Patents

Literature

48results about How to "Precisely control delivery volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

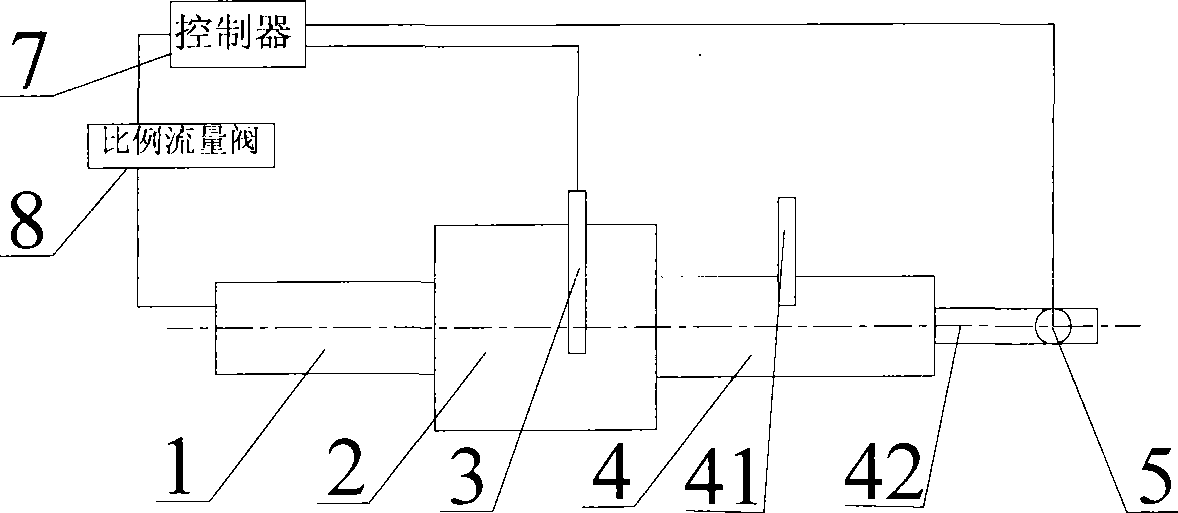

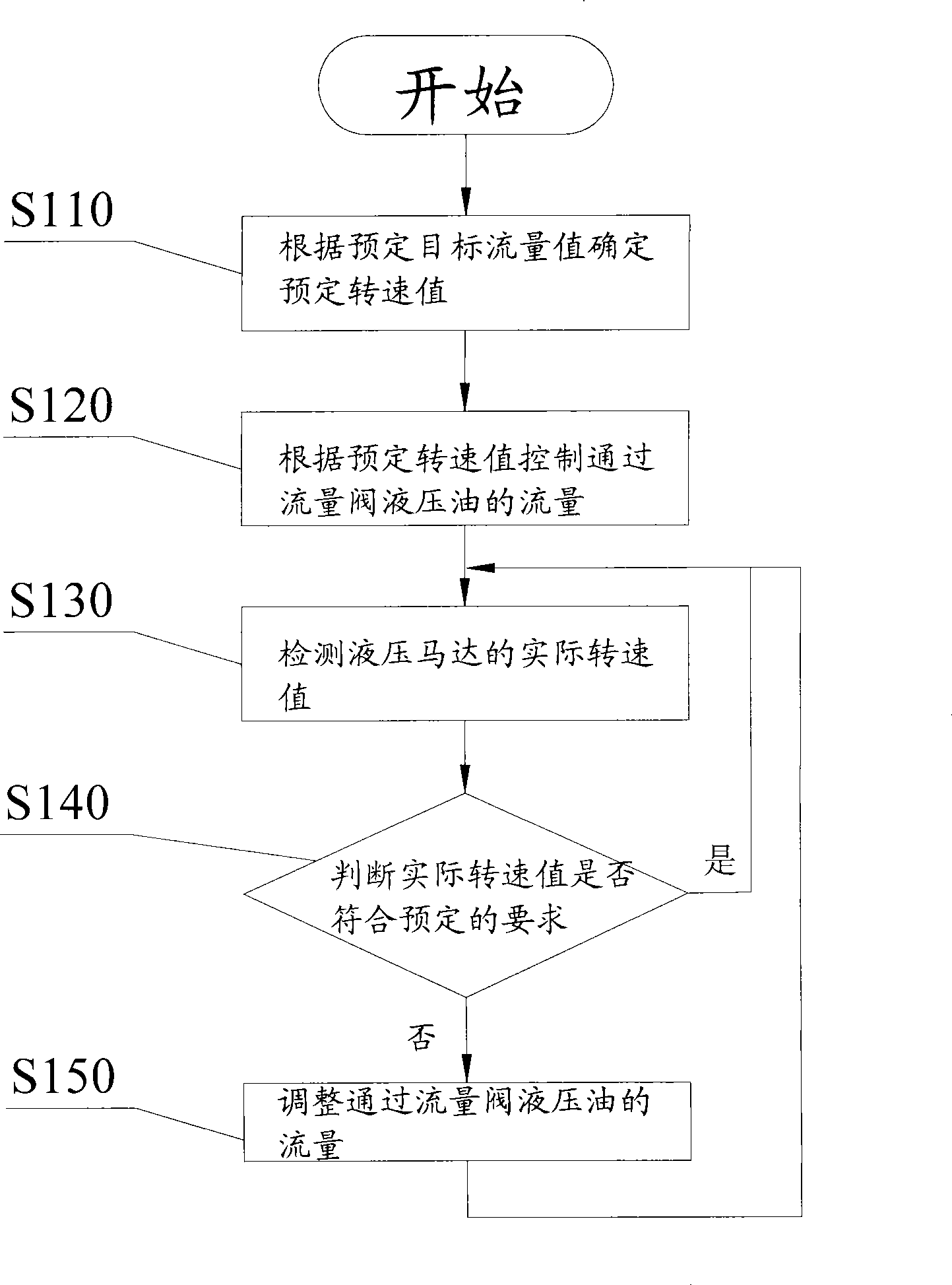

Metering control system, concrete spraying machine and metering control method

InactiveCN101398690ALow costPrecise control of output flowServomotor componentsFlow control using electric meansHydraulic motorControl system

The invention discloses a measure control system and a measure control method. The disclosed measure control system comprises a controller, a measure pump, a proportional flow valve and a hydraulic motor. The proportional flow value and the hydraulic motor are connected in a hydraulic oil path of a hydraulic system in series. The controller can control the hydraulic oil flux passing through the proportional flow valve according a preset rotate speed. A hydraulic motor output shaft is connected with the measure pump and can drive the measure pump to rotate. The disclosed measure control system also comprises a rotate speed sensor which is connected with the controller. The rotate speed sensor can outputs a rotate speed signal to the controller according to the rotate speed of the hydraulic motor. The controller can detect the actual rotate speed value of the hydraulic motor according to the rotate speed signal. The controller can judge whether the actual rotate speed value meets the preset requirement and changes the hydraulic oil flux passing through the proportional flow valve according to the judgement result. The measure control system and the measure control method provided by the invention are fit for the measure control towards liquid flux.

Owner:SANY HEAVY IND CO LTD (CN)

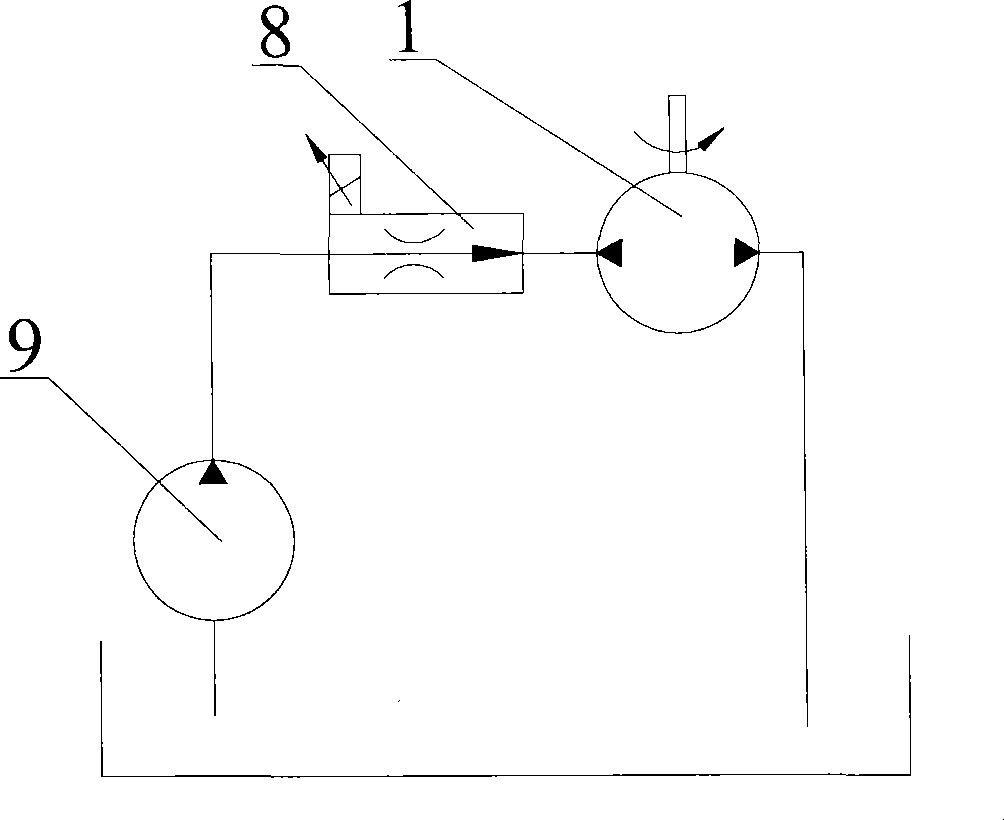

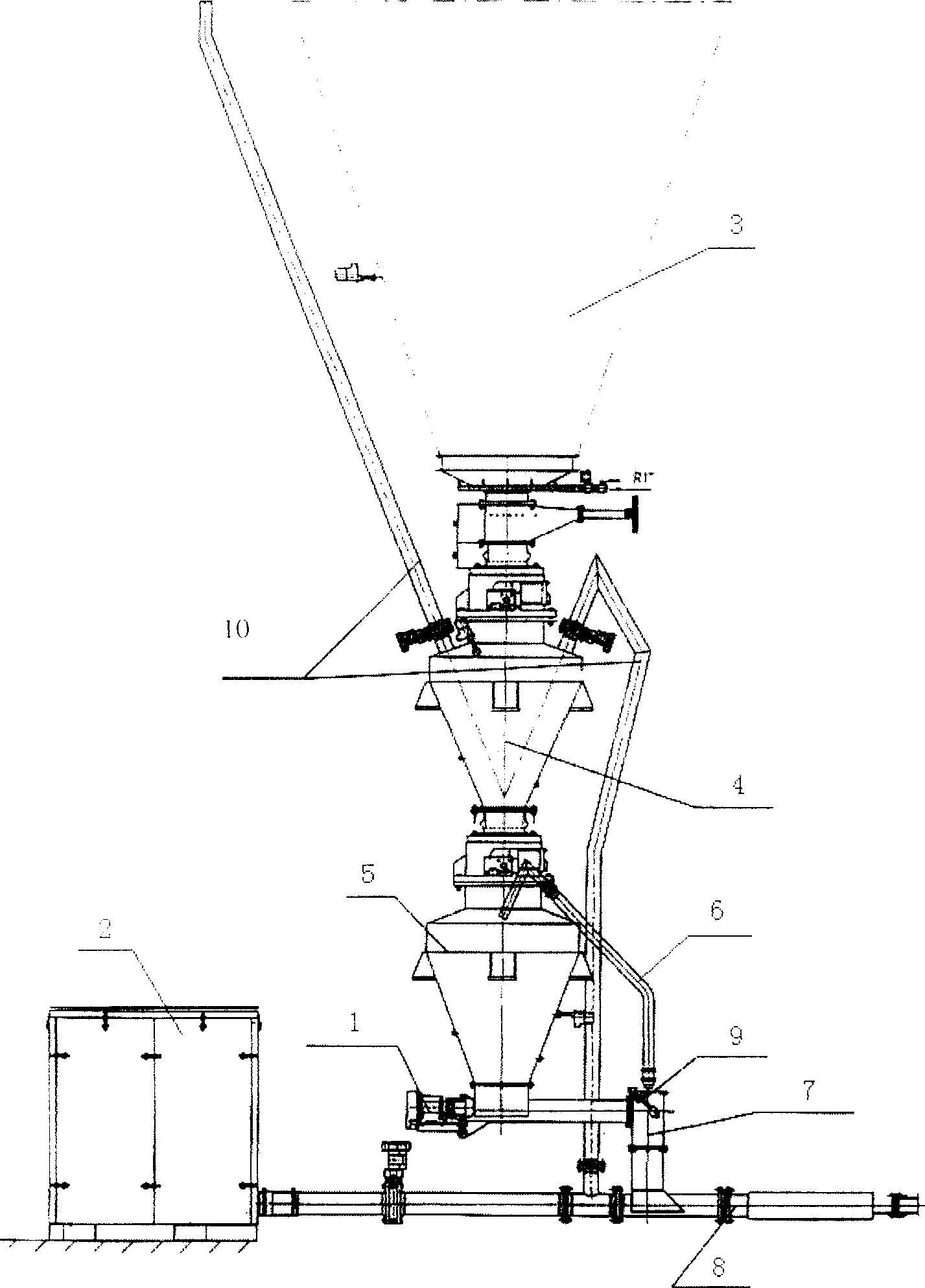

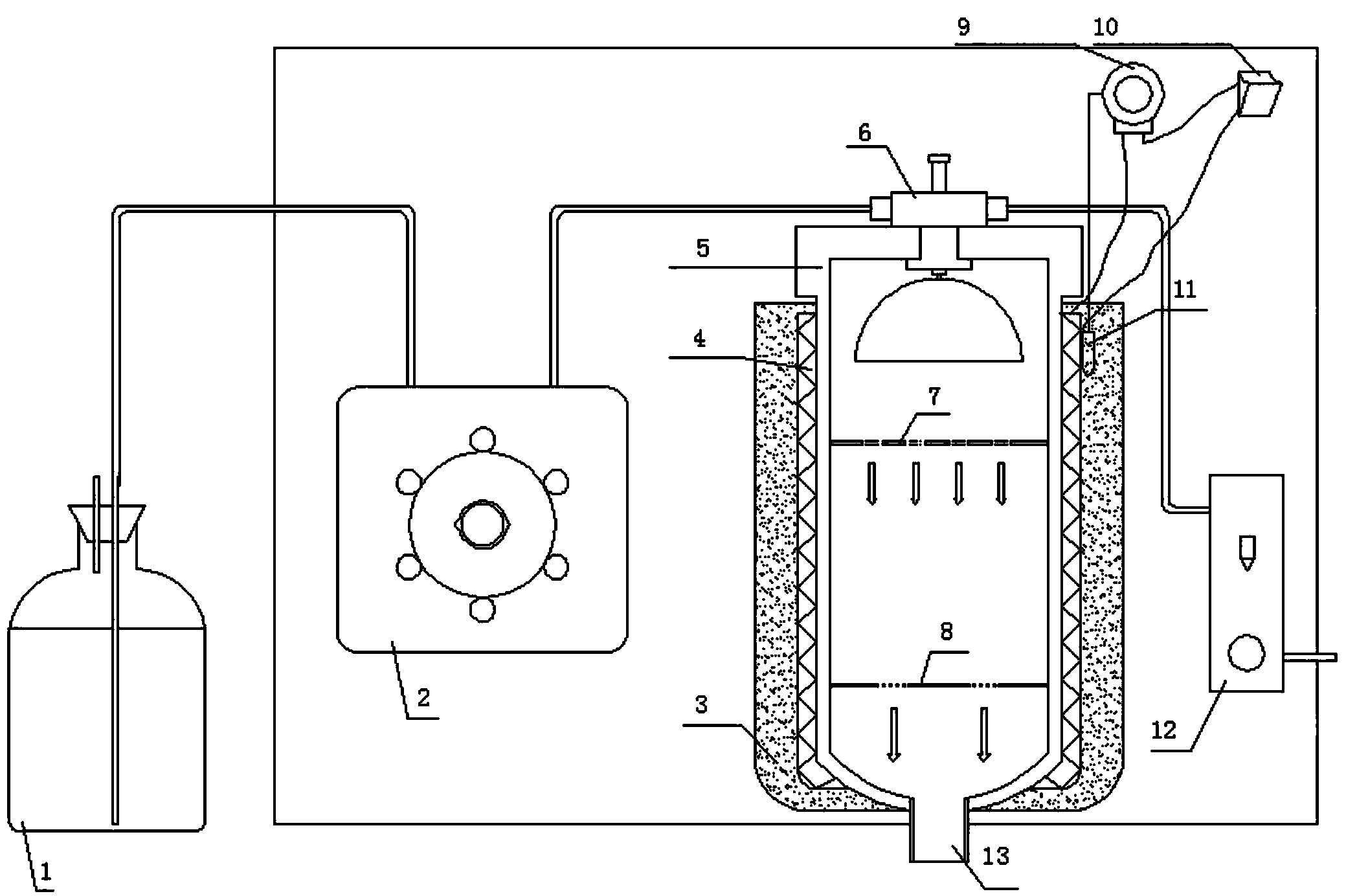

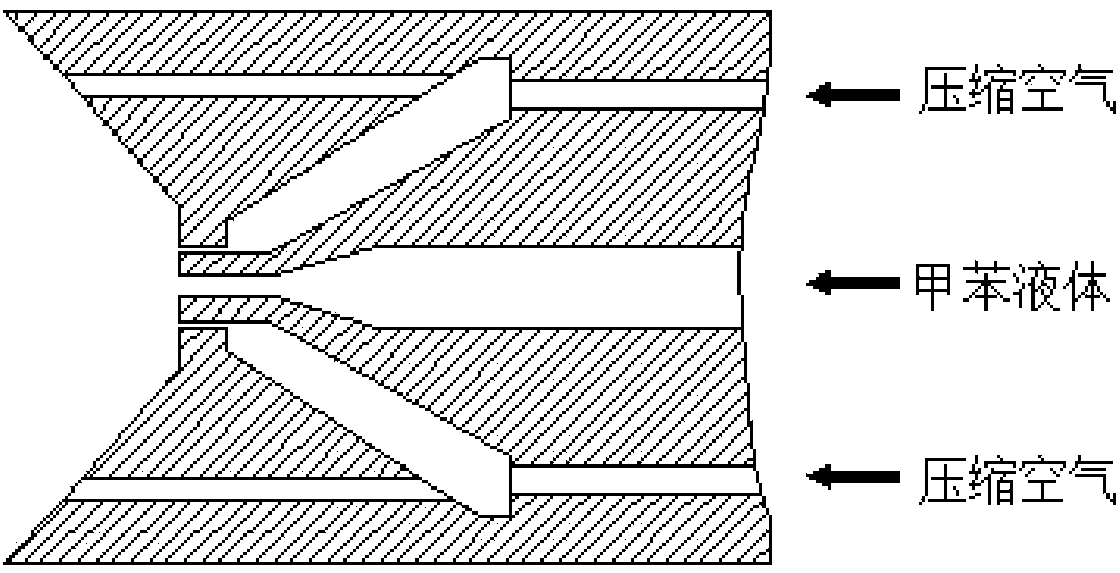

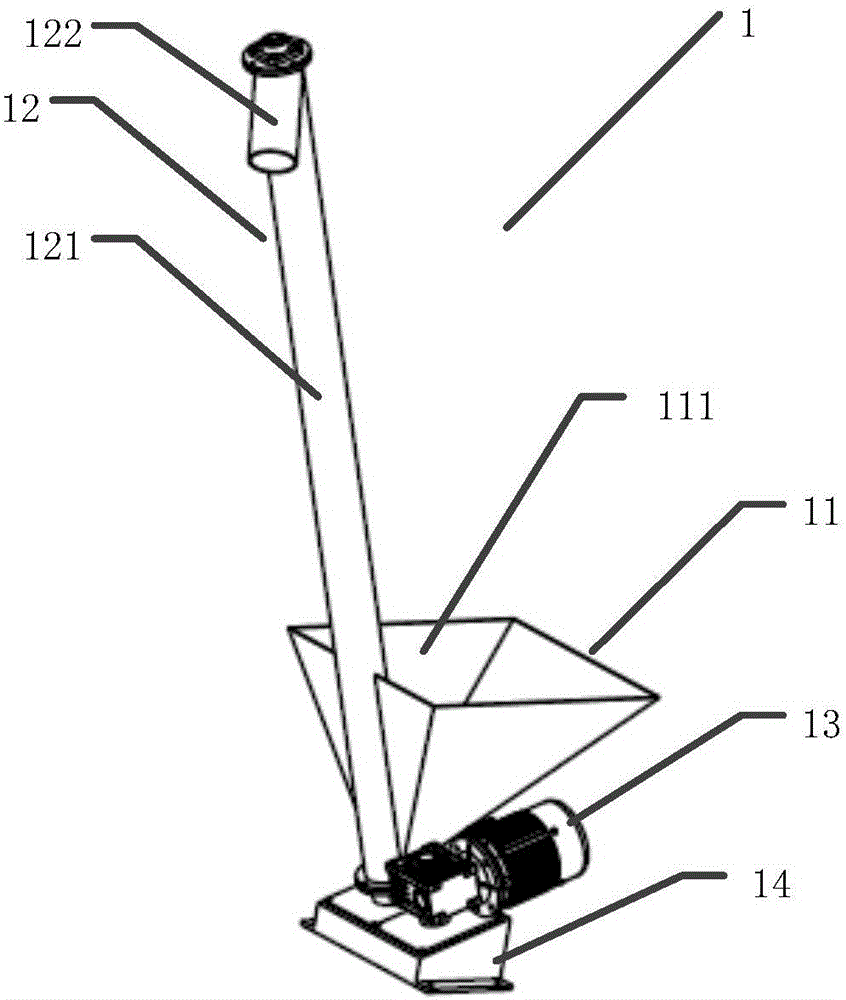

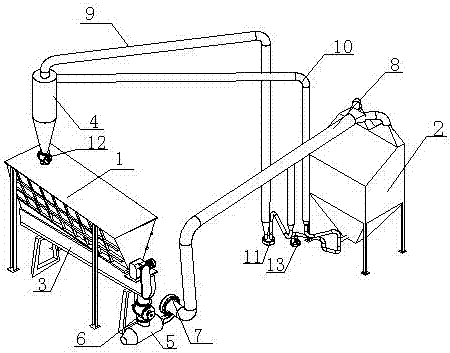

Pneumatic conveying system for spraying calcium in stokehole

InactiveCN1704647AReduce energy consumptionPrecisely control delivery volumeLighting and heating apparatusFrequency changerVolumetric Mass Density

This invention relates to a front furnace calcium injection delivery system, which comprises bin, upper bucket, lower bucket, auger conveyor and fan, wherein the outlet of the lower bucket connects with the auger conveyor, and the discharge port of the auger conveyor connects with a vertical cut pipe through a level delivery pipe; the air outlet of the fan connects with one air pipe, and the other end of the air pipe connects with the inlet of the transporting material pipe; the lower end of the cut connects to the transporting material pipe, the auger conveyor is driven by the variable-frequency control motor which is connected with the frequency-changer electric. The control device comprises controlling machine, frequency-changer and sulfur dioxide density sensor, which can control the transporting quantity of limestone powder precisely; the auger conveyor can mix the limestone powder and high pressure draught evenly.

