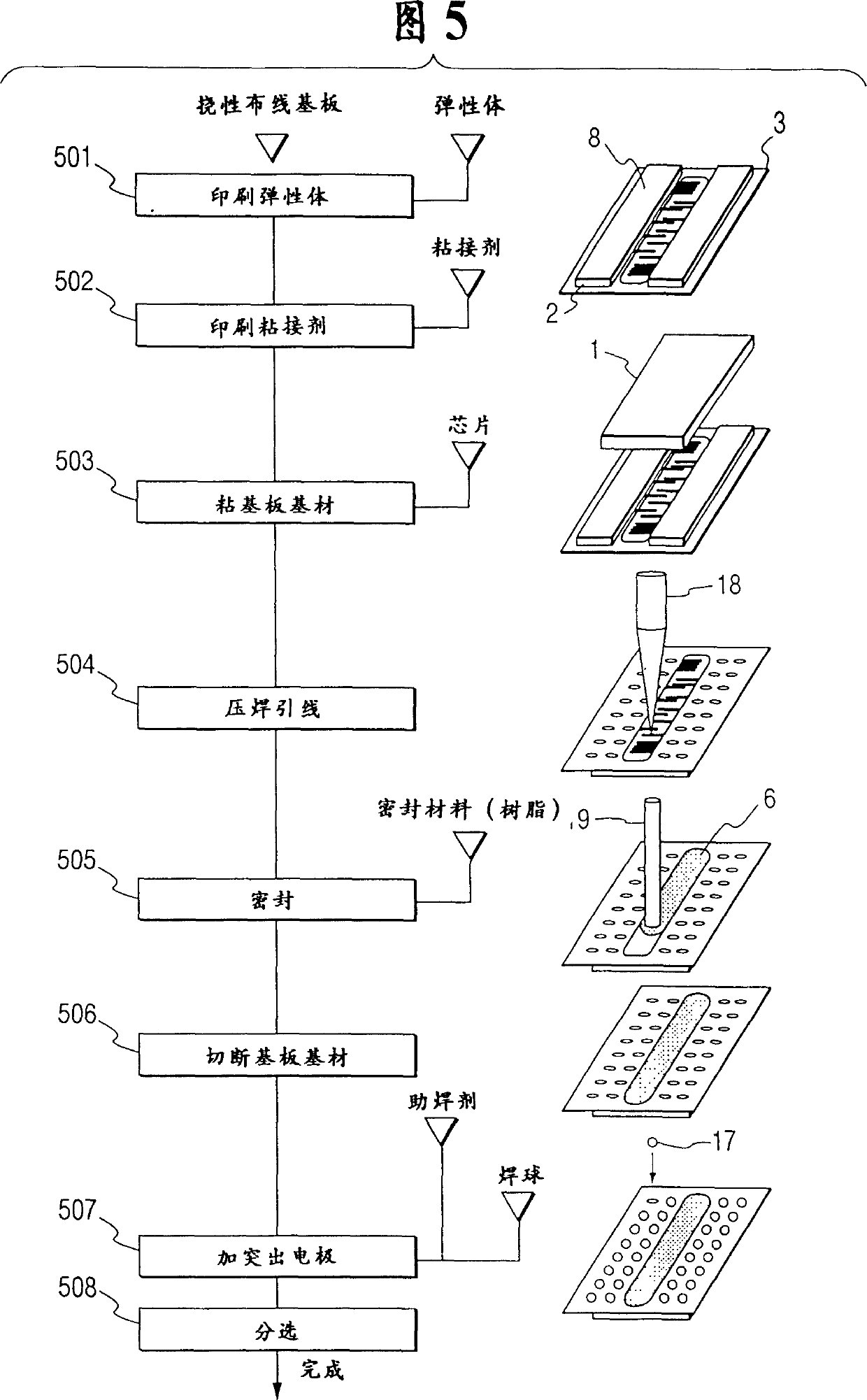

Printed board and method of displaying an identification mark on the same

InactiveUS20050045370A1Stable solder processingStable welding processPrinted circuit assemblingPrinted circuit aspectsWeight distributionSoldering

The invention is intended to provide a printed board wherein a stable soldering processing can be executed on the basis of weight distribution in the printed board, and storage as well as control can be implemented on the basis of the weight distribution, and a method of displaying the identification mark on the printed board. The weight distribution in the printed board is found on the basis of weight information and reference position information, on circuit components to be mounted on the printed board, and mount information on the circuit components. That is, on the basis of the reference position information and the mount information, the coordinates of the center positions of the respective circuit components, on the printed board, are calculated, and weights of the respective circuit components are assigned to the coordinates of center positions of the respective circuit components, thereby finding the weight distribution. Identification marks 2 to 4, indicating heavy parts in terms of the weight distribution, respectively, are displayed on the printed board.

