Conveying system for vacuum reflow soldering furnace

A transmission system and vacuum reflow technology, applied in welding equipment, electric heating devices, auxiliary devices, etc., can solve problems such as inconvenient use, difficulty in achieving synchronous width adjustment, inconvenient adjustment of transmission belt width, etc., to ensure stability and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

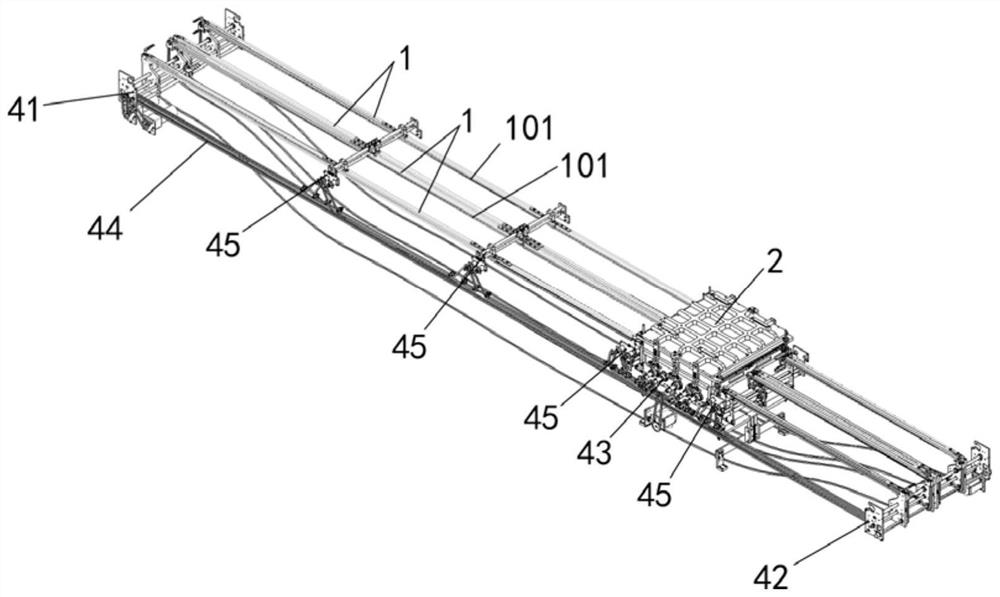

[0035] Such as figure 1 As shown, this embodiment provides a conveying system for a vacuum reflow oven, including an in-furnace conveying device, a vacuum device 2 and a track width adjusting device. The conveying system is integrally arranged inside the vacuum reflow oven. The in-furnace transport device includes at least one in-furnace transport track 1. In this embodiment, two parallel in-furnace transport tracks 1 are used, and each in-furnace transport track 1 includes two parallel transport chains 101.