Owner:SINOFINN NEW ENERGY INVESTMENT

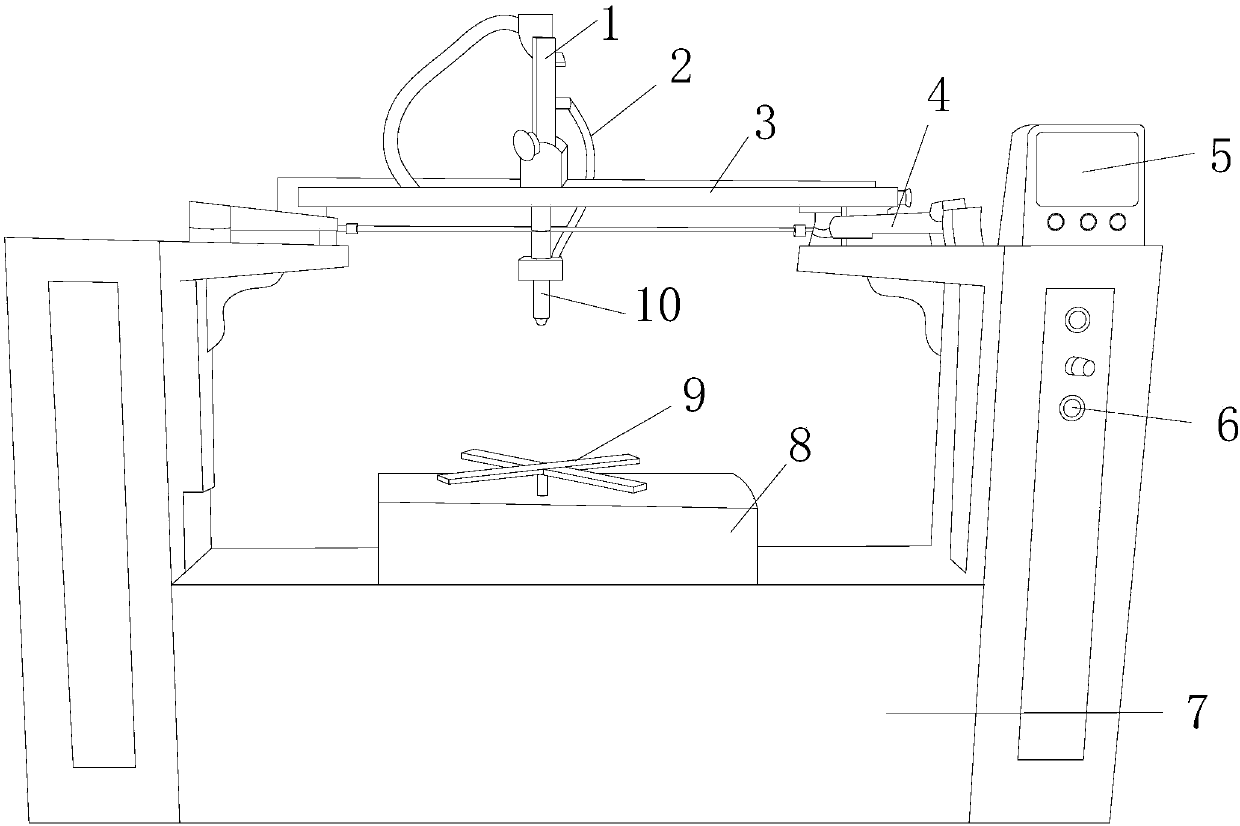

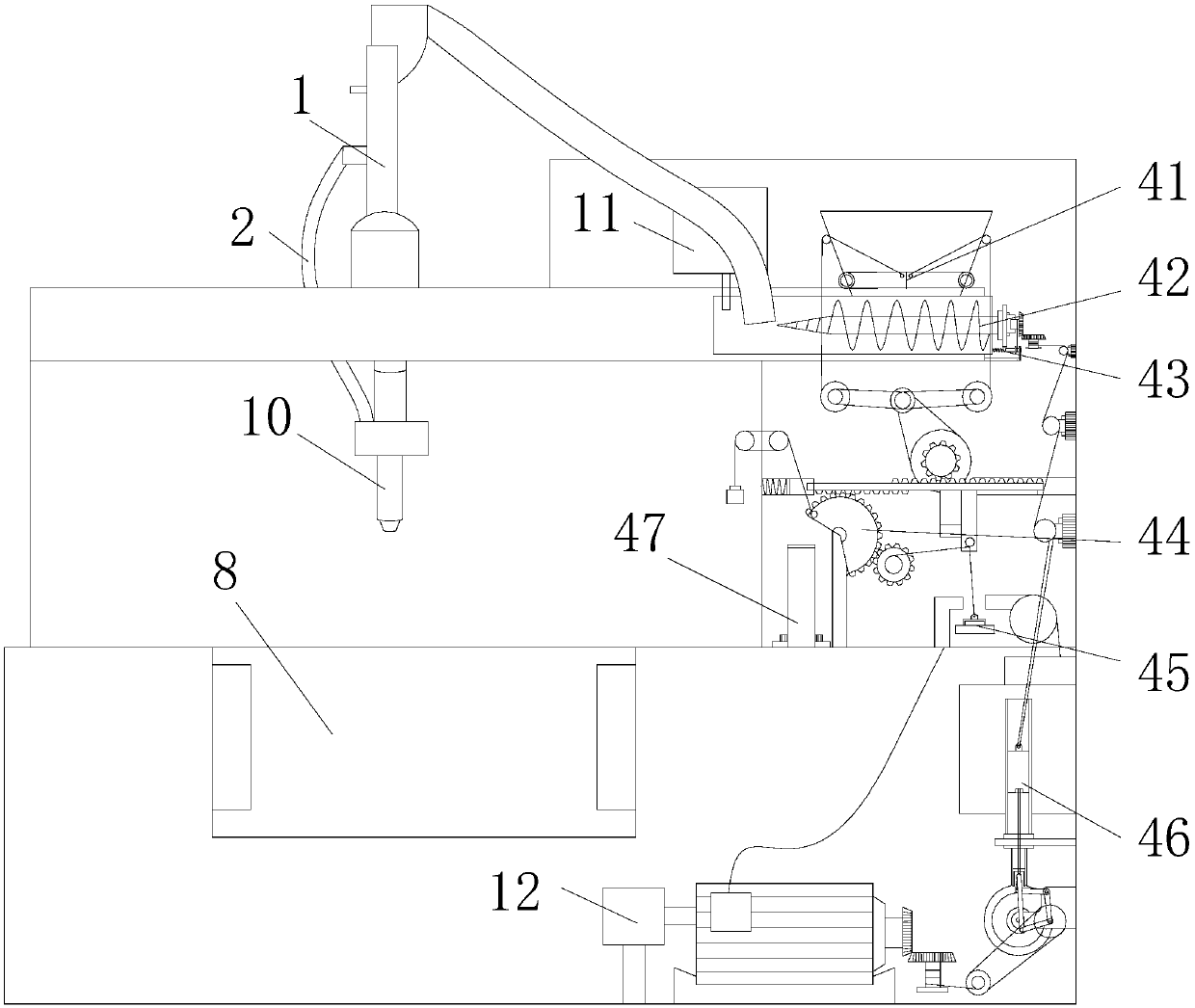

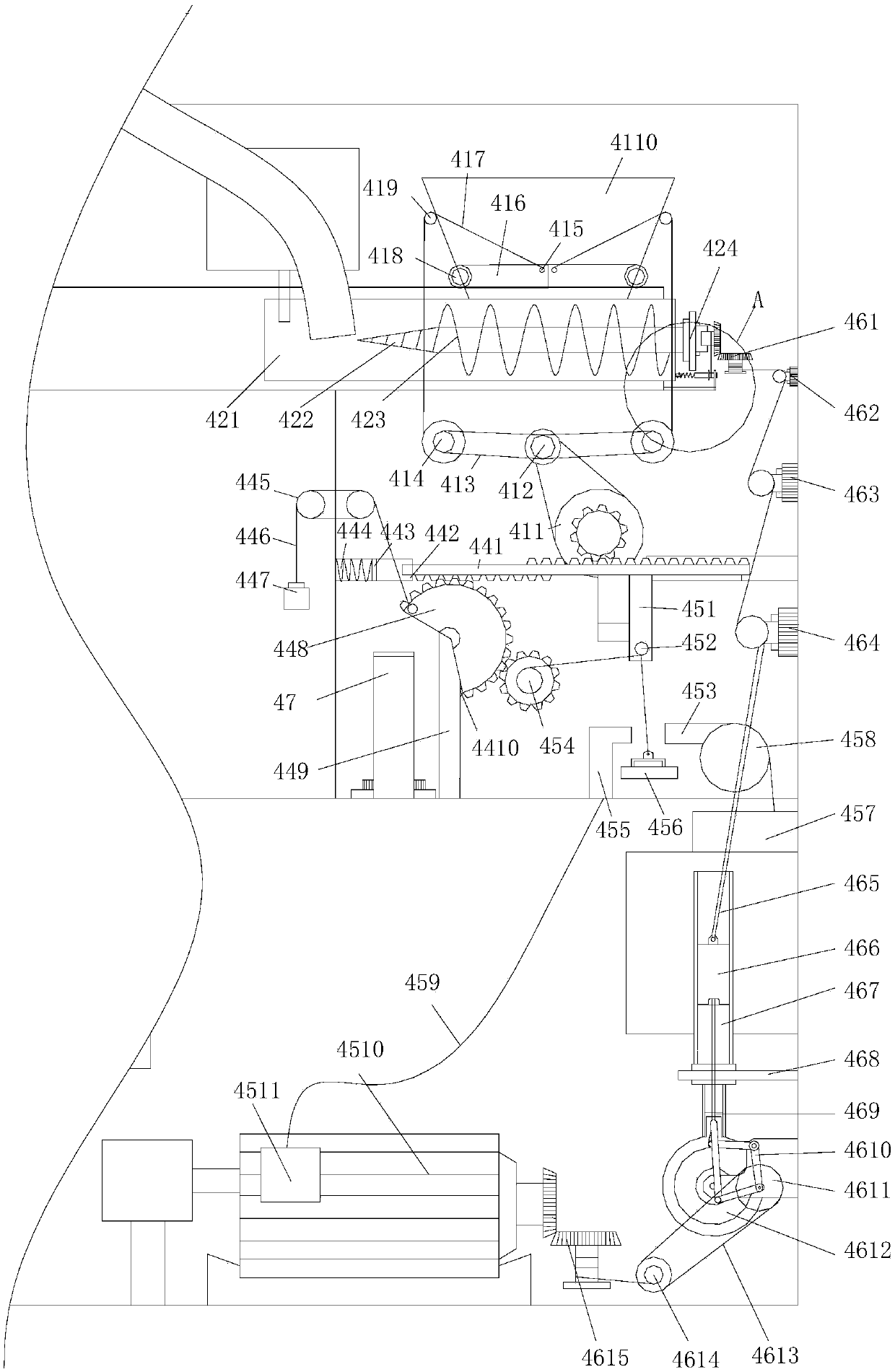

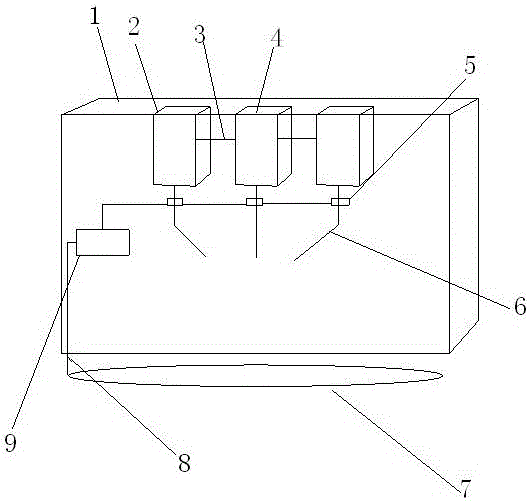

Paint spraying device for wheel hubs

ActiveCN107755130AGreat suctionLarge deformationSpraying apparatusProgrammable logic controllerLacquer

The invention discloses a paint spraying device for wheel hubs. The paint spraying device for the wheel hubs structurally comprises a spray head body, a feeding pipe, a cross beam, a paint spraying quantitation mechanism, a programmable logic controller (PLC), a control panel, a main body, a wheel hub sliding seat, a wheel hub placing frame, a spray head, a flow sensor and a frequency converter. The main body is of a U-shaped structure; the wheel hub sliding seat is arranged in a U-shaped groove; the wheel hub placing frame is arranged in the center of the wheel hub sliding seat and directly faces the spray head; and two ends of the main body are connected through the cross beam. According to the paint spraying device for the wheel hubs provided by the invention, a reverse take-up device,a hopper opening and closing mechanism, a paint conveying device, a feeding starting mechanism, a conveying switching system and an indirect transmission device are arranged, and manual starting and programming are combined, so that an intelligent degree of the device is improved; and the rotation speed of a screw rod is changed according to the rotation speed of a motor, so that the conveying capacity of paint is further controlled, the paint spraying amount can be accurately controlled, and the occurrence of the phenomenon that the paint spraying waste is caused due to excessive paint is avoided.

