Patents

Literature

115results about How to "Avoid emptying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

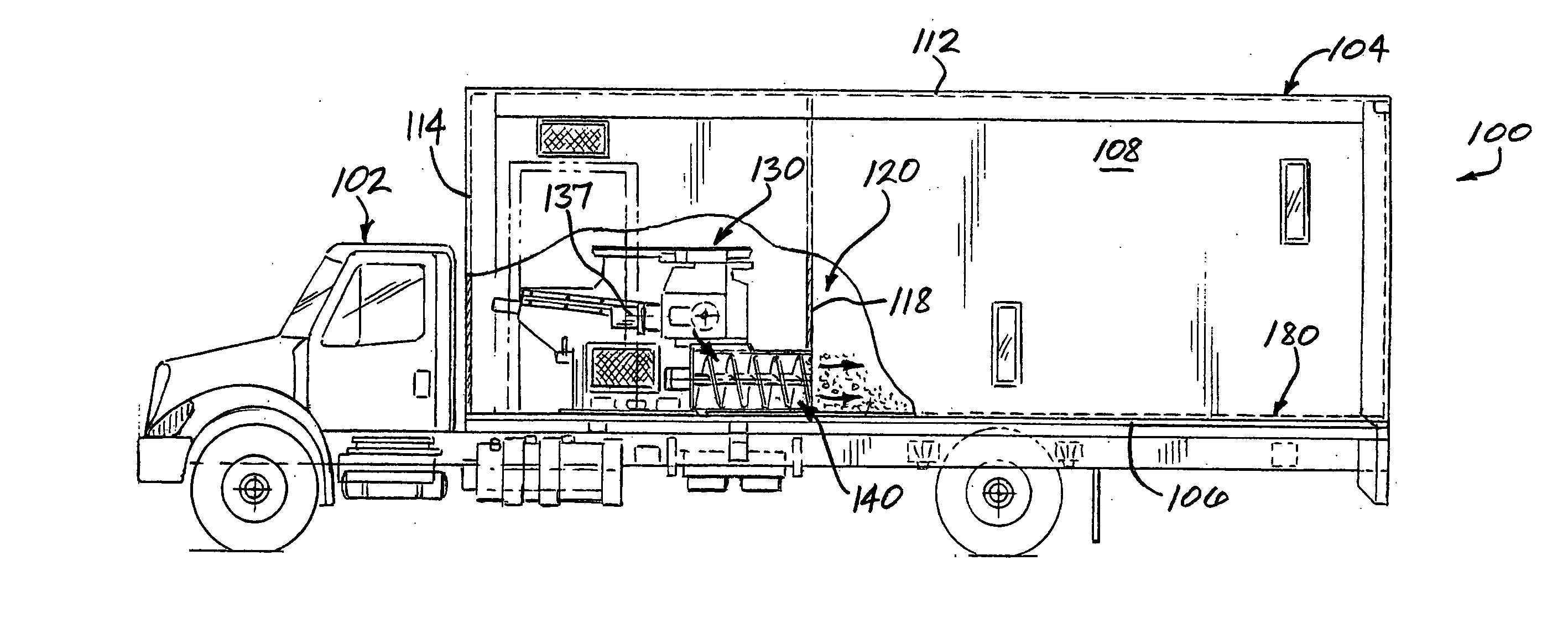

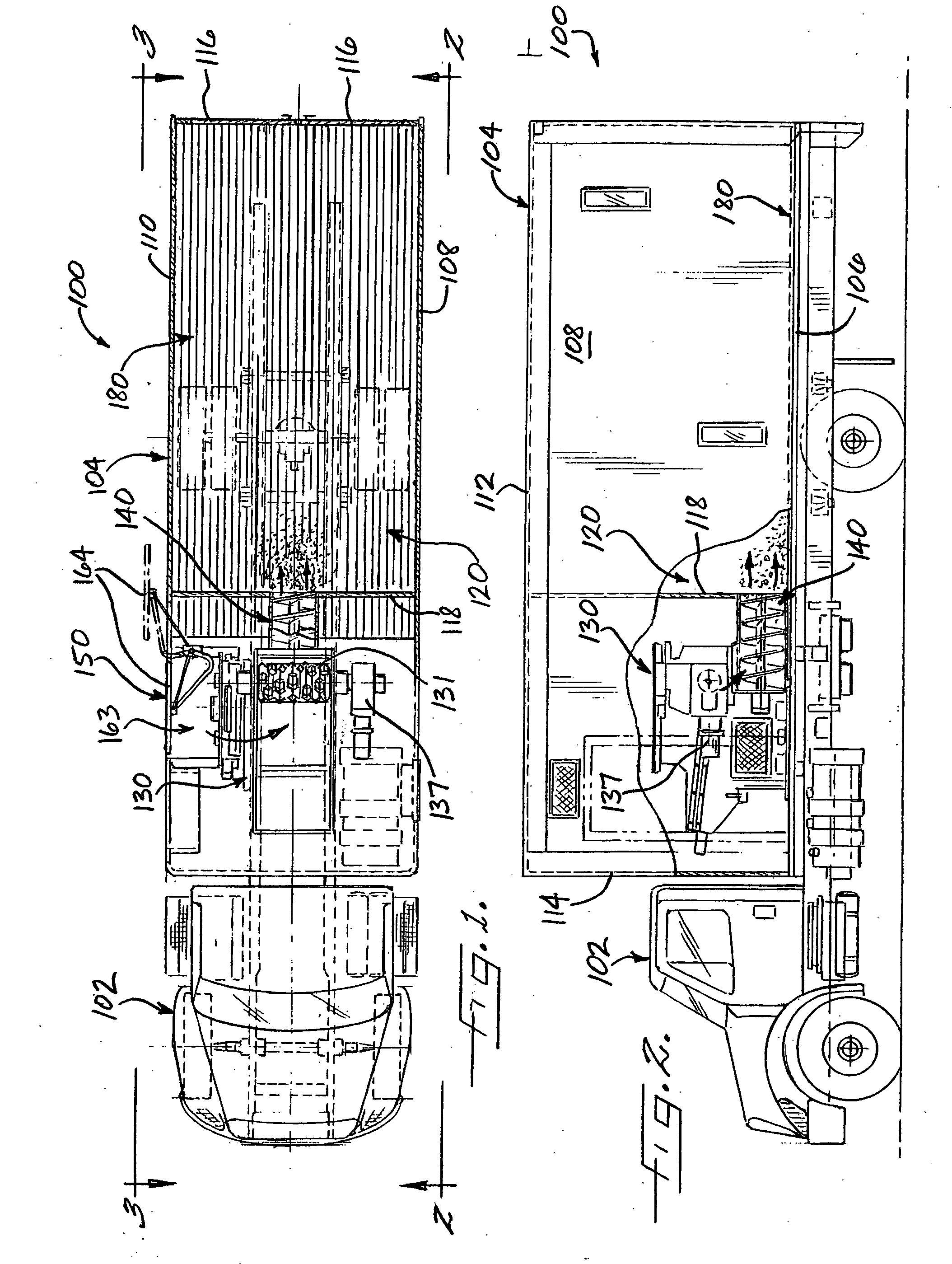

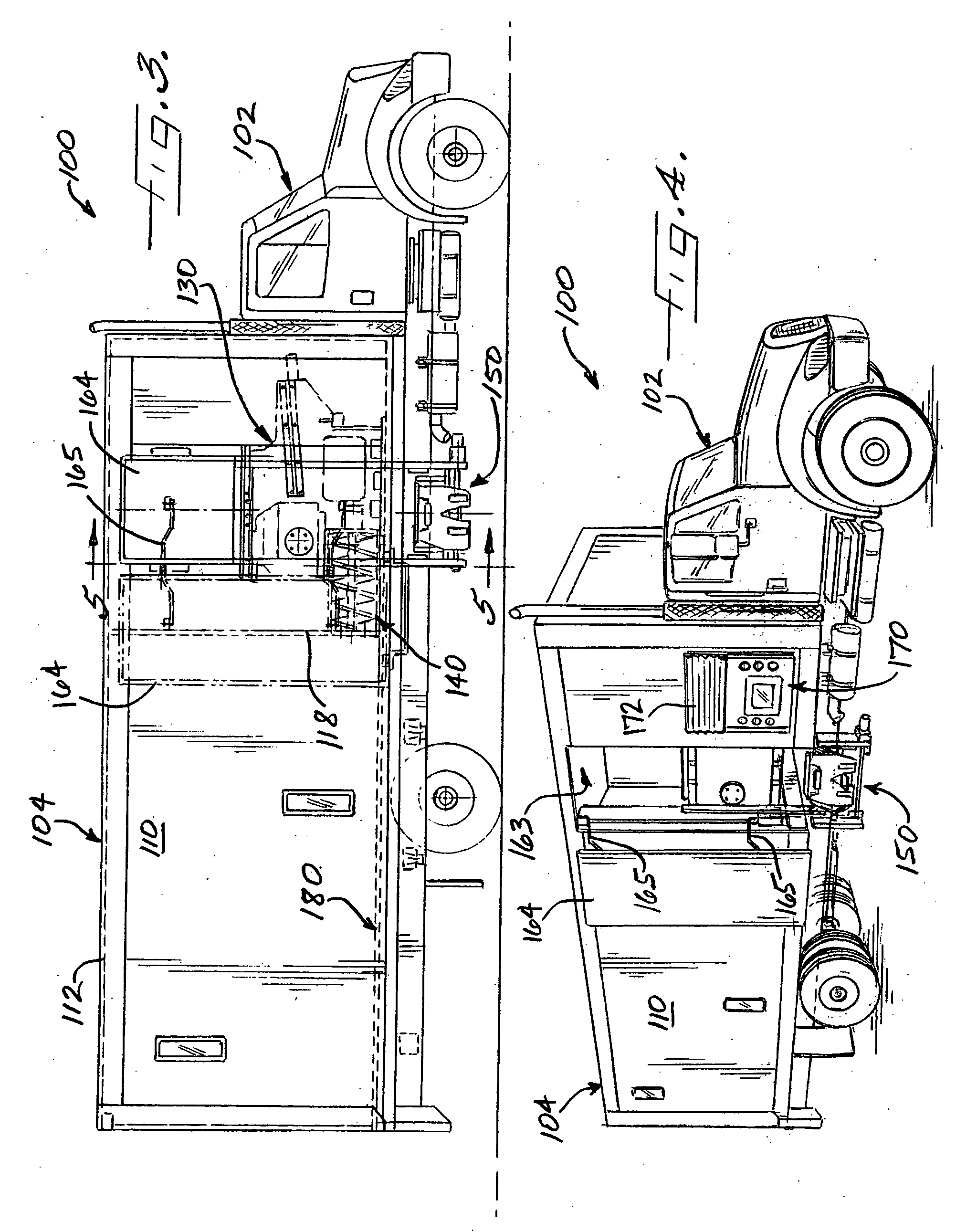

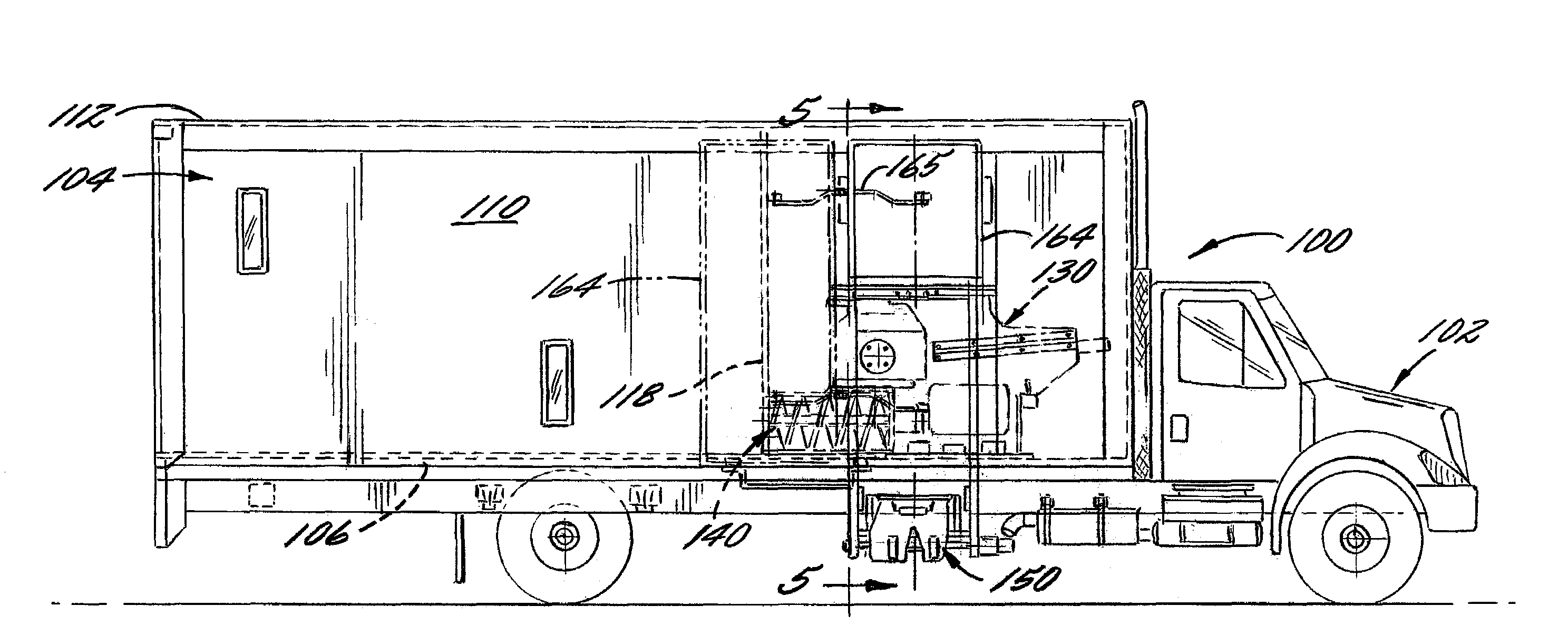

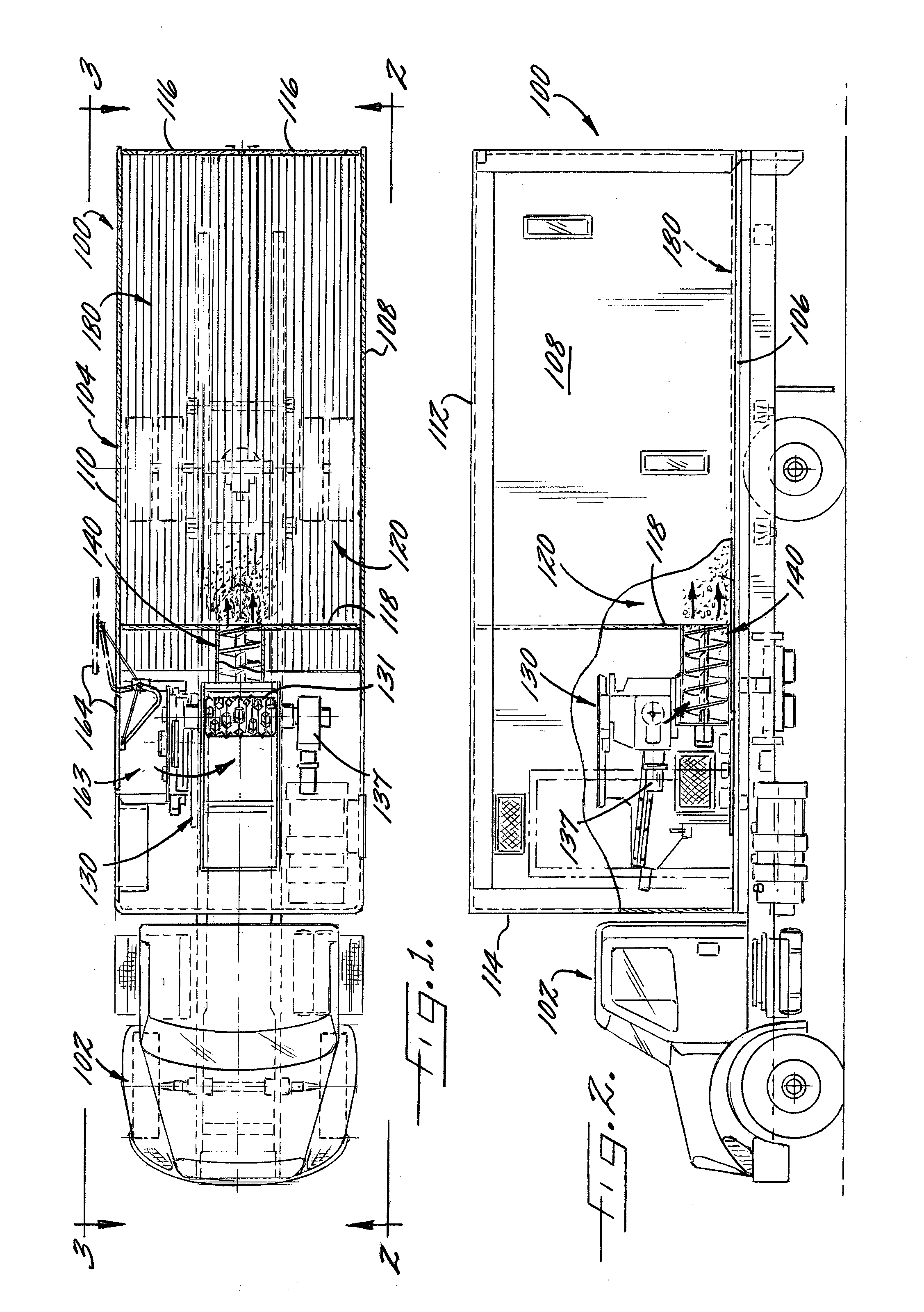

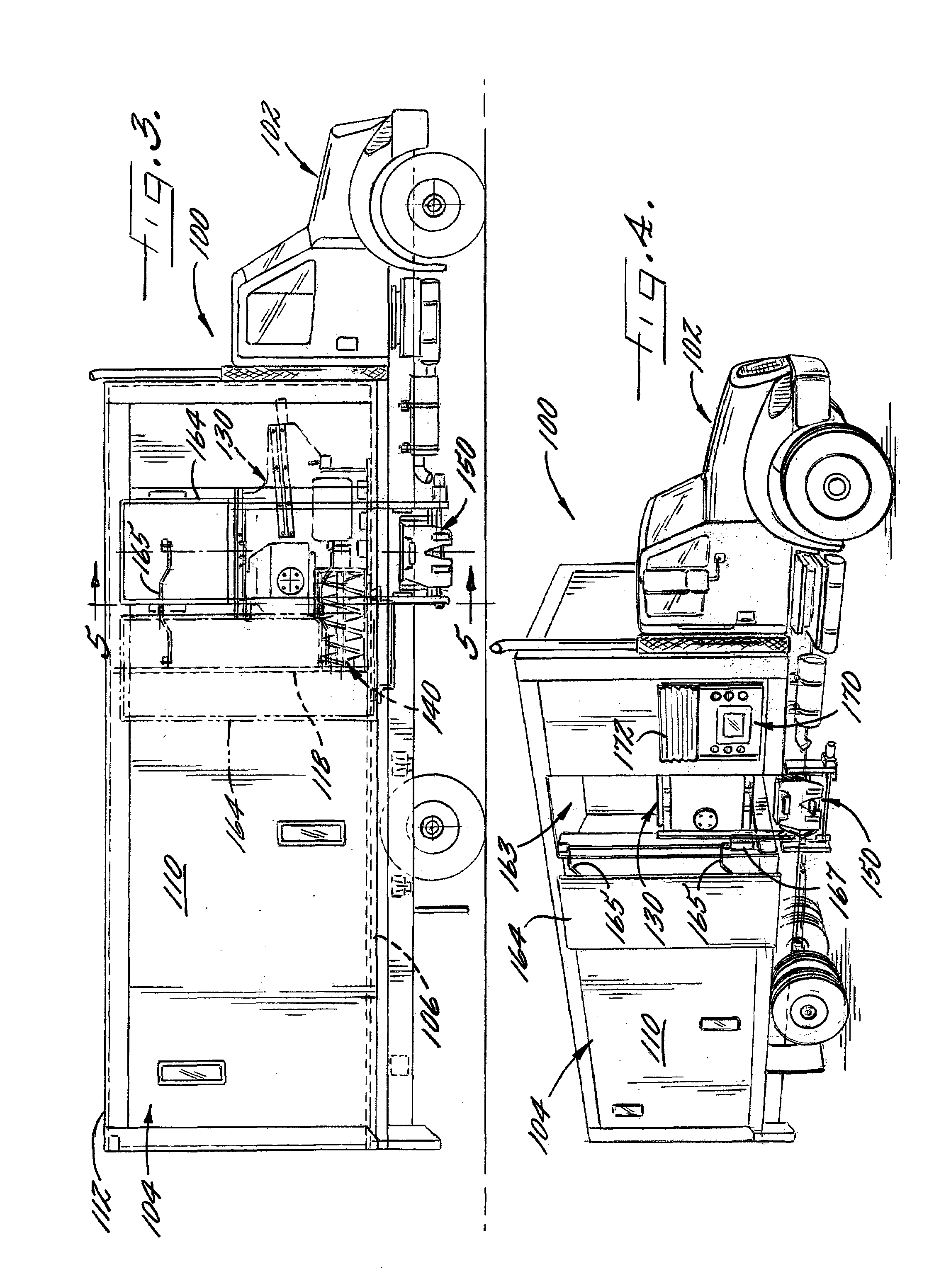

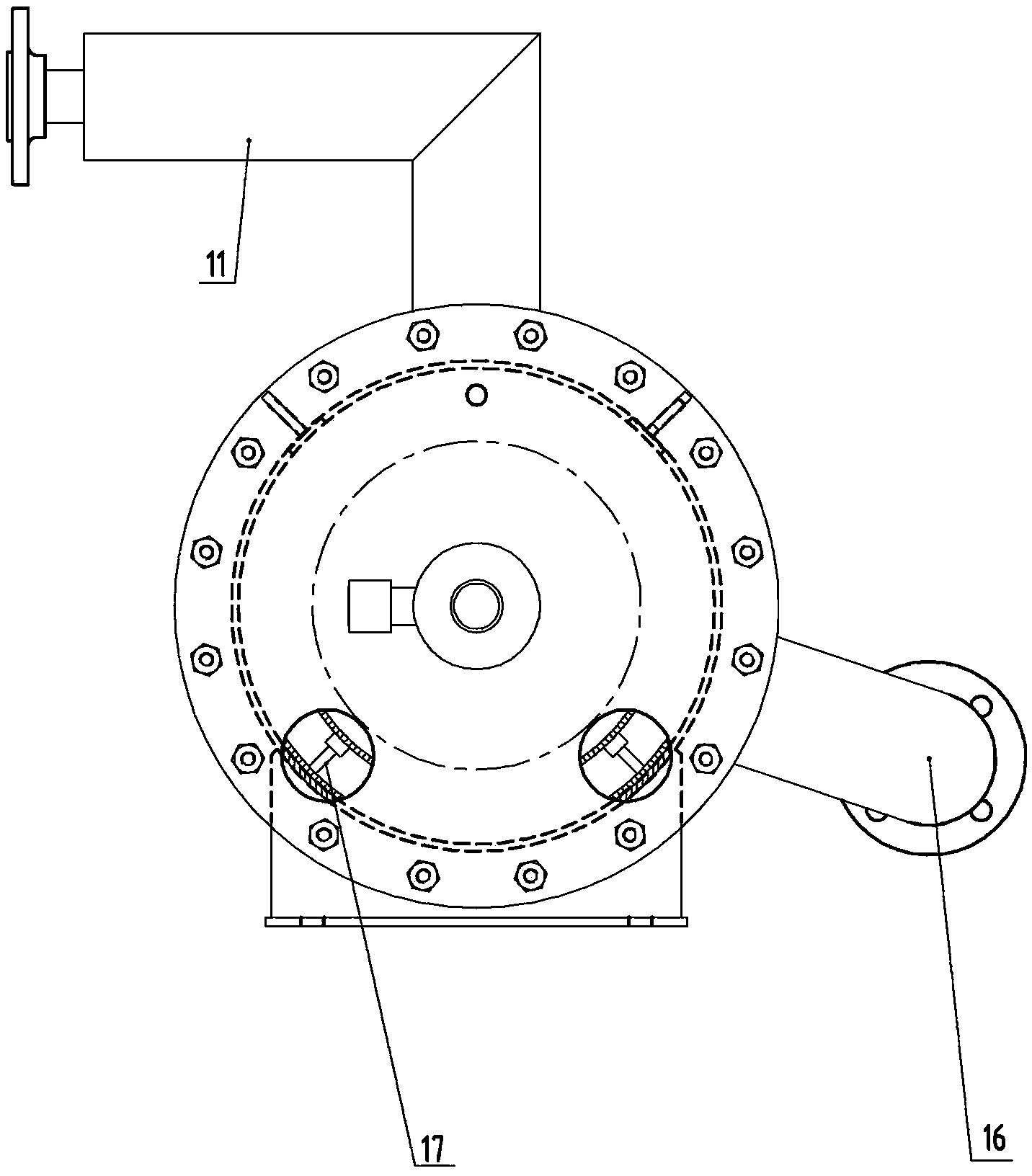

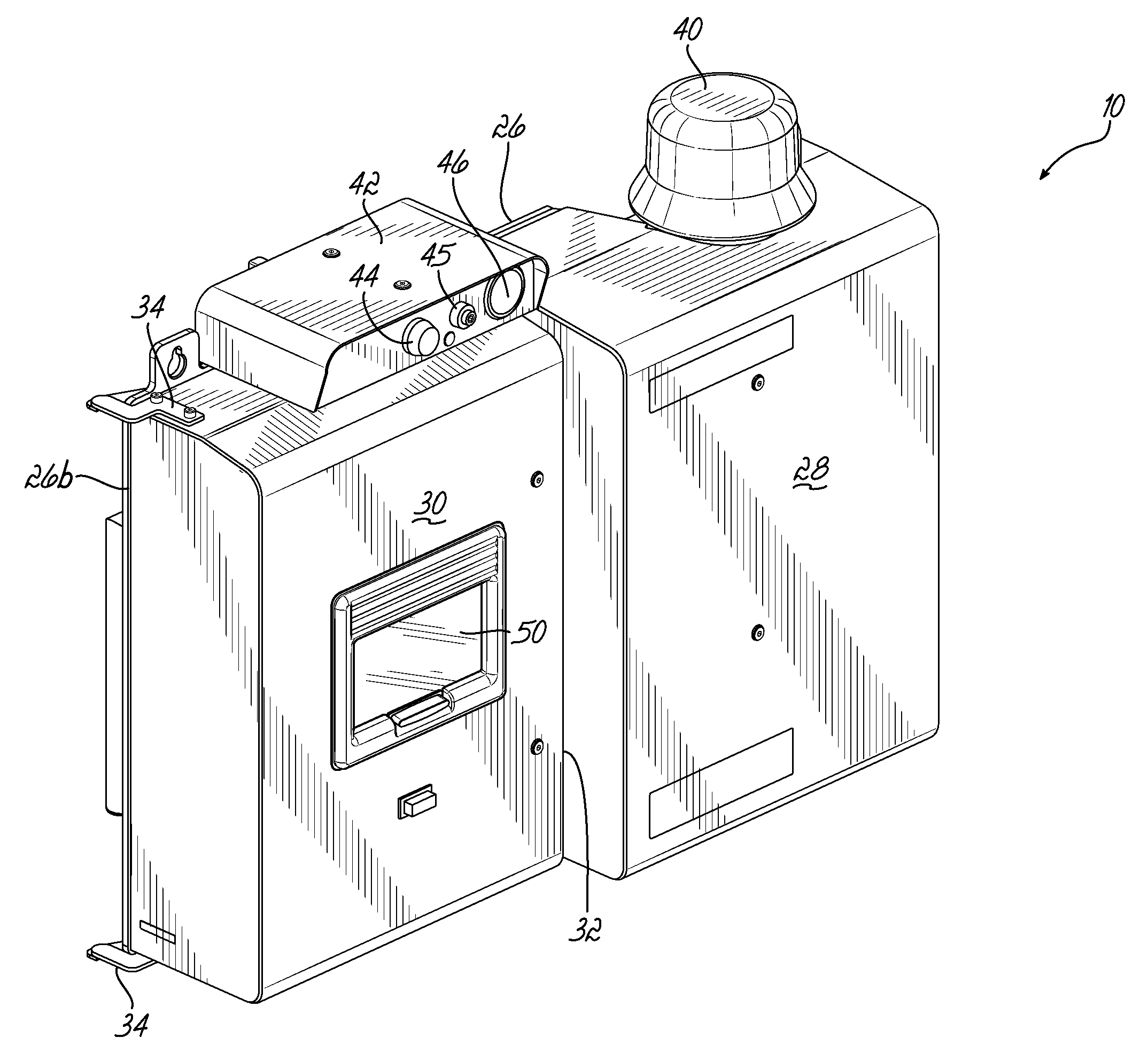

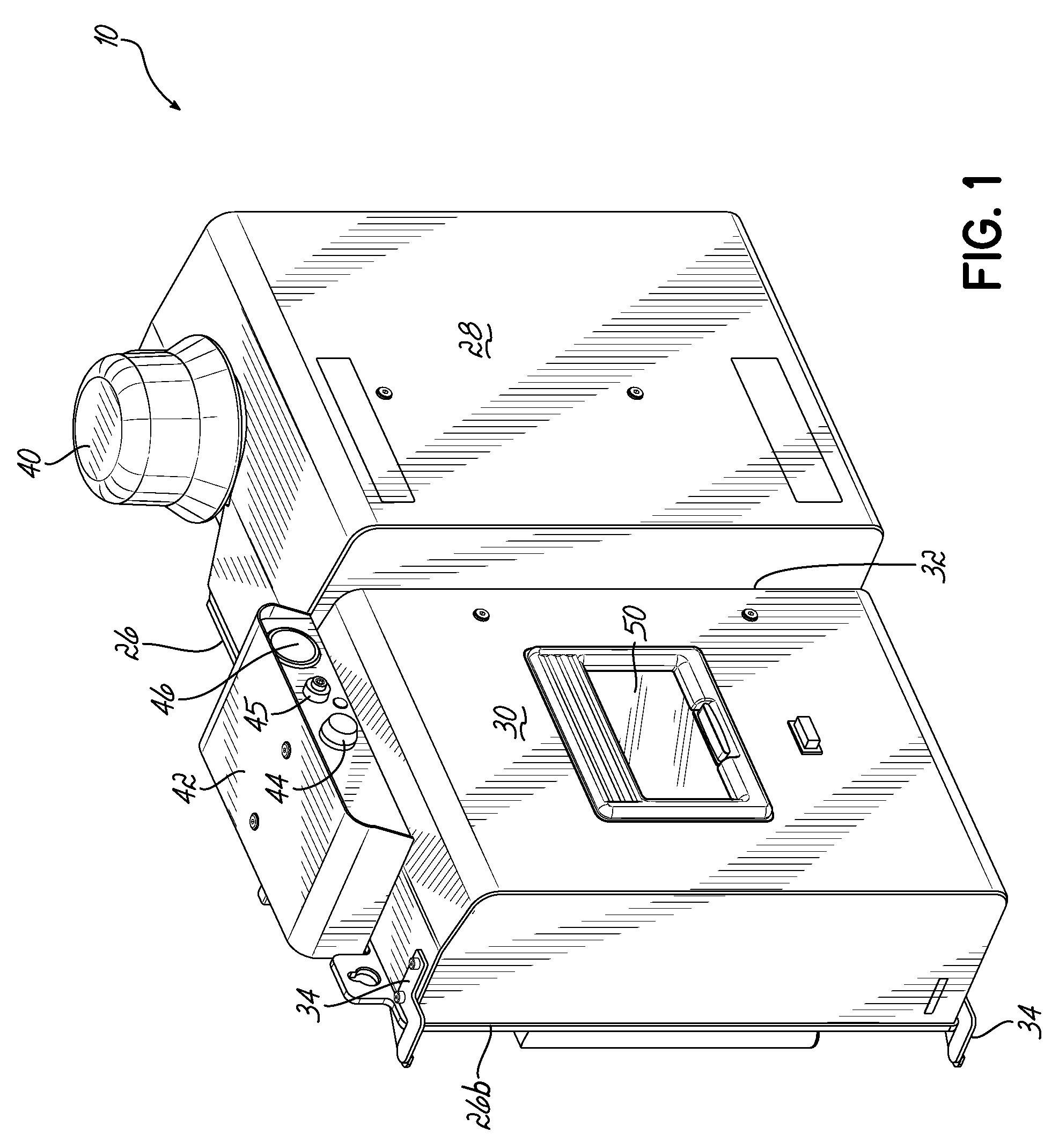

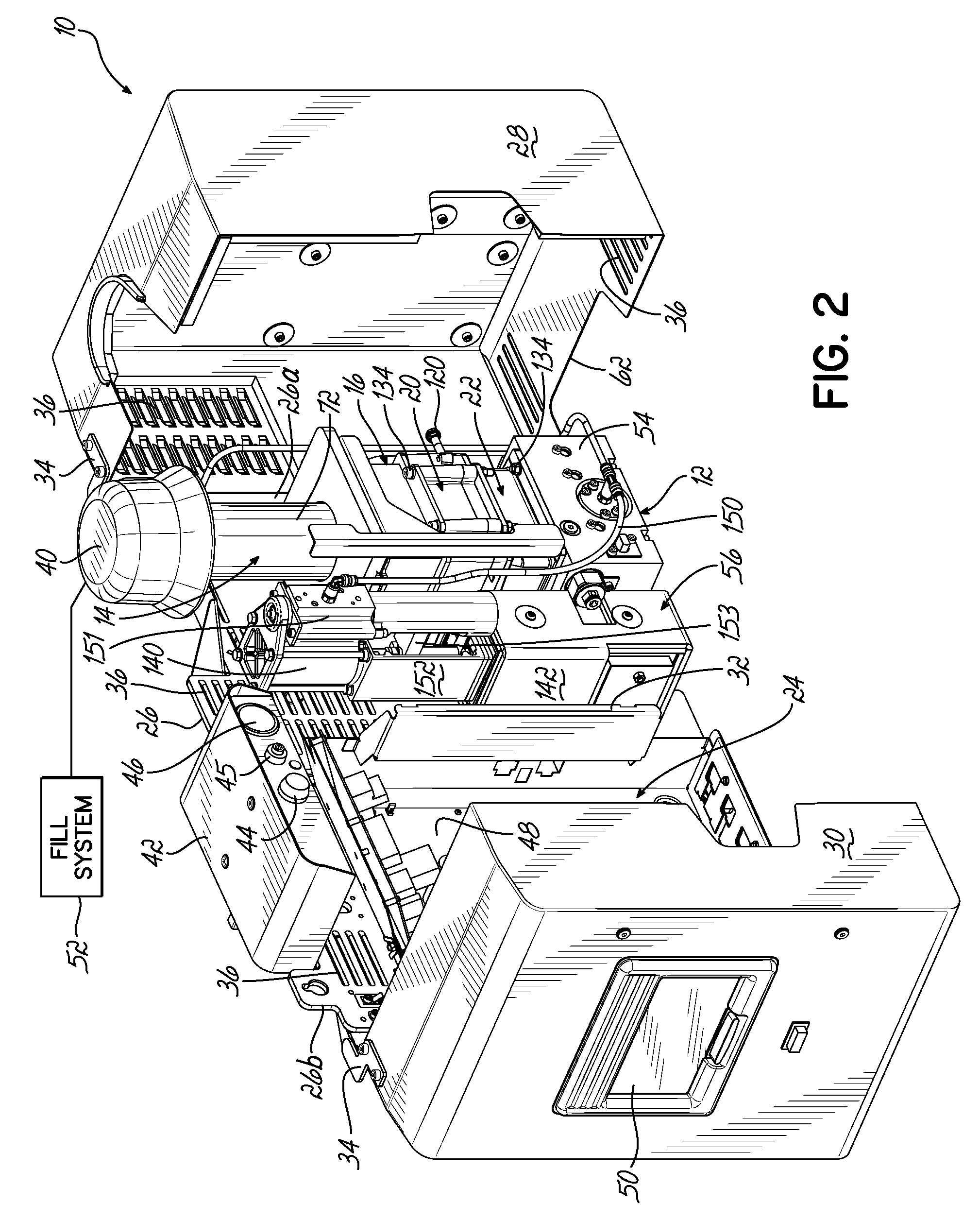

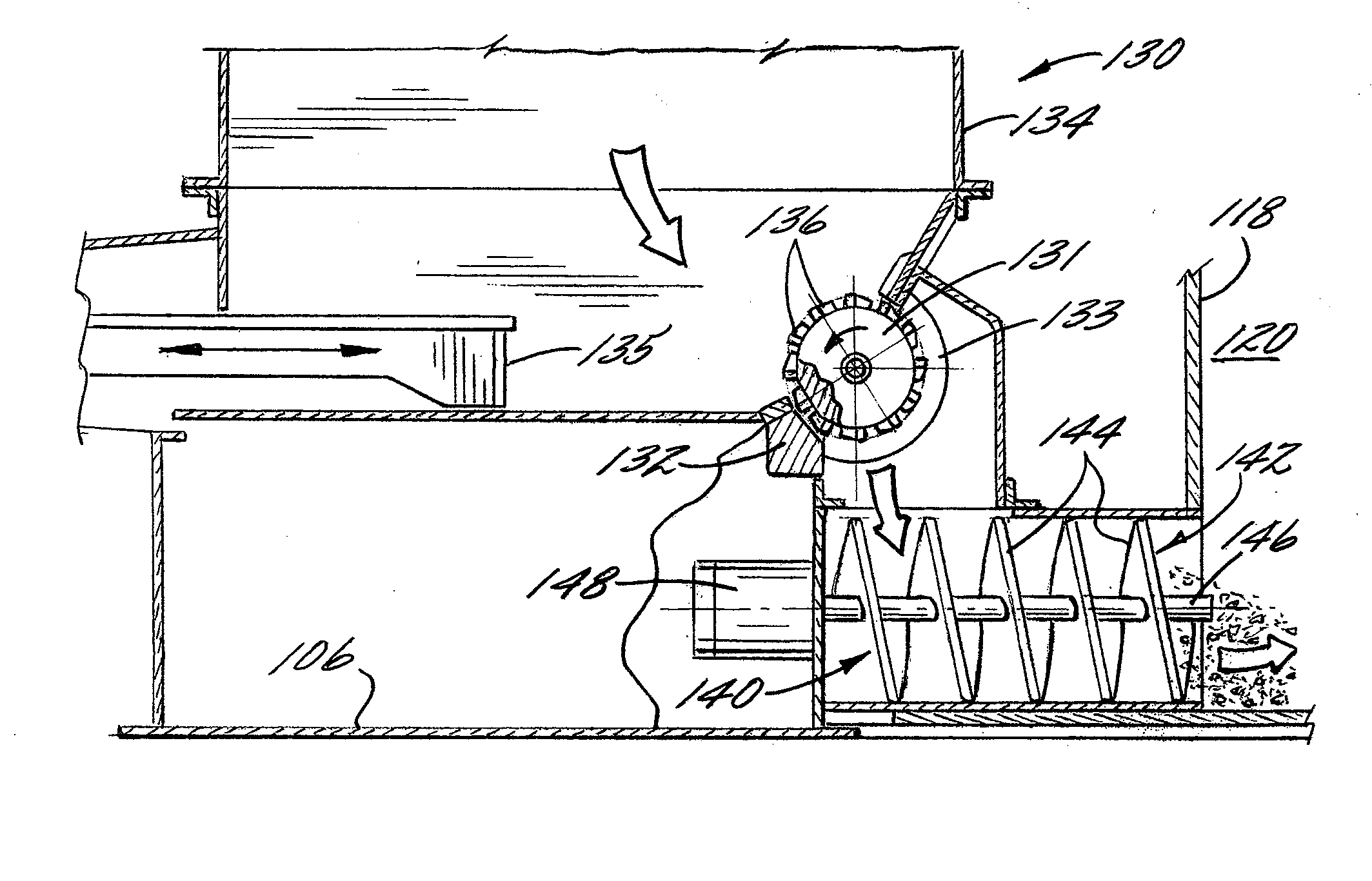

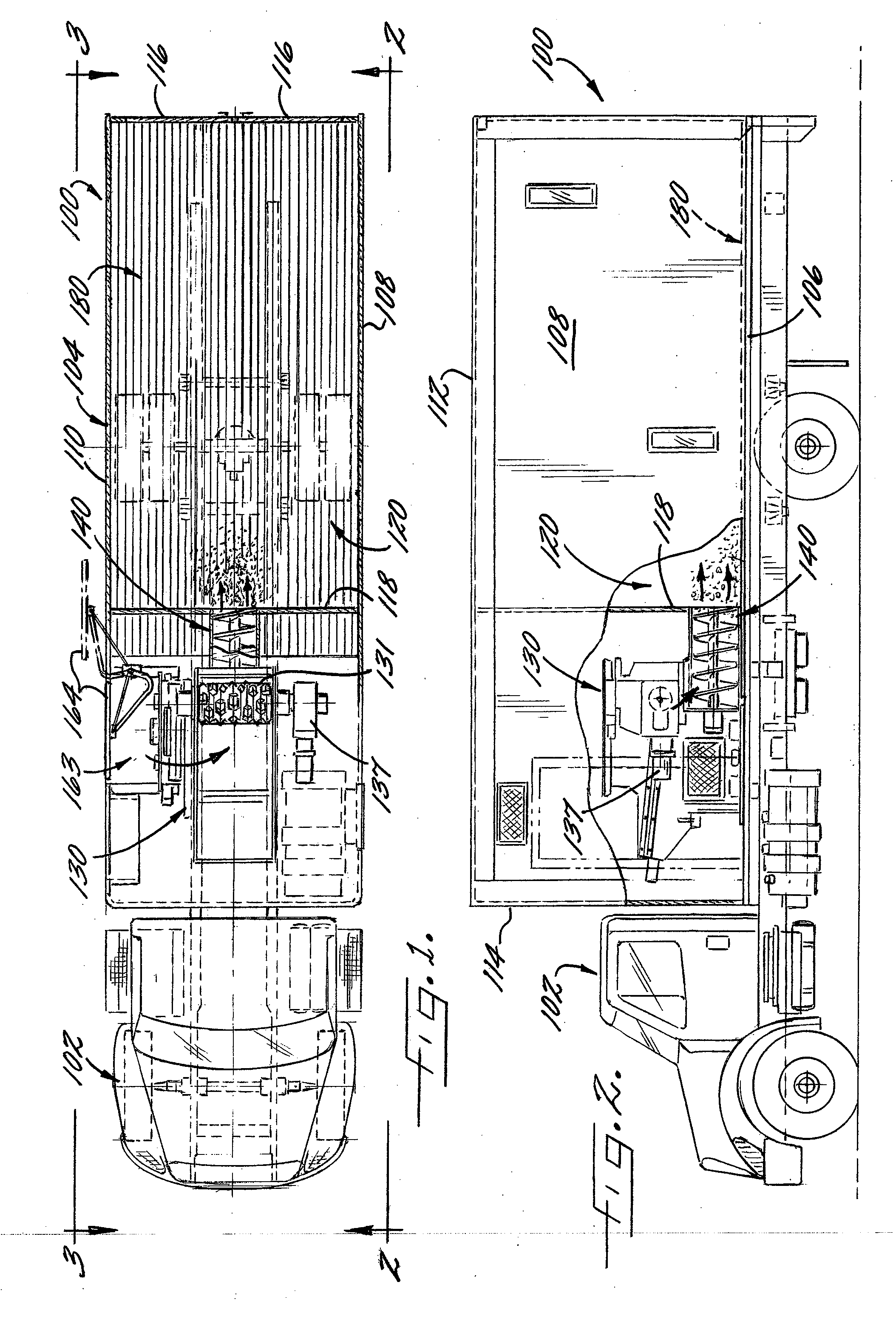

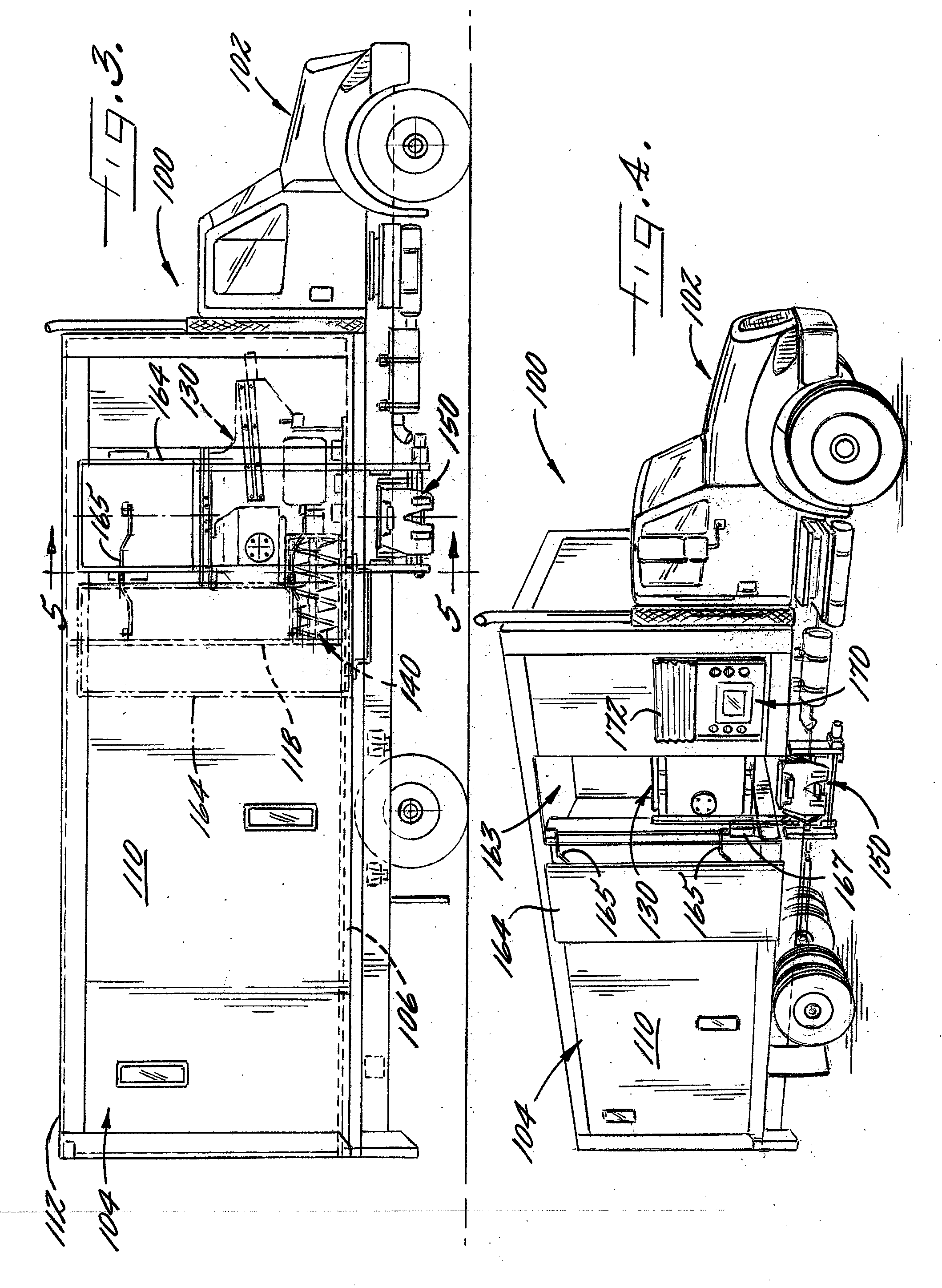

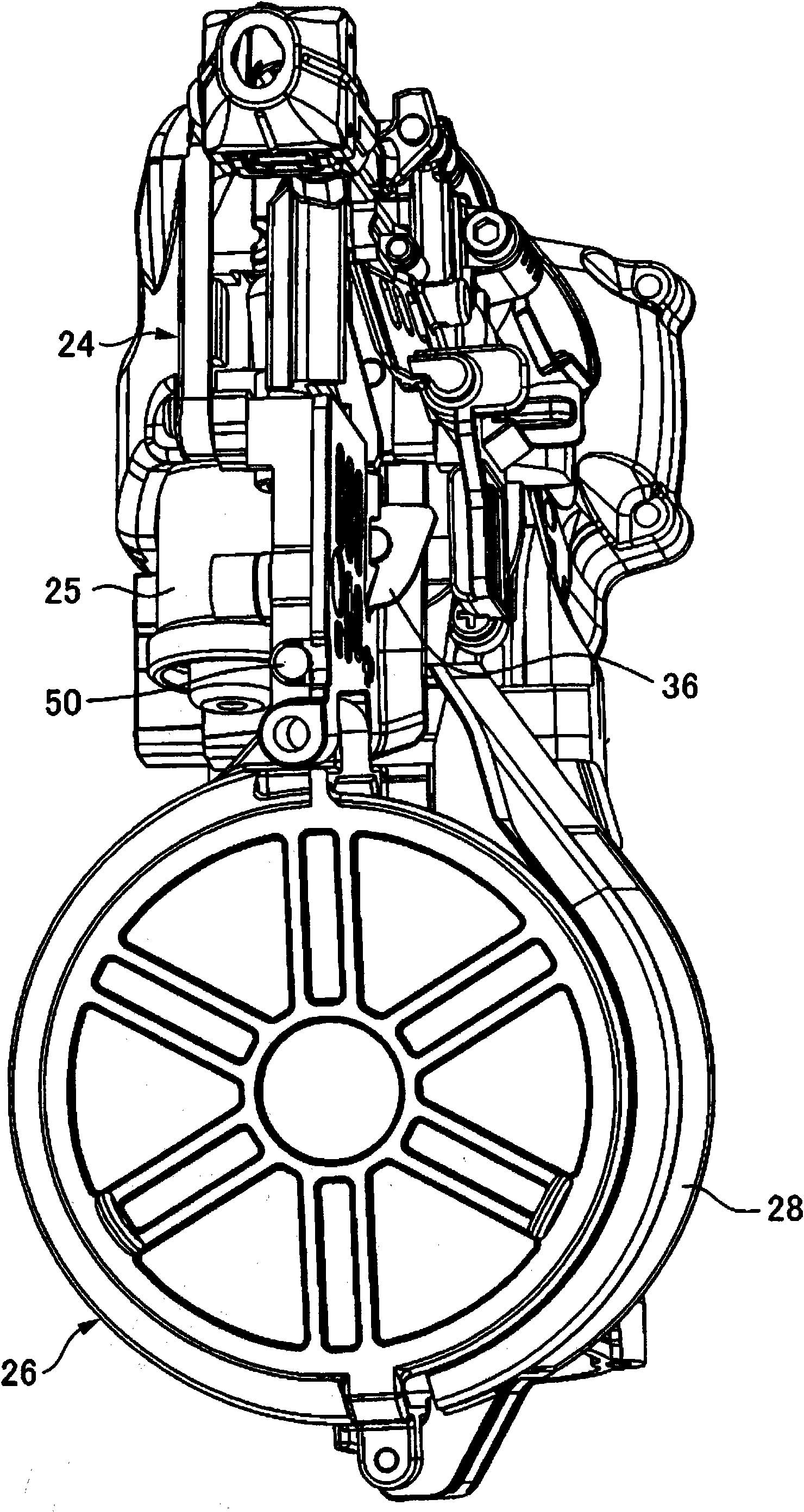

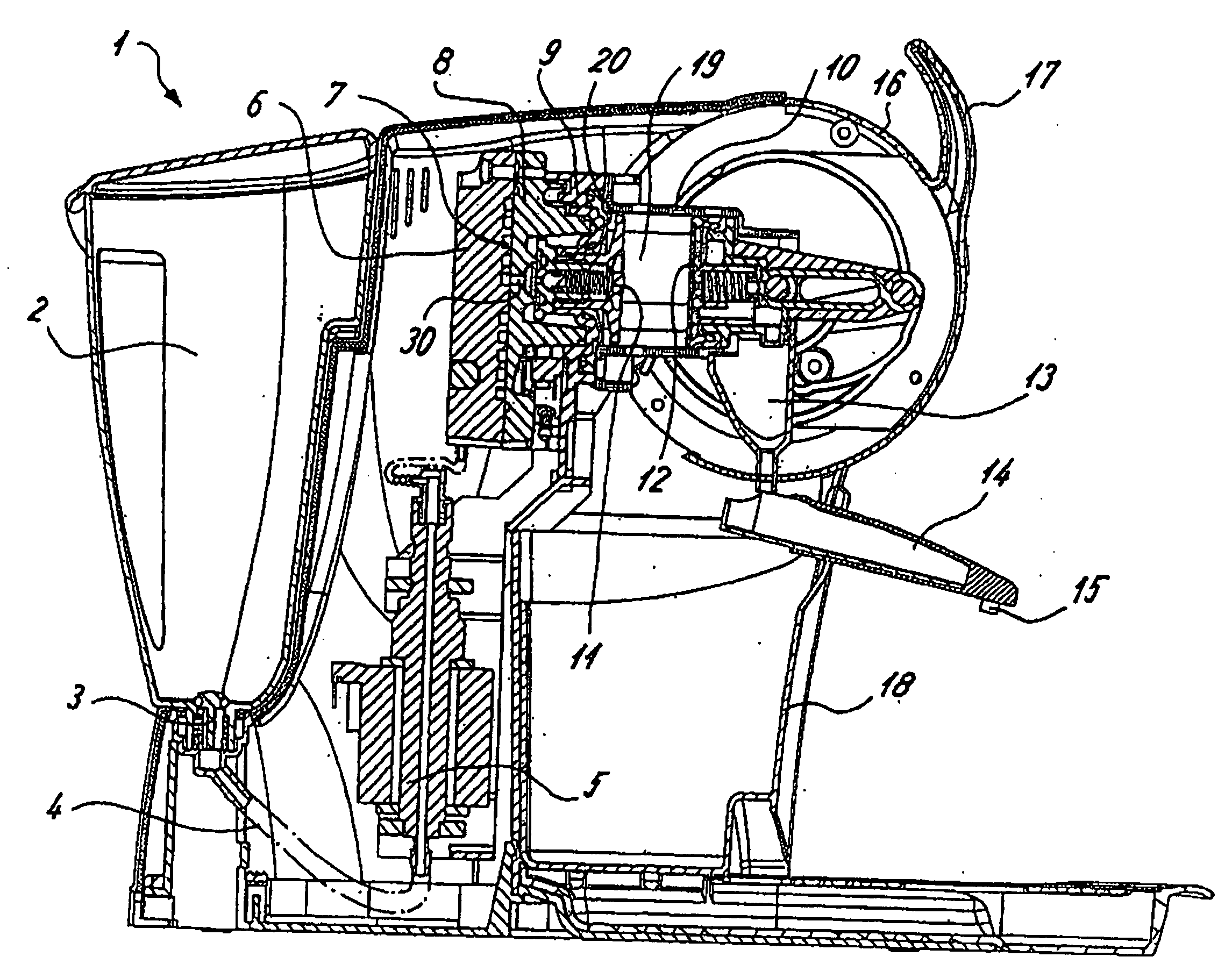

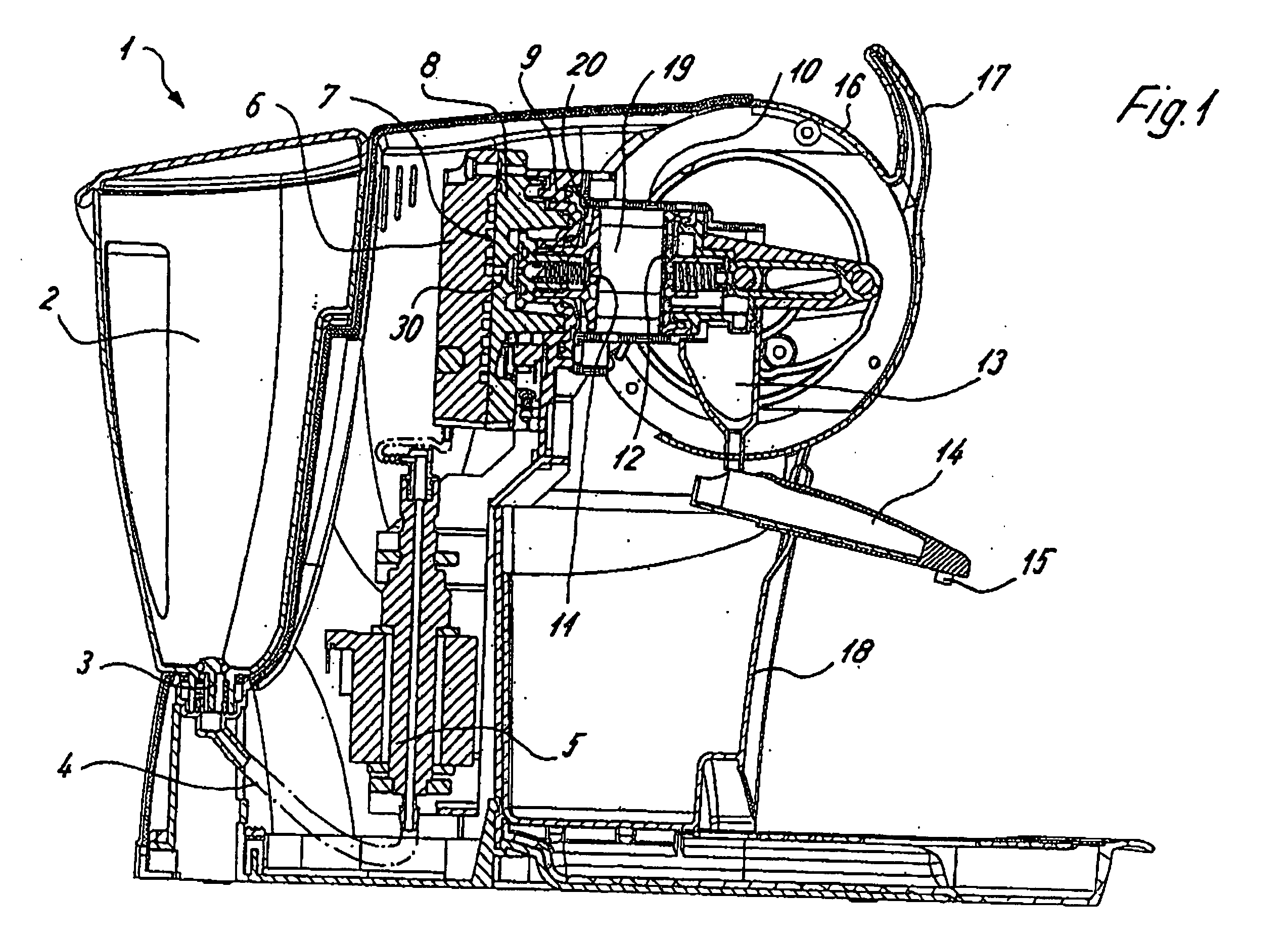

Mobile shredder

A mobile shredder comprises a truck having a truck body defining an enclosure and including a partition in the enclosure that divides a storage volume from the remainder of the enclosure for storage of shredded material in the storage volume, a single-shaft rotary shredder mounted in the enclosure outside the storage volume, the rotary shredder comprising a rotor having cutters rigidly mounted thereon, a bin lift and dump mechanism operable to transport material to be shredded from outside to inside the enclosure so as to deliver material to the rotary shredder, and a discharge conveyor operable to transport shredded material from the rotary shredder through the partition to the storage volume. The floor of the storage volume can comprise a walking floor, and the enclosure can have rear doors that are openable to allow shredded material to be discharged through the open rear doors when the walking floor is operated.

