A constant pressure hydraulic station

A technology of hydraulic station and constant pressure pump, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo motor components, etc. It can solve the problems of shortened life, non-adjustable, total output flow of the system cannot reach the rated flow, etc. problems, to achieve the effect of improving reliability and life, improving reliability, and reducing standby power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

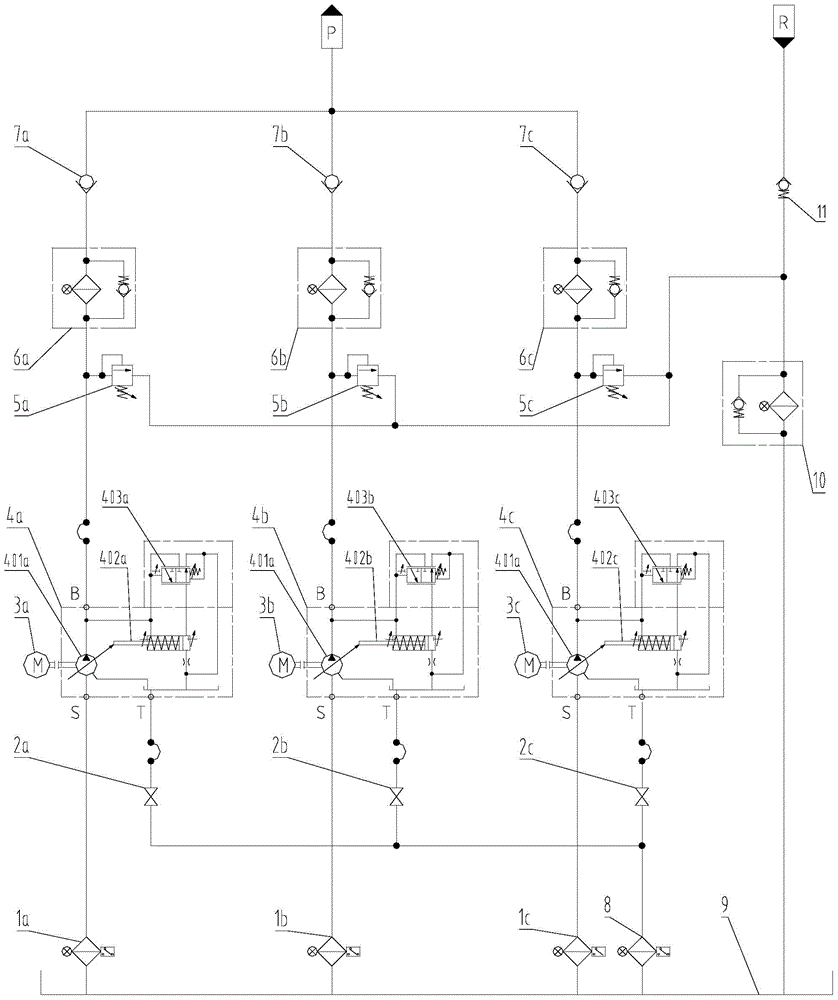

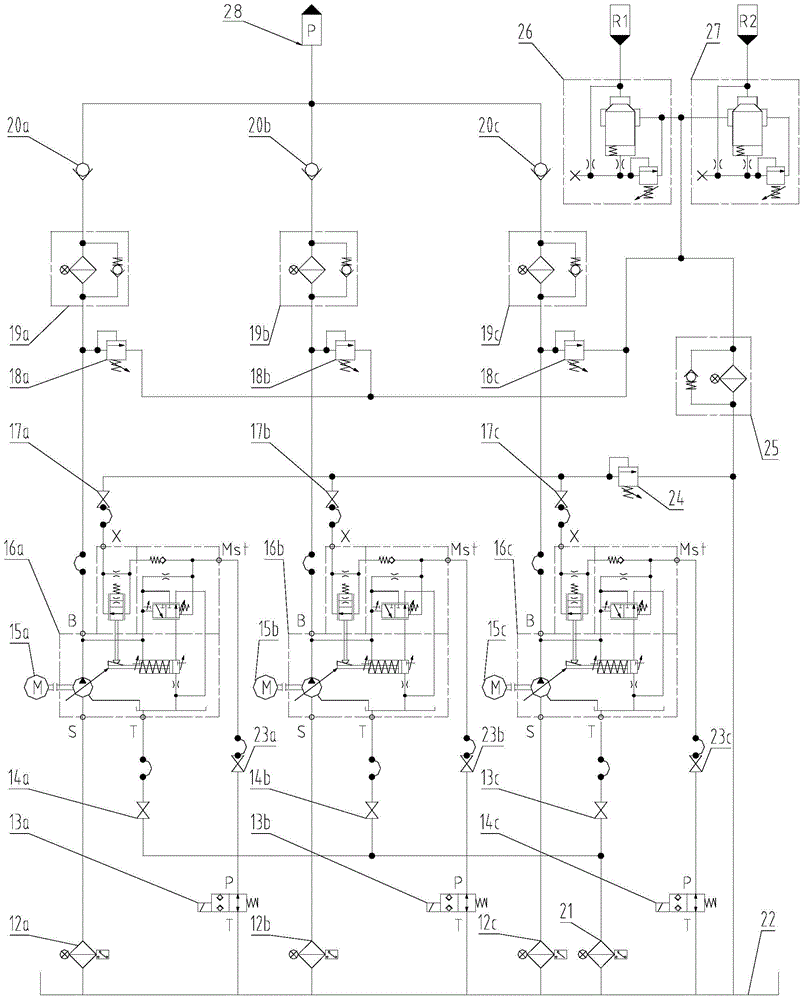

[0031] Such as figure 2 As shown, the constant pressure hydraulic station of the present invention includes at least one set of pump sets, preferably three or more sets of pump sets, each set of pump sets is arranged side by side, and any set of pump sets is used