Owner:新沂市达婷黄沙有限公司

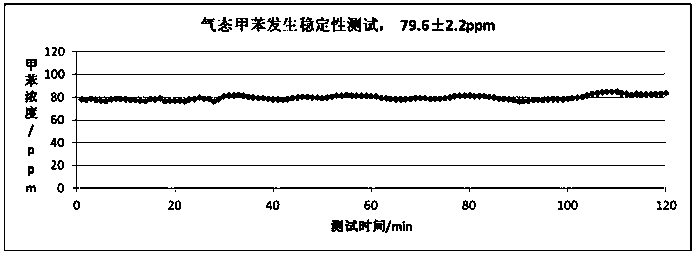

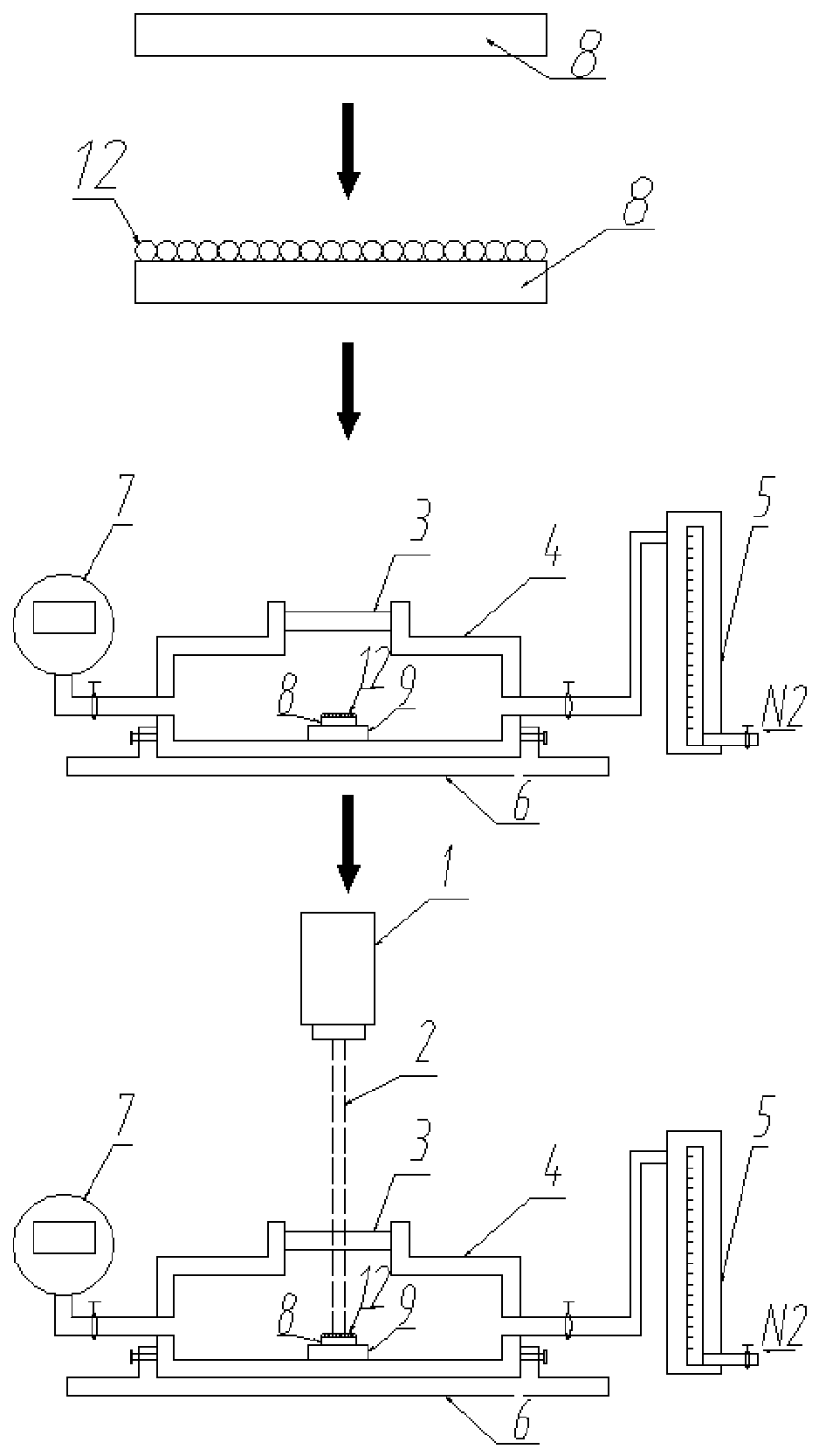

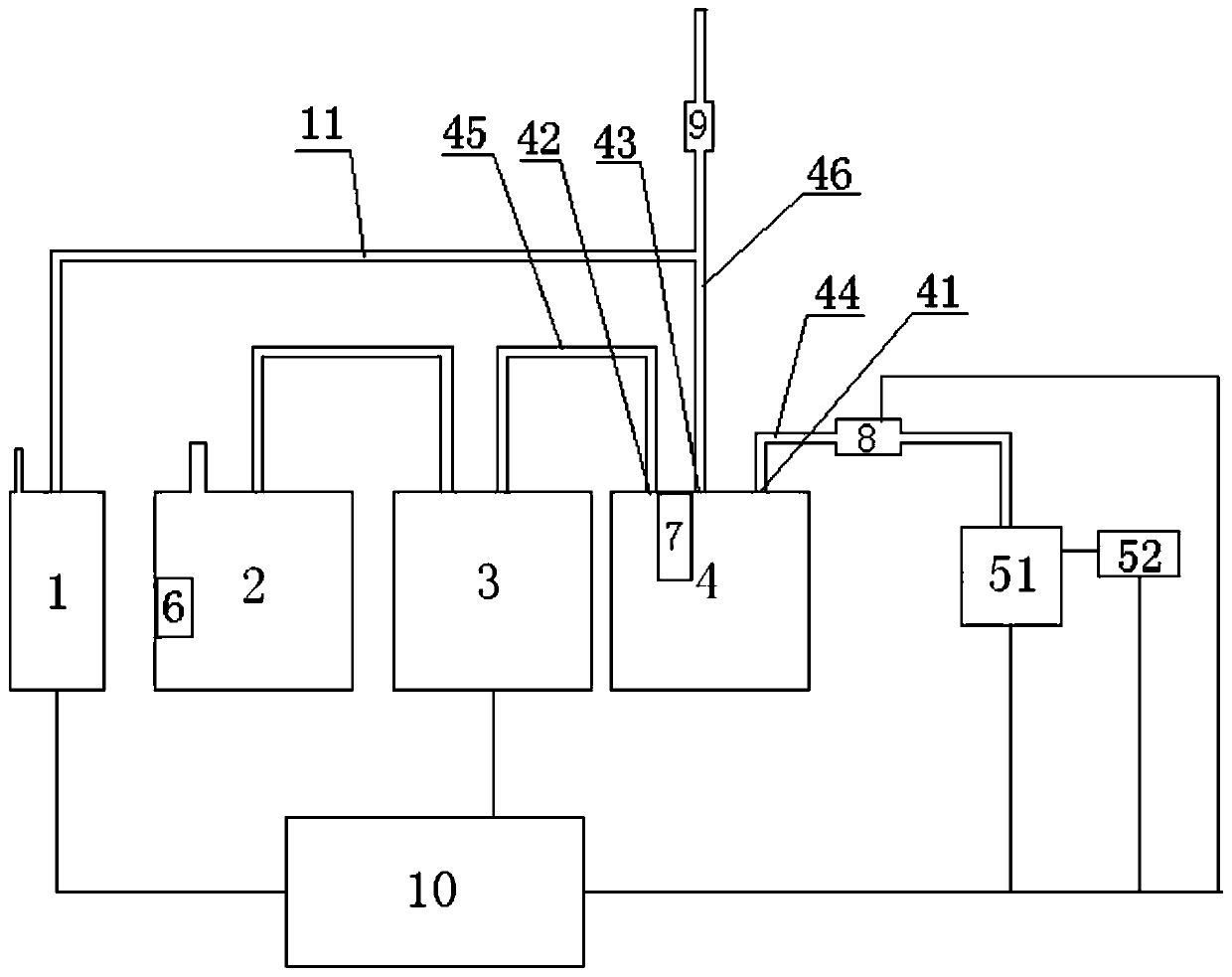

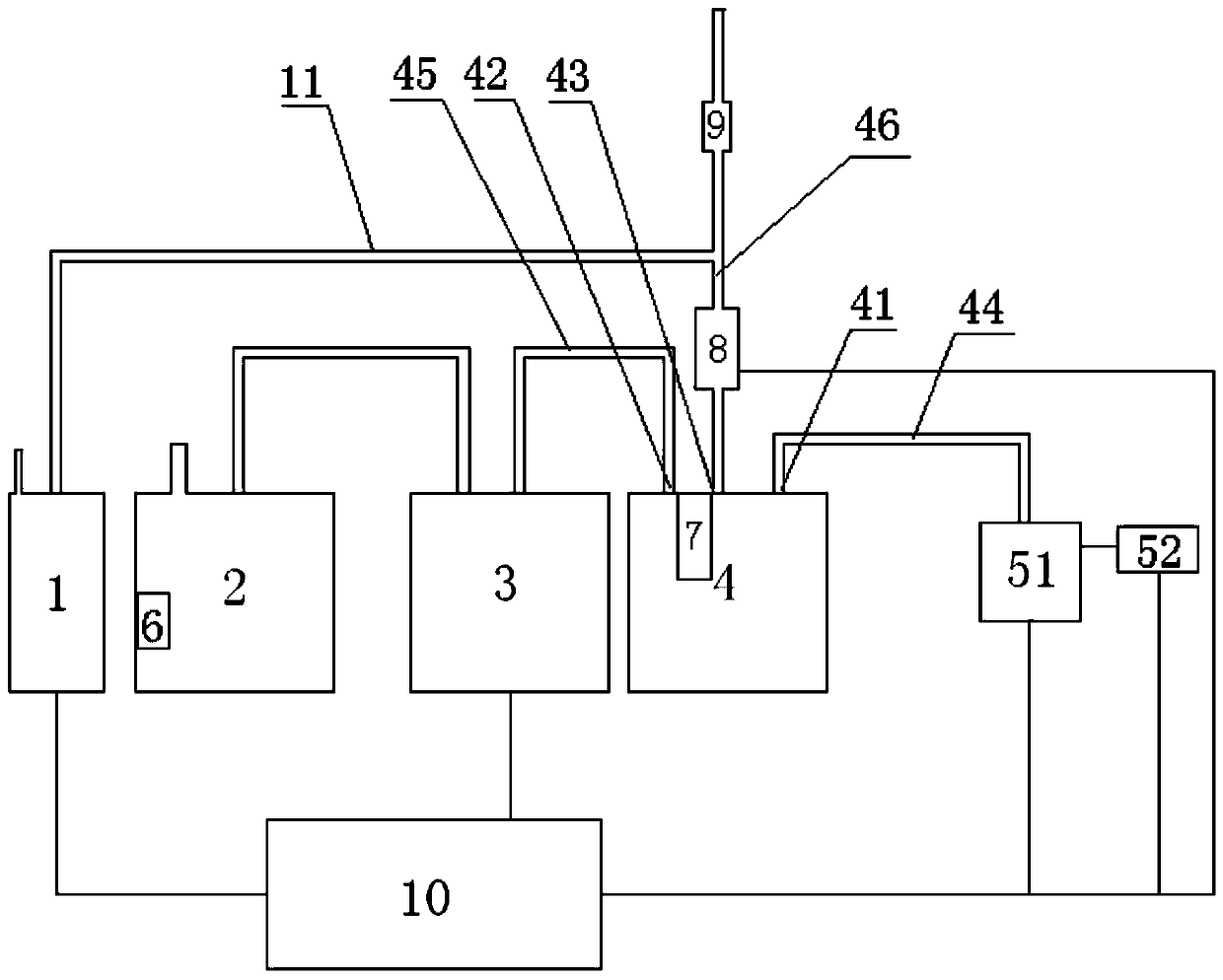

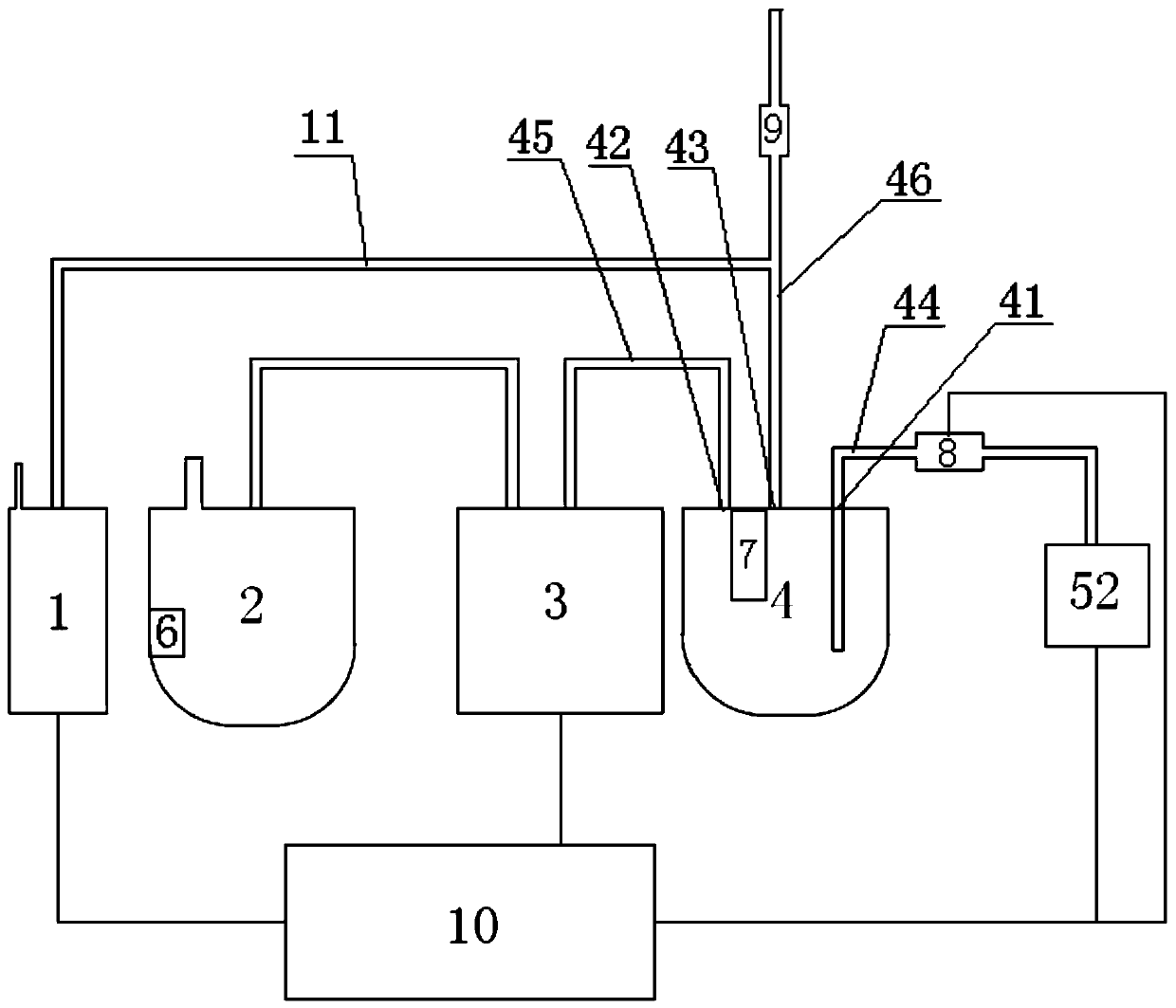

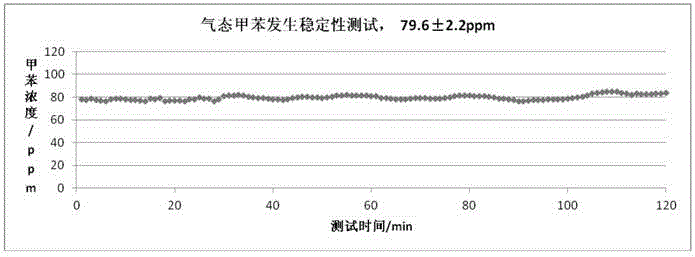

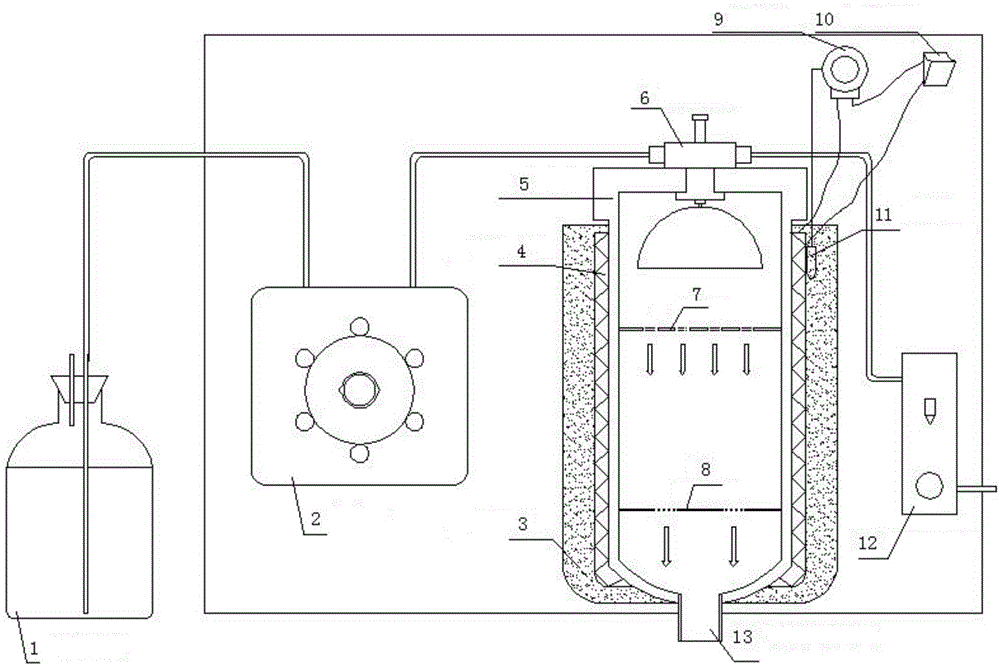

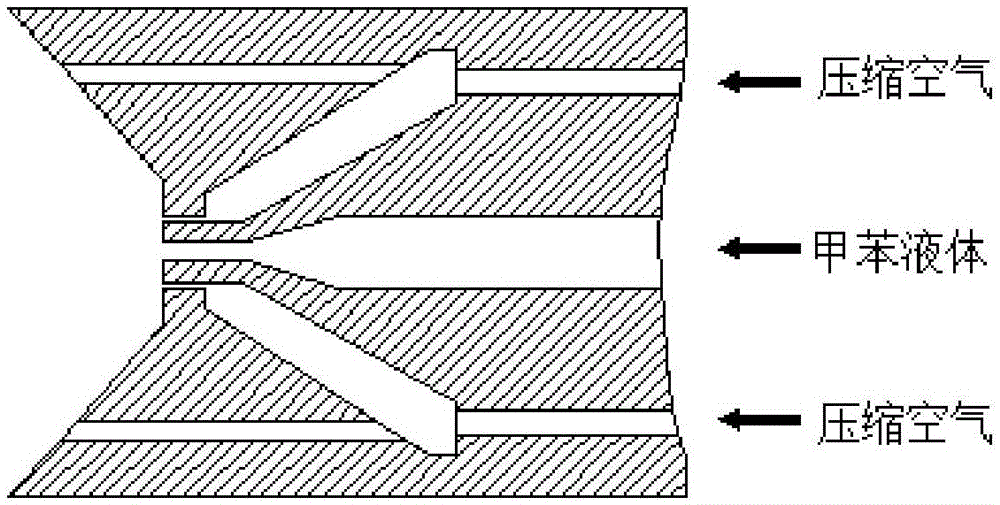

Gas-state pollutant generating device and method for detecting performance of air purifier

ActiveCN103411779APrecisely control delivery volumeRapid change in concentrationVehicle testingElectricityAir purifiers

The invention discloses a gas-state pollutant generating device and method for detecting performance of an air purifier. The device comprises a constant-flow pump, the constant-flow pump is connected with the liquid inlet of an atomization nozzle, the air inlet of the atomization nozzle is connected with a floater flowmeter, atomized liquid enters an evaporation chamber, an electric heating band is arranged outside the evaporation chamber, a temperature comptroller is arranged on the electric heating band, a heat preservation layer is arranged outside the electric heating band, and the outlet of the evaporation chamber is connected with a purifier test system. The gas-state pollutant generating device and generating method are simple in principle, low in cost, suitable for various pollutants which are formed by liquid evaporation and generate gas, economical and practical. A computer can remotely control the rotating speed of the constant-flow pump, control and adjust the occurrence number of the pollutants and adjust the temperature of the electric heating band, a certain quantity of gas-state pollutants can be generated, and the operation is simple and convenient.

Owner:天津中天环境科技有限公司

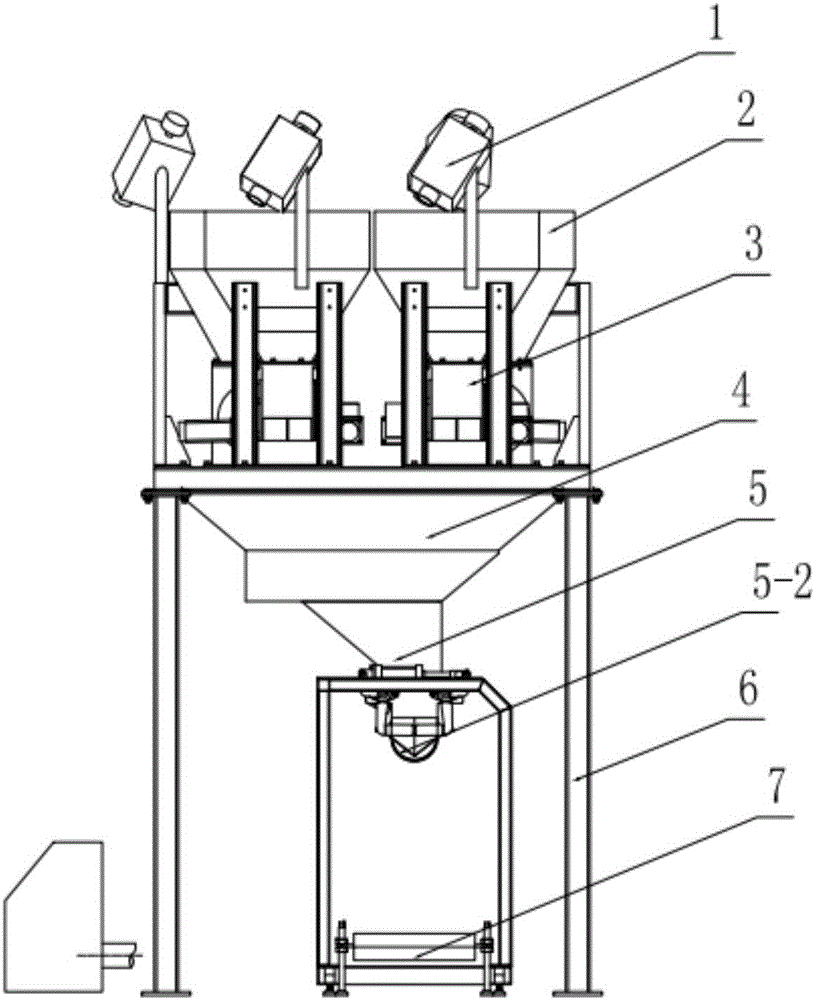

Batching, mixing and packaging all-in-one machine

The invention provides a batching, mixing and packaging all-in-one machine. For an existing way of connecting a batching device with a mixing device by the aid of a bucket conveyor, the height of a workshop is lowered to a certain degree, however, equipment is complicated in integral structure, poor in sealing performance, easy to pollute materials oversize in dust and not applicable due to adding of the conveyor. The batching, mixing and packaging all-in-one machine comprises a quantitative batching device, a mixing barrel (1) is mounted below the quantitative batching device, a spiral stirrer (2) is mounted inside the mixing barrel, a packaging conveyor (3) is mounted below the mixing barrel, and a bag-sewing machine (4) is arranged on the packaging conveyor which is connected with a finished product conveyor (5). The batching, mixing and packaging all-in-one machine can be used for simultaneously performing material mixing and packaging.

Owner:NANJING CHANGJIANG PAINT

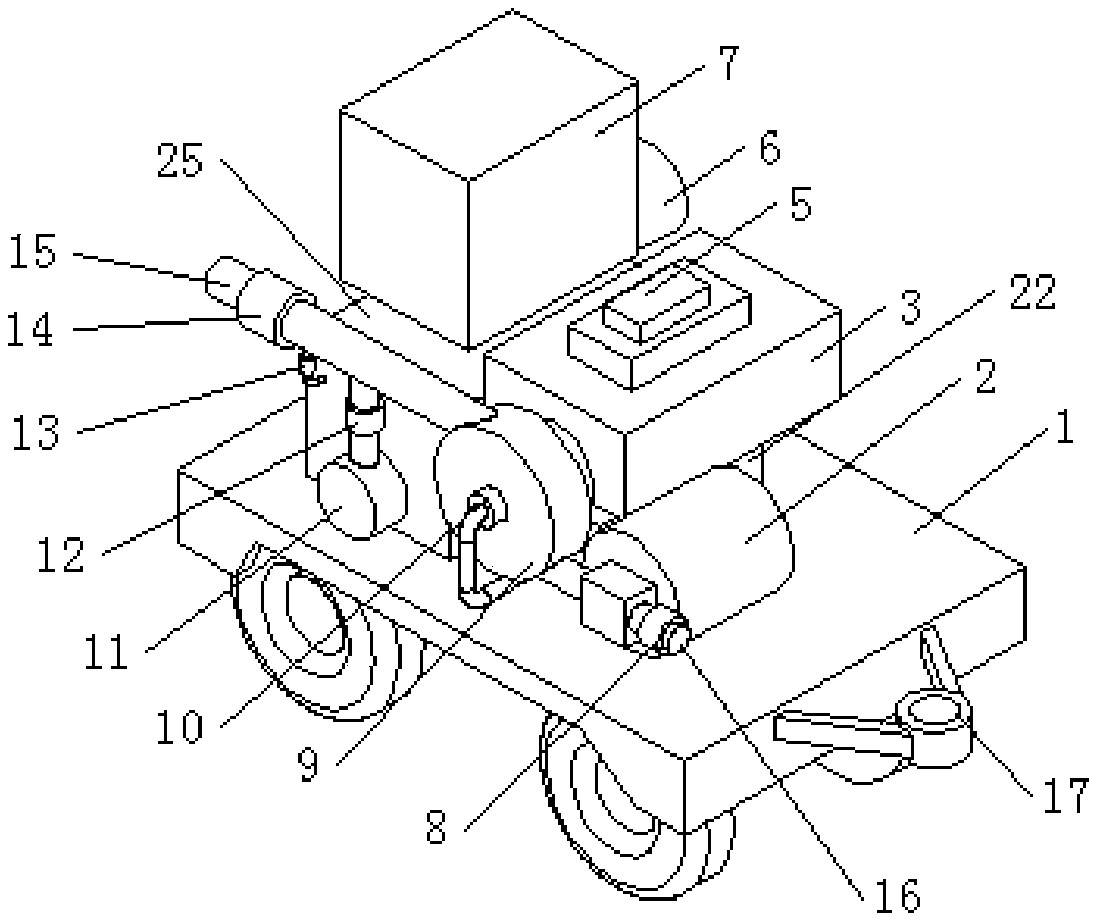

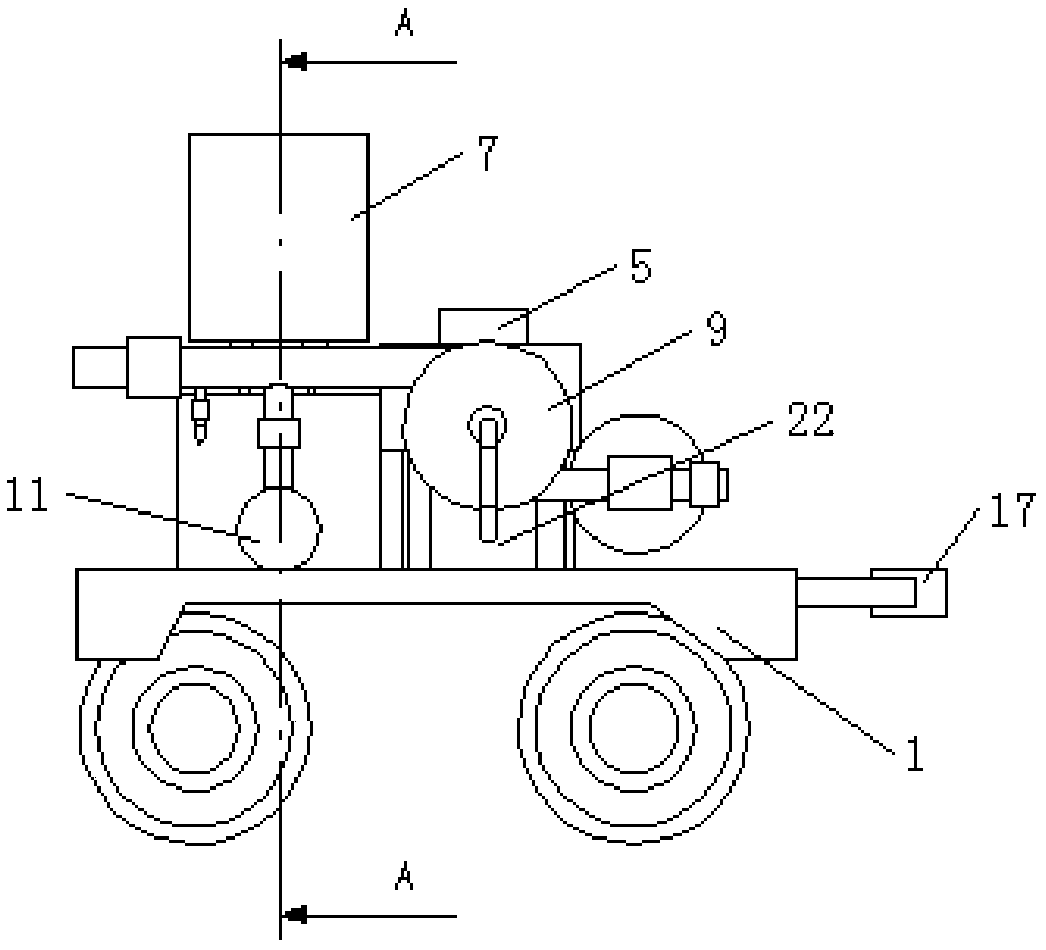

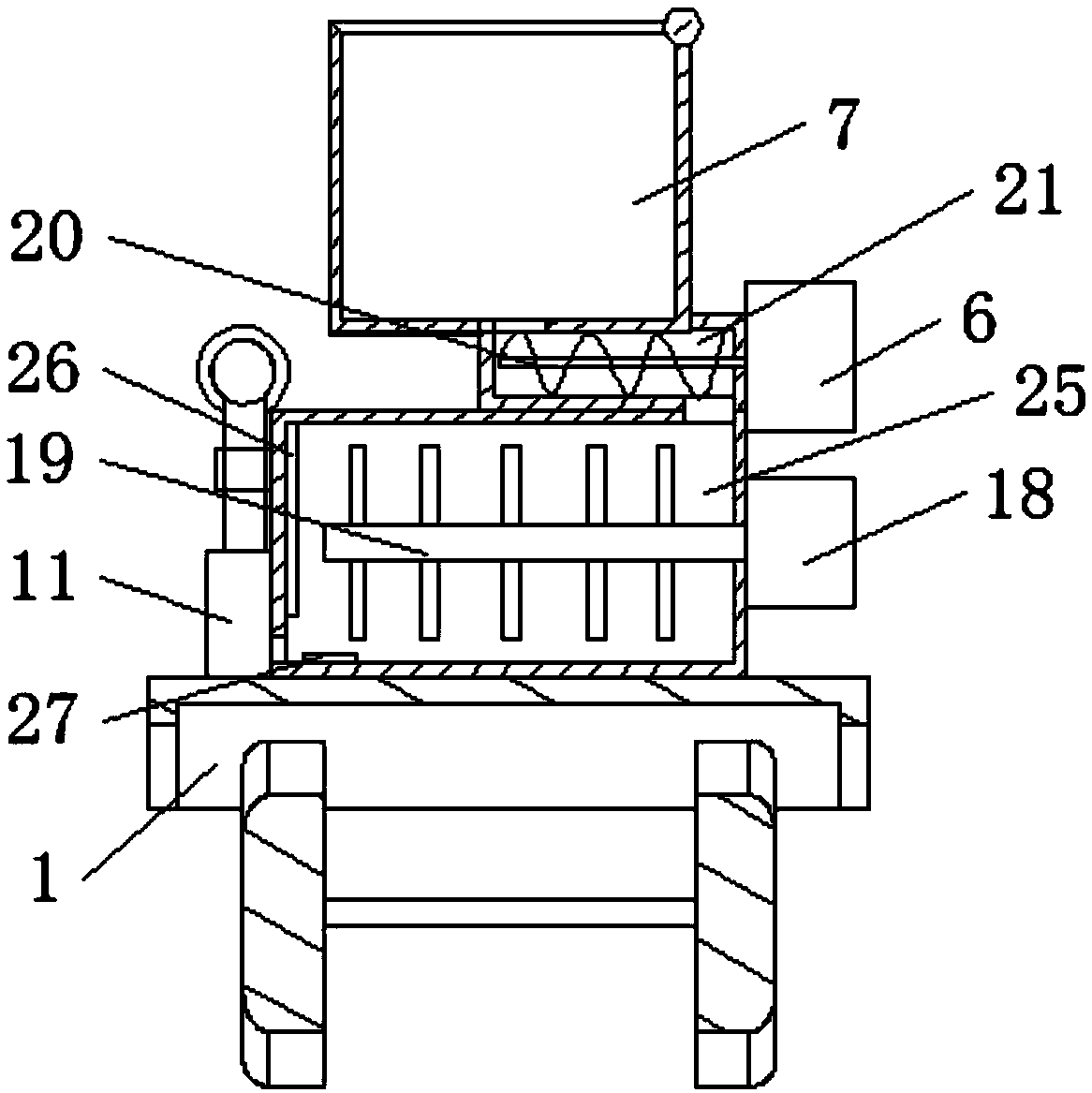

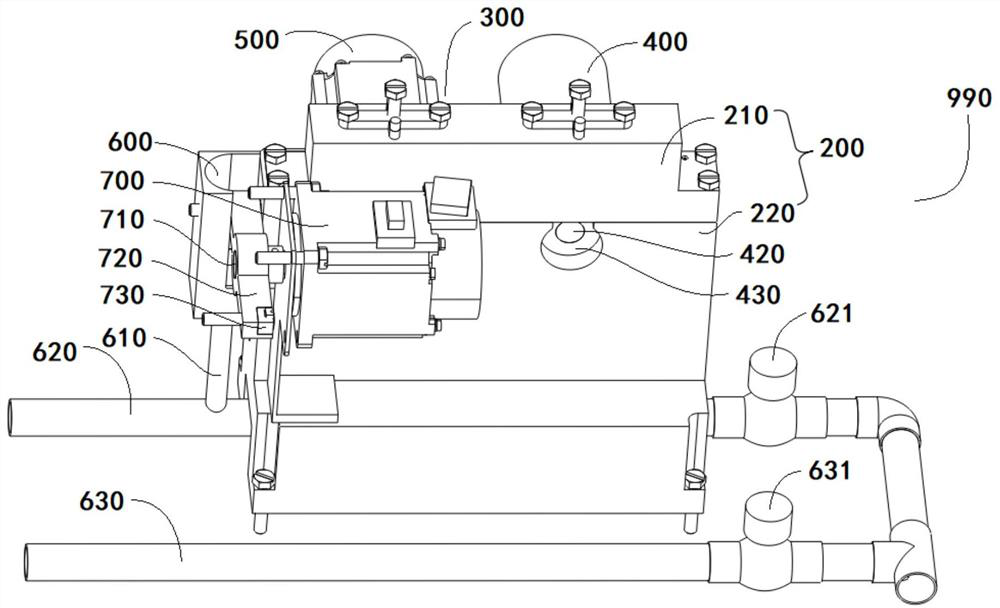

Movable type water, fertilizer and air drip irrigation all-in-one machine

InactiveCN109104969AReduce storage timeExtend the mixing timePressurised distribution of liquid fertiliserHorticulture methodsDrip irrigationMovable type

The invention discloses a movable type water, fertilizer and air drip irrigation all-in-one machine. The movable type water, fertilizer and air drip irrigation all-in-one machine comprises a vehicle body, wherein a traction ring is arranged at the front end of the vehicle body; a fertilizer box is fixedly arranged above the vehicle body; a discharging opening is formed below the fertilizer box; afertilizer mixing box is arranged at the discharging opening of the fertilizer box; a feeding opening of the fertilizer mixing box is communicated with the fertilizer box; a feeding opening of the fertilizer mixing box is communicated with the fertilizer box; a water inlet is formed in the upper end of a side edge of the fertilizer mixing box; the water inlet is communicated with a water inlet pipe through a pipeline; a water outlet is formed in the lower end of the fertilizer mixing box; a self-priming pump is mounted at the water outlet in a matching manner; a water inlet of the self-primingpump is communicated with the water outlet of the fertilizer mixing box. According to the movable type water, fertilizer and air drip irrigation all-in-one machine, equipment is integrated on the vehicle body on the basis of an existing drip irrigation system, and is convenient to move; region oxygen supply, fertilizer supply and irrigation are carried out on a drip irrigation system, and the irrigation quality is ensured.