Owner:VECOPLAN

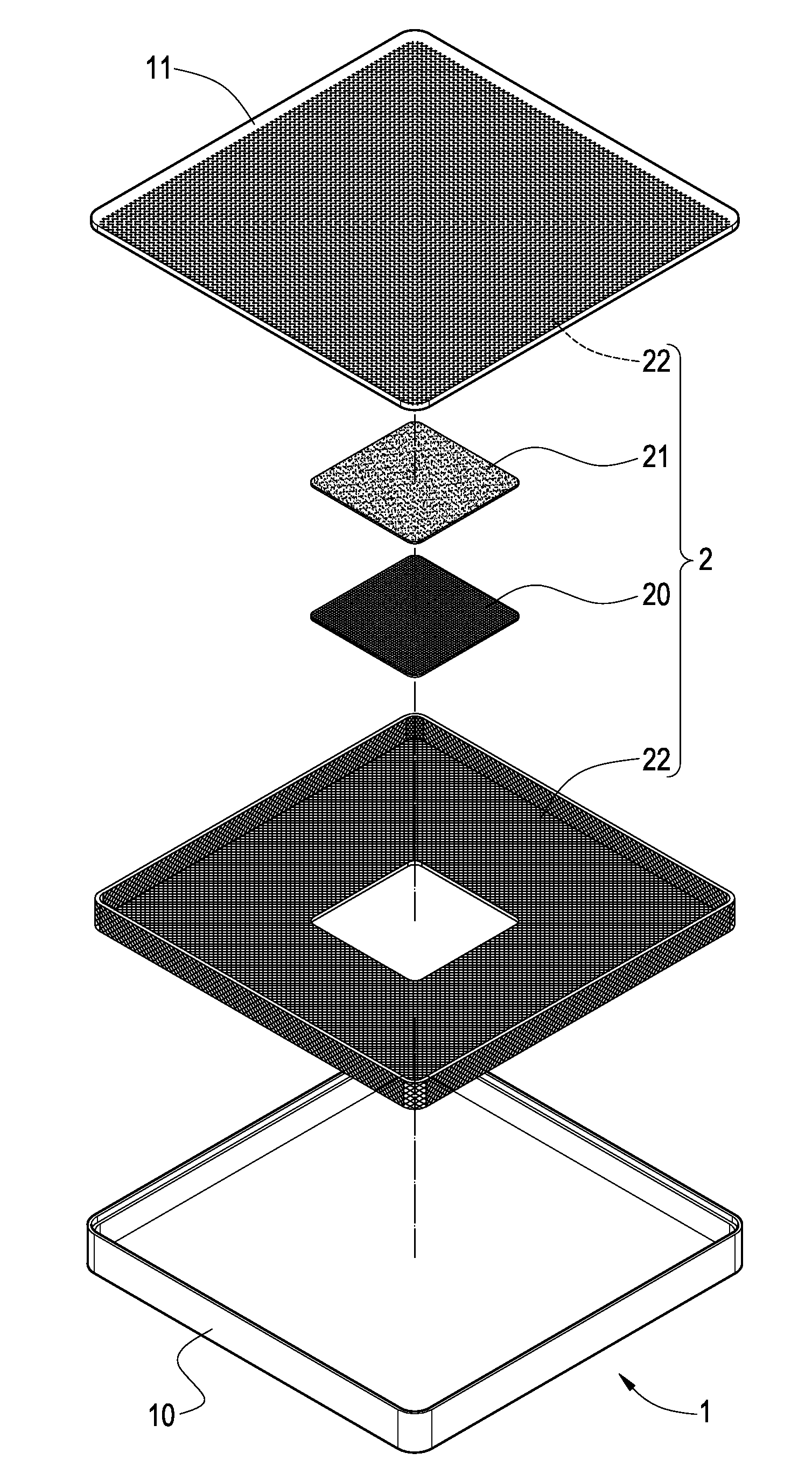

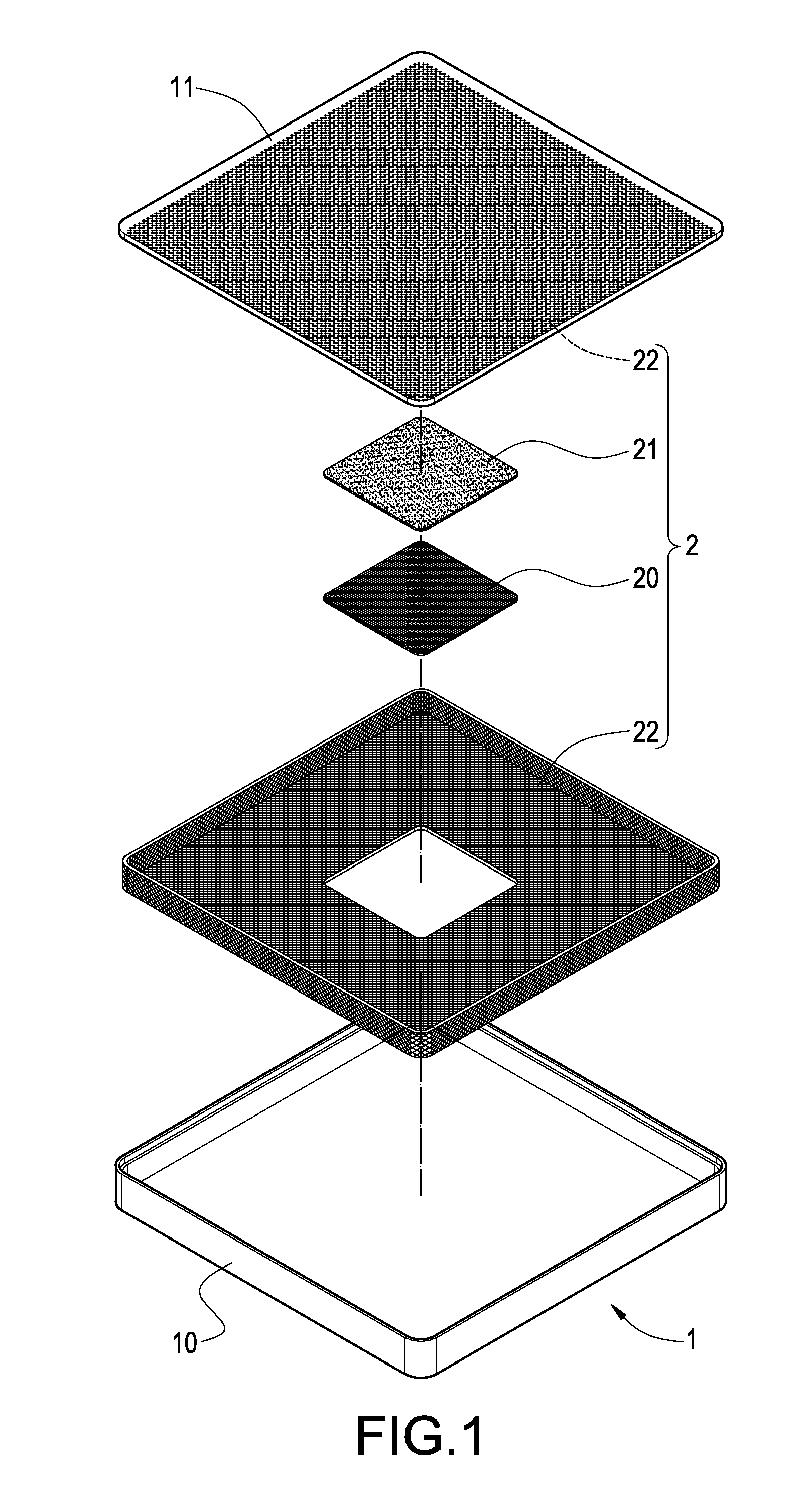

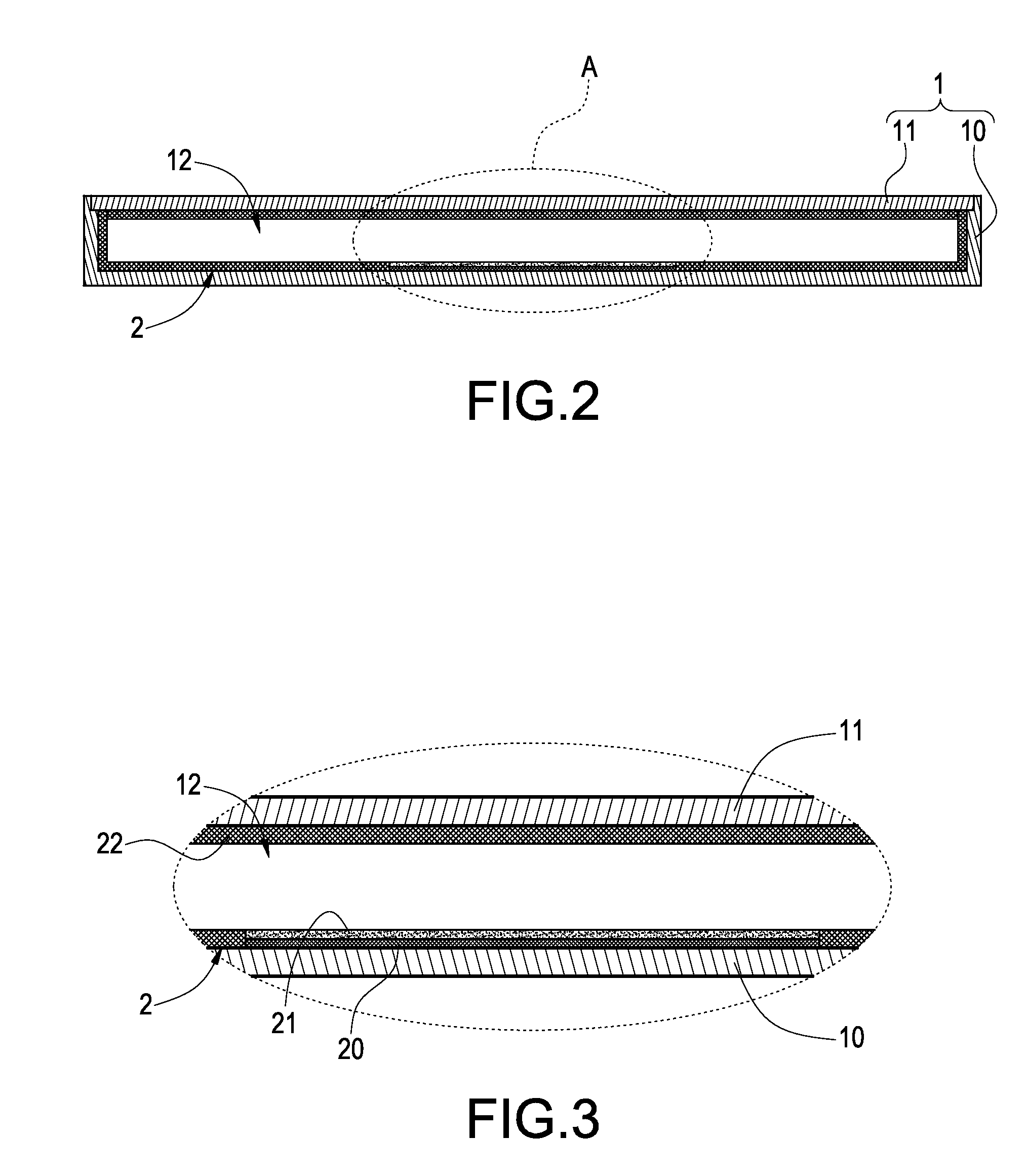

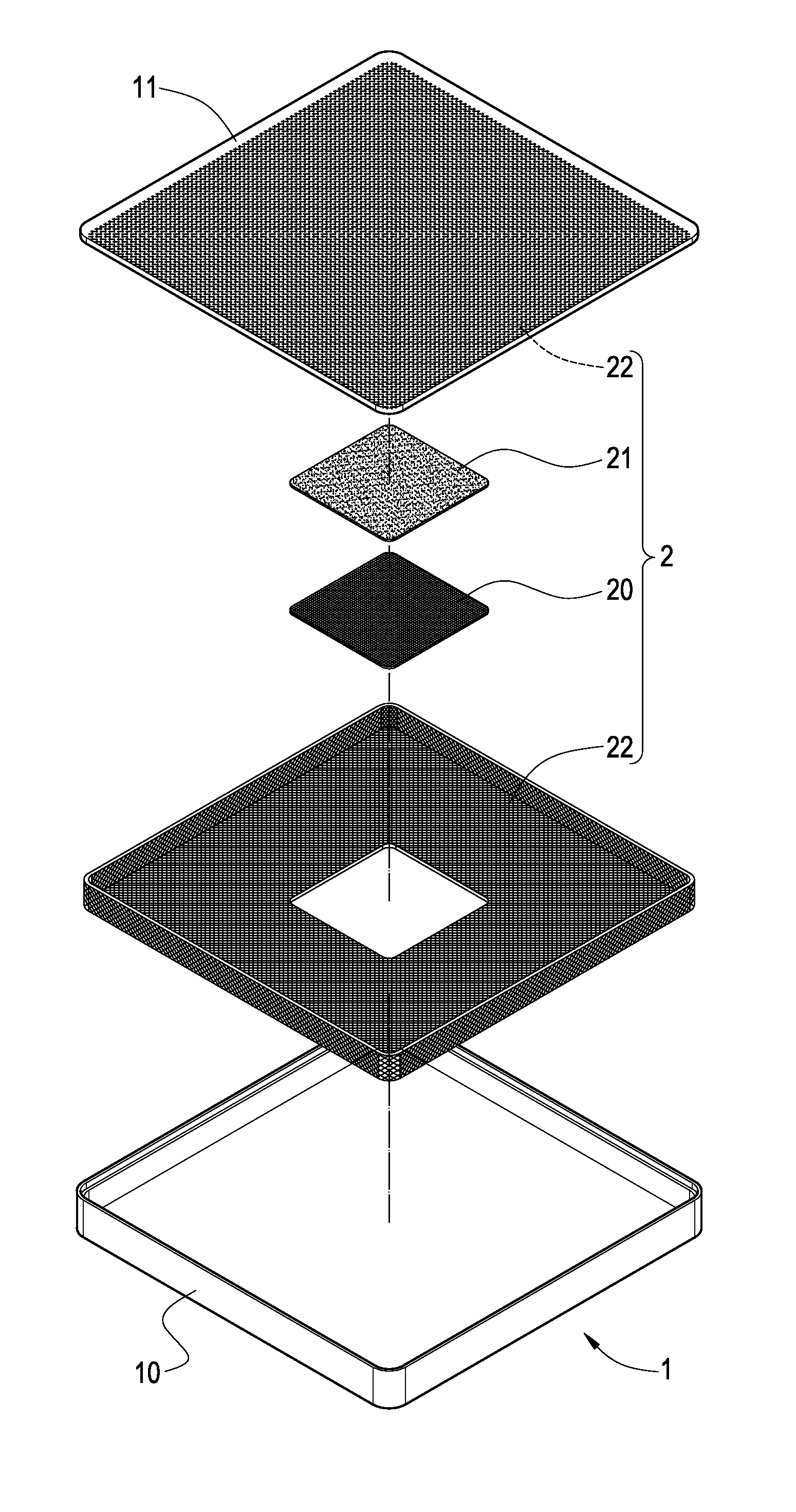

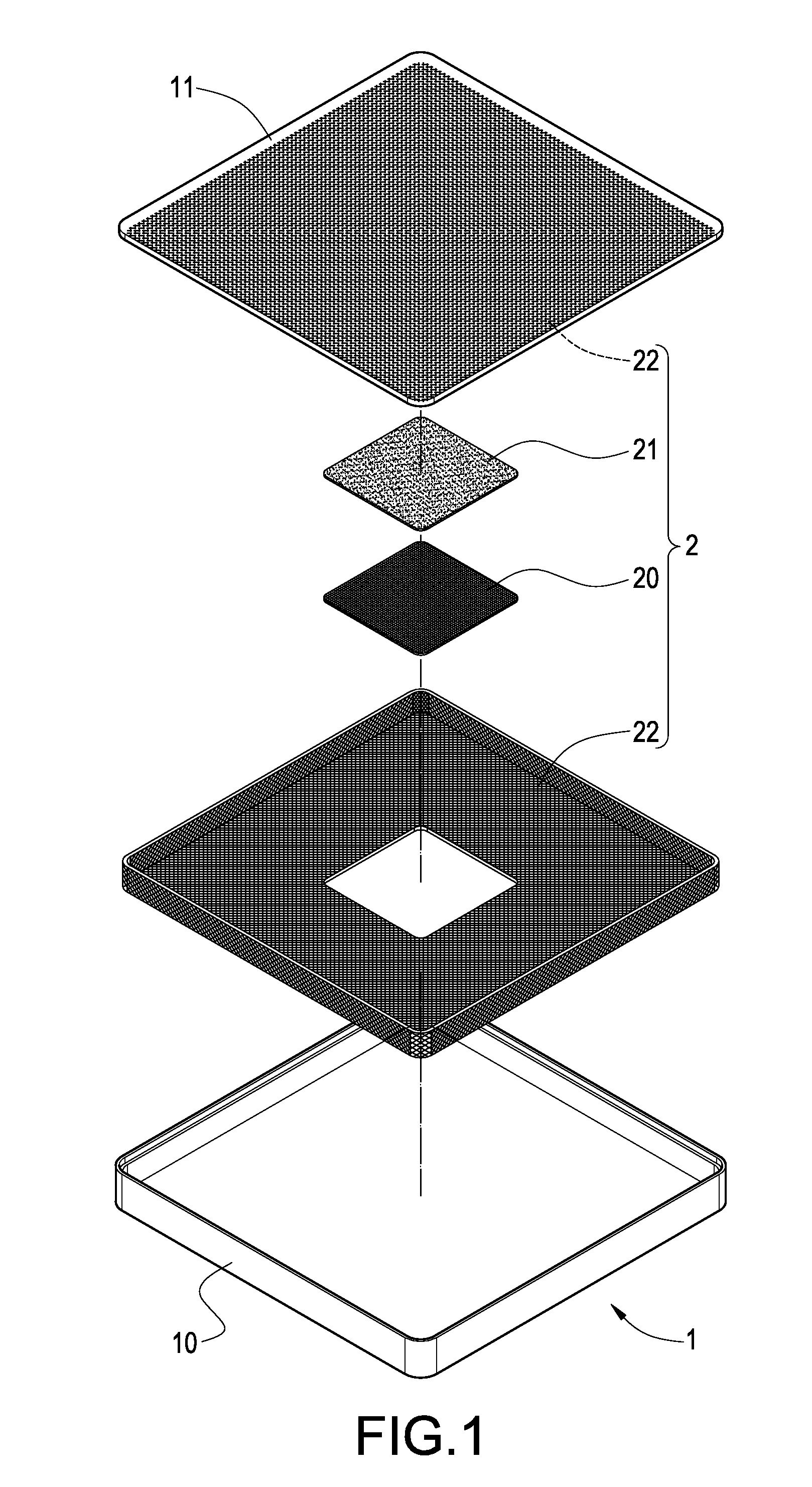

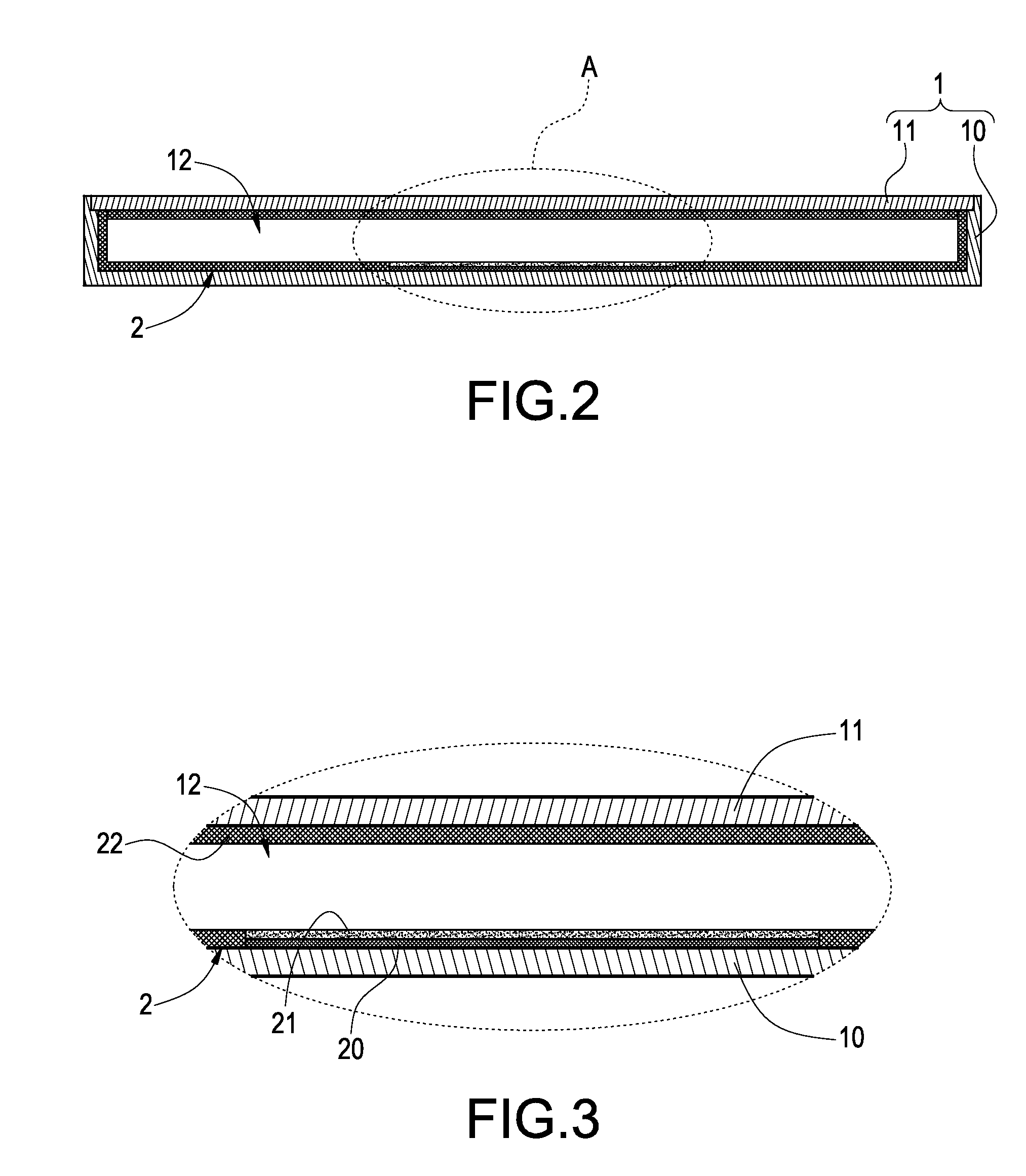

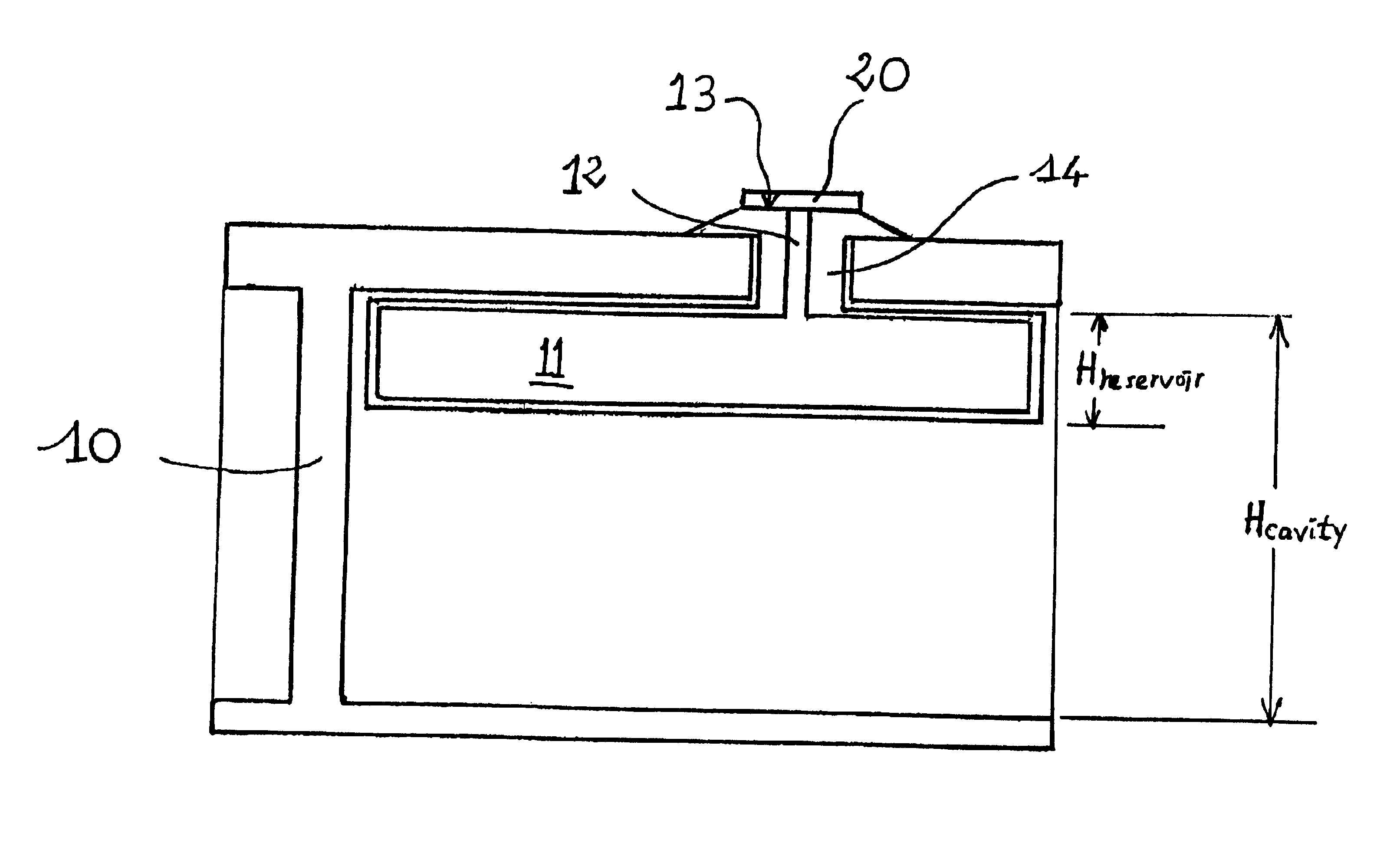

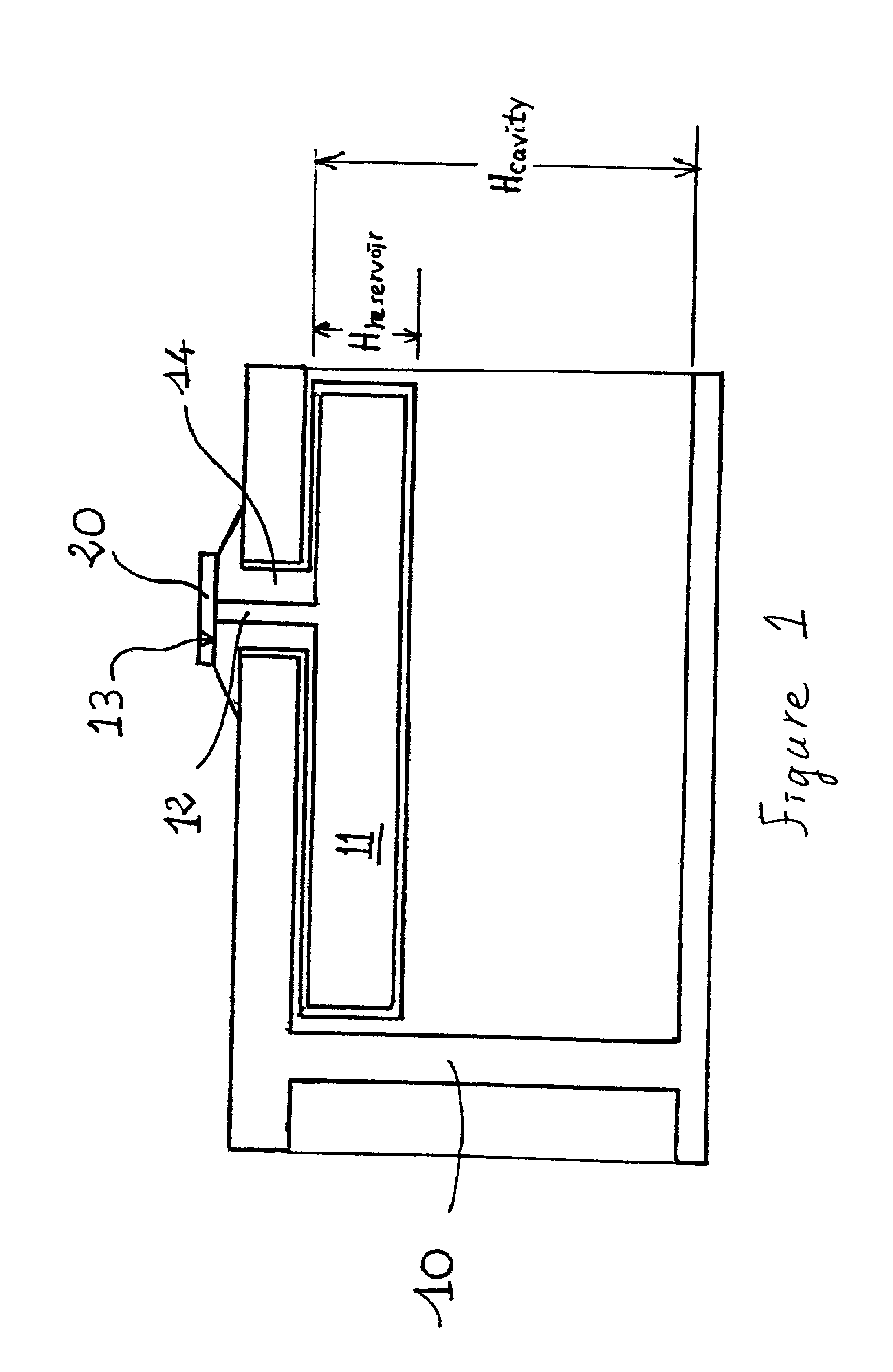

Vapor chamber

InactiveUS20090294104A1Vaporization fastShorten the timeSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

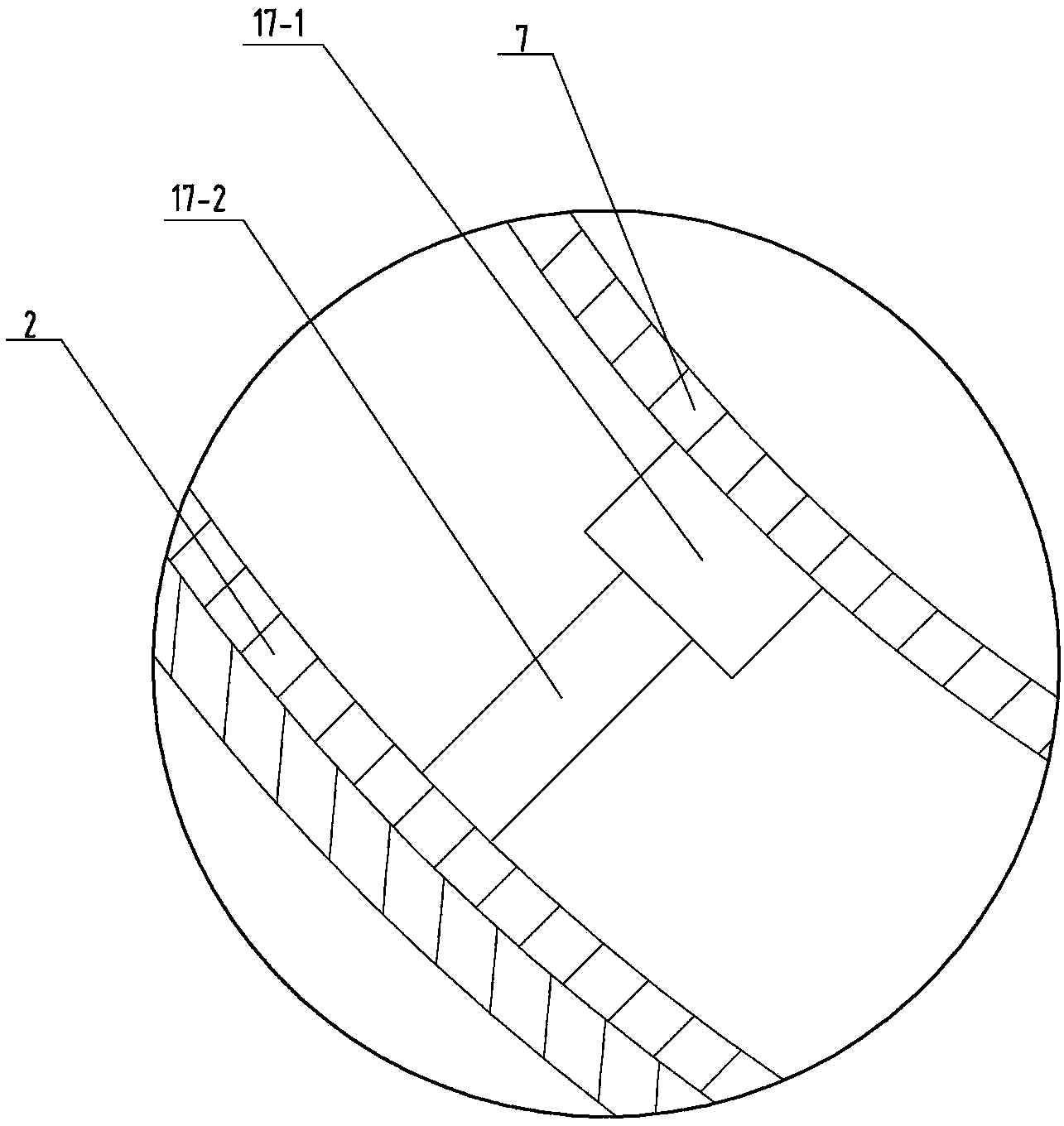

A vapor chamber includes a plate and a wick structure. The plate is provided therein with a working fluid, and the plate has a heated end and a condensed end. The wick structure comprises a first wick portion adhered to be opposite to the heated end, a second wick portion overlapping on the first wick portion, and a third wick portion adhered on the rest portion of a chamber. The aperture diameter of the first wick portion is larger than that of the second wick portion, or the aperture density of the first wick portion is smaller than that of the second wick portion. Therefore, the amount of working fluid attached to the second wick portion is smaller than of the first wick portion. As a result, after heated, the working fluid attached to the second wick portion will be vaporized more quickly, thereby increasing the efficiency of heat transfer and improving the heat-dissipating effect.

Owner:GOLDEN SUN NEWS TECHN +1

Mobile shredder

A mobile shredder comprises a truck having a truck body defining an enclosure and including a partition in the enclosure that divides a storage volume from the remainder of the enclosure for storage of shredded material in the storage volume, a single-shaft rotary shredder mounted in the enclosure outside the storage volume, the rotary shredder comprising a rotor having cutters rigidly mounted thereon, a bin lift and dump mechanism operable to transport material to be shredded from outside to inside the enclosure so as to deliver material to the rotary shredder, and a discharge conveyor operable to transport shredded material from the rotary shredder through the partition to the storage volume. The floor of the storage volume can comprise a walking floor, and the enclosure can have rear doors that are openable to allow shredded material to be discharged through the open rear doors when the walking floor is operated.