Owner:ORION ELECTRIC CO LTD

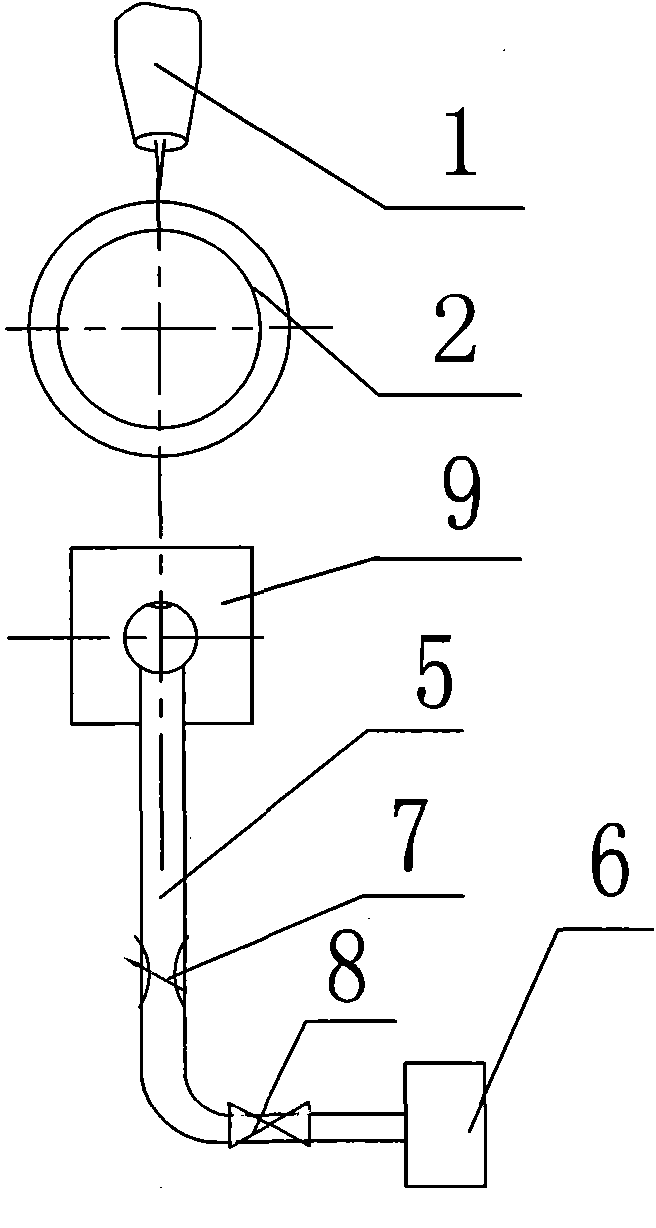

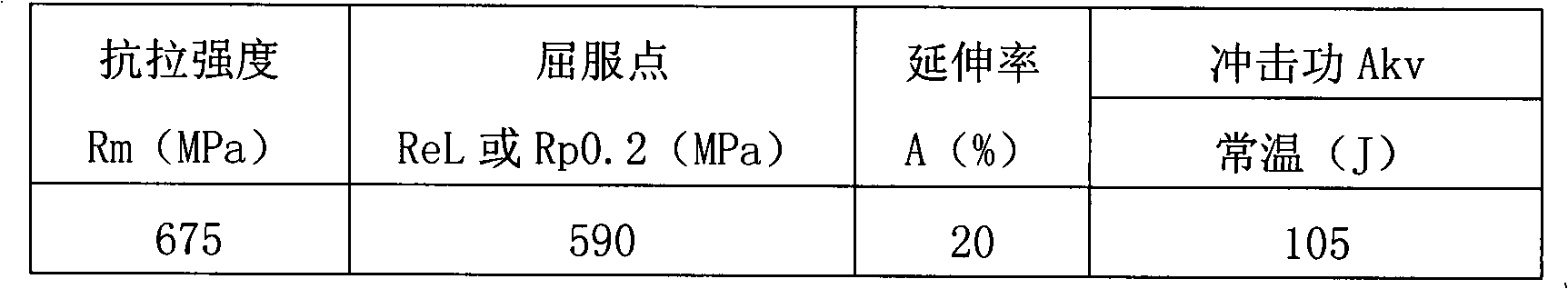

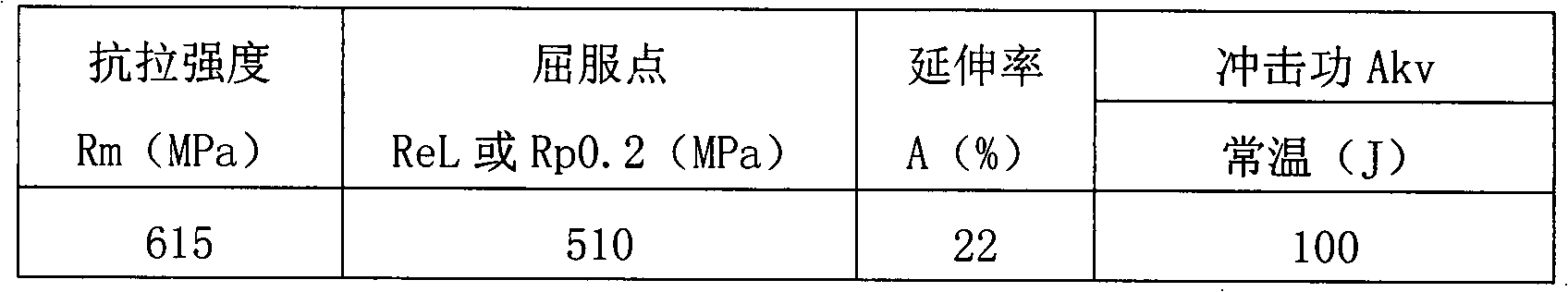

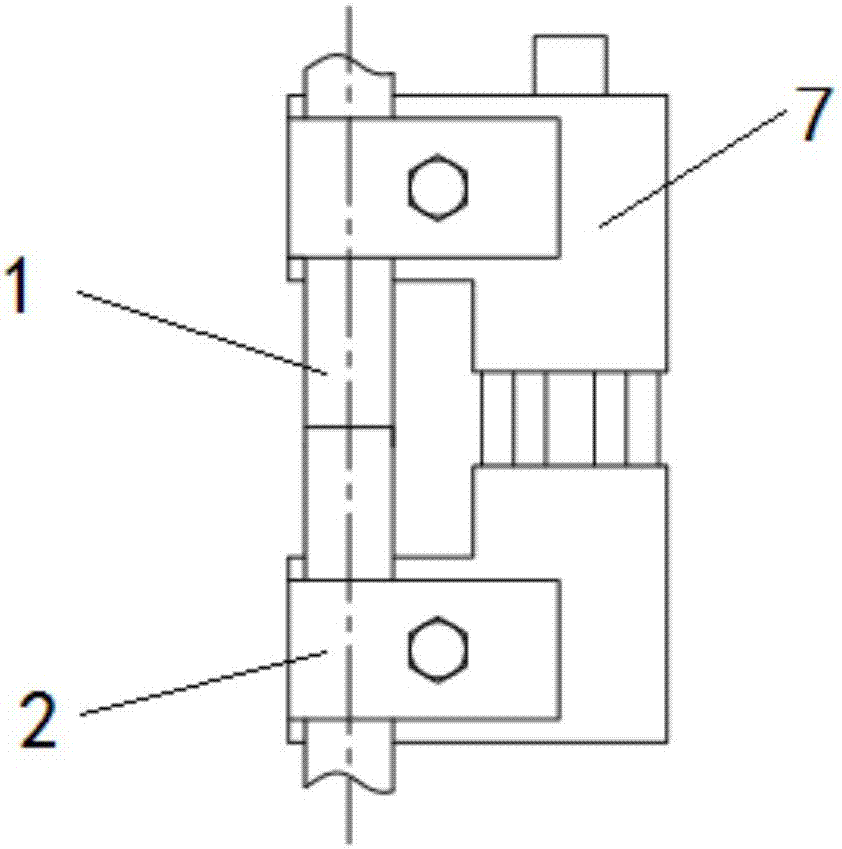

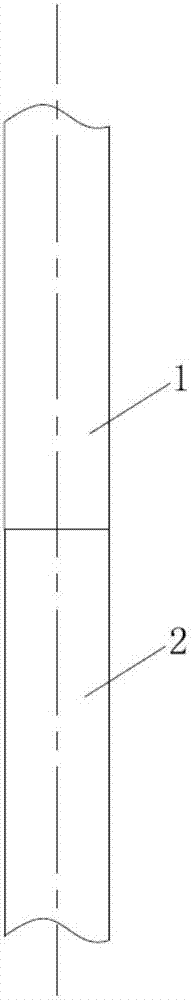

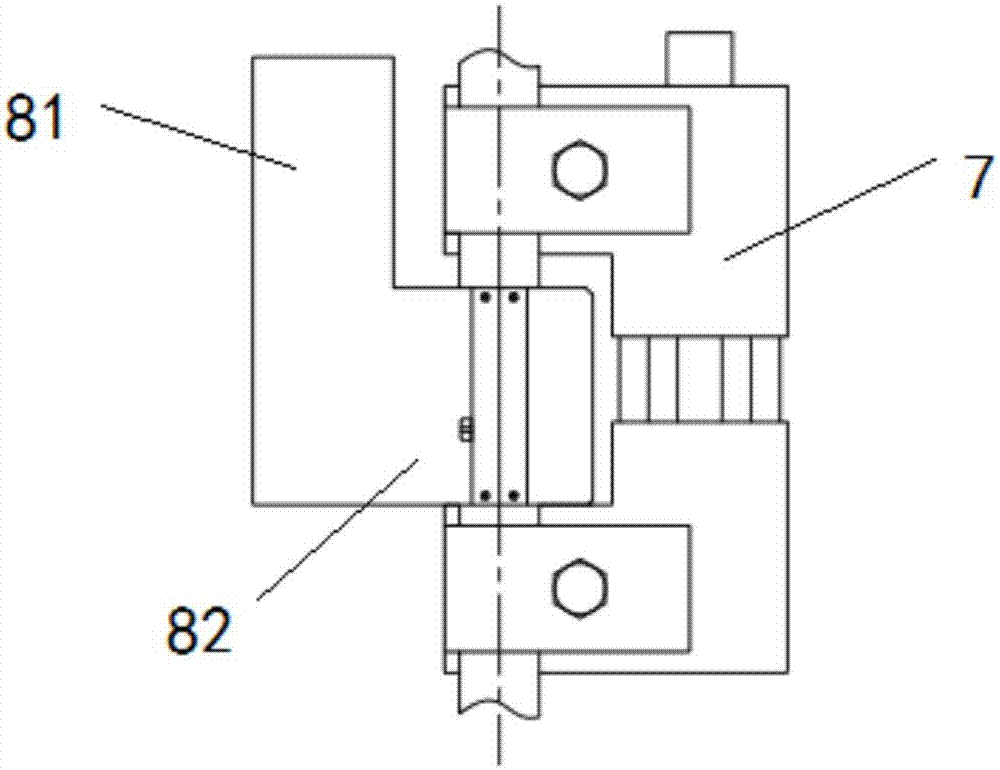

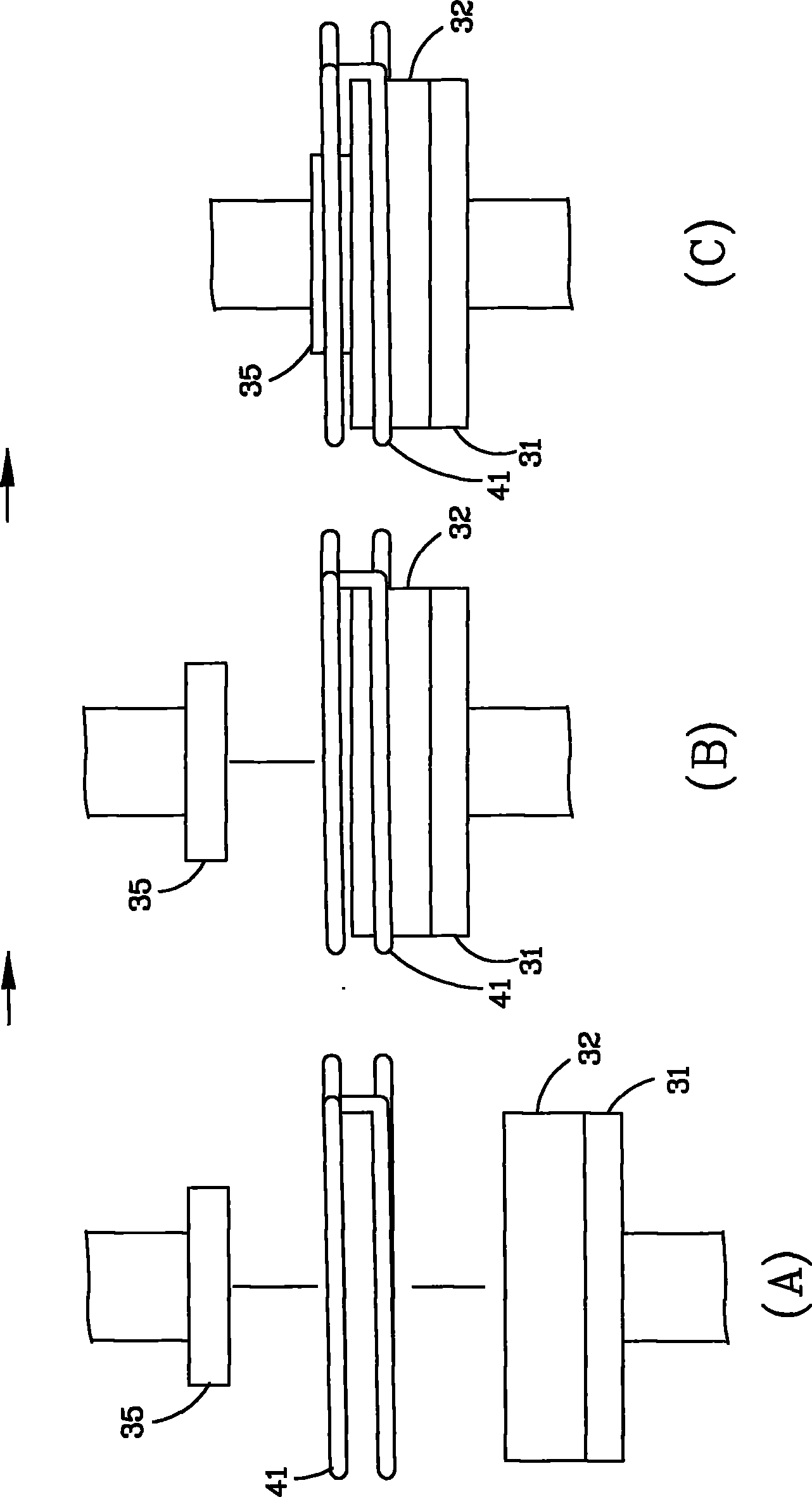

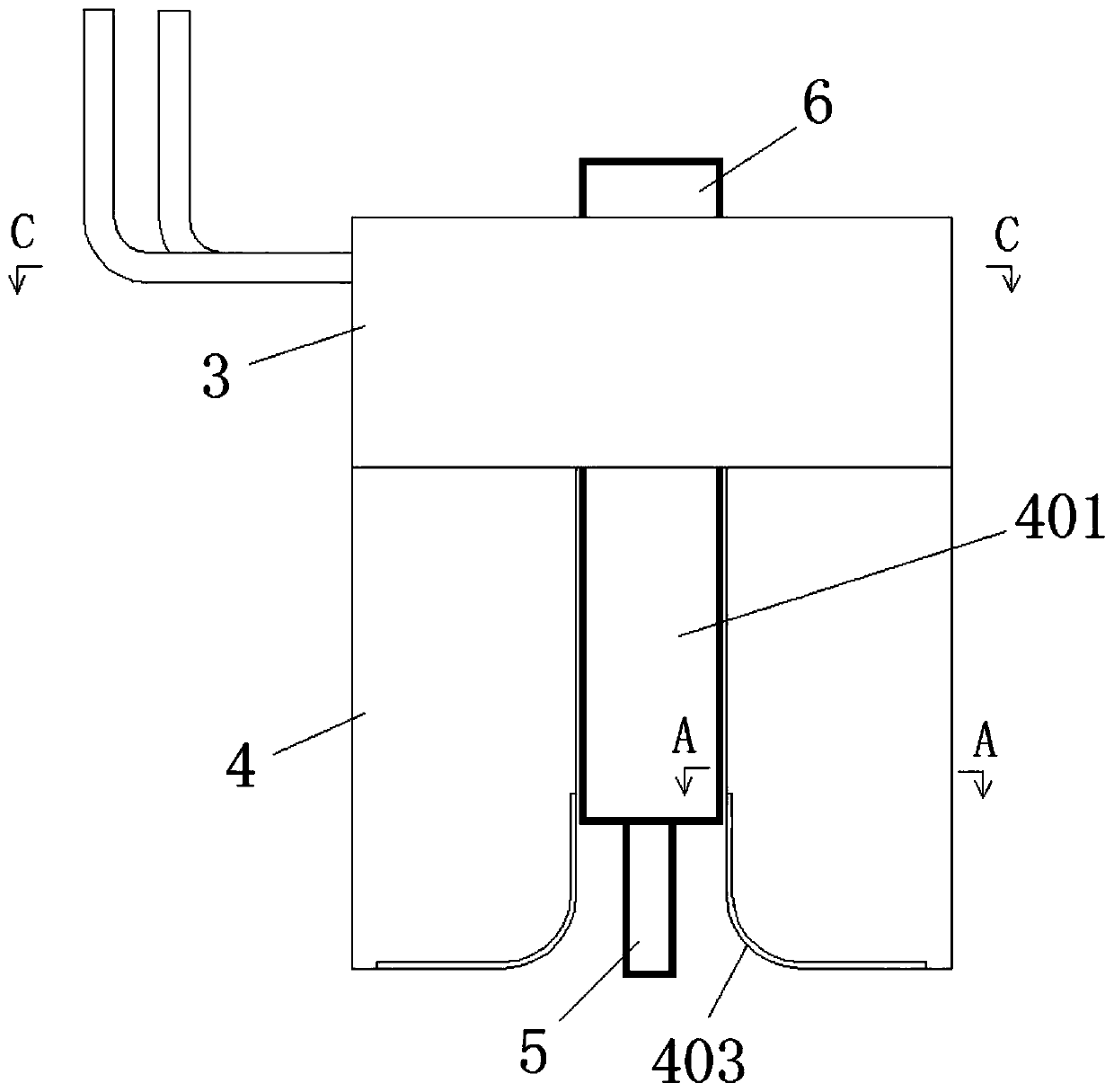

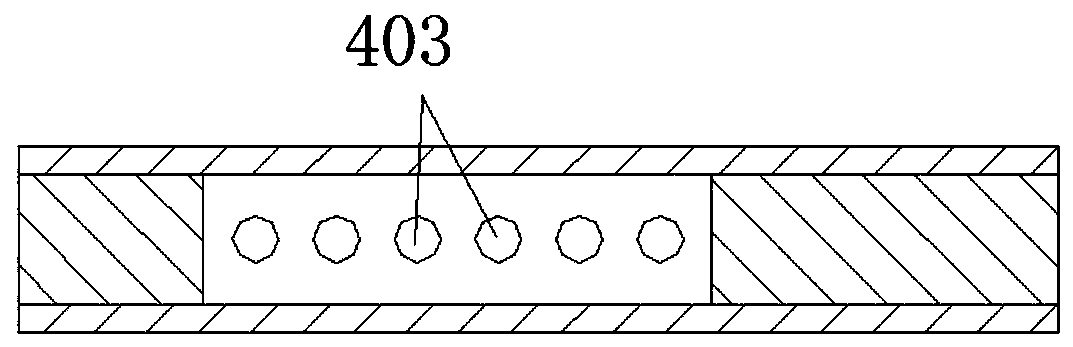

Filling-material-free low-alloy steel heat-exchange pipe butt-joint automatic welding technique

ActiveCN107052536AGuarantee welding qualityFully formedArc welding apparatusWelding/soldering/cutting articlesButt jointFilling materials