Owner:安徽瓦大现代农业科技有限公司

Full-automatic material mixing assembly

InactiveCN105035380APrecisely control delivery volumeAvoid it happening againSolid materialPackaging automatic controlComputer control systemProcess engineering

The invention discloses a full-automatic material mixing assembly, and relates to the field of environment-friendly machines. The full-automatic material mixing assembly comprises a weighing system, a conveying system and a charging system. The several major systems of the whole technical process are connected in series, the systems are controlled through a computer control system, and automation and unmanned operation in the whole process are achieved; and the work efficiency is improved, weighing is accurate, and the product quality is high.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

Fertilizer distribution device and control method thereof

PendingCN106621903APrecisely control delivery volumeImprove feeding and conveying efficiencyRotary stirring mixersTransportation and packagingAutomationControl unit

The invention provides a fertilizer distribution device and a control method of the fertilizer distribution device. The fertilizer distribution device comprises feeding mechanisms, weighing mechanisms, a stirring mechanism and a control unit; the feeding mechanisms are communicated with the weighing mechanisms, and the weighing mechanisms are communicated with the stirring mechanism; each feeding mechanism comprises a first accommodating chamber, a feeding conveying mechanism, a first screw mechanism and a first power mechanism; one end of the feeding conveying mechanism is arranged in the first accommodating chamber, and the other end of the feeding conveying mechanism extends to each weighing mechanism; the first screw mechanism is arranged in the feeding conveying mechanism, and the first power mechanism is connected with the first screw mechanism; the control unit is connected with the first power mechanism and controls the first power mechanism to drive the first screw mechanism to rotate. The fertilizer distribution device and the control method of the fertilizer distribution device provided by the invention are high in automation degree and control accuracy, and capable of accurately controlling the conveying capacity of materials.

Owner:YUNNAN YUNTIANHUA AGRI TECH CO LTD

Abrasive material rotary storage tank device

InactiveCN103803202AAffects the effect of jet drillingMeasure weight in real timeSievingScreeningDrive shaftScrew conveyor

The invention belongs to the field of a drilling fluidic device and particularly relates to an abrasive material rotary storage tank device. The abrasive material rotary storage tank device comprises a storage tank; the storage tank comprises a tank body; one end of the tank body is connected with a hydraulic driving device by a transmission shaft and the periphery of the other end of the tank body is provided with a slide rail; corresponding to the slide rail, a sliding wheel is arranged; the sliding wheel is arranged on a storage tank bracket; the open end of the tank body is provided with a guide cylinder; the upper part of the outer end of the guide cylinder is provided with a feeding hopper; the inner end of the guide cylinder is arranged in a screen drum; the screen drum is positioned in the tank body; sieve pores are distributed on the drum wall of the screen drum; the periphery of the bottom of the screen drum is connected with a screen drum support frame; one side of the screen drum is provided with a conveying blade; both the screen drum support frame and the conveying blade are arranged on the inner wall of the tank body; corresponding to the tail end of the conveying blade, the tank body is provided with a discharge port; a buffer hopper is arranged below the discharge port; the bottom of the buffer hopper is provided with a screw conveyor; the screw conveyor is arranged on a conveyor bracket. The abrasive material rotary storage tank device has a simple and reasonable structure, can simultaneously implement rotary feeding and conveying works, can accurately control the conveying amount of abrasive materials and has a great effect on recycling of the abrasive materials.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

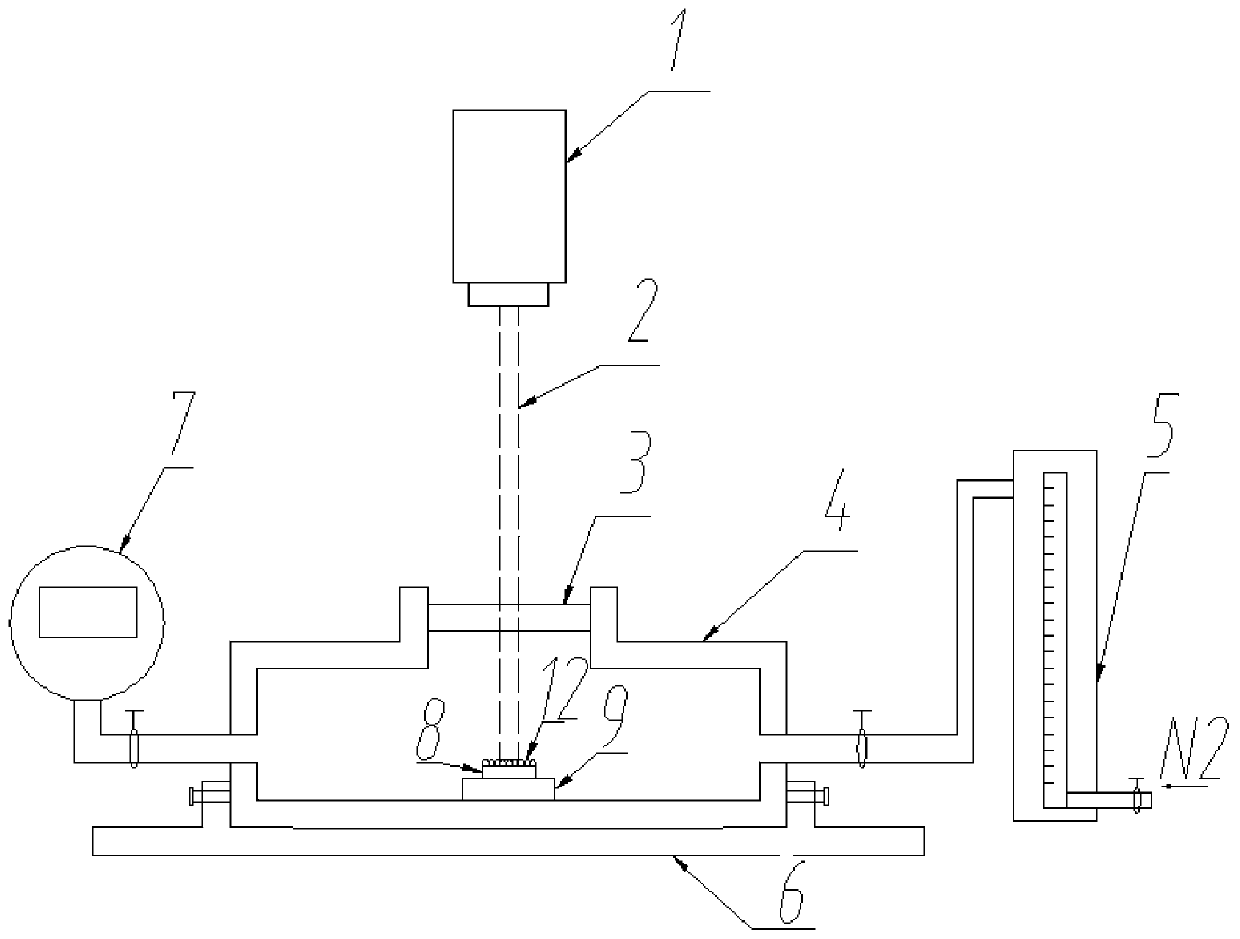

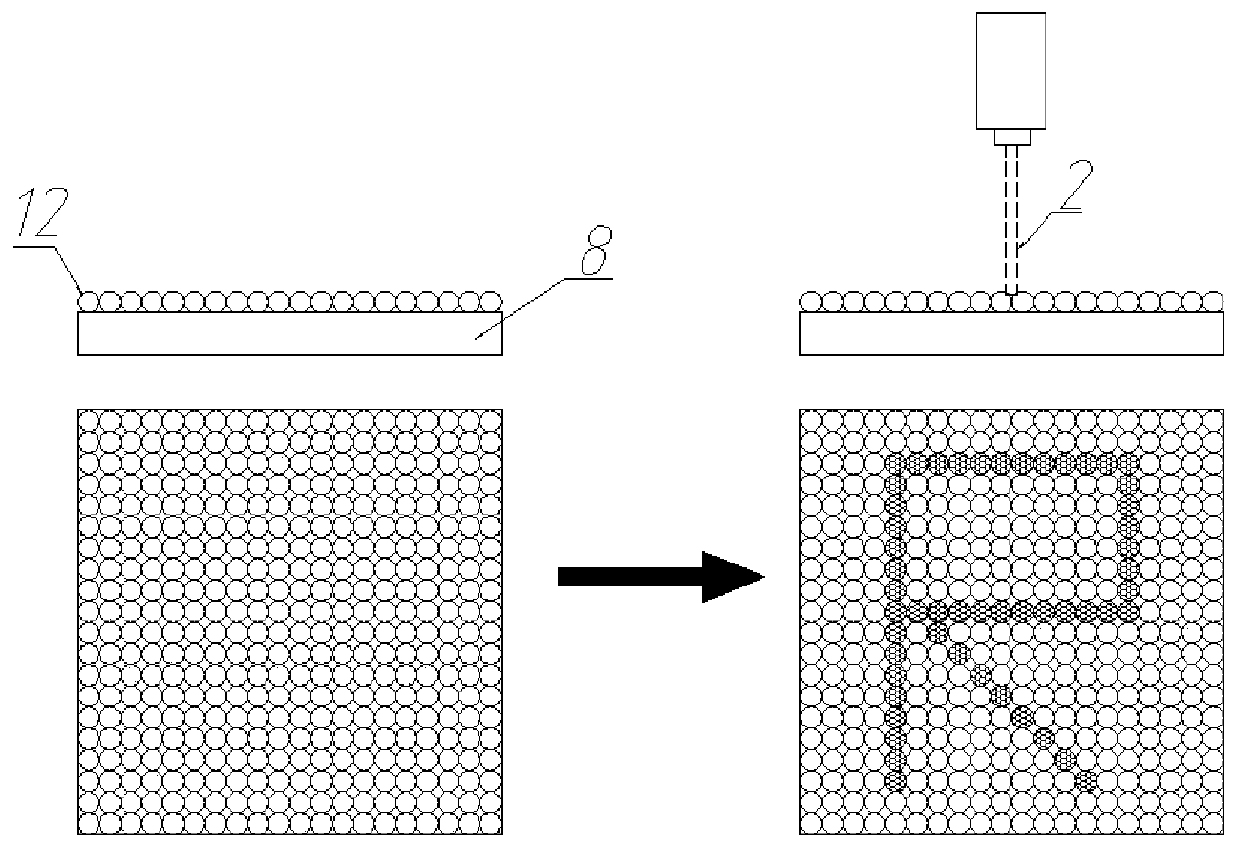

Method and device for processing polystyrene and graphene nanocomposite microstructure array

ActiveCN109762194AWon't hurtPrecisely control delivery volumeDecorative surface effectsSolid-state devicesGraphene nanocompositesPolystyrene

The invention provides a device for processing a polystyrene and graphene nanocomposite microstructure array. The device comprises a laser generator, a vacuum cavity, an objective table, an ultraviolet filter lens and a gas flow control unit; the objective table is installed at the bottom inside the vacuum cavity in a detachable fixing mode, and the vacuum cavity is provided with open and closed channels; the ultraviolet filter lens is installed on the vacuum cavity, the laser generator emits a laser to irradiate theobjective table located in the vacuum cavity through the ultraviolet filter lens, and the objective table is used for placing to-be-processed objects; the gas flow control unit communicates with the vacuum cavity, and used for controlling gas entering the vacuum cavity; and thevacuum cavity is fixedly installed on a triaxial precision motion platform through a vacuum cavity fixture. As for the problem that the polystyrene and graphene nanocomposite material microstructurearray is difficult to process at present, the device for processing the polystyrene and graphene nanocomposite microstructure array is provided.

Owner:GUANGDONG UNIV OF TECH

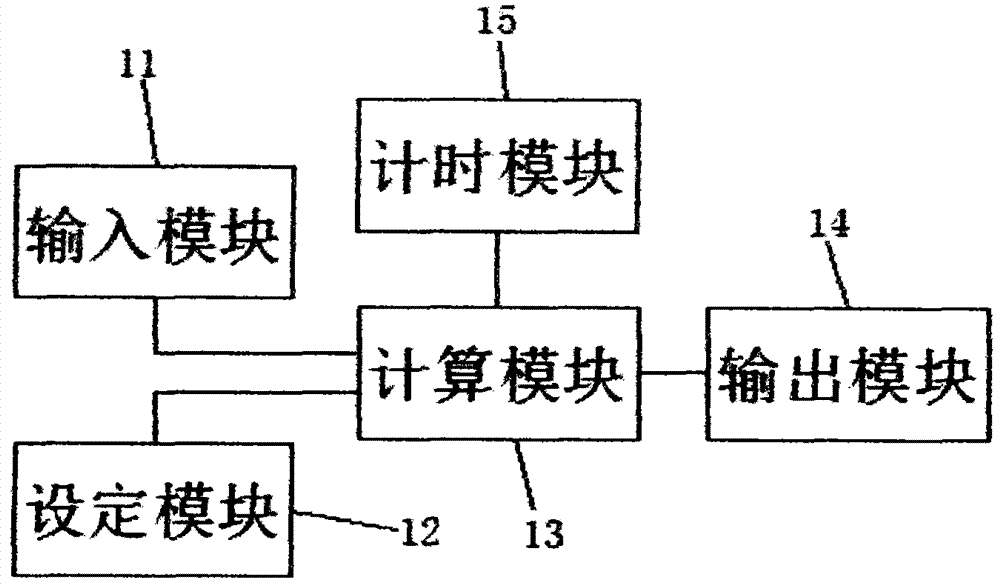

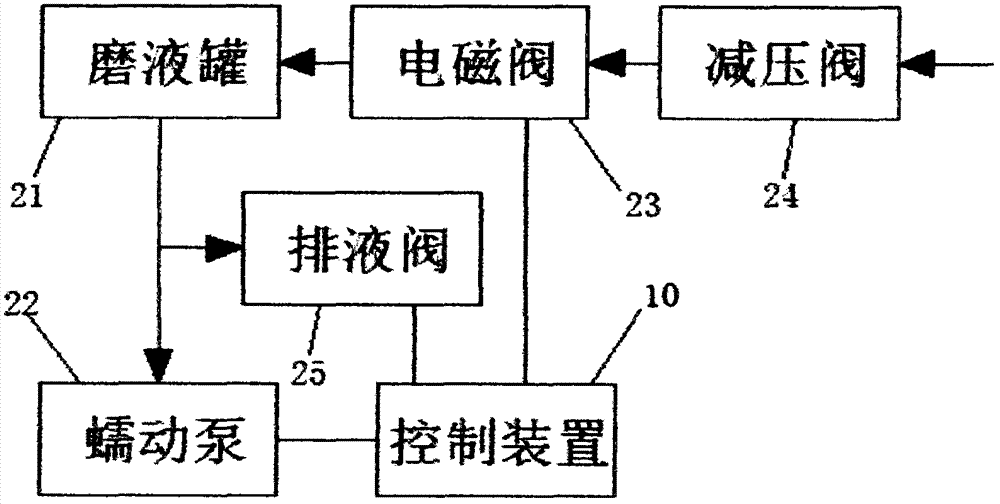

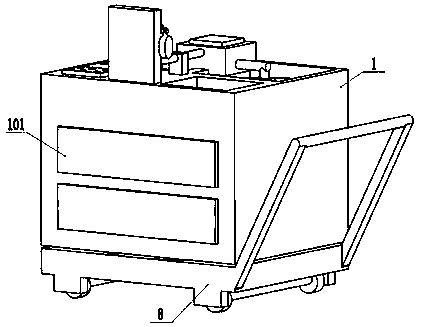

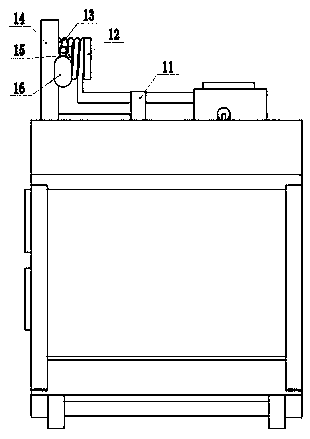

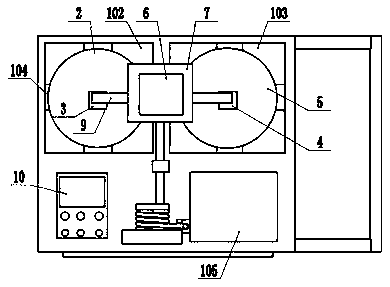

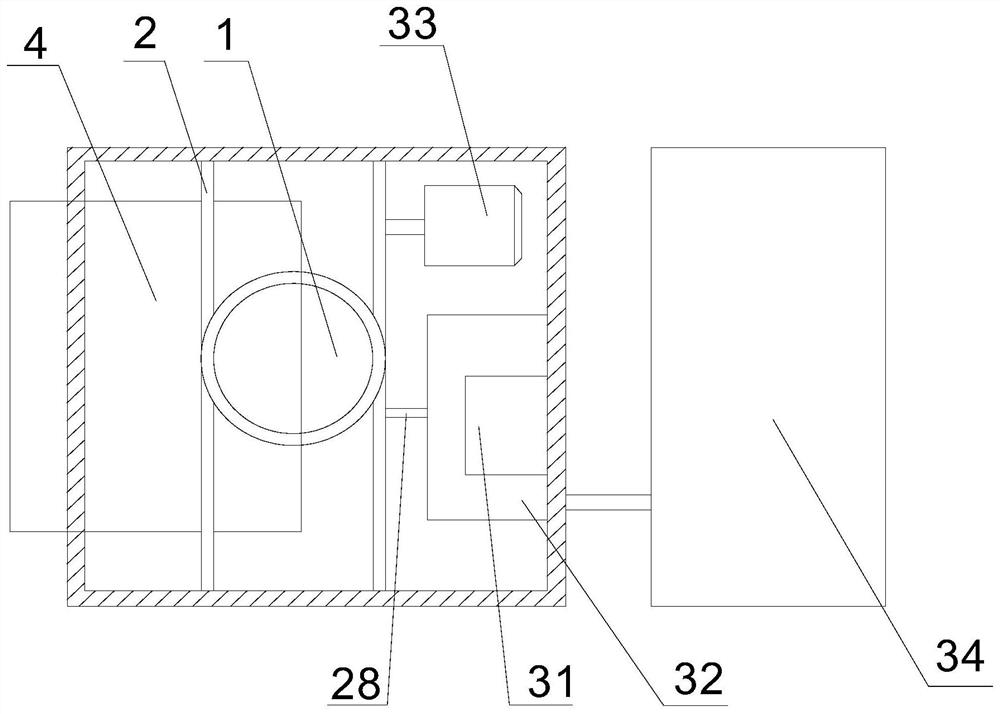

Control device of trace addition instrument and trace addition instrument

ActiveCN104765295APrecisely control delivery volumeIncrease usageProgramme control in sequence/logic controllersPeristaltic pumpComputer module

The invention provides a control device of a trace addition instrument. A start signal is received through an input module (11), a setting module (12) sets grinding liquid addition amount information, a calculation module (13) then calculates the number of circles by which a peristaltic pump (22) needs to rotate according to the addition amount information, pulse information which needs to be sent out is calculated according to the number of the circles, an output module (14) sends pulses to the peristaltic pump (22) according to the pulse information so as to make the peristaltic pump (22) rotate, and therefore grinding liquid in a grinding liquid tank (21) is thrown out. Meanwhile, the invention further provides the trace addition instrument with the control device (10). By means of the control device, the throwing amount and the throwing time of polishing liquid can be accurately controlled, and the polishing effect can be conveniently improved.

Owner:BLTY HUNAN TECH

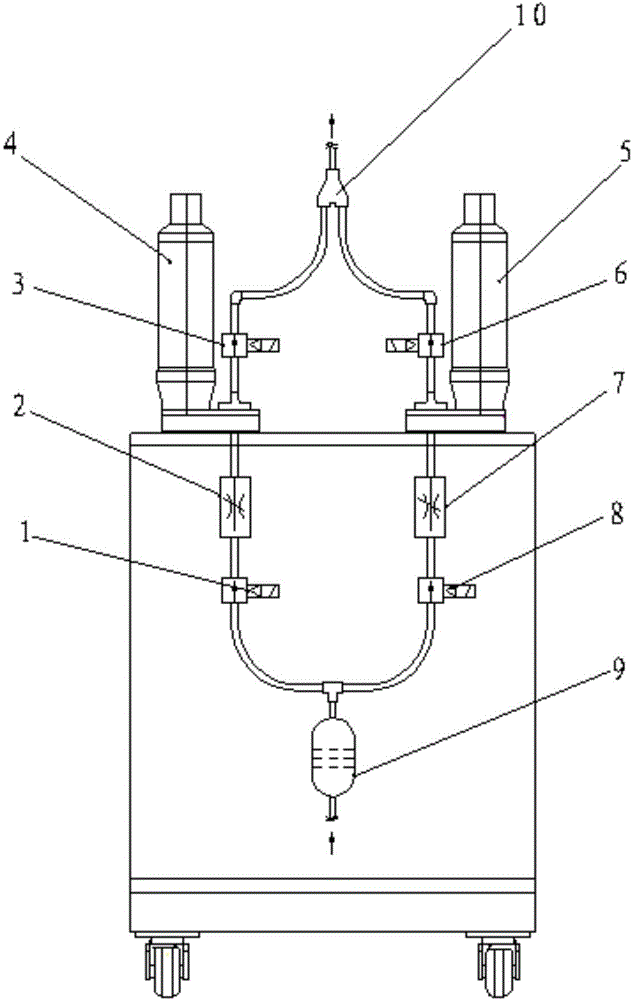

Concentration-regulating type anaesthesia apparatus in department of anesthesiology

InactiveCN110681016ATake the hassle out of movingGuaranteed uniformityRespiratorsMedical devicesEngineeringGas mixing

The invention discloses a concentration-regulating type anaesthesia apparatus in department of anesthesiology. The concentration-regulating type anaesthesia apparatus comprises a box body and a trolley, wherein the trolley comprises a support base; a rotary disc groove is formed in the upper end face of the support base; a rotating column is arranged in the middle of the rotary disc groove; a rotating disc is arranged at the lower end of the box body and is fixedly connected with the box body; a fixed hole is formed in the middle of the rotary disc; the rotary disc is matched with the rotary disc groove; the rotating column is matched with the fixed hole; a storage chamber I and a storage chamber II are sequentially arranged on one side of the upper end of the box body; a gas mixing box isarranged between the storage chamber I and the storage chamber II; an oxygen bottle and an anaesthesia bottle are sequentially arranged in the storage chamber I and the storage chamber II; a solenoidvalve I is arranged at a gas outlet of the oxygen bottle; a solenoid valve II is arranged a gas outlet of the anaesthesia bottle; the oxygen bottle and the anaesthesia bottle are connected with the gas mixing box; the gas mixing box is connected with a facial mask through a pipeline; a flow survey meter is arranged on a pipeline which is positioned between the gas mixing box and the facial mask;a controller is arranged on one side of the upper end of the box body; and the controller is separately and electronically connected with the solenoid valve I, the solenoid valve II and the flow survey meter.