Owner:VECOPLAN

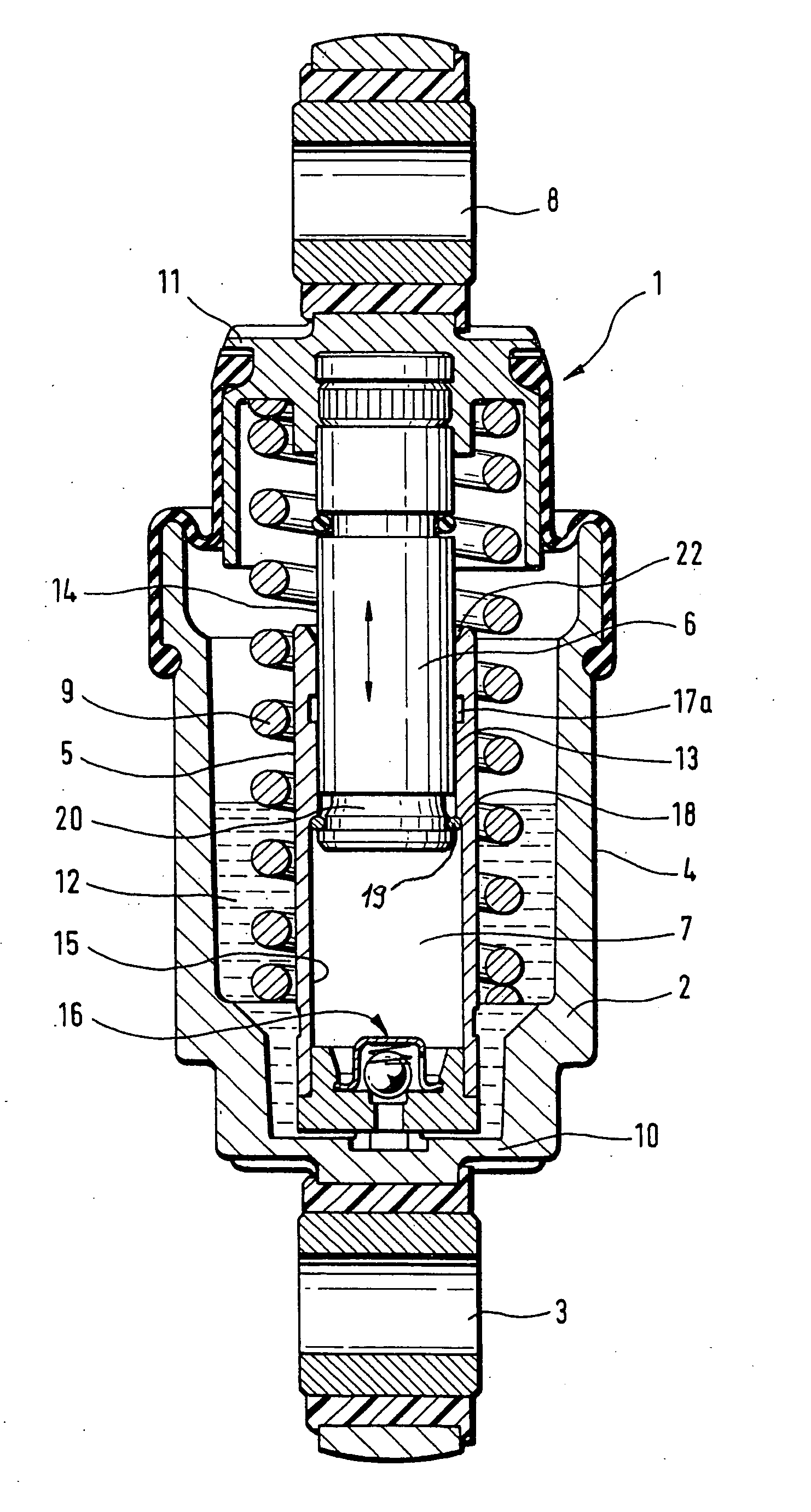

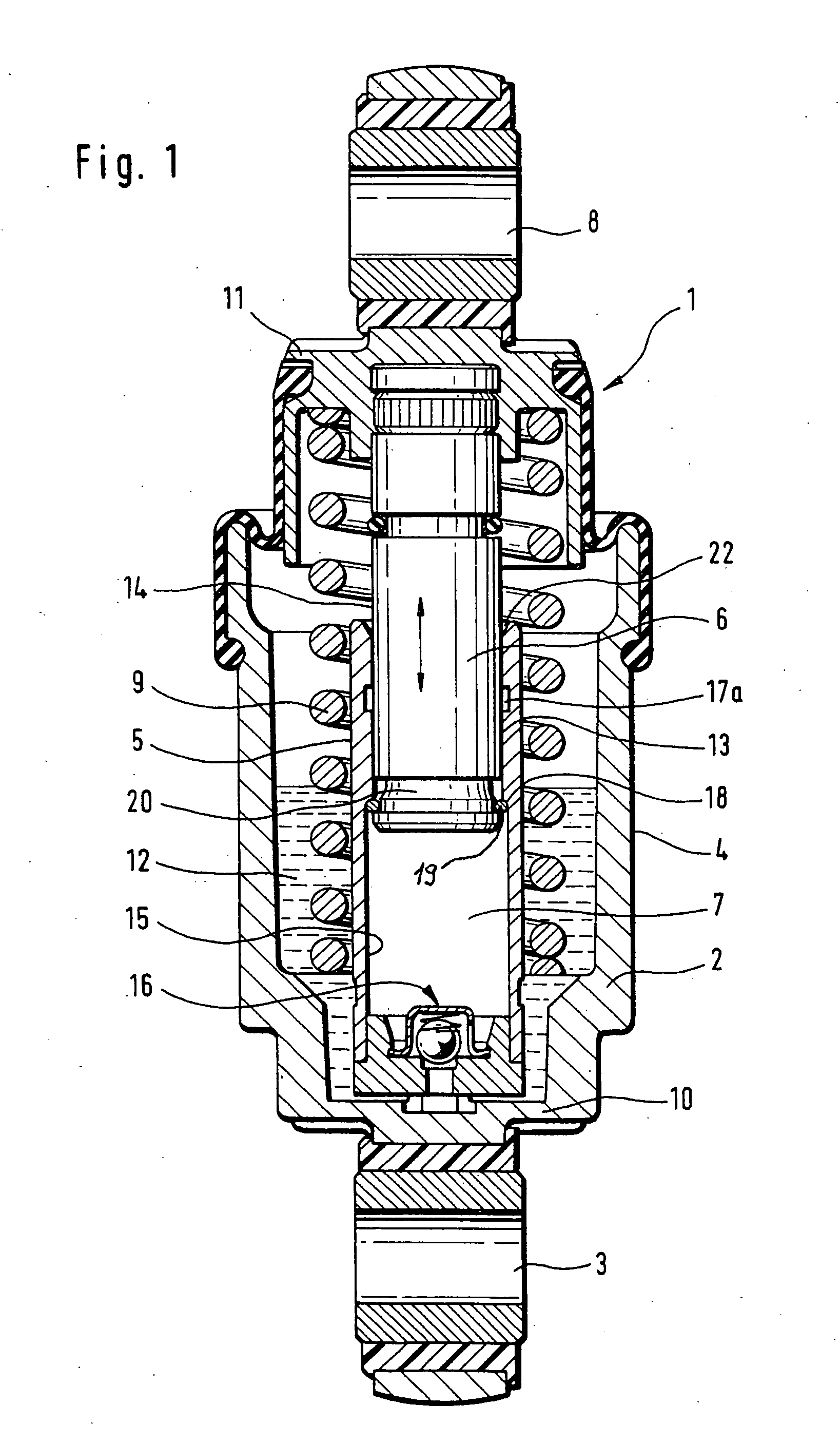

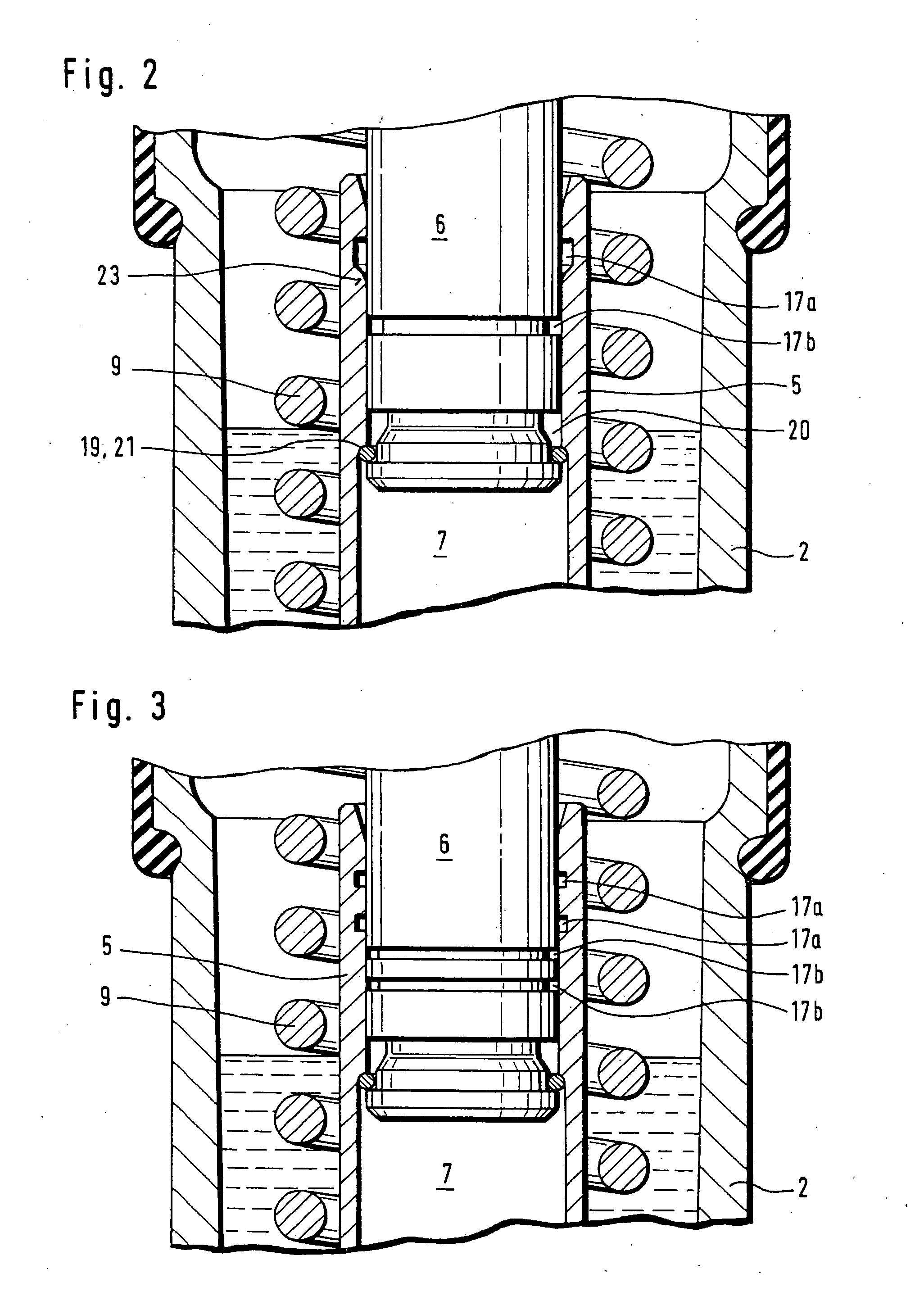

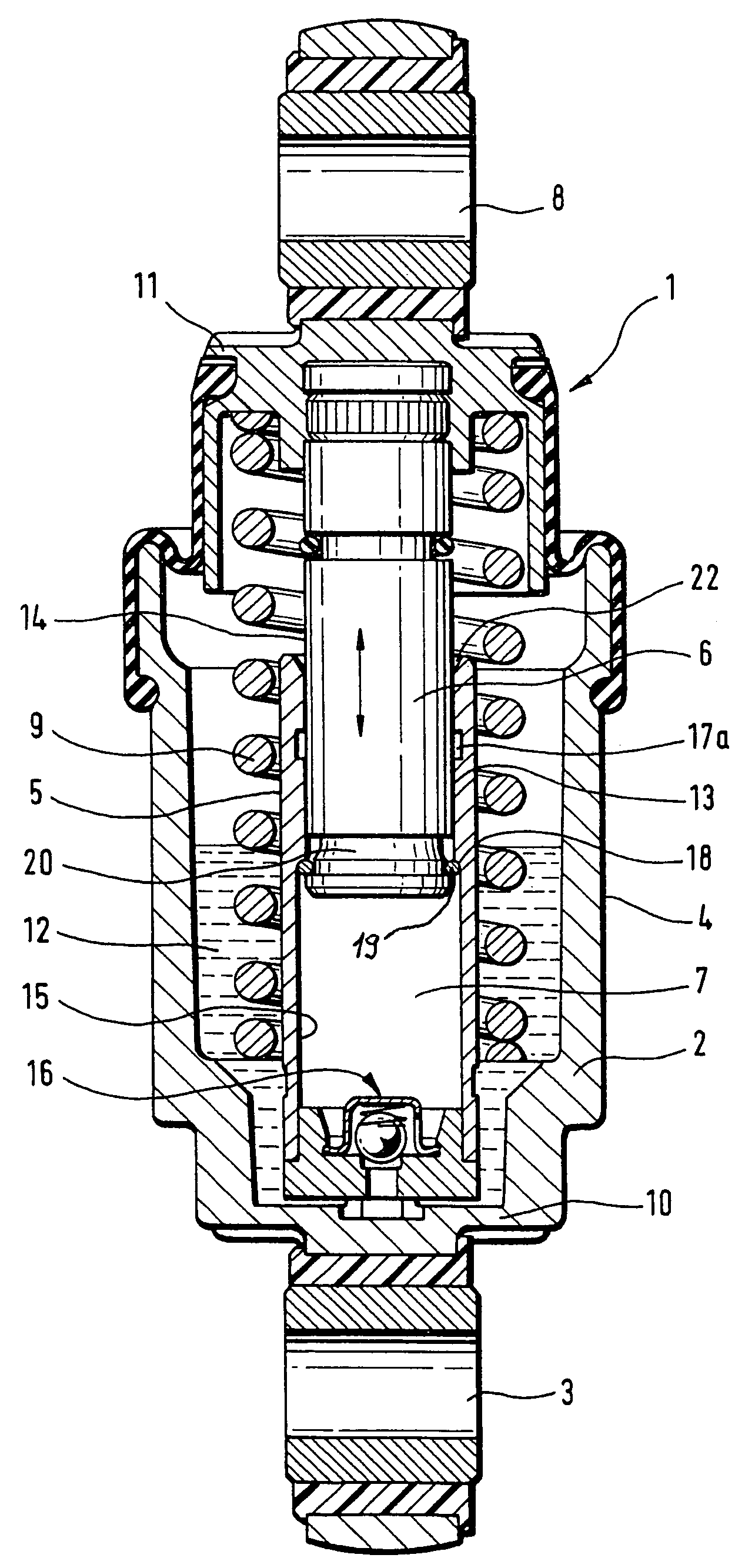

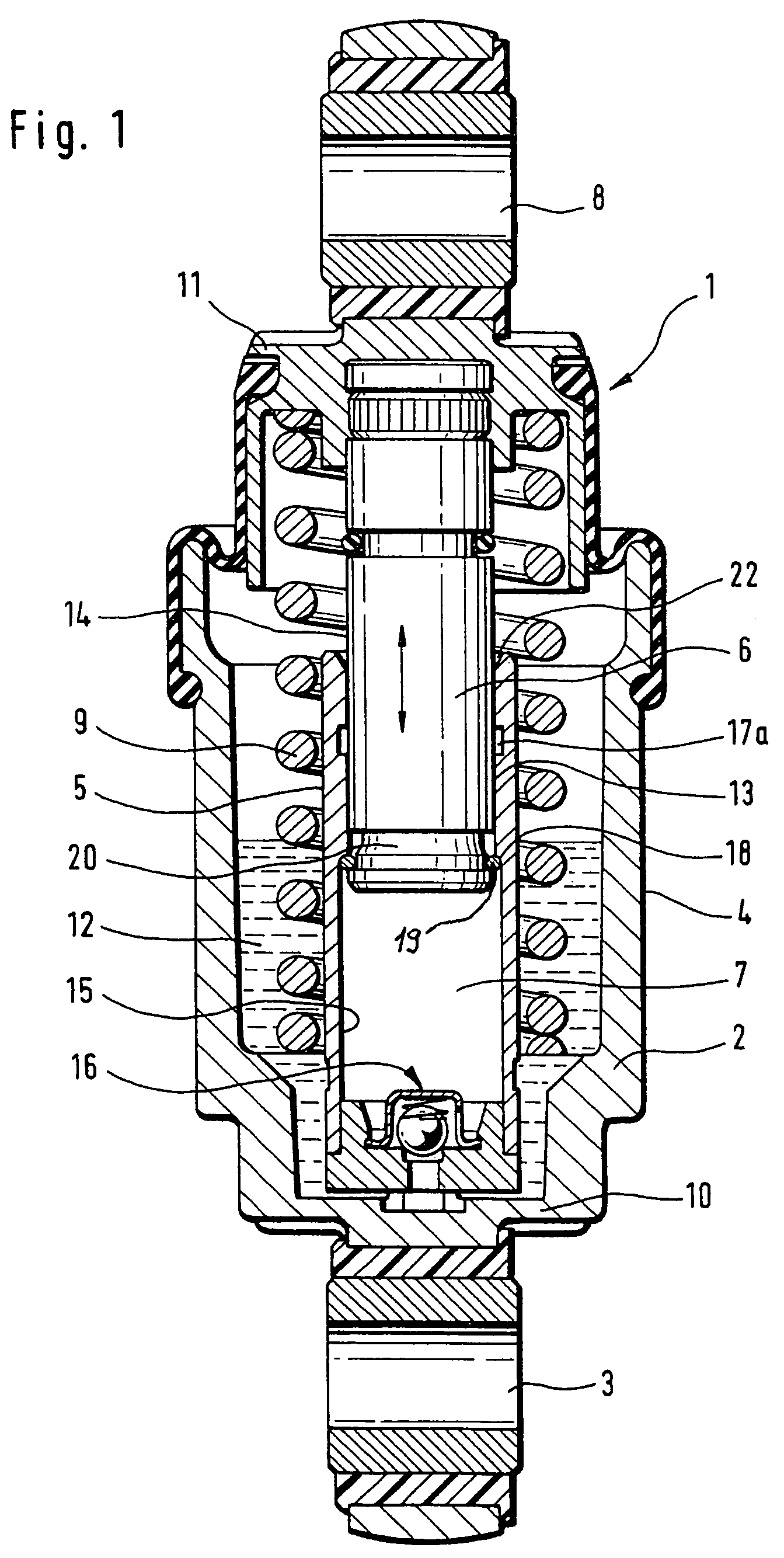

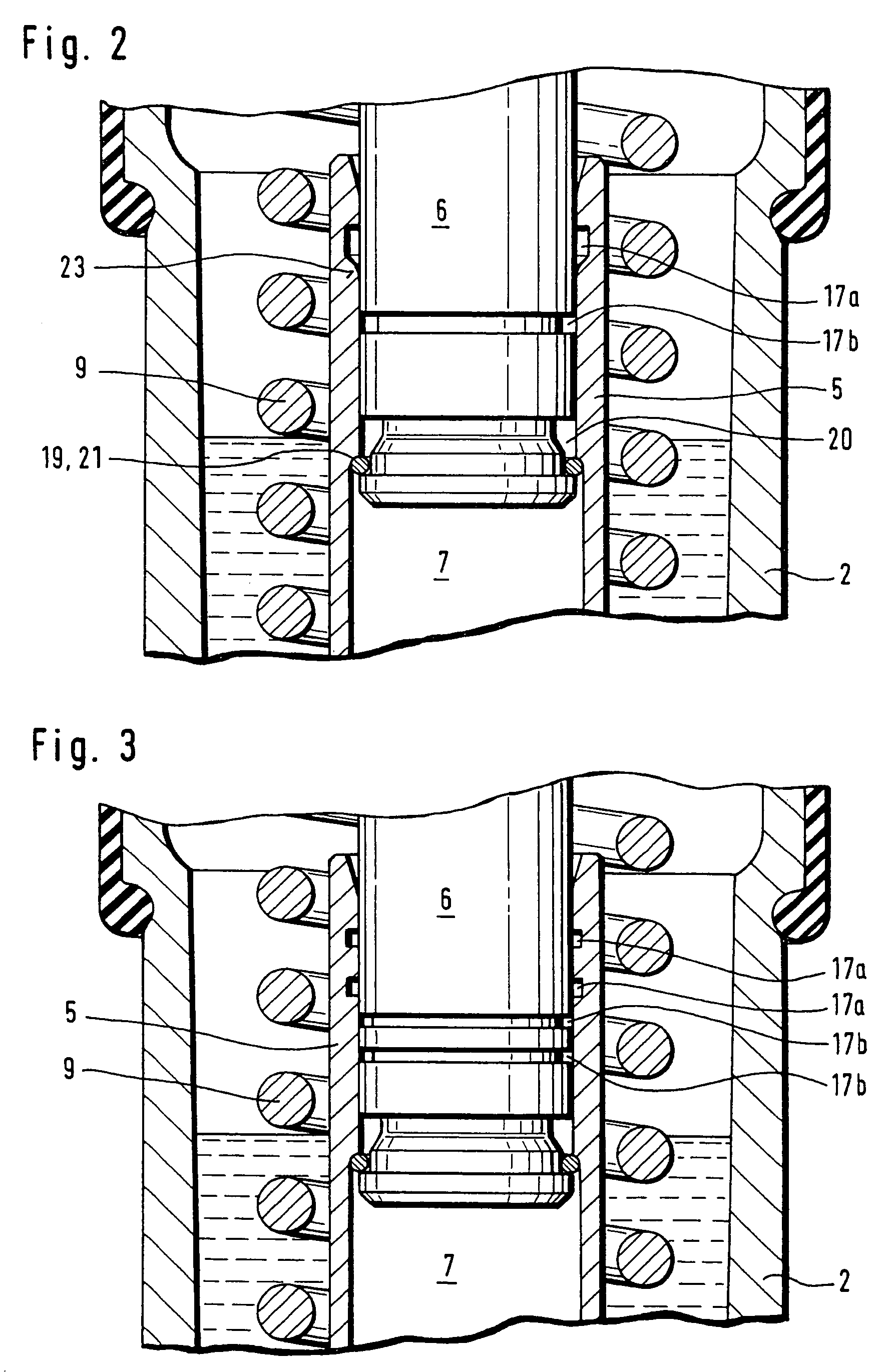

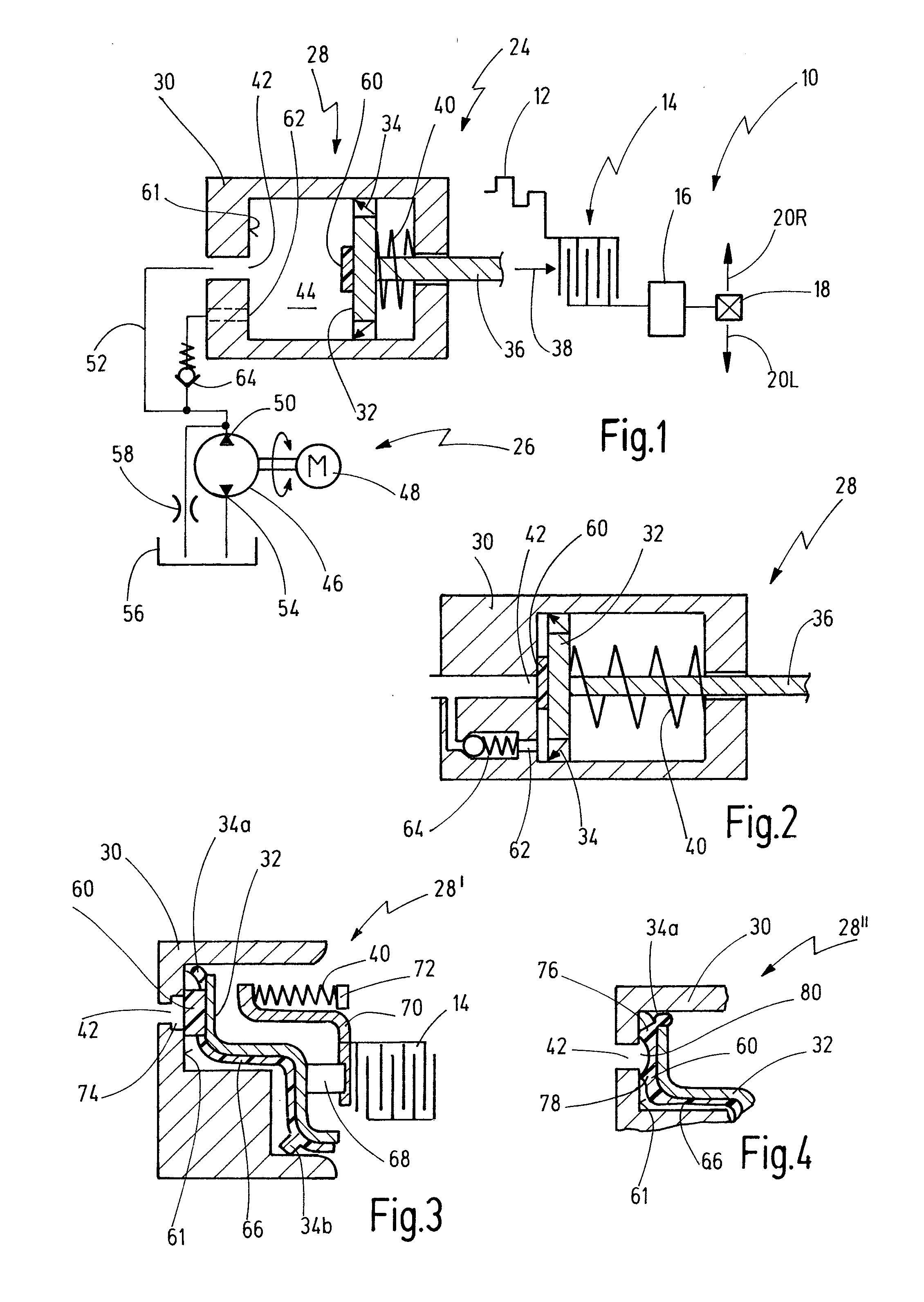

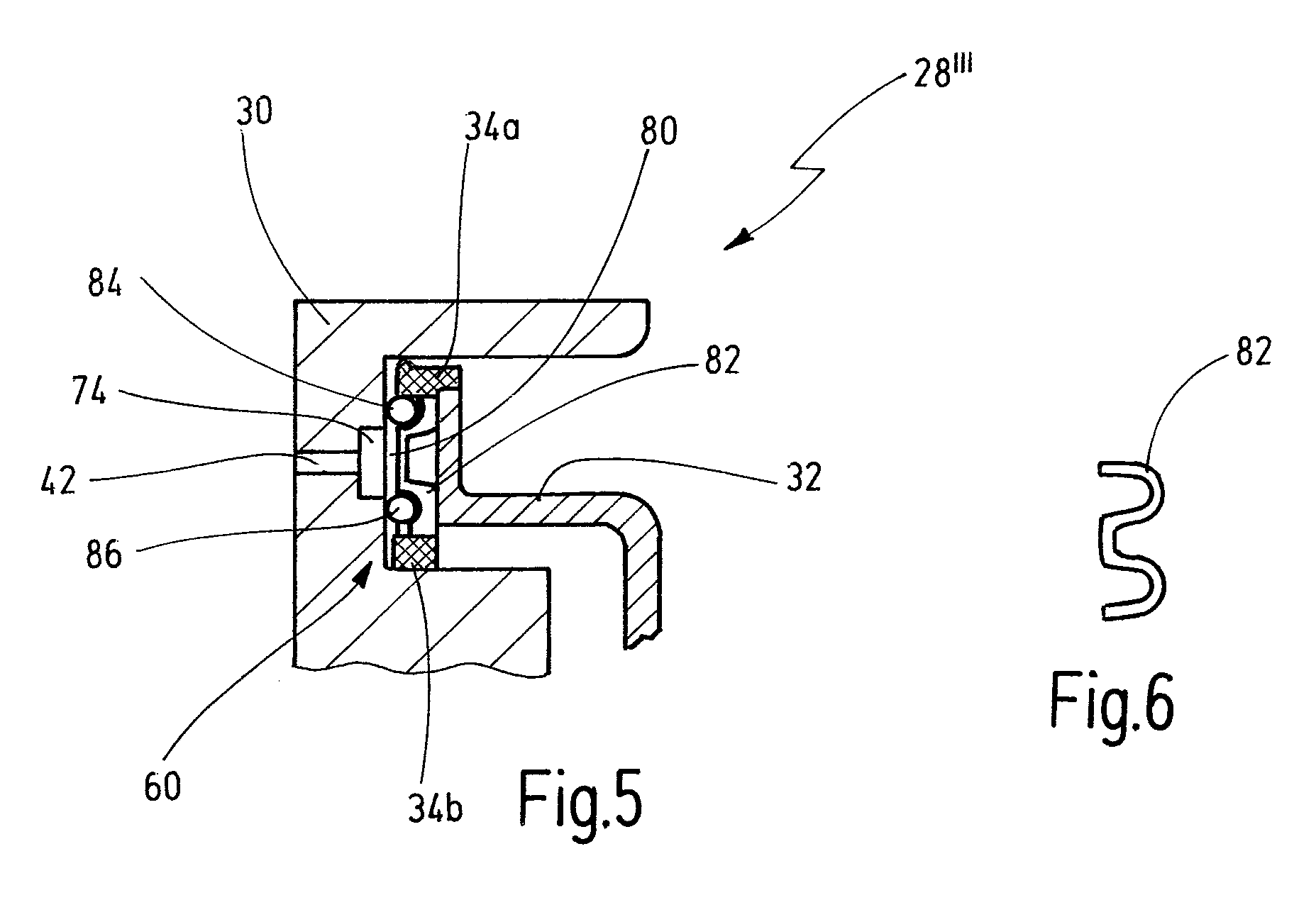

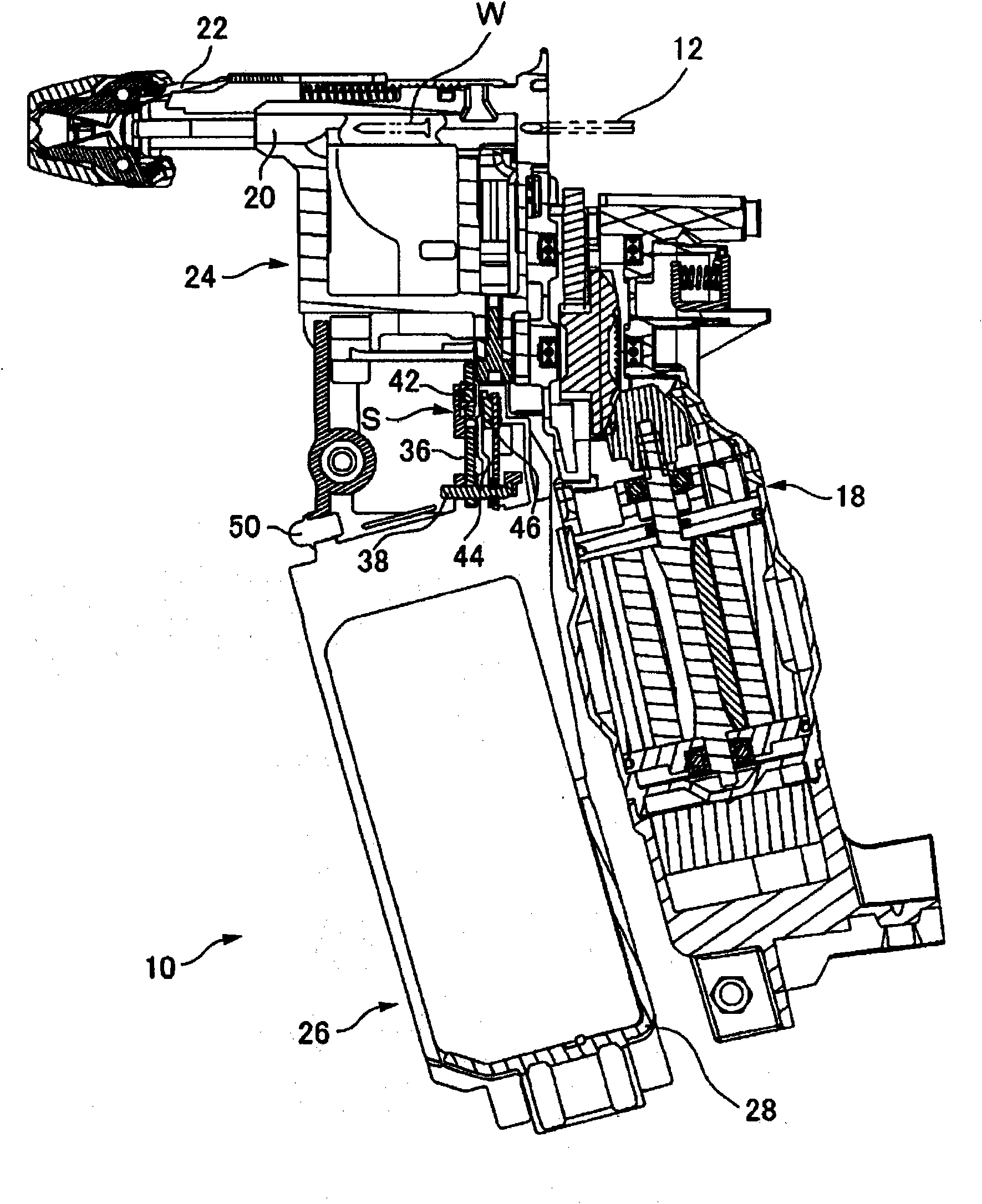

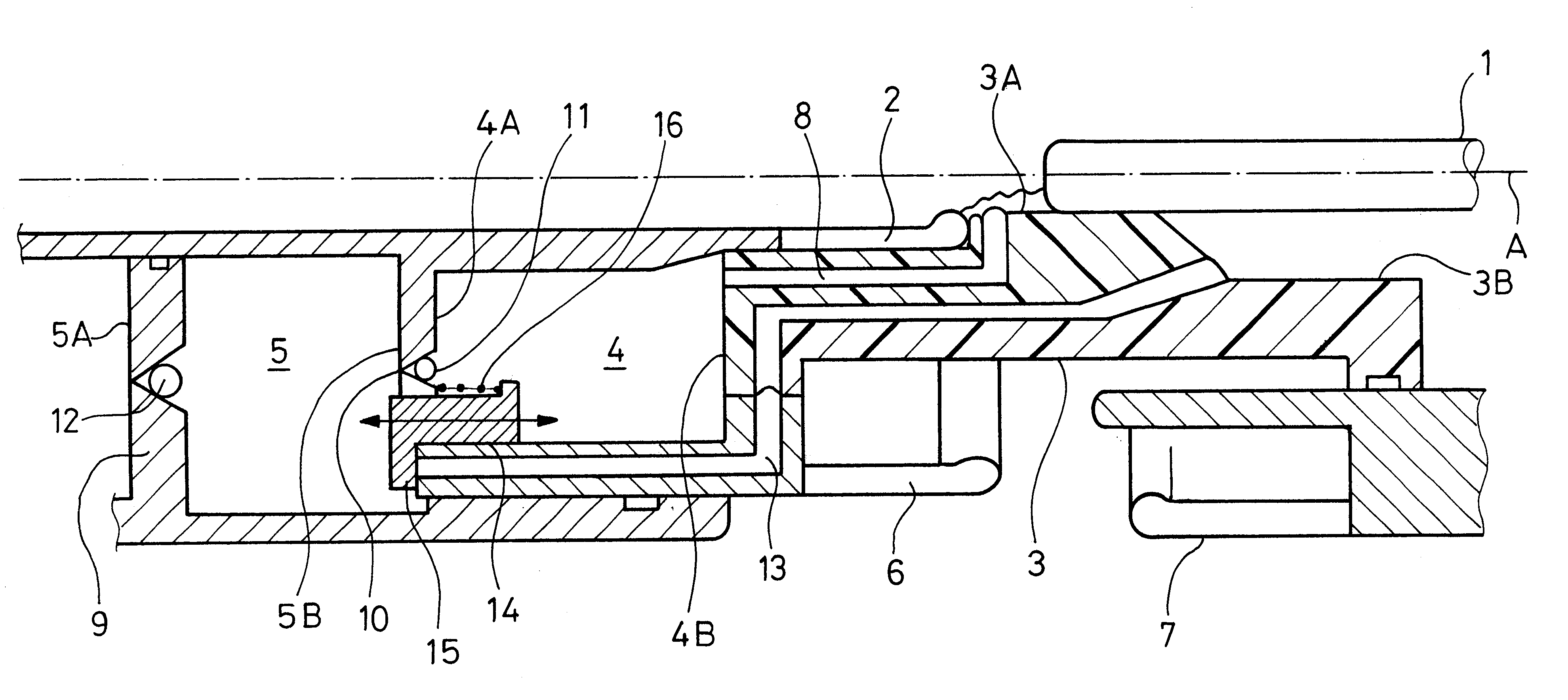

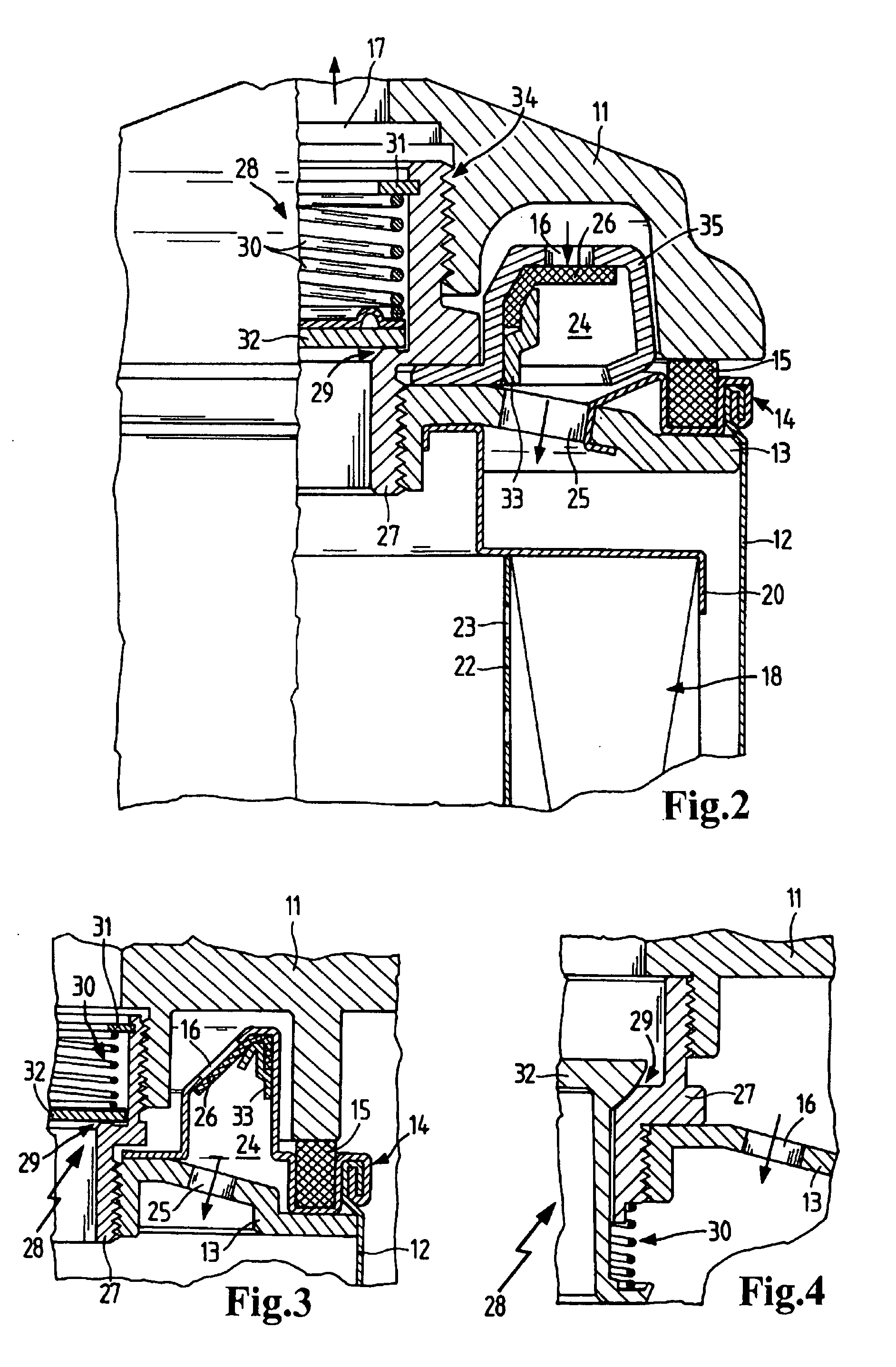

Hydraulic tensioner

A tensioner for a traction drive includes a cylinder arranged in a housing at a distance to a housing wall to thereby define an interior space which contains hydraulic fluid. A piston is received in the cylinder for back-and-forth movement and bounds a pressure chamber containing hydraulic fluid. The piston has a cylinder-distal end which is operatively connected to a spring-biased tension roller supported on a traction member. Formed between the piston and the cylinder is a leakage gap, and a reservoir for hydraulic fluid is provided in an area of the leakage gap to prevent ingress of air into the pressure chamber, when the traction drive is at a rest.

Owner:SCHAEFFLER TECH AG & CO KG

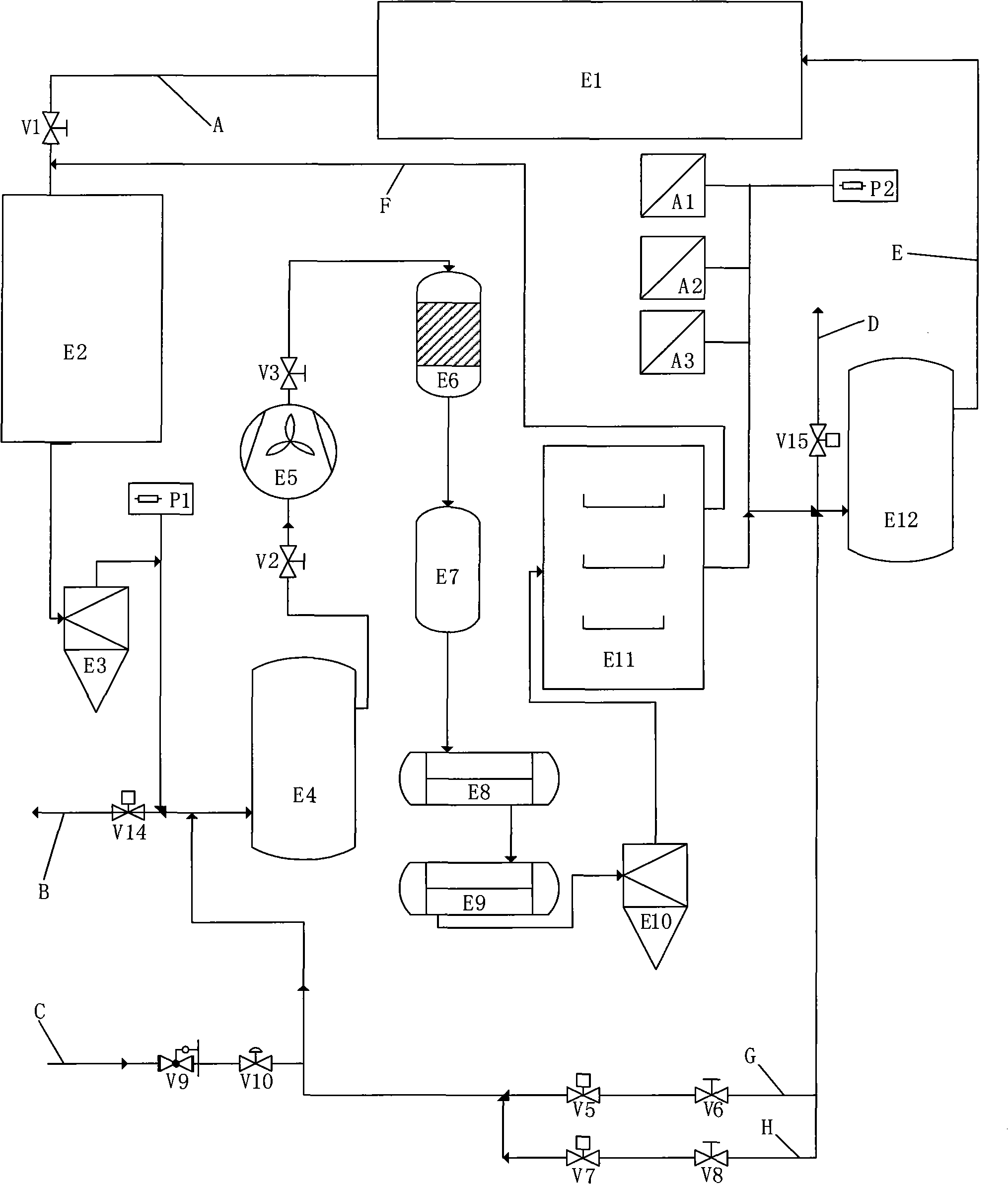

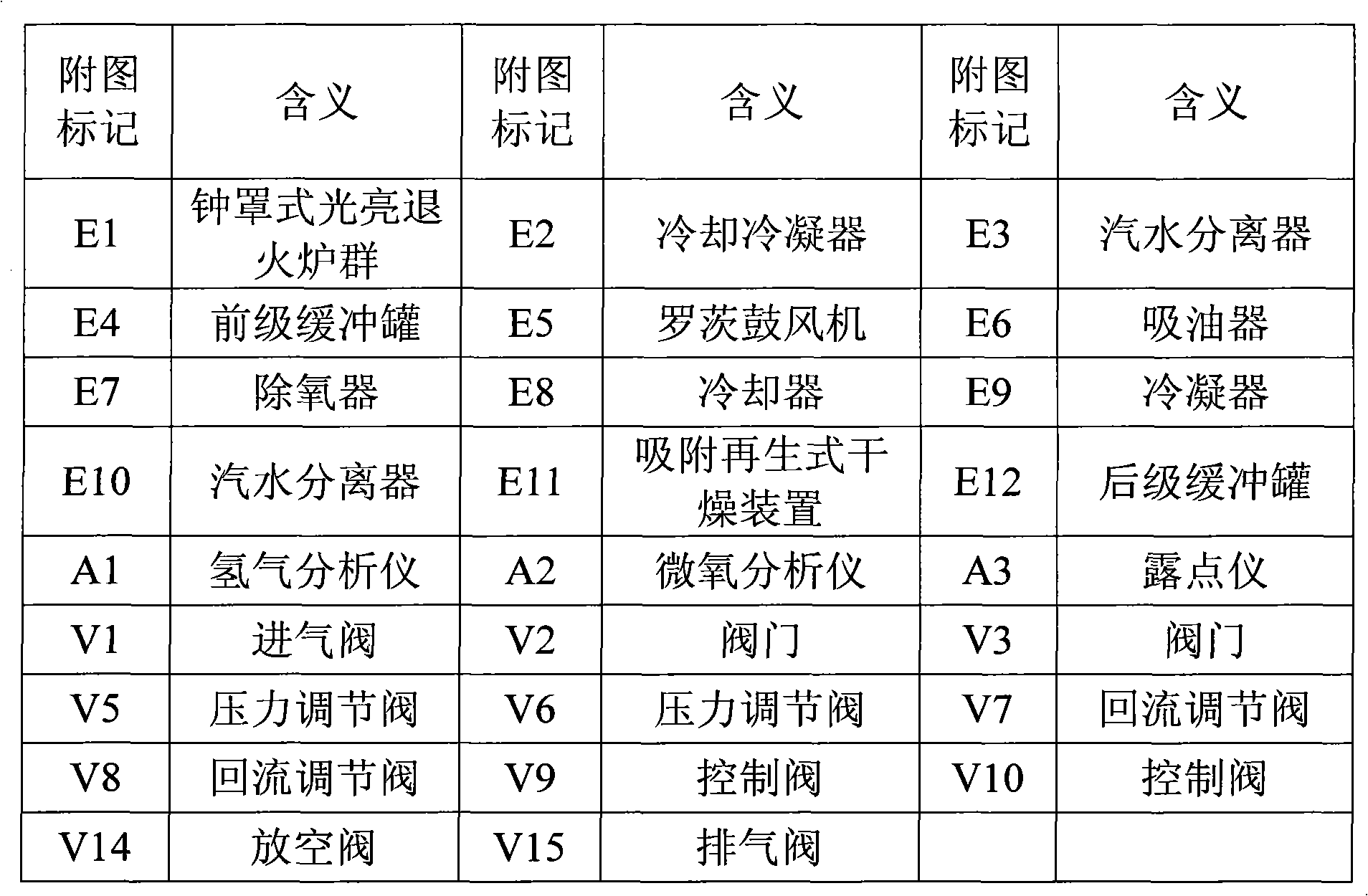

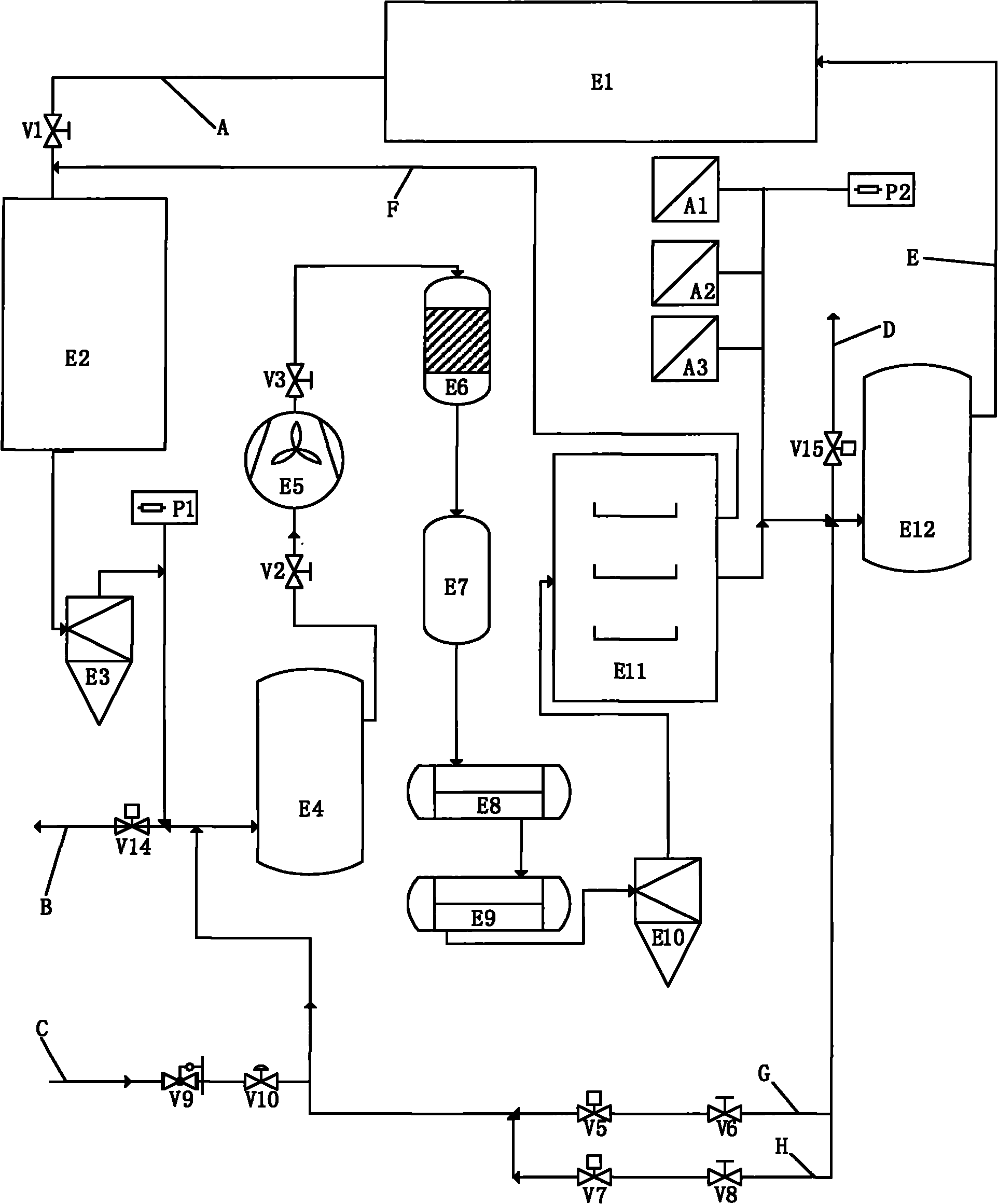

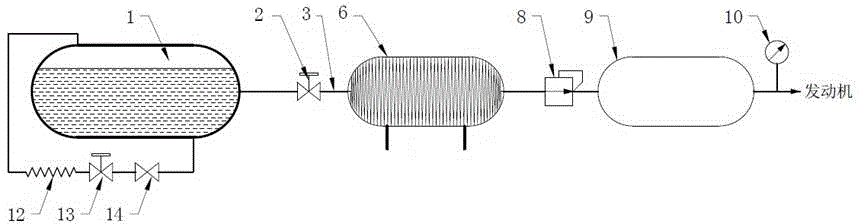

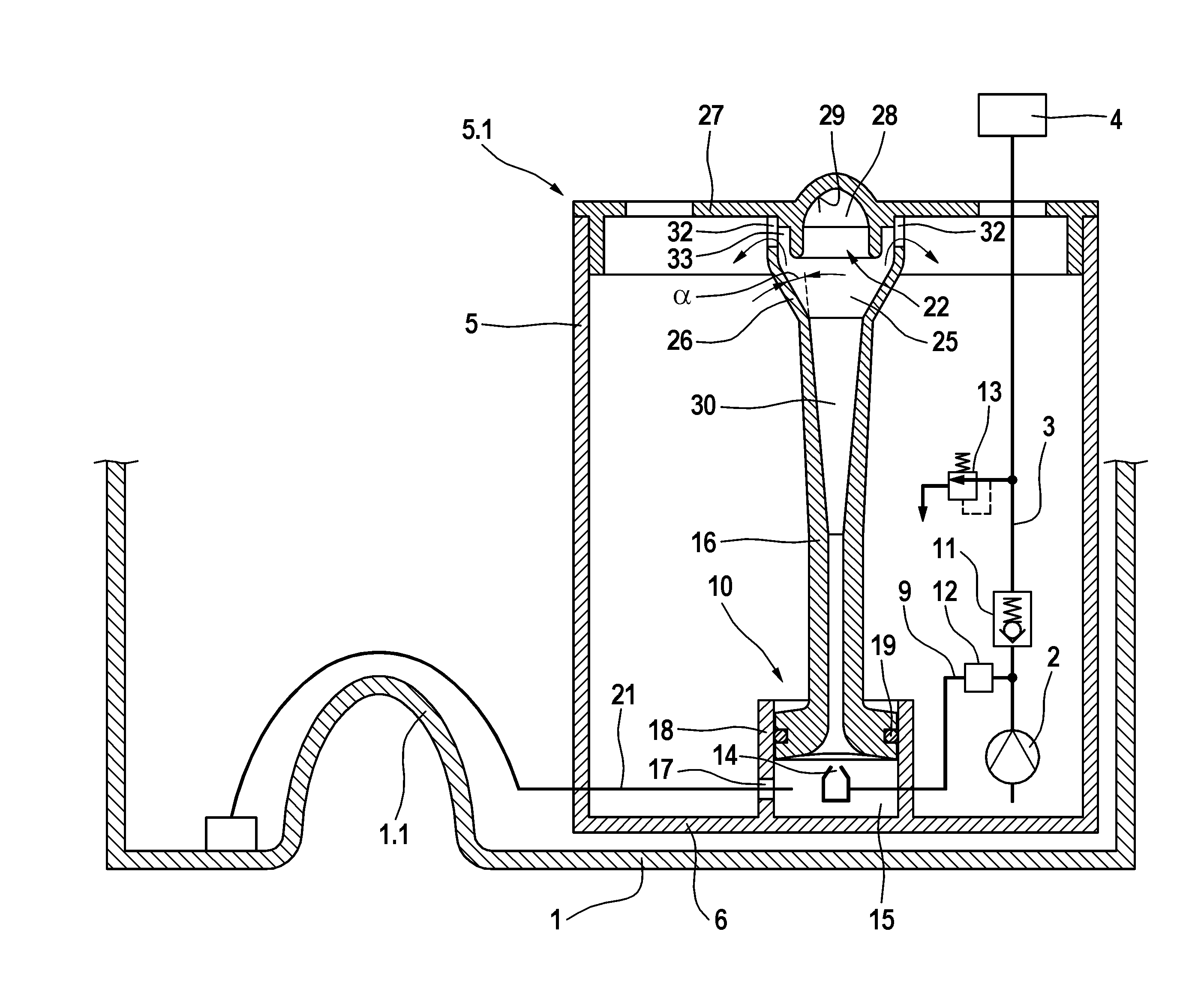

Process and device for recovering and recycling protective gas of bell-type bright annealing furnace

ActiveCN101956061AAvoid direct burningAvoid emptyingMaintainance of heating chambersBell type furnacesBuffer tankDeaerator

The invention relates to a process and a device for recovering and recycling protective gas of a bell-type bright annealing furnace. The process comprises the following steps of: performing cooling and condensation of oil and gas in refluxing protective gas of a bell-type bright annealing furnace group; allowing the cooled and condensed protective gas to enter a water separator to remove most of water and oil; allowing the cooled protective gas from which the oil and the gas are removed to enter a preceding stage buffer tank; after the protective gas is buffered by the preceding stage buffer tank, pressurizing by using a roots blower; allowing the pressurized protective gas to enter an oil absorption device to remove oil and enter a deaerator to remove oxygen; reacting in the deaerator to generate water and discharge heat; cooling the protective gas by using a cooler and removing water from the protective gas by using a condenser; allowing the cooled and dehydrated protective gas to enter the water separator to separate water; allowing the protective gas to enter an absorption regeneration drying device for removing water and impurities deeply; and performing decompression and voltage stabilization on the purified gas by using a post-stage buffering tank and then supplying the purified gas to the bell-type bright annealing furnace group. Through the process and the device, the refluxing protective gas of the bell-type bright annealing furnace group is recovered and purified and enters the annealing furnace to be recycled as the protective gas again.

