Detecting and early-warning system for liquid and liquid level and method

An early warning system, liquid technology, applied in liquid/fluid solid measurement, measuring device, liquid level indicator, etc. Reduce residual liquid, save manufacturing cost, and avoid the effect of pipeline emptying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

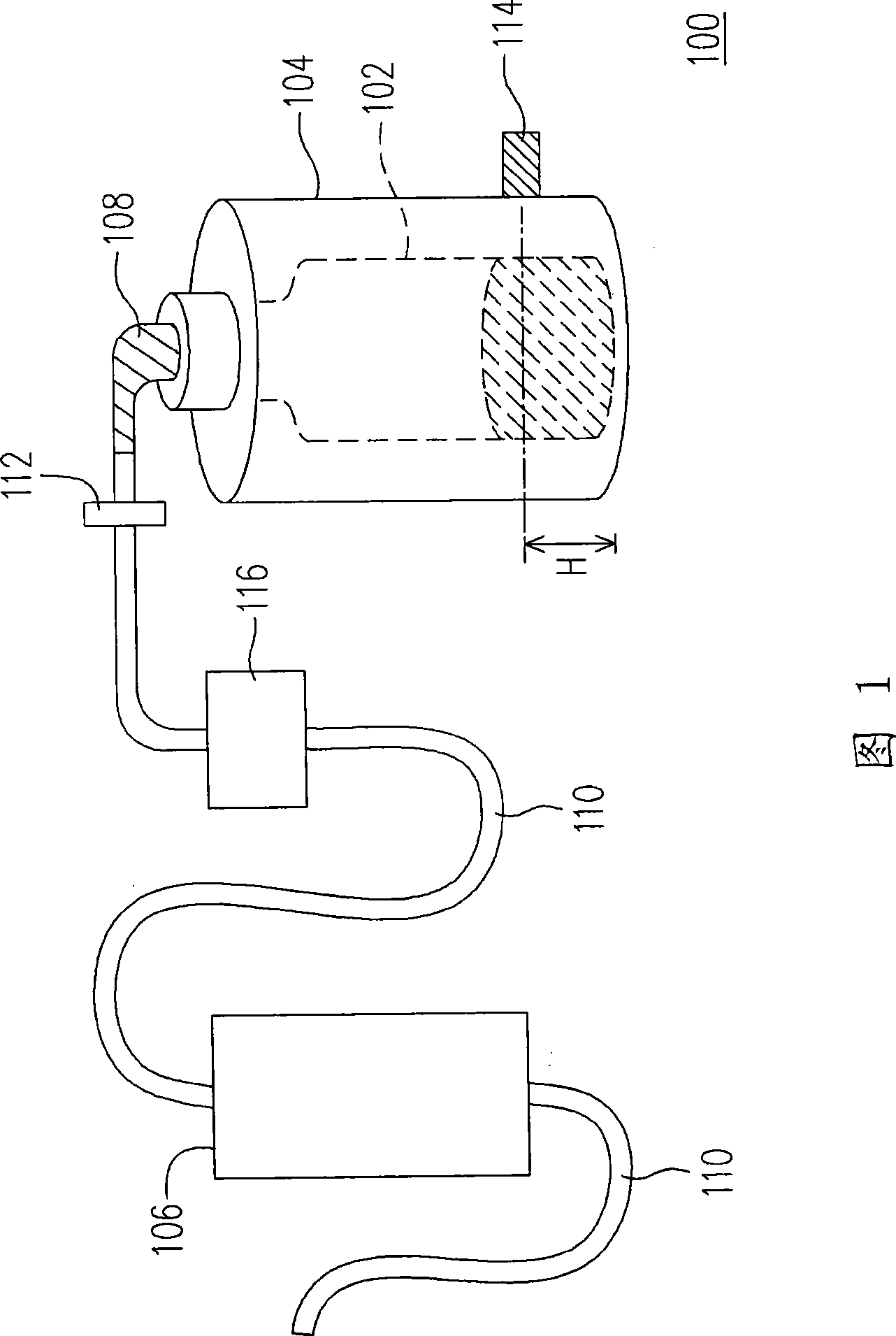

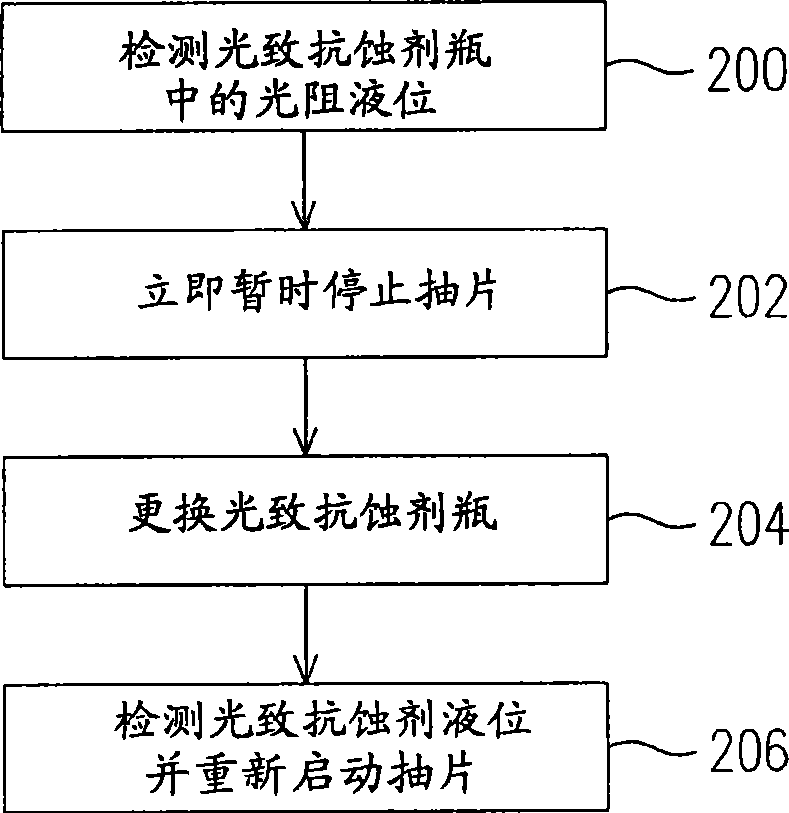

[0039] In the liquid and liquid level detection and early warning system of the present invention, at least one liquid level sensor in the cylinder is additionally configured, so as to avoid the known pipe spraying, the inability to precisely control the amount of photoresist and The remaining amount and the bubbles contained in the photoresist.

[0040] Hereinafter, examples are given to illustrate the liquid and liquid level detection and early warning system of the present invention. In the following embodiments, the application of the liquid and liquid level detection and early warning system of the present invention to the photoresist coating process equipment is taken as an example for illustration, but it is not limited to this. Of course, the liquid and liquid level detection and early warning system of the present invention can be used in high-tech industries such as semiconductor factories and optical power plants, and can also be applied to other appropriate fields, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com