Patents

Literature

47results about How to "Realize collinear production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

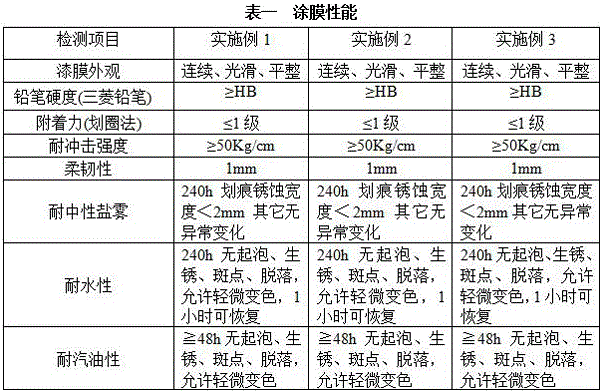

Oil paint coating line-based process for coating water paint in two layers on automotive plastic exterior trimming part

InactiveCN101670332ARealize collinear productionLess investmentPretreated surfacesCoatingsWater basedProduction line

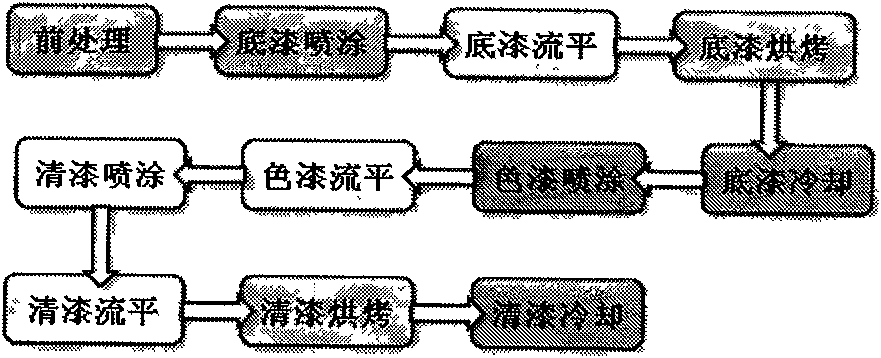

The invention discloses an oil paint coating line-based process for coating water paint in two layers on an automotive plastic exterior trimming part. In the process, to implement two-layer coating technology, an oil / water-based insulation combined system of a robot is imporved and the temperature of a base paint oven in an oil-based production line is regulated by process control of a pretreatment step and by using stable industrial propane (with a purity of more than 95 percent) as a flame treatment fuel and executing base material flame treatment experimental design, base paint spraying isavoided, water-based color paint is directly sprayed on a plastic base material, and a varnish is an oil-based varnish. After equipment improvement is completed, original oil-based paint can still beused in normal production.