Owner:朱超

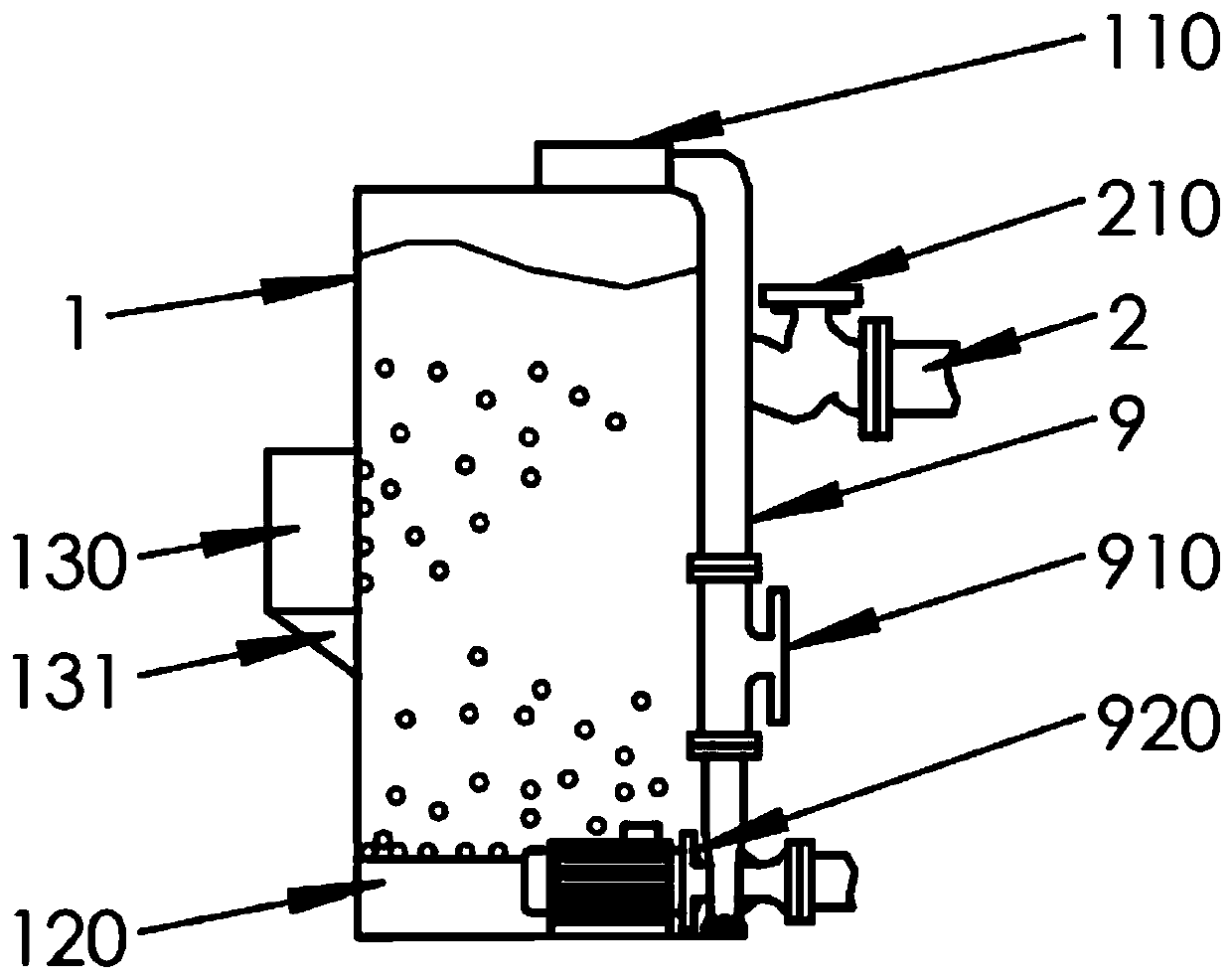

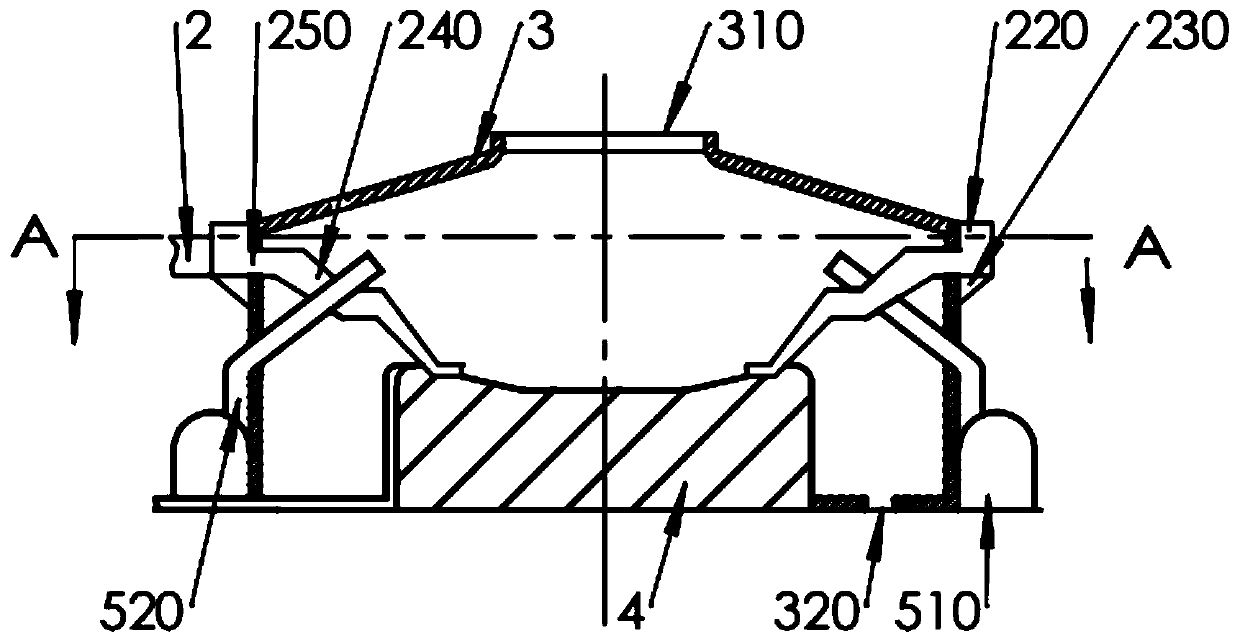

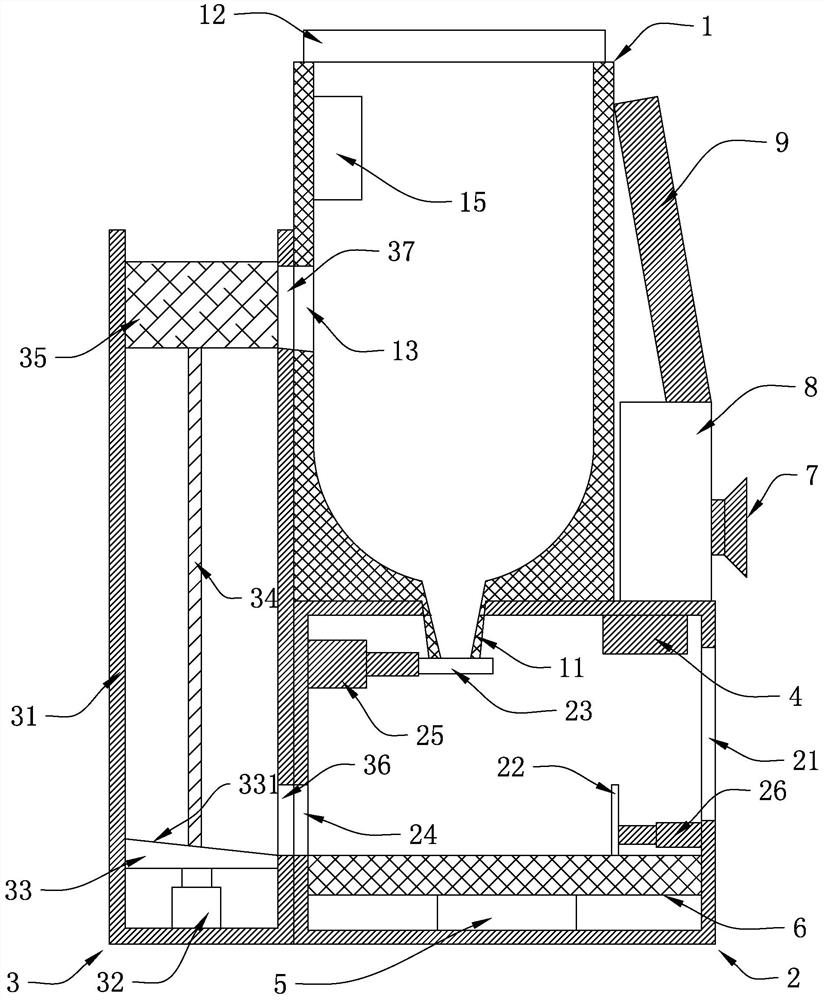

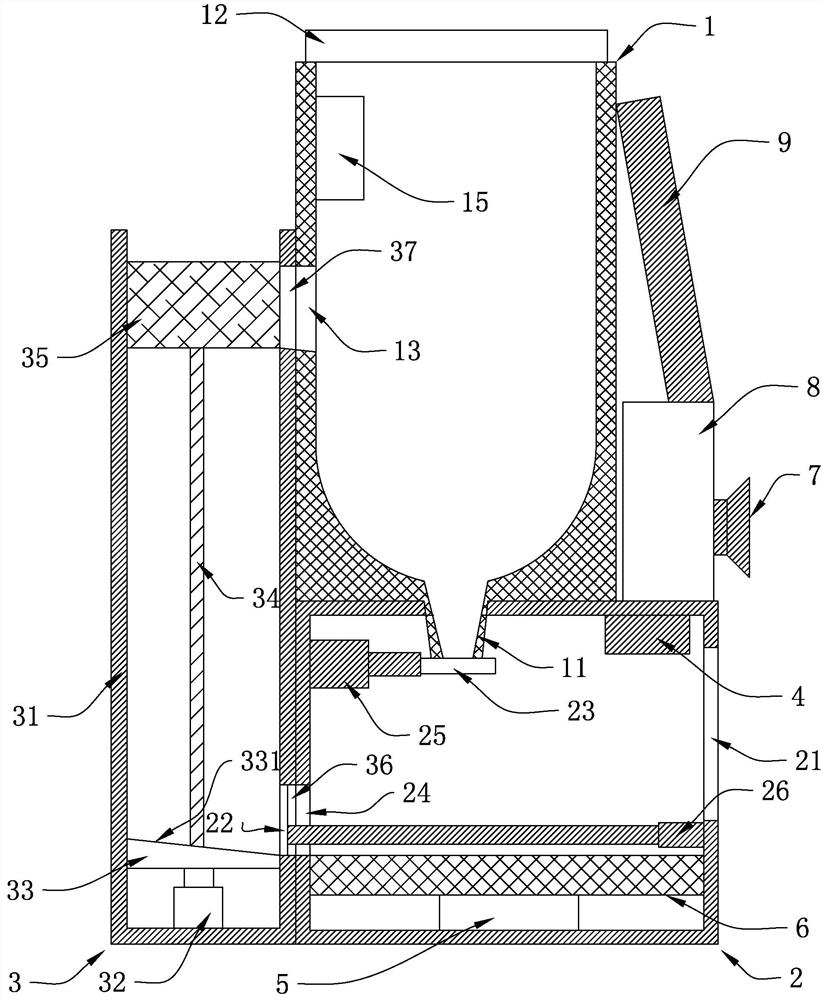

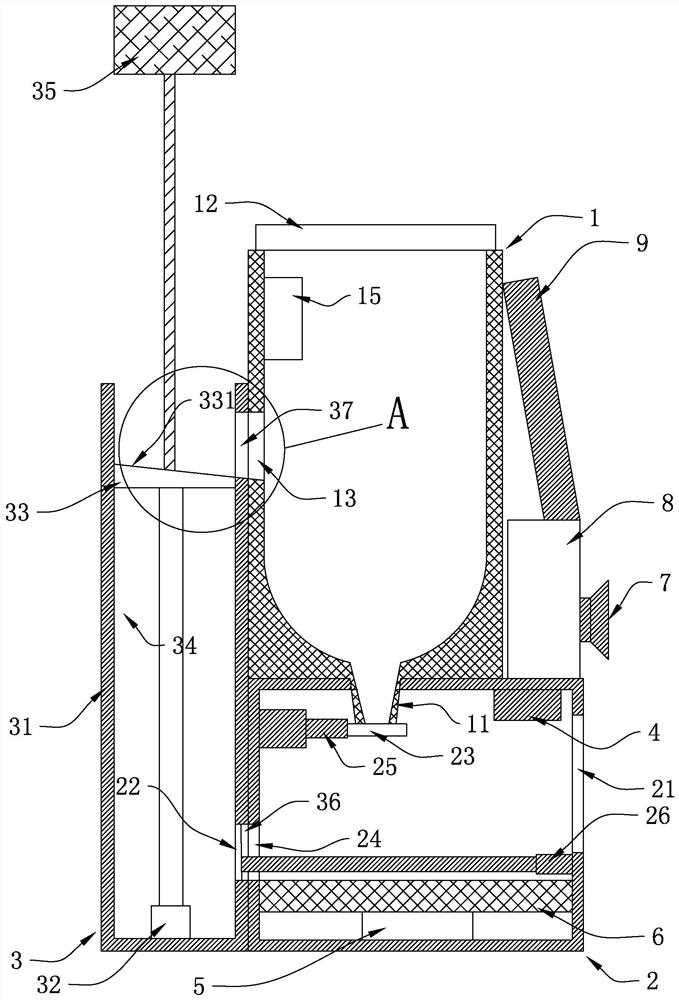

Hydrodynamic foaming system and foaming method and closestool comprising foaming system

PendingCN110093962APrecisely control delivery volumeAccurately control the dosageLavatory sanitoryFoaming agentProduct gas

The invention discloses a hydrodynamic foaming system. The system comprises a water inlet mechanism, a liquid inlet mechanism, an air inlet mechanism, a hydrodynamic mixing box, a foaming pipe and a control mechanism; a water inlet and a liquid inlet are formed in the side wall or the top of the hydrodynamic mixing box; a liquid outlet is formed in the top of the hydrodynamic mixing box, the waterinlet is connected with a water outlet pipe of the water inlet mechanism, the liquid inlet is connected with a liquid outlet pipe of the liquid inlet mechanism, the liquid outlet is connected with aninlet of the foaming pipe through a connecting pipe, the connecting pipe further communicates with an air outlet pipe of the air inlet mechanism, and the control mechanism is connected with the waterinlet mechanism, the liquid inlet mechanism and the air inlet mechanism. A closestool and a foaming method are also disclosed. By adding the hydrodynamic mixing box, a foaming agent is injected in advance, and the use amount of the foaming agent is accurately controlled by logically controlling the working time of a liquid pump. The uniformly mixed foaming liquid is mixed with gas by utilizing the pushing force of water to finally generate foam, so that the application range is wide. The system is simple in structure, low in cost, intelligent in control and capable of rapidly generating foamand better meeting the requirements of customers.