The invention provides a low-alloy steel heat-exchange pipe butt-joint automatic welding technique. The technique comprises the following steps that a first heat exchange pipe (1) and a second heat exchange pipe (2) are assembled; welding equipment is mounted and debugged; and welding technological parameters are arranged, and welding treatment is conducted. The low-alloy steel heat-exchange pipe butt-joint automatic welding technique is free of a filling material, a tool (7) is adopted for assembly of the heat exchange pipes, and the coaxial effect is ensured; and a welding machine head and the tool (7) are matched for clamping, and the positions of a tungsten electrode and the heat exchange pipes are controlled; and according to the welding parameters and the operating requirements of the technique, the rotation center of the welding machine head drives the tungsten electrode to rotate to conduct self-melting automatic welding, the welding process is stable, the welding seam quality and welding seam forming can be effectively controlled, and the performance of a heat exchange pipe butt-joint connector meet the requirement of a product.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

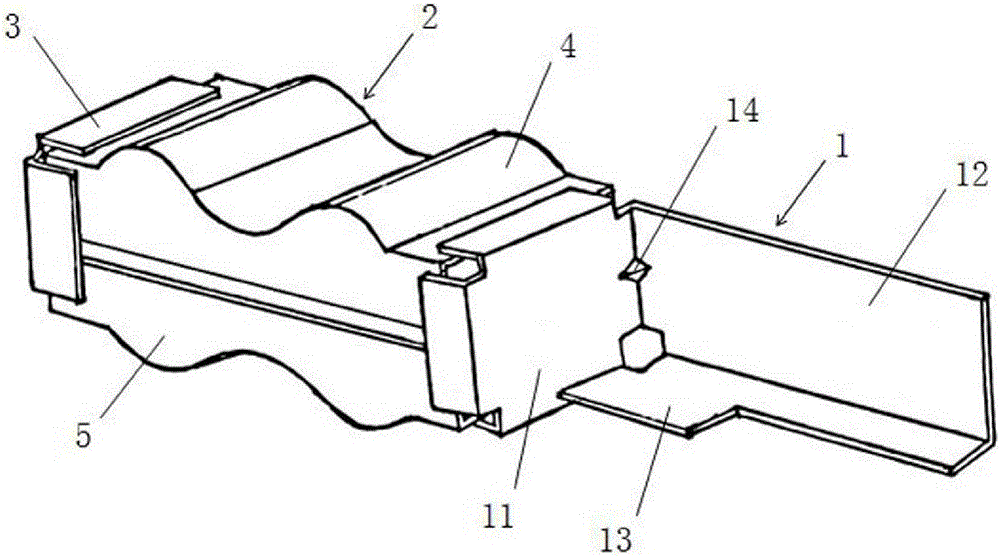

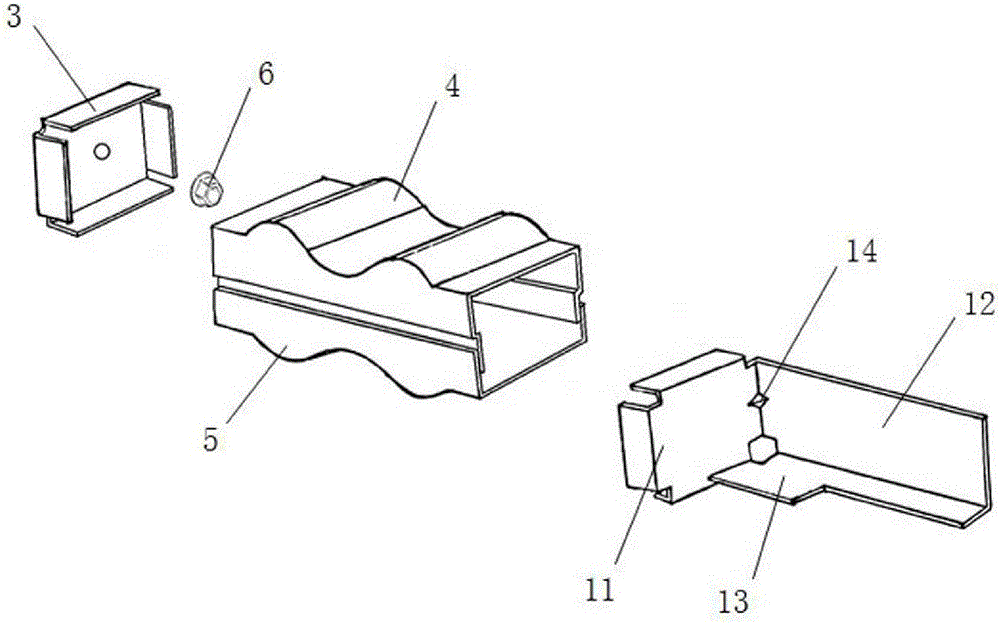

Processing method of automobile collision box

The invention discloses a processing method of an automobile collision box. The automobile collision box is made of a sheet metal serving as a raw material; a cantilever and a box body of the automobile collision box are formed by welding the sheet metal. The processing method of the automobile collision box comprises the following steps: (a) performing multi-station stamping processing through a progressive die to obtain each sheet metal: the cantilever, and cover plates, an upper cover and a lower cover which form the box body, wherein the upper cover and the lower cover have wavy curved surfaces and provided with flanges on both sides; (b) welding nuts on the cover plates; (c) welding the cover plates, the upper cover and the lower cover to form the box body with a cross section like a hollow square; (d) welding the box body and the cantilever. The automobile collision box processed can meet the requirements on the intensity and the impact resistance performance, and the weight cannot be increased; the procedure is simplified, the automation degree is high, and the manufacturing cost is reduced.