Owner:SHENYANG MINGHUA MOULD & PLASTIC TECH CO LTD

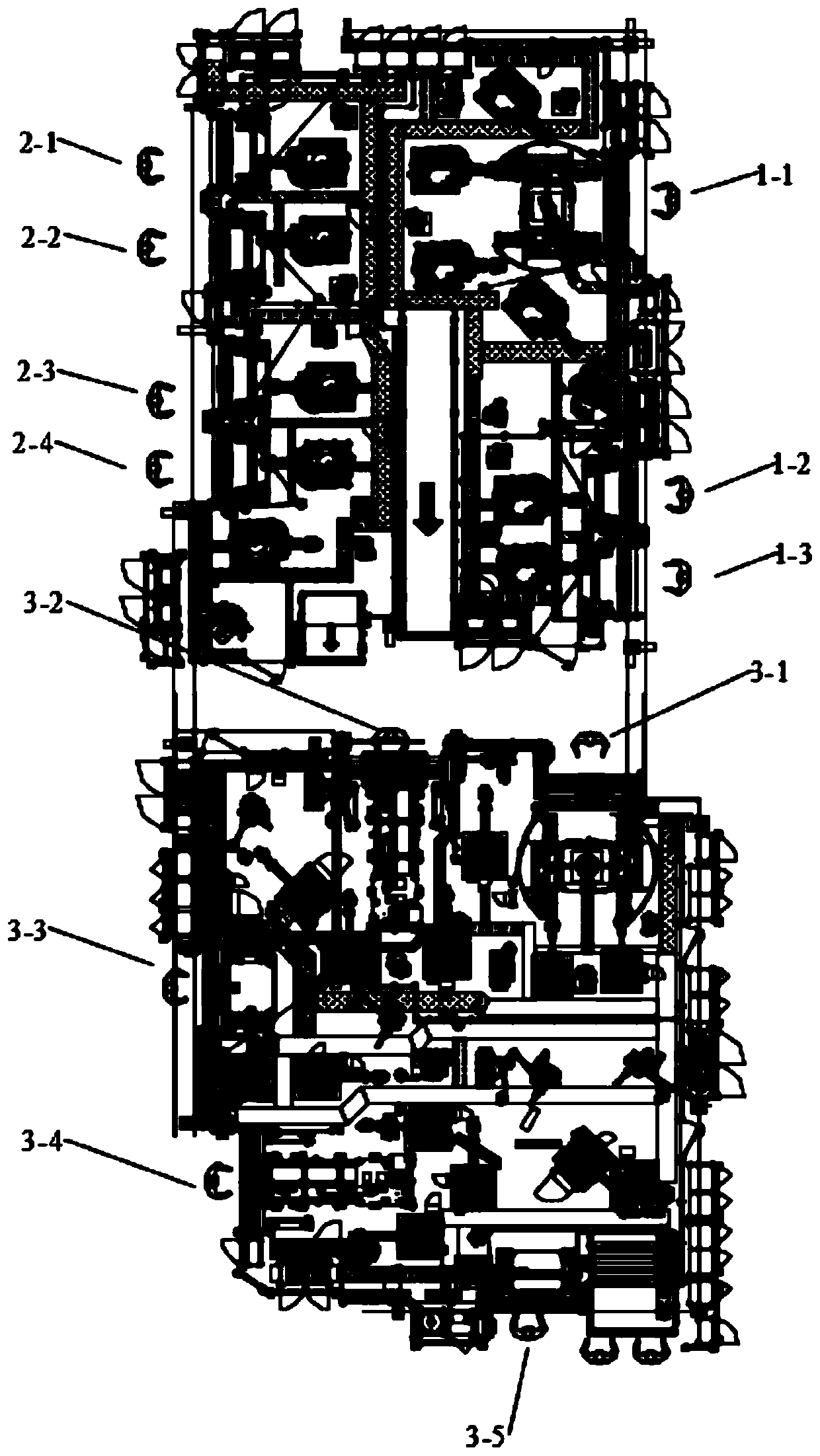

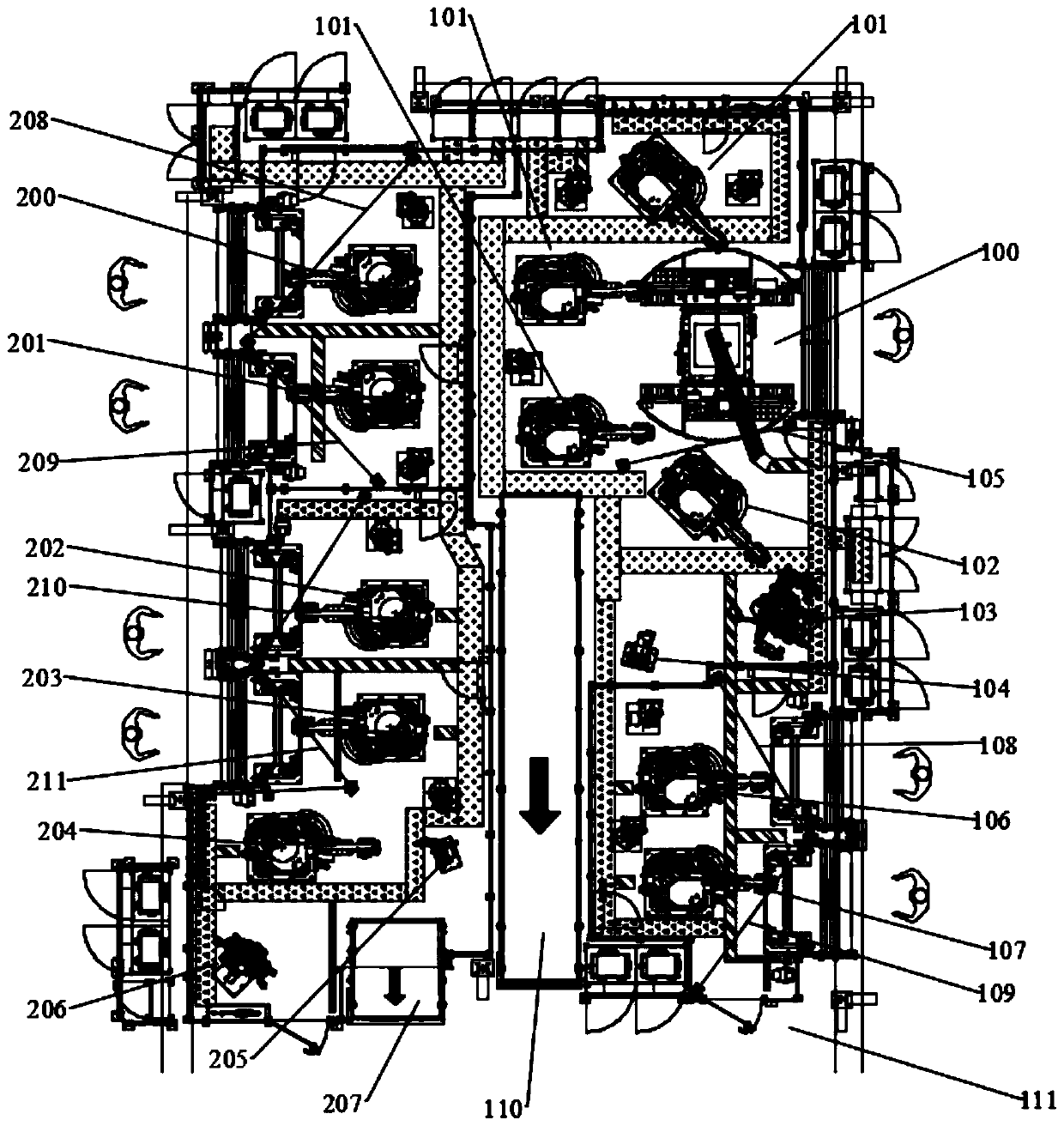

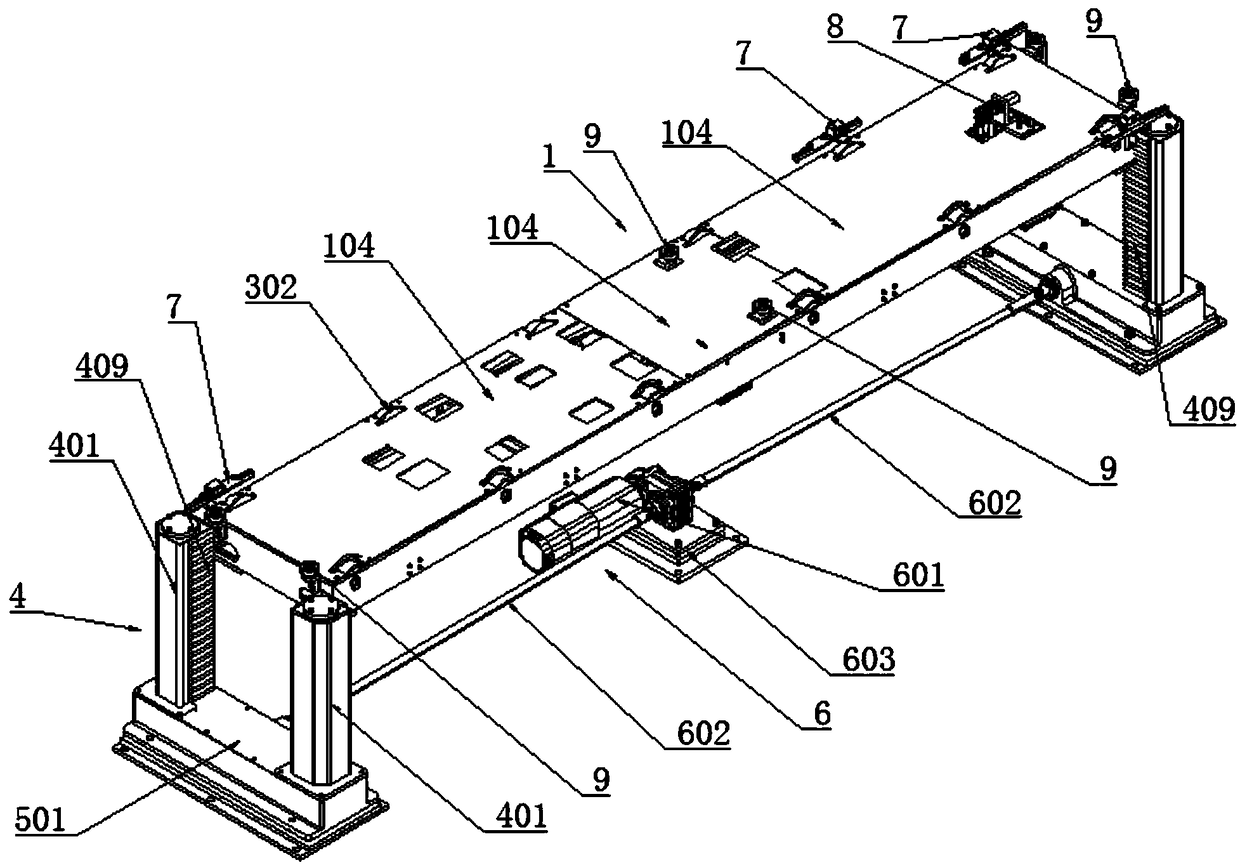

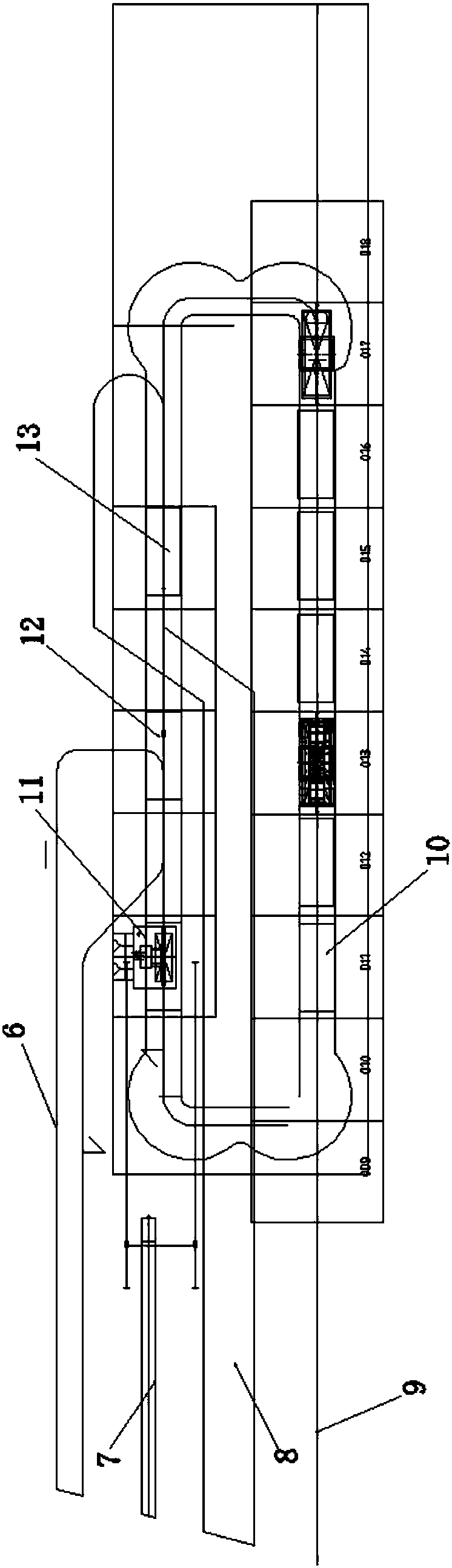

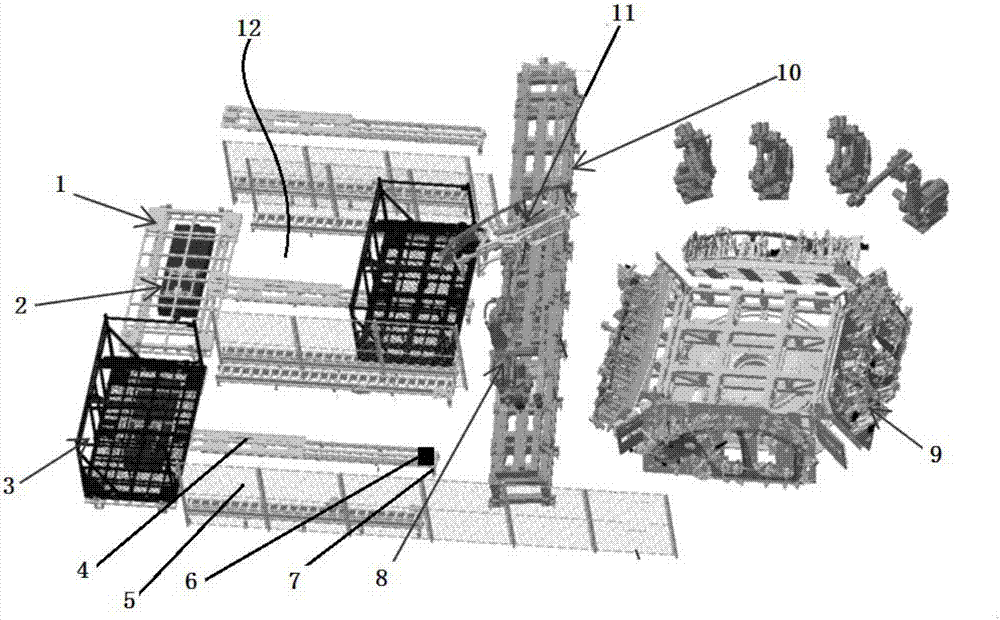

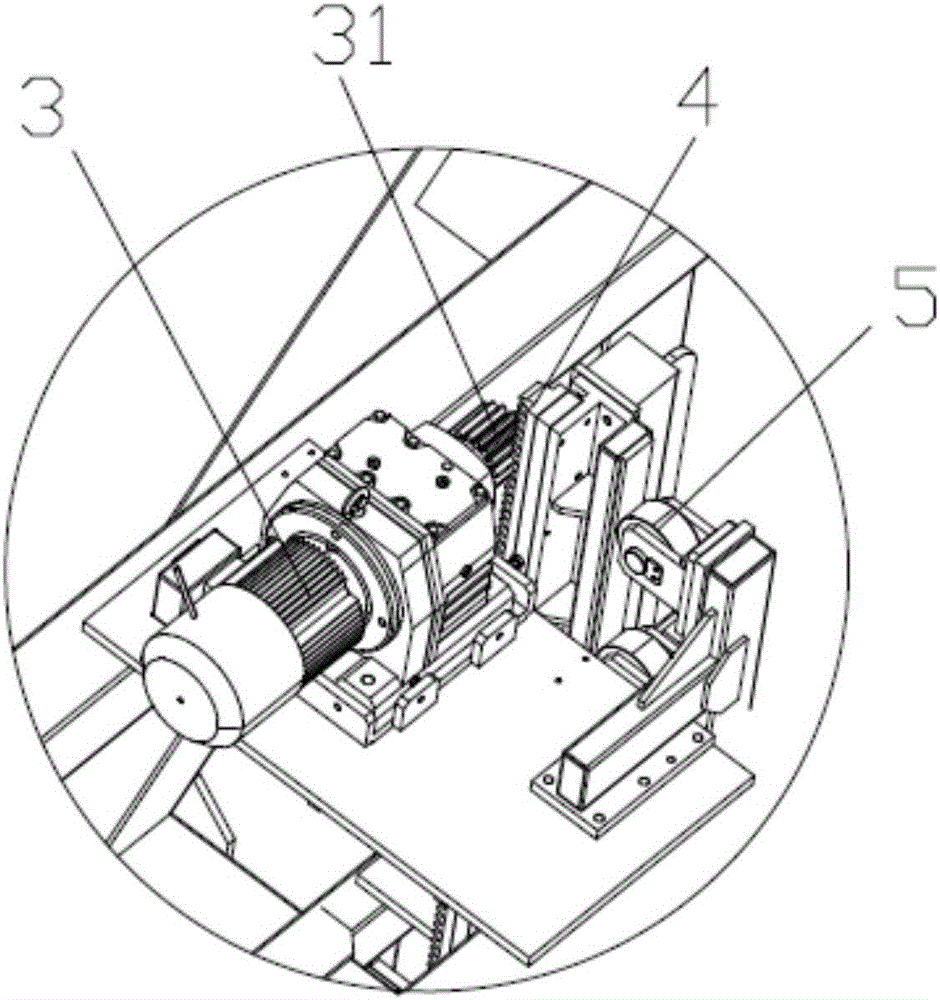

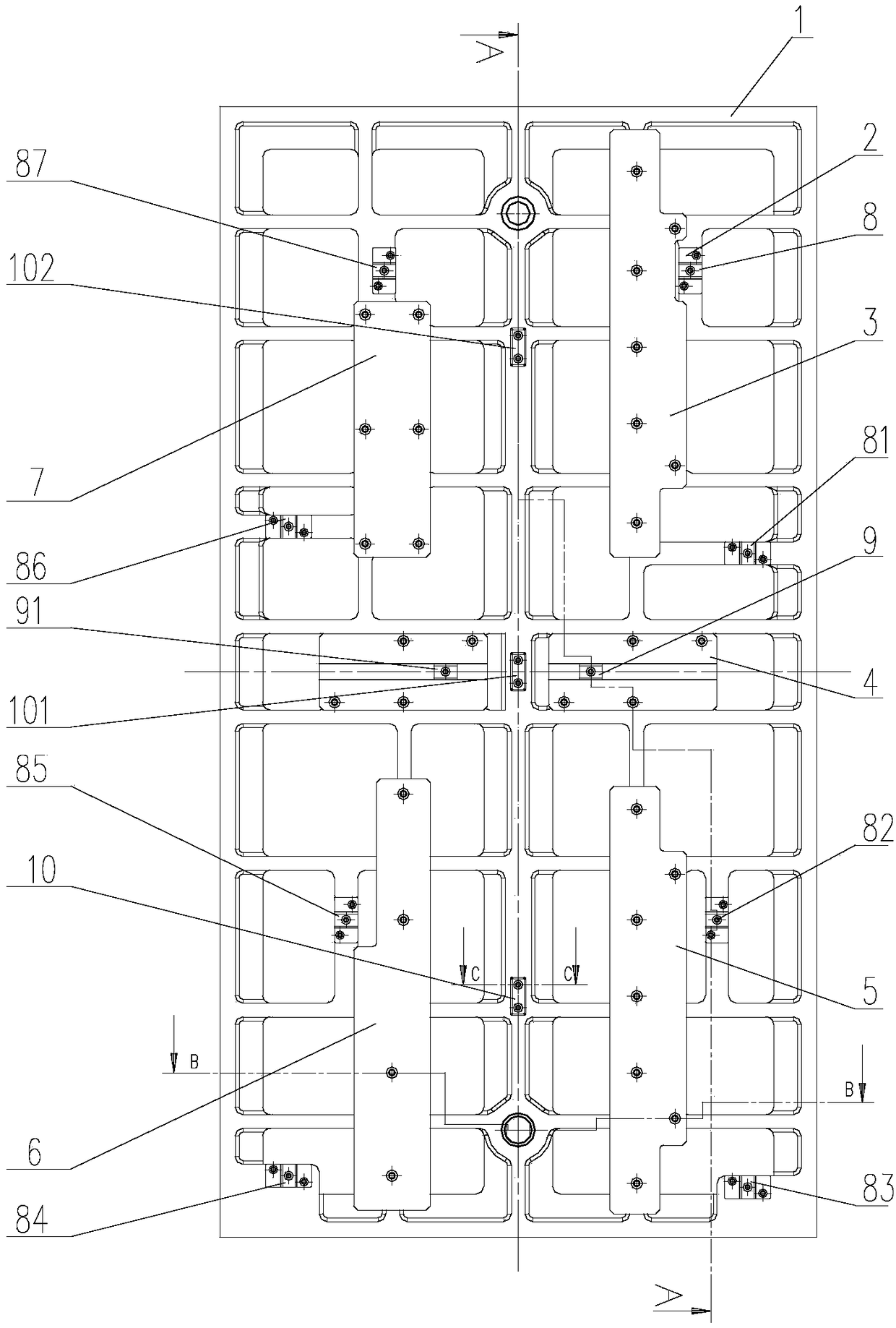

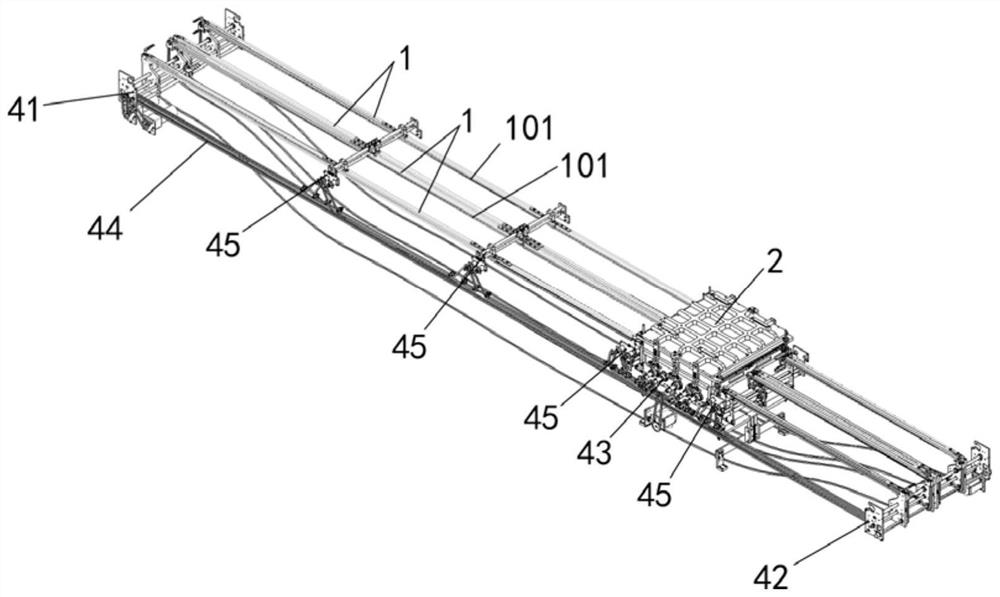

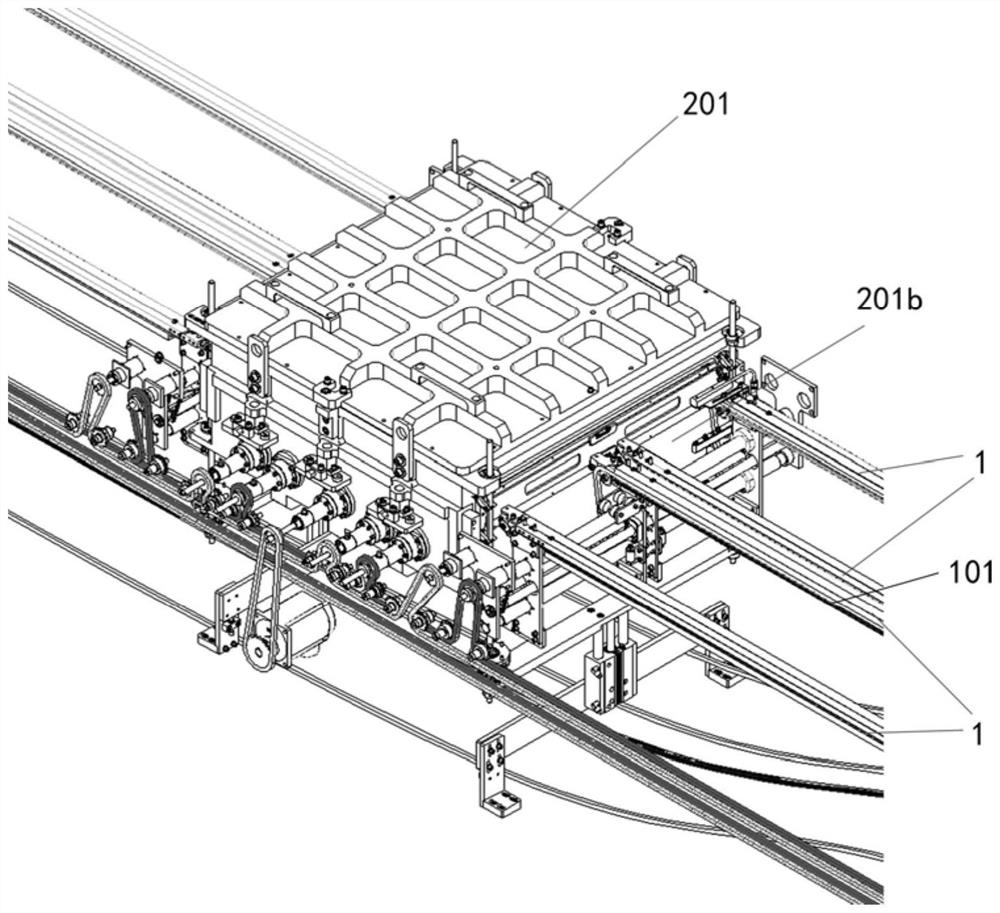

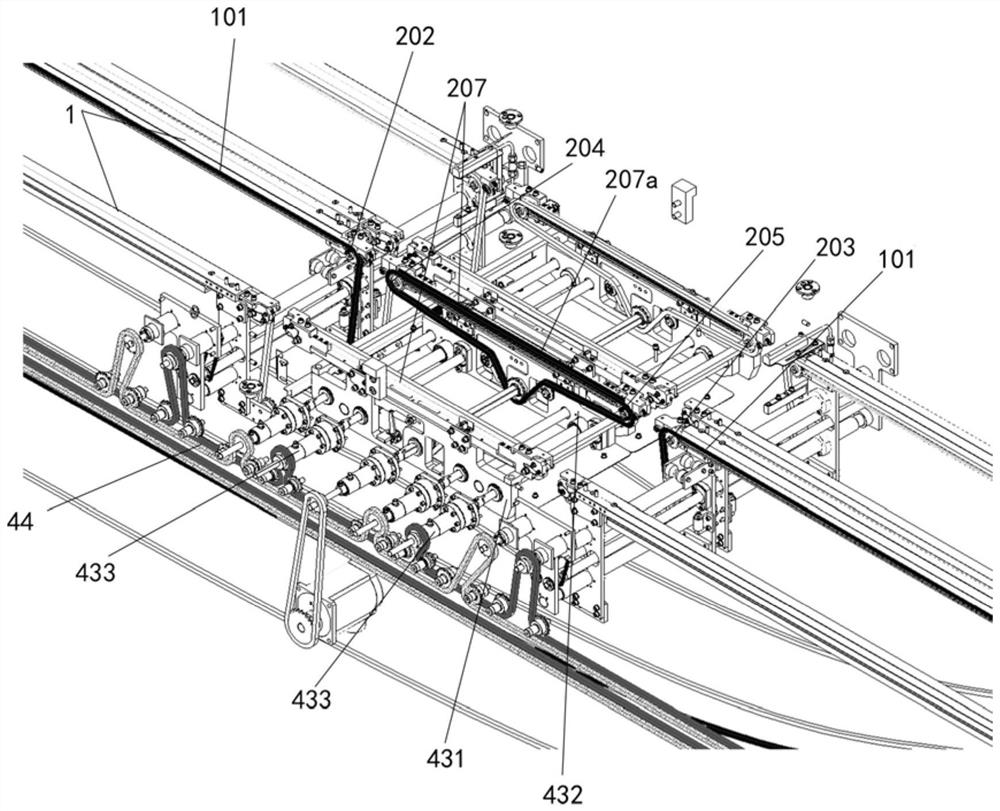

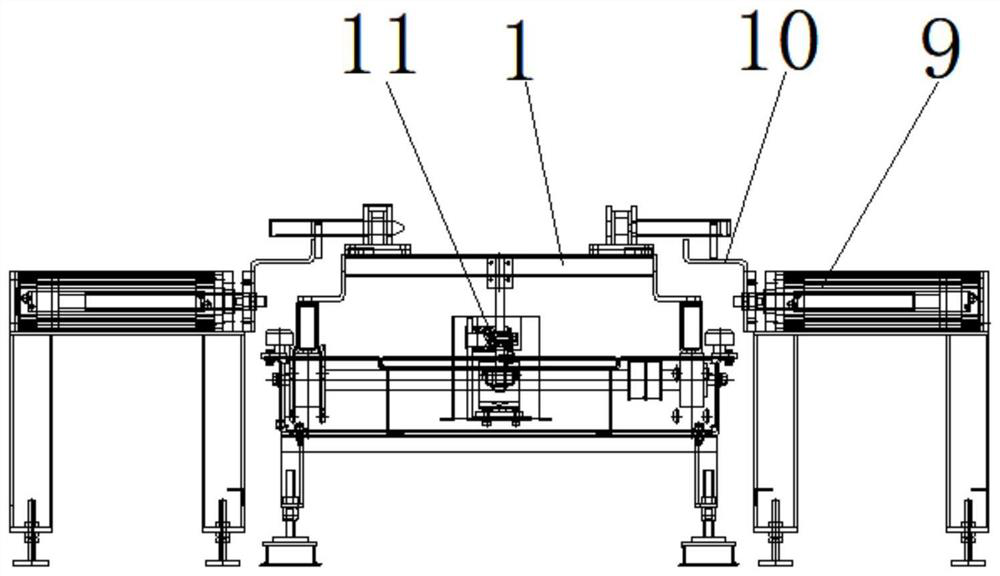

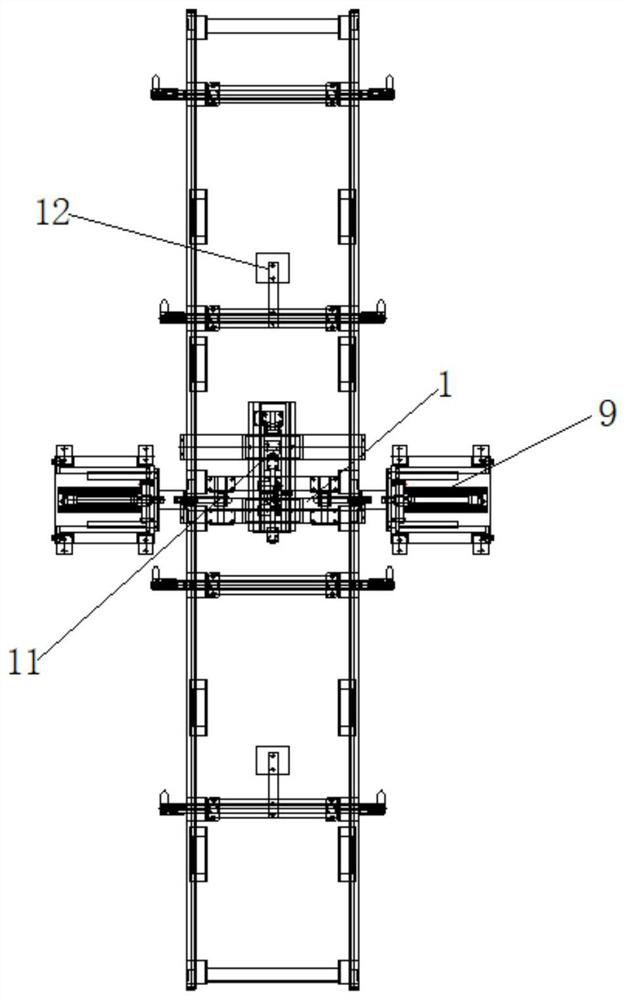

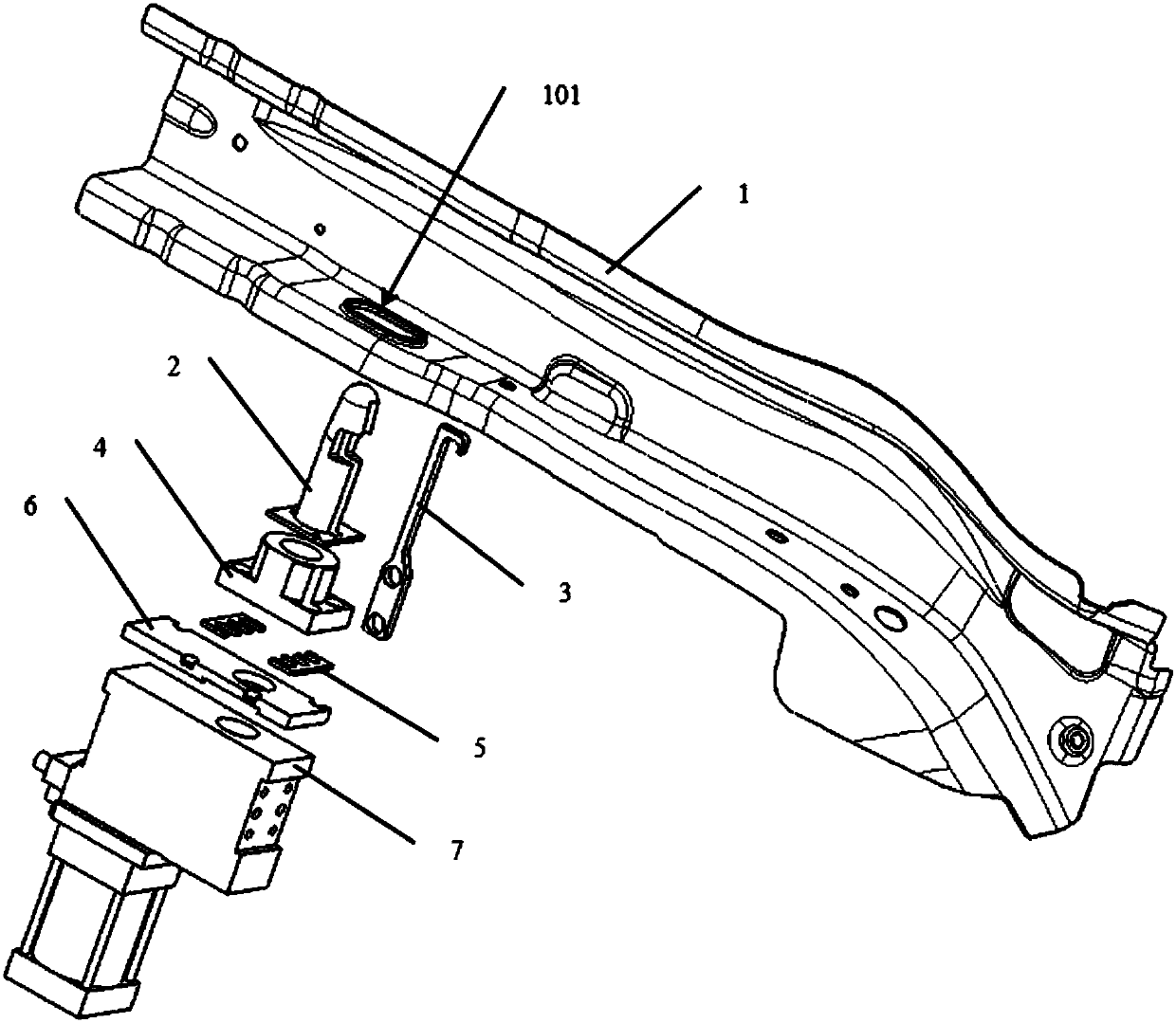

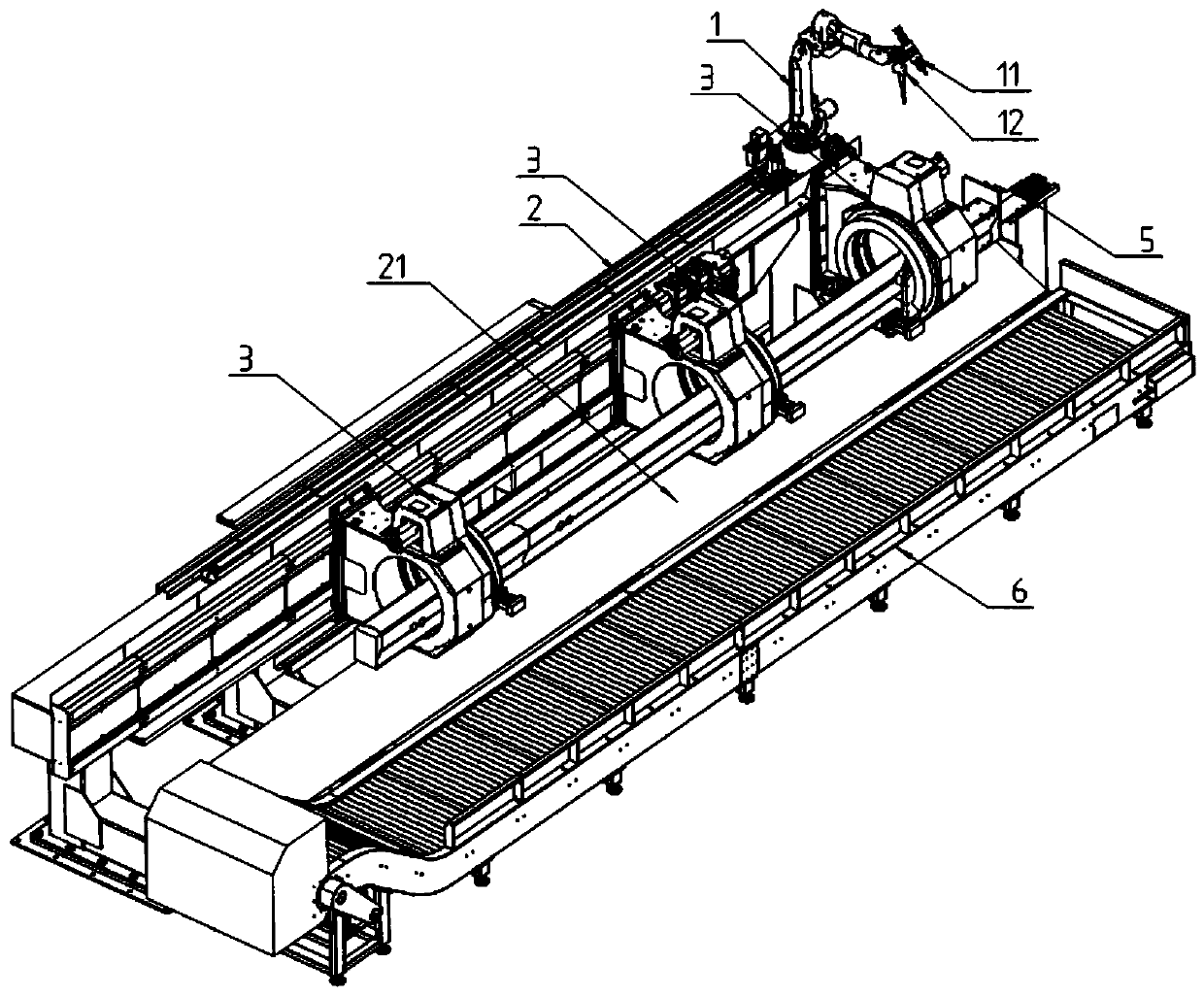

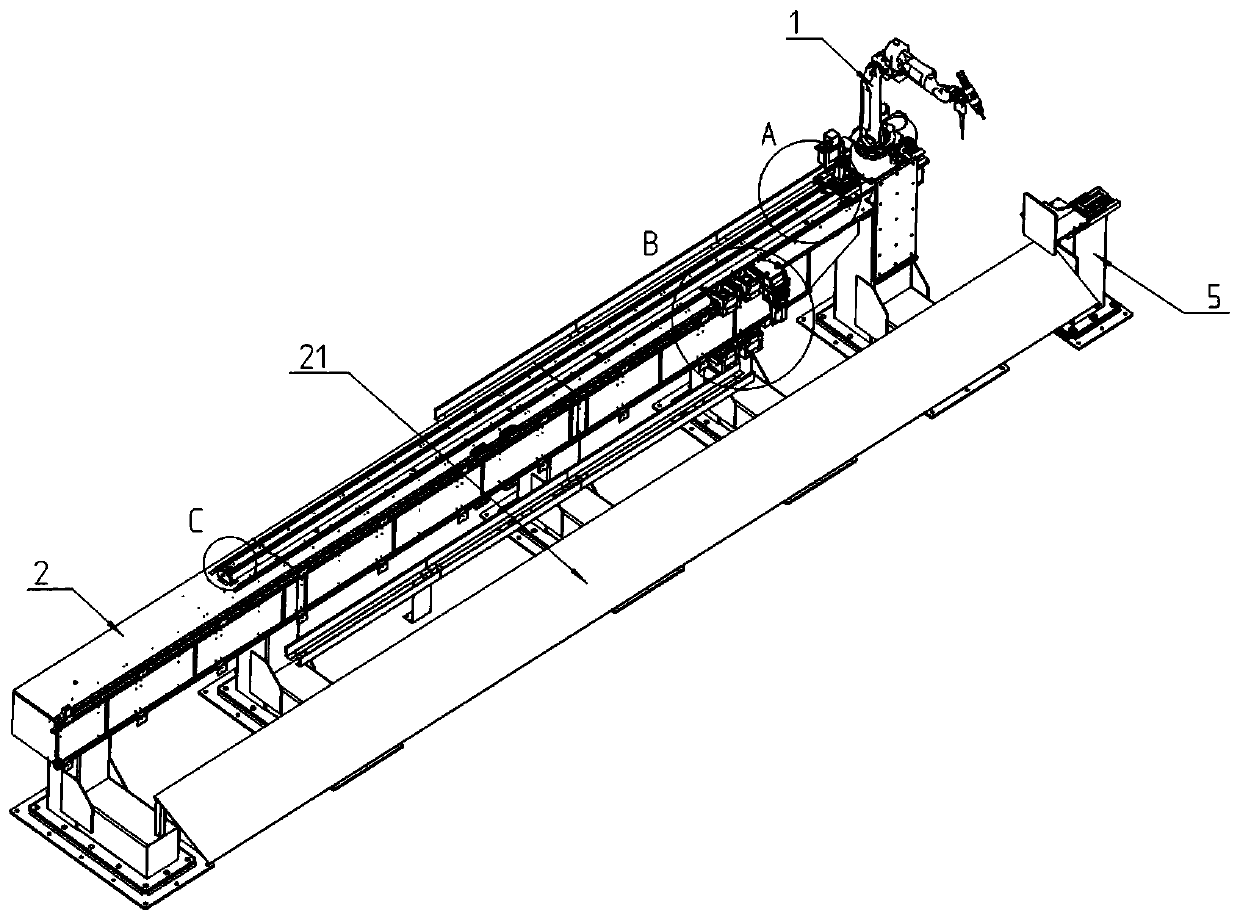

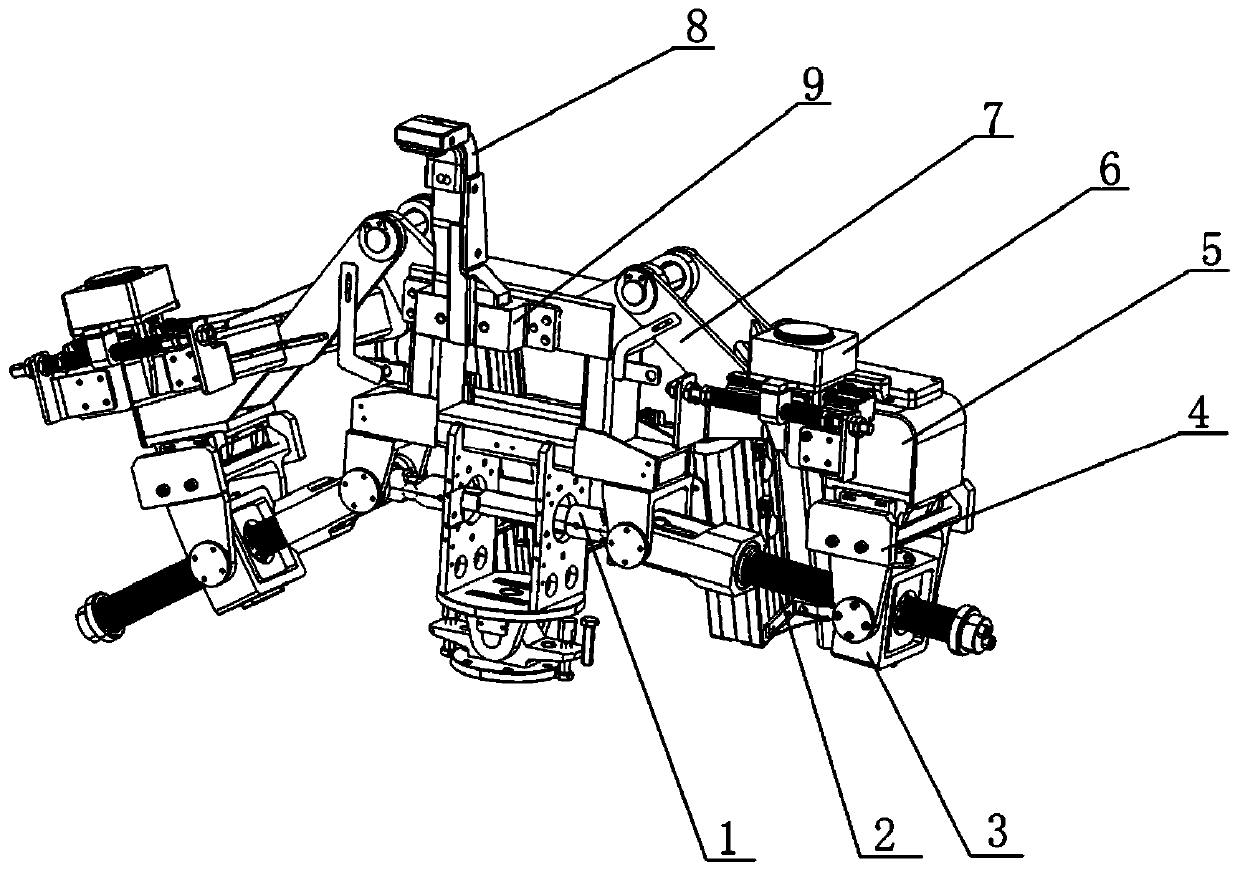

Flexible automatic production line of automobile left front girders

InactiveCN110355577ARealize collinear productionEfficient use ofProgramme-controlled manipulatorOther manufacturing equipments/toolsProduction lineOrder form

The invention discloses a flexible automatic production line of automobile left front girders. The flexible automatic production line comprises a PLC control device, a first-region production line, asecond-region production line and a third-region production line. Multiple part feeding stations, multiple welding stations, multiple carrying stations and a part discharging station are arranged on each of the first-region production line, the second-region production line and the third-region production line. Manual part feeding tables are arranged on the part feeding stations. Clamp switching devices provided with part feeding detection inductors and clamp storage devices used for containing multiple types of clamps are arranged on the manual part feeding tables. Welding robots, gripper storage racks used for containing multiple types of grippers and fixed welding guns are arranged on the welding stations. Carrying robots are arranged on the carrying stations. The first-region production line further comprises a gluing station provided with a gluing machine and a conveying station provided with a conveying belt. The third-region production line further comprises an arc welding workbench provided with an arc welding machine and a moving sliding table. The production line can achieve collinear production of multiple s, and more automobile type orders can be borne under the limitedsite and equipment.

Owner:广州广汽荻原模具冲压有限公司

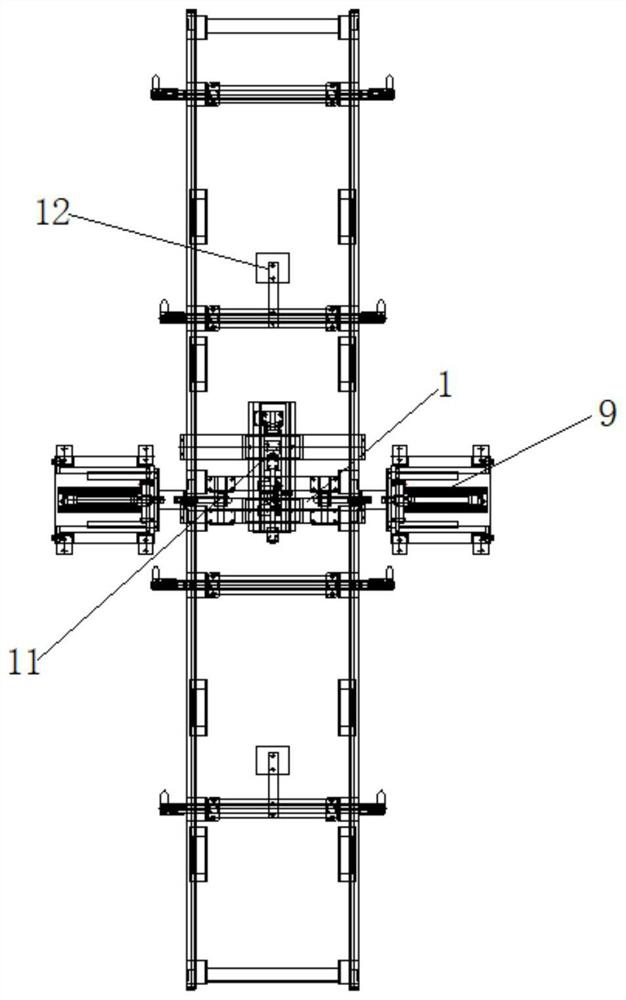

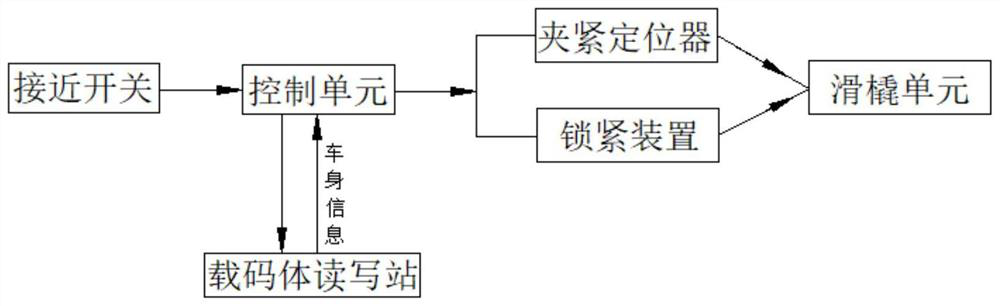

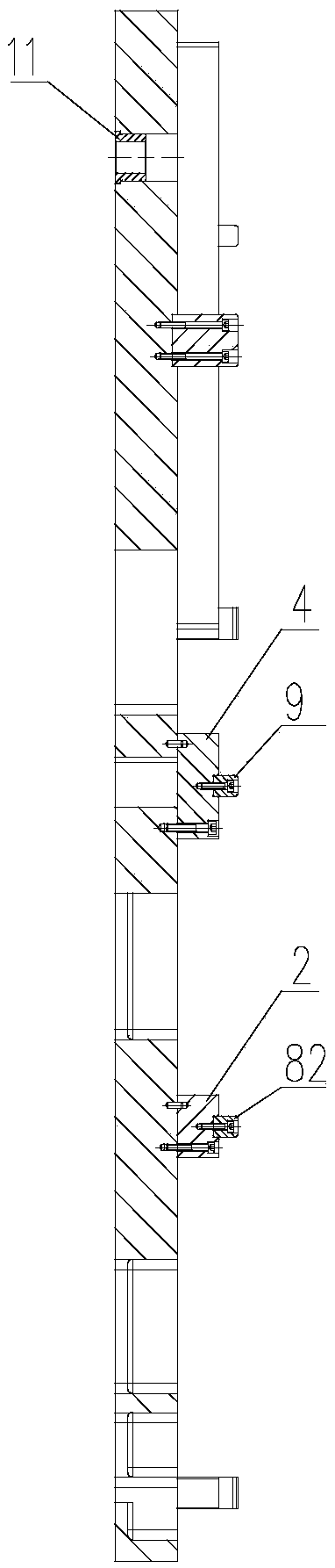

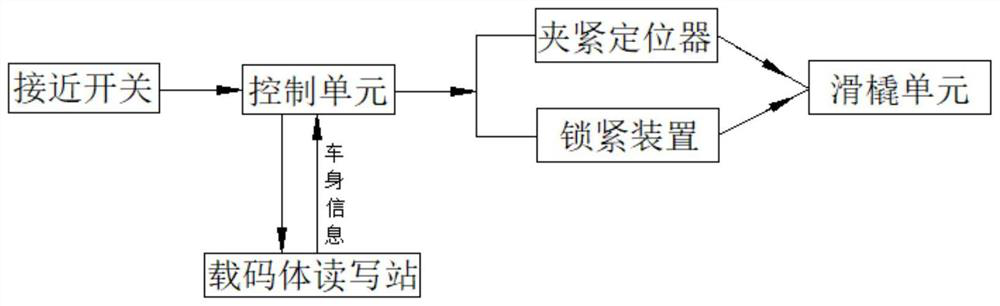

Switching system of sliding rail

InactiveCN105033524ARealize collinear productionReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPiston rod

The invention discloses a switching system of a sliding rail and belongs to the technical field of automobile welding production. The switching system of the sliding rail is characterized by comprising a fixed rail set, a servo drive mechanism, a sliding trolley and single-unit switching mechanisms, wherein the single-unit switching mechanisms are located at the intersecting position of rails of the fixed rail set, and each single-unit switching mechanism comprises a rotating rail set, a universal supporting wheel set and an air cylinder drive set; each rotating rail set comprises a rotating rail, a rotating wheel and a rotating side arm; the two ends of each rotating rail are connected with the rails of the fixed rail set, and each rotating rail is fixedly connected to the corresponding rotating wheel; each rotating wheel is fixedly connected with the corresponding rotating side arm, and the other end of each rotating side arm is hinged to a piston rod of the corresponding air cylinder; each universal supporting wheel set comprises a fixed wheel, a connecting body, a universal sphere and a sliding wheel, and each sliding trolley is fixedly connected with the corresponding fixed wheel; and the sliding wheels are arranged at the lower end of the corresponding universal sphere and clamped on the two sides of the corresponding rotating rail. By means of the single-unit switching mechanism, production of multiple vehicle models on the same line is achieved on the same plane. The switching system of the sliding rail has the beneficial effects of reducing cost and improving efficiency.