as a backup. In this embodiment, three sets of pump sets are used. The constant pressure hydraulic station of the present invention also includes an oil drain filter 21 , an oil tank 22 , an overflow valve 24 , an oil return filter 25 , a first socket pressure valve 26 , and a second socket pressure valve 27 .

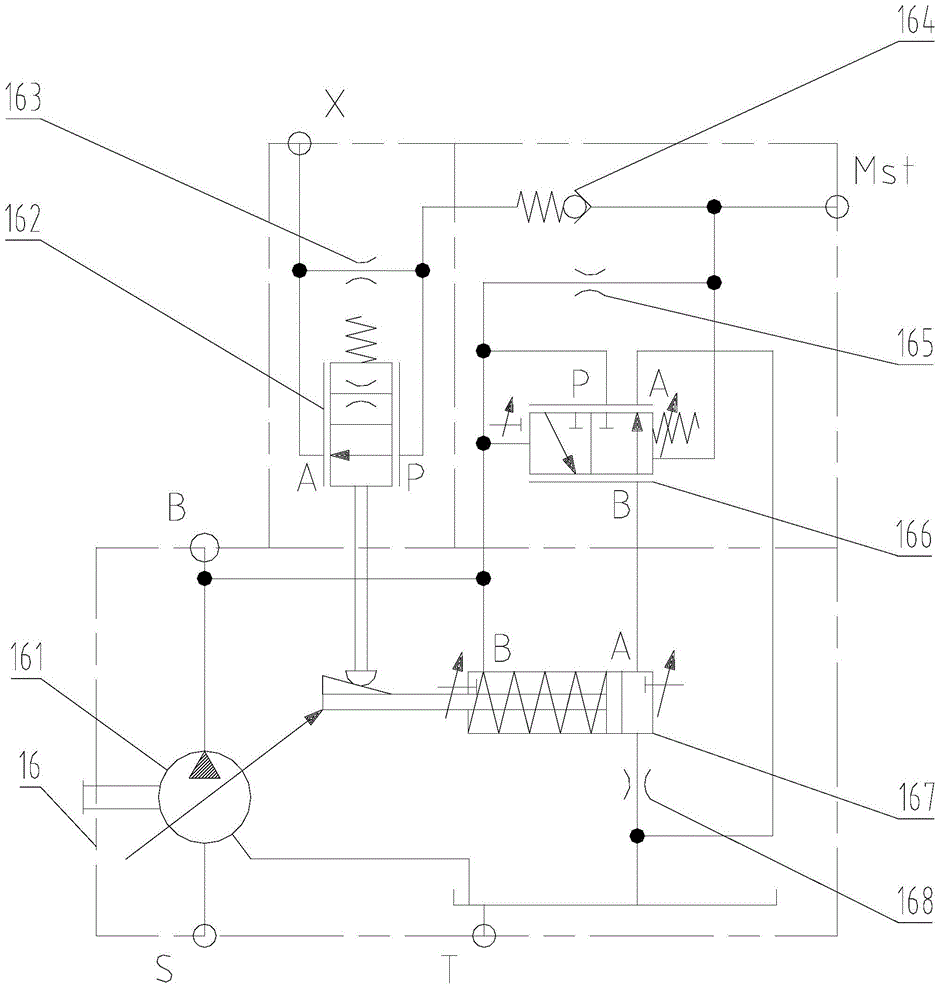

[0032] Each pump set includes an oil suction filter 12 (respectively represented by 12a, 12b and 12c in the figure), a solenoid valve 13 (respectively represented by 13a, 13b and 13c), a ball valve 14 (respectively represented by 14a, 14b and 14c), Motor 15 (respectively represented by 15a, 15b and 15c), constant pressure pump 16 (respectively represented by 16a, 16b and 16c), ball valve 2 17 (respectively re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com