Full-automatic build-up welding machine

A surfacing welding machine, fully automatic technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of stable welding process performance, simple structure, and improved product technical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

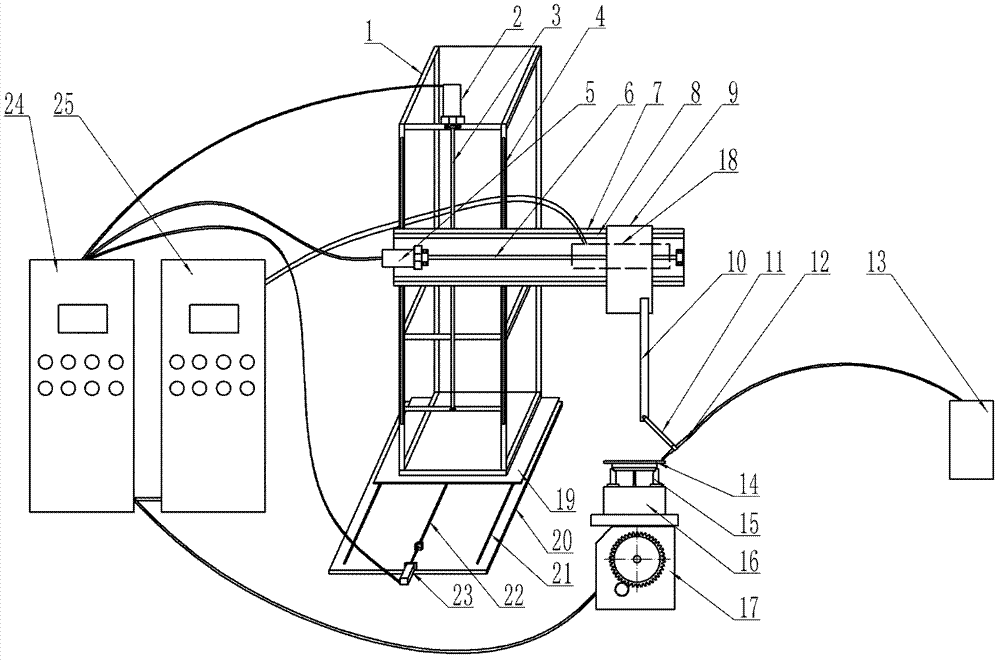

[0012] Example 1, such as figure 1 As shown, the present invention includes a mobile frame 1, a horizontal support 7, a mobile frame base 19, a machine base 20, and an electrical control cabinet 24. The mobile frame 1 is fixedly installed on the mobile frame base 19, and the mobile frame base 19 is installed on the machine base 20. On the frame guide rail 21, the frame drive screw 22 is installed on the frame 20, the frame drive screw 22 passes through the screw hole sleeve installed at the lower part of the movable frame base 19 to form a movable matching relationship, the frame drive screw 22 and the movable frame drive motor 23 is connected, can be driven by the mobile frame drive motor 23 connected to the electrical control cabinet 24 to drive the base drive screw 22 to accurately control the horizontal movement distance of the mobile frame 1; the vertical guide rail 4 and vertical are installed on one side of the mobile frame 1 The drive screw 3, the vertical drive screw 3...

Embodiment 2

[0016] In Embodiment 2, the present invention can also provide a workpiece clamping device 15 matching the workpiece on the positioner turntable 16 of the positioner 17, and the clamping device 15 can be mechanically controlled or pneumatically. Or hydraulically clamp the workpiece 14 firmly. Refer to figure 1 , The rest is the same as in Example 1.

Embodiment 3

[0017] In Embodiment 3, because it may be necessary to preheat the workpiece 14 before welding the workpiece according to the process requirements, the present invention can also be provided with a heating device 18 for heating the workpiece matched with the workpiece on one side of the horizontal support 7. The heating device 18 corresponds to the vertical position of the positioner 17, and the heating device 18 is connected with the electric control cabinet 24 or connected with the special heating device electric control cabinet 25. When the workpiece 14 needs to be preheated, the vertical drive screw 3 can be driven by the vertical drive motor 2 connected to the electrical control cabinet 24 to precisely control the vertical movement of the horizontal support 7 along the moving frame 1, so that the heating device 18 is just set in The workpiece 14 is preheated and heated. When the preheating requirement is reached, the horizontal support 7 can be lifted and then the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com