Owner:ANHUI RUIXIANG IND

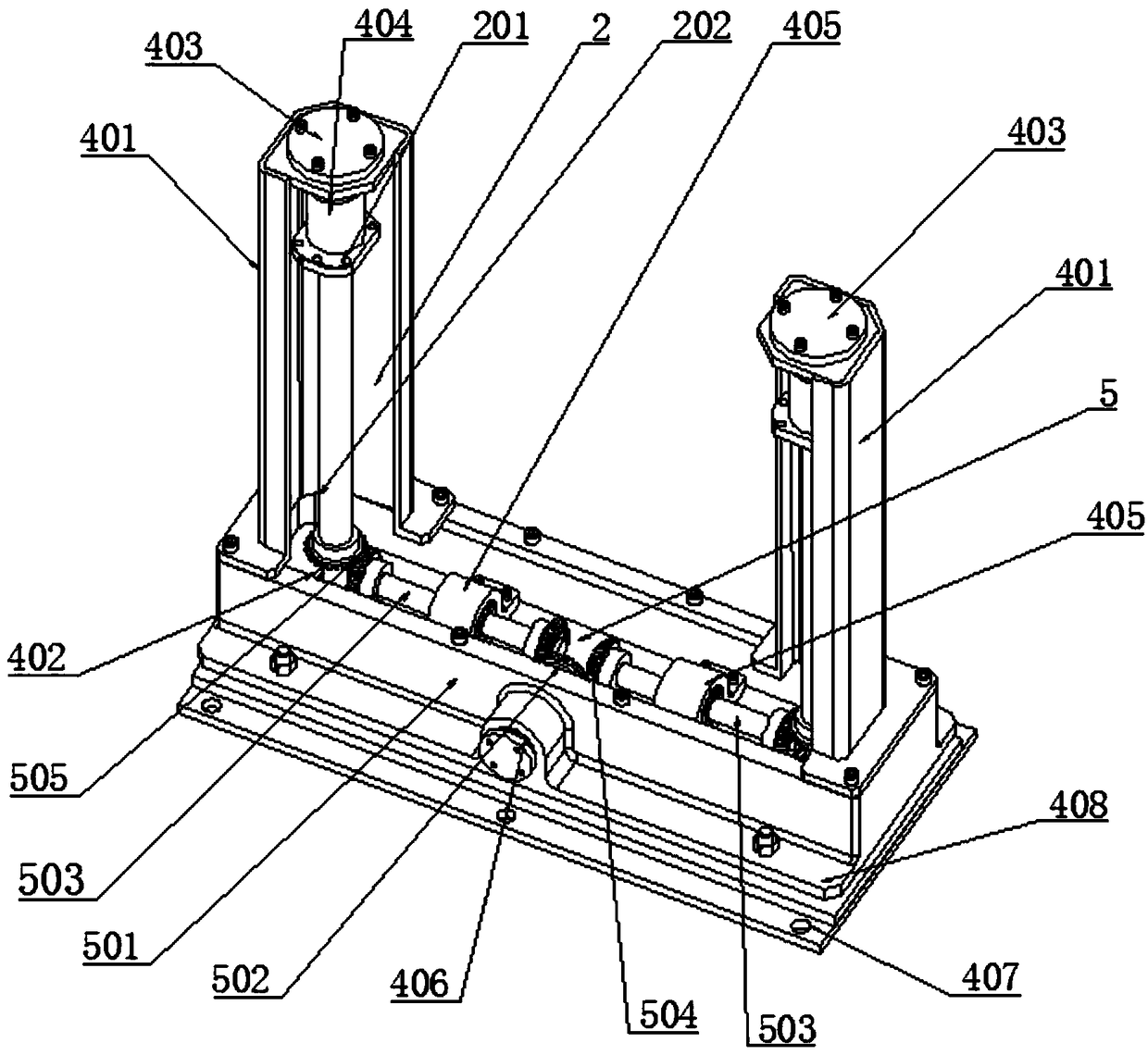

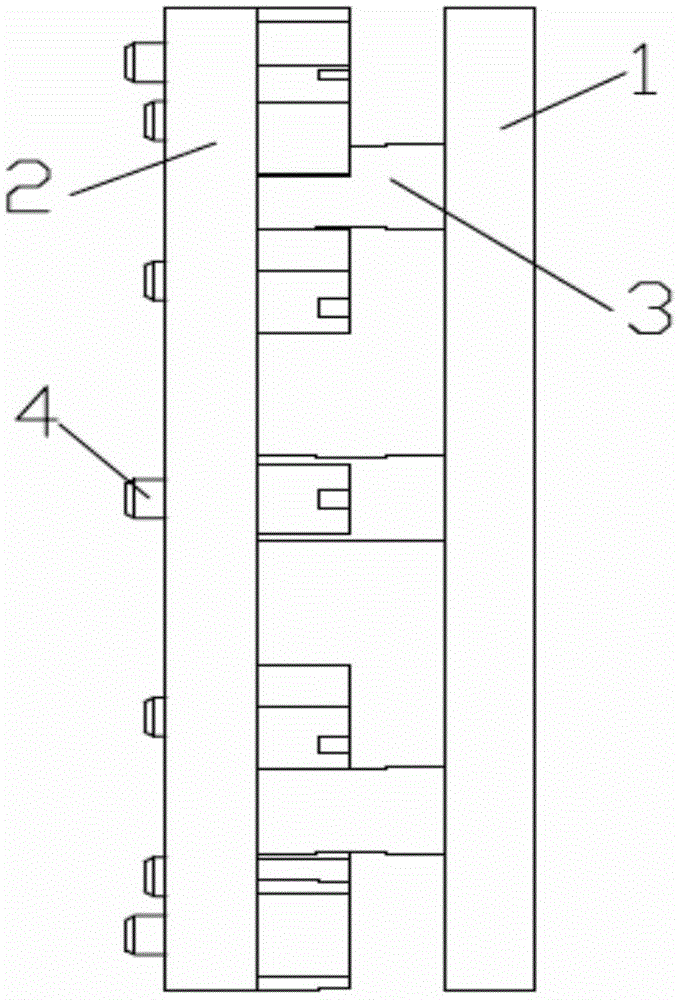

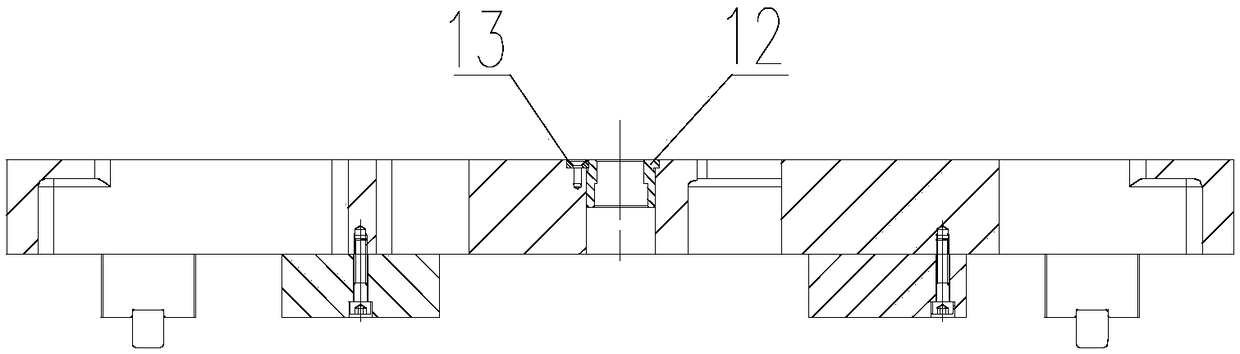

Lead screw lifting high-speed roller bed for conveying

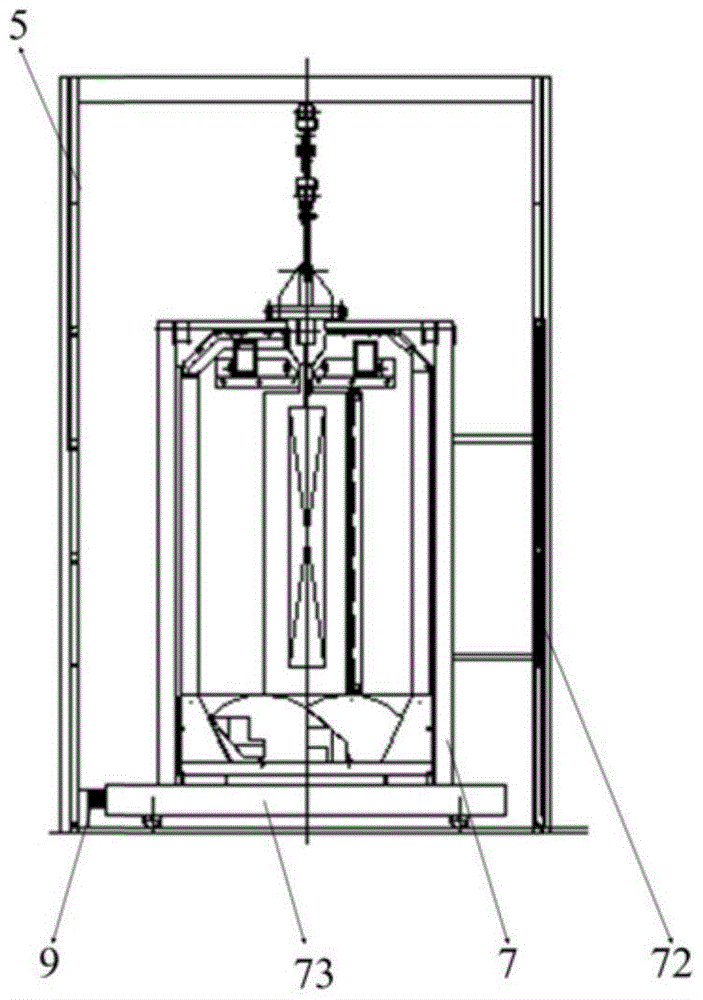

InactiveCN109051515ASolve the problem of collinear productionSmall footprintControl devices for conveyorsRoller-waysStops deviceSmall footprint

The invention discloses a lead screw lifting high-speed roller bed for conveying. The lead screw lifting high-speed roller bed comprises a conveying roller bed and two supporting frames arranged at the two ends of the conveying roller bed, each of the supporting frames is provided with a lead screw lifting mechanism for supporting the conveying roller bed, a lifting drive device capable of drivingthe two lead screw lifting mechanisms is arranged below the conveying roller bed, steering conversion mechanisms for connecting the lead screw lifting mechanisms with the lifting drive device are arranged on the supporting frames, a horizontal conveying mechanism is arranged on the conveying roller bed, a plurality of sensing devices for sensing the positions of workpieces are arranged on the side of the conveying roller bed, and the conveying roller bed is provided with a safety stopping device capable of ascending and descending. The lead screw lifting high-speed roller bed for conveying issmall in floor space and is suitable for cooperating with various peripheral devices such as a multi-axis positioning device and a windmill positioning device.

Owner:广州德恒汽车装备科技有限公司

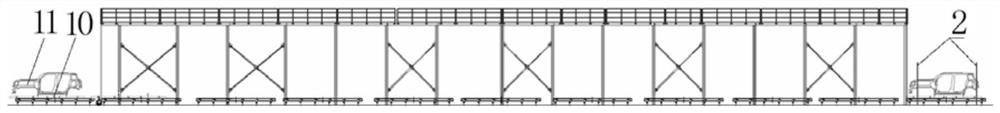

Collinear assembling production line for chassis of different bodies and use method of collinear assembling production line

ActiveCN108528566AChange the problem that cannot be collinearRealize collinear productionVehiclesProduction lineVehicle frame

The invention belongs to the technical field of automobile assembling, and particularly relates to a collinear assembling production line for chassis of different bodies and a use method of the collinear assembling production line. The collinear assembling production line comprises a powertrain sub-assembling line, a rear axle sub-assembling line, a frame sub-assembling line and a chassis line, wherein multiple combination stations for assembling all components are distributed on the chassis line; the rear axle sub-assembling line is connected with a rear axle sub-assembling AGV (Automated Guided Vehicle); the rear axle sub-assembling AGV carries rear axles to be installed onto the chassis line for installation; the assembling production line further comprises a powertrain sub-assembling AGV which is connected with the powertrain sub-assembling line and is used for conveying powertrains; the frame sub-assembling line is connected with a frame AGV for conveying frames onto the chassis line. The collinear assembling production line solves the problem that traditional unitary construction bodies and non-unitary construction bodies cannot be assembled on the same production line. By the adoption of the AGVs for conveying the components, collinear production of the unitary construction bodies and the non-unitary construction bodies can be implemented, so that one chassis line is eliminated, and the production cost is reduced.

Owner:DORCEN AUTO CO LTD +1

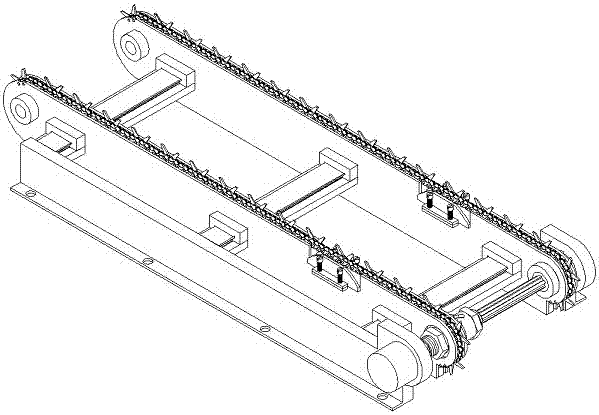

Popular type conveying device

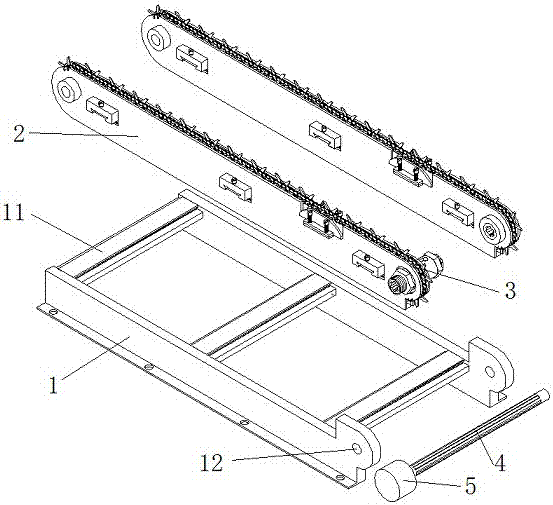

InactiveCN107235294ARealize collinear productionEasy to change production and adjustConveyorsDrive shaftEngineering

A general-purpose feeding device, including a base, a housing, a transmission system, a drive shaft, and a motor. The two housings are installed on the base in parallel, and the transmission system is installed on each housing, and the drive shaft is installed on the base end in a rotatable manner. The head and the drive shaft are connected to the transmission system, and the motor is connected to the drive shaft; the housing is slidably installed on the dovetail beam of the base through the dovetail block fixed on it to realize width adjustment; the upper end of the housing is also vertically slid to install a height adjustment chain Adjusting device; the transmission system is a sprocket chain drive, and the main sprocket has a deflection adjustment device; this device can be easily adjusted to meet the processing requirements of different shaft products.

Owner:李传聪

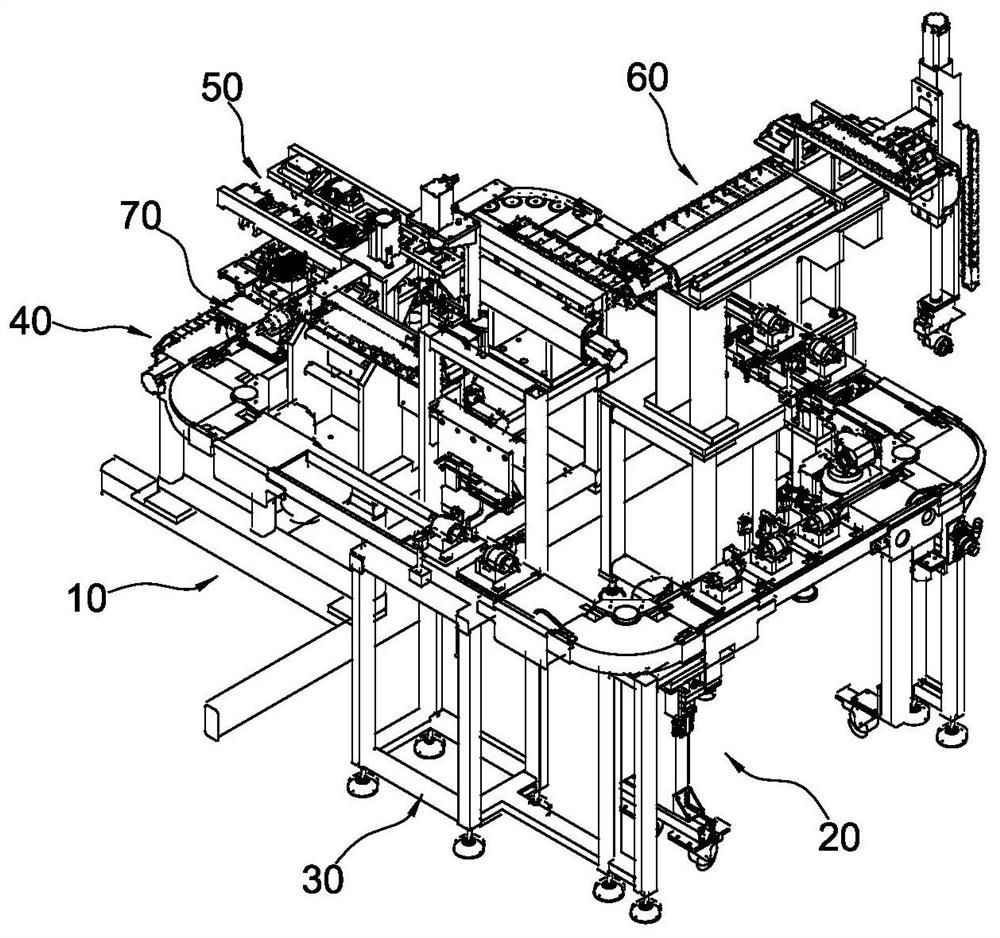

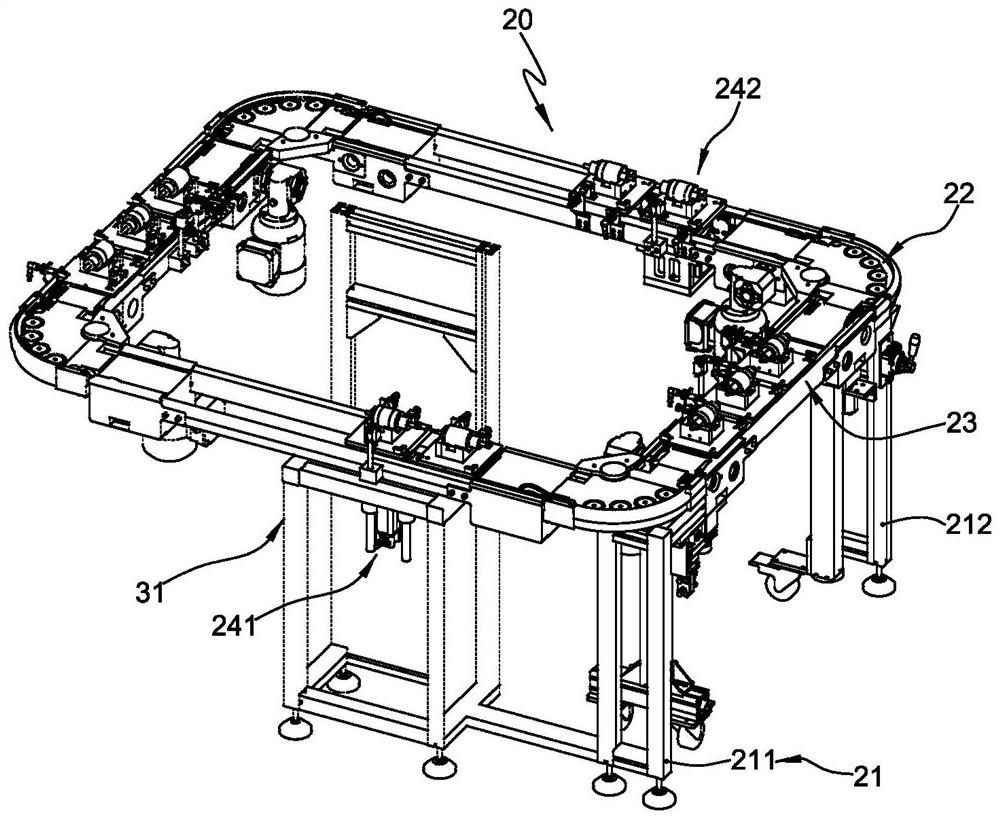

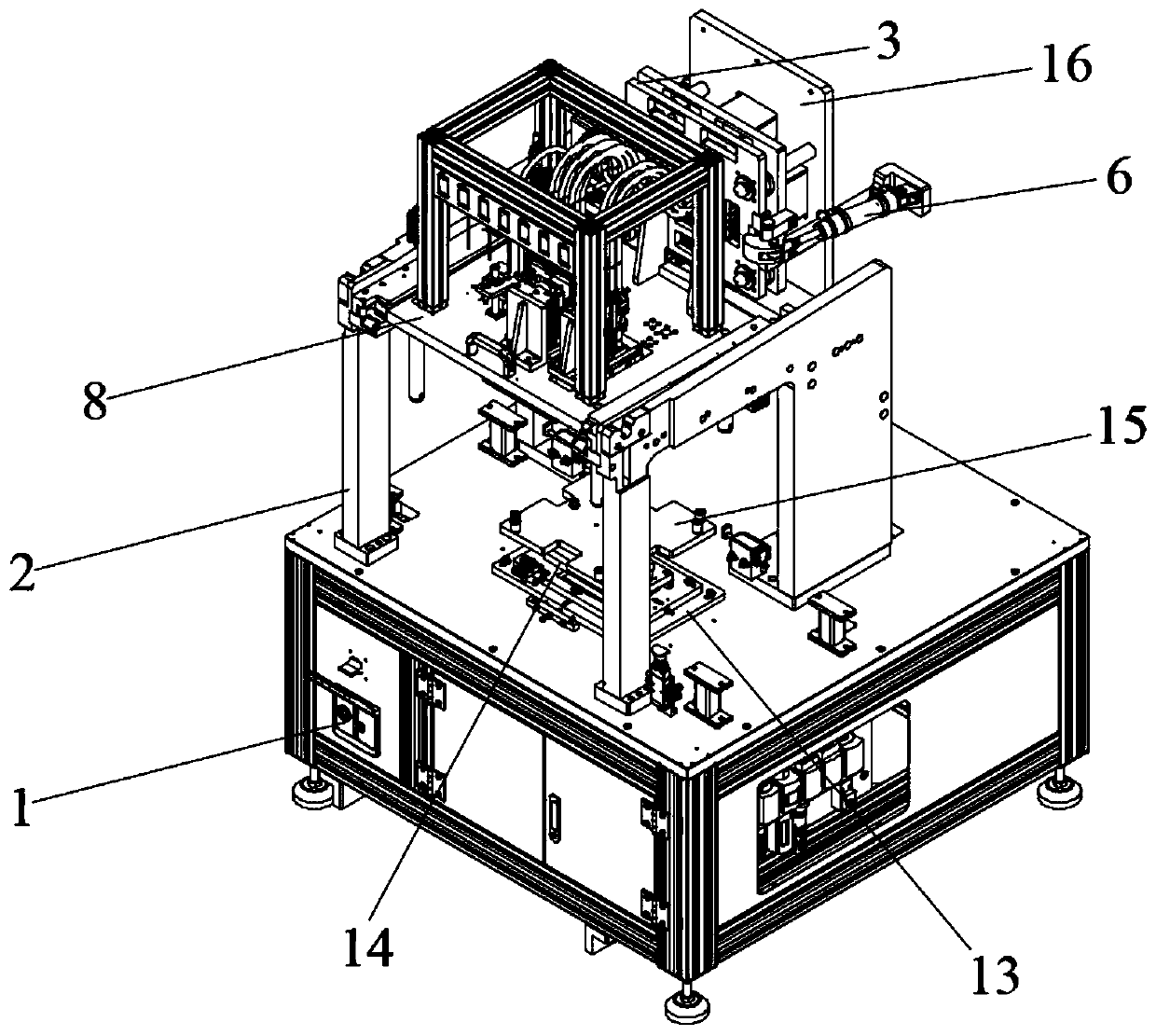

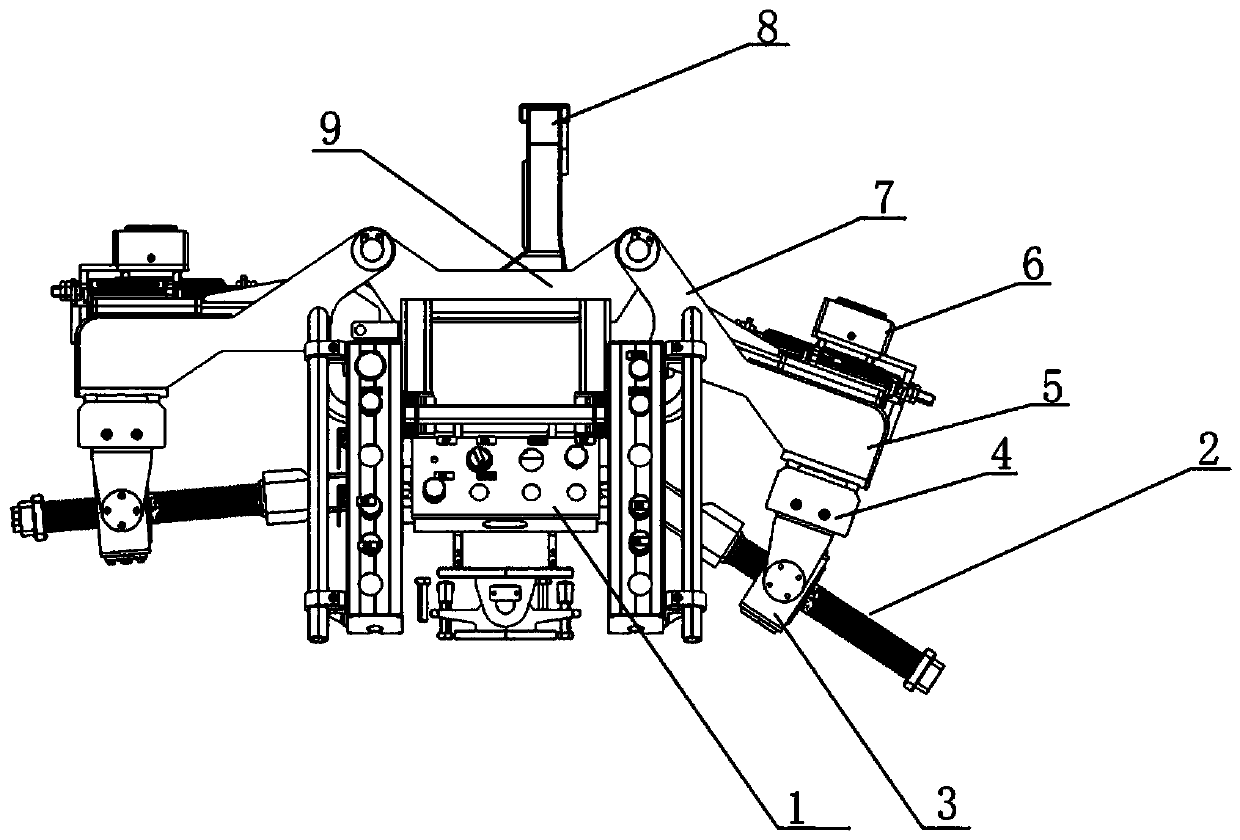

Multi-vehicle-type automatic part feeding device

ActiveCN107032065AReduce labor costsFast switching speedWelding/cutting auxillary devicesControl devices for conveyorsFixed frameEngineering

The invention relates to a multi-vehicle-type automatic part feeding device. The multi-vehicle-type automatic part feeding device comprises a material transporting unit, a material positioning unit, a material grabbing unit and a rotary table clamp. The material positioning unit comprises a plurality of fixing frames matched with the material transporting unit, during working, parts are transported into the fixing frame of the corresponding vehicle type by the material transporting unit to be fixed, the parts in the material transporting unit are grabbed onto the rotary table clamp by the material grabbing unit, and a next working procedure is conducted. According to multi-vehicle-type automatic part feeding device, compared with the prior art, outside plate part feeding workers are omitted, labor cost is reduced, and a PLC is arranged to control efficient running of an AGC automatic feeding system; in addition, stock positions can adapt to multiple vehicle types, and multi-vehicle-type collinear production is achieved.