Owner:POHANG AUSTEM SUZHOU AUTO PARTS CO LTD

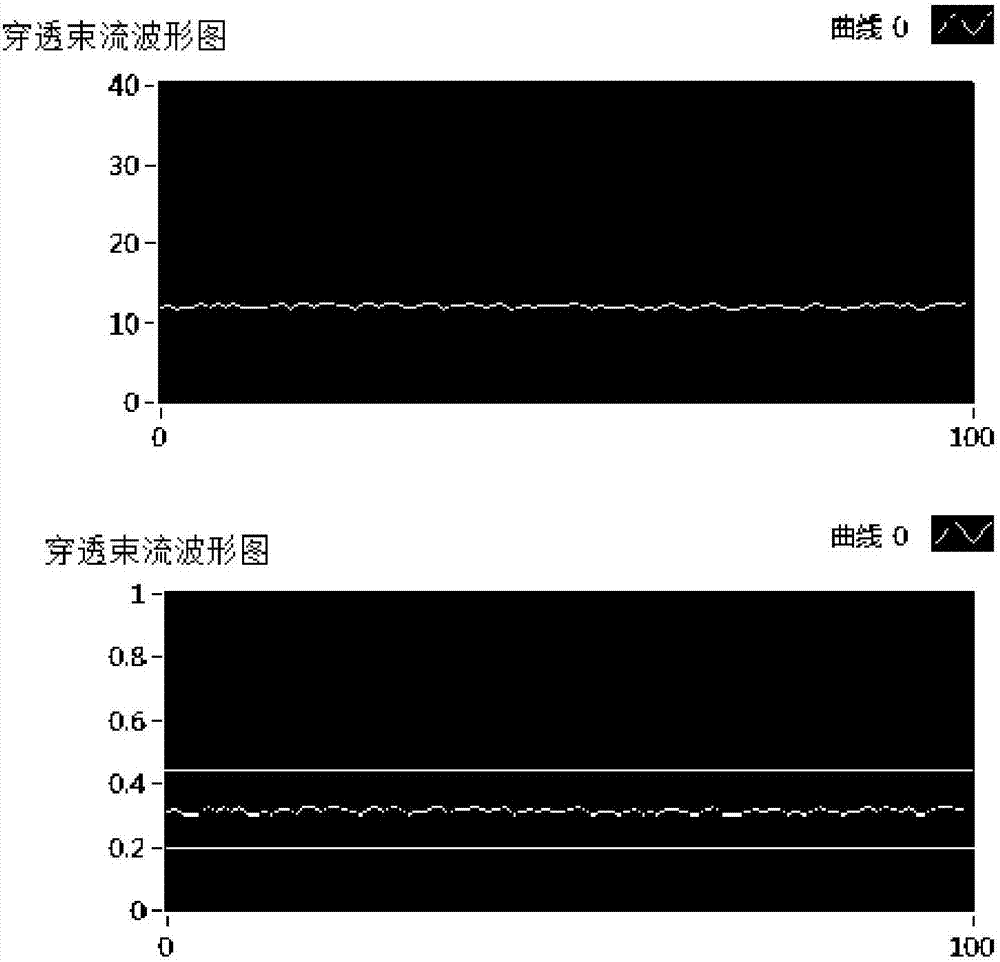

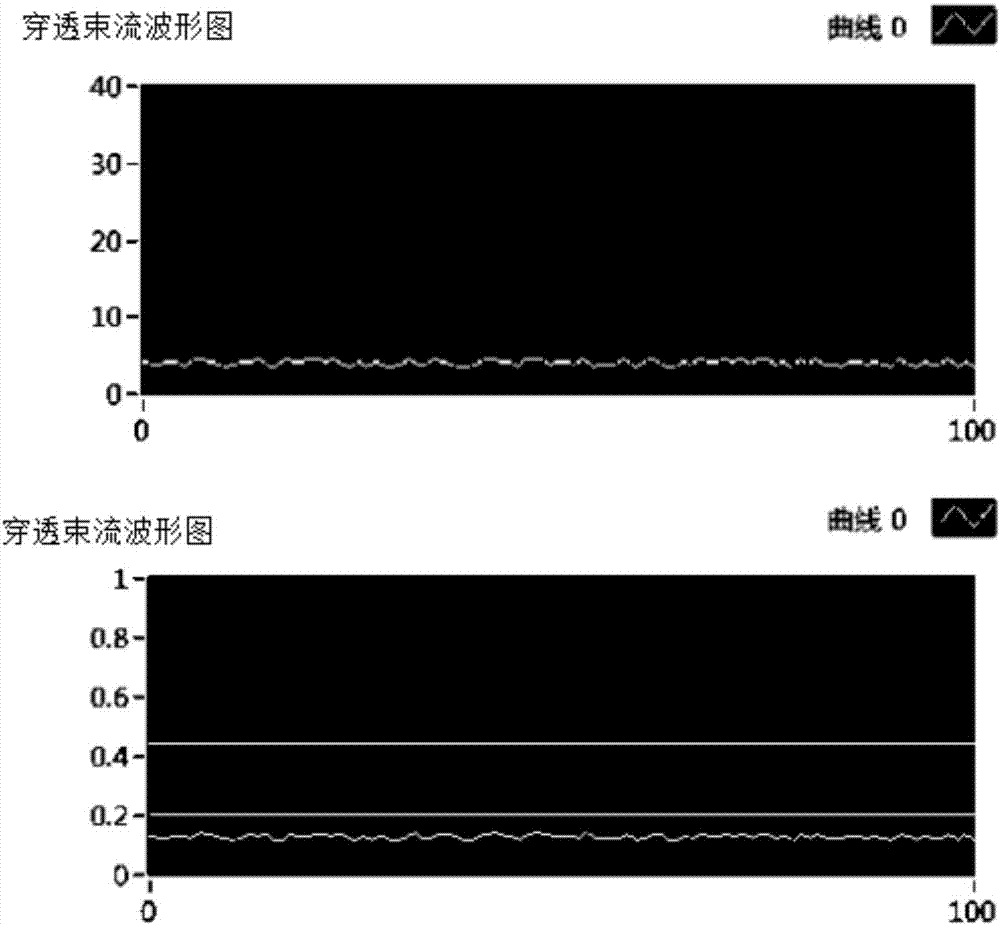

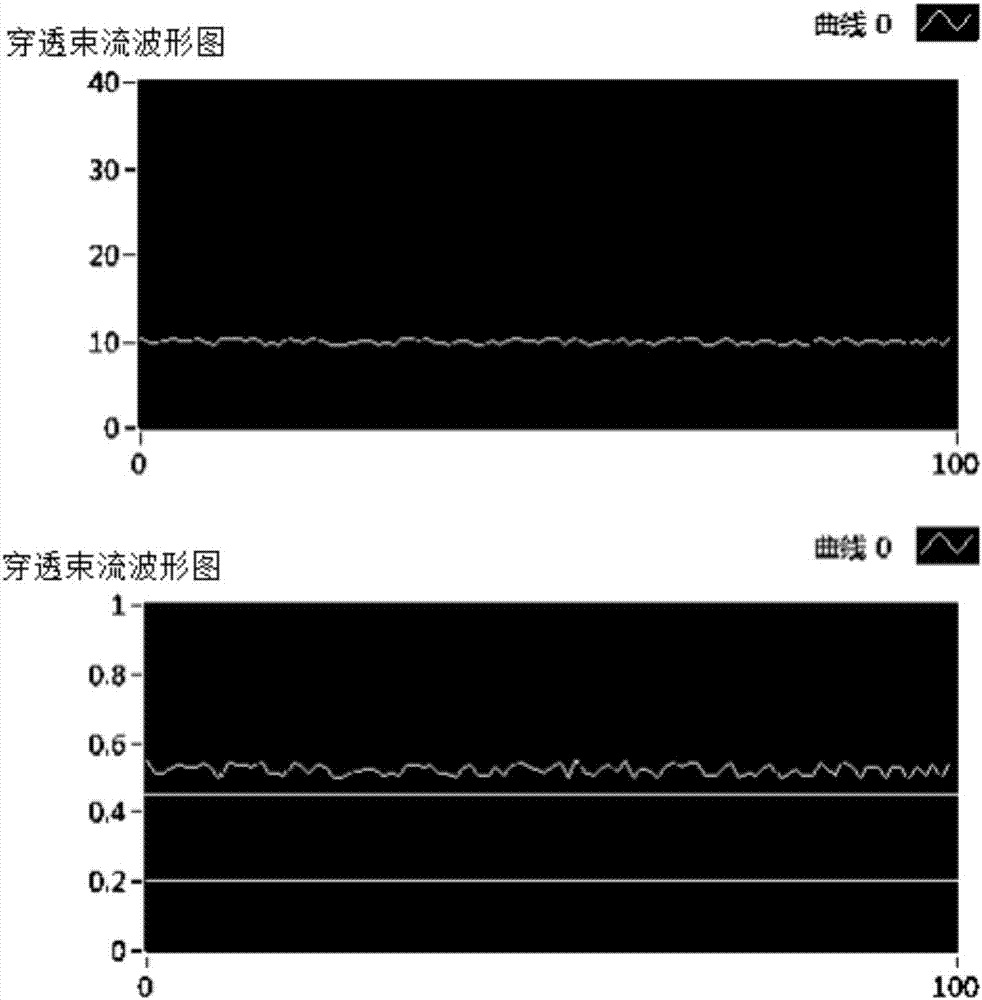

Real-time monitoring and detection method for penetration and forming during deep fusion welding for electron beam

ActiveCN107214409AStable welding processGood weld qualityElectrical testingElectron beam welding apparatusWeld seamFusion welding

The invention relates to a real-time monitoring and detection method for penetration and forming during deep fusion welding for an electron beam. Based on the law of total electron beam current and back penetration beam current relationship, the monitoring and detection method forms a criterion through the research to the law to monitor the deep fusion welding for the electron beam in real time. The real-time monitoring and detection method comprises the steps: setting welding parameters such as an electron beam current Iw, etc., and conducting welding; in the welding process, collecting real-time penetration beam currents I1, I2 and Ic through a beam current sensing and collecting module; according to a penetration current ratio Ro=Ic / Iw, calculating the penetration current ratio Ro; displaying the penetration beam current Ic measured in real time and the calculated penetration current ratio Ro on a computer. Through the monitoring method, process parameters can be adjusted, therefore a high-quality weld seam is obtained, and the efficiency is improved in the mass welding process. In the process of dynamic welding, through the criterion of the penetration current ratio, the site with welding defects on a welding plate can be found in real time, but the welding defects are unable to be seen by the naked eye on the welding plate generally.

Owner:NANJING UNIV OF SCI & TECH

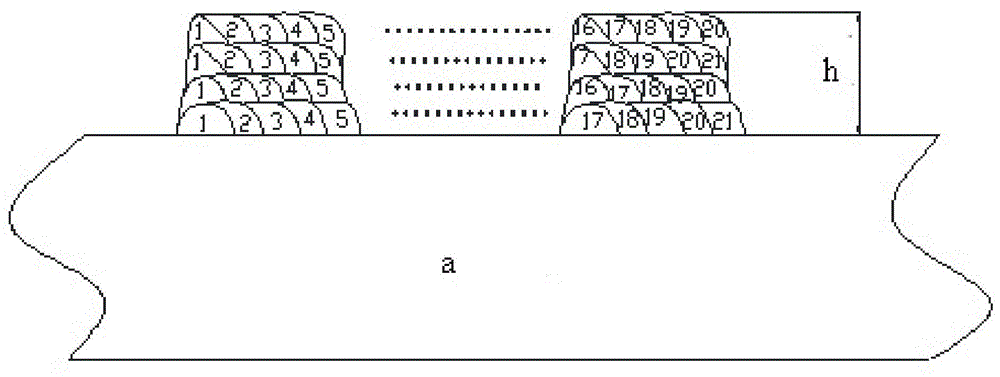

Chrome-nickel alloy overlaying welding process of multipoint mooring device

ActiveCN104084670AAvoid porosity and cracksStable welding processArc welding apparatusWelding/soldering/cutting articlesArc weldingElectrical current

The invention relates to a chrome-nickel alloy overlaying welding process of a multipoint mooring device. The chrome-nickel alloy overlaying welding process of the multipoint mooring device is characterized by comprising the following steps of 1 performing base metal treatment before welding; 2 preheating the base metal before welding, wherein the preheating temperature is not lower than 93 DEG C; 3 selecting a welding material, namely an ENiCrMo-3 welding bar, performing drying treatment on the ENiCrMo-3 welding bar before usage and then using a heat preservation bucket to use the ENiCrMo-3 welding bar in a plug-in mode; 4 adopting a manual arc welding method to strictly enable interlayer temperature to be not higher than 165 DEG C through control, wherein welding parameters are that the current polarity is DCEP, a current range is 103-151A, a voltage range is 22-28V, the welding speed is 152-187 mm / min, and thermal input is 0.73-1.67kj / mm. The chrome-nickel alloy overlaying welding process can effectively avoid pores and cracks, ensures that chemical element contents in an overlaying layer meet the requirements, is suitable for the FPSO multipoint mooring device working in a special environment, is stable in welding process, convenient to control, good in practicability and capable of producing large economic benefit and social benefit.

Owner:广州文冲船舶修造有限公司

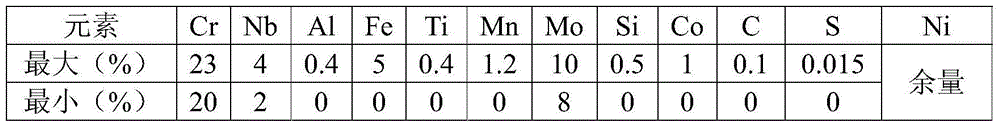

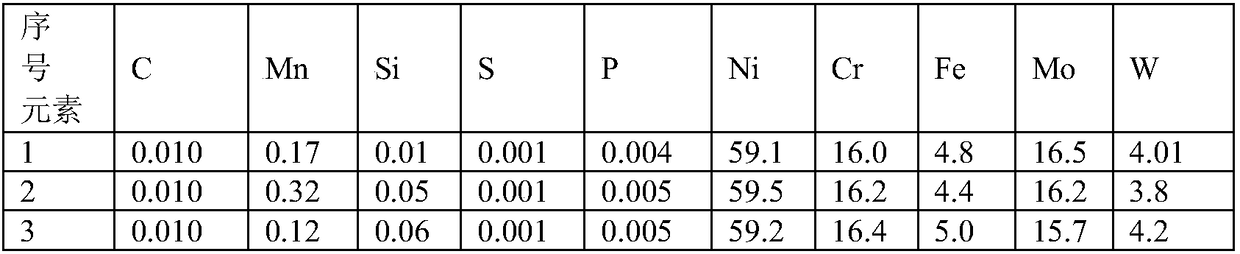

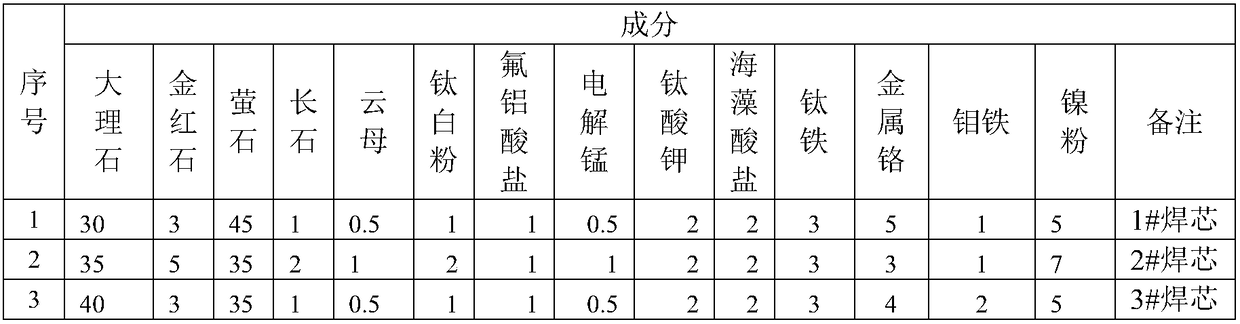

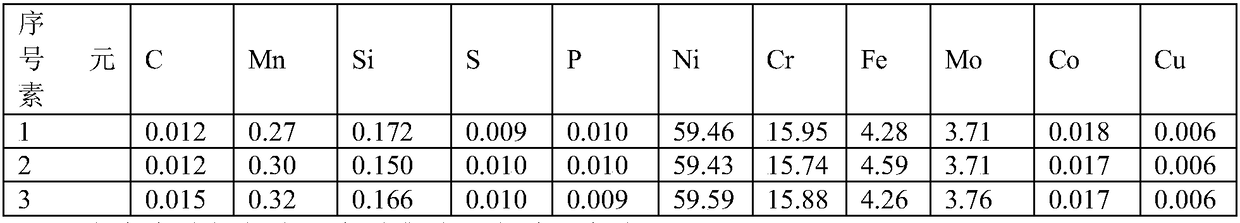

A kind of nickel-based electrode for welding uns N10276 nickel-based alloy and its preparation method

ActiveCN106425160BUniform coverageHigh purityWelding/cutting media/materialsSoldering mediaAluminateCrack resistance

The invention discloses a nickel base welding rod for welding a UNSN10276 nickel base alloy. The nickel base welding rod comprises a welding core and a cover for cladding the welding core, and is characterized in that the welding core comprises the following chemical components in percentage by weight (wt%): C not more than 0.015%, Mn not more than 0.50%, Si not more than 0.15%, Ni and S not more than 0.010%, P not more than 0.015%, 15.0-17.0% of Cr, 15.0-17.0% of Mo, 3.0-4.5% of W, 4.0-7.0% of Fe, and inevitable impurities; the cover comprises the following components in percentage by weight: 3-8% of rutile powder, 30-45% of marble powder, 35-50% of fluorite powder, 1-5% of feldspar powder, 0.5-2% of mica, 1.0-3% of titanium dioxide, 0.5-1.5% of fluorine aluminate, 0.5-1.5% of electrolytic manganese, 2-5% of potassium titanate, 1-3% of alginate, 0.3-1.0% of soda, 2-5% of metal chromium, 1-2% of ferromolybdenum, 5-10% of nickel powder, 2-8% of ferrotitanium and adhesive; and the total quantity of all the components is 100%. The nickel base welding rod has the advantages of reasonable formula ratio, excellent welding process performances and excellent welding line crack resistance.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Welding method for outer metal cover and plate body

InactiveCN103769709AEasy to control temperatureAvoid the problem of defective productsWelding/cutting auxillary devicesAuxillary welding devicesWork in processMetal

A welding method for an outer metal cover and a plate body includes the following steps that A, the outer metal cover and the plate body are prepared; B, welding material coats the plate body; C, the outer cover covers the plate body, the periphery of the outer cover abuts against the welding material in a pressing mode to form a semi-finished product, and the semi-finished product is placed on a lower jig; the lower jig is provided with a wall surrounding around the plate body and the outer cover; D, the lower jig is ascended and descended to enable the semi-finished product together with the wall to enter an induction coil, and an upper jig abuts against the semi-finished product in a pressing mode; E, the induction coil generates oscillation currents at preset time and preset power, and then the periphery of the outer cover is heated to be at the temperature higher than the melting point of the welding material by 20-100 DEG C, so that the welding material is melt; F, cooling is performed until the welding material is solidified, so that welding is finished.