Owner:河北态及环保科技有限公司

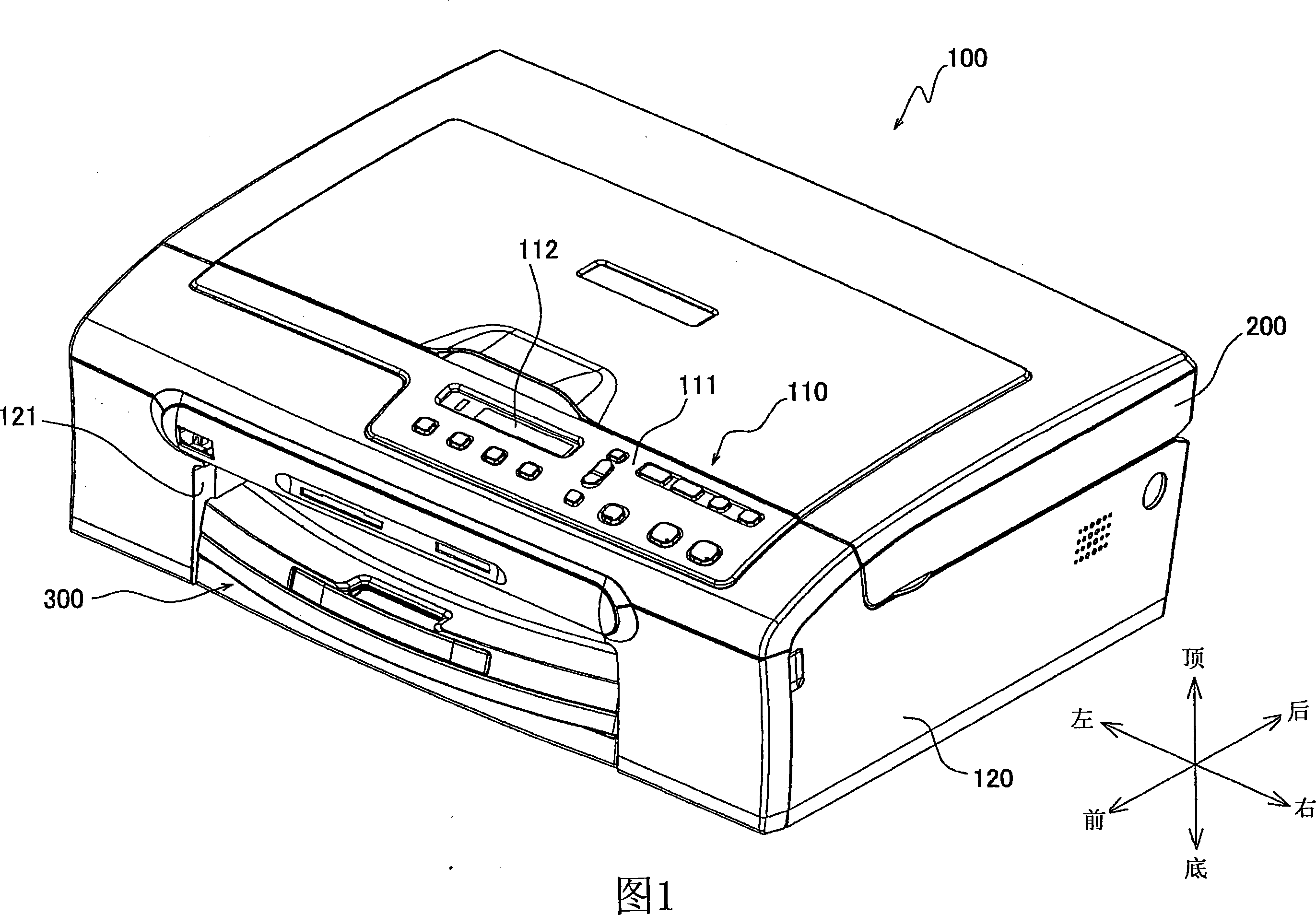

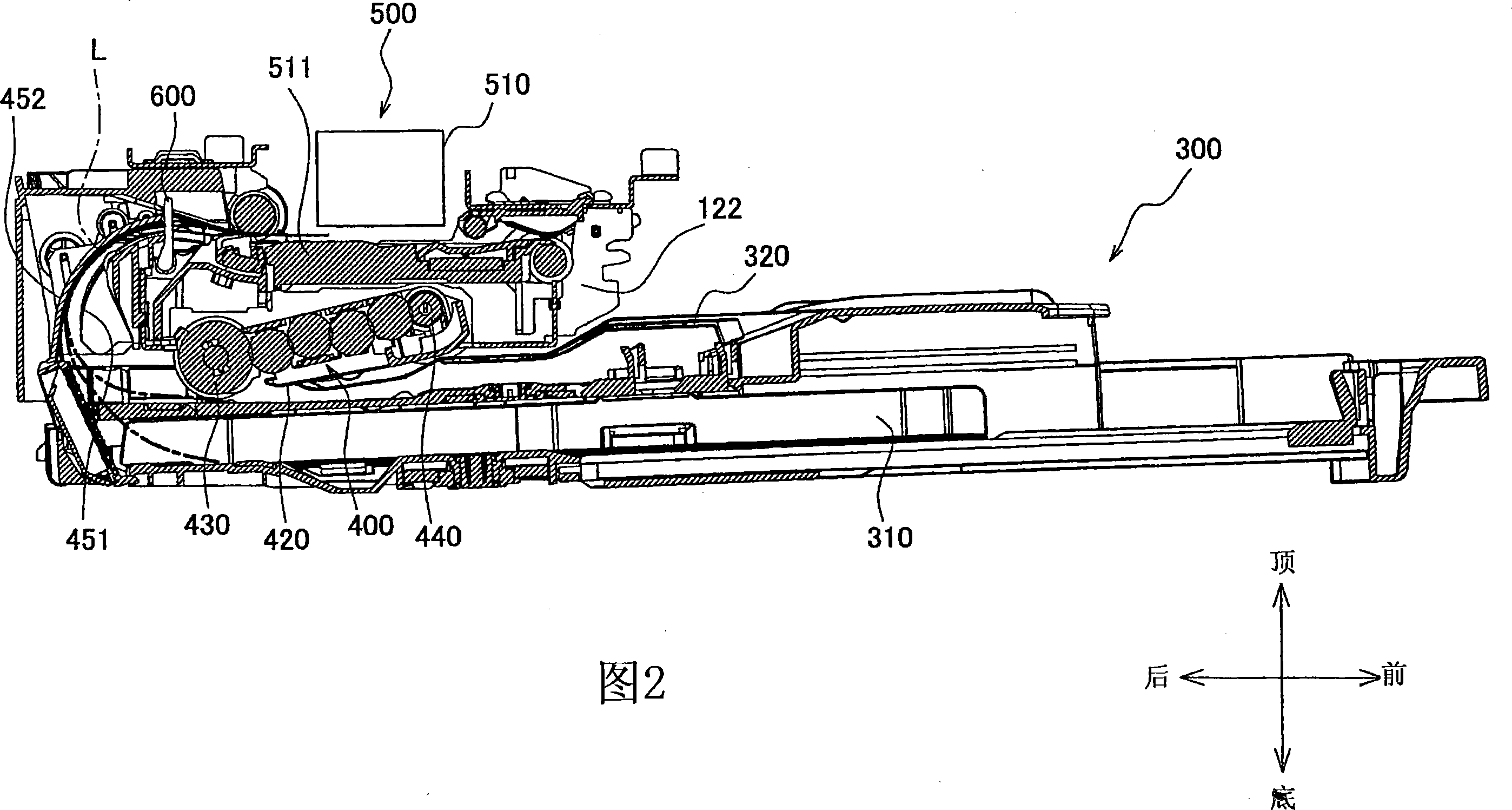

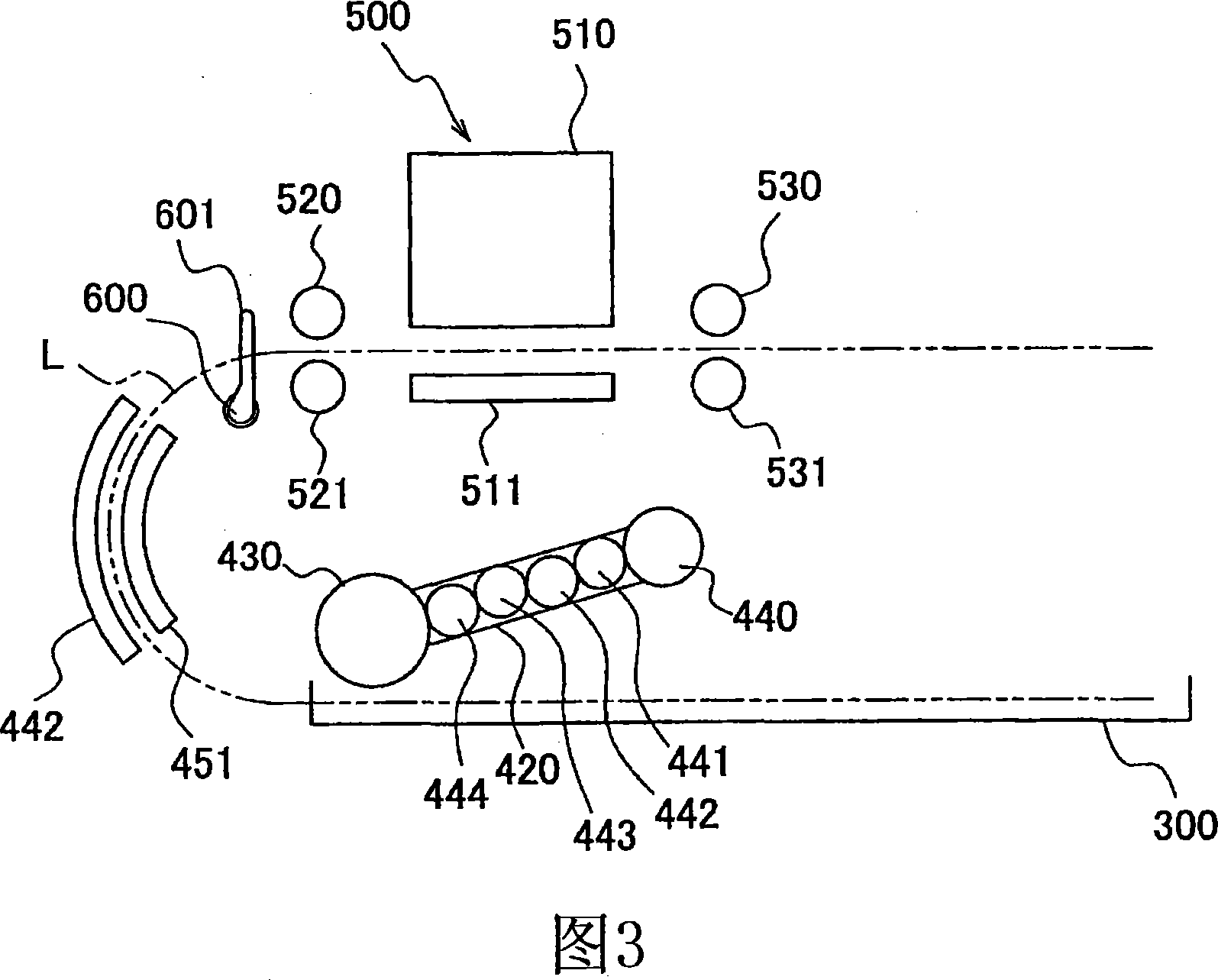

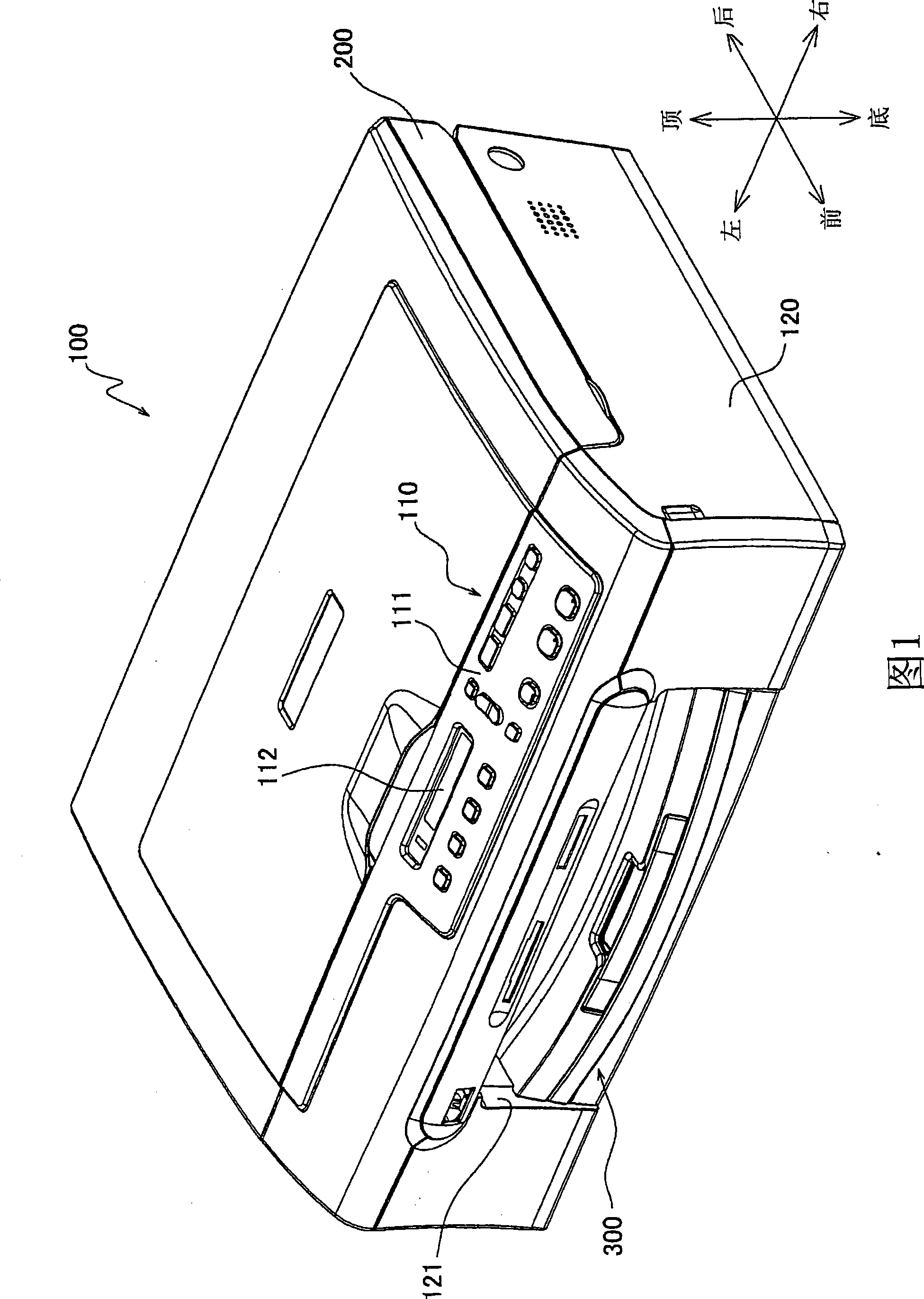

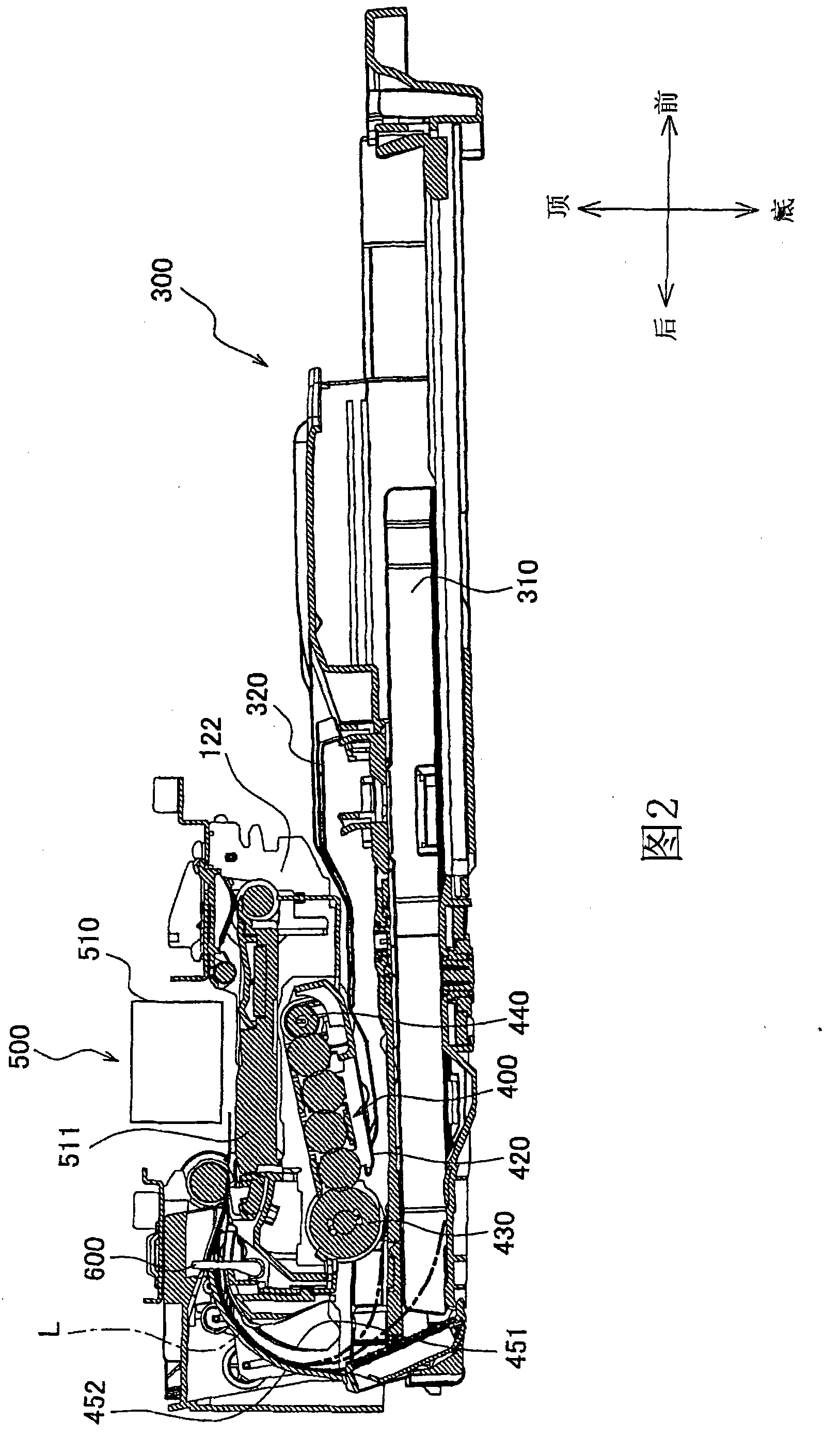

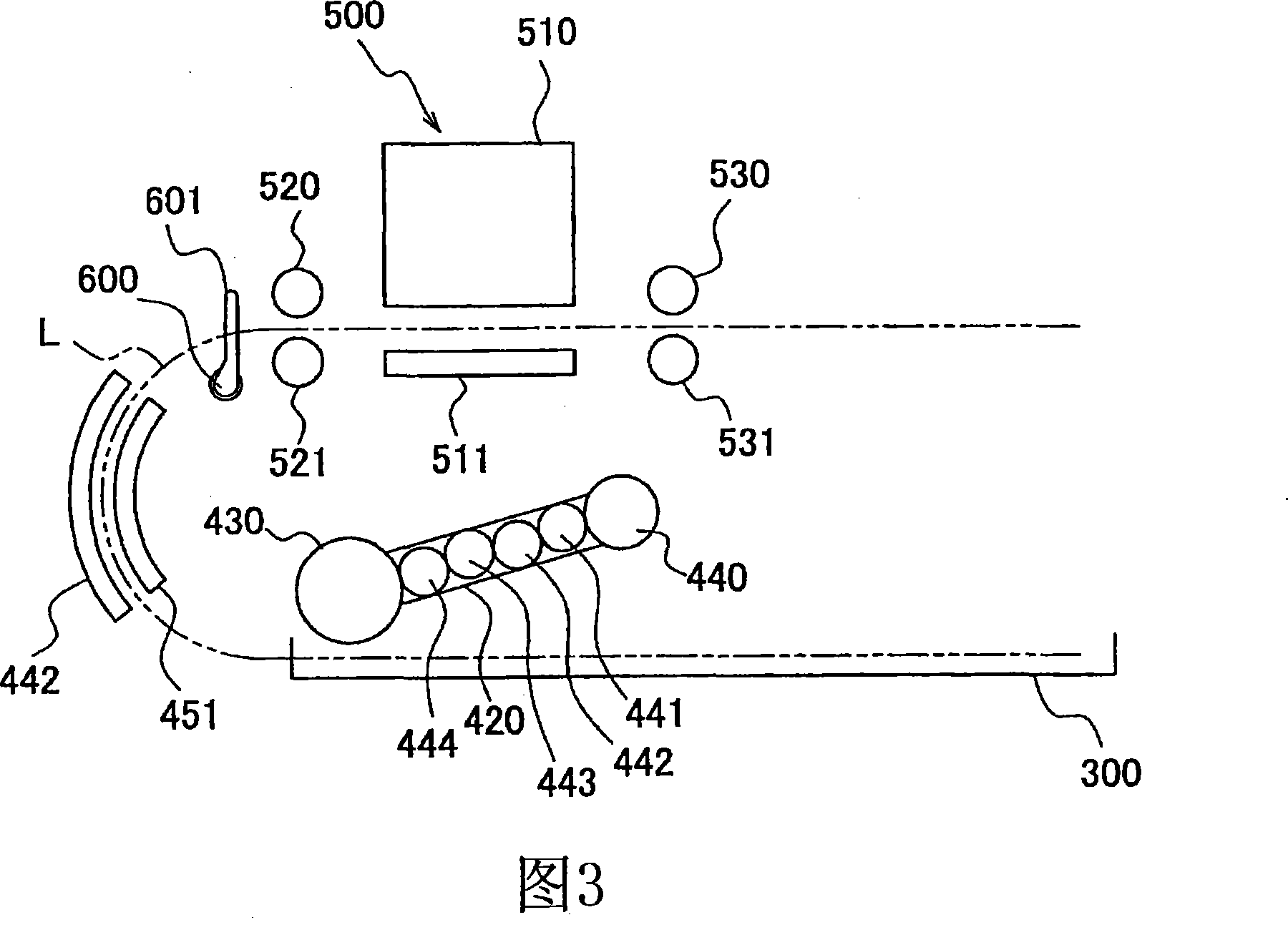

Imaging equipment

InactiveCN101143525APrecisely control delivery volumeOther printing apparatusFeeding forceImaging equipment

The invention provides an imaging device comprising: sheet feeding disc for loading the recording sheet; sheet feeding roller for feeding the recording sheet to the imaging device; delivery roller at the downstream of the sheet feeding roller along the shet feeding direction and applying the feeding force to the recording sheet; sheet position detecting device for detecting the position of the recording sheet on the feeding path; and feeding roller control device for controlling the rotation amount of the feeding roller based on the detected position. The said control device allow that the rotation amount of the delivery roller when the recording sheet contacts with the sheet feeding roller and the delivery roller is more than the rotation amount of the delivery roller when the recording sheet can not contact with the sheet feeding roller.

Owner:BROTHER KOGYO KK

Intelligent medicine putting device of traditional Chinese medicine footbath

InactiveCN106511064AScientific and reasonable deliveryPrecisely control delivery volumeMedical devicesBathing devicesDiseaseInformation processing

The invention relates to the field of footbath tools, in particular to an intelligent medicine putting device of a traditional Chinese medicine footbath. The intelligent medicine putting device comprises an outer body, medicine containing boxes, connecting shafts, box covers, flow detection and control devices, guide pipes, a detection device, a wire and an information processing feedback device. According to the intelligent medicine putting device, the foot problems are scientifically and accurately detected and analyzed by adopting an intelligent operation system, and needed medicines are scientifically and reasonably matched for symptomatic treatment through an information processing device; not only are foot diseases of a user treated, but also an optimal health-care effect is achieved; the foot diseases of the user can be automatically detected, and the medicines are scientifically and reasonably put automatically according to the disease conditions; the medicine put amount can be accurately controlled.

Owner:HENAN ZHIJIN NETWORK TECH CO LTD

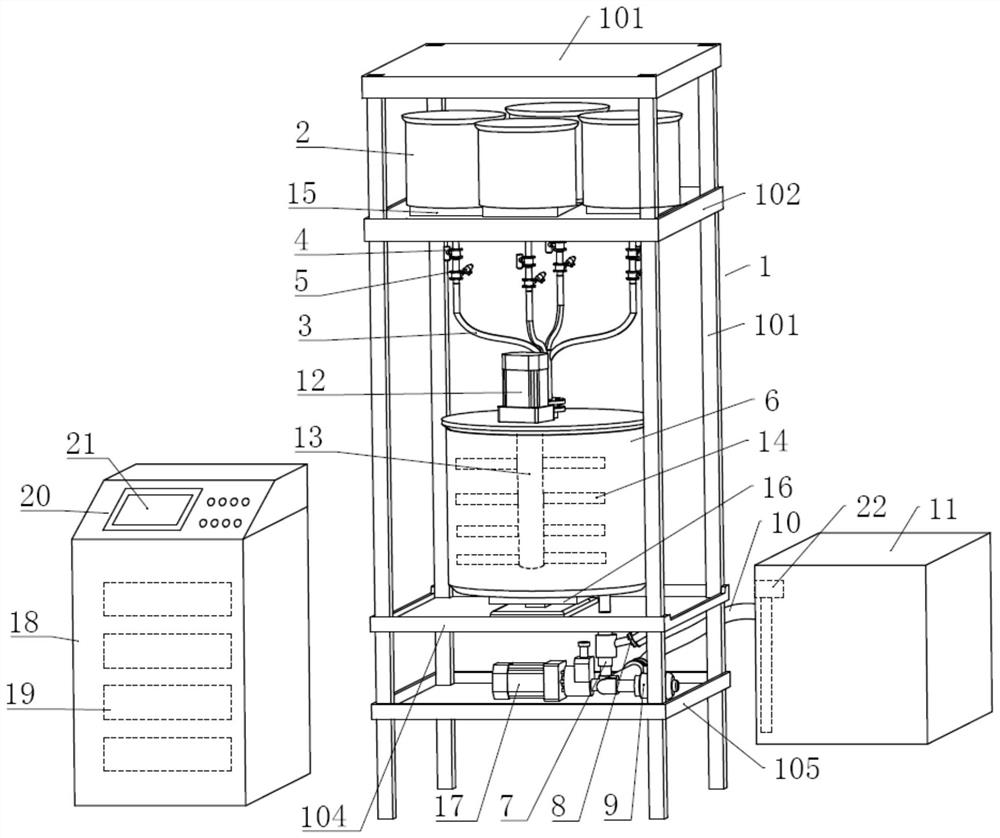

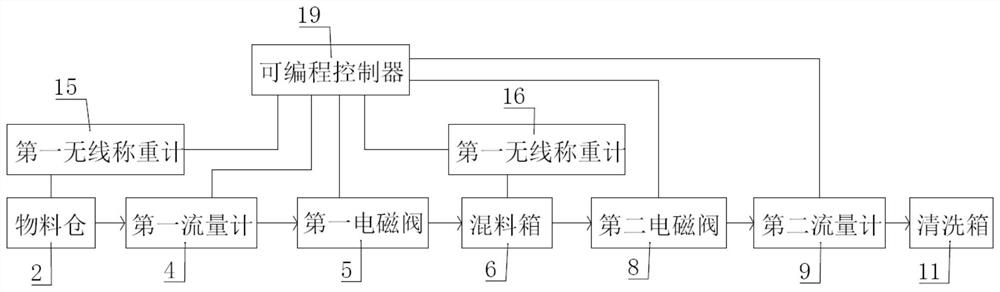

Multi-material full-automatic mixing device for SV type cleaning equipment and control system thereof

InactiveCN111701480AControl inputPrecise ratioRotary stirring mixersTransportation and packagingControl systemWireless traffic

The invention relates to the technical field of material mixing devices for cleaning equipment. The invention provides a multi-material full-automatic mixing device for SV type cleaning equipment anda control system thereof. The multi-material full-automatic mixing device for the SV-type cleaning equipment comprises: a machine frame, wherein a plurality of material bins are arranged at the top ofthe rack; the bottoms of the multiple material bins communicate with conveying pipes; a first wireless flow meter and a first electromagnetic valve are installed on each conveying pipe; the ends, away from the material bin, of the multiple conveying pipes communicate with the material mixing barrel; the bottom of the material mixing barrel communicates with a discharging pipe, and a second electromagnetic valve and a second wireless flow meter are installed on the discharging pipe; the end, away from the material mixing barrel, of the discharging pipe communicates with a connecting pipe whichcommunicates with the cleaning box. According to the invention, automatic and accurate control of material conveying, proportioning and stirring is realized, the operation is simple, and the materialproportioning is accurate and uniform.