Owner:博飞特(上海)智能设备股份有限公司

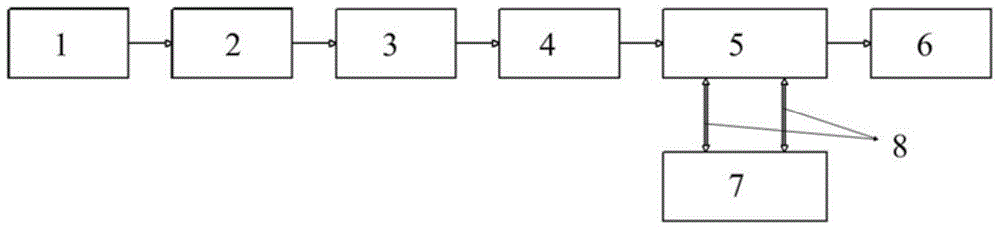

Powder-spraying and paint-spraying single-line spray system and process

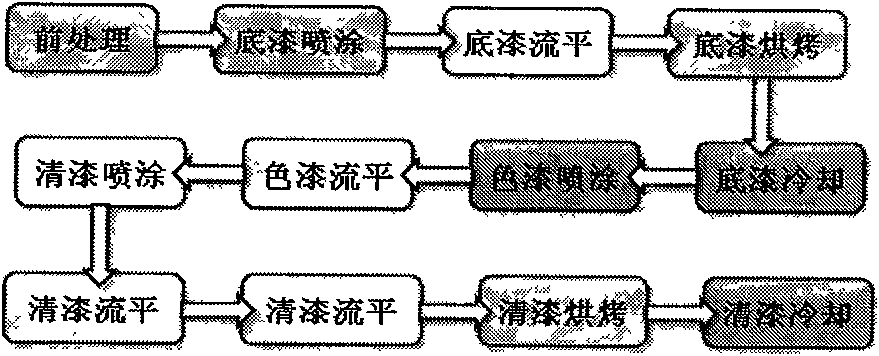

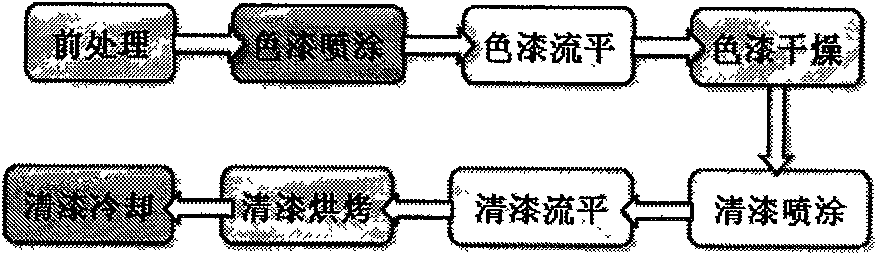

ActiveCN105057153AImprove production taktLow investment costLiquid surface applicatorsCoatingsLacquerEngineering

The invention relates to the technical field of coating, and discloses a powder-spraying and paint-spraying single-line spray system. The powder-spraying and paint-spraying single-line spray system comprises a gluing chamber, a colored paint spraying chamber, a leveling chamber I, a clear lacquer spraying chamber, a leveling chamber II and a drying chamber, which are sequentially arranged, and further comprises a mobile powder room, wherein an opening for allowing the mobile powder room to get in and get out is formed in the leveling chamber II; and an opening-closing device is corresponding to the opening. The system can realize powder-spraying and paint-spraying on a single production line. In the meantime of achieving advantages of zero VOC emission and low input of powder spraying, requirements for spraying in different colors for work pieces can be met conveniently by utilizing an advantage that multi-color spraying can be realized by utilizing paint spraying, and the cost is reduced. The invention further provides a powder-spraying process and a paint-spraying process. The powder-spraying process comprises the steps of gluing, carrying out powder-spraying pretreatment, carrying out powder-spraying, drying and the like; and the paint-spraying process comprises the steps of gluing, spraying colored paint, carrying out primary leveling, spraying clear lacquer, carrying out secondary leveling, drying and the like. The powder-spraying process and the paint-spraying process can be carried out on the same production line, and are convenient in coating.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

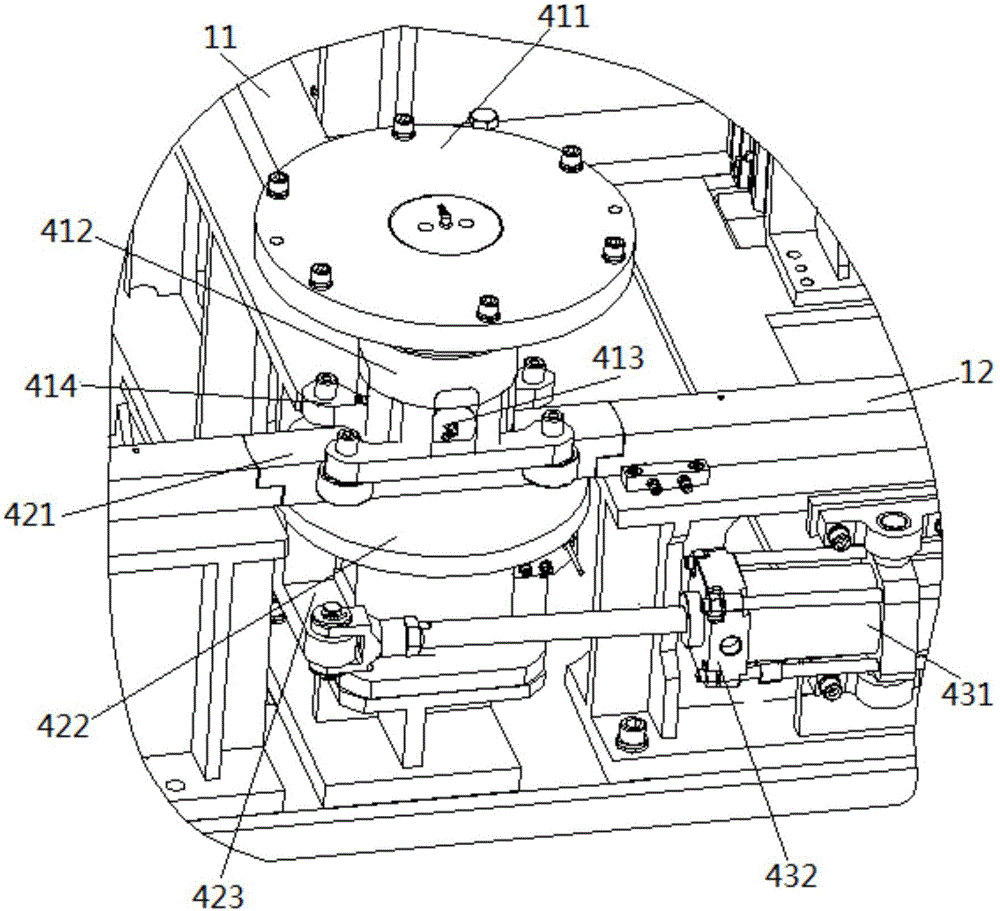

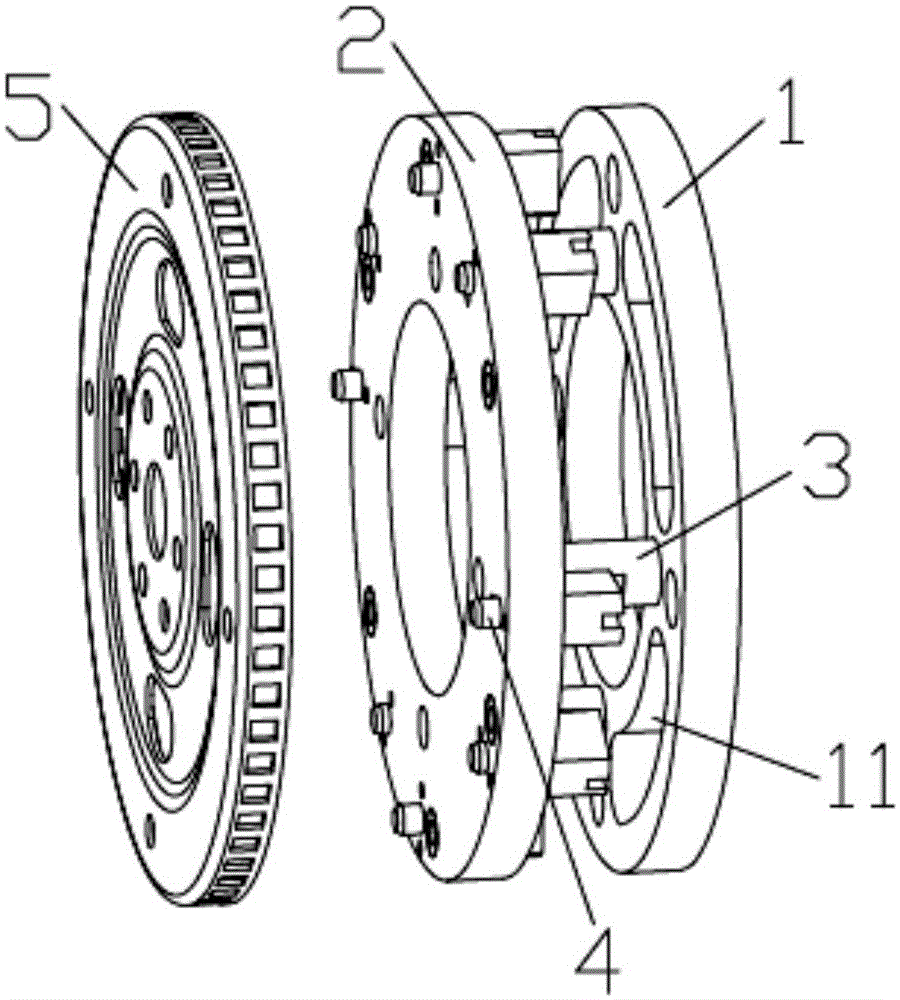

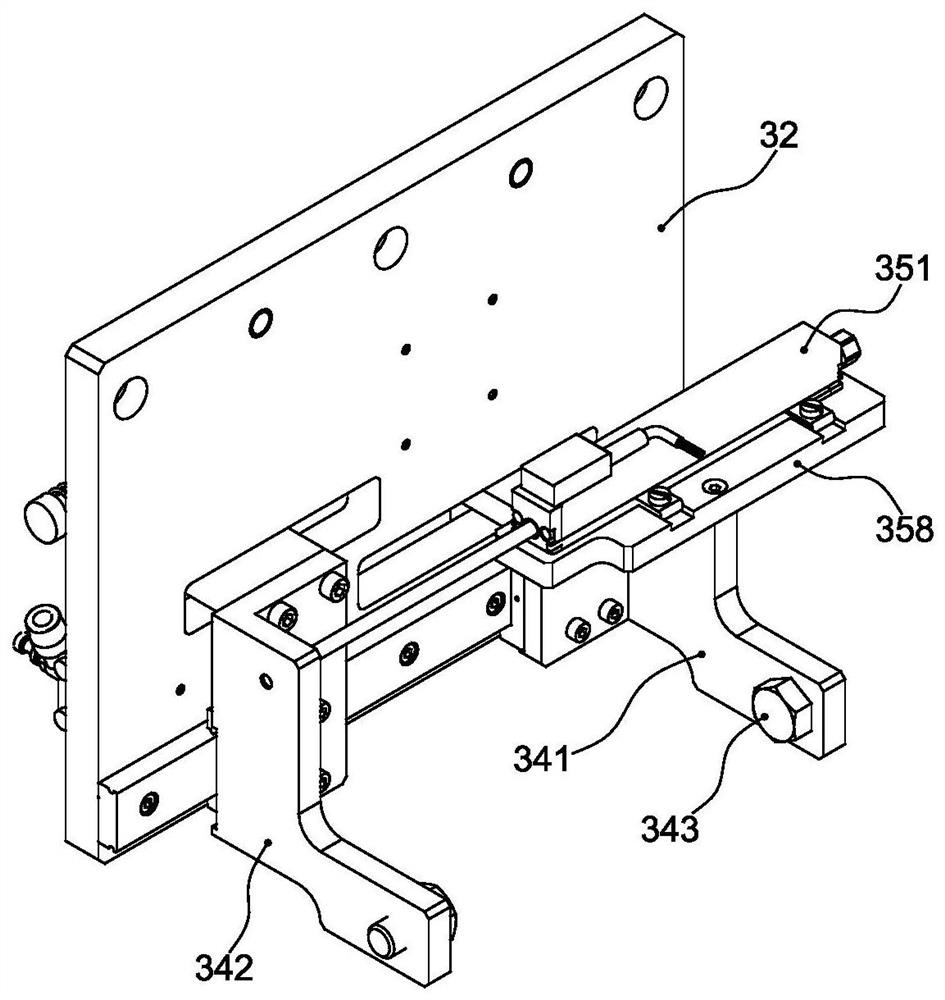

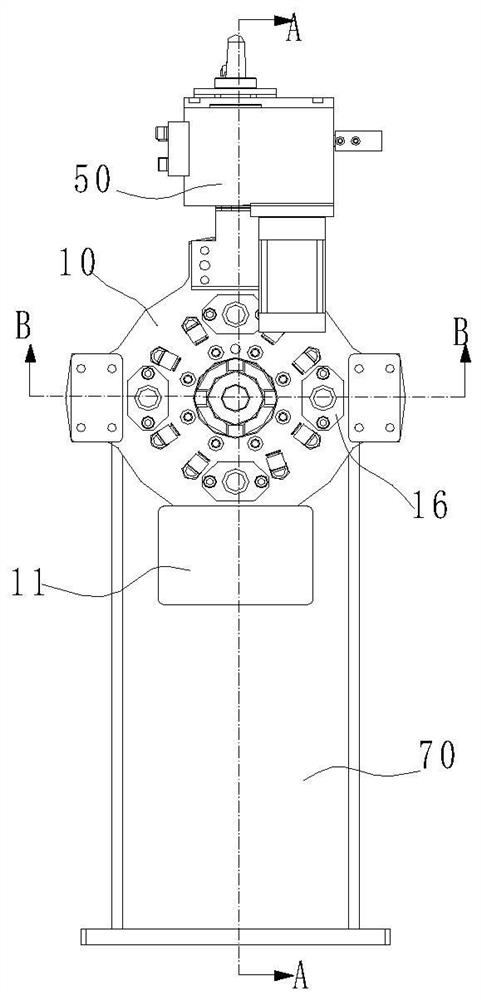

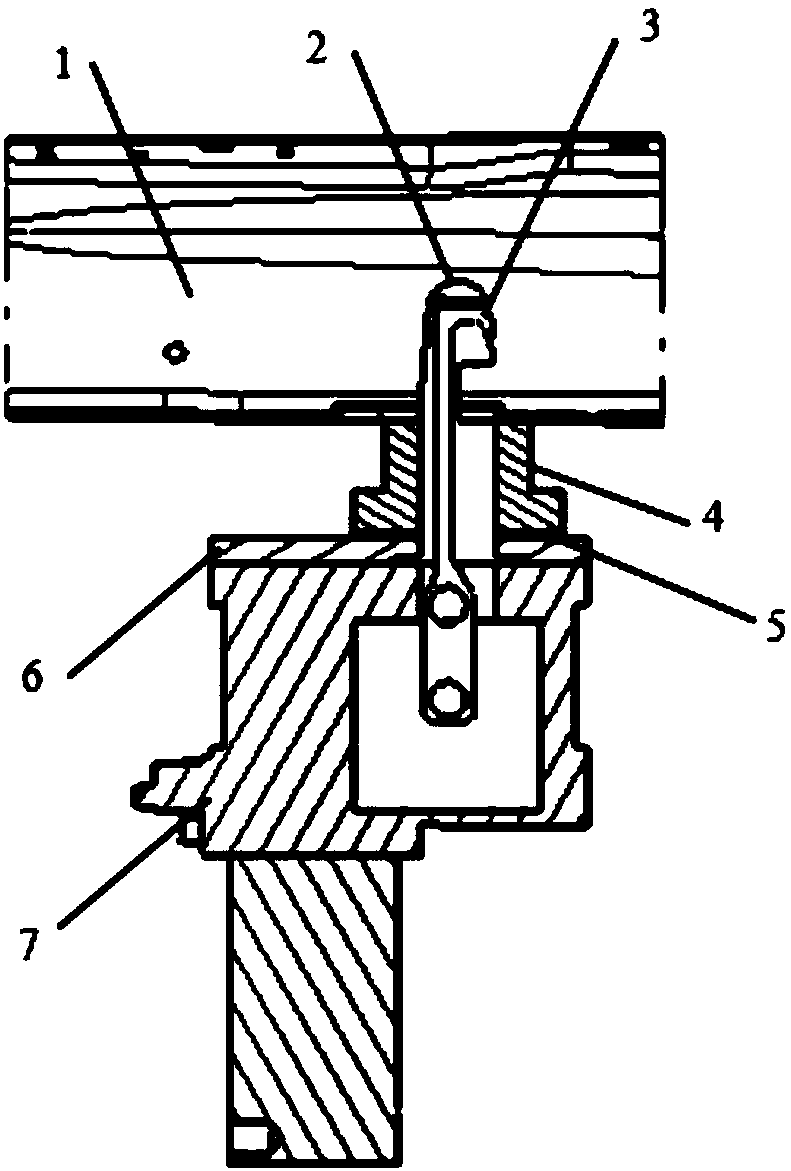

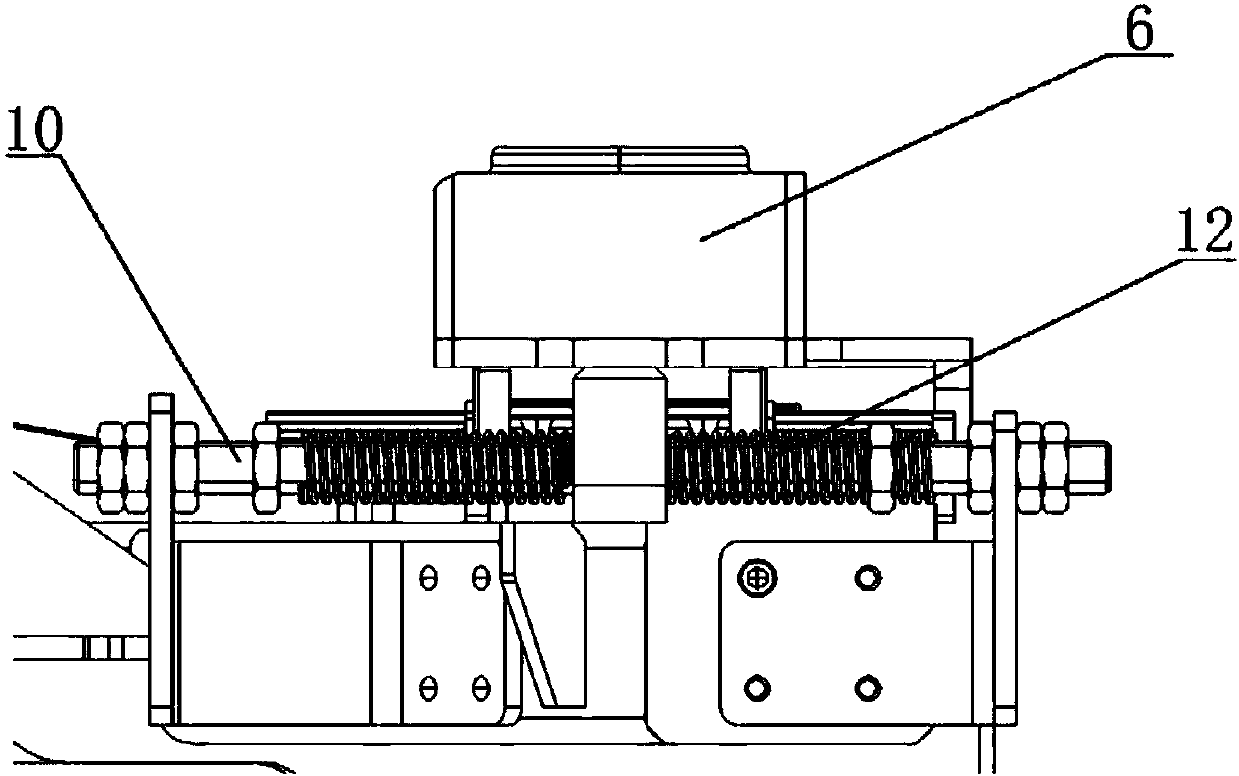

Clamp switching device

ActiveCN112008313ARealize collinear productionImprove flexibilityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention aims to provide a clamp switching device which can achieve the collinear production of multiple vehicle types and enhance the flexibility of a welding main line. A clamping mechanism used for clamping a vehicle body is arranged on the circumferential surface of an installation disc in a separated mode, the installation disc and a rotating shaft are coaxially fixed, and the rotating shaft is rotationally arranged on a fixing base. Locating pins are further arranged on the fixing base, and the locating pins are inserted into locating holes formed in the installation disc to be locked or are separated from the locating holes to be unlocked when sliding in the axial directions of the locating pins. When the device is normally used, the locating pins are inserted into the locatingholes to limit the rotation of the installation disc, the clamping mechanism clamps vehicle body, when the vehicle type needs to be switched, the external force is inserted into the locating holes topush the locating pins out of the locating holes to be separated, the constraint of the locating pins on the installation disc is relieved at this moment, then the rotation is conducted through the external force, the external force is withdrawn after the installation disc rotates to the position of the clamping mechanism corresponding to the switched vehicle type along with the device, the locating pins are inserted into the locating holes again to lock the installation disc again, and therefore the switching usage of different vehicle types is achieved.

Owner:CHERY AUTOMOBILE CO LTD

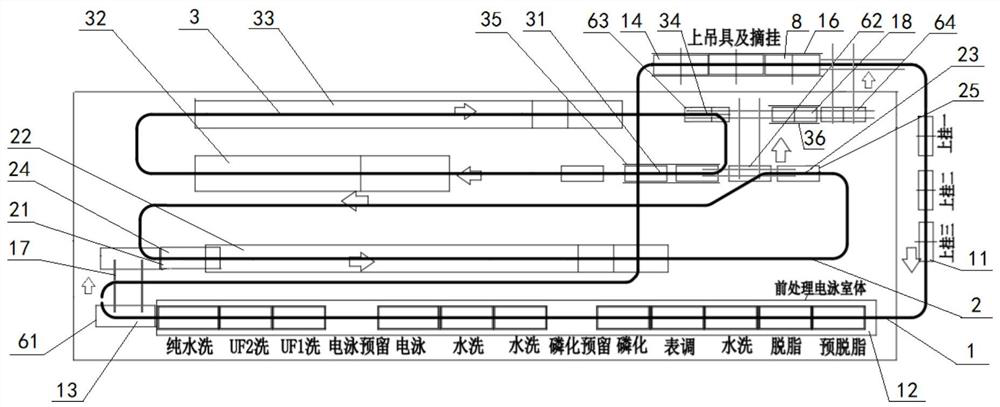

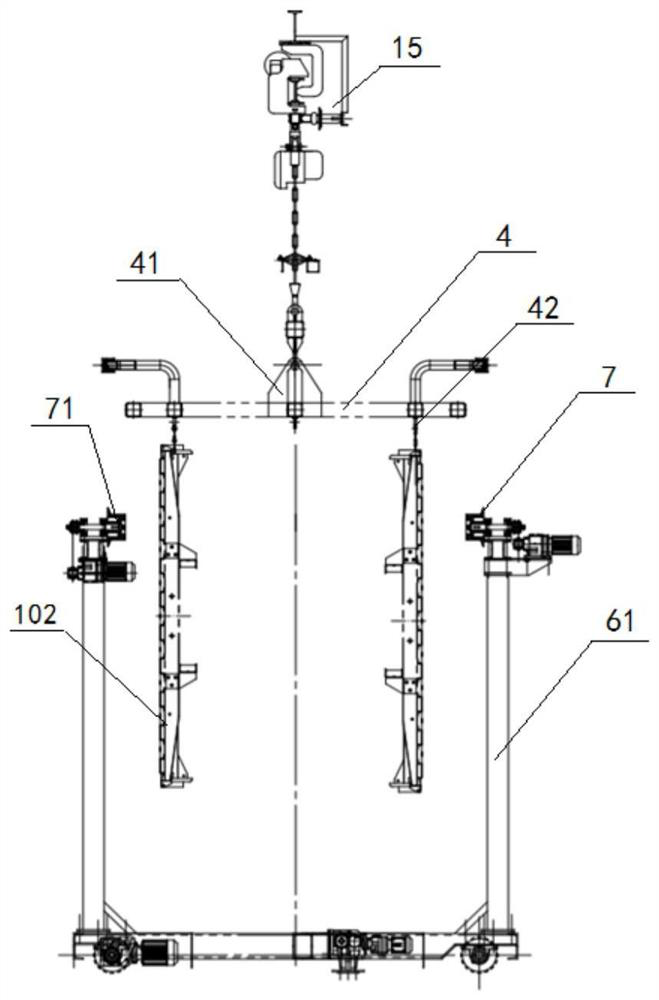

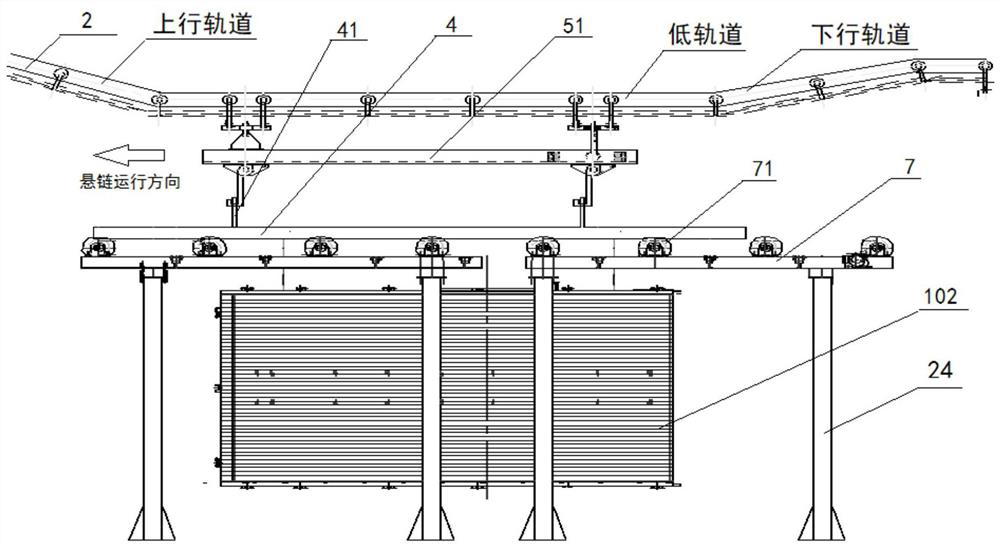

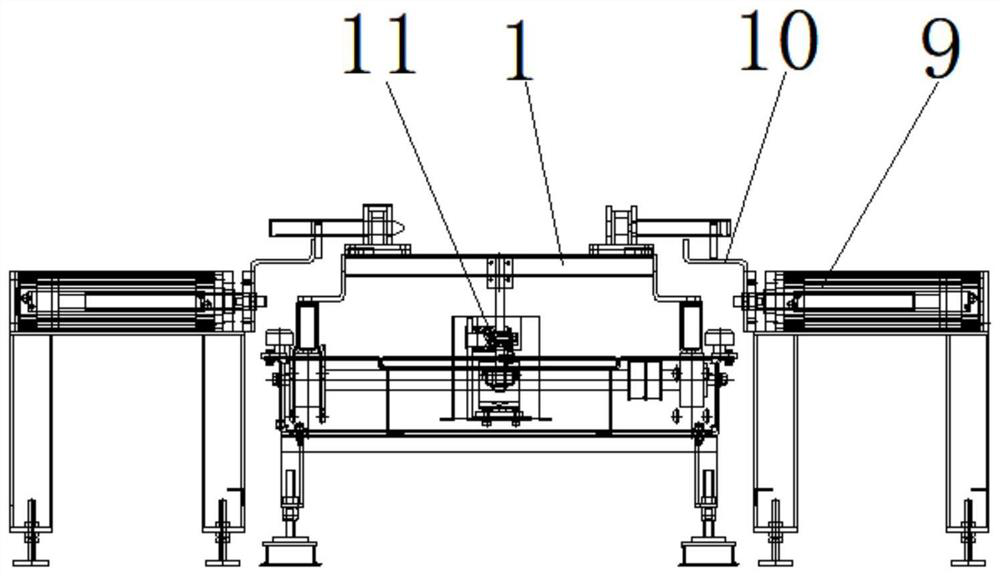

Mixed flow coating line and mixed flow coating method for standard compartment and van vehicles

The invention relates to a mixed flow coating line and a mixed flow coating method for standard compartment and van vehicles. The mixed flow coating line comprises an annular pretreatment track, a primer treatment suspension chain and a finish treatment suspension chain, wherein a hanging station, a pretreatment electrophoresis chamber, a pretreatment discharging station and a picking and hangingstation are sequentially arranged below the pretreatment track in the running direction of an electric hoist; a primer feeding station, a primer drying furnace and a primer discharging station are sequentially arranged below the primer drying suspension chain in the rotating direction of a suspension chain track; a finish feeding station, a paint spraying chamber, a finish drying furnace and a finish discharging station are sequentially arranged below the finish treatment suspension chain in the rotating direction of the suspension chain track; and to-be-coated parts are suspended on a movablehanging bracket for conveying and a high-position roller way and a transverse moving trolley are matched through a descending track, a low track and an ascending track which are arranged on the suspension chains for rotary hanging and feeding and discharging. According to the design, mixed flow production of the standard compartment and van vehicles is realized through unique coating line arrangement and suspension conveying and rotary hanging modes.