Owner:POWER MATE TECH CO LTD

Laser-arc composite welding device based on heat input control and welding method

ActiveCN103071935BLow heat inputReduce thermal deformationLaser beam welding apparatusHeat-affected zoneInput control

The invention provides a laser-arc composite welding device based on heat input control and a welding method. The laser-arc composite welding device based on the heat input control comprises a laser device, a laser head, an arc-welding power supply, a main consumable-electrode welding gun and a wire feeding mechanism and also comprises a bypass welding gun and a rheostat, wherein the laser head is connected with the laser device, the laser head is arranged above a workpiece, the main consumable-electrode welding gun and the bypass welding gun are symmetrically placed at both sides of a laser beam formed by the laser head, the main consumable-electrode welding gun is connected with the positive pole of the arc-welding power supply, the electrifying end of the workpiece is connected with the negative pole of the arc-welding power supply, and the bypass welding gun is connected with the negative pole of the arc-welding power supply by the rheostat. According to the laser-arc composite welding device based on the heat input control and the welding method, the welding heat input of a composite laser-arc heat source can be controlled, the heat affected zone and the welding deformation are reduced, and the metallurgical performance and the microstructure of a welding seam are improved. The laser-arc composite welding device based on the heat input control and the welding method not only are suitable for the fusion welding of homogeneous metal but also are suitable for the braze (fusion) welding of dissimilar metal, such as aluminum or steel and magnesium or steel.