Owner:WEIFANG VOCATIONAL COLLEGE

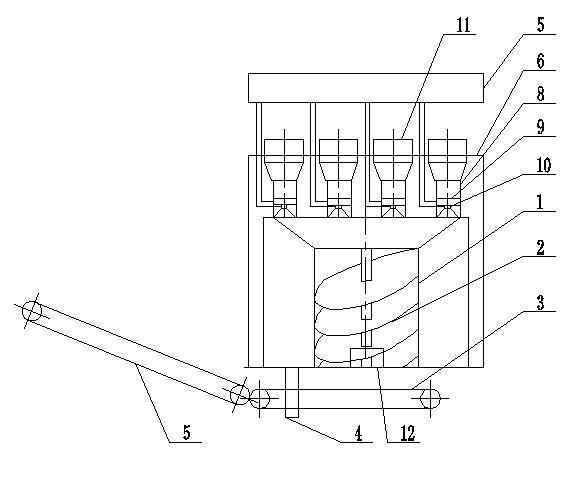

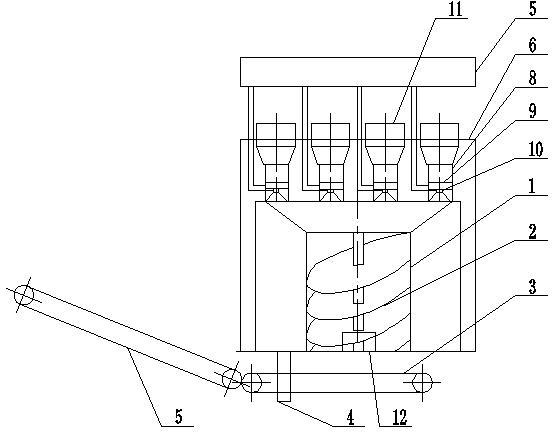

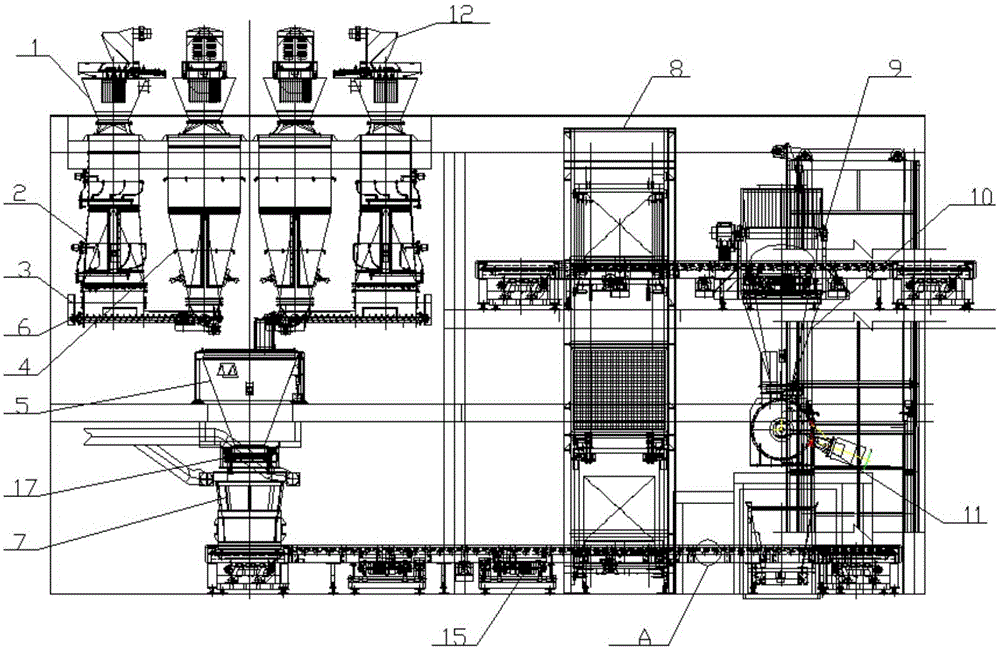

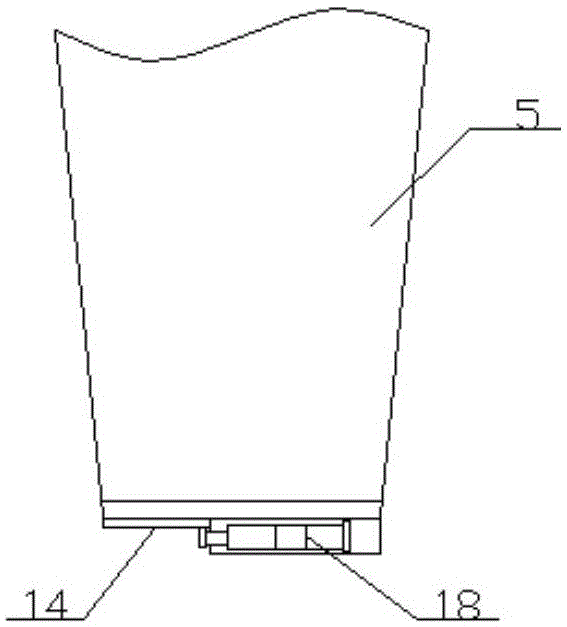

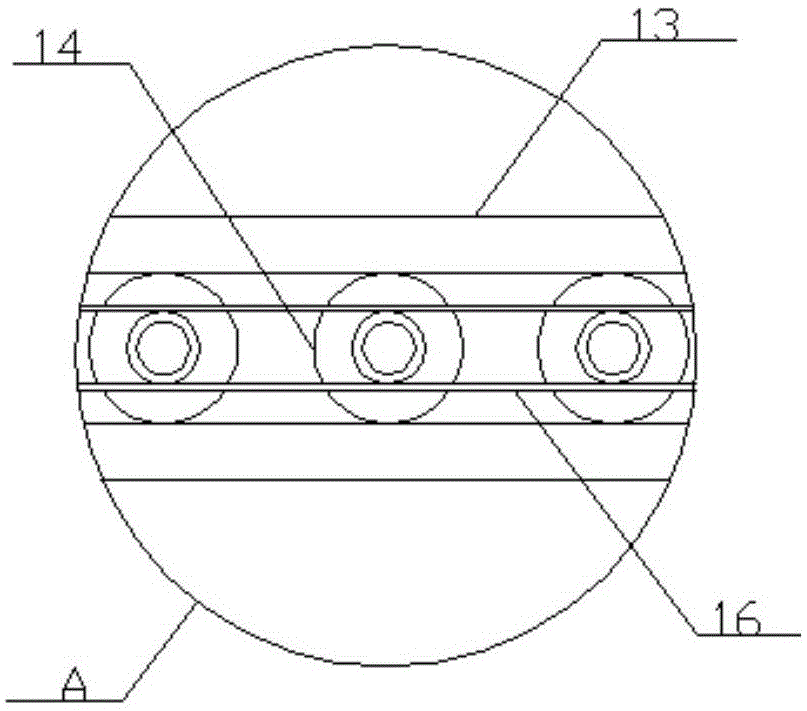

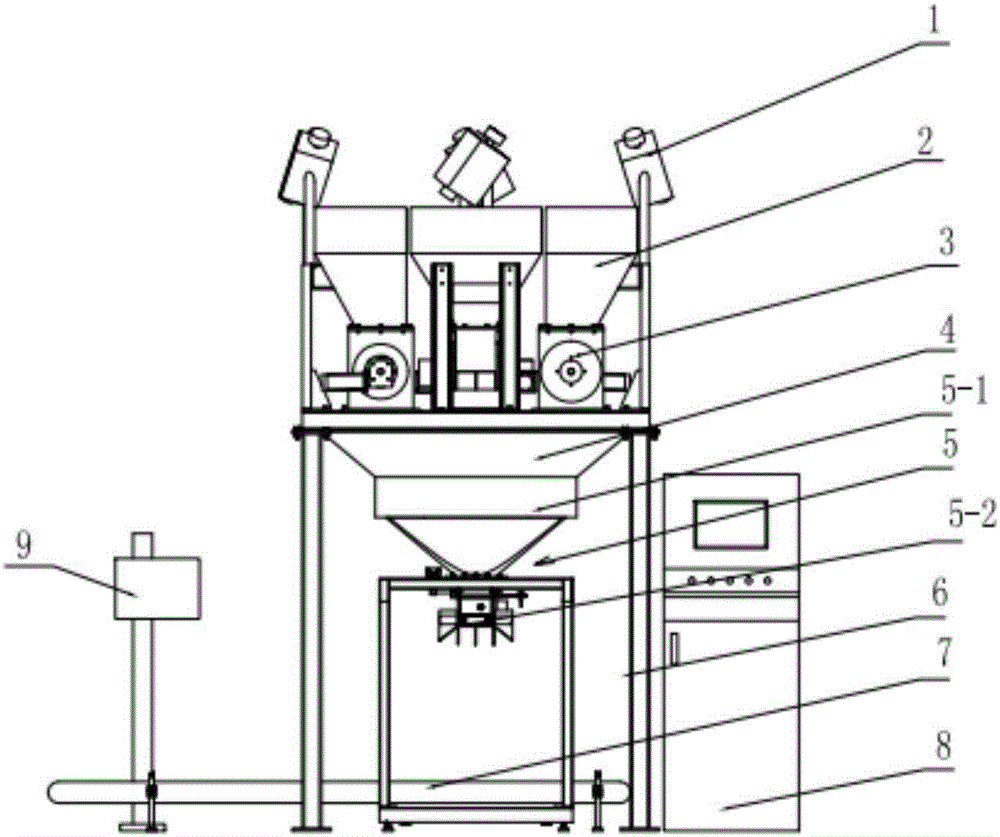

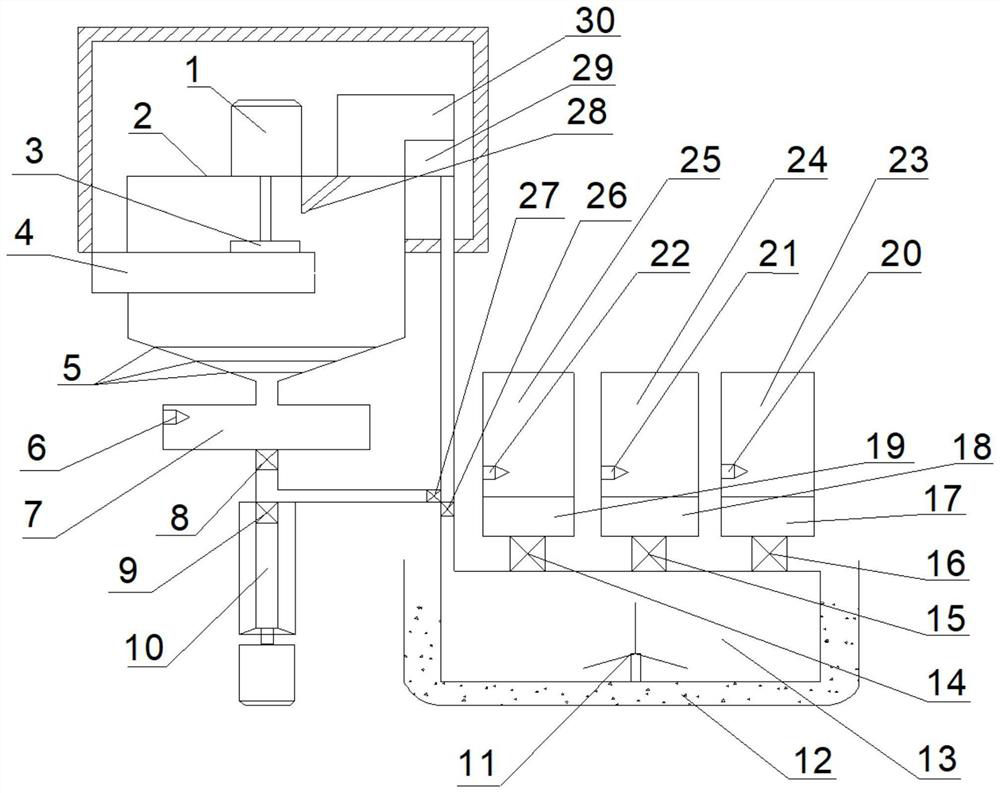

Small-size fertilizer preparation machine

PendingCN106475001AAvoid breakingReduce time spentTransportation and packagingMixer accessoriesAgricultural engineeringMaterial storage

The invention relates to the technical field of agricultural bulk blended fertilizer preparation, in particular to a small-size fertilizer preparation machine. The small-size fertilizer preparation machine comprises a rack. The small-size fertilizer preparation machine is characterized in that multiple metering and feeding devices are arranged at the upper part of the rack, and a hopper is correspondingly arranged above each metering and feeding device; the small-size fertilizer preparation machine also comprises conveying devices used for feeding the hoppers and material storage cabins; the lower ends of the conveying devices are connected with the material storage cabins, and material outlets formed in the upper ends of the conveying devices stretch to the upper parts of the hoppers; a material mixing cabin is arranged under the metering and feeding devices, the material mixing cabin is of a reversed cone cylindrical structure with an opening formed in the upper part, and a material falling outlet is formed in the lower part; a material receiving device is arranged under the material mixing cabin; the material mixing cabin comprises an annular inner wall, the middle part of the inner wall is a material falling annular surface, and at least the material falling annular surface is a hyperbolic annular surface or a parabolic annular surface. The small-size fertilizer preparation machine disclosed by the invention has the beneficial effects that the structure is simple, and crushing of fertilizer granules caused by material stirring and mixing can be avoided; time for fertilizer preparation is saved; the land occupation of the whole machine is small.

Owner:烟台中正新技术有限公司

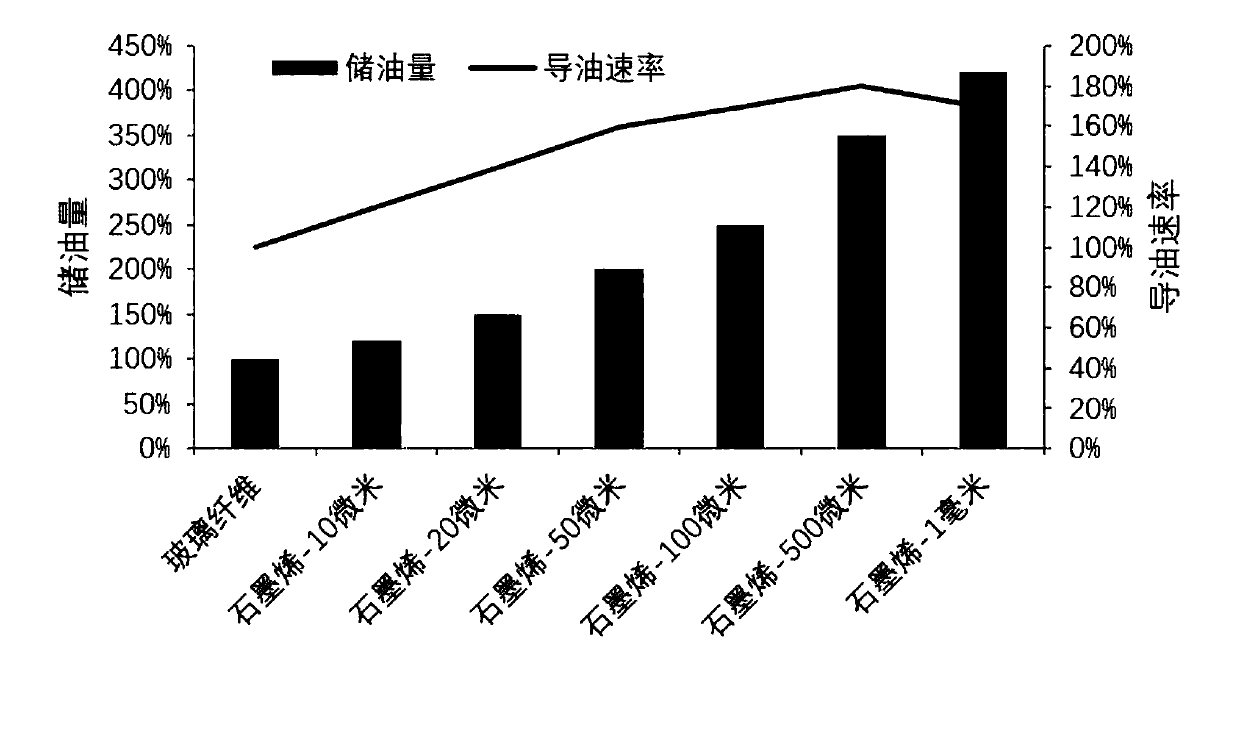

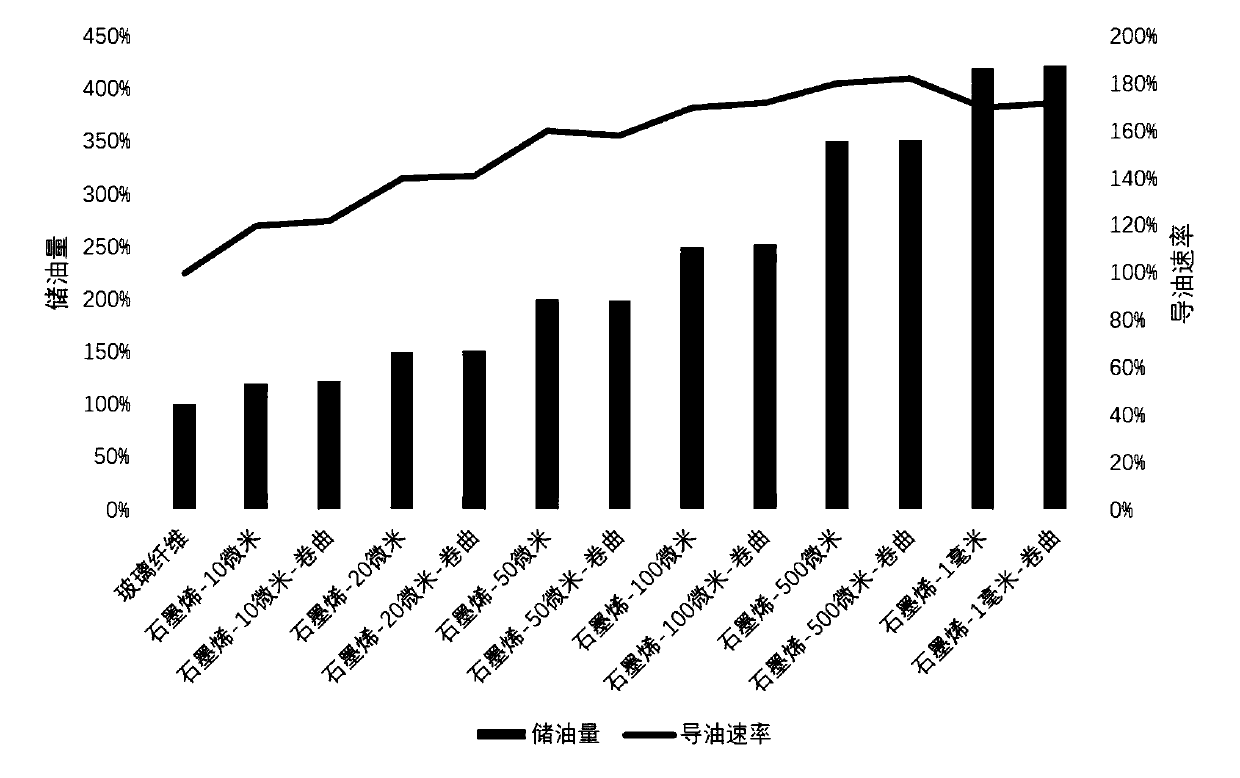

Preparation method for oil conduction material

ActiveCN109744583APrecisely control delivery volumePrecise control of conveying directionTobacco devicesFibre chemical featuresCvd grapheneMaterials science

The invention provides a preparation method for an oil conduction material, and is used for solving the problems that the heat conduction performance, the oil conduction performance and the oil storage performance of the oil conduction material are low in the prior art. The invention provides the preparation method for the oil conduction material, and the preparation method comprises the followingsteps: forming: graphene and / or graphene oxide is formed into a required shape; when the material contains the graphene oxide, an annealing step is contained before and after the forming step. The annealing step comprises the following step of carrying out annealing on the formed or non-formed graphene oxide to form the oxide. According to the preparation method, the preparation of the grapheneoil conduction material is realized.

Owner:重庆石墨烯研究院有限公司 +1

Material continuous or mixed conveying device and method for laser cladding

InactiveCN104561993AImprove continuityGuaranteed total flowMetallic material coating processesAir filterProcess engineering

The invention relates to the technical field of laser cladding and discloses material continuous or mixed conveying device and method for laser cladding. The material continuous or mixed conveying device comprises at least two stock bins, at least two material level monitoring elements, at least two conveying pipelines, an air filter, at least two gas flowmeters, at least two valves and at least two nozzles, wherein the conveying pipelines are connected with the corresponding stock bins and the corresponding nozzles; the material level monitoring elements are arranged on the corresponding stock bins; the valves are arranged on the corresponding conveying pipelines; the air filter is introduced into the conveying pipelines; the gas flowmeters are arranged on the corresponding conveying pipelines. According to the material continuous or mixed conveying device disclosed by the invention, when the material level monitoring elements monitor that materials in the stock bins descend to the preset positions, other stock bins are started to feed the materials, and the materials are continuously conveyed; in the conveying process of the materials, gas flows in the conveying pipelines are controlled by virtue of the corresponding gas flowmeters, so that the conveying quantity of each stock bin is controlled, and the needed proportion of the materials after mixing is achieved. The material continuous or mixed conveying device and method satisfy the needs of a user for conveying the materials.

Owner:武汉武钢华工激光大型装备有限公司

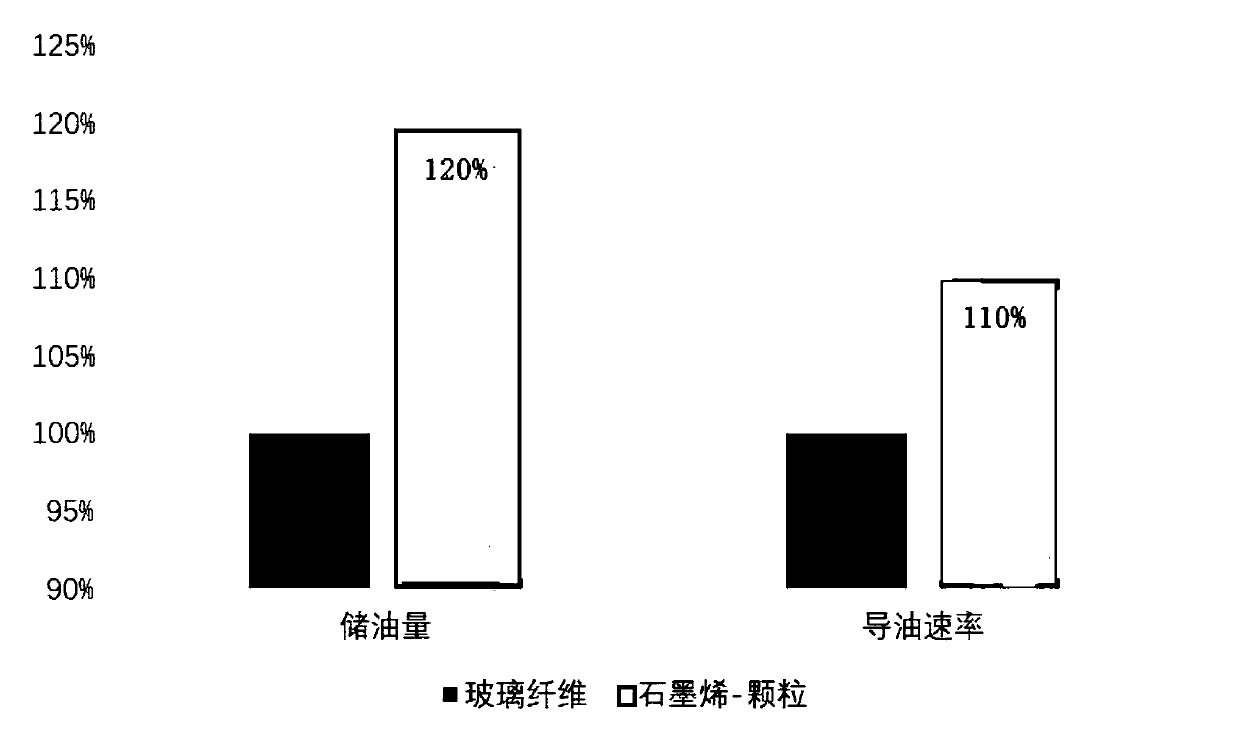

Graphene oil conducting material, oil conducting group, electronic cigarette and oil conducting device

PendingCN109602095APrecisely control delivery volumePrecise control of conveying directionTobacco devicesParticulatesElectronic cigarette

The invention provides a graphene oil conducting material, an oil conducting group, an electronic cigarette and an oil conducting device, and is used for solving the problems of poor stability or lowoil conducting rate or low oil storage amount of the oil conducting material in the prior art. The invention provides the graphene oil conducting material which comprises a plurality of superposed layers of graphene. The graphene oil conducting material is particulate graphene, filamentary graphene or flake graphene, and has the characteristics of high thermal stability, high oil conducting rate and high oil storage amount.

Owner:重庆石墨烯研究院有限公司 +1

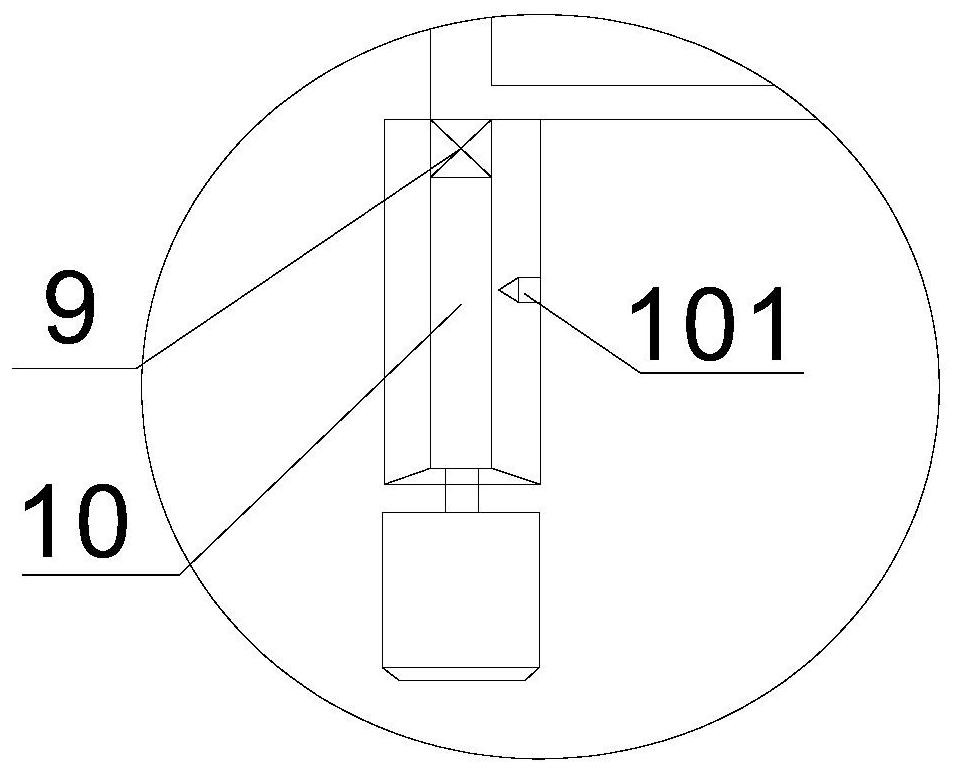

Nano-particle ultrasonic atomization and classification device and method

ActiveCN111420792AReasonable structureEasy to operateDispersed particle separationLiquid spraying apparatusNanoparticleUltrasonic atomization

The invention discloses a nano-particle ultrasonic atomization and classification device and method and belongs to the technical field of nano powder classification. The ultrasonic atomization and classification device comprises an ultrafine powder solution tank, a material inlet pipe, a ring-shaped feeding pipe, a variable cross section draining pipe, a material return pipe, an ultrasonic atomization reaction tank, an ultrasonic atomization device, an air blowing device, a water mist collecting pipe, a gas-liquid separation device and a water mist collecting tank. By means of the nano-particle ultrasonic atomization and classification device, the classification precision meets the classification requirement of nanoscale particles, the problems that a current nano powder classification device has the problems that the material liquid utilization rate is low, the material liquid input amount is not matched with the atomization amount of a transducer, the material liquid input position is not matched with the position of the transducer, and water mist collection is insufficient are solved, and the classification precision, the material liquid utilization rate and the classification efficiency can be effectively improved.

Owner:JIANGNAN UNIV

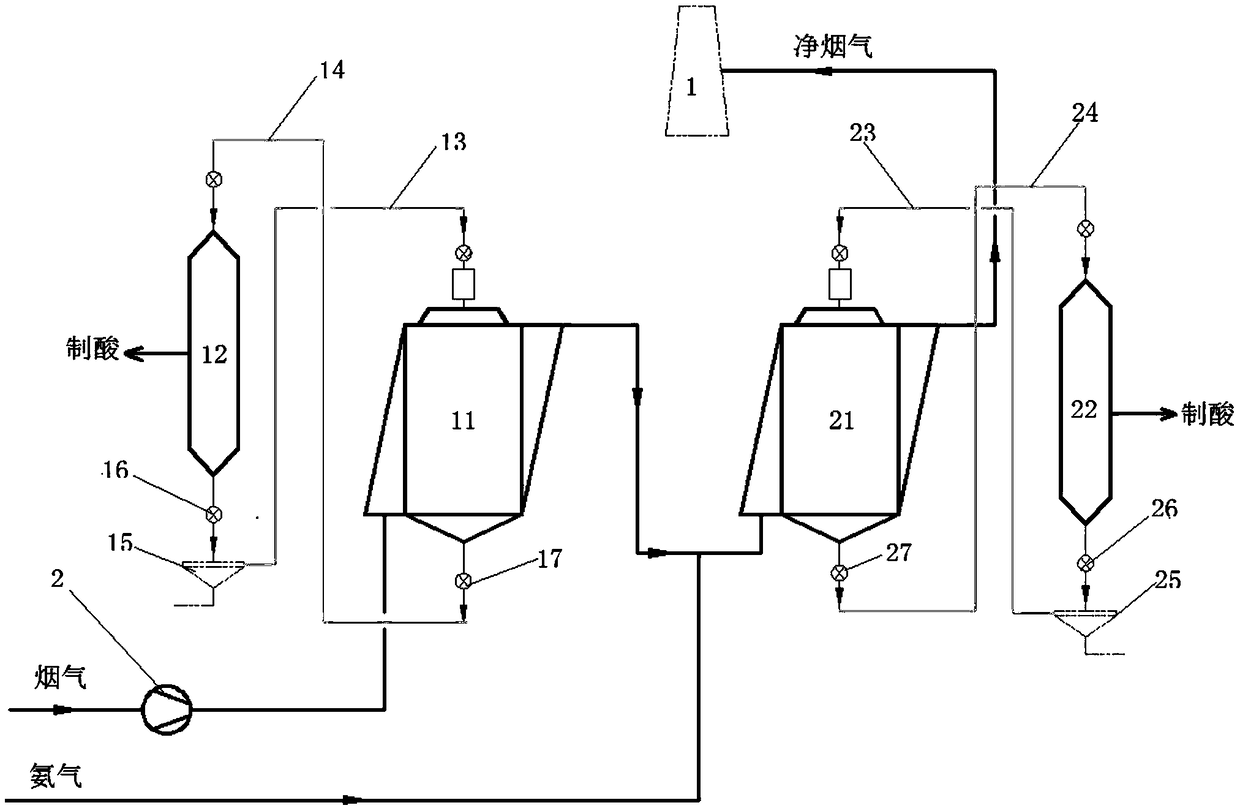

Flue gas series desulfurization and denitration system and method

PendingCN109395529APrecisely control delivery volumePrecise control of conveying speedDispersed particle separationFlue gasProcess engineering

The invention belongs to the technical field of industrial waste gas treatment, and particularly provides a flue gas series desulfurization and denitration system and method. Flue gas is purified by sequentially causing flue gas to pass through a desulfurization adsorption tower and a denitration adsorption tower in series; meanwhile, active coke is conveyed to the desulfurization adsorption towerand the denitration adsorption tower independently respectively through an active coke conveying unit, and the active coke after the reaction is conveyed to an analytical tower for independent analysis and recycling. On the one hand, by independently controlling conveying amounts and conveying speeds of the active coke in the desulfurization adsorption tower and the denitration adsorption tower,the desulfurization and denitration efficiency is improved; on the other hand, by precisely controlling the conveying amounts and the conveying speeds of the active coke, the desynchrony of the two inthe use amount of the active coke is achieved, the physical loss of the active coke is reduced, and the running cost is reduced; the heating is not required before and after the flue gas treatment, and the overall energy consumption is low.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Abrasive preparation device, polishing system and working method

ActiveCN114590814AMeet job needsOmit dispersionPolishing machinesSilicaEngineeringProcess engineering

The invention provides an abrasive preparation device, a polishing system and a working method, and relates to the technical field of polishing equipment, the abrasive preparation device comprises a generation box, a stirring mechanism and a plurality of feeding mechanisms, and the stirring mechanism is arranged in the generation box; the feeding mechanism comprises a raw material box, a raw material pump and a raw material valve which are sequentially connected, the output end of the raw material valve communicates with the generation box, the raw material valve and the raw material pump are connected to the controller, and the controller is used for adjusting the discharging speed of the raw material box and the discharging ratio of different raw material boxes so as to adjust the particle size of the prepared abrasive in the generation box; aiming at the problem that an existing abrasive preparation device is inconvenient to adjust the grain size of polishing abrasives, various raw materials are used for manufacturing the abrasives, the abrasives with different grain sizes are obtained by adjusting the adding speed and proportion of the raw materials, and a polishing pump is kept to output a polishing solution while the grain size of the abrasives is adjusted; in the working process, polishing, recycling and preparing are continuously linked, work is independently carried out, mutual influence is avoided, and the working requirement of continuous polishing is met.