Owner:DONGFENG AUTOMOBILE COMPANY

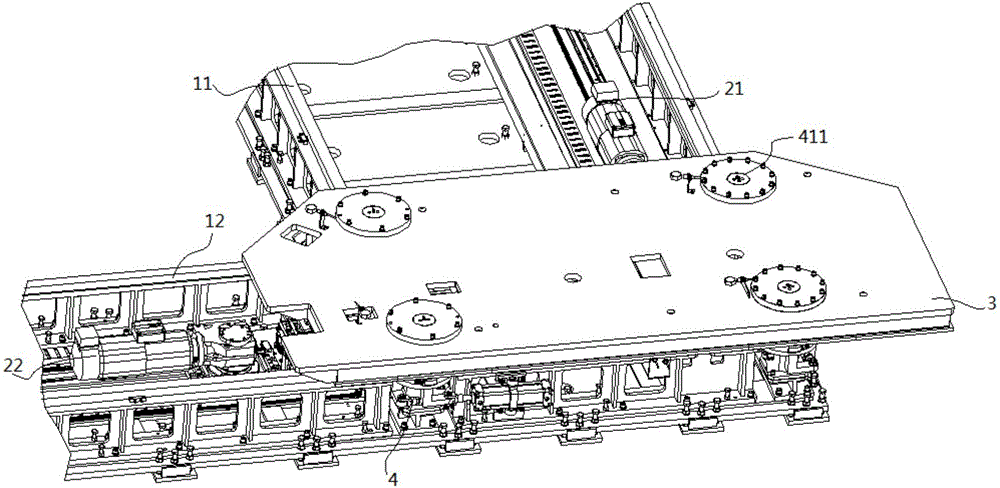

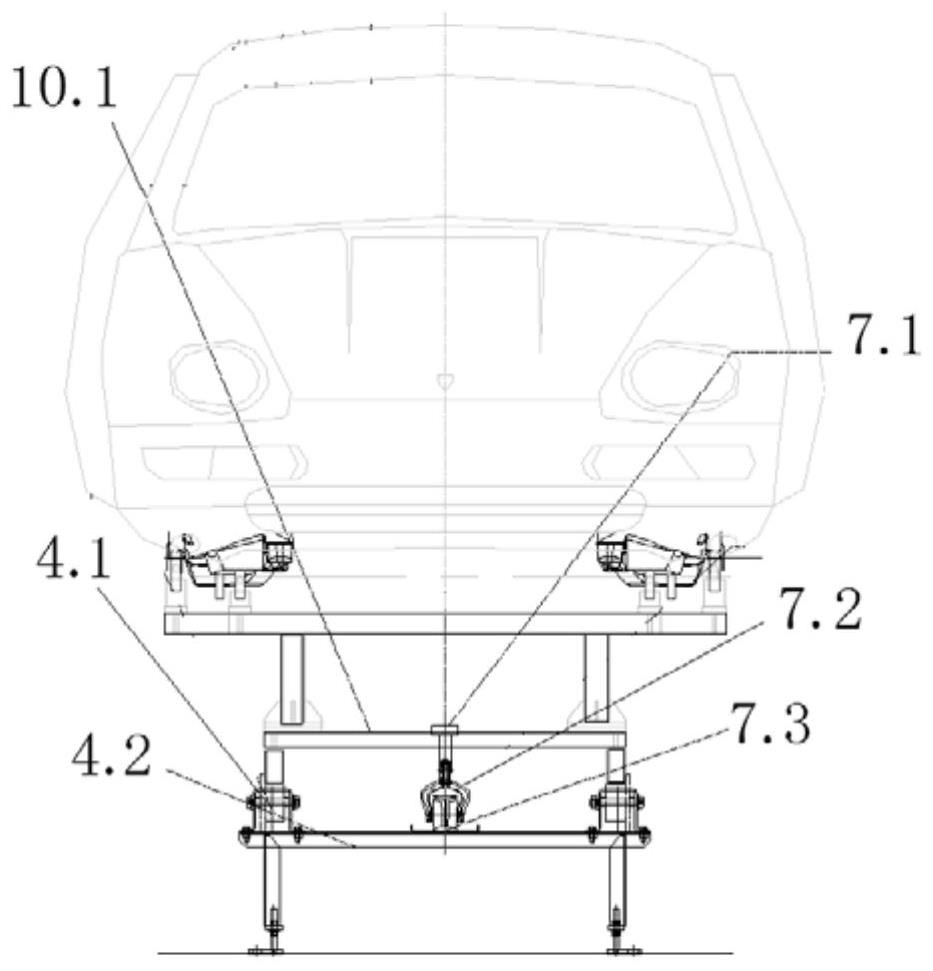

Skid and automobile production line thereof

ActiveCN112046998AIngenious ideaReasonable designLiquid surface applicatorsSpraying apparatusProduction lineSkid (automobile)

The invention discloses a skid and an automobile production line thereof. The automobile production line comprises one or more than two skid units, a separating and combining mechanism and a locking and unlocking device, wherein the separating and combining mechanism is arranged on the skid units, is connected to the two skid units end to end, and is used for combining two or more than two skid units into a whole according to different production requirements or separating two or more than two combined skid units into independent skid units; the separating and combining mechanism comprises male connectors, female connectors and plug pins; the male connector is arranged at one end of the skid unit; the female connector is arranged at the other end of the skid unit; the male connector corresponds to the female connector in position; and the plug pin used for fixing the male connector and the female connector is arranged between the male connector and the female connector. According to the skid and the automobile production line thereof, each skid can serve as an independent unit, the independent skid units can be combined and separated through the locking and unlocking mechanism according to different production automobile types, and the collinear production of multiple automobile types of different sizes is achieved.

Owner:JIANGLING MOTORS +3

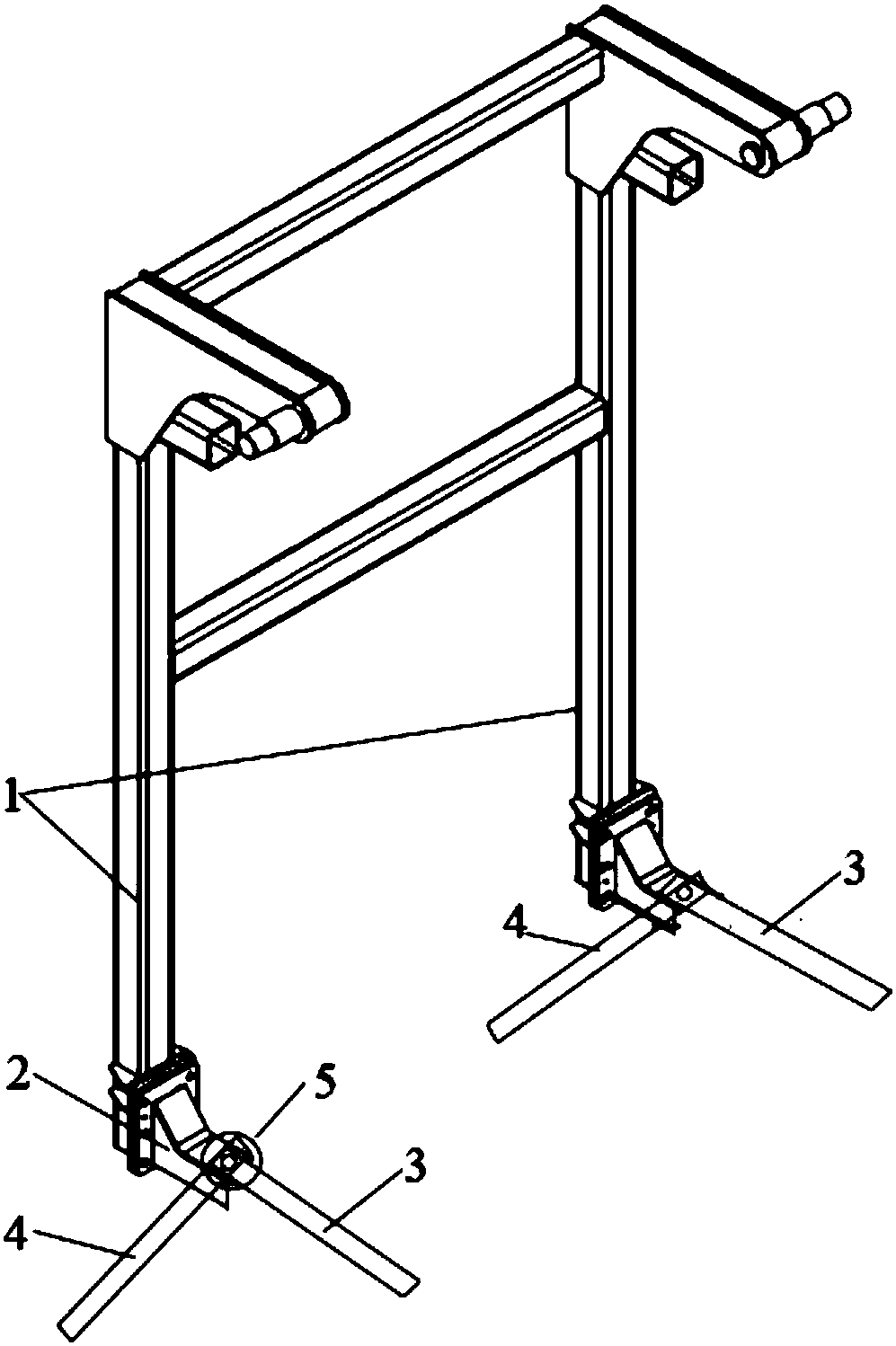

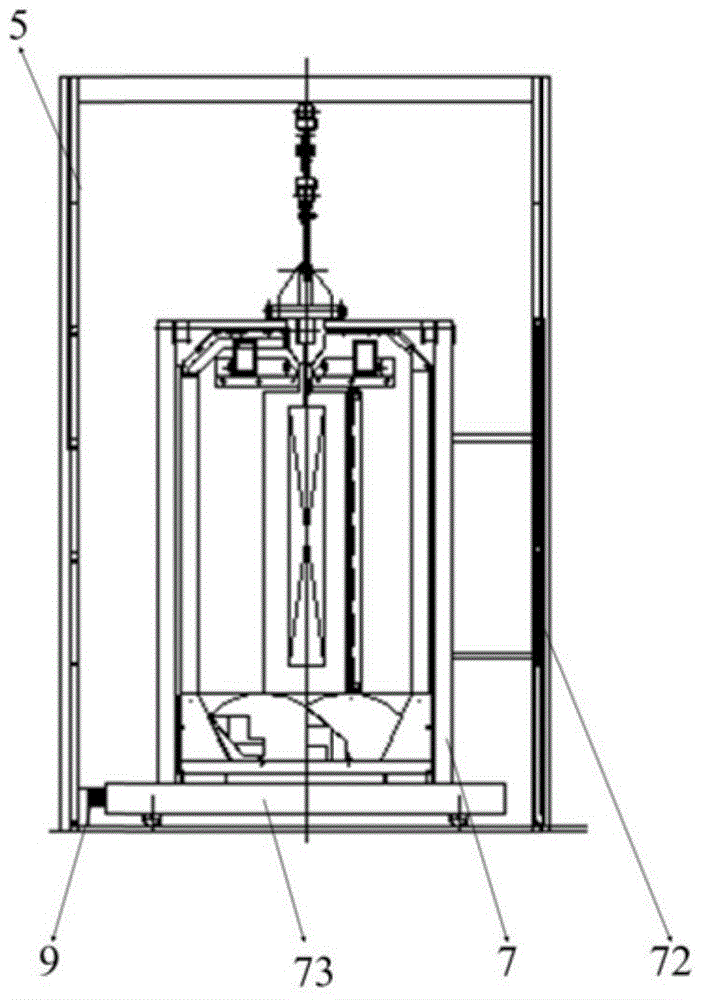

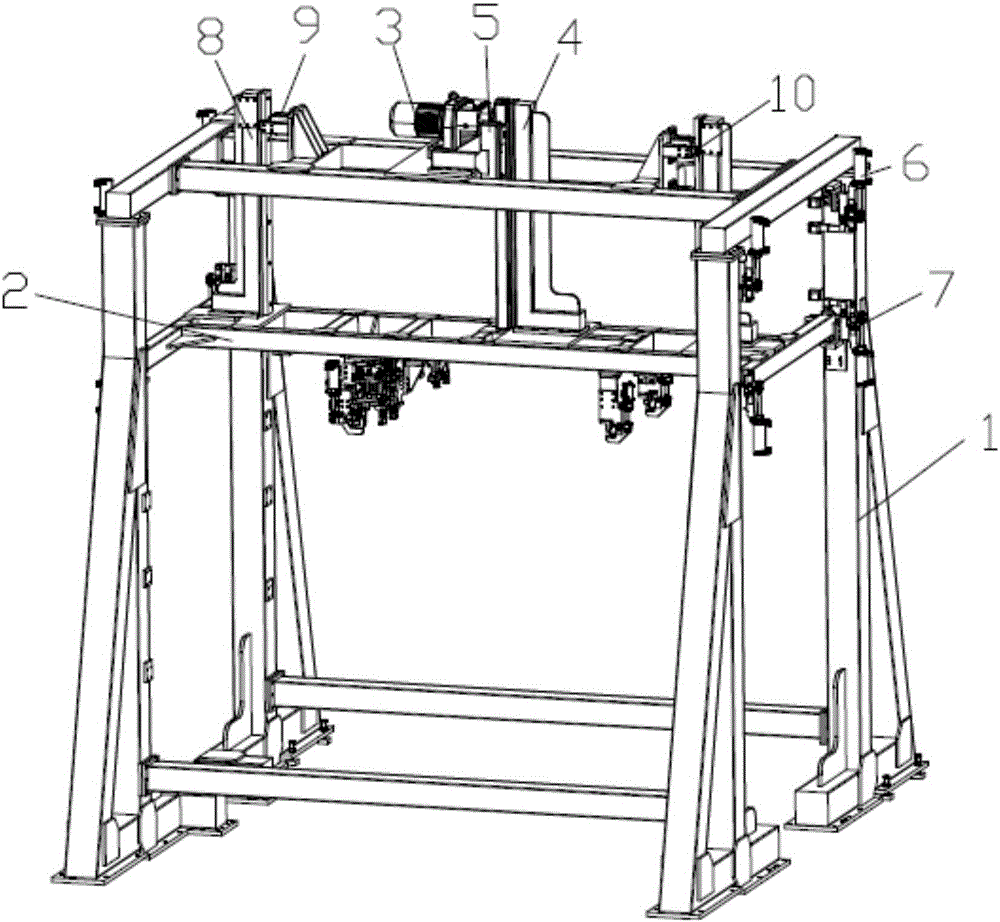

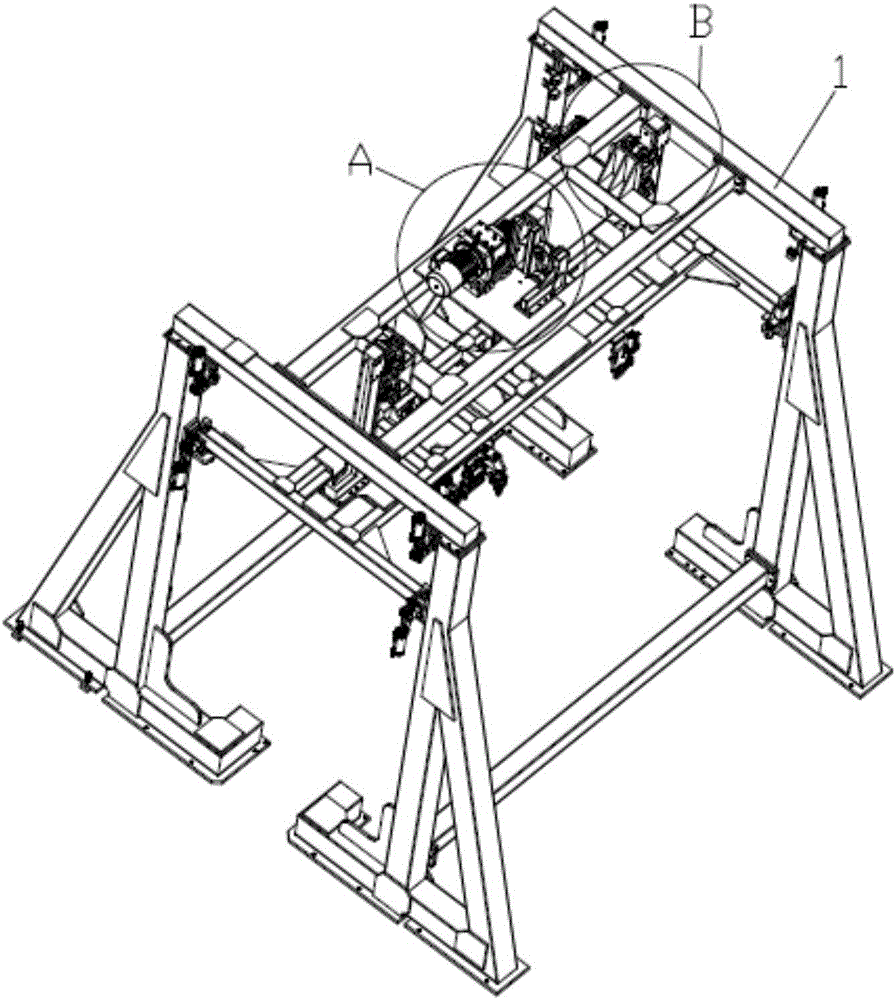

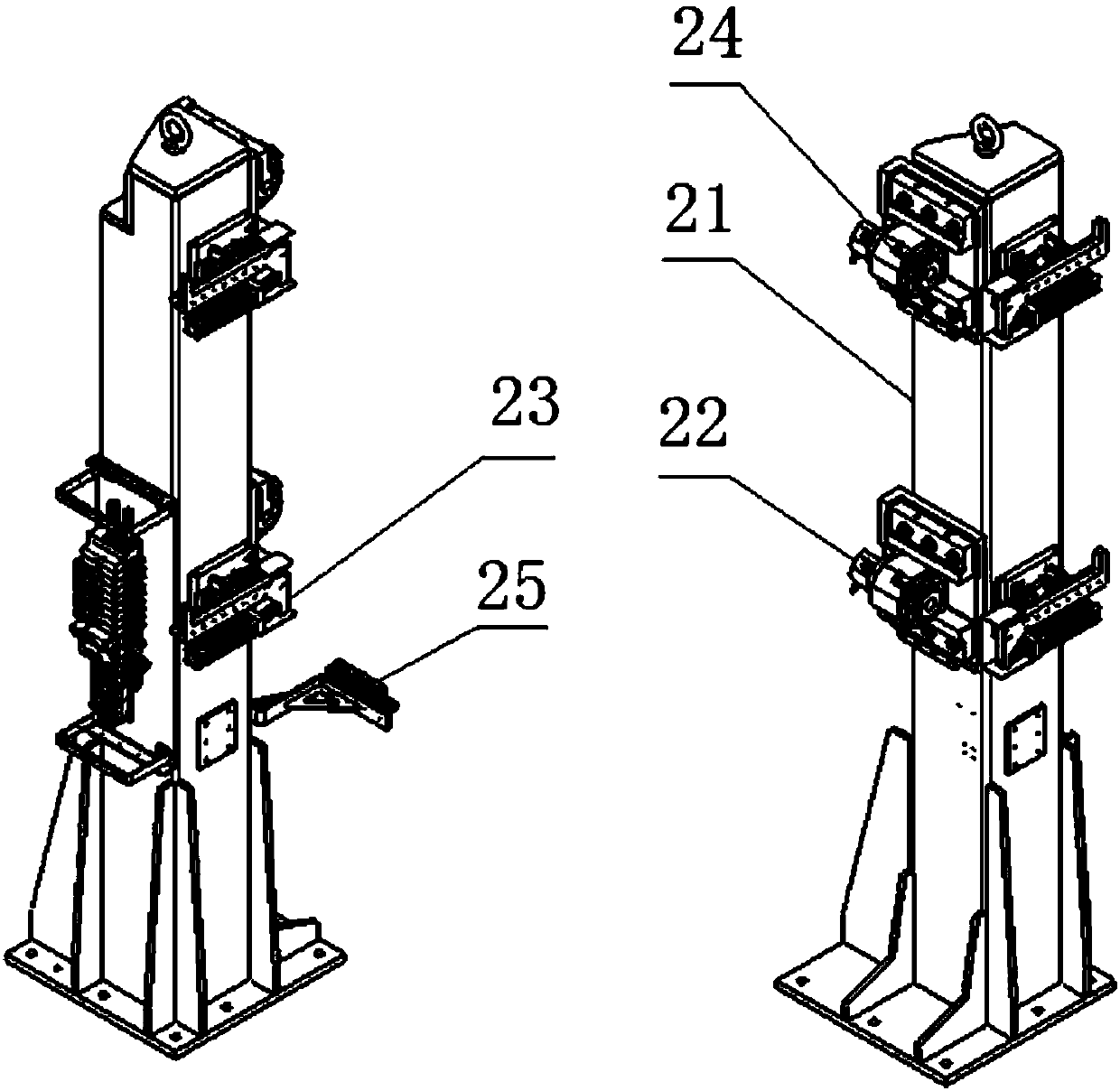

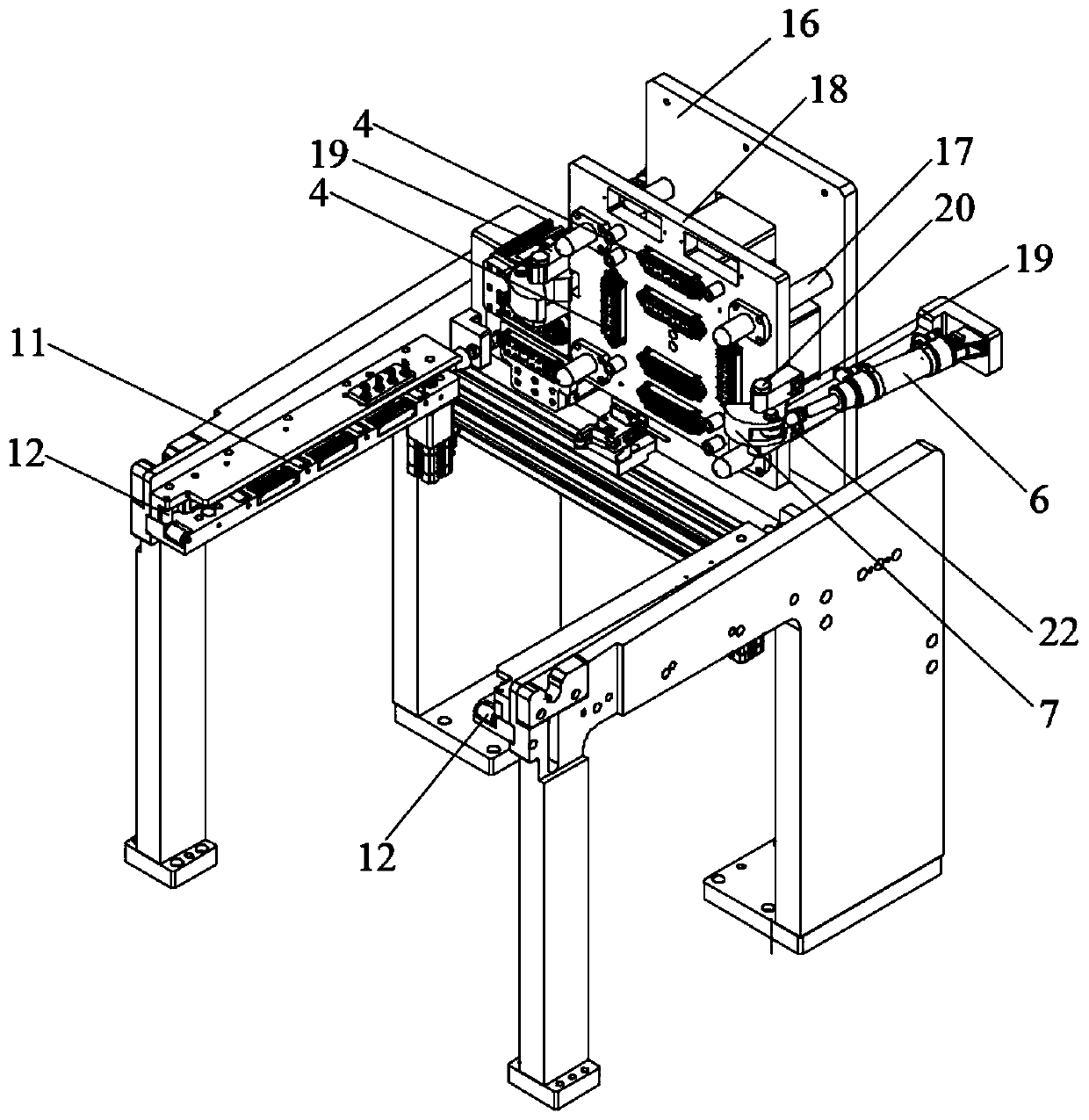

Lifting gantry structure

ActiveCN106736159APrecise Positioning WeldingRealize collinear productionWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention discloses a lifting gantry structure. The lifting gantry structure comprises a bracket. A drive mechanism for driving a moving seat to move up and down is arranged on the bracket. Guide mechanisms for controlling the movement direction are arranged on the two sides of the drive mechanism. An upper locking mechanism and a lower locking mechanism which are used for fixing the position of the moving seat are arranged on the side edges of the bracket. By the adoption of the lifting gantry structure, the moving seat is stably and effectively driven by the drive mechanism to move up and down, positioning and welding of a top cover is precisely guaranteed, meanwhile the lifting gantry structure can meet the welding requirements of top covers of multiple models of vehicles due to the movable moving seat, collinear production is achieved, the production cost is lowered, and the lifting gantry structure has the good application prospects.