Owner:哈尔滨哈船特装科技发展有限公司

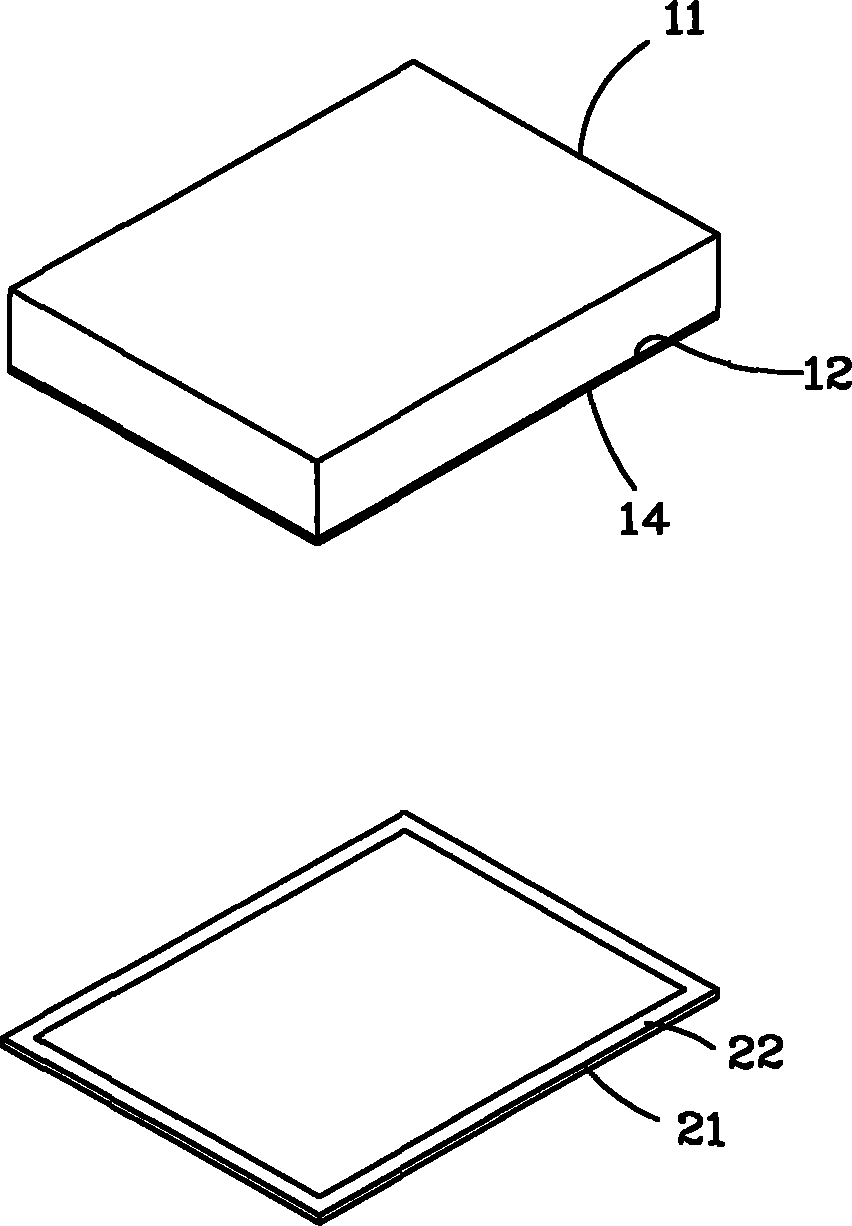

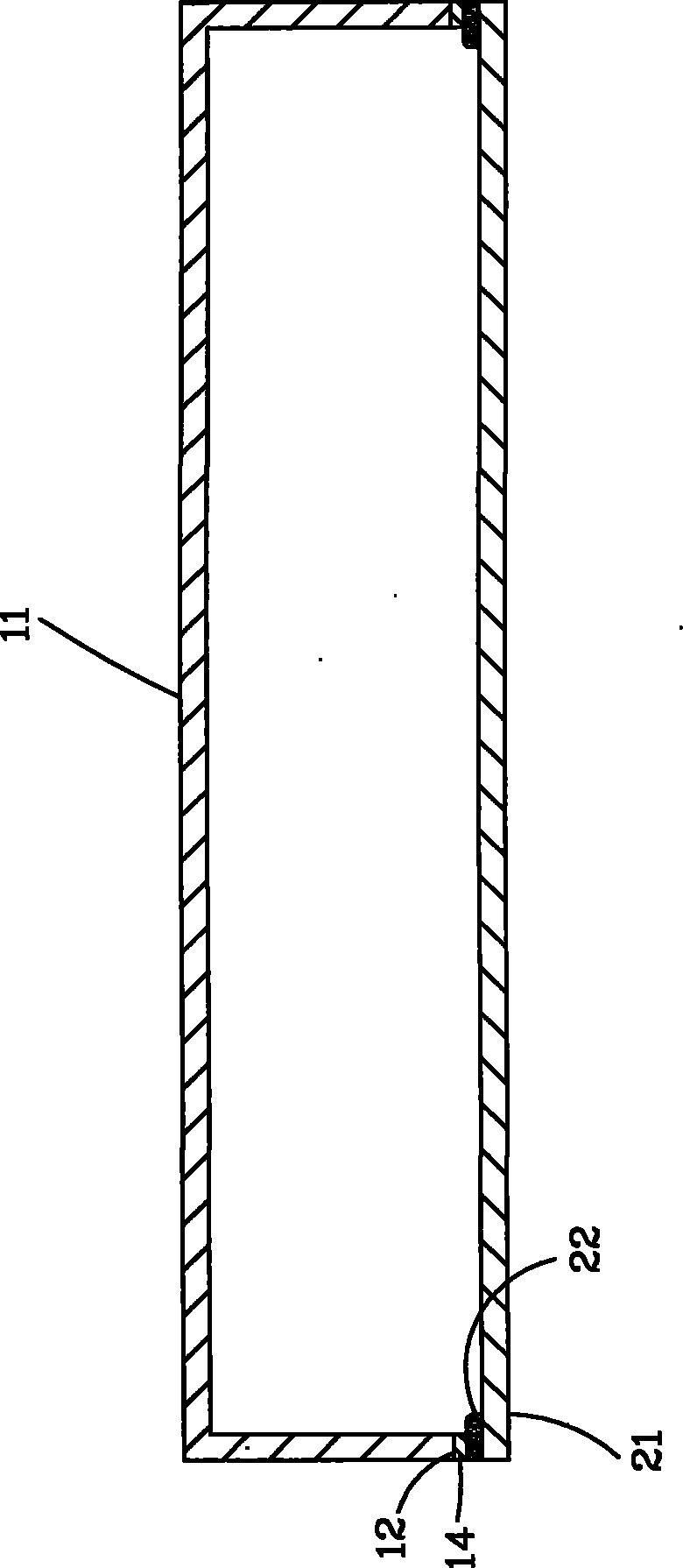

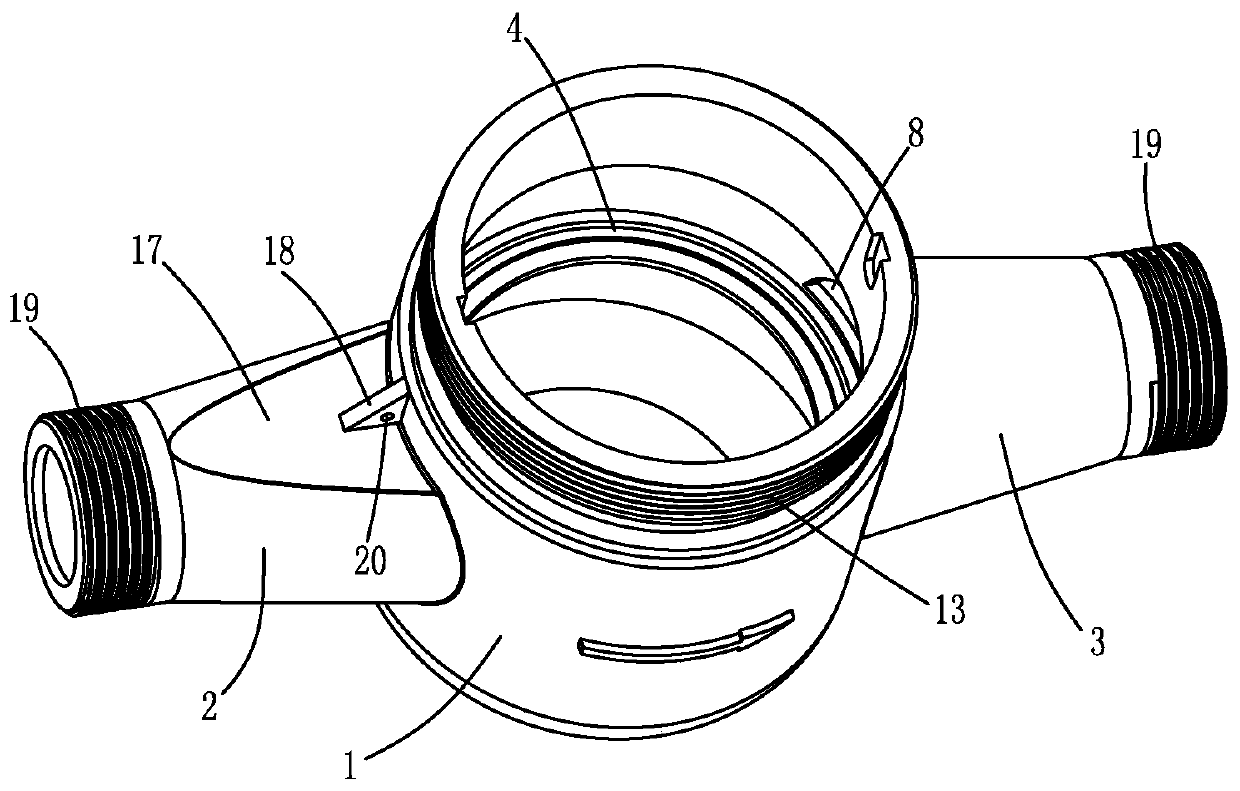

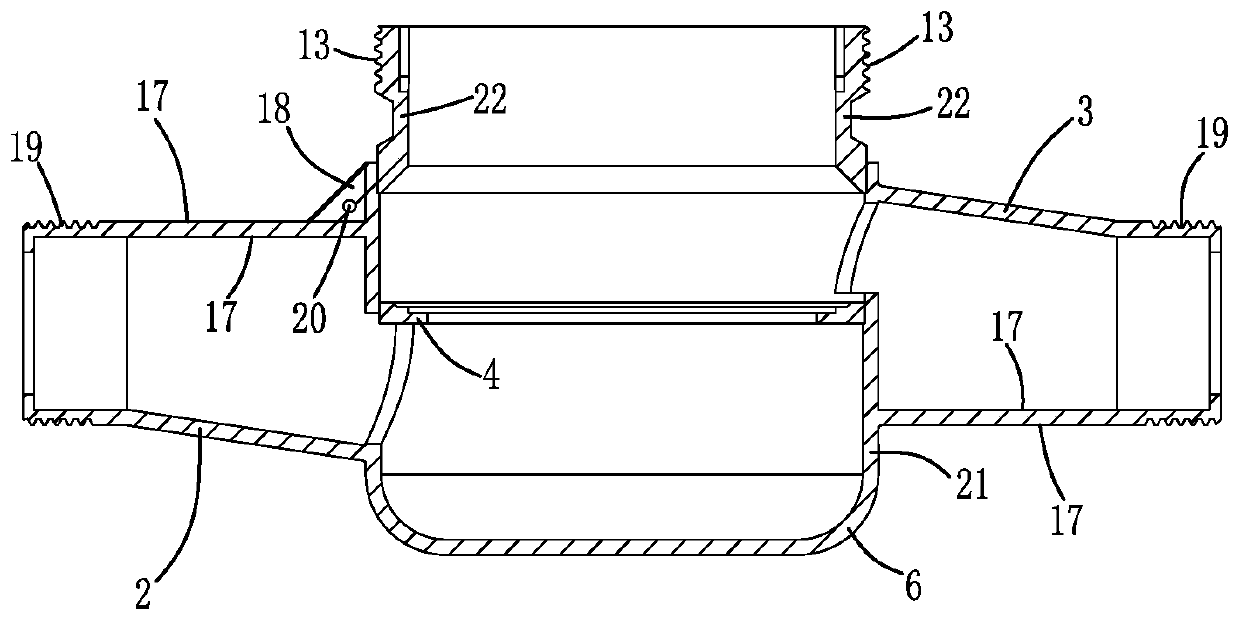

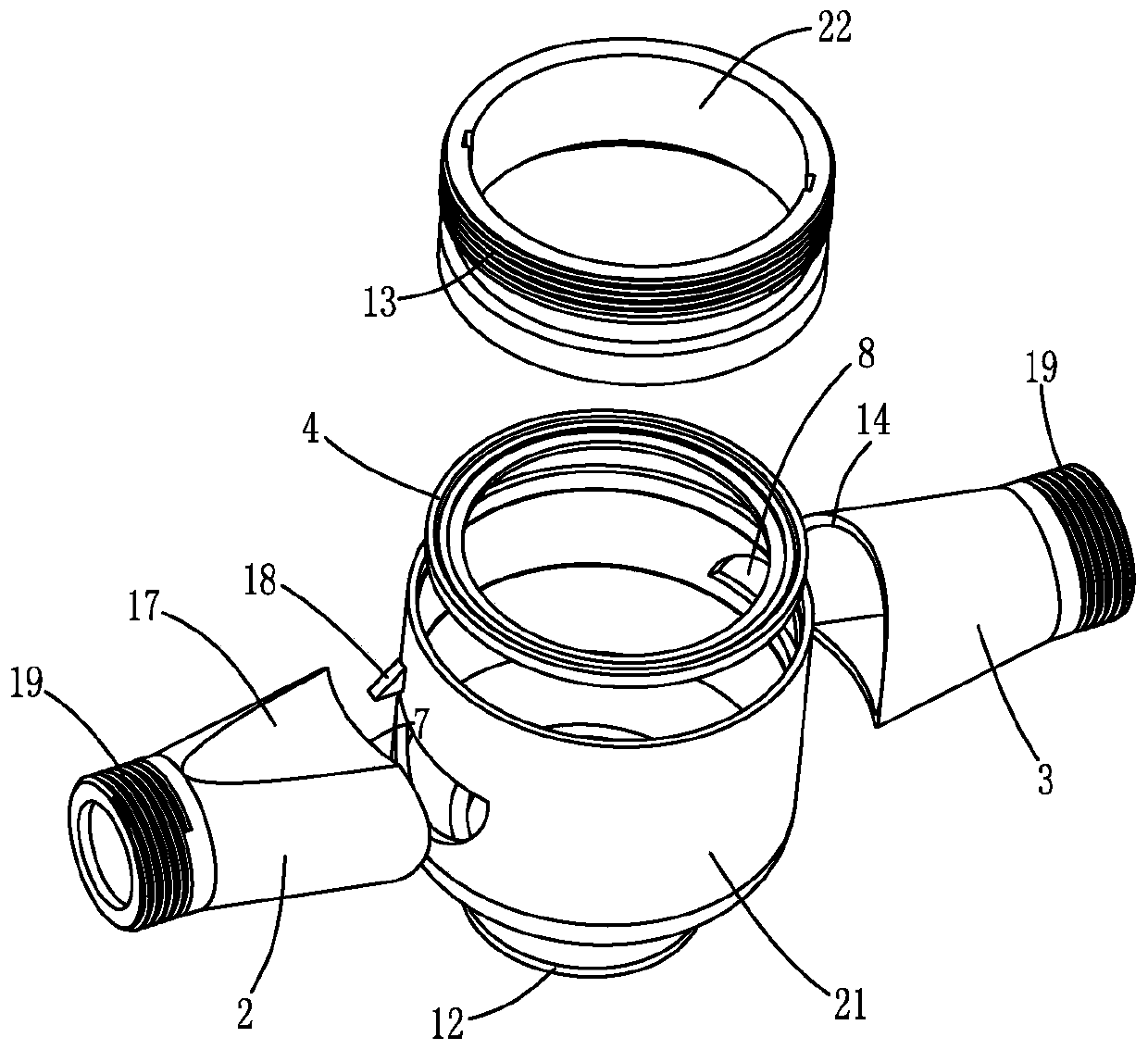

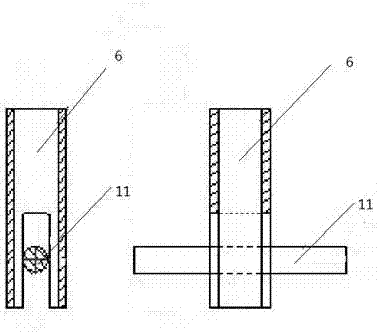

Water meter shell

PendingCN109932006ALess materialReduce manufacturing costVolume meteringWater conservationSheet steelPunching

The invention provides a water meter shell, and the shell comprises a meter body (1), a water inlet pipe (2), a water outlet pipe (3) and a movement positioning ring (4). The meter body (1) comprisesa body (21) and an embedded upper end ring (22). The body (21), the upper end ring (22), the meter body (1), the water inlet pipe (2) and the water outlet pipe (3) are formed by punching of steel pipes, and an arc-shaped contraction ring (6) surrounding a lower port (5) is formed at the lower end of the meter body (1). A water inlet (7) and a water outlet (8) are formed at the two sides of the body (21). The lower port (5) is welded with a small circular steel plate (12), serving as a shell bottom. A port external thread (13) is arranged at the upper end; connecting pipe external threads (19)are arranged at the outer ends of the water inlet pipe (2) and the water outlet pipe (3), and the inner ends of the water inlet pipe (2) and the water outlet pipe (3) form cambered surface openings (14) through laser cutting and are respectively welded to the outer surfaces of a water inlet (7) and a water outlet (8) of the meter body (1). The water meter shell is made of light and thin materials,light in weight, low in manufacturing cost and capable of meeting the environment-friendly requirement.

Owner:宁波宁水仪表有限公司

Full automatic dip soldering machine

InactiveCN104002007AEasy to operateStable welding processPrinted circuit assemblingMetal working apparatusDip solderingAutomatic control

The invention relates to the technical field of floating machines, in particular to a full automatic dip soldering machine which comprises a machine body. An atomizing device, a preheating device, an automatic lifting tin furnace, an angle deflection device and a printed circuit board (PCB) conveying line are installed in the machine body. A chain wheel is installed on a main beam on the PCB conveying line, and a hinge, a chain connector and a transmission assembly are installed on the main beam. When tin feeding operation is conducted, a PCB can enter a floating machine automatically to achieve angle soldering in a tin soldering area and automatically flow to the next procedure after soldering. Therefore, the full automatic dip soldering machine is simple in operation, has advantages of being high in yield, low in cost and the like and is applicable to dip soldering operation. Product quality can be well guaranteed due to automatic control.

Owner:谢玉强

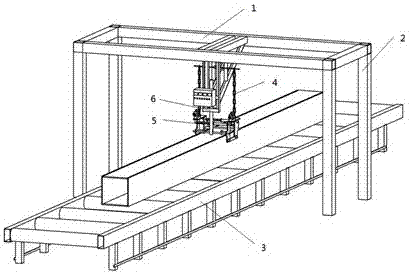

Steel beam machining device

InactiveCN107020472AStable welding processImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringScrew thread

The invention provides a steel beam machining device. The steel beam machining device comprises a portal support and conveying rollers. The portal support is matched with the conveying rollers. The portal support is provided with a cross beam. A traction rod is arranged on the cross beam. A bottom groove of the traction rod is clamped and fixed to drawing rods of a welding trolley. Pulleys are arranged on the cross beam, and chains are assembled inside the pulleys. One end of each chain is fixedly connected with the corresponding drawing rod of the welding trolley. A welding gun is arranged on the welding trolley. According to the structure of the welding trolley, fixed rods are arranged between two supporting plates, fixed clamping plates are arranged at the two ends of the supporting plates, each drawing rod is fixed to two corresponding fixed clamping plates; the ends of each fixed rod and each drawing rod are both provided with threads and provided with bolts, the two sides of the bottom of each supporting plate are both provided with walking wheels, guide rolling wheels are arranged in the middle of base plates, and welding gun fixing clamping cylinders are arranged at the ends of the supporting plates. The steel beam machining device is high in machining efficiency, stable in machining quality and particularly suitable for machining of long steel beams.