Owner:苏州品源气体设备有限公司

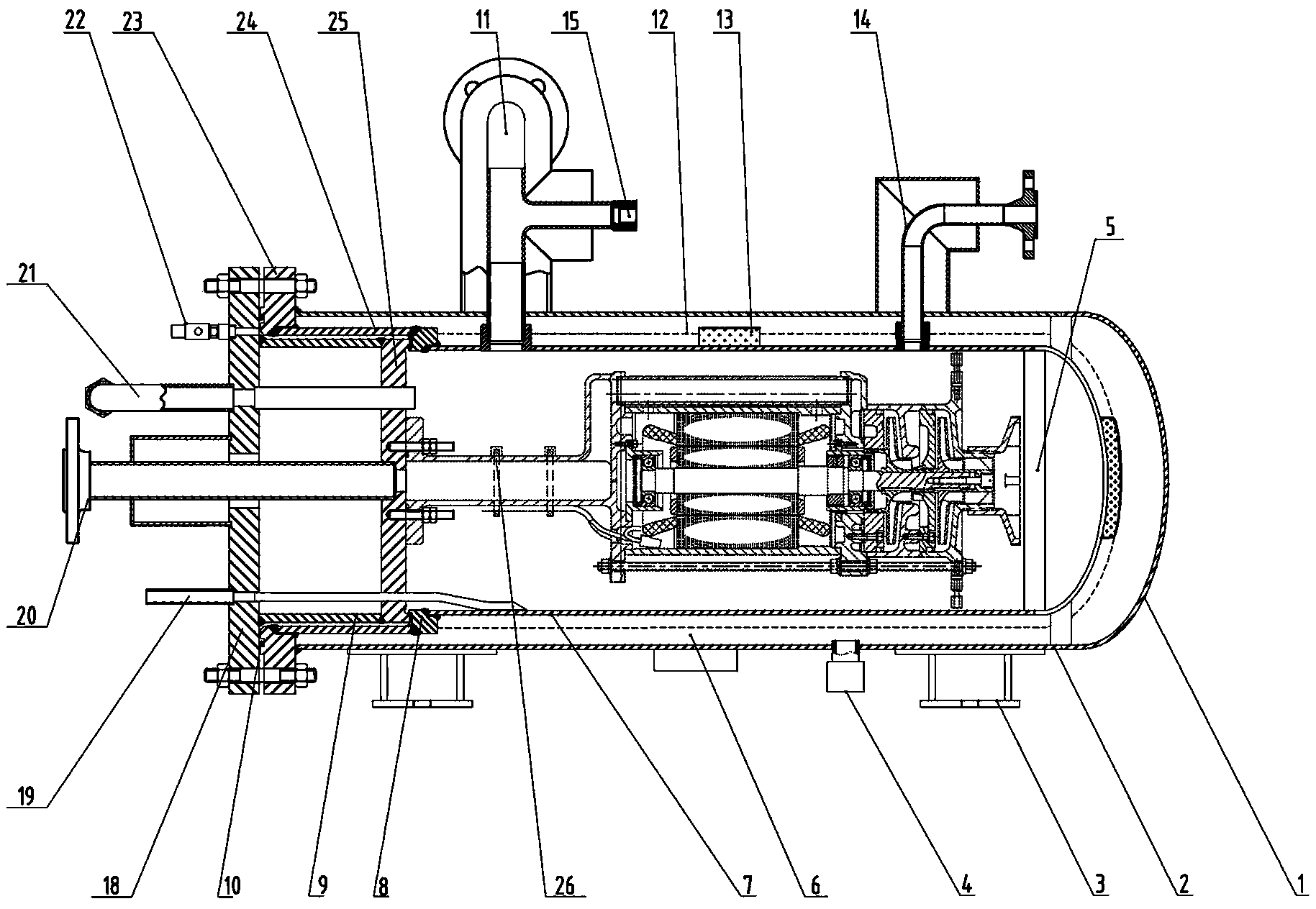

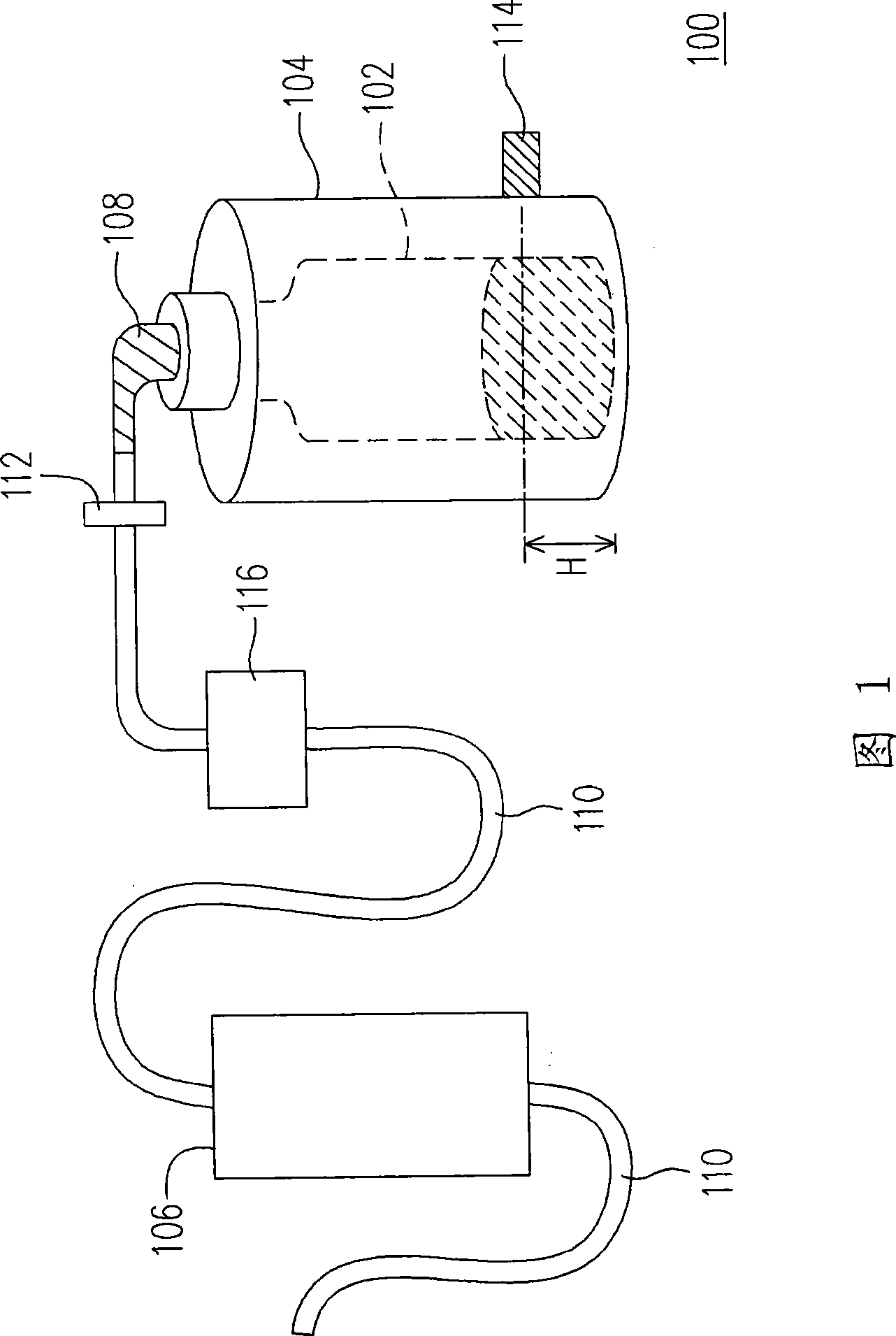

Full-vacuum horizontal liquefied natural gas (LNG) submerged pump pool

InactiveCN103711720AImprove the cooling effectLow running costPump componentsPumpsThermodynamicsIn vehicle

The invention discloses a full-vacuum horizontal liquefied natural gas (LNG) submerged pump pool. The full-vacuum horizontal LNG submerged pump pool comprises a pump pool body, a submerged pump pool and a support. A liquid outlet device which is arranged on the inner side of a pump pool cap is in a structure of high vacuum and heat insulation and an outer casing tube which is arranged on the outer side of the pump poop cap is fixedly connected with a vacuumized joint. The vacuumized joint is communicated with the liquid outlet device and the structure of high vacuum and heat insulation of the full-vacuum horizontal LNG submerged pump pool is formed by the vacuumized joint and a high-vacuum and heat-insulated interlayer between an outer cylinder and inner cylinder of the full-vacuum horizontal LNG submerged pump pool. According to this arrangement, all ways of heat leakage, such as convention, conduction and radiation can be eradicated so that good cold-insulated effect can be ensured. The rate of evaporation per day of LNG in the full-vacuum horizontal LNG submerged pump pool can be reduced by 21.5% to 31.5% compared with the vertical submerged pump pool in the prior art. The full-vacuum horizontal LNG submerged pump pool can be used for filling vehicles or transporting vehicle-mounted LNG, so as to greatly improve the economic benefit of LNG filling stations, LNG transportation and filling vehicles.

Owner:河南开元气体装备有限公司

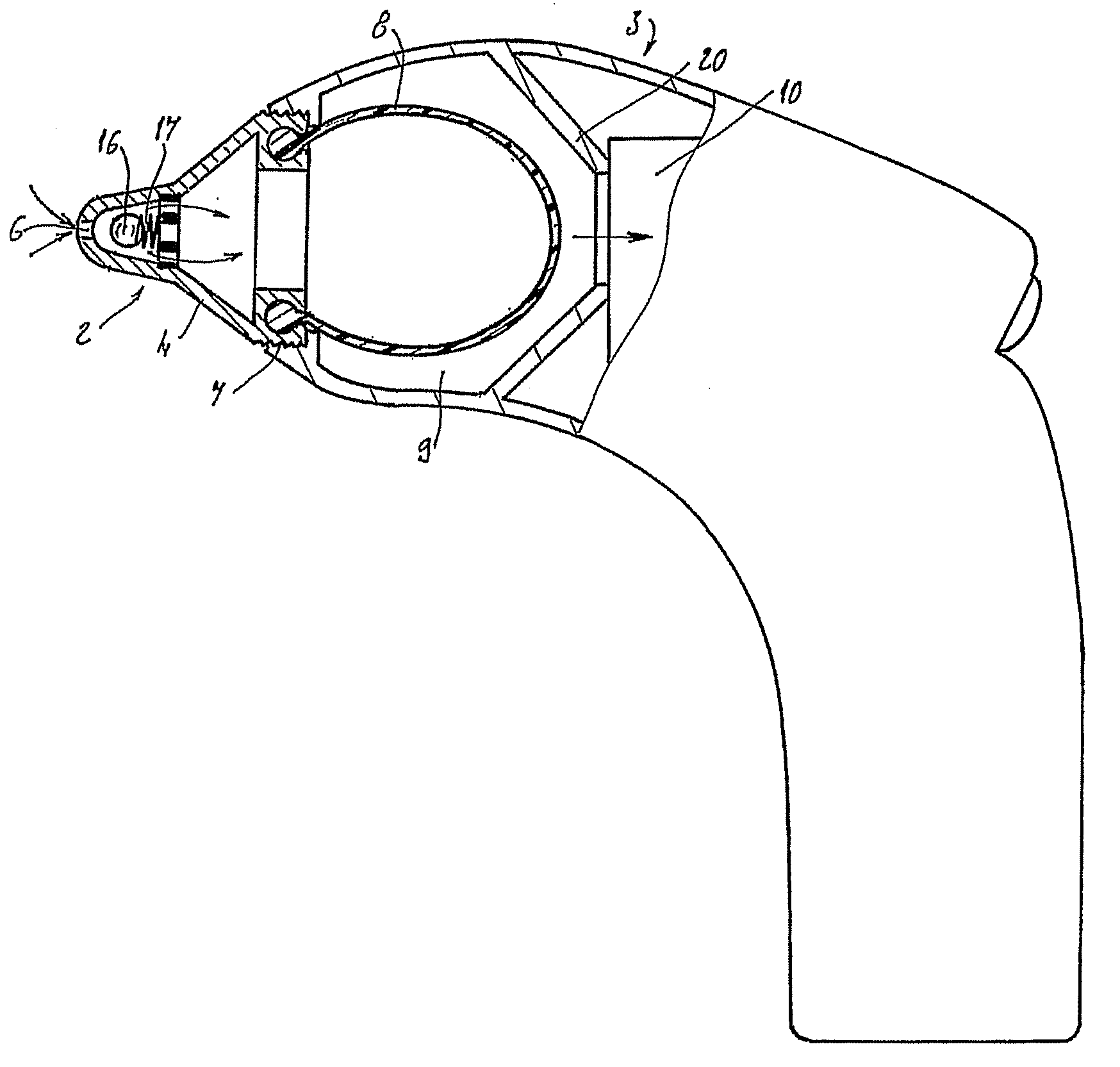

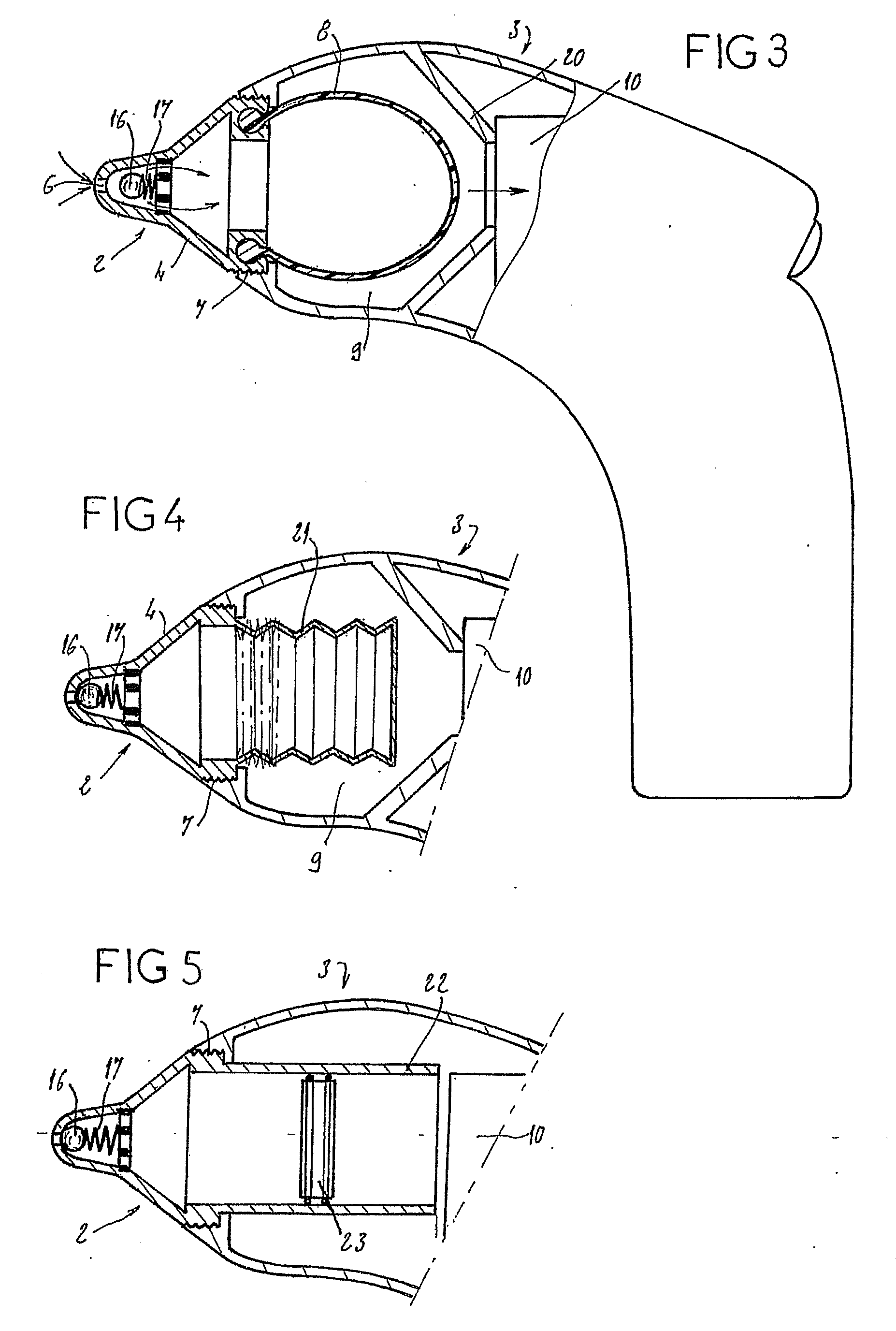

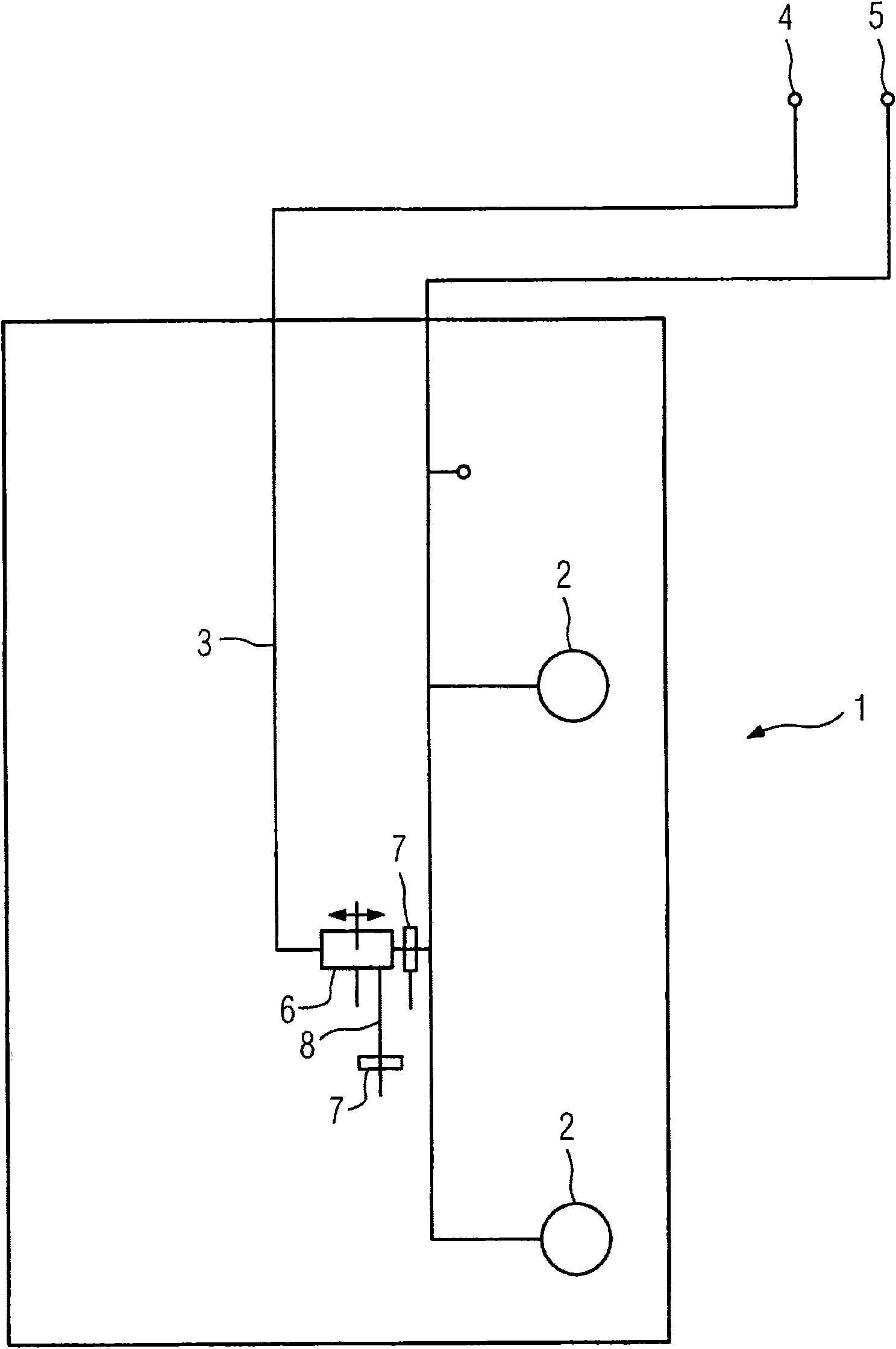

Nasal Secretion Aspiration Device

The invention relates to a nasal secretion aspiration device. The inventive device consists of: a hollow body (3) which defines a vacuum chamber (9) that can be connected to a vacuum source (10), said chamber (9) comprising an opening (13); and a nasal end piece (2) comprising a first open end (5) which is designed to be inserted into a person's nose and a second open end (7) which is equipped with means for fixing same in a leak-tight, removable manner in the opening (13) of the hollow body (3). According to the invention, the second end (7) is sealed by a non-porous deformable element (8) under a vacuum created in the vacuum chamber (9) by the vacuum source (10).

Owner:UBIMED LLC

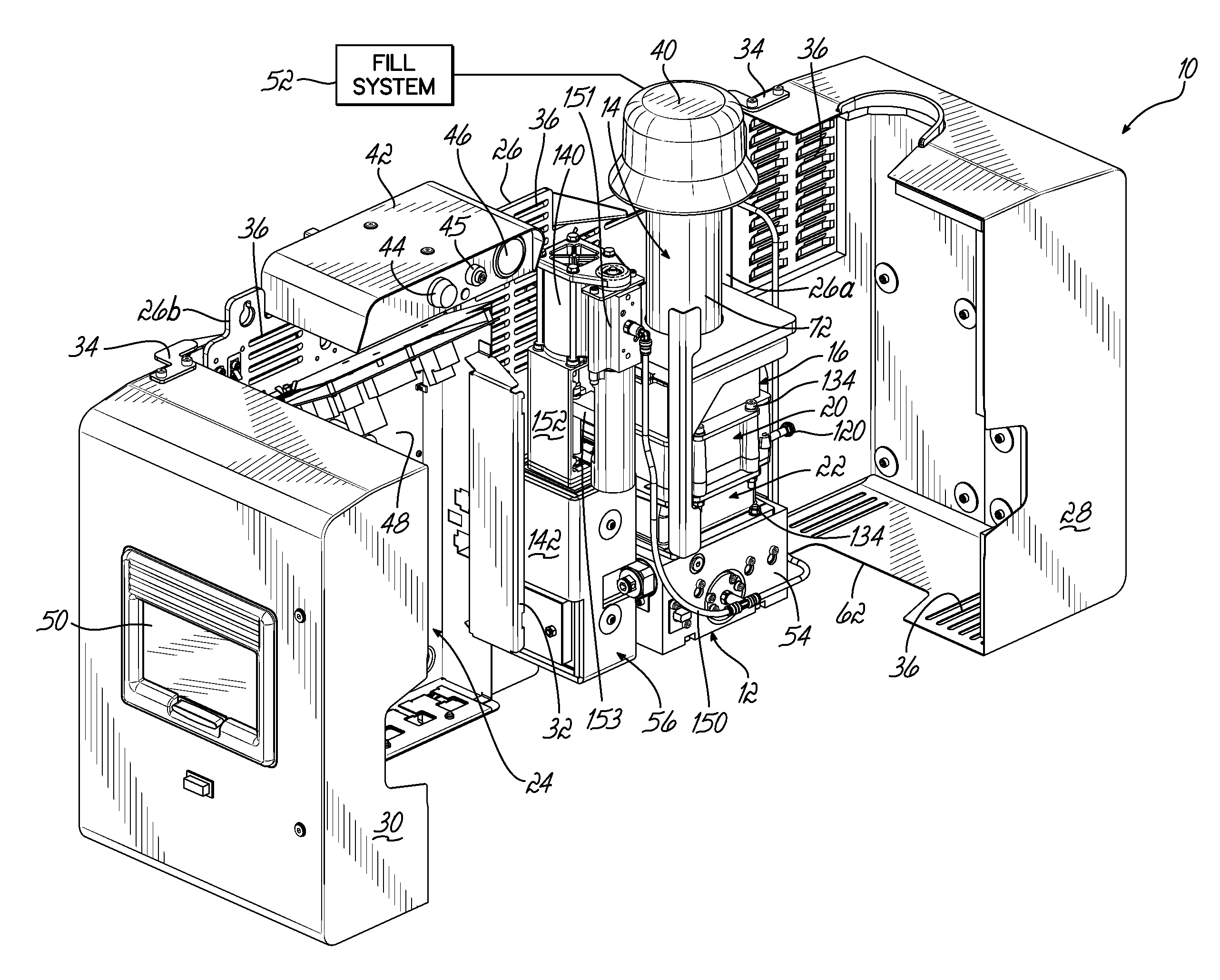

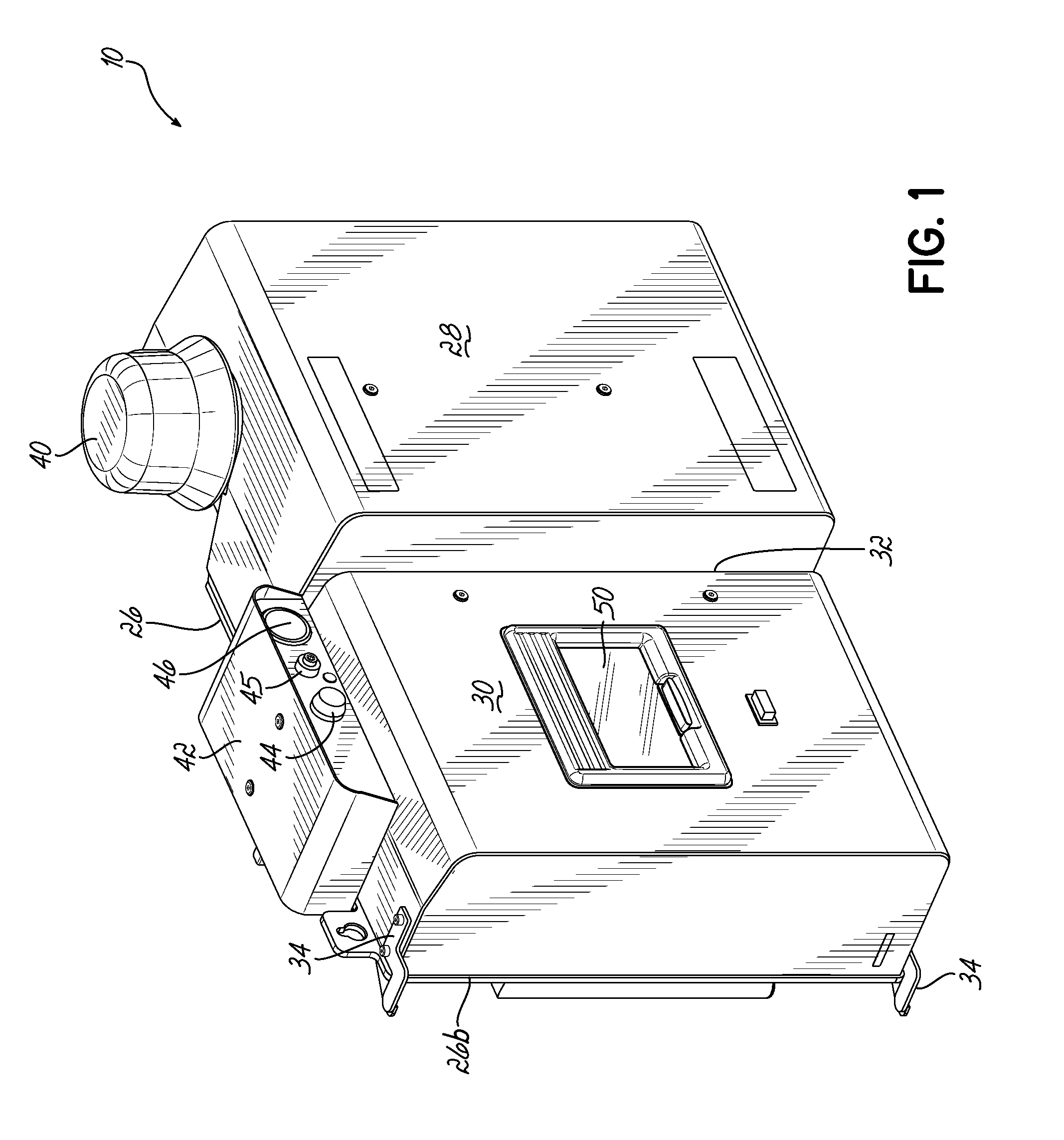

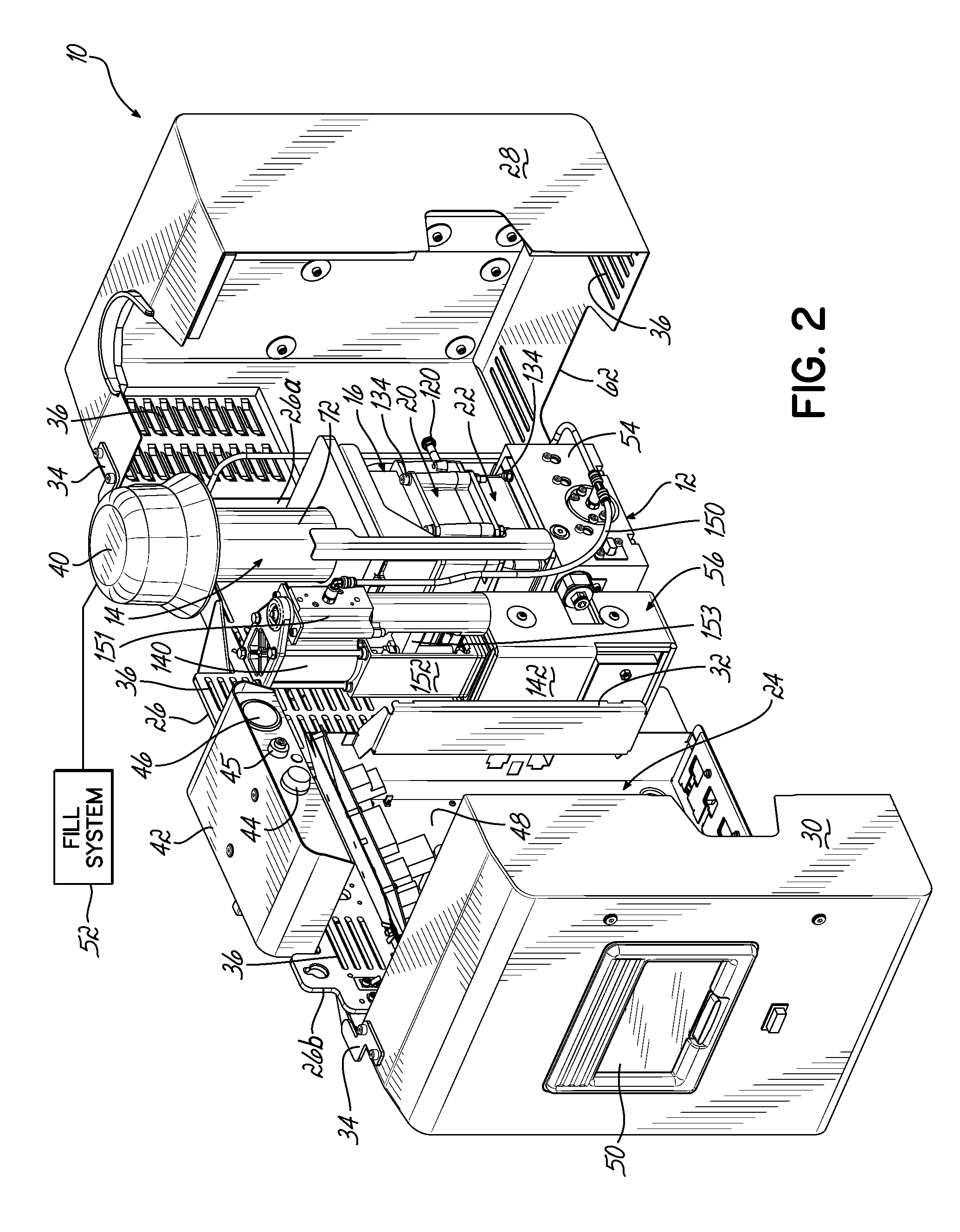

Adhesive dispensing device having optimized cyclonic separator unit

InactiveUS20140079493A1Reduce flow rateAvoid accumulationLiquid surface applicatorsReversed direction vortexMechanical engineeringAdhesive materials

An adhesive dispensing device includes a heater unit for melting adhesive material, a receiving space for feeding the heater unit, and a cyclonic separator unit for delivering adhesive pellets to the receiving space. The cyclonic separator unit includes a tangential inlet pipe proximate to a top end of a generally cylindrical pipe, which is connected to the receiving space at an open bottom end. The tangential or spiral flow of air and adhesive pellets generated through the cyclonic separator unit reduces the speed of the air and adhesive pellets to avoid splashing of molten adhesive material while maintaining enough speed to avoid adhesive build up on the generally cylindrical pipe.

Owner:NORDSON CORP

Adhesive dispensing device having optimized cyclonic separator unit

InactiveUS9169088B2Reduce flow rateAvoid accumulationLiquid surface applicatorsReversed direction vortexEngineeringSpiral flow

Owner:NORDSON CORP

Vapor chamber

InactiveUS7913748B2Vaporization fastShorten the timeSemiconductor/solid-state device detailsSolid-state devicesEngineering

A vapor chamber includes a plate and a wick structure. The plate is provided therein with a working fluid, and the plate has a heated end and a condensed end. The wick structure includes a first wick portion adhered to be opposite to the heated end, a second wick portion overlapping on the first wick portion, and a third wick portion adhered on the rest portion of a chamber. The aperture diameter of the first wick portion is larger than that of the second wick portion, or the aperture density of the first wick portion is smaller than that of the second wick portion. The amount of working fluid attached to the second wick portion is smaller than that of the first wick portion. After heating, the working fluid attached to the second wick portion is vaporized more quickly.

Owner:GOLDEN SUN NEWS TECHN +1

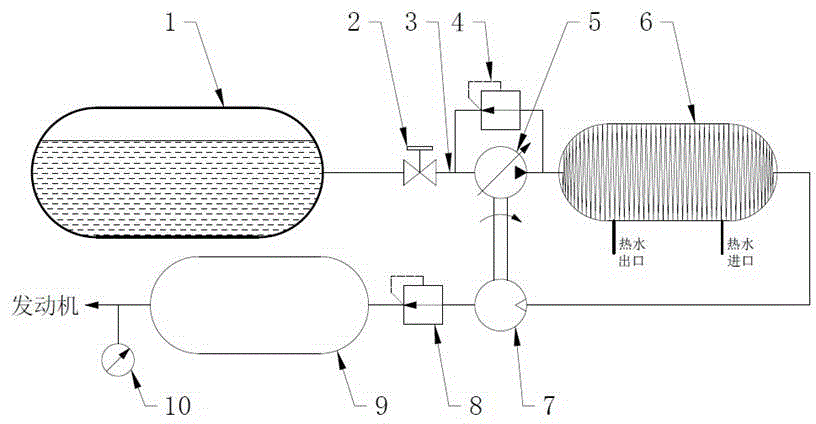

Novel vehicle-mounted natural gas supply system and stable gas supply method thereof

ActiveCN104088726AStable air supplyHigh powerInternal combustion piston enginesFuel supply apparatusProcess engineeringProduct gas

The invention discloses a novel vehicle-mounted natural gas supply system and a stable gas supply method of the novel vehicle-mounted natural gas supply system. The novel vehicle-mounted natural gas supply system comprises an LNG storage tank, a gasification device, a liquid outlet pipe connected between the LNG storage tank and the gasification device, an LNG pump used for extracting liquefied natural gas from the LNG storage tank and a gas pressure driven device driving the LNG pump to work. The LNG pump is arranged on the liquid outlet pipe. The gas pressure driven device is arranged on a pipeline on the downstream of the gasification device and driven through gas pressure of natural gas flowing through the pipeline and connected with the LNG pump through a driving pipeline. The gas pressure driven device of the system is driven through gas pressure of the gasified natural gas in the gasification device to work and drive the LNG pump to extract the liquefied natural gas from the LNG tank, the natural gas flows through the liquid outlet pipe to the gasification device, and therefore the passive circulatory system is formed. According to the system, gas fuel can be stably supplied to an engine, a self-pressurization system is omitted, evacuation loss of natural gas is reduced, and resource waste is avoided.

Owner:成都市珑熙科技有限公司

Mobile Shredder

A mobile shredder comprises a truck having a truck body defining an enclosure and including a partition in the enclosure that divides a storage volume from the remainder of the enclosure for storage of shredded material in the storage volume, a single-shaft rotary shredder mounted in the enclosure outside the storage volume, the rotary shredder comprising a rotor having cutters rigidly mounted thereon, a bin lift and dump mechanism operable to transport material to be shredded from outside to inside the enclosure so as to deliver material to the rotary shredder, and a discharge conveyor operable to transport shredded material from the rotary shredder through the partition to the storage volume. The floor of the storage volume can comprise a walking floor, and the enclosure can have rear doors that are openable to allow shredded material to be discharged through the open rear doors when the walking floor is operated.

Owner:VECOPLAN

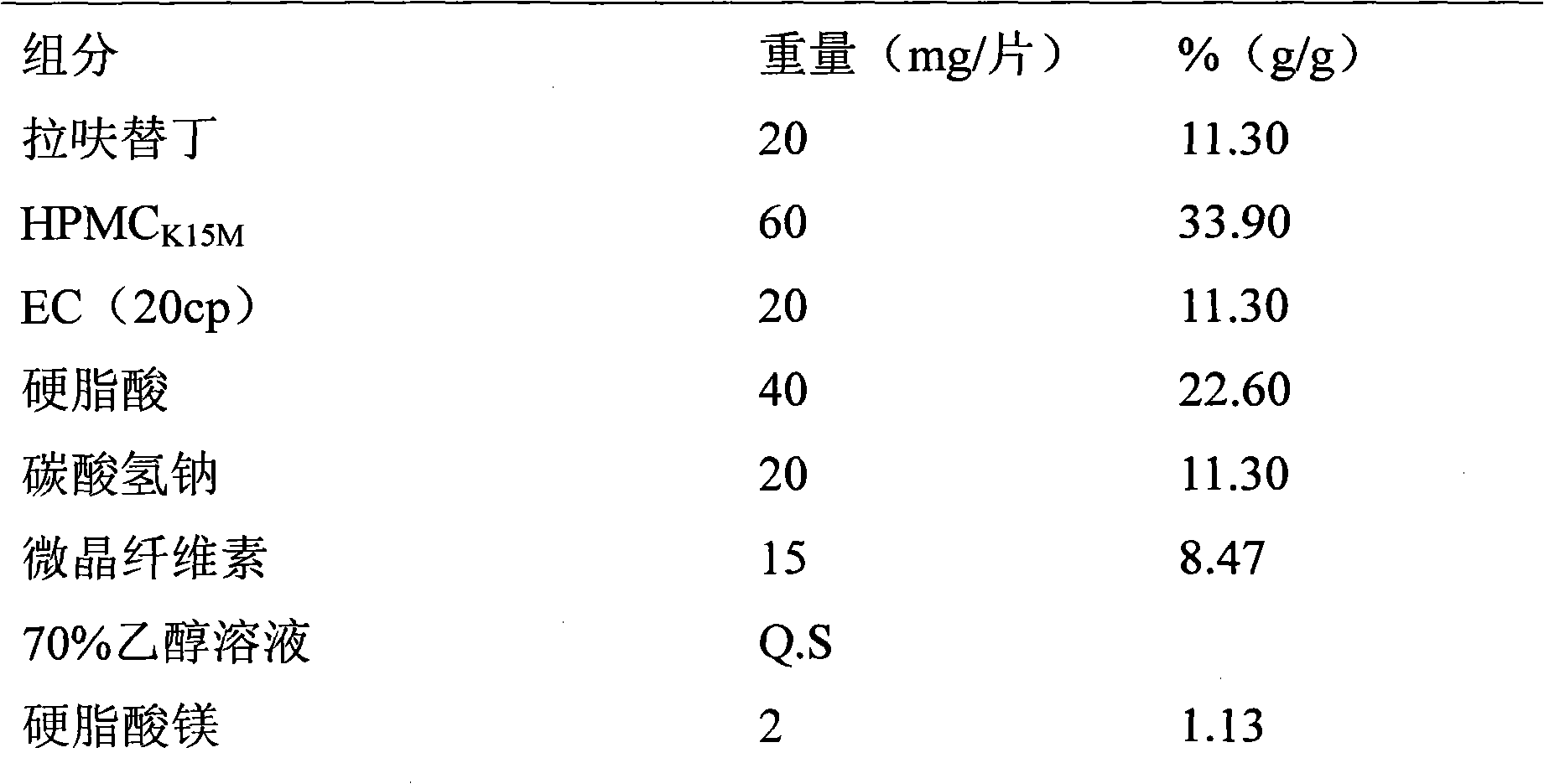

Lafutidine gastric-retention controlled-release composite

ActiveCN101919817AFacilitated releaseRegulatory releaseOrganic active ingredientsDigestive systemUse medicationControl release

The invention relates to a lafutidine gastric-retention controlled-release composite belonging to the field of pharmaceutic preparations. The lafutidine gastric-retention controlled-release composite is characterized by comprising the following components in percentage by weight: 5%-20% of the lafutidine, 10%-40% of framework materials, 10%-30% of assistant bleaching agents, 5%-15% of foaming agents, 5%-15% of filling agents and 0.5%-10% of lubricating agents. The composite has reasonability and simple preparation process; compared with same pharmaceuticals, the lafutidine gastric-retention controlled-release composite has little dose, good tolerance, little side effect, and the like; and in addition, compared with the conventional tablets, the lafutidine gastric-retention controlled-release composite enhances the solubility of lafutidine, prolongs the action time (prolonged from 2-3 hours to 5-6 hours) on the upper parts of a stomach and a small intestine, promotes the absorption, enhances the bioavailability, reduces the pharmaceutical usage times, achieves the maximum treatment effect through minimum doses, reduces the concentration change of peaks and valleys and has good patient compliance.