Owner:ANHUI RUIXIANG IND

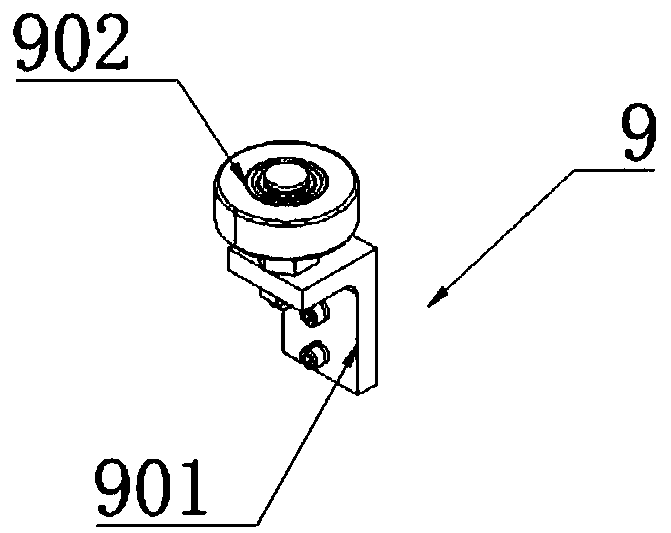

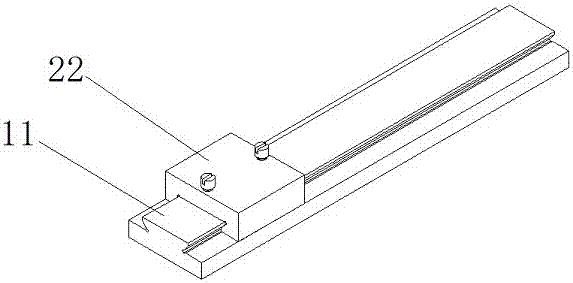

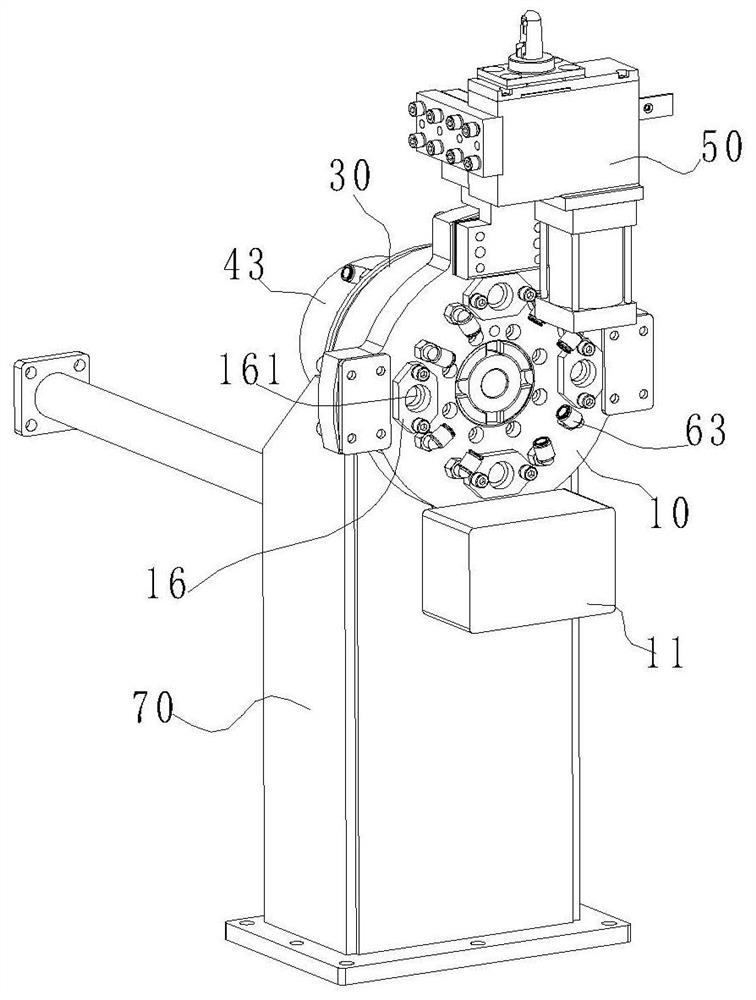

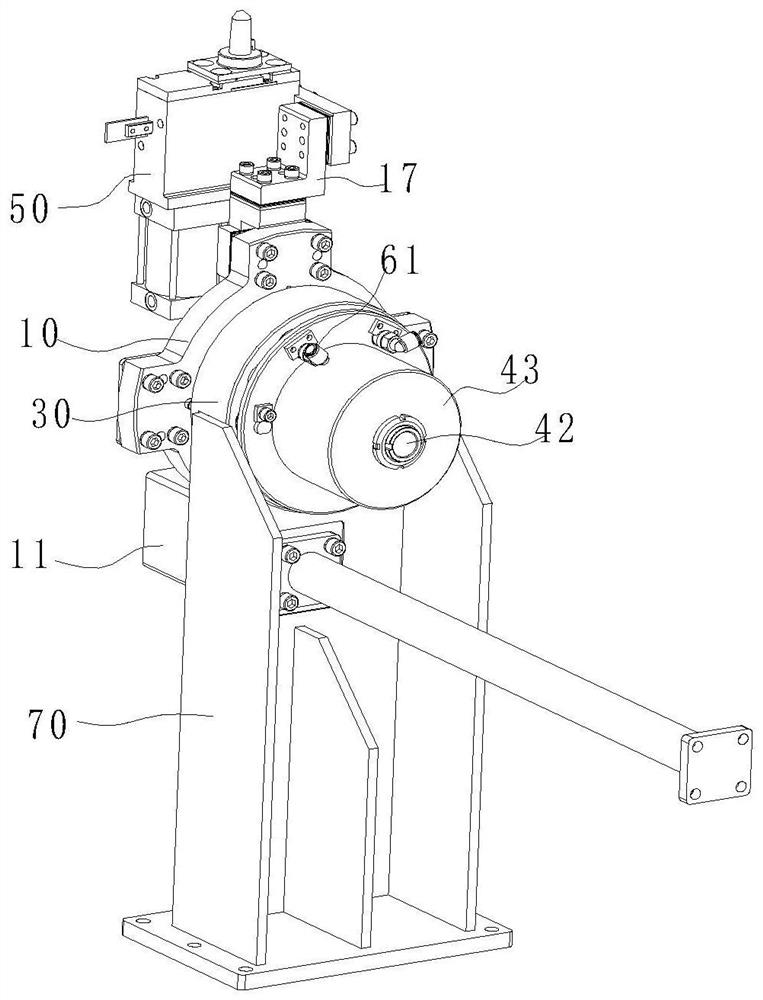

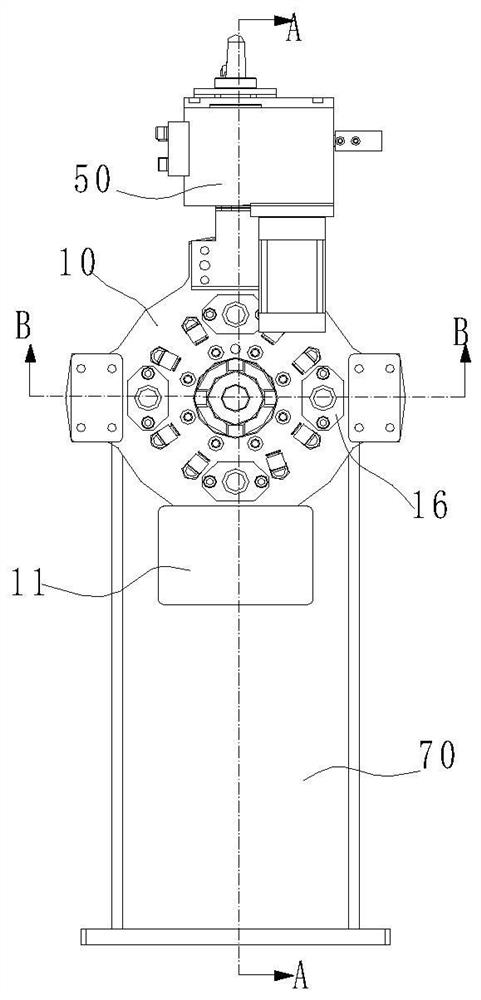

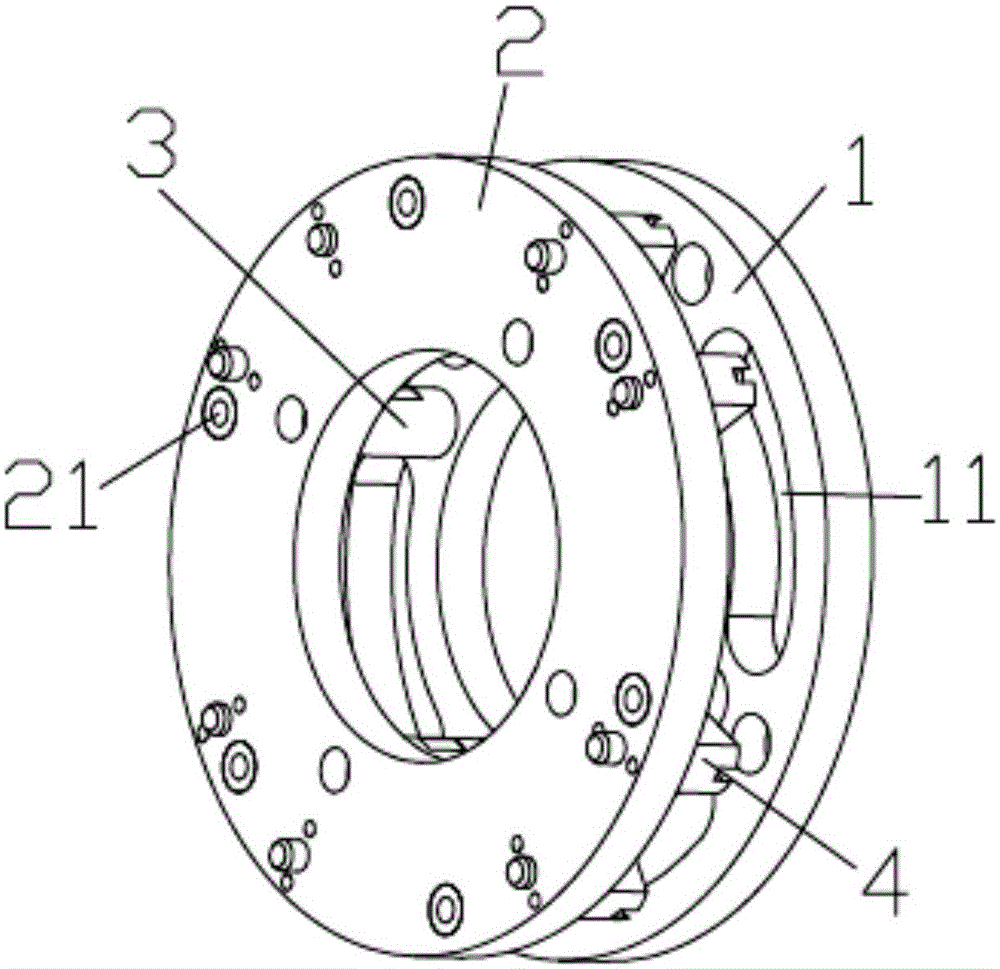

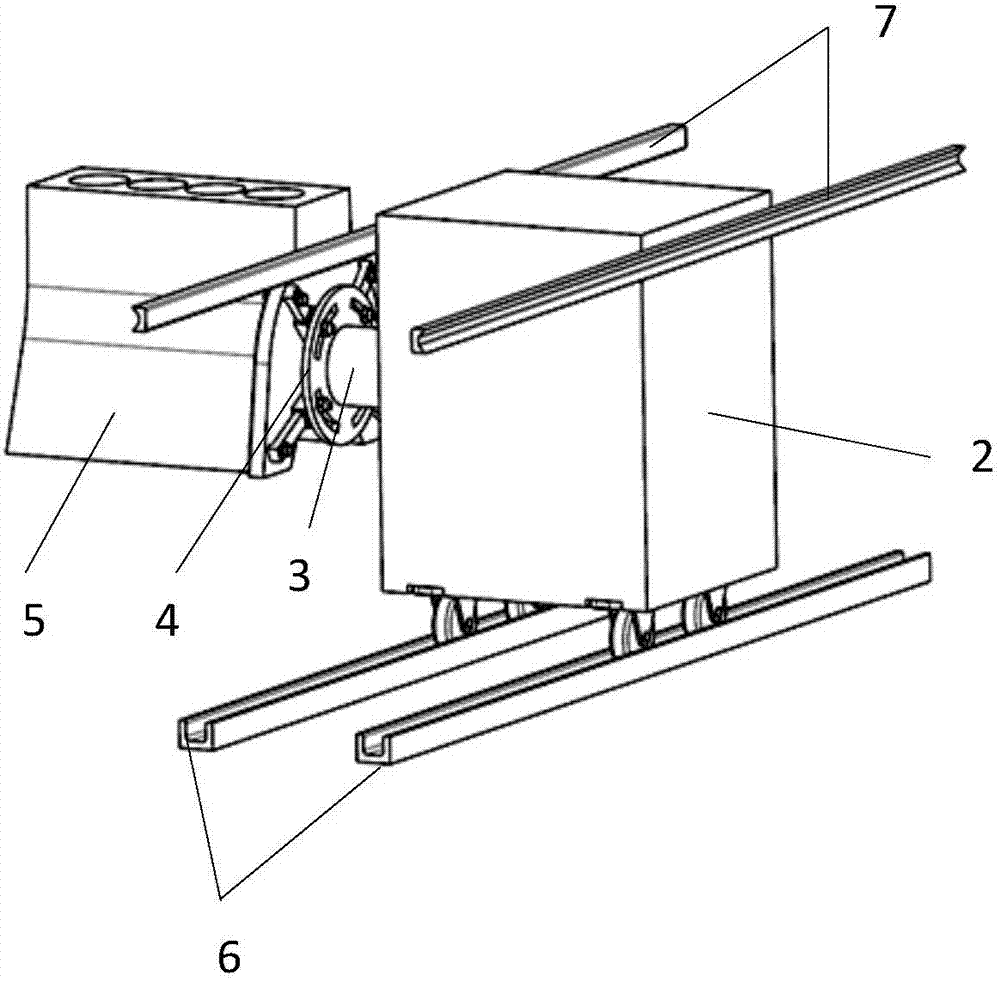

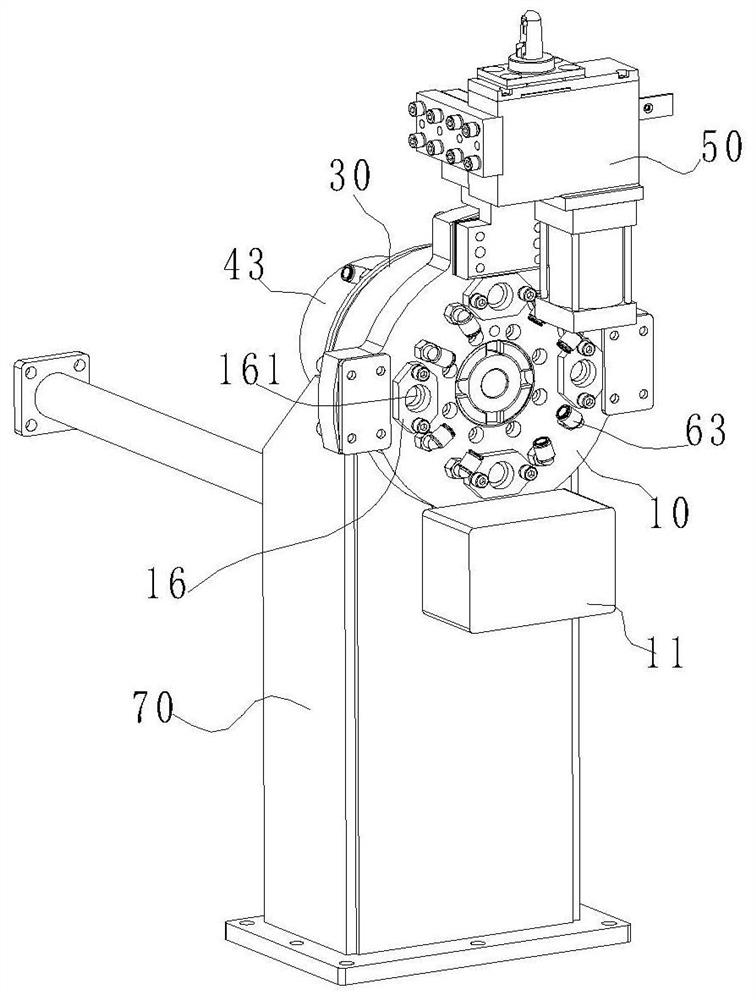

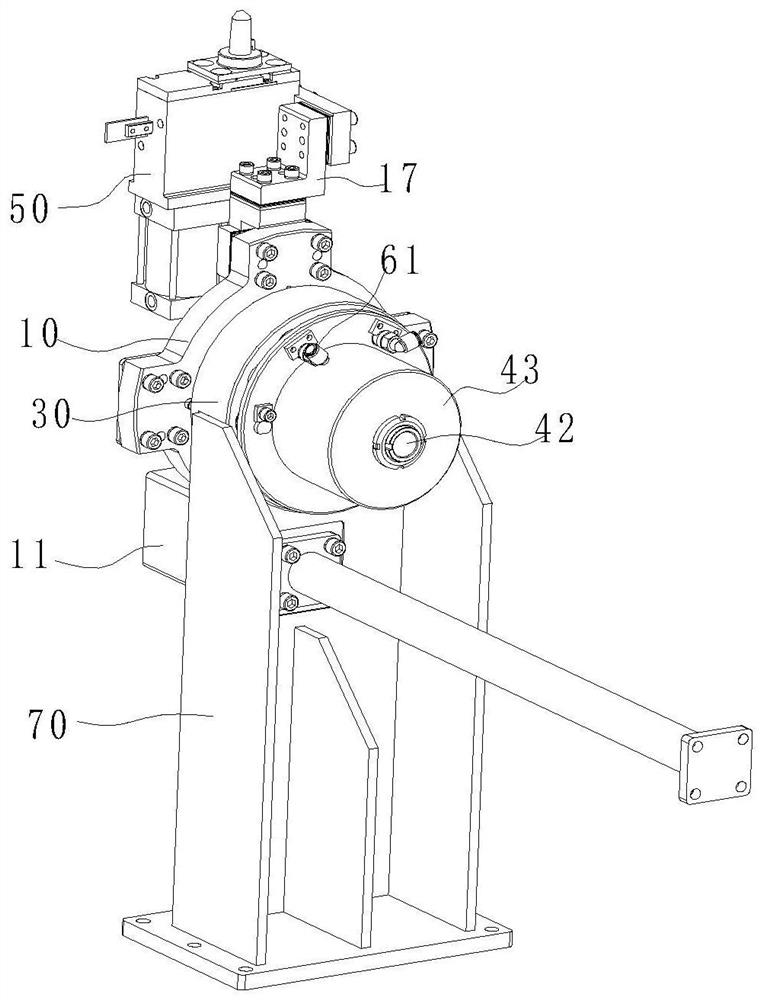

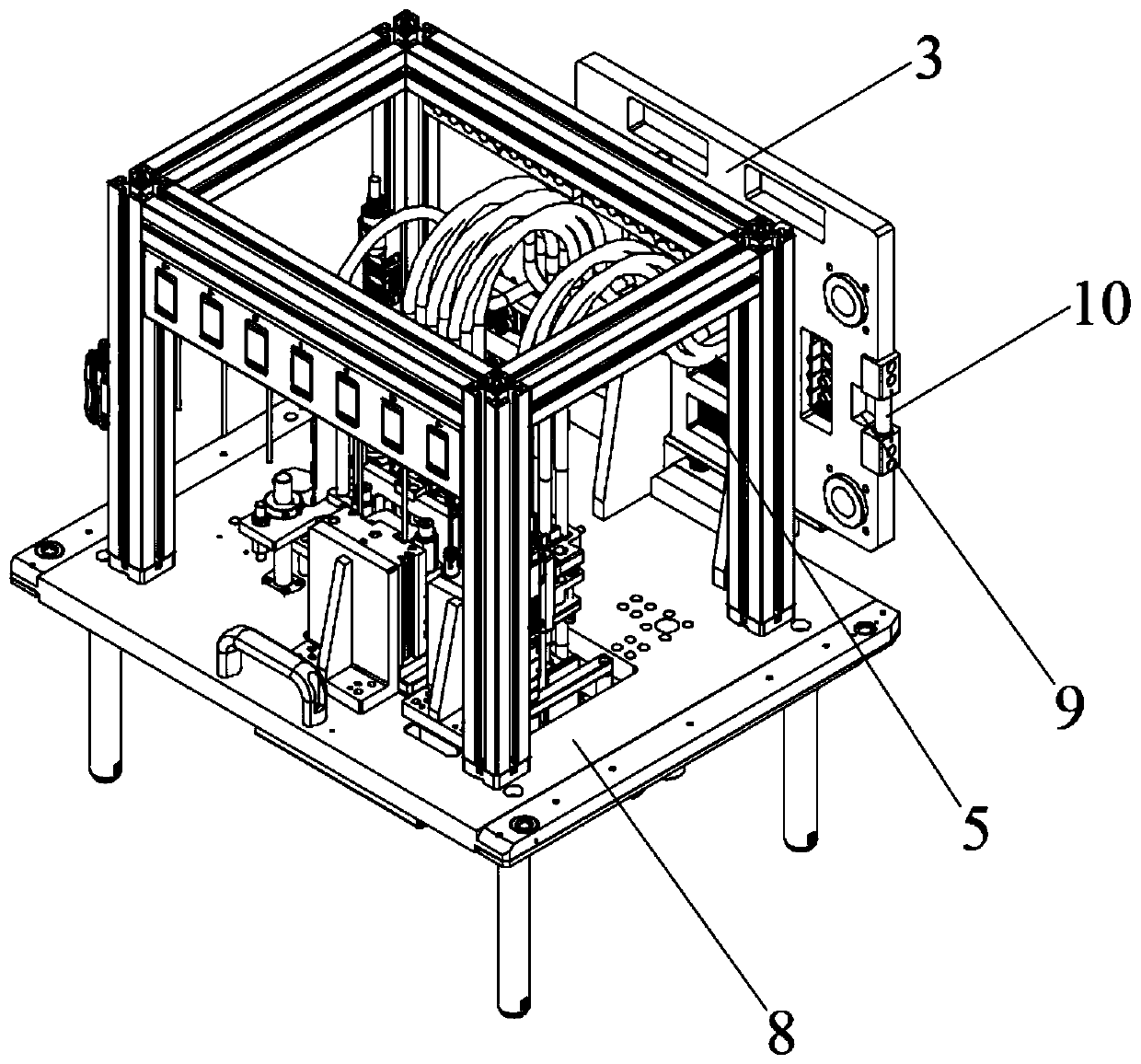

Flywheel bolt screwing mechanism

ActiveCN105150172AEasy to useRealize collinear productionMetal-working hand toolsFreewheelDrive motor

The invention discloses a flywheel bolt screwing mechanism. The flywheel bolt screwing mechanism comprises a bolt screwing rod. A drive motor drives the bolt screwing rod to rotate. The flywheel bolt screwing mechanism further comprises a positioning mechanism positioning a flywheel. The positioning mechanism is provided with positioning pin holes (21) matched with pins on the flywheel (6) on a manual gear engine, and elastic positioning pins (4) matched with positioning holes in a flexible disc (5) on an automatic catch engine. Pin head ends of the elastic positioning pins (4) are elastically shrunk in a pin base. The flywheel bolt screwing mechanism is simple in structure and convenient to use and has good application prospects, the production efficiency is improved, and the production cost is reduced.

Owner:CHERY AUTOMOBILE CO LTD

Coating process for applying water paint to elevator door and door pocket sheet metal parts

InactiveCN106622914ARealize collinear productionCoating production is highly automatedPretreated surfacesElectrophoretic coatingsWater basedCoating system

The invention discloses a coating process for applying water paint to an elevator door and door pocket sheet metal parts. The process sequentially comprises the following steps: firstly, pretreatment is carried out, wherein the surface of the elevator door and the surfaces of the door pocket sheet metal parts are sequentially subject to pre-degreasing, degreasing, primary washing, surface conditioning, phosphorization and secondary washing, a uniform gray phosphating film not prone to rusting is generated on the surface of a workpiece, and then an electrophoretic primer coating system is used for conducting operation; secondly, anticorrosive primer is applied in an electrophoretic painting manner; thirdly, a high-pressure electrostatic spraying manner is adopted to spray water-based top-coat or water-based top-coat and water-based finishing paint. According to the process, the water paint can be effectively applied to coating of the elevator door and the door pocket sheet metal parts, the environmental harm and potential safety hazard, caused by the traditional coating process, of the elevator door and the door pocket sheet metal parts can be solved, meanwhile, same-line production of electrophoretic primer and water-based top-coat can be achieved, high automation of coating production can be achieved, the coating process is environment-friendly, and the coating product quality and the production efficiency can be obviously improved.

Owner:GUANGZHOU KINTE IND

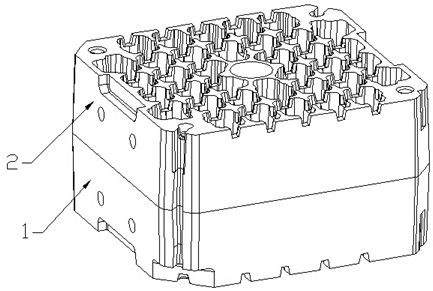

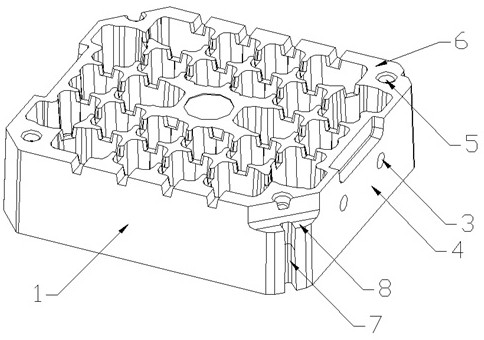

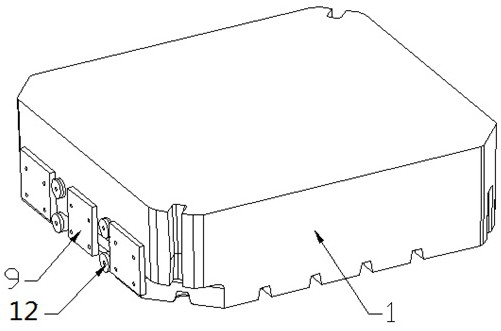

Tray for robotic automatic core arrangement applicable to collinear production of cylinder body cover cores

ActiveCN108889911ARealize collinear productionReduce typesMoulding toolsFoundry mouldsEngineeringCylinder block

The invention relates to a tray for robotic automatic core arrangement applicable to collinear production of cylinder body cores and cylinder body cover cores. The tray comprises a bottom plate, a support block component and a positioning key component. Guide mechanisms on the two sides of a conveyer roller bed assist the tray in entering a core arrangement spot in a robotic workstation; a positioning sleeve at the bottom of a tray component helps precisely position the tray. Cores are arranged on the support block component of the tray; positioning keys on the cores and the positioning key component of the tray help precisely position the cores; the eight cylinder cover core poisoning keys of the ray component are optimized to allow the cylinder body core sand the cylinder cover cores toshare the tray. The tray herein allows precise positioning for the tray and the roller bed and operation contents for robotic automatic core arrangement; the precision of robotic automatic core assembly later is ensured; fewer types of trays are used; production cost is reduced; the problem of sharing the tray in the collinear production of cylinder block cores and cylinder cover cores is solved.