Owner:河南华斯豪智能科技有限公司

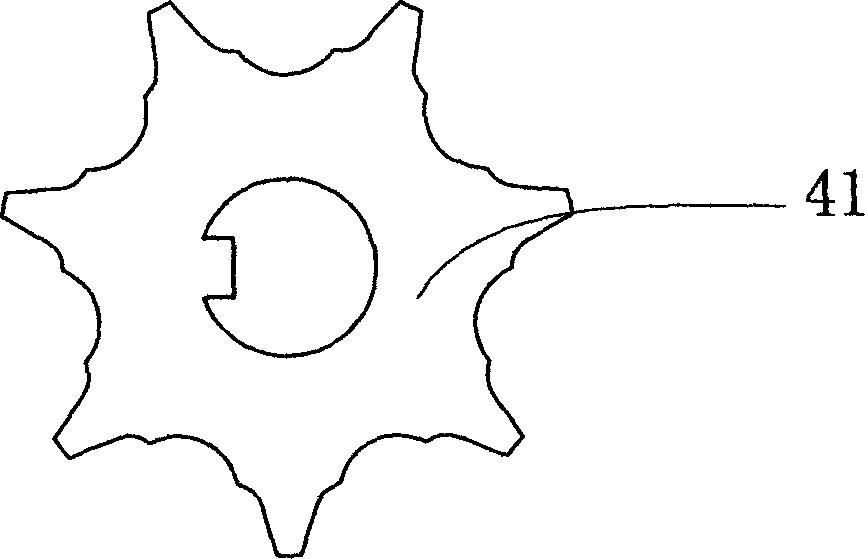

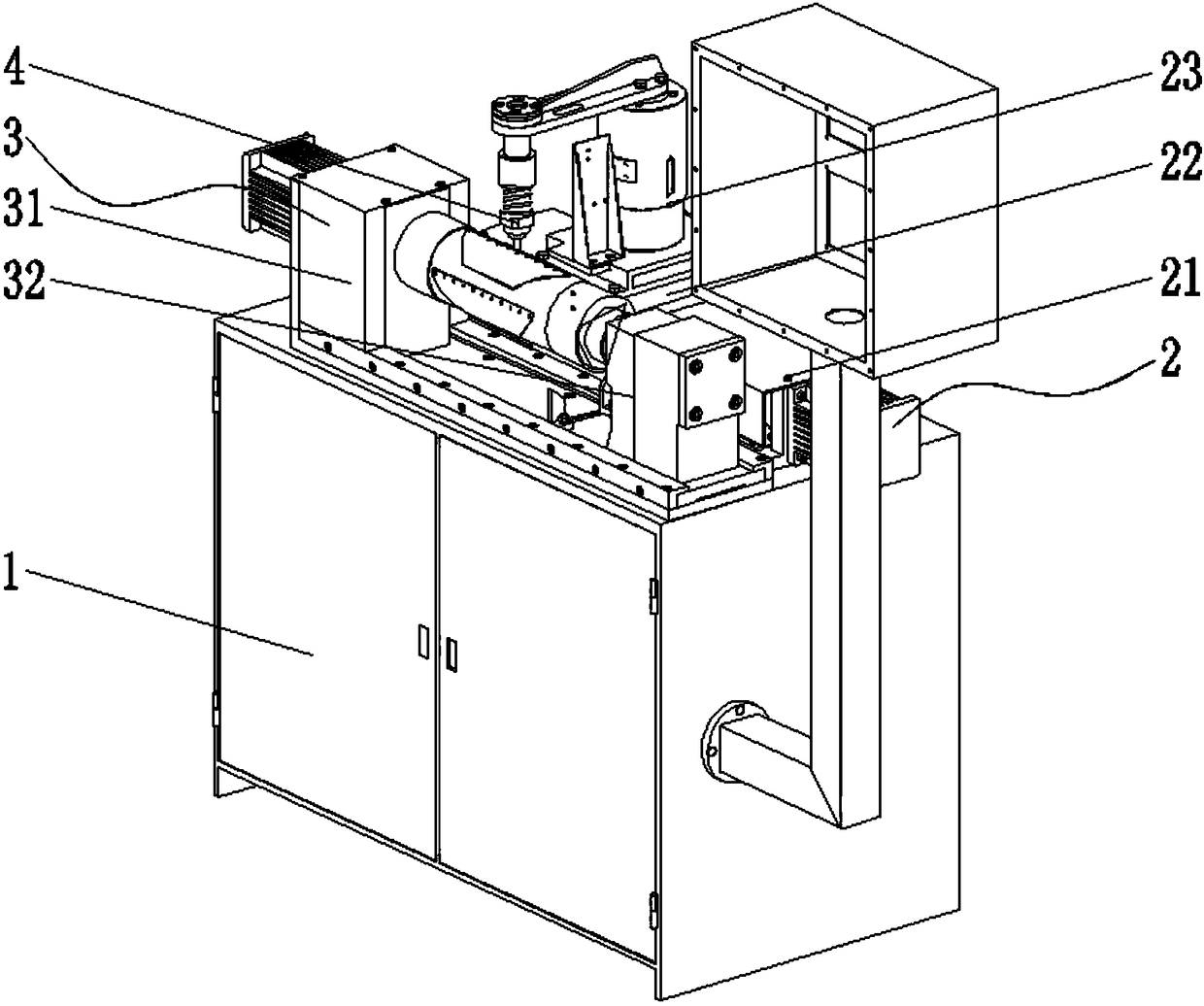

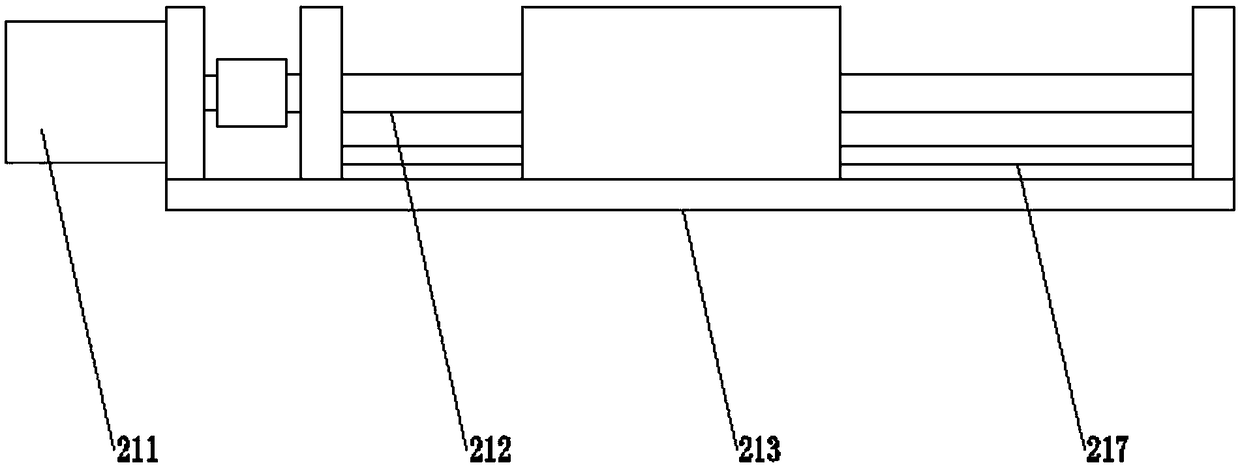

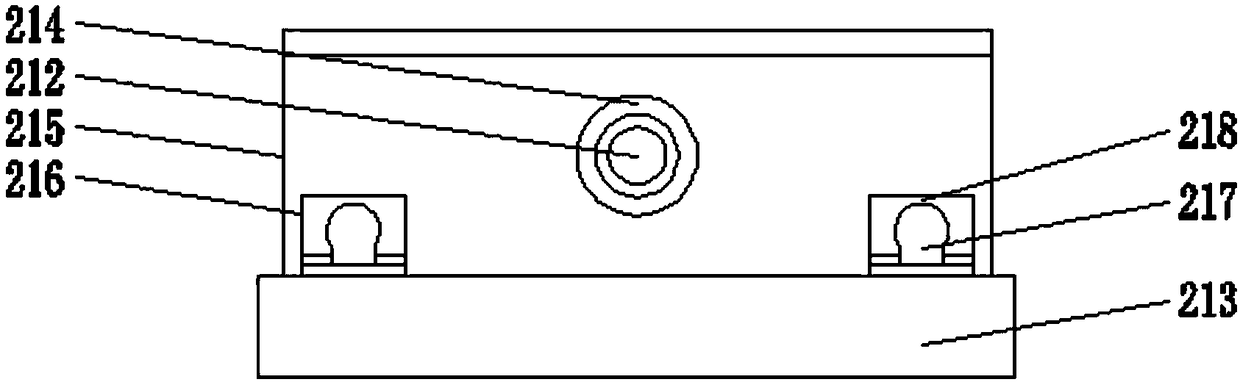

Numerical control point welding machine used for shell rotation reducing sheet

InactiveCN108526670ASmall transmission errorReduce indexing positioning errorResistance electrode holdersWelding/cutting auxillary devicesEngineeringNumerical control system

The invention relates to the technical field of shell part machining machines, in particular to a numerical control point welding machine used for a shell rotation reducing sheet. The numerical control point welding machine comprises a tool body base, a point welding machine driving device, a main shaft driving device, a point welding machine body and a numerical control system; and the tool bodybase is fixedly provided with the main shaft driving device, the point welding machine driving device is arranged beside the main shaft driving device and is fixedly provided with the point welding machine body, and the main shaft driving device, the point welding machine body and the point welding machine driving device are all connected with the numerical control system. According to the numerical control point welding machine, the point welding machine special for a shell casing and the rotation reducing sheet is arranged, and the welding position accuracy is guaranteed through numerical control over the main shaft driving device, the point welding machine body and the point welding machine driving device; and meanwhile, automatic welding is achieved, the welding efficiency is improved,and the welding labor force is reduced.

Owner:QIQIHAR UNIVERSITY

Electric welding electrode

InactiveCN101559542ASimple welding processStable welding processWelding/cutting media/materialsSoldering mediaCopperImpurity

The invention discloses an electric welding electrode which consists of a welding core, a copper pipe and a coating from inside to outside. The welding core, the copper pipe and the coating account for the following percentages of the total mass of the electric welding electrode respectively: 36 percent to 40 percent; 33 percent to 37 percent; and 23 percent to 31 percent. The welding core is made of H08A steel and the coating is the coating of a J422 welding electrode; the components of the copper pipe are as follows (account for percentages of the total mass of the copper pipe): 0.21 to 1.34 percent of C; 1.28 to 3.59 percent of Mn; 0.53 to 0.98 percent of Ni; 0.38 to 0.7 percent of Si; 0.32 to 0.7 percent of Cr; 0.86 to 2.7 percent of P; 0.075 to 0.09 percent of S; and the balance of Cu and unavoidable impurities.

Owner:张好文

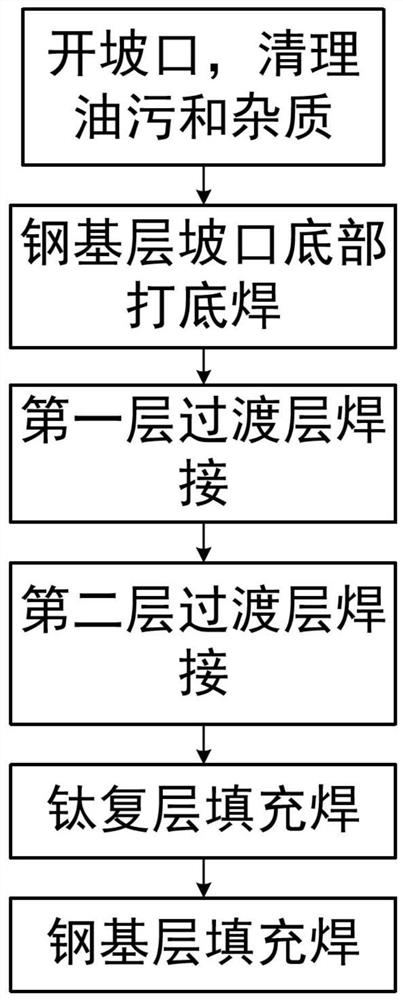

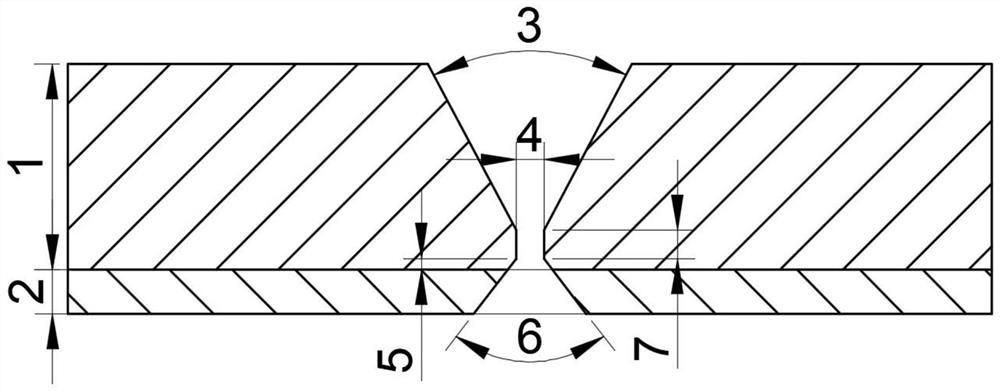

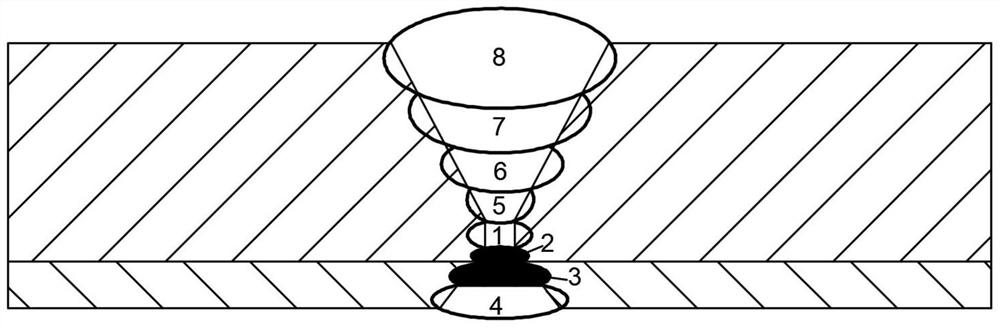

A kind of titanium-steel composite plate double-wire MIG gas shielded welding welding method

ActiveCN113319405BInhibit grain coarseningReduce residual stressWelding/soldering/cutting articlesWelding accessoriesHeat-affected zoneWeld seam

The invention relates to the technical field of welding, and specifically discloses a double-wire melting electrode gas shielded welding method for a titanium-steel composite plate. In the method for welding titanium-steel composite plates, groove design is performed on the titanium-steel composite plate; double-wire bottom welding is performed from the steel side; copper-based welding wires are used for both wires, and double-wire welding is performed from the titanium side to form a first-layer transition layer; double-wire is made of either niobium-based welding wire and vanadium-based welding wire, and double-wire welding is performed from the titanium side to form the second transition layer; multi-layer double-wire filling welding is performed from the titanium side until it is filled with titanium complex. Layer groove; multi-layer double wire filler welding is performed from the steel side until the groove of the steel base layer is filled. The welding method provided by the invention has the advantages of stable welding process, high welding efficiency, good welding seam formation, low welding heat input, good isolation effect of transition layer, and can effectively suppress the formation of brittle intermetallic compounds and grain coarsening in the heat affected zone. The residual stress and deformation of the joint are small, the purity of the weld is high, and the performance of the welded joint is good.