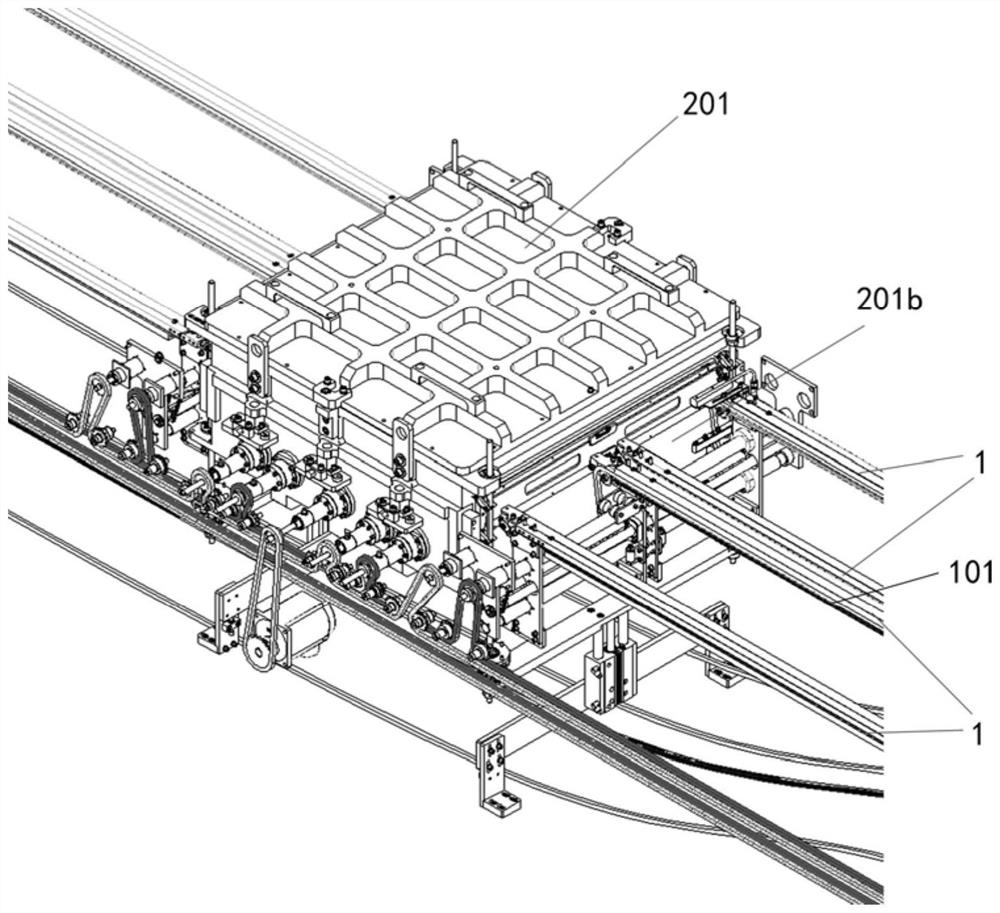

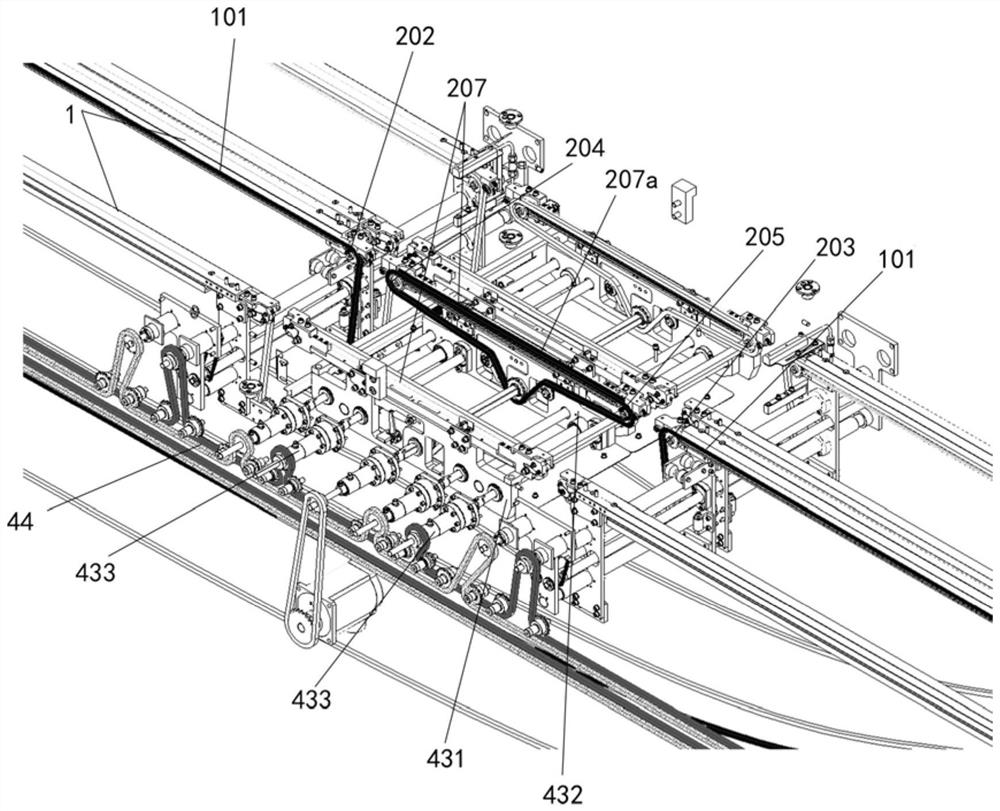

[0036] Such as Figure 2~4 As shown, the vacuum device 2 includes a housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com