Owner:KUNMING YUNNEI POWER

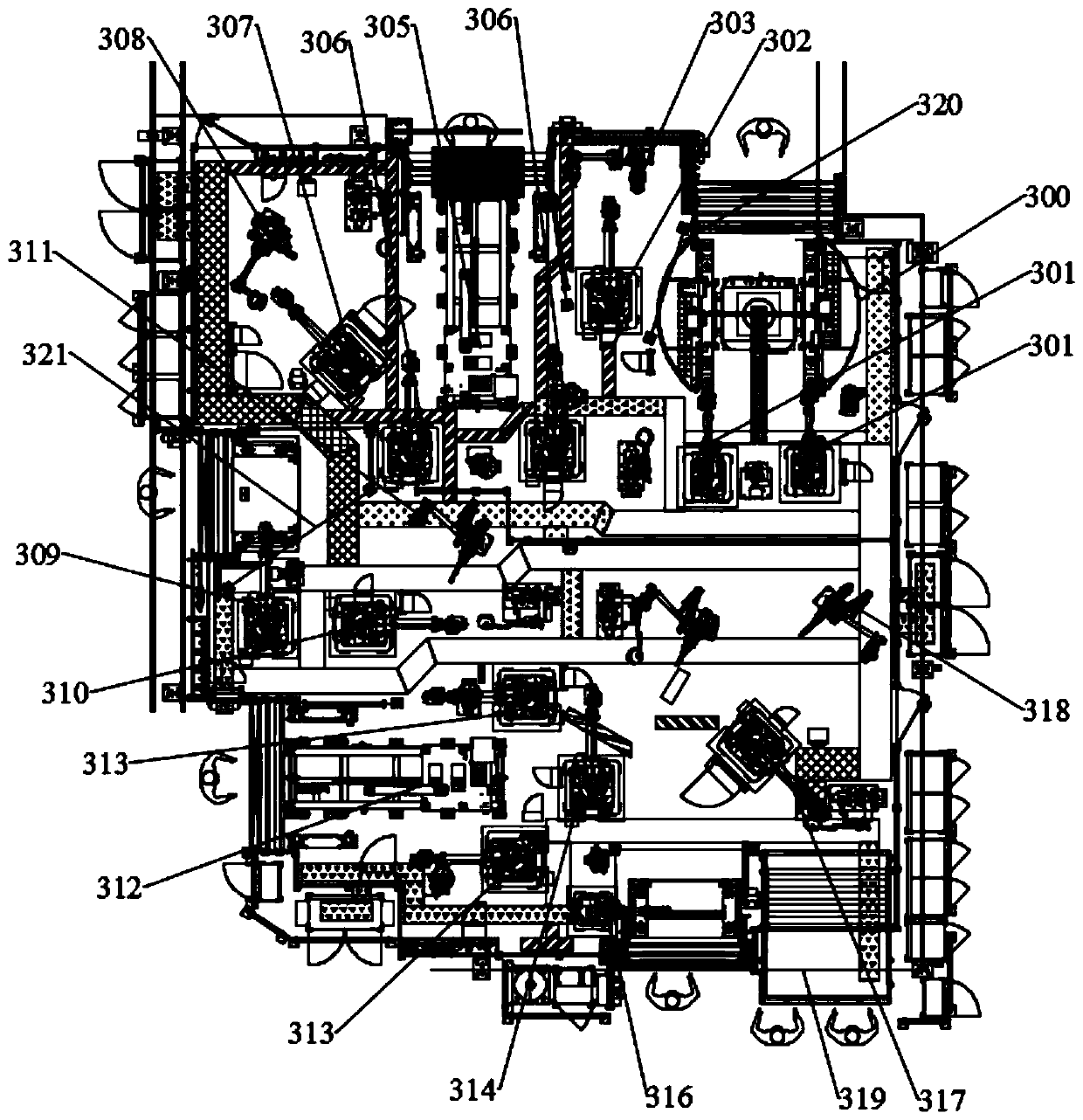

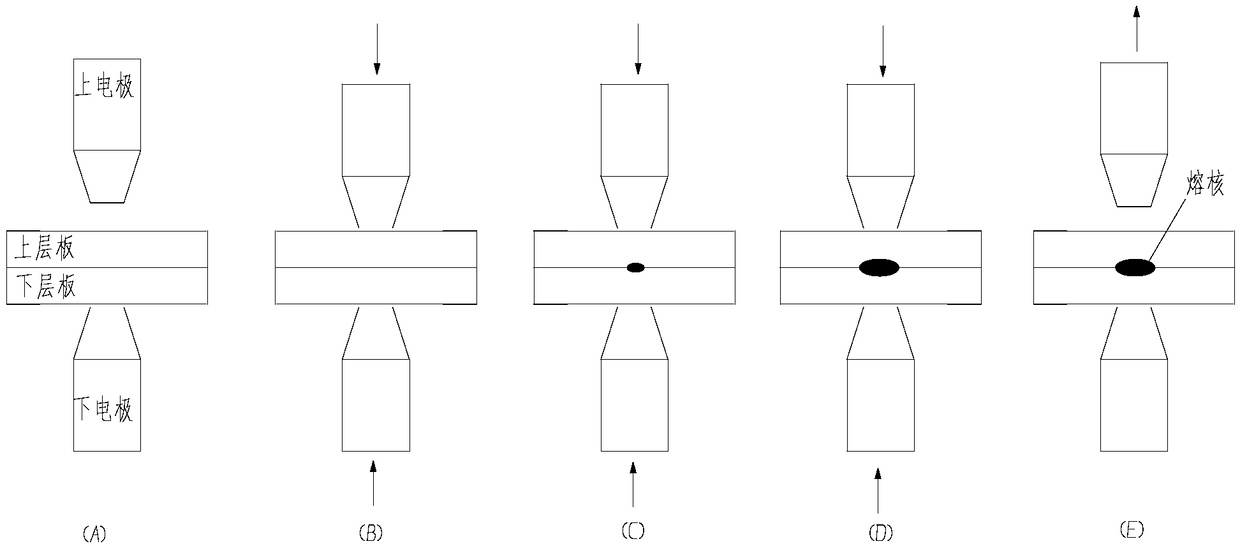

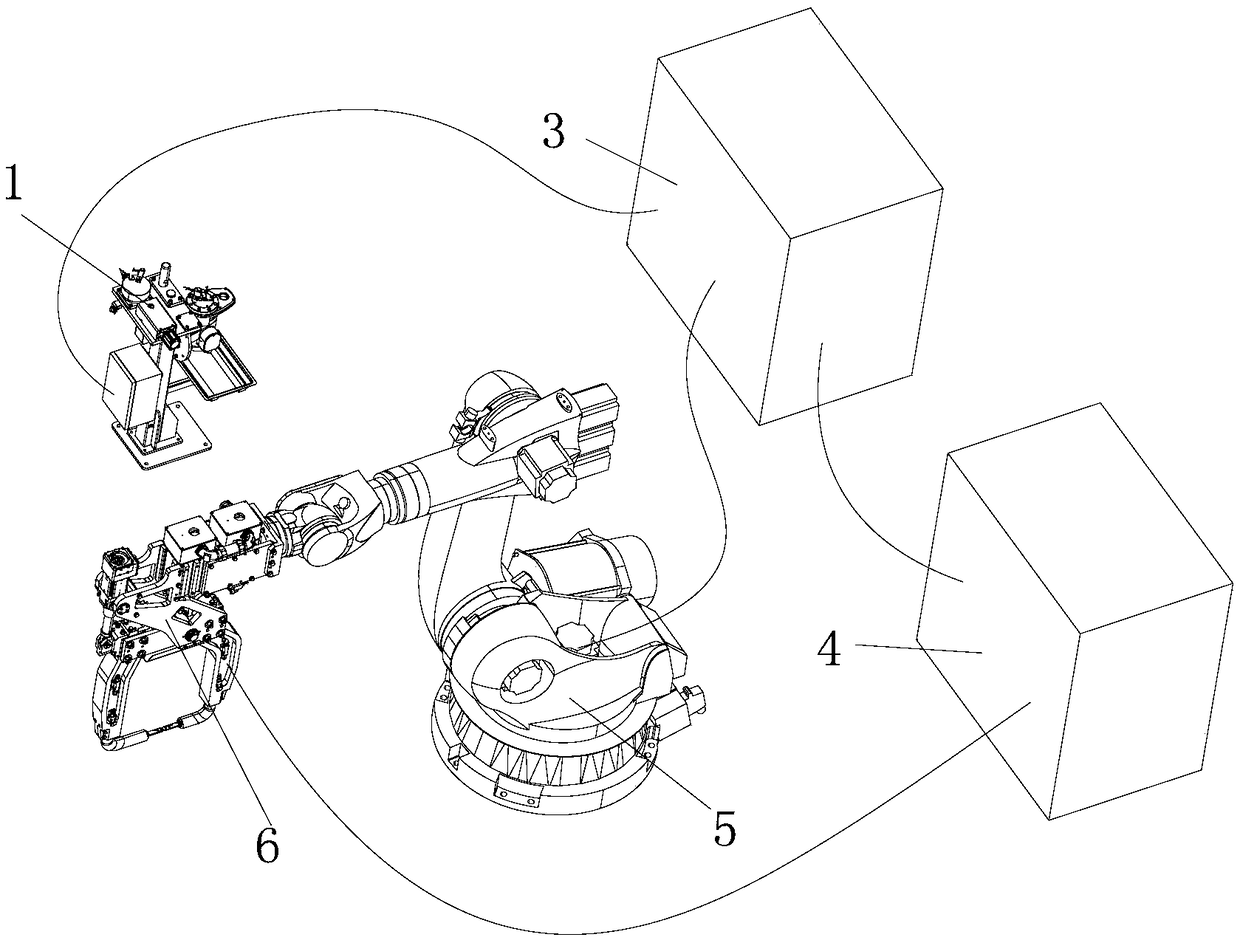

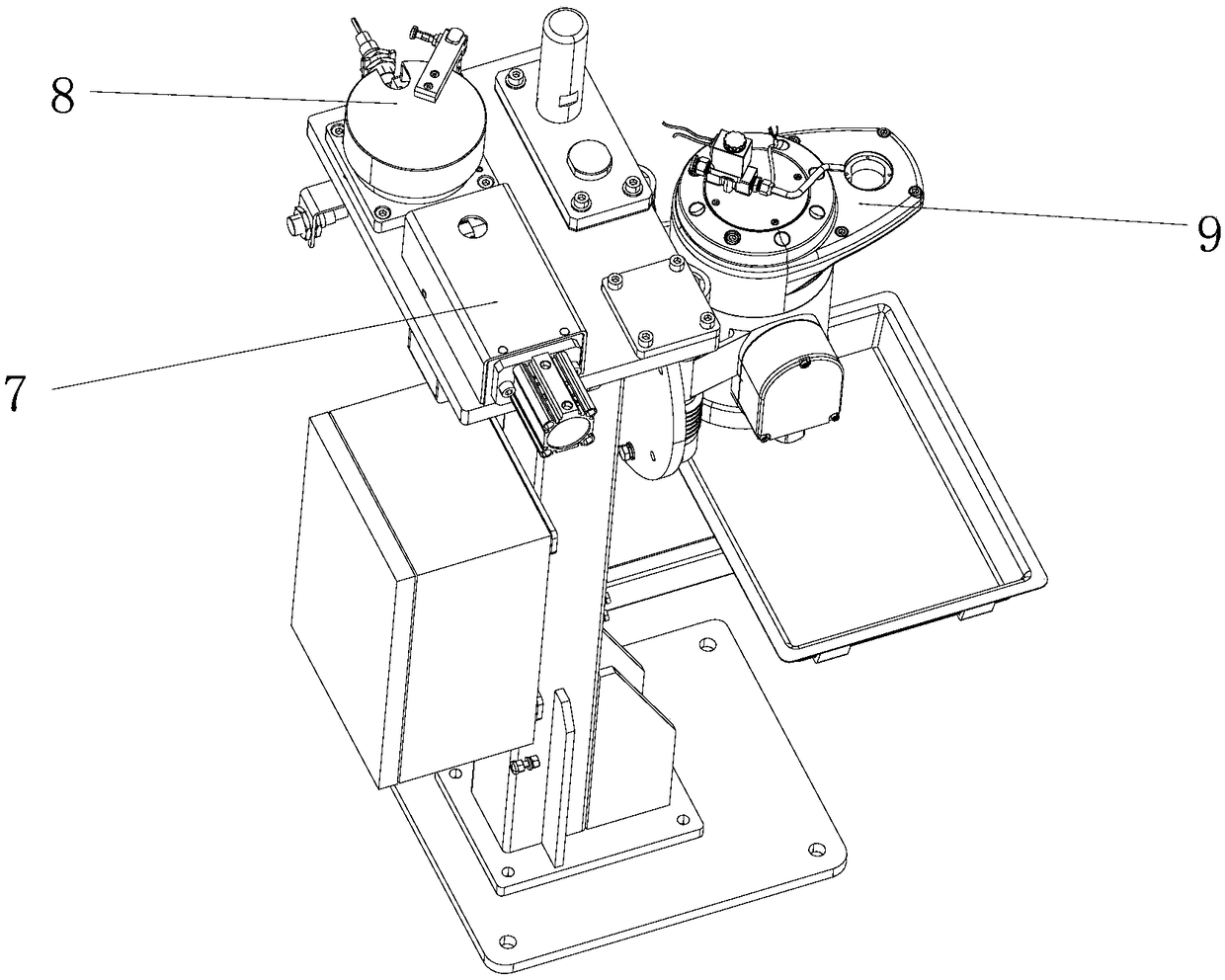

Resistance spot welding method and system suitable for steel and aluminum vehicle body mixed-line production

InactiveCN109175648ARealize collinear productionRealize the different needs of the shapeResistance electrode holdersElectrode maintenanceElectrical resistance and conductanceSpot welding

The invention discloses a resistance spot welding system and method suitable for steel and aluminum vehicle body mixed-line production. The resistance spot welding system comprises a welding robot body, a welding gun, a robot control cabinet, a welding gun control cabinet, a first cap changing and sharpening machine for a steel vehicle body and a second cap changing and sharpening machine for an aluminum vehicle body, the welding gun control cabinet is used for storing a steel vehicle body welding program and an aluminum vehicle body welding program, welding parameters set in the steel vehiclebody welding program are used for welding of steel pieces, welding parameters set in the aluminum vehicle body welding program are used for welding of aluminum pieces, and the welding gun control cabinet is used for calling a corresponding vehicle body welding program, controlling the welding gun to cooperate with the cap changing and sharpening machines and performing the vehicle body welding flow after a vehicle body welding signal is received. According to the system and the method, the optimized-configuration spot welding system is adopted, and line-sharing production of a steel piece vehicle body and an aluminum piece vehicle body can be realized.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

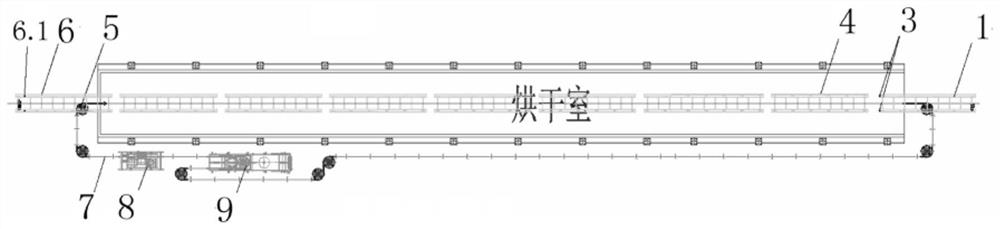

Automobile coating drying and conveying device and conveying control method thereof

PendingCN113844852AAvoid Skid Collision RiskReasonable designPretreated surfacesControl devices for conveyorsControl engineeringMachine

The invention discloses an automobile coating drying and conveying device and a conveying control method thereof. An identification sensor is used for identifying the type of an automobile body carried by a skid located on an inlet variable-speed single-side roller machine, and according to judgment of the identification sensor, whether an in-place switch directly releases or delays to release is judged; when the automobile body is long, the in-place switch delays by one station for releasing in order to avoid the collision risk of the automobile body, and vice versa; and in the process, a chain keeps running continuously, and after the in-place switch is released, a push head of the chain hooks a cross beam on the skid and takes away the skid and the automobile body on the skid, so that different distances between different automobile bodies in the conveying process are realized. Therefore, collinear production of large and small automobile types is realized, and kinetic energy loss and beat loss of collinear production are greatly reduced; and moreover, the production takt is improved, the collision risk of the skid in a coating drying furnace is avoided, and the operation is stable and reliable.

Owner:CHERY COMML VEHICLE ANHUI

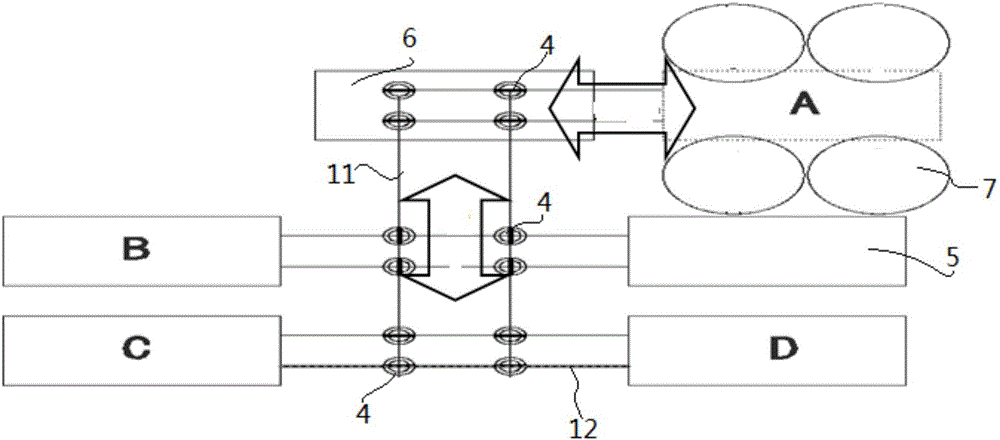

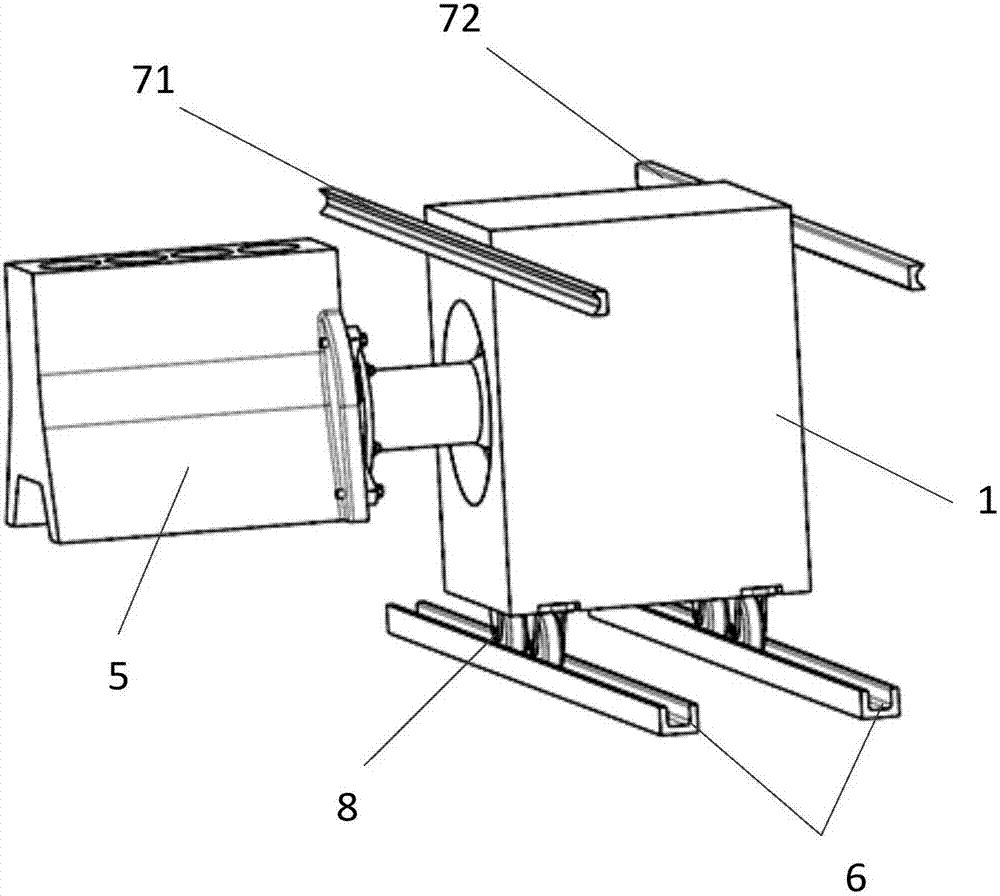

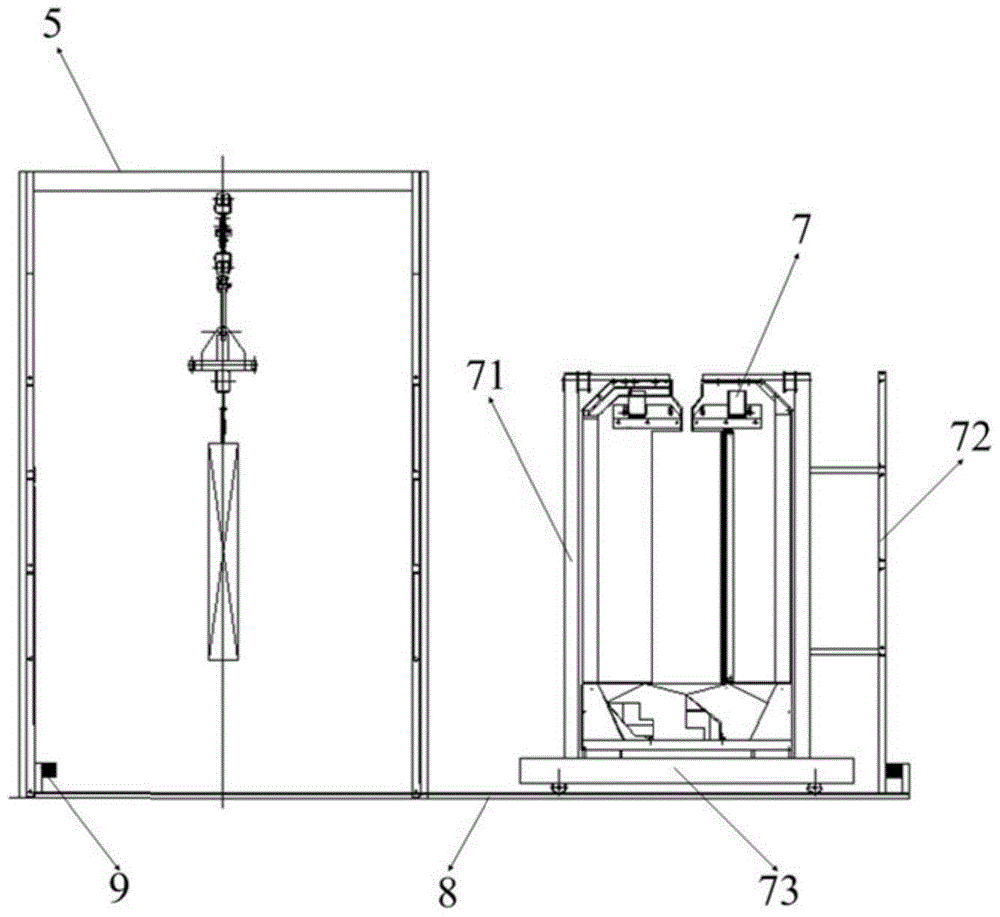

An armature production equipment

ActiveCN109649984BImprove automationImprove intelligenceControl devices for conveyorsMechanical conveyorsProduction lineProcess equipment

Owner:湖南中伟智能制造有限公司

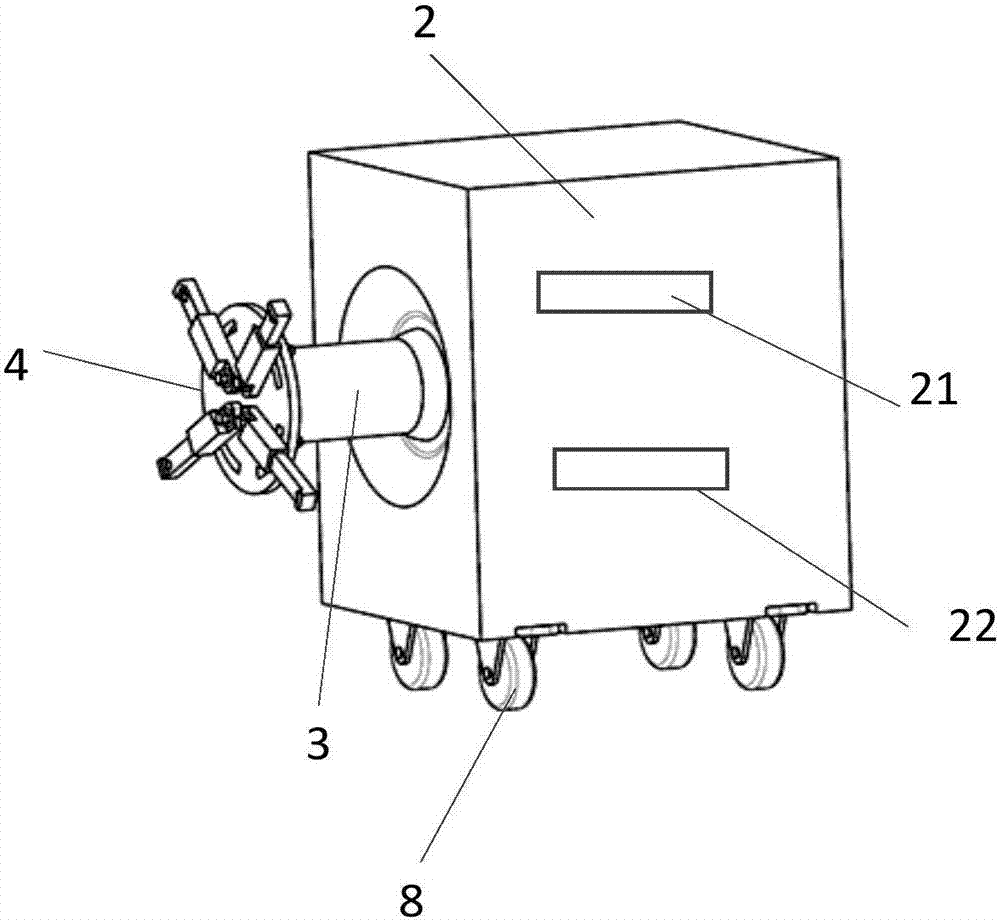

Engine assembly system and method

InactiveCN107283160AImprove assembly efficiencyRealize multi-angle adjustmentAssembly machinesProduction lineAssembly line

The invention provides an engine assembly system and method. The engine assembly system comprises an engine assembly line sliding structure. The engine assembly line sliding structure comprises an engine assembly line sliding body, a connecting arm, a connecting plate and first sliding rails, wherein the connecting arm is located on one side of the engine assembly line sliding body, a connecting angle between the connecting arm and the engine assembly line sliding body is adjustable, the connecting plate is arranged at one end of the connecting arm and used for supporting and positioning an engine to be assembled, and the first sliding rails are arranged on a working platform and matched with the engine assembly line sliding structure. According to the engine assembly system, according to the connecting arm with the adjustable angle, multi-angle adjustment of the engine to be assembled is achieved, the assembly efficiency of the engine is improved, positioning of the engine to be assembled is achieved by utilizing the connecting plate, the assembly accuracy of components and parts can be ensured, production in the same line of different types of engines can be achieved, and the utilization rate of a production line is improved.