Owner:SHANDONG QIDU PHARMA

Hydraulic tensioner

A tensioner for a traction drive includes a cylinder arranged in a housing at a distance to a housing wall to thereby define an interior space which contains hydraulic fluid. A piston is received in the cylinder for back-and-forth movement and bounds a pressure chamber containing hydraulic fluid. The piston has a cylinder-distal end which is operatively connected to a spring-biased tension roller supported on a traction member. Formed between the piston and the cylinder is a leakage gap, and a reservoir for hydraulic fluid is provided in an area of the leakage gap to prevent ingress of air into the pressure chamber, when the traction drive is at a rest.

Owner:SCHAEFFLER TECH AG & CO KG

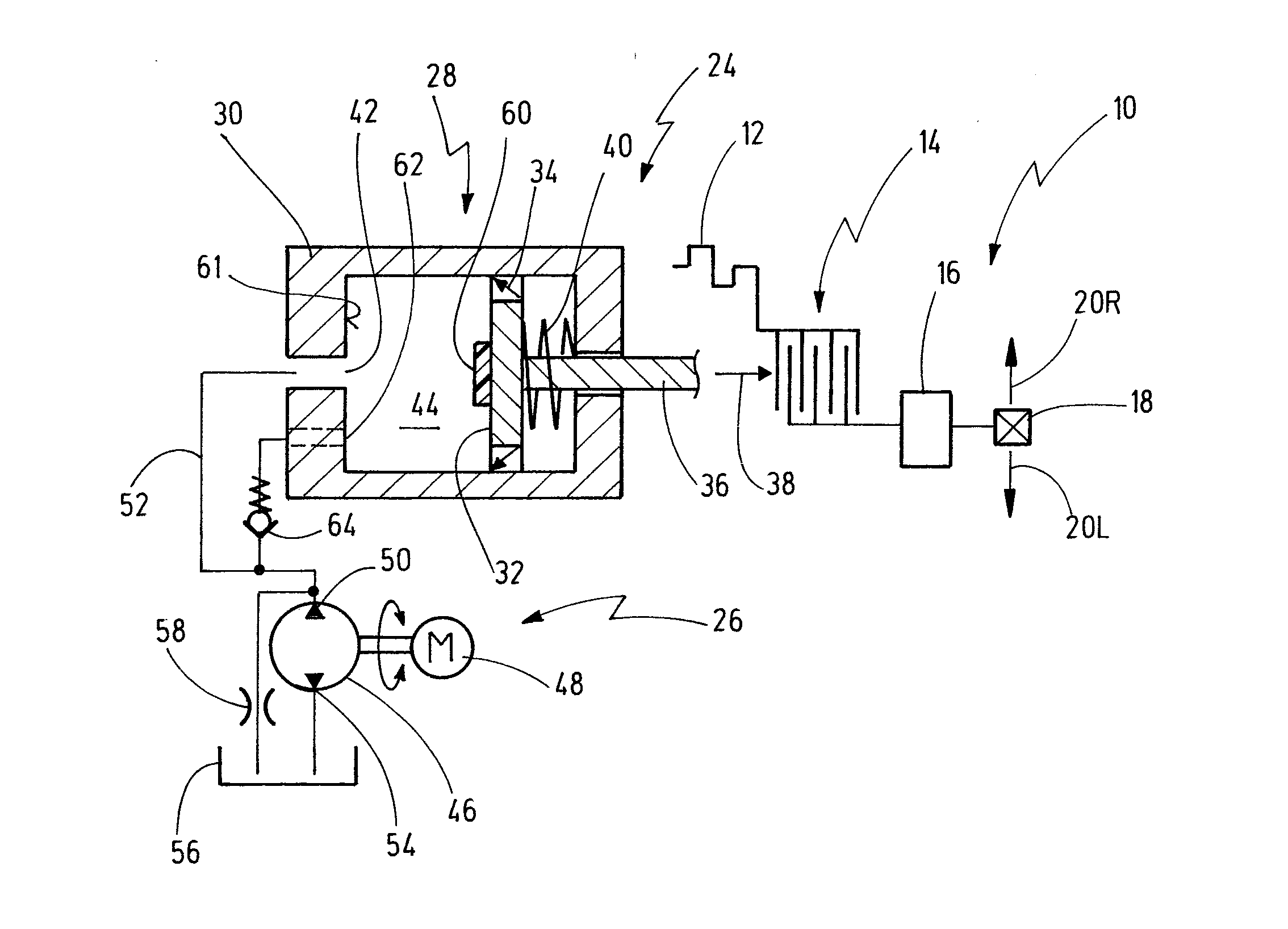

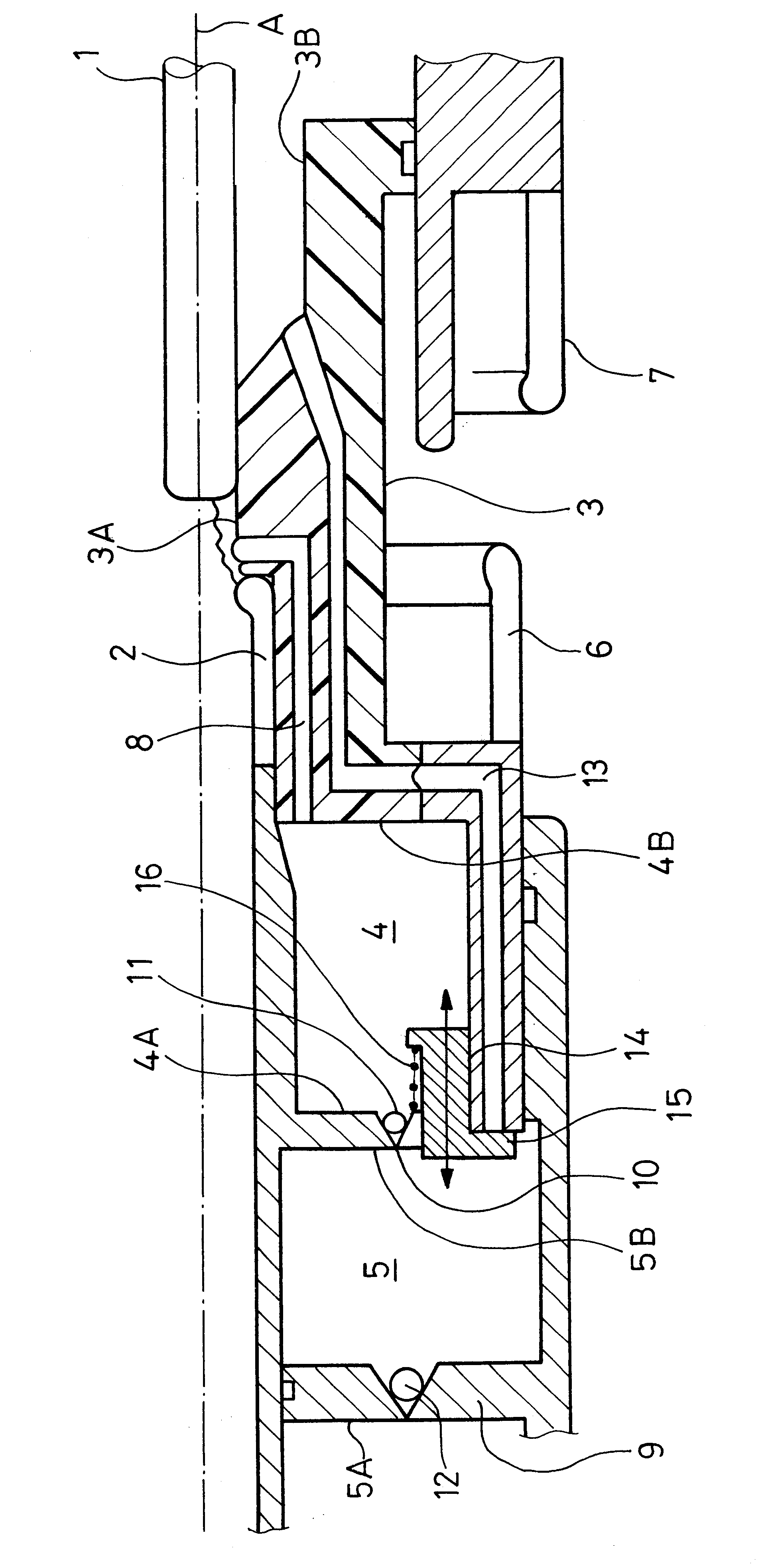

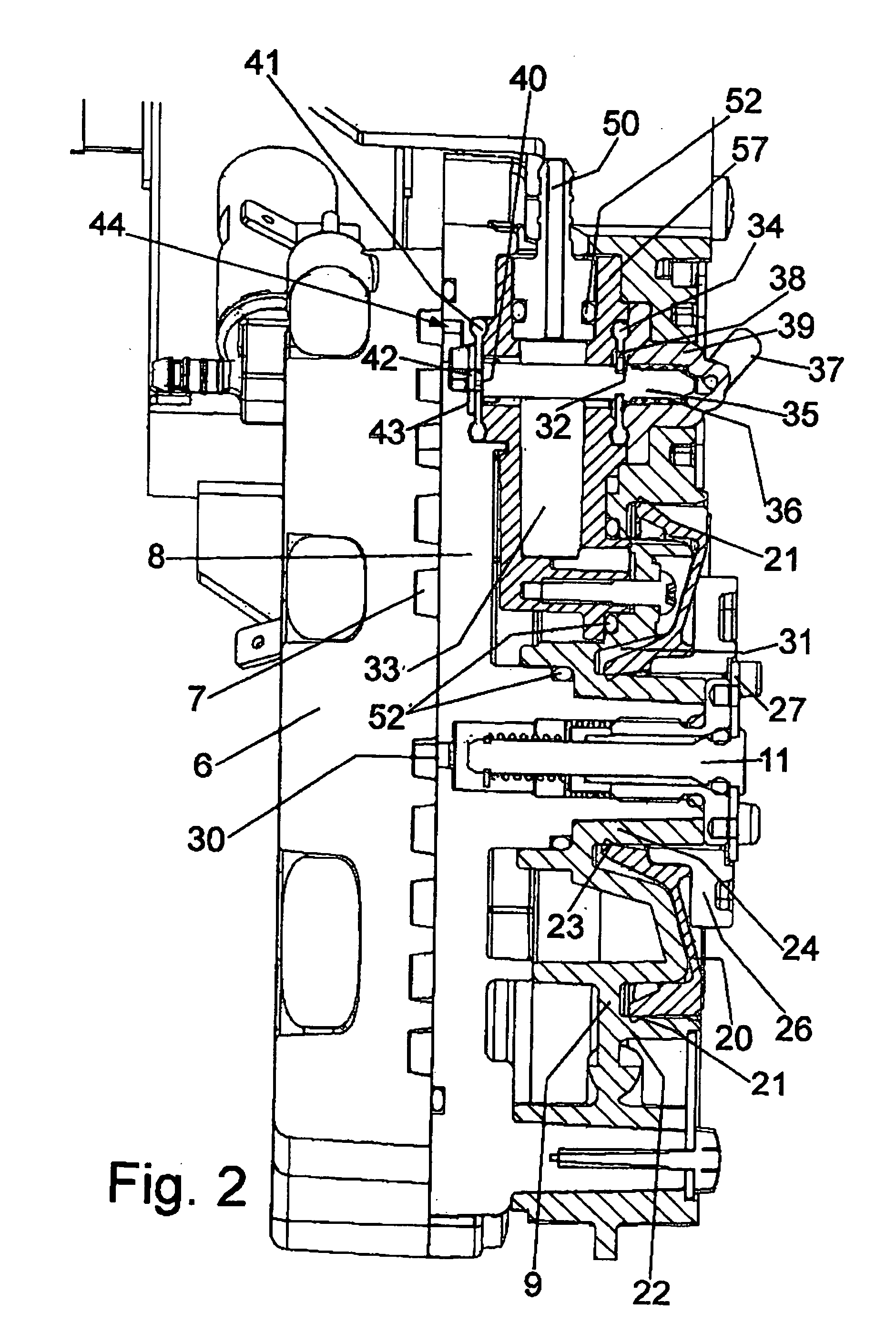

Drivetrain-clutch arrangement and fluid cylinder therefor

ActiveUS20130192948A1Prevent and reduce noiseIntake of air can be preventedEngine sealsFluid actuated clutchesDrivetrainEngineering

Fluid cylinder for activating an element of a drivetrain of a motor vehicle. The fluid cylinder has a cylinder housing and a piston. The piston is sealed off from the cylinder housing by means of a piston seal. At least one fluid chamber is formed between the cylinder housing and the piston, which fluid chamber can be connected via at least a first fluid connection to a fluid supply device. The piston in a piston stop position rests against a stop surface of the cylinder housing. The first fluid connection is formed in the region of the stop surface of the cylinder housing. The piston is connected to a sealing device which seals off the first fluid connection in the piston stop position.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

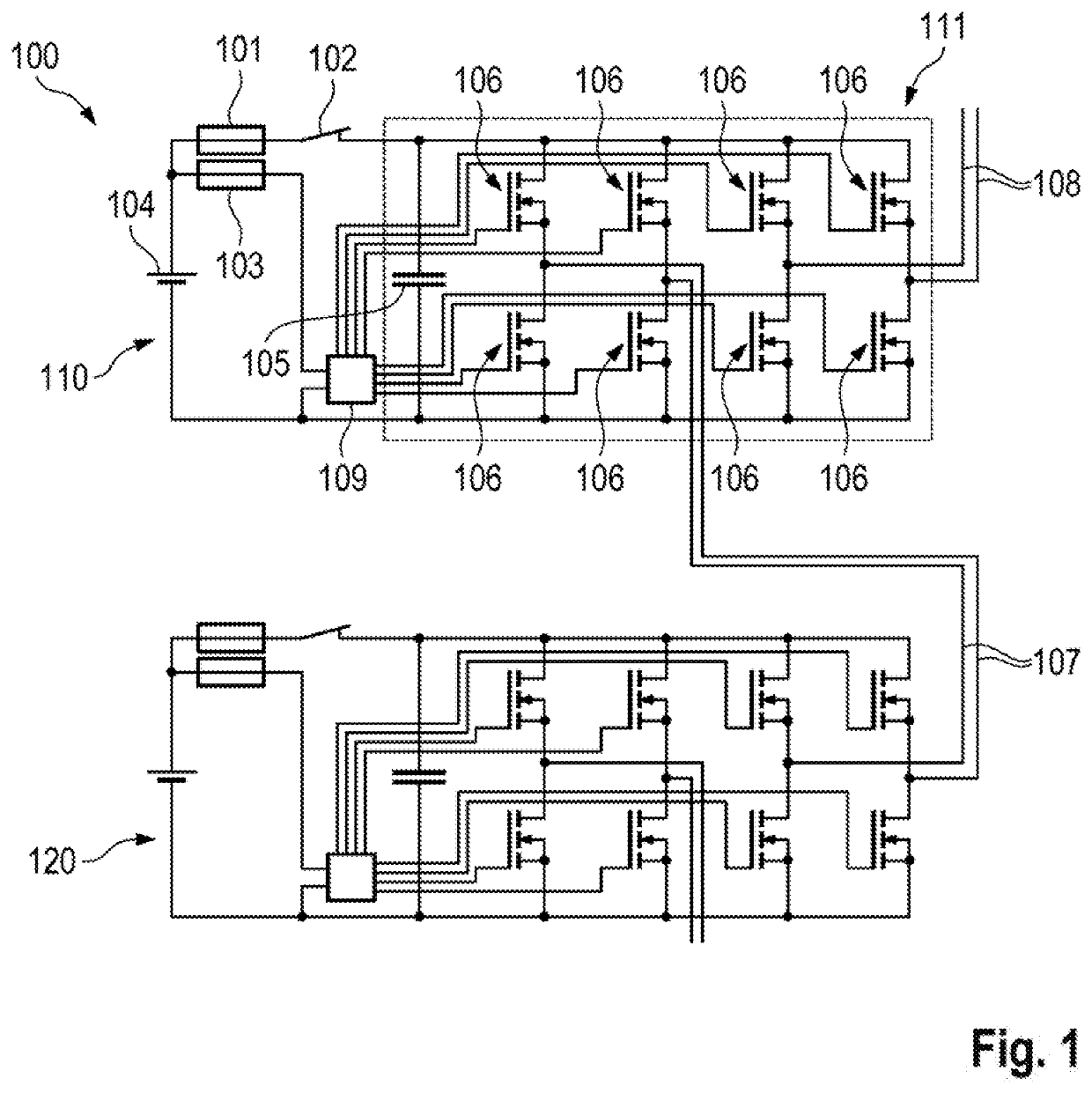

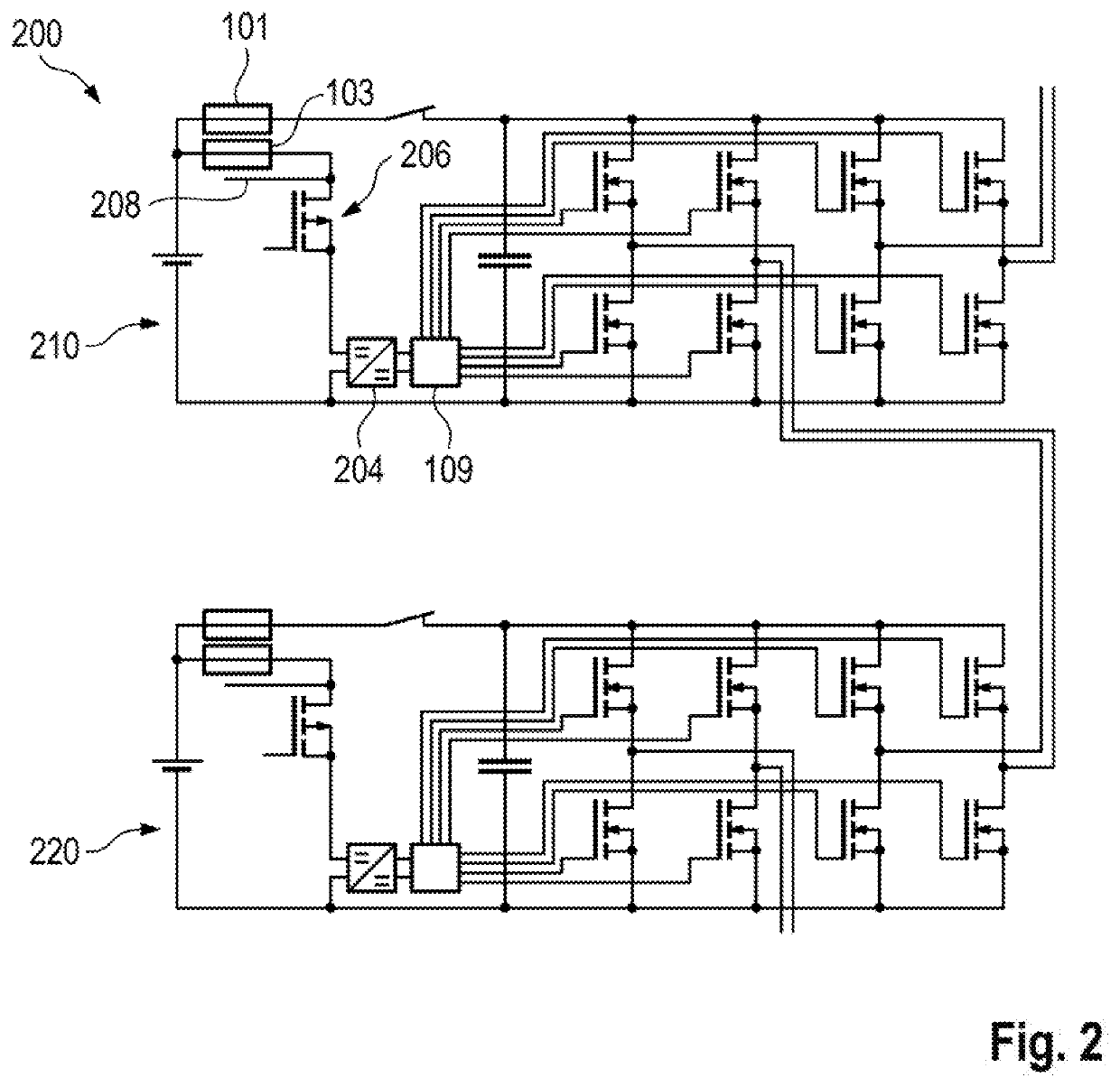

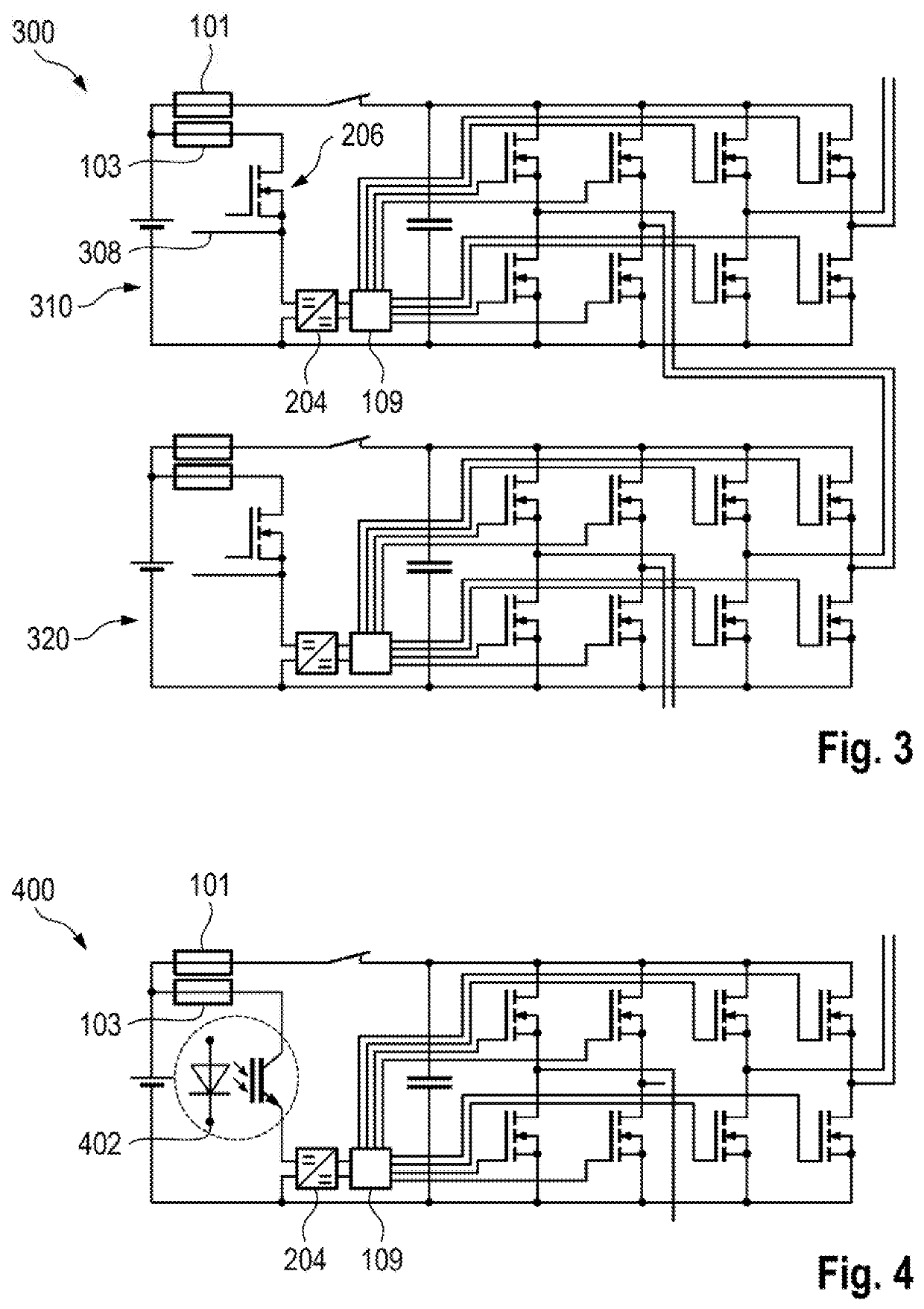

Double fusing of the module store interface

A circuit for protecting energy storage cells in which at least one energy storage cell is part of an AC battery having at least one module. The at least one module includes at least one half-bridge having two power semiconductor switches, a module storage element and a module controller. The at least one module is connected to the at least one energy storage cell to form a first connection and the first connection between the at least one module and the at least one energy storage cell has a first fuse that can interrupt the first connection. The circuit has a second connection between the module controller of the at least one module and the at least one energy storage cell.

Owner:DR ING H C F PORSCHE AG

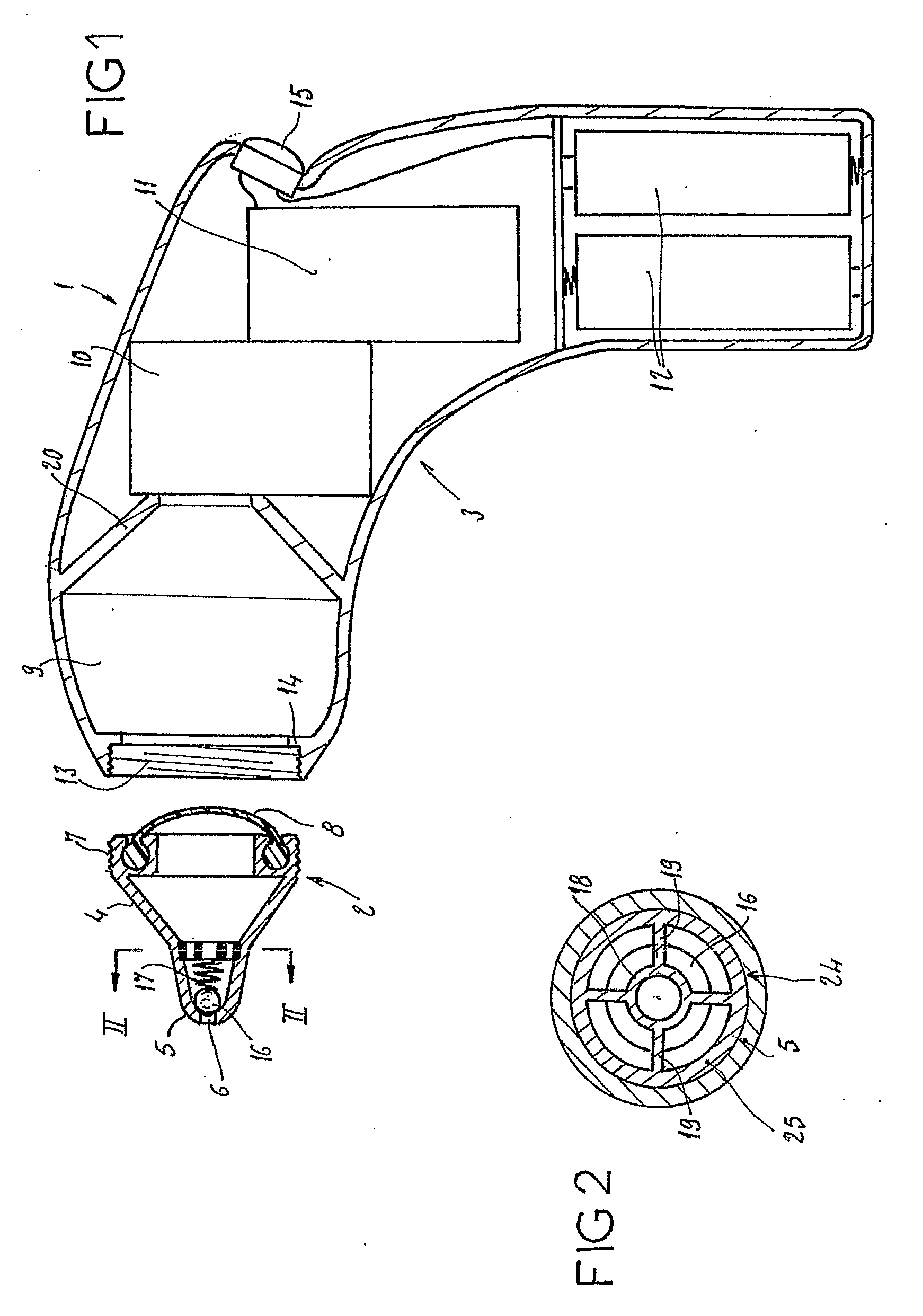

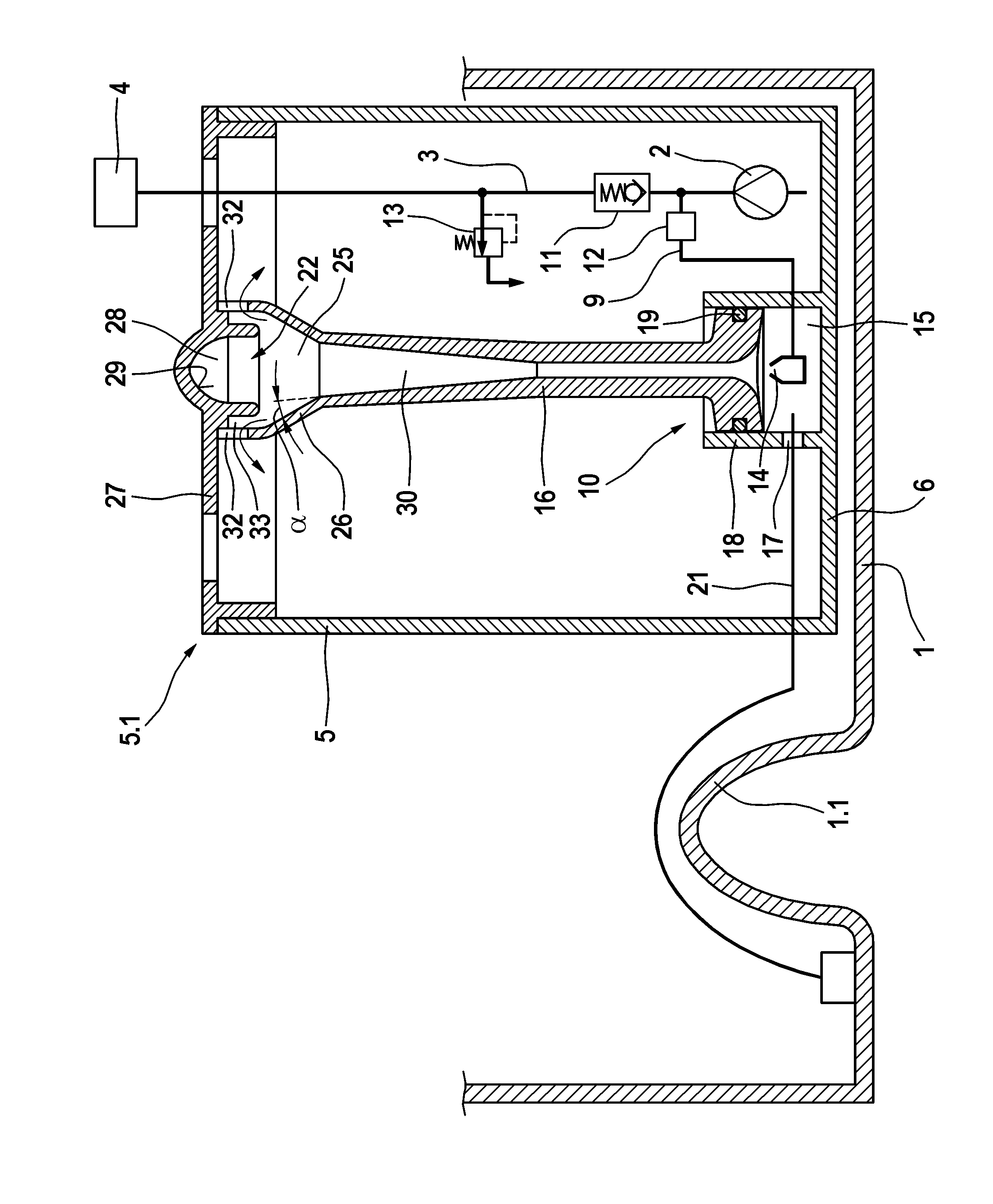

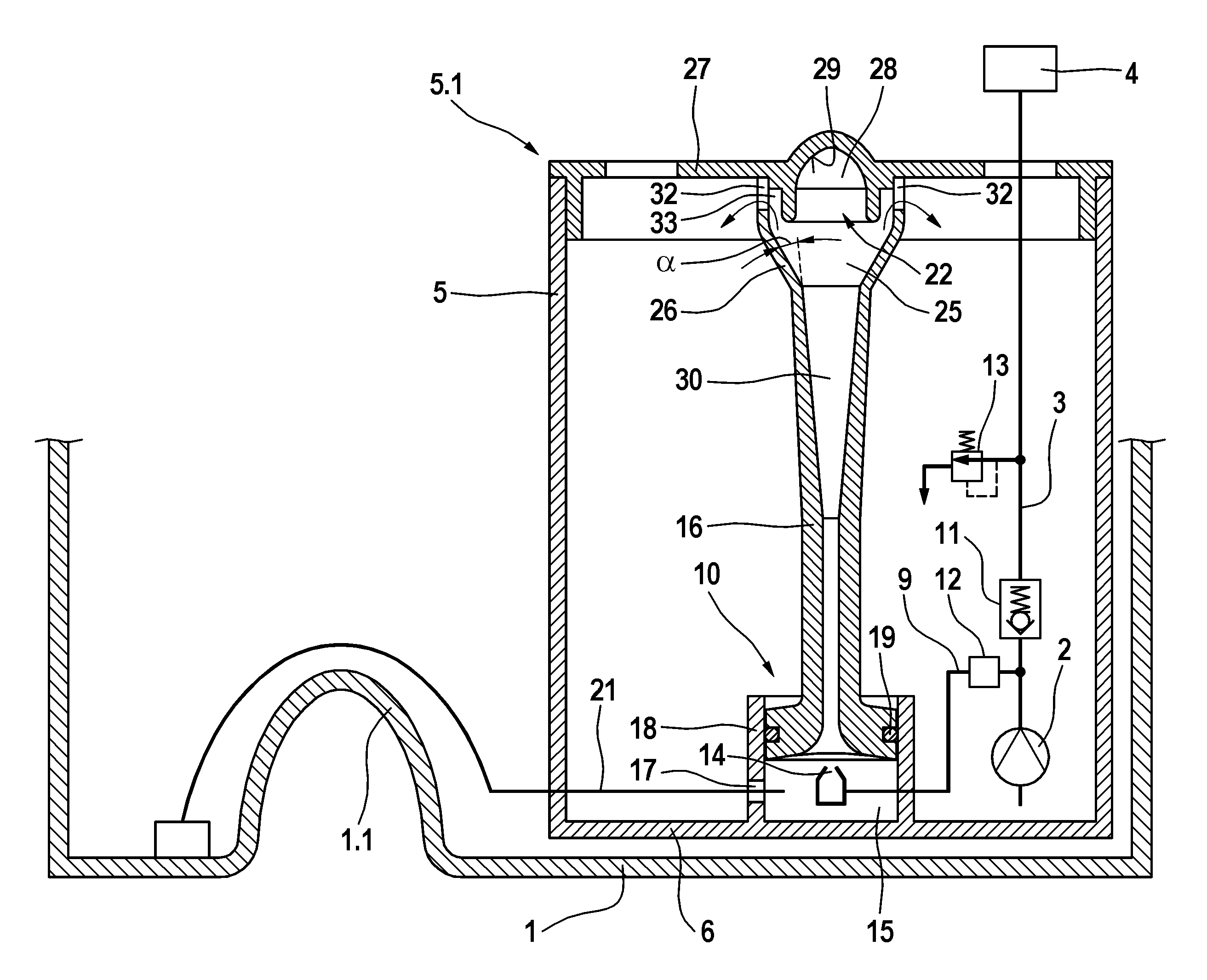

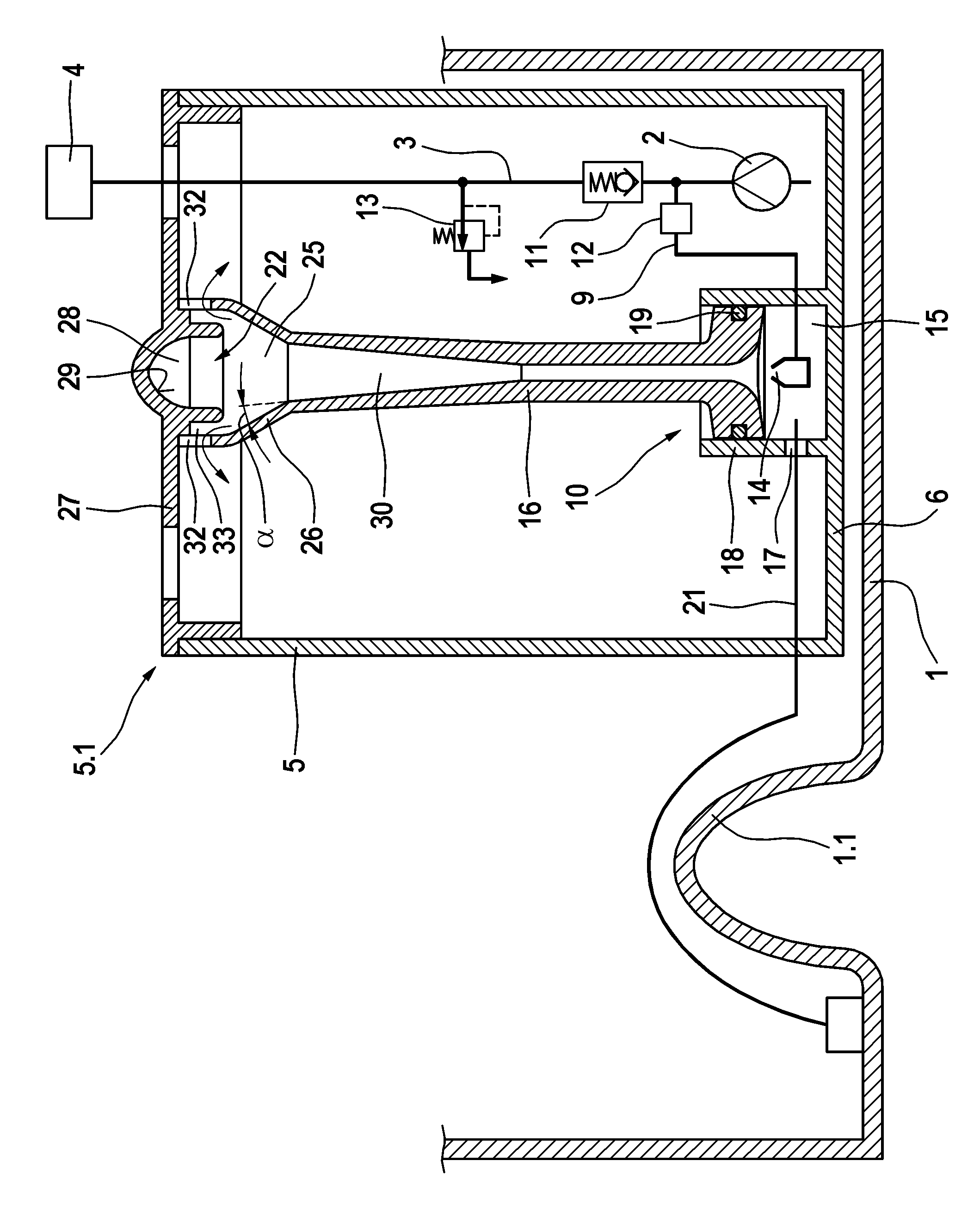

Device for delivering fuel

ActiveUS20120018019A1Good capture and returnAvoid emptyingPump componentsUsing liquid separation agentInjection pumpFirst Fill

Devices for delivering fuel are already known, comprising a suction jet pump that is arranged in a storage crucible and has a nozzle and a mixer duct provided downstream of the nozzle and arranged perpendicular to the bottom of the storage crucible, wherein at the outlet of the mixer duct an impingement means is arranged, against which the jet of the nozzle impinges in the substantially unfilled mixer duct, and in doing so is at least partially returned into the mixer duct. It has been found that despite the impingement means the propulsive jet tends to eject the liquid column present in the mixer duct. As soon as the liquid level in the storage crucible has decreased below the outlet of the mixer duct, no more fuel can replenish from above into the mixer duct so that the mixer duct may be unfilled after switching off the suction jet pump. Upon restarting the suction jet pump, an unsatisfying high delay until suction of the suction jet pump occurs, because the volume of the propulsive jet must first fill the mixer duct in order to create a vacuum and suction power. Using the device according to the invention, a pushing out of the liquid column of the mixer duct by the propulsive jet of the suction jet pump is avoided. Thus the lead time of the suction jet pump is approximately equal in all operating states. According to the invention, an additional volume (25) is formed at the outlet of the mixer duct (16) by an off-set widening (26) of the mixer duct (16).

