Full-automatic pipe correction control system

A control system and fully automatic technology, which is applied in the field of automatic pipe straightening control system, can solve problems such as difficult to realize, achieve consistent displacement and achieve straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] This embodiment provides that the purpose of the present invention is to solve the existing gears, chains, belts and friction transmissions that have large energy losses, are prone to hard impacts, low transmission efficiency, short service life of parts, and difficult to realize automatic control. Provided is an automatic pipe correction control system.

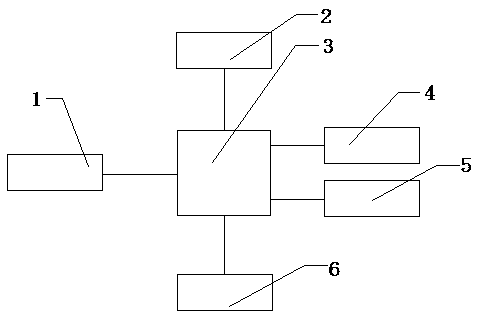

[0013] The invention provides a full-automatic pipe correction control system, characterized in that: the full-automatic pipe correction control system includes a control panel (1), a frequency converter (2), a PLC controller (3), a drive station (4 ), drive station controller (5), position sensor (6);

[0014] Among them: the PLC controller (3) is respectively connected with the control panel (1), the frequency converter (2), and the driving system. The driving system includes a position sensor (6), a driving station (4) and a driving station controller (5). The displacement of the straightening roller and the suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com