Owner:北京汽车动力总成有限公司

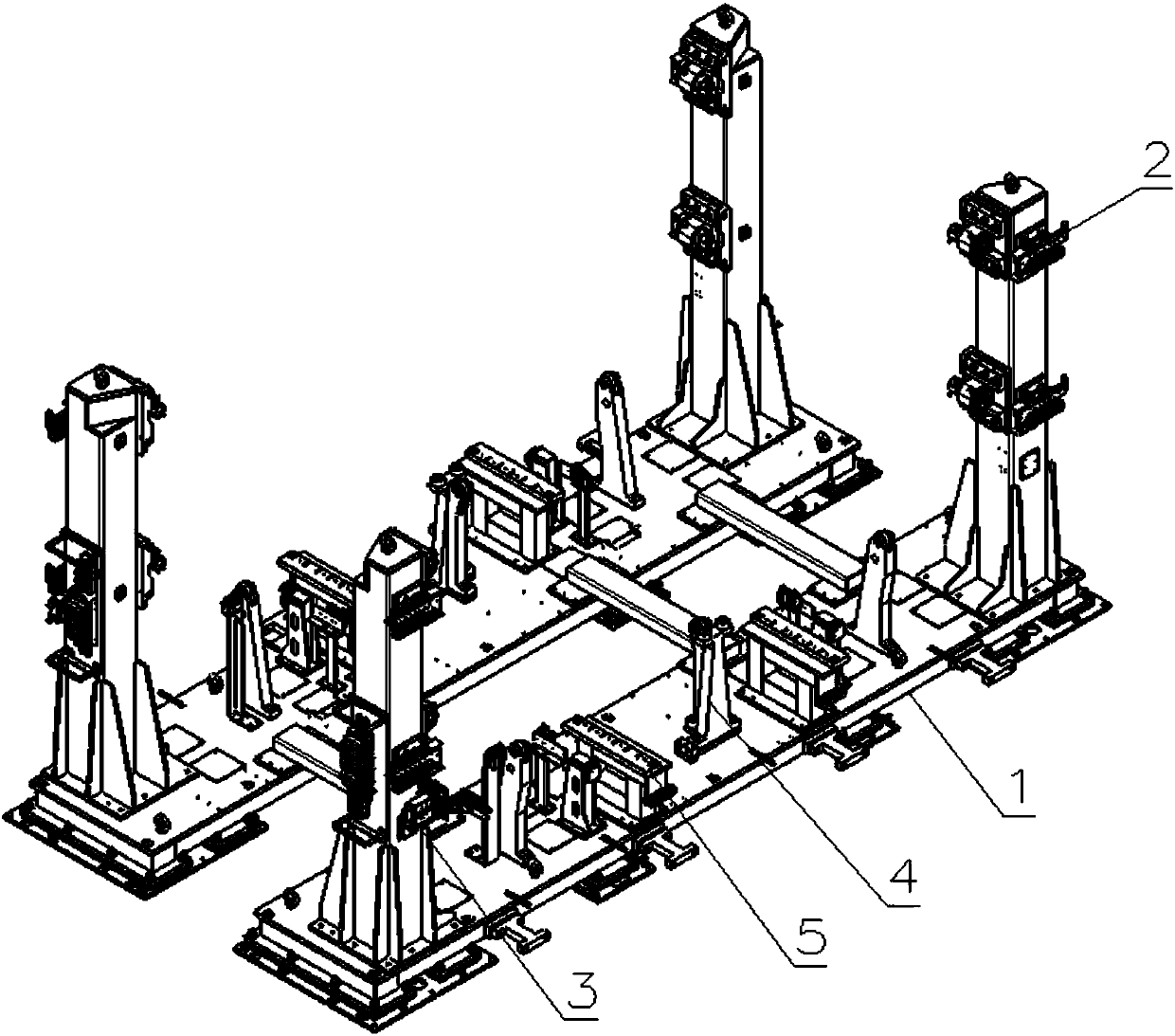

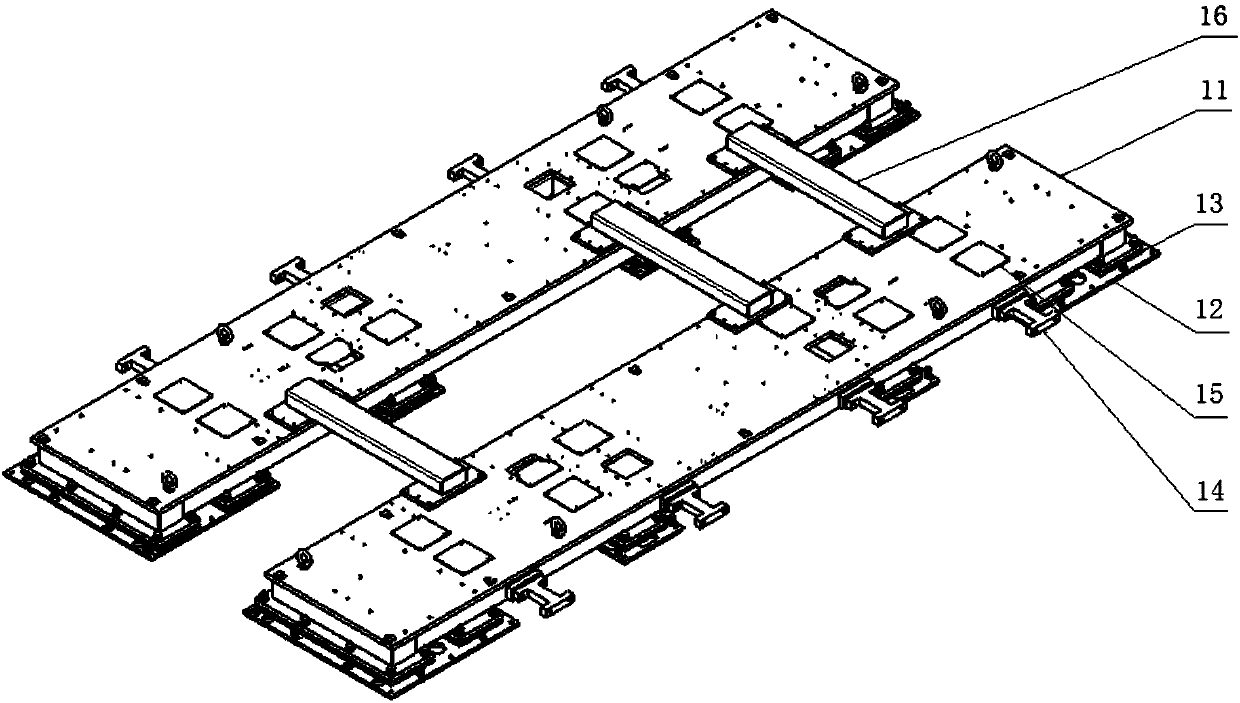

Steel structure system for precisely positioning side wall total assembly frames

PendingCN109676304AEasy to transportEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to a steel structure system for precisely positioning side wall total assembly frames. The steel structure system is applied to a white automobile body welding production line and comprises bottom plate frame units, guide rail units, guiding and supporting units and positioning and clamping stand column units, wherein the bottom plate frame units are arranged at the bottom and are used for supporting and mounting function units; the guide rail units are arranged on the bottom plate frame units and are butted with a mobile device for conveying the side wall total assemblyframes; the guiding and supporting units are mounted on the bottom plate frame units and are used for correcting positions of the side wall total assembly frames, supporting and positioning the side wall total assembly frames; the positioning and clamping stand column units are vertically mounted at corners of the bottom plate frame units and are used for clamping and fixing the side wall total assembly frames; clamp components and electrical quick inserting units are arranged at the upper parts of the positioning and clamping stand column units. According to the steel structure system, the guide rail units are arranged, can be conveniently matched and are capable of smoothly conveying the side wall frames into stations of the system; the guiding and supporting units are arranged, so thatthe side wall frames can be accurately adjusted to predetermined stations; the positioning and clamping stand column units are arranged and are used for clamping and fixing; the positioning manner issimple and reliable; the repeated positioning accuracy is high; the automobile body welding quality is improved.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

Fixture switching device

ActiveCN112008313BRealize collinear productionImprove flexibilityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The purpose of the present invention is to provide a clamp switching device that can realize the collinear production of multiple models and enhance the flexibility of the welding main line. The peripheral surface of the mounting plate is provided with a clamping mechanism for clamping the vehicle body at intervals. The mounting plate is coaxially fixed with a rotating shaft, the rotating shaft is rotatably arranged on the fixed seat, and the fixed seat is also provided with a positioning pin. In normal use, the locating pin is inserted into the locating hole to limit the rotation of the mounting plate, and the clamping mechanism clamps the vehicle body. If the vehicle model needs to be switched, the external force is inserted into the locating hole to push the locating pin out of the locating hole and separate. The restraint of the plate is released, and then the external force rotates, and the mounting plate rotates along with it to the position of the clamping mechanism corresponding to the switching model. .

Owner:CHERY AUTOMOBILE CO LTD

Co-linear spraying system and process of powder spraying and paint spraying

ActiveCN105057153BRealize collinear productionMeet the needs of various color sprayingLiquid surface applicatorsCoatingsProduction lineEngineering

The invention relates to the technical field of coating, and discloses a powder-spraying and paint-spraying single-line spray system. The powder-spraying and paint-spraying single-line spray system comprises a gluing chamber, a colored paint spraying chamber, a leveling chamber I, a clear lacquer spraying chamber, a leveling chamber II and a drying chamber, which are sequentially arranged, and further comprises a mobile powder room, wherein an opening for allowing the mobile powder room to get in and get out is formed in the leveling chamber II; and an opening-closing device is corresponding to the opening. The system can realize powder-spraying and paint-spraying on a single production line. In the meantime of achieving advantages of zero VOC emission and low input of powder spraying, requirements for spraying in different colors for work pieces can be met conveniently by utilizing an advantage that multi-color spraying can be realized by utilizing paint spraying, and the cost is reduced. The invention further provides a powder-spraying process and a paint-spraying process. The powder-spraying process comprises the steps of gluing, carrying out powder-spraying pretreatment, carrying out powder-spraying, drying and the like; and the paint-spraying process comprises the steps of gluing, spraying colored paint, carrying out primary leveling, spraying clear lacquer, carrying out secondary leveling, drying and the like. The powder-spraying process and the paint-spraying process can be carried out on the same production line, and are convenient in coating.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Quick die exchanging device

InactiveCN111283428ARealize collinear productionQuick changeoverAssembly machinesEngineeringMechanical engineering

The invention provides a quick die exchanging device. The device can realize multi-machine-type collinear production and quick type change, greatly shorten device supply period, and reduce the productdevelopment cost. The device comprises a rack, wherein a die exchanging seat is mounted on the rack, a die exchanging plate assembly is mounted on the die exchanging seat, the die exchanging plate assembly comprises a die exchanging plate, the die exchanging seat is provided with a gas-electric integrated female connector, the die exchanging plate is provided with a gas- electric integrated maleconnector corresponding to the gas-electric integrated female connector, the die exchanging seat is provided with a holding device, the holding device further comprises a telescopic air cylinder mounted on the die exchanging seat, the telescopic air cylinder is connected with a clamping head, and the die exchanging plate is assembled on the die exchanging seat through the clamping head.

Owner:昆山迈征自动化科技有限公司

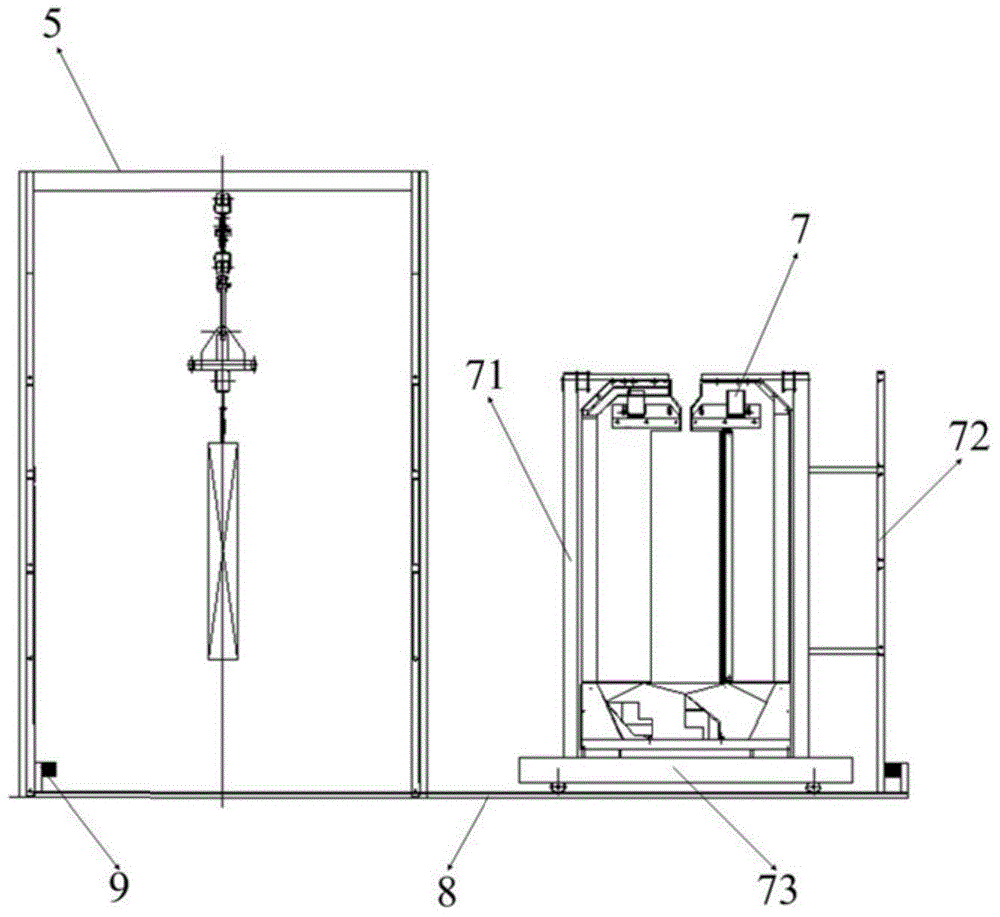

Conveying system for vacuum reflow soldering furnace

PendingCN113492240ASynchronous width adjustment functionConsistent displacementHeating appliancesPrinted circuitsEngineeringBack door

The invention relates to a conveying system for a vacuum reflow soldering furnace. The system is characterized by comprising an in-furnace transmission device, a vacuum device and a track width adjusting device. The in-furnace transmission device comprises at least one in-furnace transmission track; the vacuum device comprises a shell, a vacuum transmission module, a front door connecting shaft, a rear door connecting shaft, a first connecting shaft, a second connecting shaft and a plurality of transition shafts, and the positions of the vacuum transmission track and the in-furnace transmission track are collinearly corresponding one by one; the track width adjusting device is connected with each conveying chain in the in-furnace conveying track and each vacuum conveying chain in the vacuum conveying track, and the distance between the two conveying chains in the in-furnace conveying track and the distance between the two vacuum conveying chains in the vacuum conveying track which are collinearly corresponding to the in-furnace conveying track are synchronously adjusted. Compared with the prior art, the in-furnace conveying track in the in-furnace conveying device and the vacuum conveying track in the vacuum conveying module achieve a synchronous width adjusting function.

Owner:上海朗仕电子设备有限公司

General sand core structure and usage method of supercharger on foundry production line

ActiveCN111515344BIncrease productivityRealize collinear productionFoundry mouldsFoundry coresEngineeringManufacturing line

A universal sand core structure and usage method for superchargers on a casting production line, comprising: a lower shell, and an upper shell molded on the lower shell, wherein the lower shell and the upper shell are equipped with clamping positioning, clamping tightening, and transport pallets Positioning and transport pallets are placed, and the lower shell is also provided with hoisting guides and hoisting planes; clamping positioning columns are installed in the clamping positioning; On the top of the shell; the positioning of the transport pallet is equipped with a pallet positioning column; the transport pallet is placed on the positioning of the transport pallet and has the same shape as the pallet; the hoisting guide is a vertical groove set at the corner of the lower shell and the upper shell; the hoisting plane is set In the plane of the four corners of the lower shell and the upper shell. The present invention not only enables the same supercharger sand core structure to carry out the production work of sand core positioning, sand core clamping, sand core hoisting and other products at the same time; moreover, it can also realize the collinear production of multiple products, which improves the Production efficiency of the production line.

Owner:TIANJIN NEW WEISAN INDS

Method for producing nonferrous metal wire rods with different specifications by high-speed wire rod mill

InactiveCN111530924AOvercome the problem of singularityIncrease productivityWork cooling devicesWork heating devicesWire rodTemperature control

The invention provides a method for producing nonferrous metal wire rods with different specifications by a high-speed wire rod mill. The method comprises the following steps that materials are selected; heating is carried out; plain-barreled roll micro-rolling or pre-rough rolling is carried out; rough rolling is carried out; pre-finish rolling is carried out; pre-water-cooling temperature control is carried out; finish rolling is carried out; water-penetrating cooling temperature control is carried out; spinning is carried out; air cooling temperature control is carried out; and packing is carried out, firstly nonferrous metal blanks with different specification lengths are made into square blanks through plain-barreled rolling, then round rod materials are obtained through pre-finish rolling, and finally, the nonferrous metal wire rods with the different specifications are obtained through finish rolling. According to the method for producing the nonferrous metal wire rods with thedifferent specifications by the high-speed wire rod mill, the multiple nonferrous metal blanks with the different specifications are rolled on the high-speed wire rod mill through plain-barreled rollmicro-rolling, the problem of unicity of high-speed wire rod mill hole-type rolled blanks is solved, the collinear production of nonferrous metals such as nickel and titanium or alloy wire rods thereof and steel wire rods is realized, the yield and quality of the nonferrous metal wire rods are greatly improved, and the economic benefit is improved.

Owner:LINGYUAN IRON & STEEL CO LTD

A skid and its automobile production line

ActiveCN112046998BIngenious ideaReasonable designLiquid surface applicatorsSpraying apparatusControl theoryManufacturing line

The invention discloses a skid and its automobile production line, comprising one or more than two skid units, a splitting mechanism and a locking and unlocking device; the splitting mechanism is arranged on the skid unit, connecting two The skid unit is used to combine two or more skid units into a whole according to different production requirements, or split two or more skid units combined into independent The sled unit, the opening and closing mechanism includes a male head, a female head and a latch, the male head is arranged at one end of the sled unit, the female head is arranged at the other end of the sled unit, and the positions of the male head and the female head correspond to each other. There is a pin used to fix the male head and the female head between the male head and the female head. The skid and its automobile production line can use each skid as an independent unit, or can be locked by a lock according to the different production models. Combination and disassembly of independent skid units by means of a tightening mechanism to achieve collinear production of multiple models of different sizes.

Owner:JIANGLING MOTORS +3

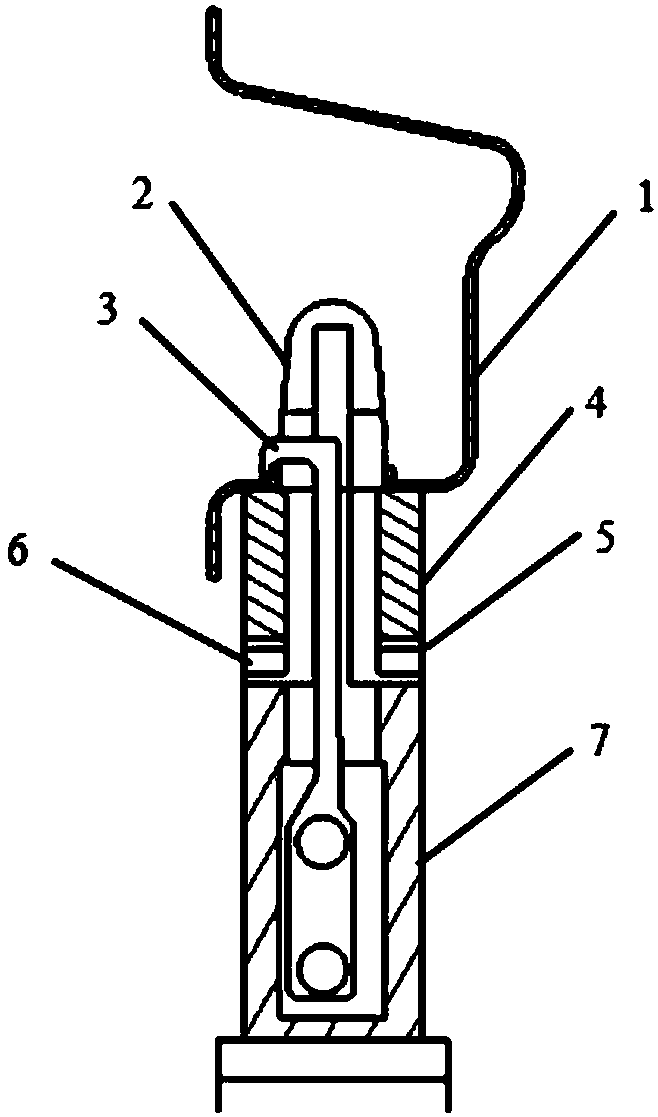

Positioning and clamping device and positioning and clamping method using same

The invention discloses a positioning and clamping device and a positioning and clamping method using the same. The positioning and clamping device comprises a dowel pin, a clamping piece and a driving unit, wherein the dowel pin is provided with a vertical groove and a transverse groove, which communicate with each other; the vertical groove penetrates through the bottom wall of the dowel pin, and extends in the axial direction; the transverse groove is at least opened on a first side and a second side of the peripheral wall of the dowel pin; the first side is opposite to the vertical groove,and the second side is staggered from the vertical groove; the clamping piece is arranged in the dowel pin; and the driving unit is connected with the clamping piece to drive the clamping piece to move among a first position, a second position and a third position; in the first position, a working head part of the clamping piece is positioned in the vertical groove; in the second position, the working head part of the clamping piece extends out from the first side; and in the third position, the working head part of the clamping piece is rotated to extend out from the second side to clamp sheet metal parts to be machined. The positioning and clamping device is low in space demand in the positioning process, and can realize collinear production of multiple vehicle types.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

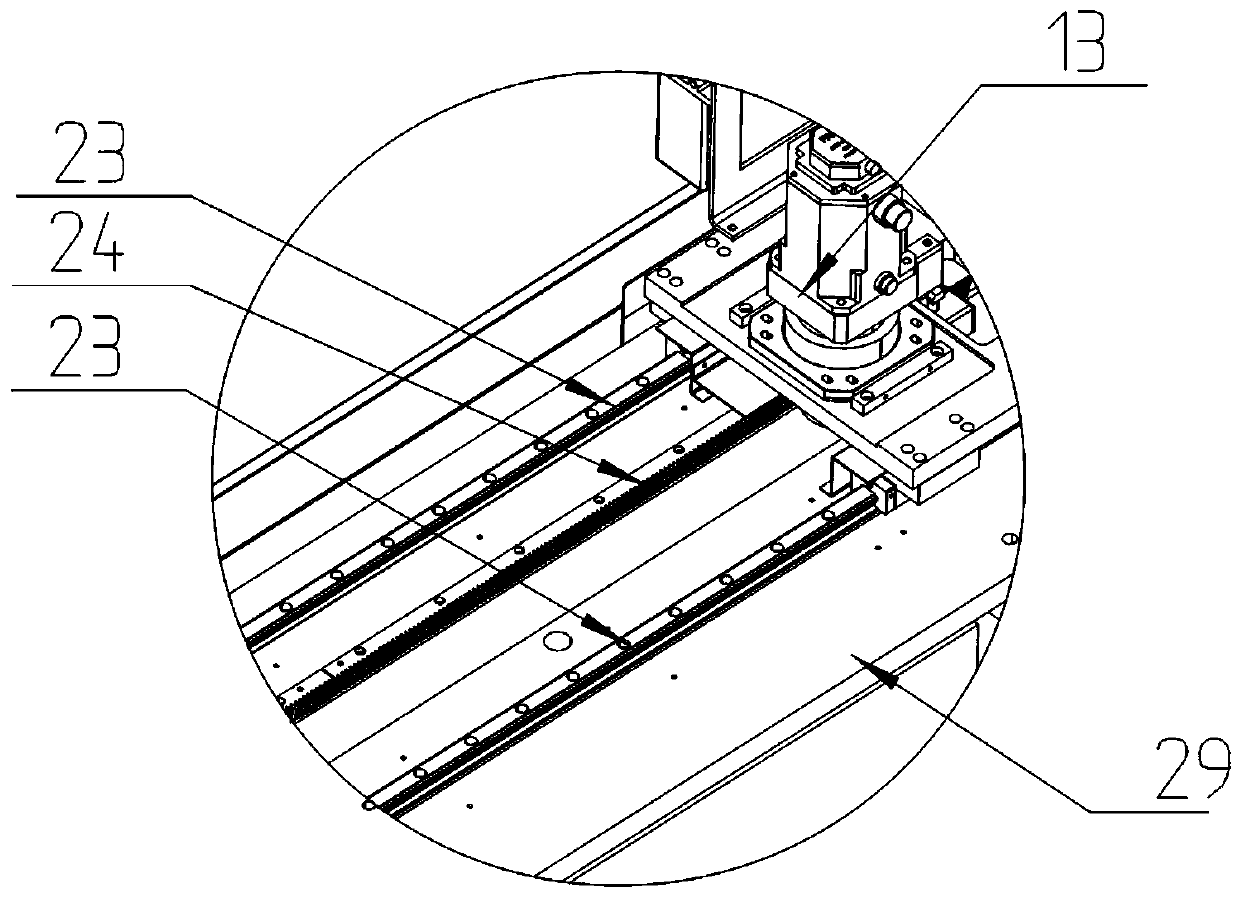

Automatic flexible cutting system for box-type section beam and cutting method thereof

PendingCN111375887ARealize all-round cuttingRealize collinear productionWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses an automatic flexible cutting system for a box-type section beam. The automatic flexible cutting system comprises a cutting mechanical arm, double seven shafts, a plurality ofrotary flexible brackets, an axial positioning mechanism and a plate link chain, the double seven shafts comprise a frame, a pair of upper guide rails are installed on the top face of the frame in theaxial direction, an upper rack is installed between the two upper guide rails in the axial direction; and the invention further discloses a cutting method of the automatic flexible cutting system forthe box-type section beam. The automatic flexible cutting system for the box-type section beam and the cutting method thereof have the beneficial effects that firstly, the flexible cutting system isprovided with the plurality of rotary flexible brackets, 360-degree rotation of box beams can be achieved, 360-degree all-dimensional cutting of the box-type section beam is achieved; and secondly, the flexible cutting system realizes collinear production of the box beams with different sizes by reasonably arranging the number (flexibility in the length direction) of the rotary flexible brackets and flexible positioning and clamping devices (functions of lateral positioning magnets, vertical positioning magnets and clamping seats) of the rotary flexible brackets.

Owner:上海晓奥享荣自动化设备有限公司 +2

Jacking equipment for rear suspension assembly

PendingCN110640427AFlexible operationBig spaceAssembly machinesMetal working apparatusUniversal jointMan machine

The invention provides jacking equipment for a rear suspension assembly. The jacking equipment for the rear suspension assembly comprises a suspended balance power-assisting mechanism and an operatingmechanism. The operating mechanism comprises a rack, a hook, a power mechanism, a screw rod, a sliding block and a jacking structure. The hook is located at the top of the rack, the bottom of the rack is connected to the balance power-assisting mechanism, the screw rod is in transmission connection with the power mechanism through a universal joint, the sliding block is connected to the screw rodthrough internal threads, the sliding block is hinged to the jacking structure, the jacking structure is hinged to the rack, and the sliding block moves on the screw rod to drive the jacking structure to ascend and descend. According to the jacking equipment, the operation mechanism is ingenious in structure, the operator can operate the equipment more flexibly, the operation man-machine performance is high, and the fatigue strength of the operating personnel can be lowered.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com