Owner:SHIJIAZHUANG TIEDAO UNIV

Full-automatic build-up welding machine

InactiveCN102350565BPrecise Positioning WeldingImprove wear resistanceArc welding apparatusEngineeringTechnical performance

Owner:湘潭大唐焊接材料有限公司

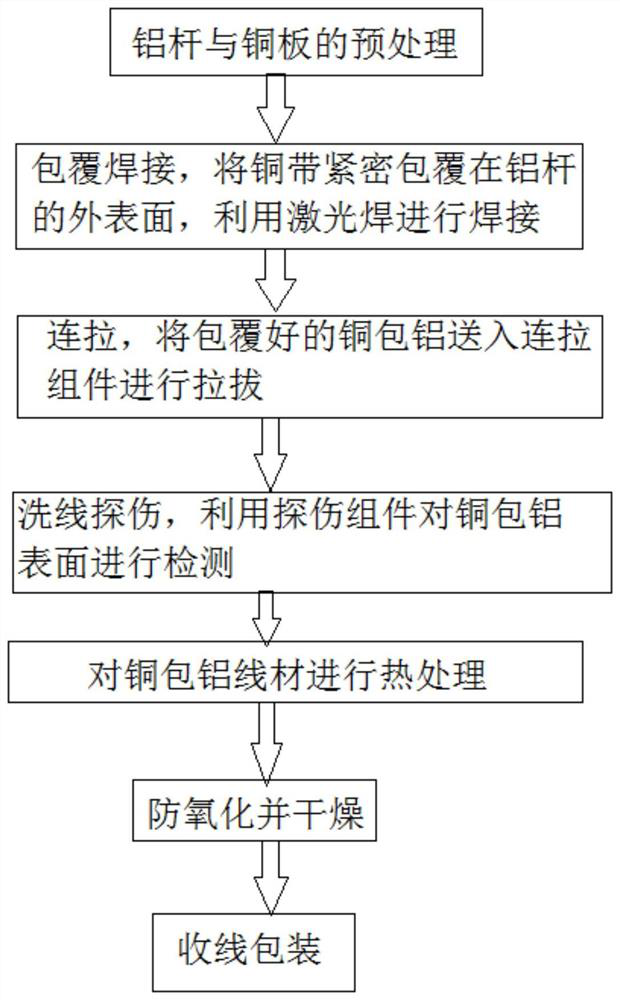

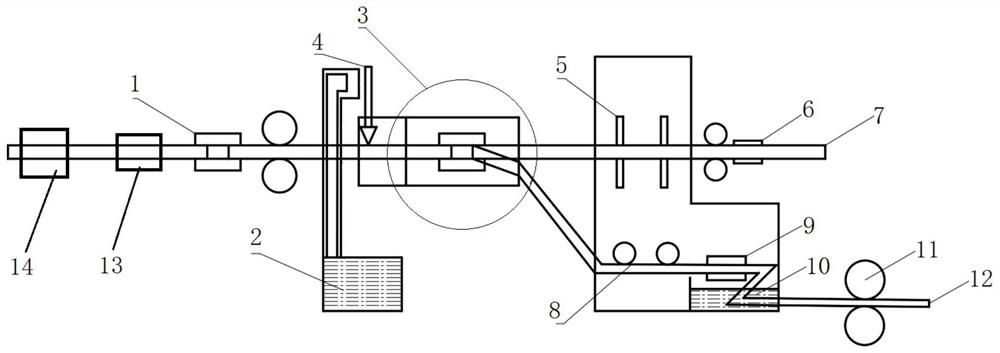

Device and method for preparing copper-clad aluminum wire through laser welding

The invention relates to a device and method for preparing a copper-clad aluminum wire through laser welding. The device comprises a first straightening assembly, a water cooling assembly, a cladding assembly, a welding assembly, a polishing assembly, a second straightening assembly, an aluminum rod, a surface polishing and brushing assembly, a wiping assembly, a cleaning assembly, rollers, a copper plate, a continuous pulling assembly and a flaw detection assembly; the rollers are rotatably arranged on the two sides of the copper plate; the cleaning assembly, the wiping assembly and the surface polishing and brushing assembly are sequentially arranged on one sides of the rollers; the second straightening assembly and the polishing assembly are arranged on the aluminum rod; the coating assembly is arranged on the same side of the surface polishing and brushing assembly and the polishing assembly; and the welding assembly is arranged on the other side of the cladding assembly. The device is high in automation degree, and the problem of surface damage of copper-clad aluminum can be effectively solved; the welding process is stable, the weld surface and internal quality are good, and the performance is high; and the device is green, environment-friendly, pollution-free, free of interference of electric and magnetic fields and free of vacuum protection.

Owner:YANCHENG TONGJI NEW MATERIAL TECH CO LTD

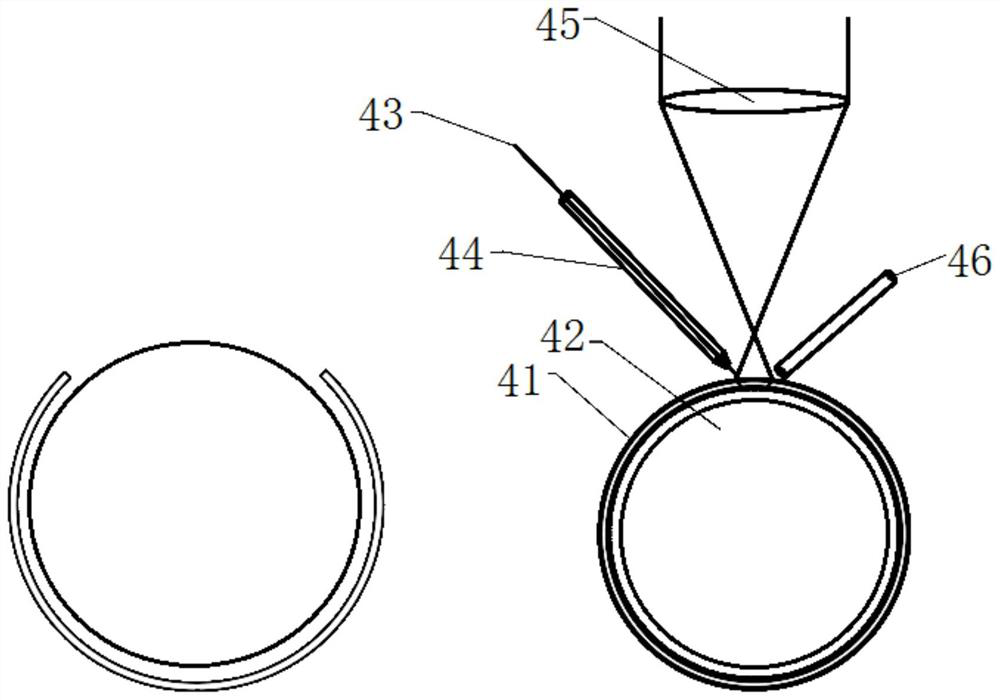

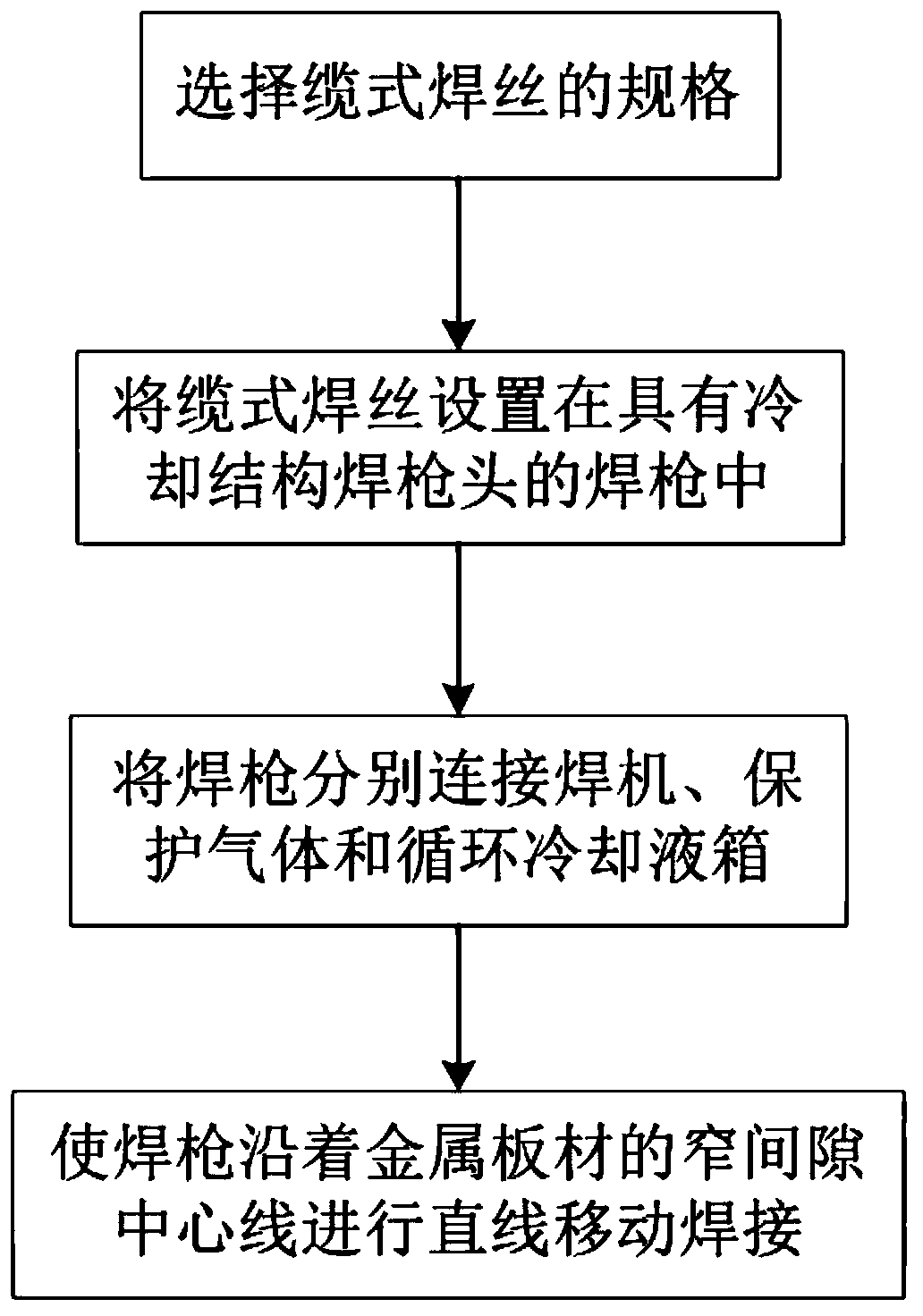

Cable welding wire narrow gap welding method, protective gas nozzle and welding gun

InactiveCN109909591AStable welding processExtended service lifeElectrode supporting devicesElectrode accessoriesSpray nozzleElectric arc

Owner:SUZHOU YINLI WELDING IND TECH CO LTD

A copper laser welding device and method

InactiveCN104907695BSolve the failure to convergeSolve quality problemsWelding/soldering/cutting articlesLaser beam welding apparatusTemperature controlBrick

The invention discloses a red copper laser welding device. The device comprises a control system, a laser, a laser welding head, a pre-heating mechanism and a temperature control mechanism. A laser welding mechanism comprises the laser and the laser welding head. The pre-heating mechanism comprises a heating insulation tank, insulation bricks are arranged in the heating insulation tank, and a clamp is arranged on the insulation bricks. Dry burning heating tubes are arranged on the two side walls in the heating insulation tank, and a cover plate and a pulling plate are arranged above the heating insulation tank. A motor I and a motor II are arranged on the two sides of the heating insulation tank. The motor I drives the cover plate to move along the axial direction of a tank body through the action of a gear I and a rack I. The motor II drives the pulling plate to move along the direction vertical to the axial direction of the tank body through the action of a gear II and a rack II. The laser, the motor I, the motor II, the heating insulation tank and an infrared thermometer are in line connection with the control system respectively. By means of the device, the red copper plate laser welding energy absorptivity is improved, the work efficiency is improved, weld zones are attractive, excess weld metal is absent, additional processing is not needed basically, and the process and the cost are saved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Semiconductor device

InactiveCN1218392CDimensional and shape stableStable welding processSemiconductor/solid-state device detailsSolid-state devicesSolder maskResist

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com