Owner:ROBERT BOSCH GMBH

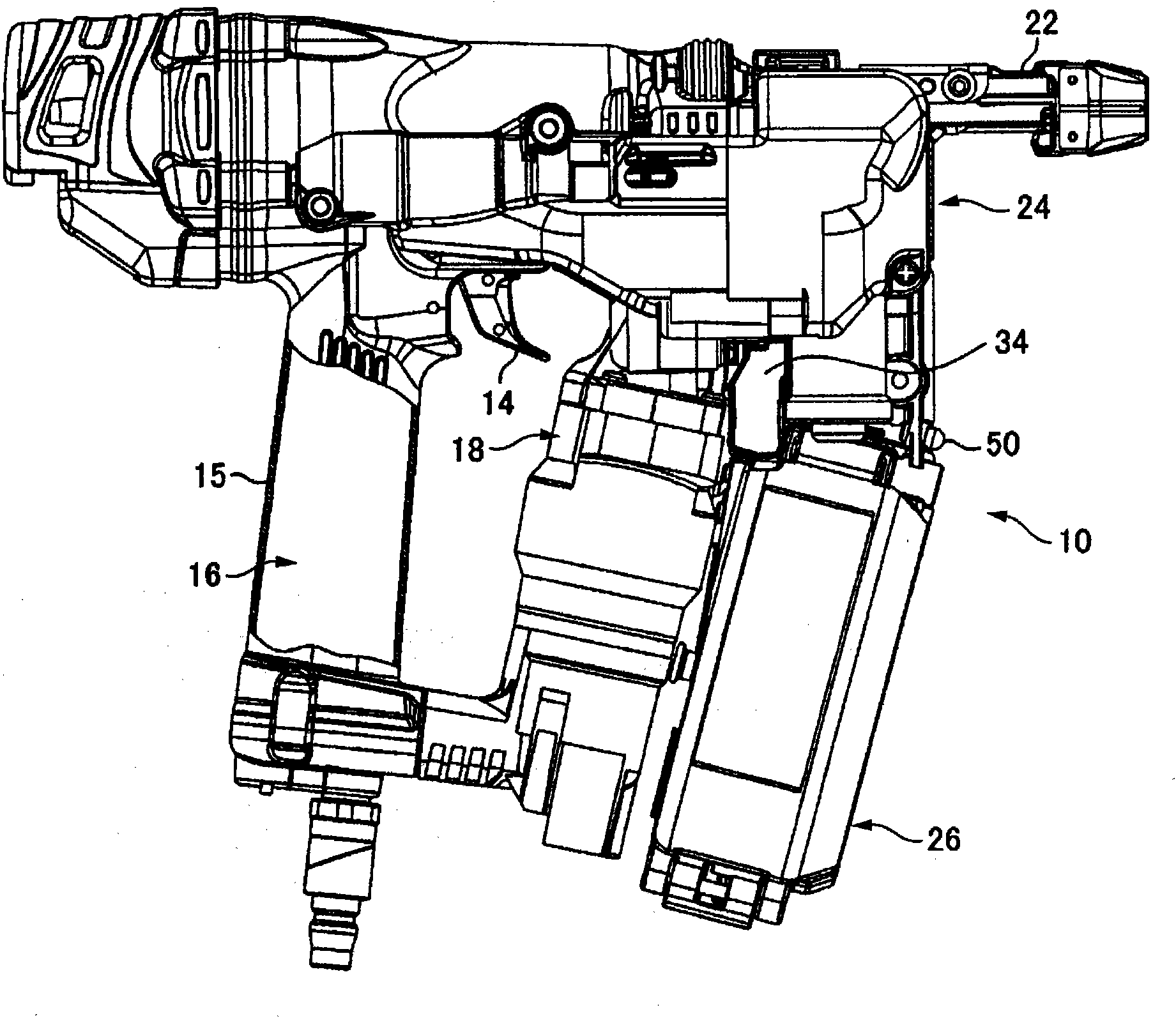

Handheld tool, remaining fastener quantity detection mechanism, remaining fastener quantity detection method, and method for conserving power

Disclosed is a handheld tool which continuously provides a plurality of fasteners and comprises: an ejection detector which detects that a fastener has been ejected; and a controller. When the ejection detector detects the ejection of a fastener, the controller switches the tool from a standby mode, which is a power-saving state with low energy consumption, to an operating mode in which normal operations can be performed; also, when the normal operations are completed, the controller switches the tool from the operating mode to the standby mode.

Owner:MAX CO LTD

Device for sealing a lubricant reservoir and method for lubricating the internal cavity of a tire

InactiveUS6944948B2Breaking sealAvoid emptyingMetal-working apparatusInflatable tyresLubricationInternal cavity

A method of lubricating a tire cavity and more particularly the interface zone between a safety support and the inside the cavity of a tire enables lubricant to be dispensed in the interface zone only when the mounted assembly comprising the support, the tire and a wheel is in a runflat condition and where the non-instantaneous contact established between the inside surface of the tread and the seal allows the lubrication port to be unblocked. The invention also concerns a lubrication device and a seal enabling the method to be implemented, and a support and a reservoir enabling implementation of the method.

Owner:MICHELIN RECH & TECH SA

Circuit-breaker including a channel for emptying the piston-driven compression chamber

InactiveUS6624371B2High dielectric strengthAvoid emptyingHigh-tension/heavy-dress switchesAir-break switchesEngineeringPiston

A circuit-breaker includes two contacts which are disposed in an interrupting space filled with a dielectric gas under pressure and between which an electric arc strikes during circuit-breaker opening, a thermal blast chamber communicating directly with the interrupting space, and a piston-driven compression chamber communicating with the thermal blast chamber. The piston-driven compression chamber communicates with the interrupting space via a discharge channel that is separate from the thermal blast chamber and that is closed by a discharge valve. The discharge valve is disposed between the thermal blast chamber and the piston-driven compression chamber in a manner such that the discharge valve opens to enable the gas under increased pressure in the piston-driven compression chamber to be discharged towards the interrupting space via the channel when the increase in the pressure of the gases in the thermal blast chamber is larger than the increase in the pressure of the gases in the piston-driven compression chamber.

Owner:ALSTOM TECH LTD

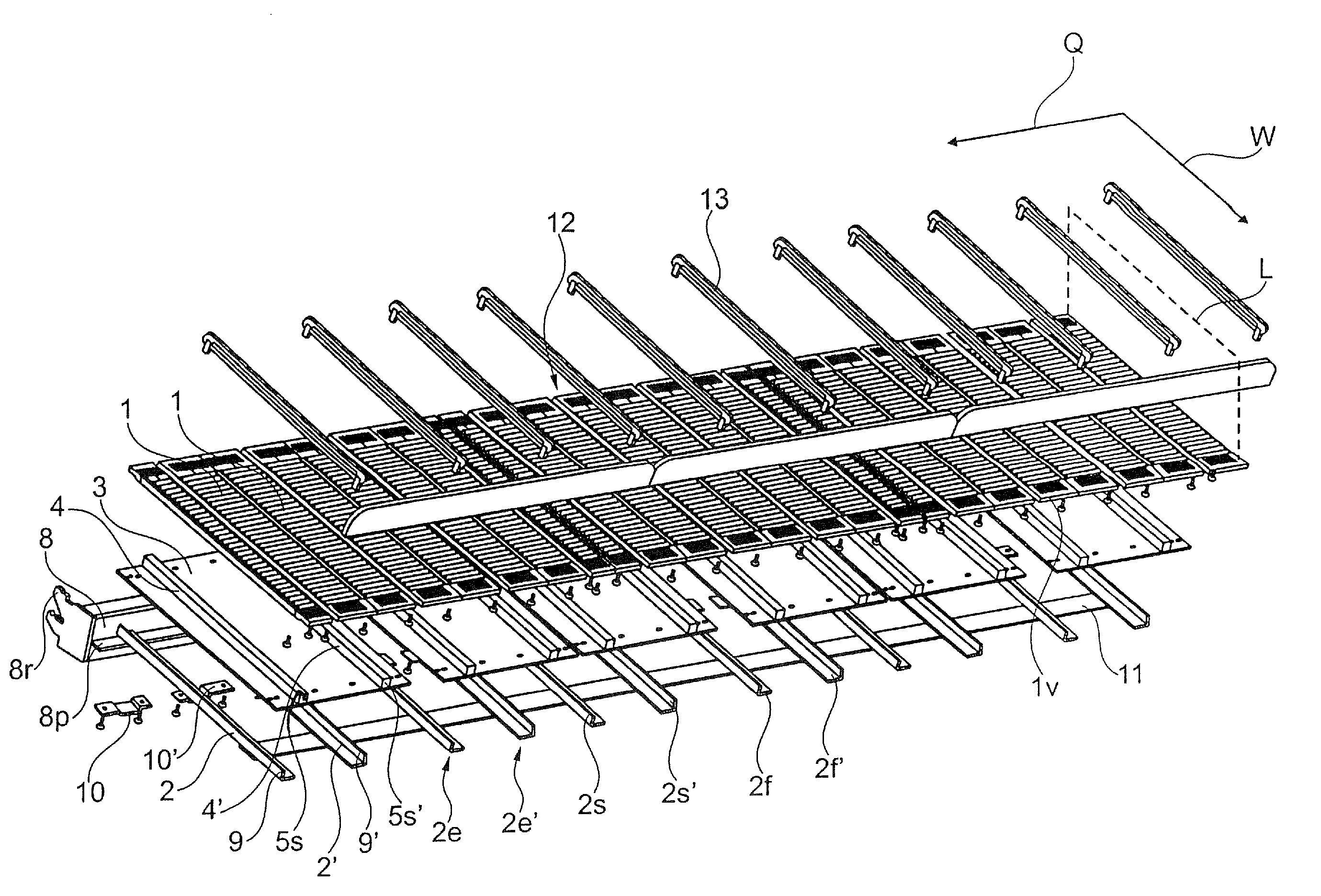

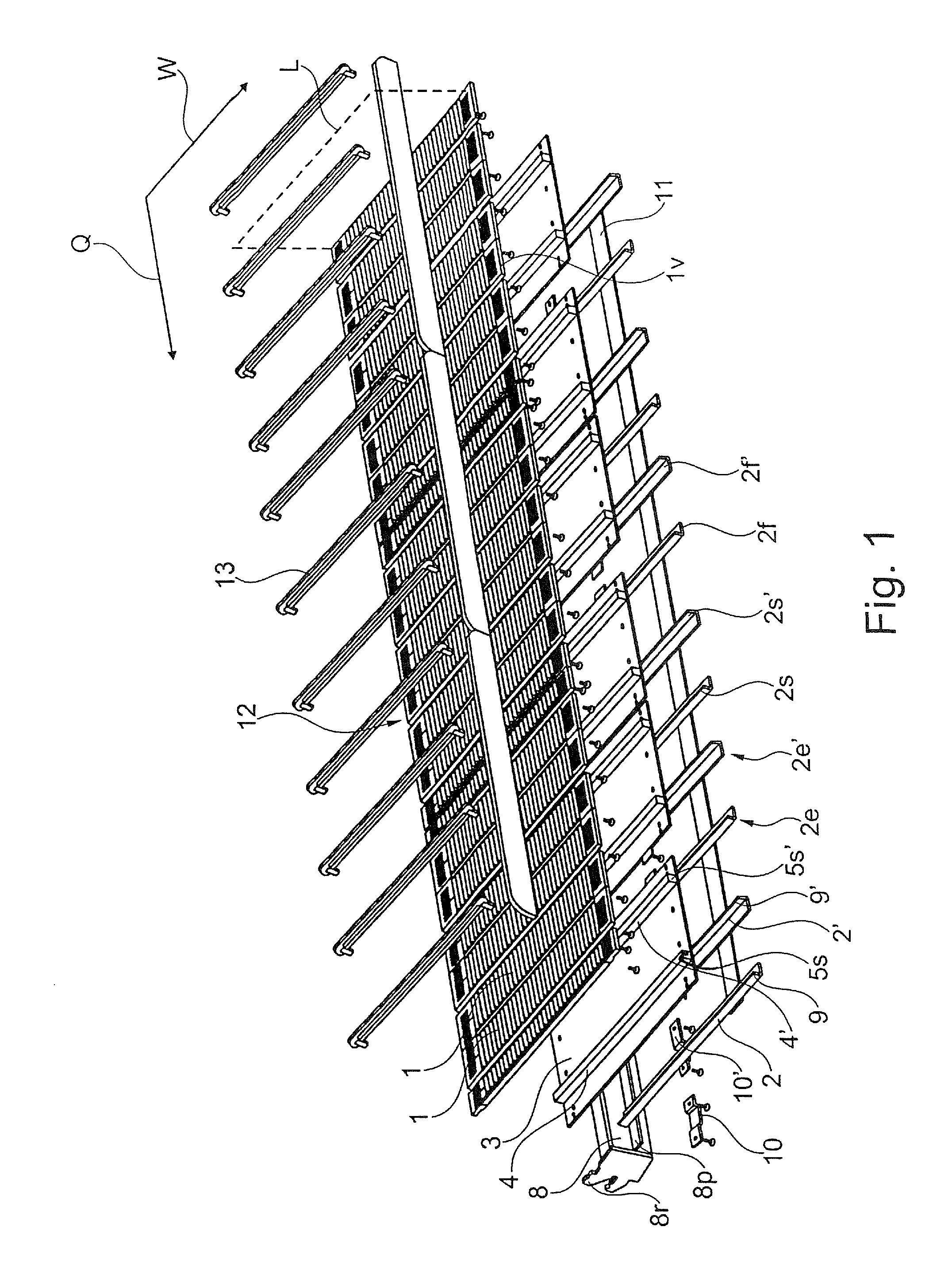

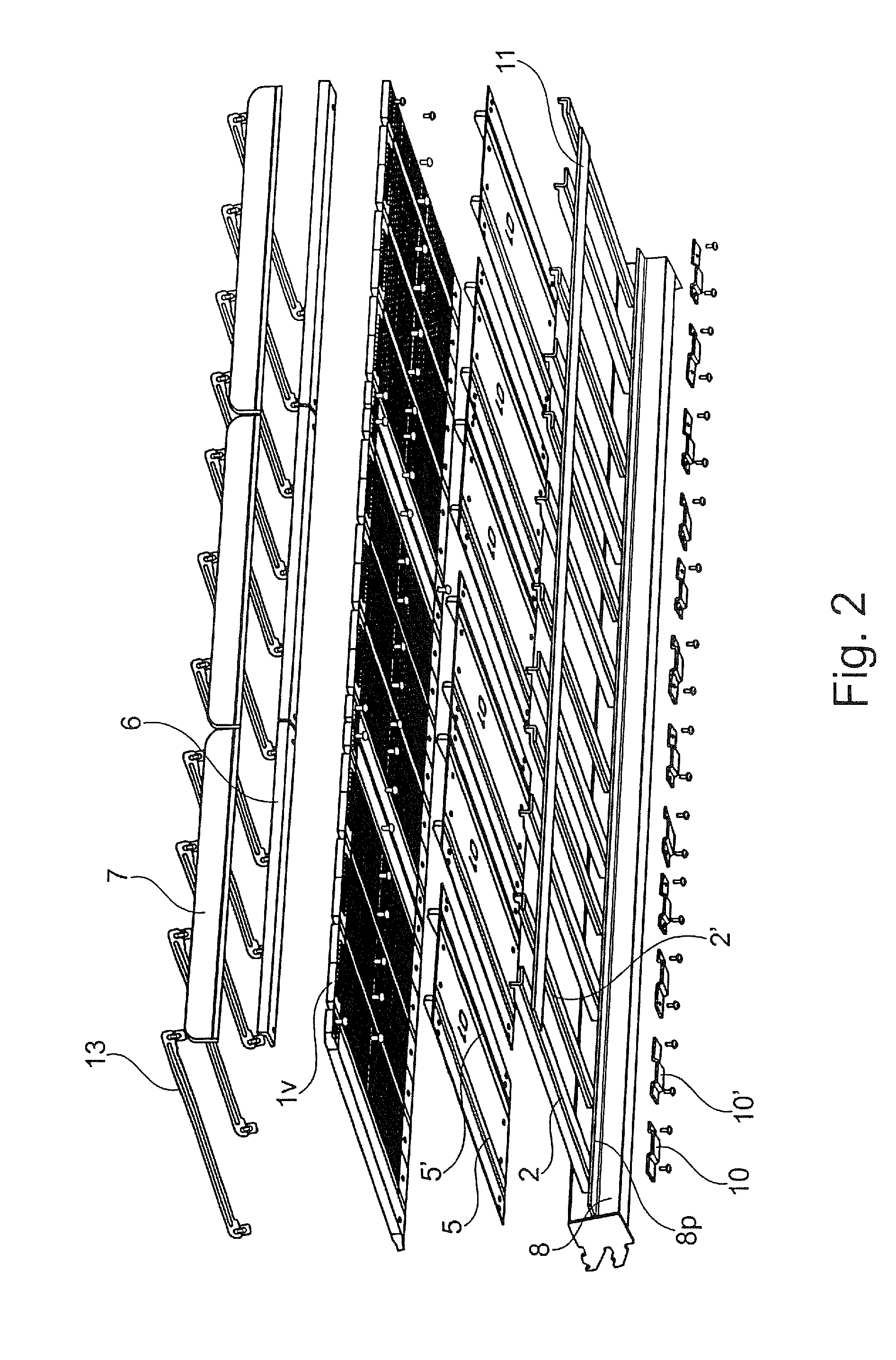

Goods feeding system for receiving and presenting goods

This invention relates to a goods feeding system for receiving and presenting goods and for receiving goods feeding attachments for automatic forwarding of goods in a goods feeding direction W with a support surface for receiving and holding goods feeding attachments, whereby the goods feeding system has a support surface length (L) along the goods feeding direction (W), and the support surface can be pulled out at least partially along the support surface length (L) in the goods feeding direction (W).

Owner:DIRK A BRUGMANN KUNST VERARBEITUNG

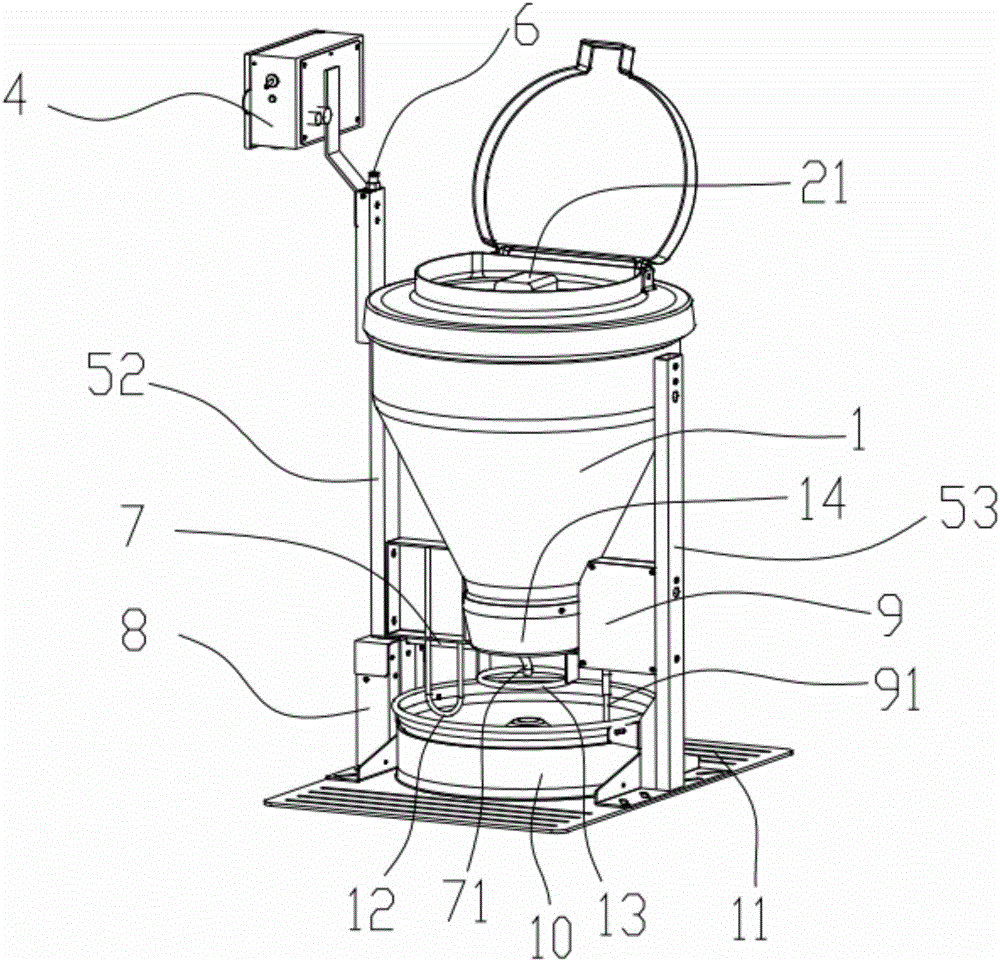

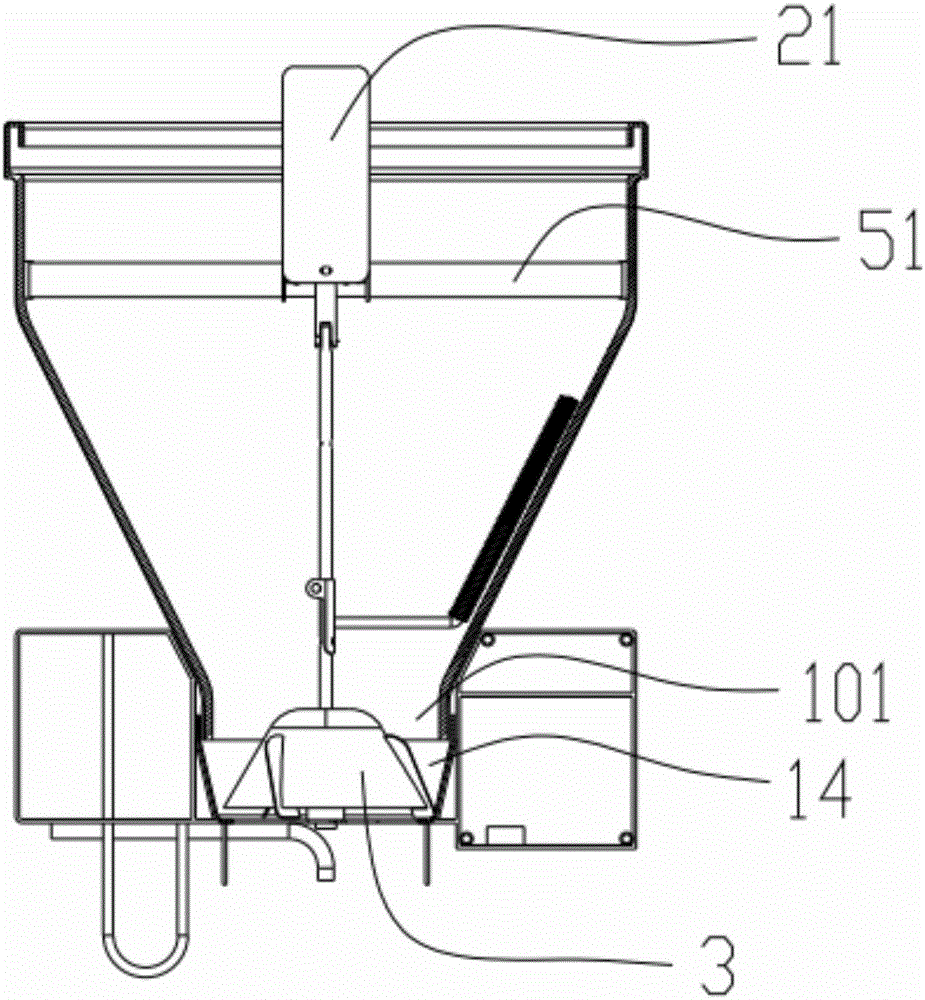

Intelligent food feeder

PendingCN106804449AAvoid emptyingPrevent archingAnimal watering devicesAnimal feeding devicesEngineeringFodder

The invention discloses an intelligent food feeder. The intelligent food feeder comprises a food barrel, an outer support, a motor, a rotary shaft and a food pushing device. The food barrel is fixed to the outer support, the motor, the rotary shaft and the food pushing device are disposed in the food barrel, the motor is fixed to an inner support of the food barrel, the top of the rotary shaft is connected with an output shaft of the motor, and the rotary shaft is connected with the food pushing device. The food pushing device comprises a discharging cone, food poking pieces and an arch breaking part, the rotary shaft is connected with the discharging cone, the food barrel is provided with a first discharging opening and a food stopping element, the discharging cone is arranged between the first discharging opening and the food stopping element, a discharge port allowing feed to fall off is formed in the bottom face of the food stopping element, a stirring rod of the arch breaking part is fixedly connected with the lower middle portion of the rotary shaft, the free end of the stirring rod is parallel to the wall of the food barrel, a gap exists between the free end and the barrel wall, the free end of the stirring rod is sleeved with a spring, and the spring is closely attached to the wall of the food barrel. Compared with the prior art, the food feeder has the advantages of preventing feed from arching, removing residues and being accurate in discharging amount.

Owner:SHENZHEN JINXINNONG FEED +1

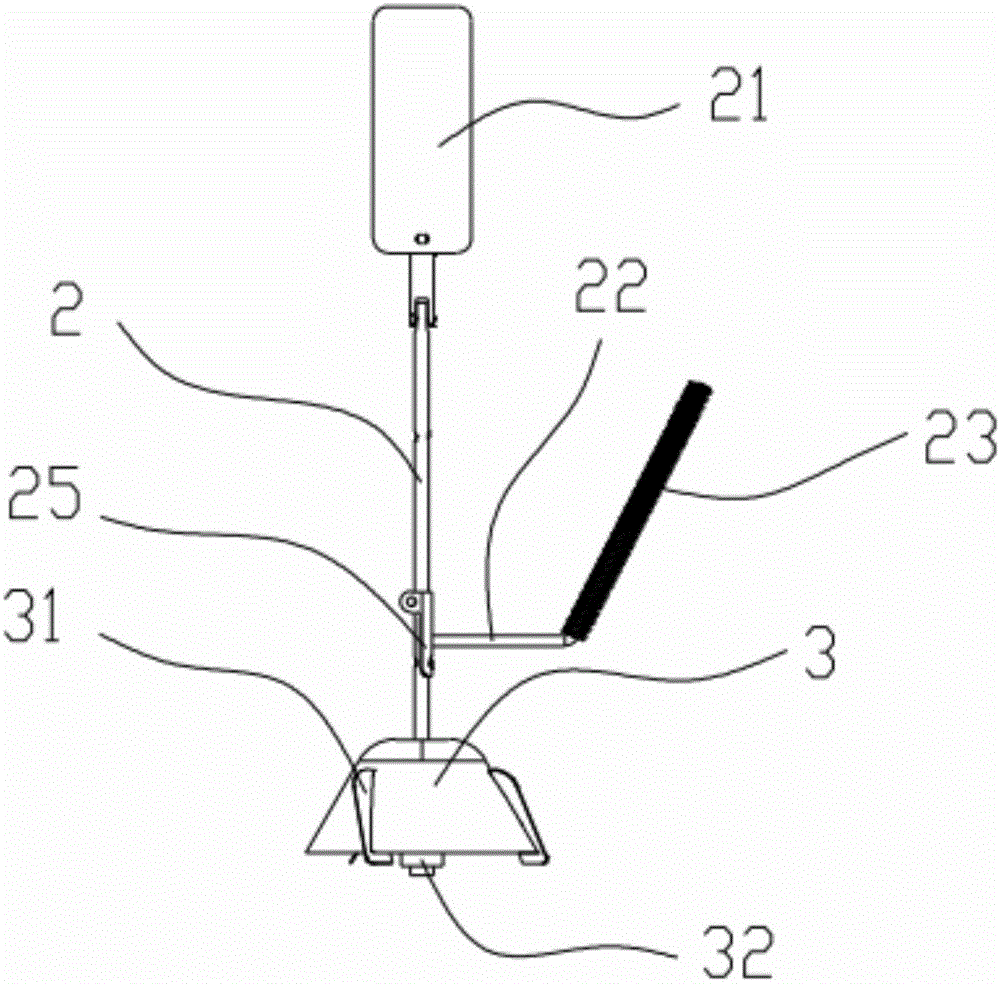

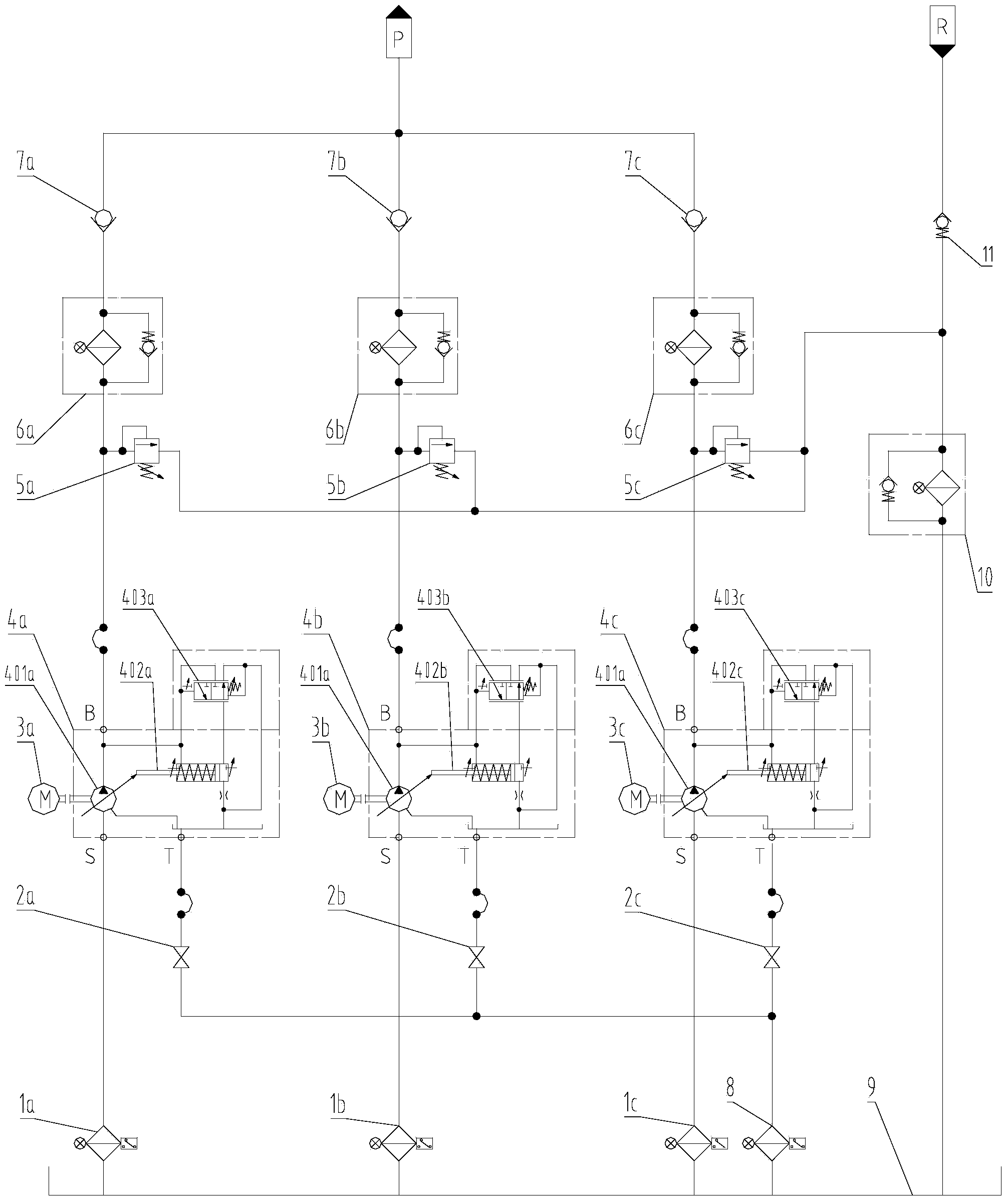

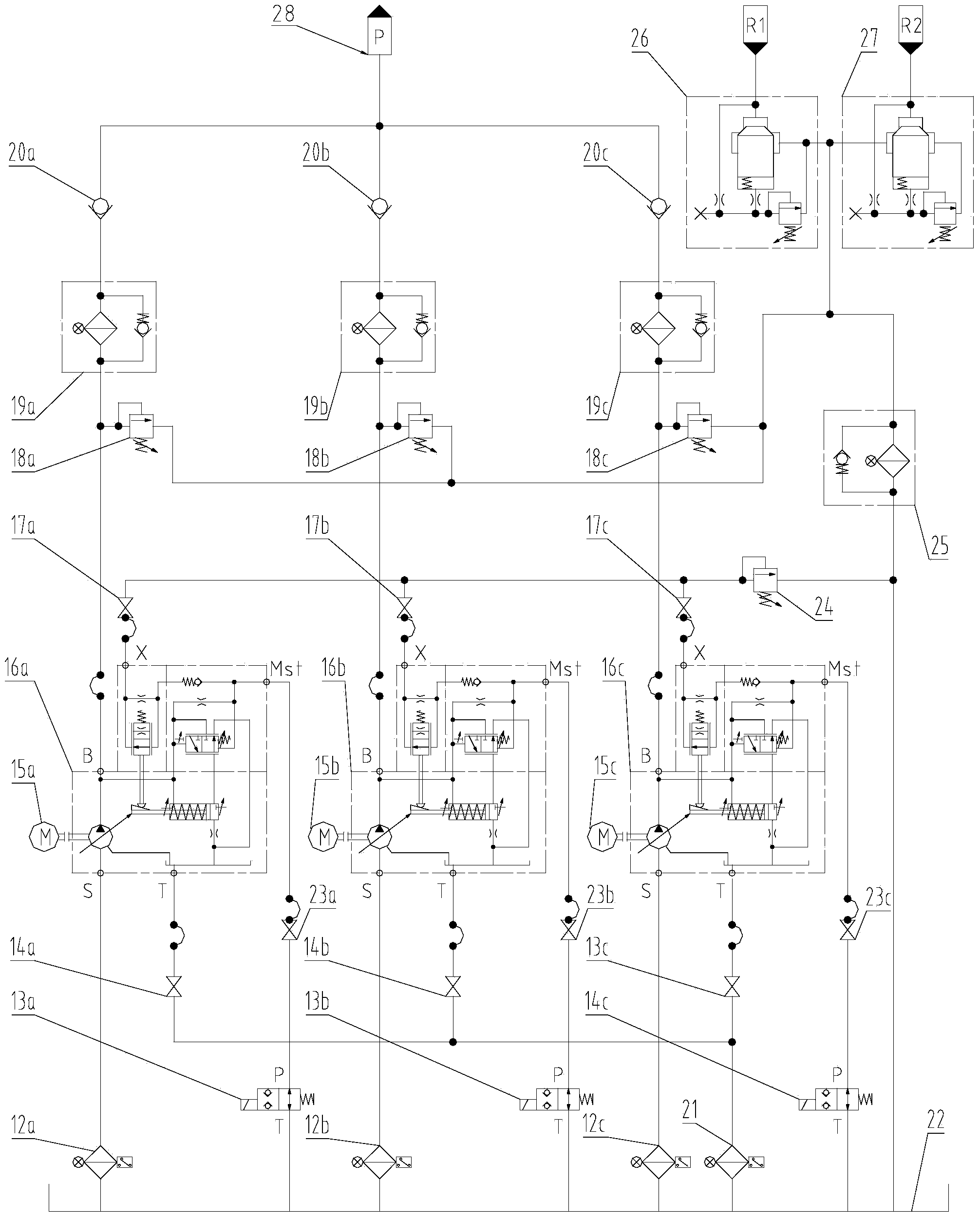

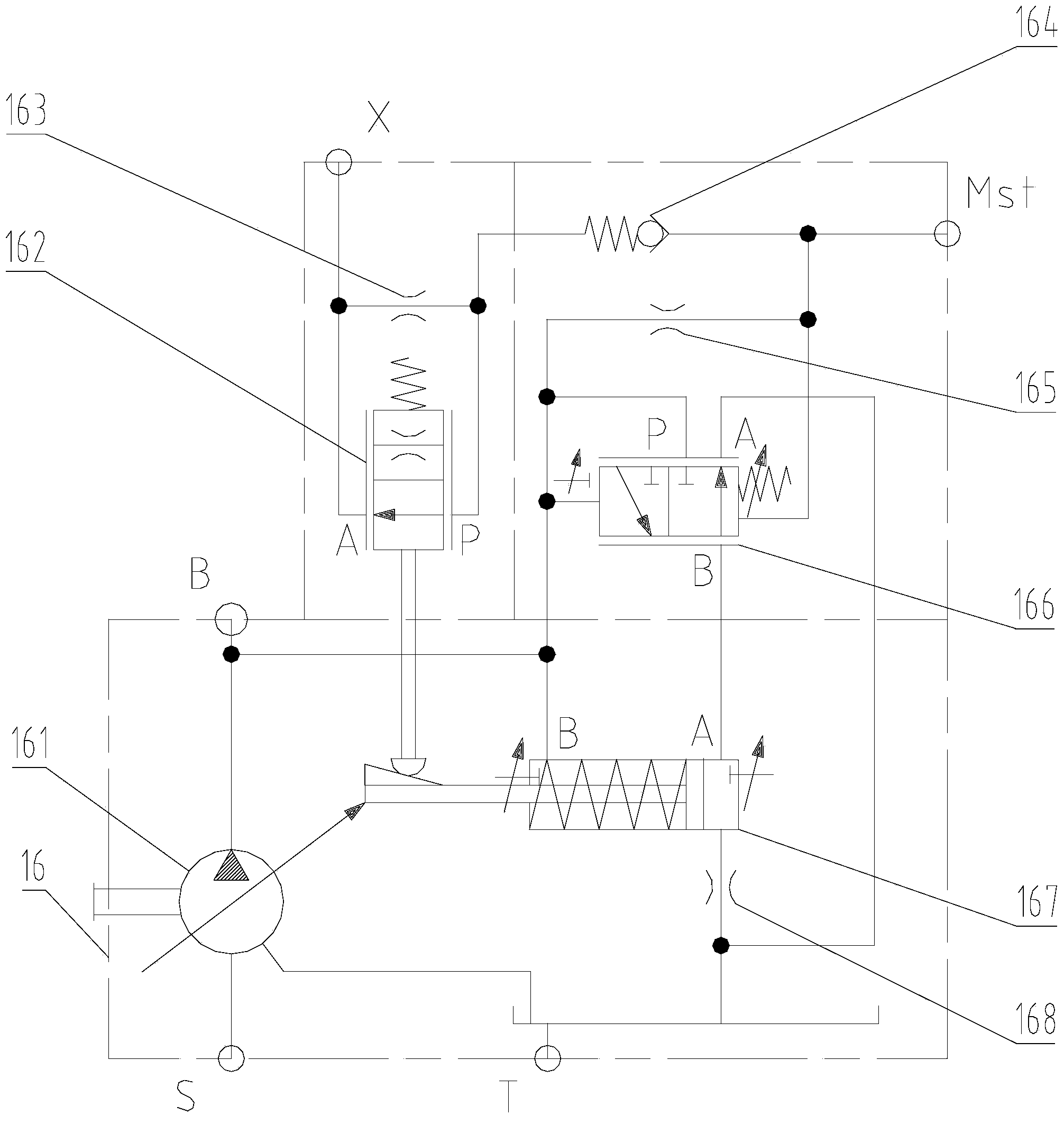

Constant pressure hydraulic station

ActiveCN103727102AImprove reliabilityExtend your lifeServomotor componentsFluid-pressure actuator componentsThermodynamicsWell drilling

The invention relates to the field of offshore drilling equipment, and specifically relates to a constant pressure hydraulic station. The constant pressure hydraulic station comprises an oil box (22), an overflow valve (24) and at least one set of pump group, wherein each pump group comprises an electromagnetic valve (13), an electromotor (15) and a constant pressure pump (16); each electromotor (15) is connected with the corresponding constant pressure pump (16), an oil absorbing opening S of each constant pressure pump (16) is connected with the oil box (22), and a drainage opening T of each constant pressure pump (16) is connected with the oil box (22). When the constant pressure hydraulic station comprises two or more pump groups, outlets B of constant pressure pumps (16) of the pump groups are connected in parallel to form a pressure opening (28) of the hydraulic pressure station; each constant pressure pump (16) also comprises a first control opening (X) and a second control opening (Mst). The constant pressure hydraulic station provided by the invention has the advantages that when the hydraulic station starts, the electromotors and the constant pressure pumps can start in a no-load manner and with low pressure, the power is small, the constant pressure hydraulic station without impact starts, and the reliability and service lives of the electromotors and the constant pressure pumps are effectively improved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

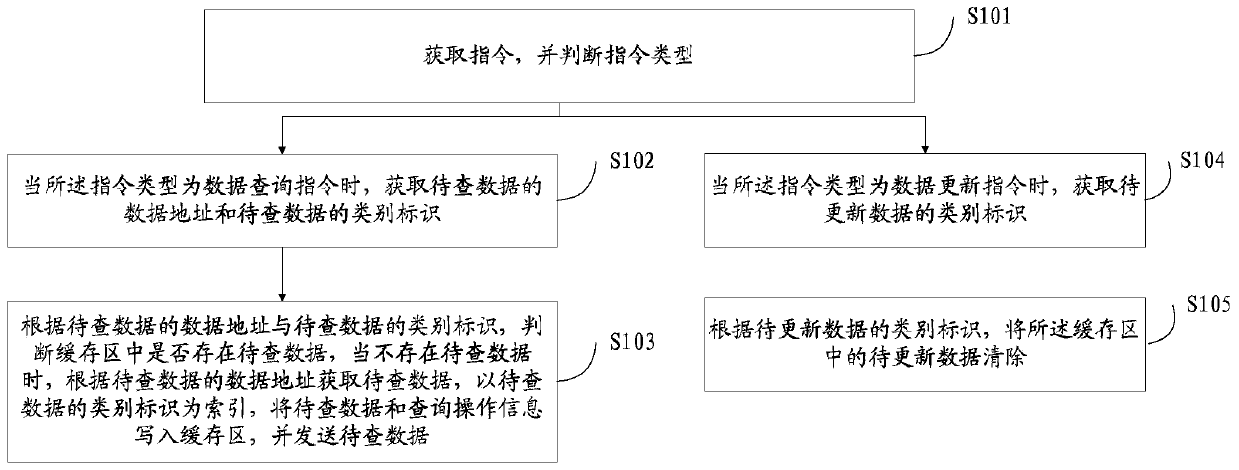

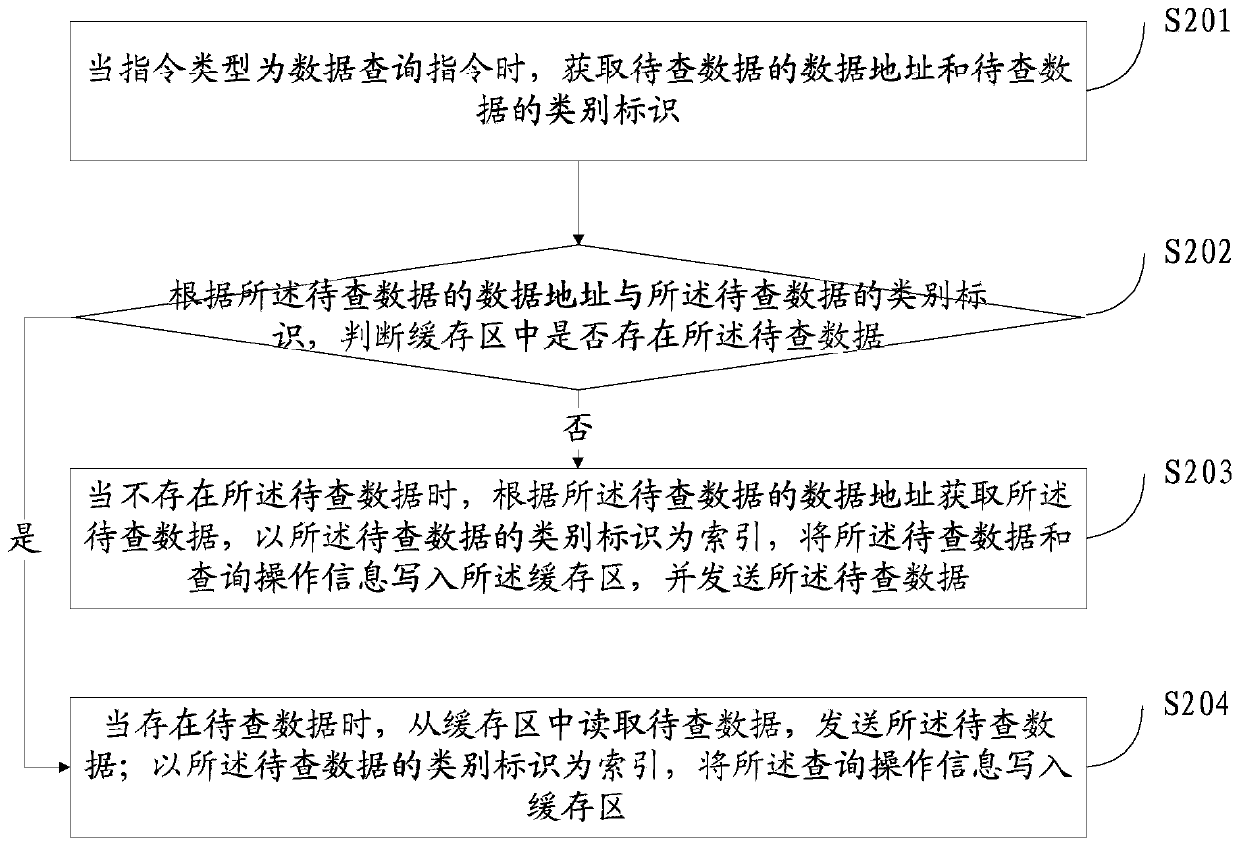

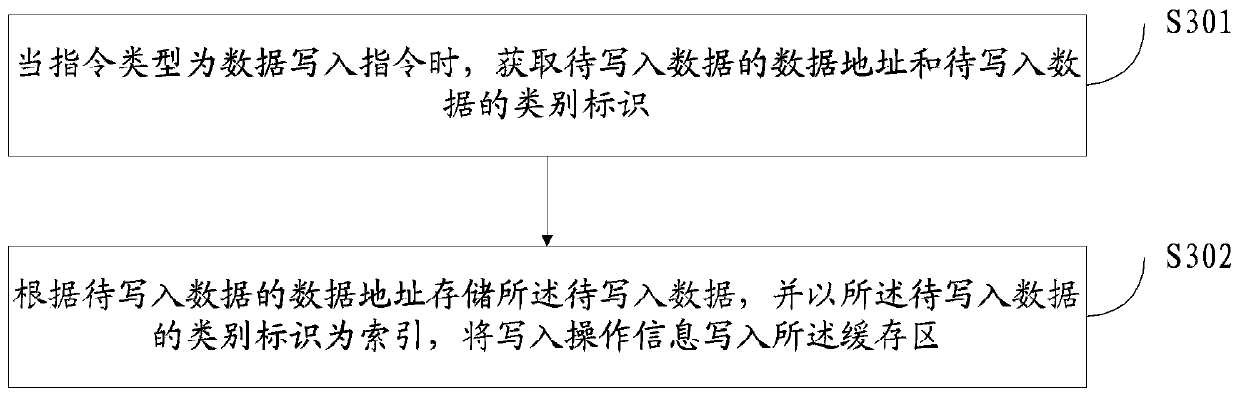

Cache data management method and device, storage medium and electronic equipment

PendingCN110737680AAvoid emptyingImprove maintenance efficiencyDatabase updatingSpecial data processing applicationsEngineeringData management

The invention discloses a cache data management method and device, a storage medium and electronic equipment, and relates to a cache management technology. According to the specific scheme, the methodcomprises the steps of obtaining an instruction and interpreting an instruction type; when the instruction type is a data query instruction, obtaining a data address and a category identifier of theto-be-queried data; judging whether to-be-queried data exists in the cache region or not according to the data address and the category identifier, acquiring the to-be-queried data according to the data address when the to-be-queried data does not exist, writing the to-be-queried data and the query operation information into the cache region by taking the category identifier as an index, and sending the to-be-queried data; when the instruction type is a data updating instruction, obtaining a type identifier of to-be-checked data cleared by the data updating instruction; and clearing the to-be-queried data taking the category identifier as the index in the cache region and the query operation information. The influence on the data query function can be avoided, and the maintenance efficiency and query efficiency of the stored data are improved.

Owner:BEIKE TECH CO LTD

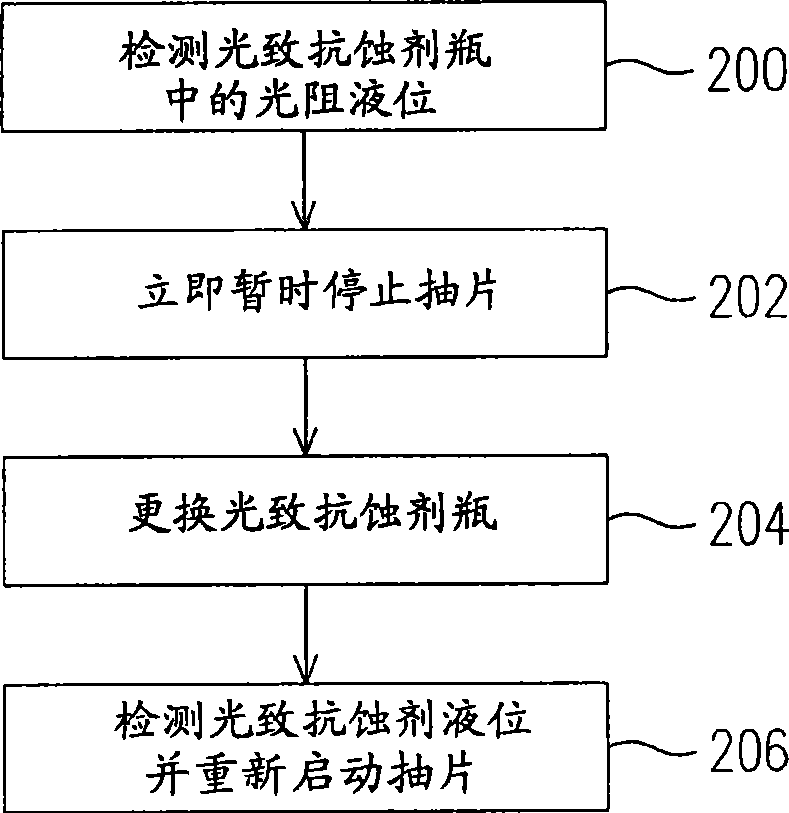

Detecting and early-warning system for liquid and liquid level and method

InactiveCN101364046APrecisely control usageIncrease usagePhotomechanical coating apparatusMachines/enginesEarly warning systemEngineering

The invention discloses a liquid / liquid-level detection / early-warning system and a liquid / liquid-level detection / early-warning method. The liquid / liquid-level detection / early-warning system is arranged in a liquid transportation device. Inside the liquid transportation device, a liquid steel cylinder for accommodating a liquid tank, a liquid temporary-storage cylinder and a discharge device are connected in sequence via a pipeline. The liquid / liquid-level detection / early-warning system comprises at least one pipeline-inside liquid sensor and at least one steel cylinder-inside liquid level sensor, wherein the pipeline-inside liquid sensor is arranged between the liquid temporary-storage cylinder and the discharge device, and the steel cylinder-inside liquid level sensor is arranged on the lateral wall of the liquid steel cylinder. The steel cylinder-inside liquid level sensor is provided with a detector for detecting whether the liquid level of the liquid tank inside the liquid steel cylinder reaches a detecting position.

Owner:POWERCHIP SEMICON CORP

Device for delivering fuel

ActiveUS8590563B2Good capture and returnAvoid emptyingPump componentsUsing liquid separation agentNozzle

The present invention includes a device that comprises a suction jet pump, that is arranged in a reservoir pot and has a nozzle and a mixing duct provided downstream the nozzle and arranged perpendicular to a pot base of the reservoir pot. The outlet of the mixing duct has a deflection means, which the jet of the nozzle impinges when the mixing duct is unfilled and has an additional volume formed at the outlet of the mixer by an offset widening of the mixer duct. This additional volume prevents the column of liquid in the mixing duct from being forced out by the propulsion jet of the suction jet pump. Thus the lead time of the suction jet pump is approximately equal in all operating states.

Owner:ROBERT BOSCH GMBH

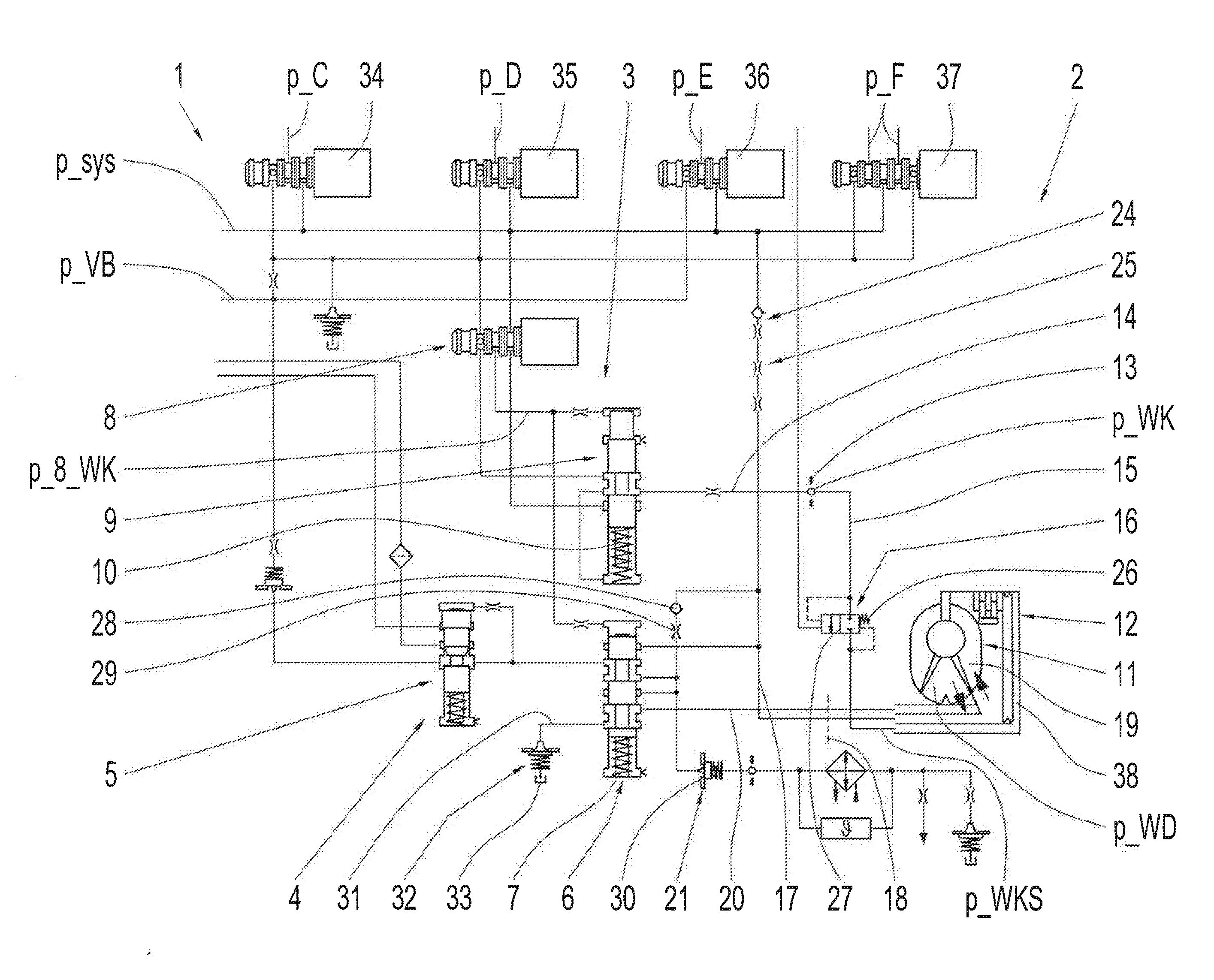

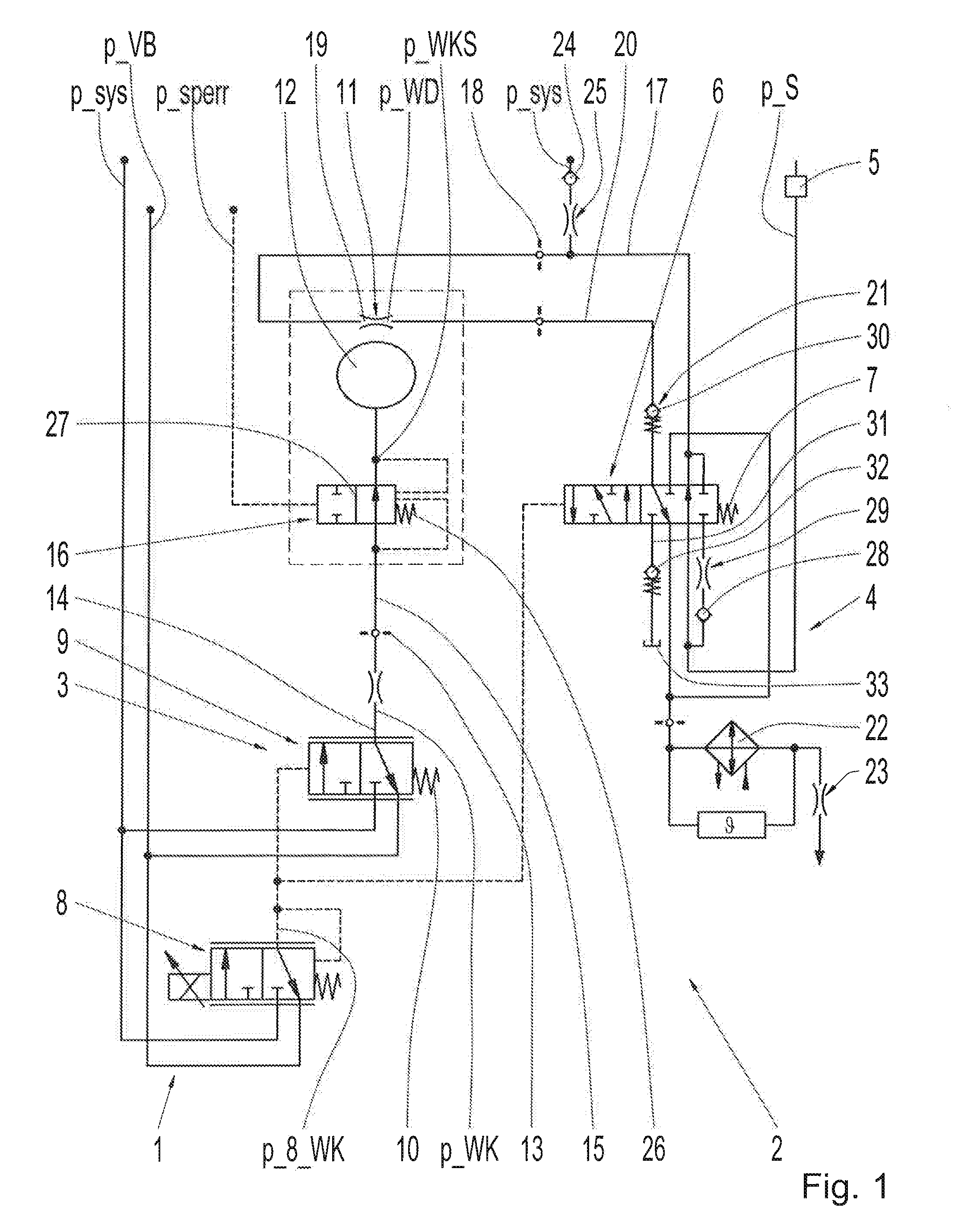

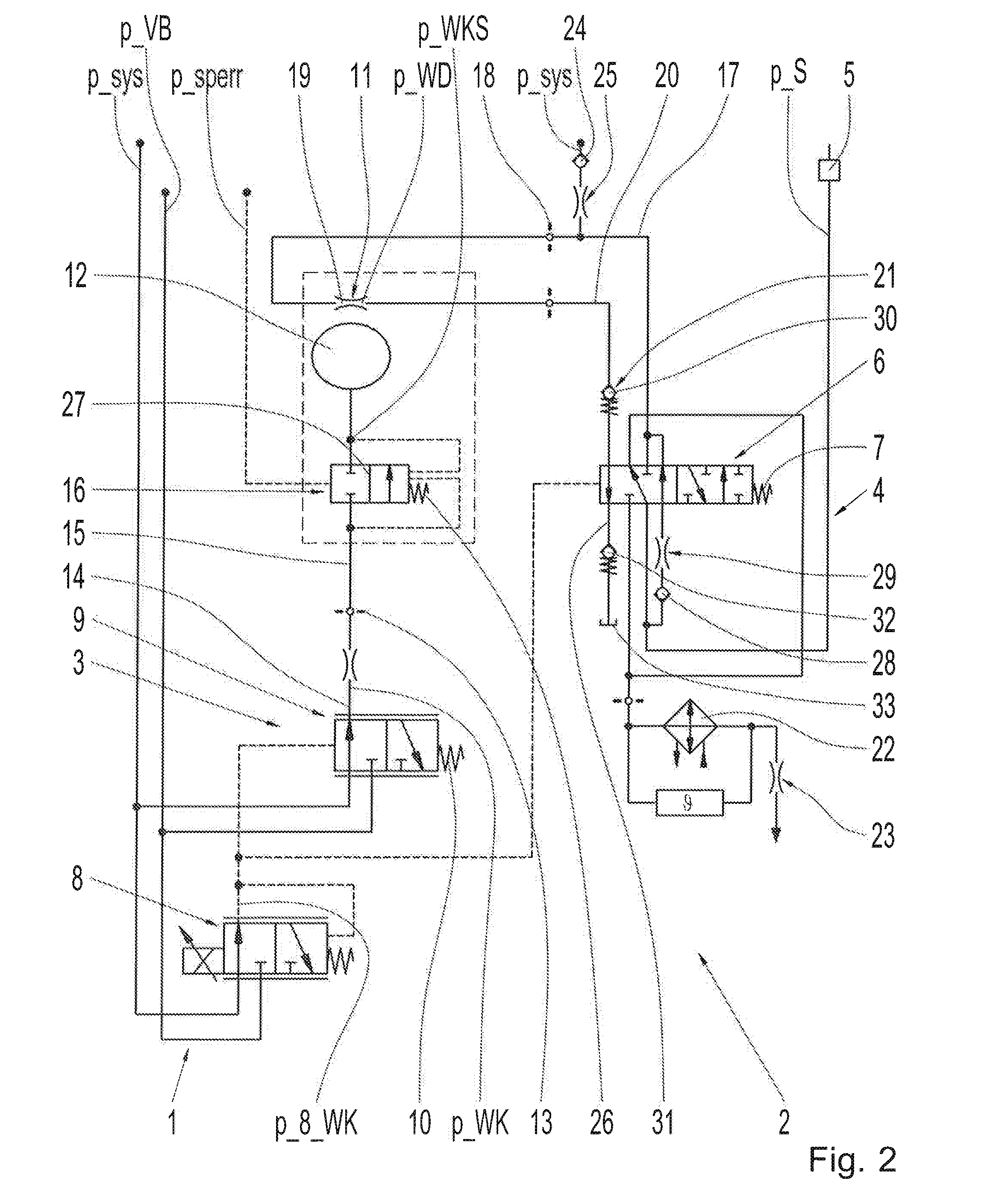

Transmission Device with a Hydraulic System

InactiveUS20170009866A1Increase demandAvoid accumulationFluid actuated clutchesGearing controlHydraulic fluidClutch

A hydraulic system for a transmission device includes a primary pressure circuit and a secondary pressure circuit suppliable with hydraulic fluid from a defined saturation condition of the primary pressure circuit. A converter lock-up clutch is subjected to an operating pressure by a converter clutch valve. An inner torus chamber is suppliable with hydraulic fluid at a converter pressure of the secondary pressure circuit by a converter switching valve and by a valve device and a throttle device of the primary pressure circuit. The throttle device of the primary pressure circuit is downstream of the valve device of the primary pressure circuit.

Owner:ZF FRIEDRICHSHAFEN AG

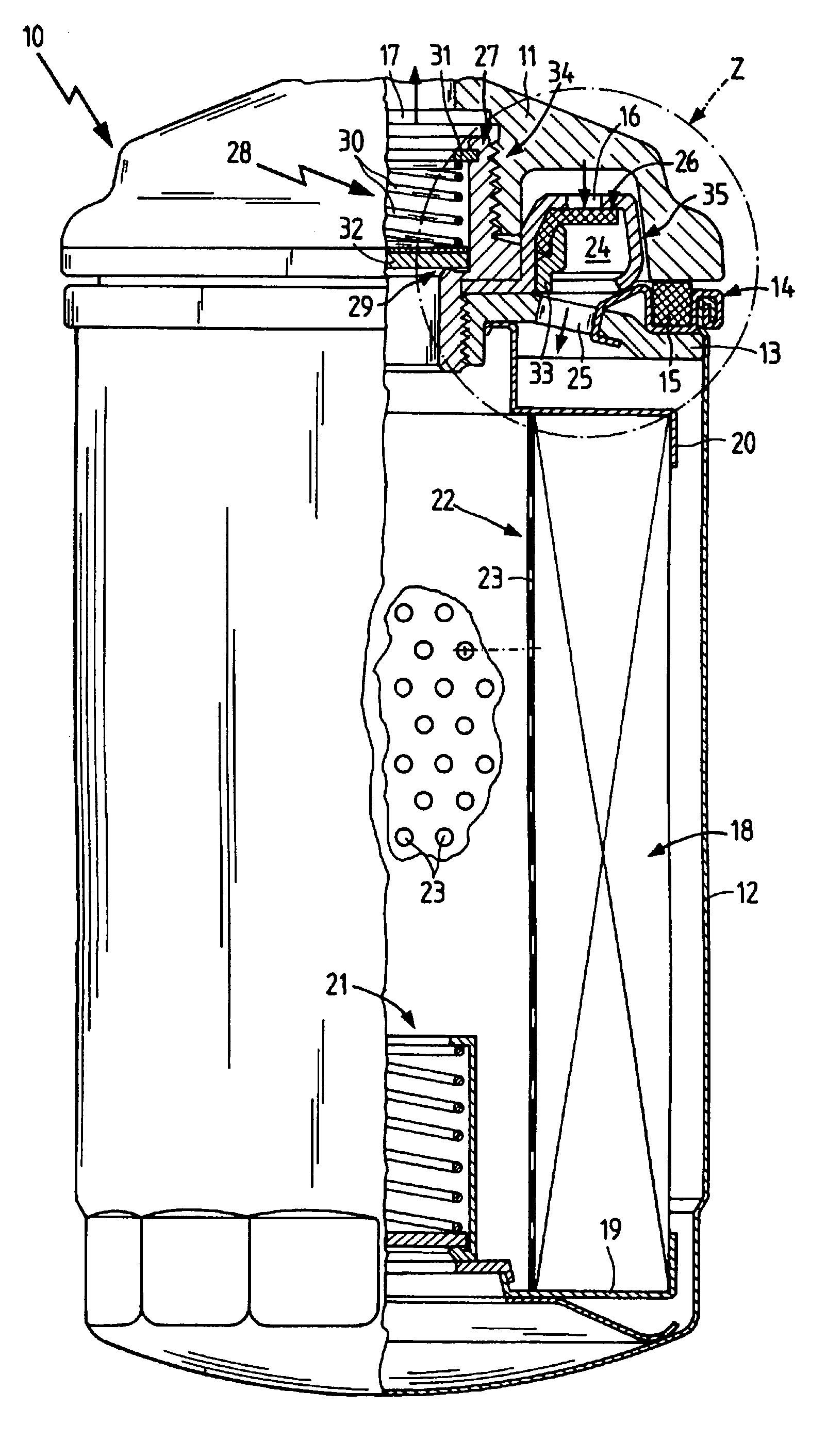

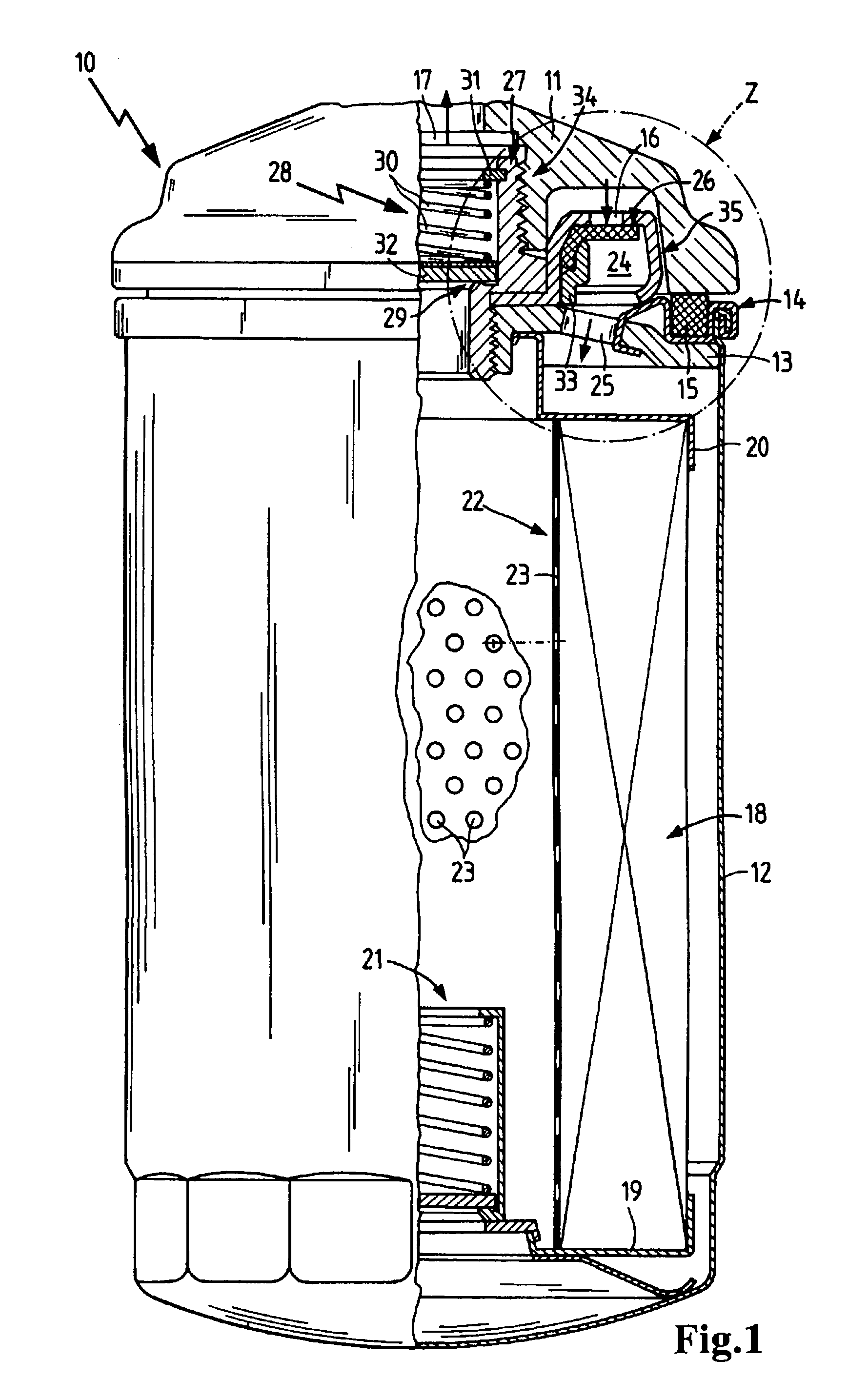

Liquid filter

ActiveUS20060131225A1Prevent leakageSimple and cost-effective to manufactureSedimentation separationCartridge filtersEngineeringInternal combustion engine

A replaceable liquid filter, particularly for the lubricating oil of an internal combustion engine, having a substantially cup-shaped housing with a concentrically disposed outlet opening for the filtered liquid and at least one inlet opening for the liquid to be filtered and a filter element sealingly disposed between the inlet opening and the outlet opening. The housing is connected to a top plate, and the top plate is connected to an end plate. A connector for releasably coupling the replaceable liquid filter to a mating part is disposed concentrically in the region of the cover plate, such that the connector extends axially beyond the contour of the replaceable liquid filter.

Owner:MANN HUMMEL GMBH

Brewing apparatus for a coffee machine

A brewing apparatus for a coffee machine, in particular for domestic use, having a housing which encloses a brewing chamber and has a nozzle assembly arranged on one side and a base with an outflow for the brewed fluid arranged on an opposite side. A flexible sealing element is provided between the nozzle assembly and housing. The brewing chamber is arranged on one side and a fluid-fillable chamber is arranged on the opposite side. The sealing element is moveable in the direction of the brewing chamber via an increase in pressure in the chamber. The chamber is connected to a venting valve in order to relieve the sealing element of loading.

Owner:ELDOM ROTHRIST

Regulation of an air spring

A device (1) having a pneumatic spring (2) for supporting a load on a bogie of a rail vehicle having a compressed air supply (4) which is pneumatically connected to the air spring (2) via an air spring valve (6) in order to vent and to fill the air spring (2) with compressed air, and having a control unit which is designed to adjust the air volume and / or the air pressure in the air spring (2), a compressed air line (3) making available the pneumatic connection between the compressed air supply (4), air spring (2), air spring valve (6) and control unit - in which unnecessary filling and venting of the air spring (2) is prevented, means are proposed for limiting the volume flow (7) into the compressed air line (3) as a function of the speed of the rail vehicle.

Owner:SIEMENS MOBILITY GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com