Owner:QILU UNIV OF TECH

Quantitative conveying system for wood flour

InactiveCN107957075AControl delivery volumePrecisely control delivery volumeLump/pulverulent fuel feeder/distributionFrequency conversionSmoke

The invention relates to a wood flour quantitative conveying system. Including storage bin, feeding bin, inclined screw, separator and Venturi, the storage bin is a rectangular structure, the lower end of the storage bin is open, the inclined screw is installed obliquely at the lower end of the storage bin, and the upper end of the inclined screw The bottom is connected with a flap valve, the separator is installed at the upper end of the storage bin, the separator is located above the lower end of the inclined screw, and the rear end of the Venturi is connected with a blower, and the air inlet of the blower is connected with the upper end of the feed bin through a suction pipe, separating The upper end of the separator is connected with the suction pipe through the smoke exhaust pipe, the side wall of the separator is provided with a feed pipe, the other end of the feed pipe is connected with the lower end of the feed bin, and the inclined screw is controlled by a frequency conversion motor. The invention has a simple structure. By using an inclined screw to convey wood powder and using a frequency conversion motor to control the inclined screw, the conveying amount of wood powder can be accurately controlled; Wind conveying; Venturi is installed at the lower end of the flap valve, so that the powder will no longer block the conveying pipe, reducing the maintenance rate; high safety.

Owner:扬州汇聚热能设备有限公司

Imaging equipment

InactiveCN101143525BPrecisely control delivery volumeOther printing apparatusFeeding forceImaging equipment

The invention provides an imaging device comprising: sheet feeding disc for loading the recording sheet; sheet feeding roller for feeding the recording sheet to the imaging device; delivery roller at the downstream of the sheet feeding roller along the shet feeding direction and applying the feeding force to the recording sheet; sheet position detecting device for detecting the position of the recording sheet on the feeding path; and feeding roller control device for controlling the rotation amount of the feeding roller based on the detected position. The said control device allow that the rotation amount of the delivery roller when the recording sheet contacts with the sheet feeding roller and the delivery roller is more than the rotation amount of the delivery roller when the recording sheet can not contact with the sheet feeding roller.

Owner:BROTHER KOGYO KK

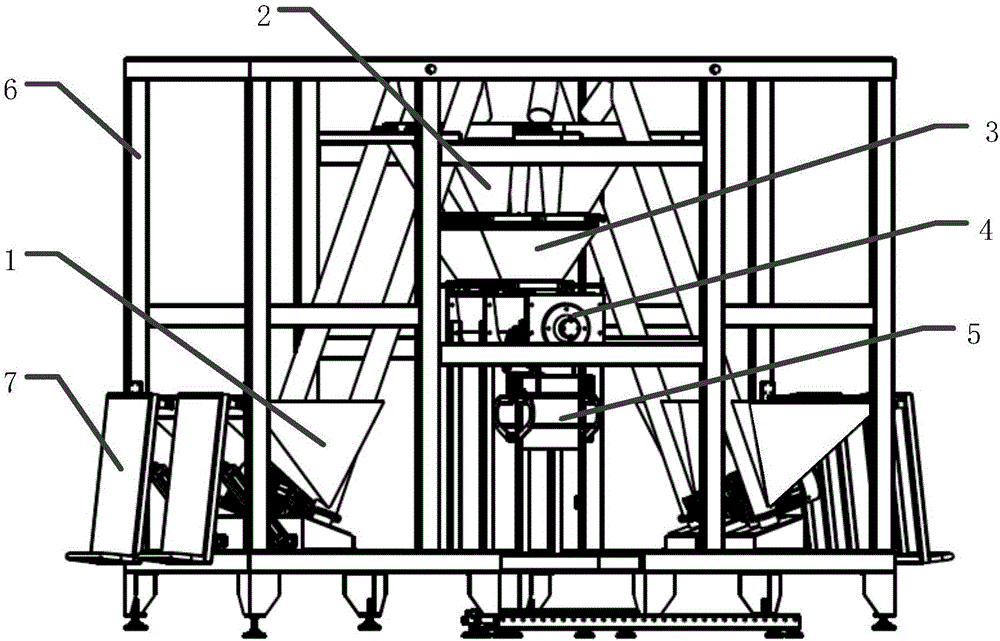

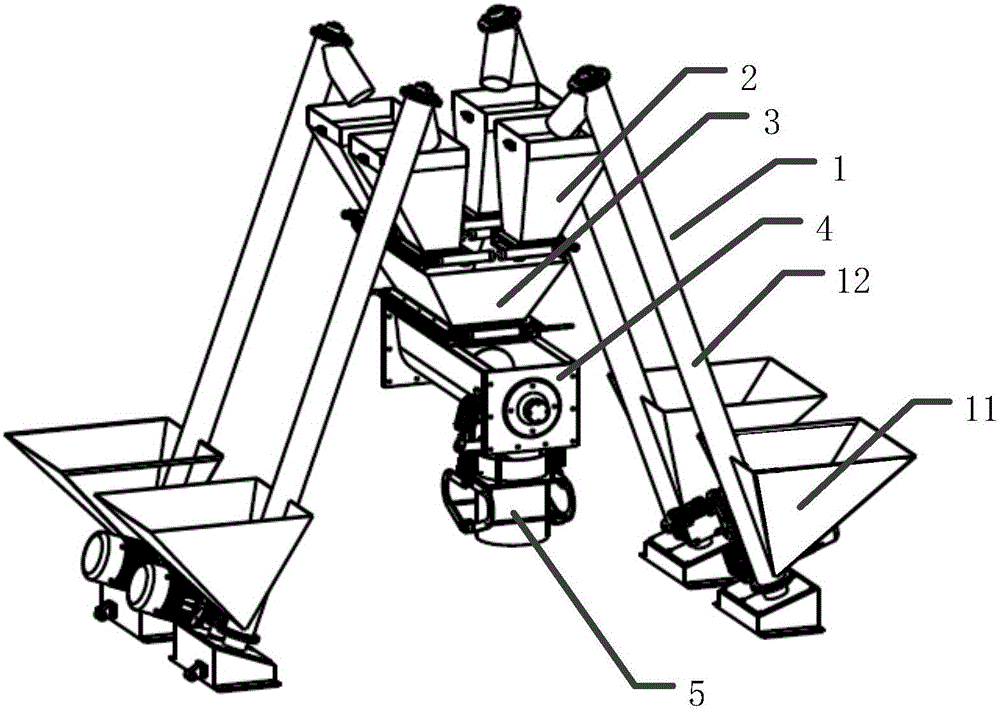

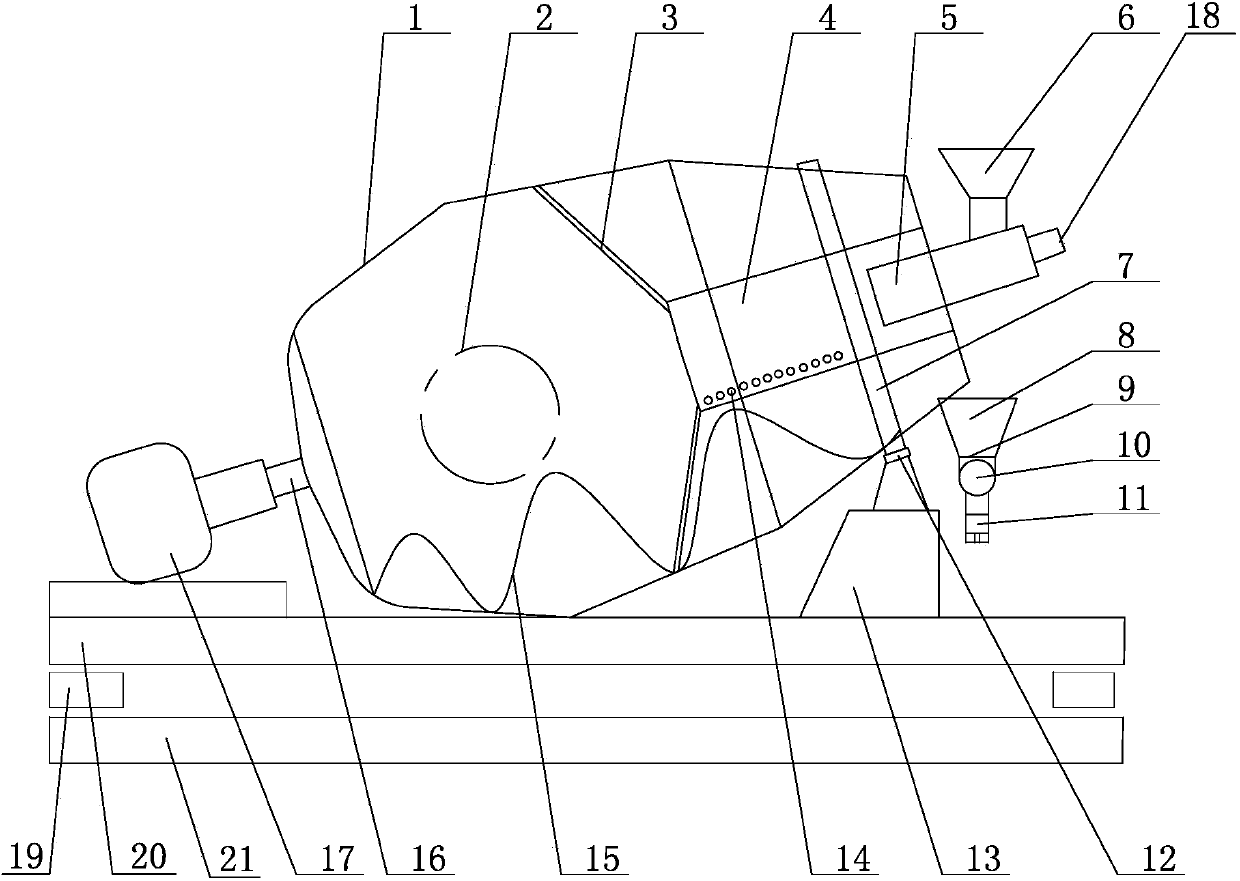

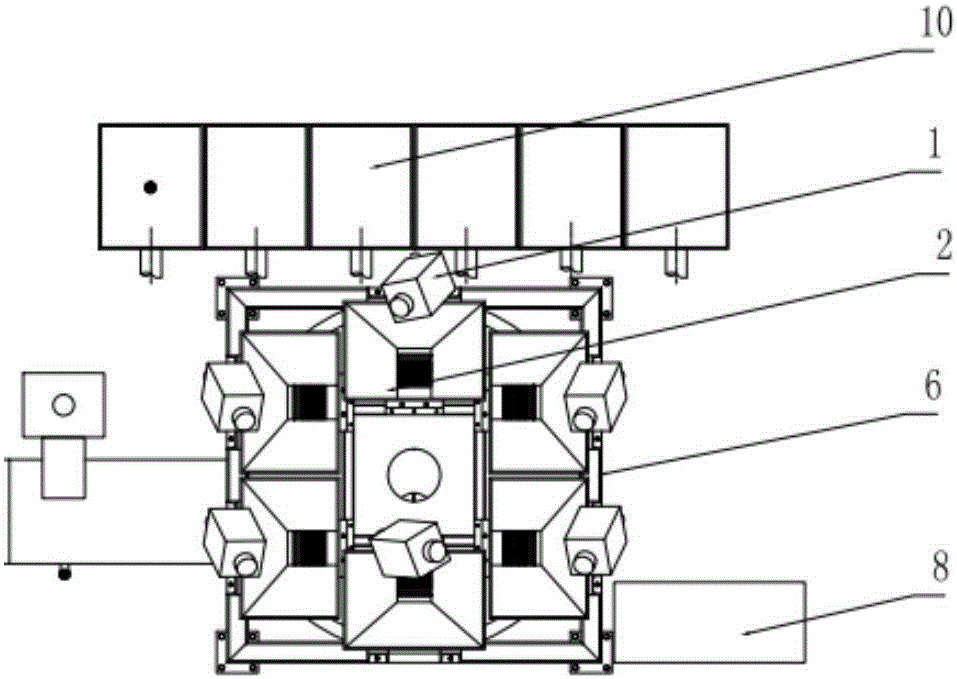

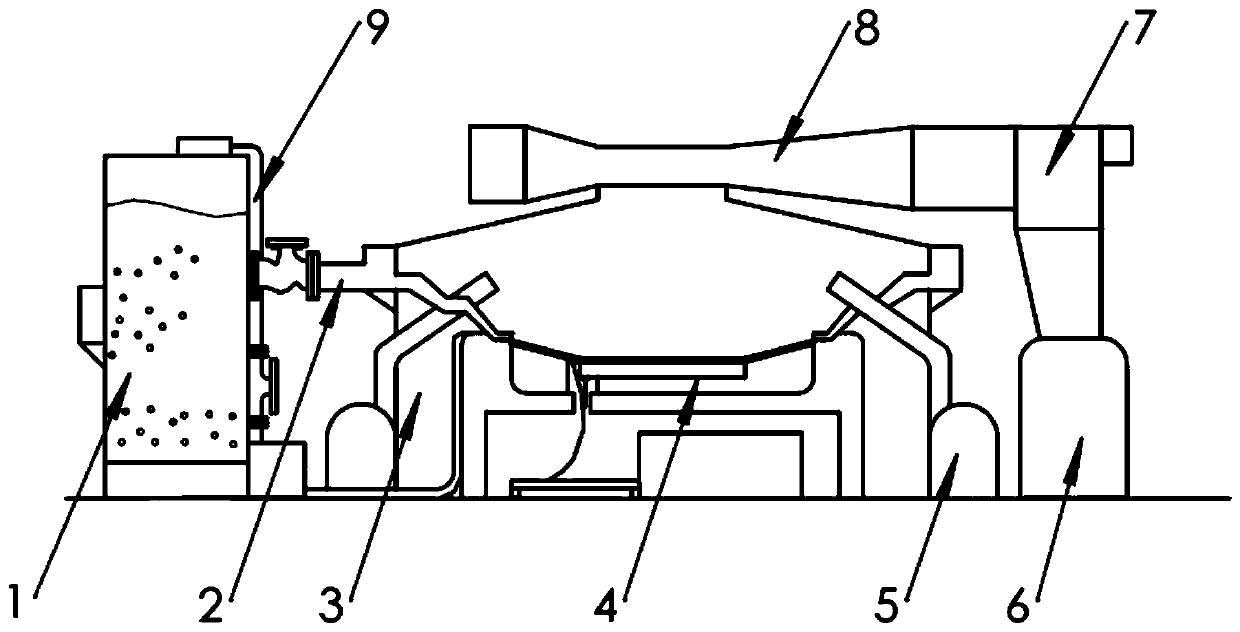

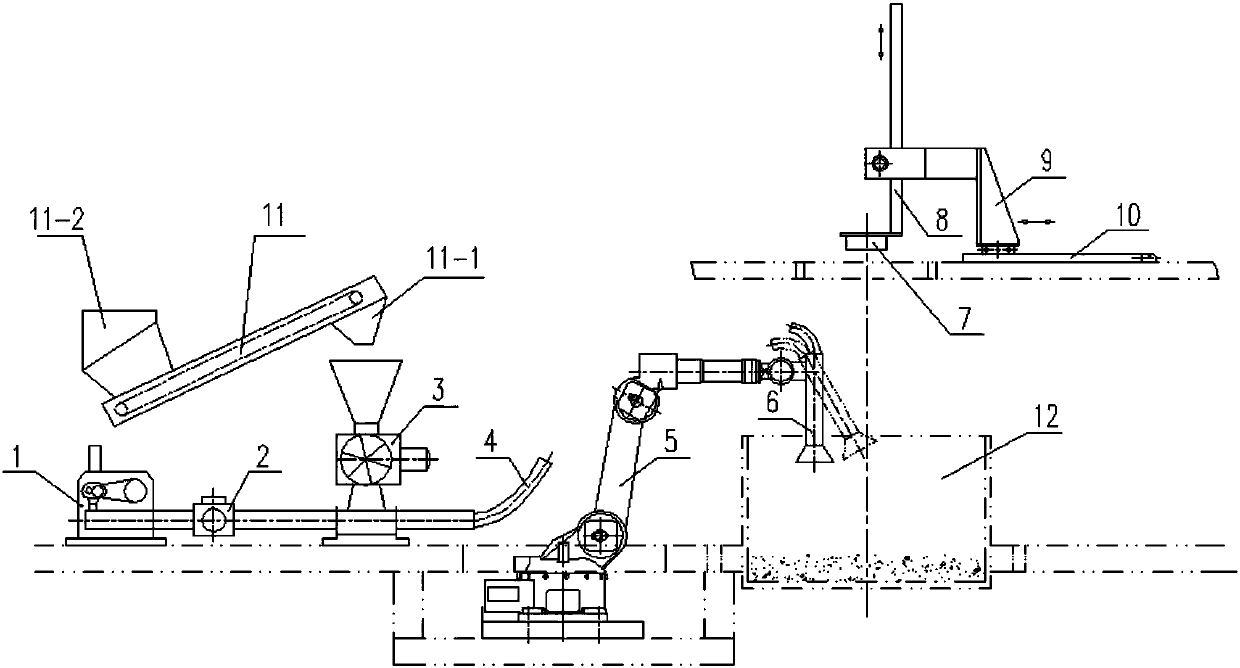

Automatic stacking system for brewing wine and its spreading method

ActiveCN105600498BIncrease productivityLow costBulk conveyorsLoading/unloadingControl systemArtificial materials

The invention discloses an automatic stacking system for brewing. The system comprises an automatic material spreading device and a feeding device, wherein the automatic material spreading device is used for spreading materials into a brewing barrel, the action of the automatic material spreading device is controlled by a central control system, the feeding device is used for supplying the brewing raw materials to the automatic material spreading device, and the output end of the feeding device is communicated with the automatic material spreading device. The invention further provides a material spreading method of the automatic stacking system for brewing. The method comprises the following steps that 1, the raw materials for brewing are fed into the automatic material spreading device through the feeding device; 2, the automatic material spreading device is controlled by the central control system to spread the raw materials for brewing into the brewing barrel. According to the automatic stacking system for brewing and the material spreading method of the system, feeding is conducted through the feeding device, pneumatic conveying is conducted through a fan, the materials are spread into the brewing barrel through a material spreading robot, the action which stimulates artificial material spreading can be achieved by being controlled by the central control system, and the production efficiency is extremely improved; only a hose needs to be fixed on a material spreading tube of the material spreading robot, the system is simple, and the cost is low.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

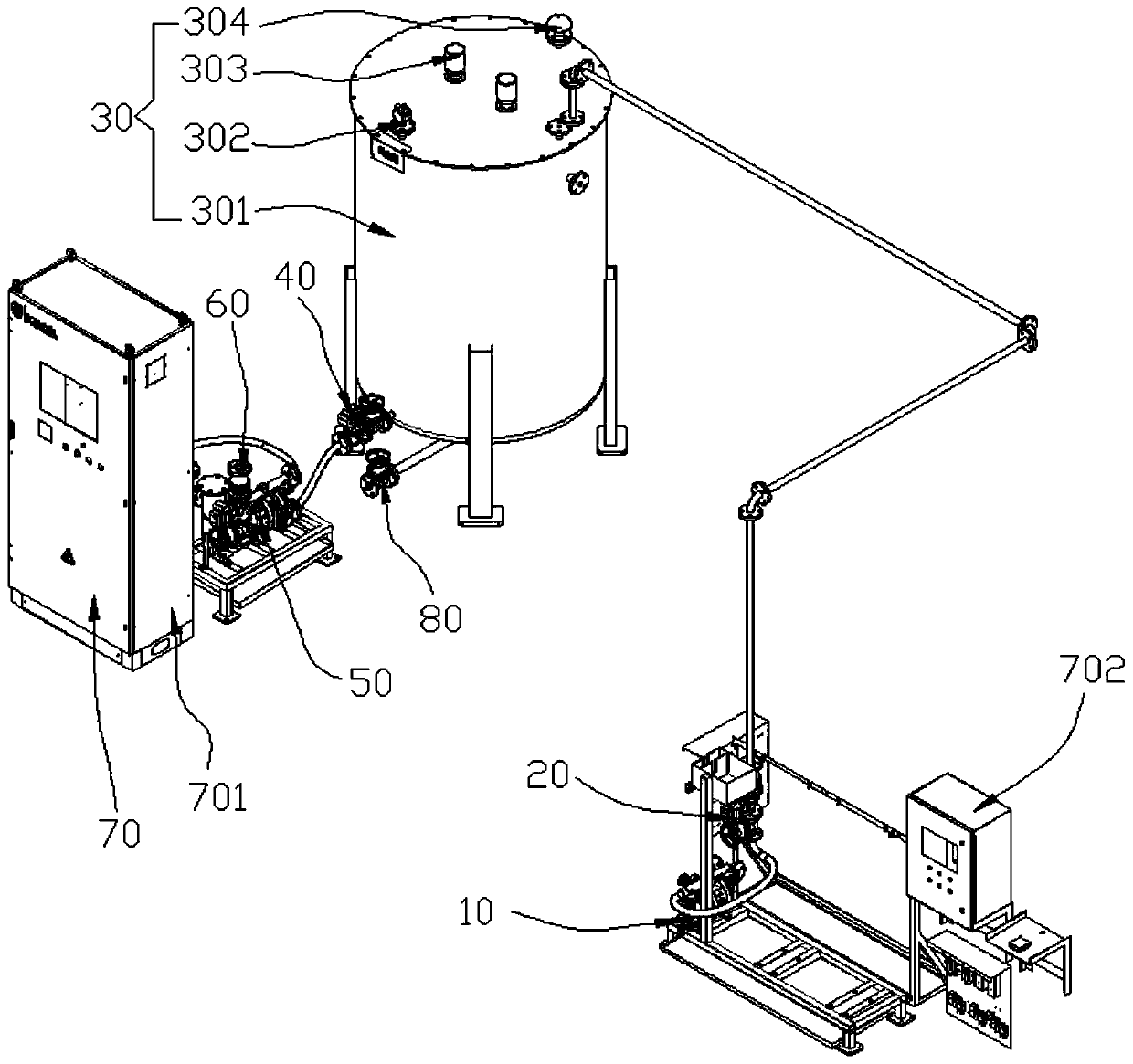

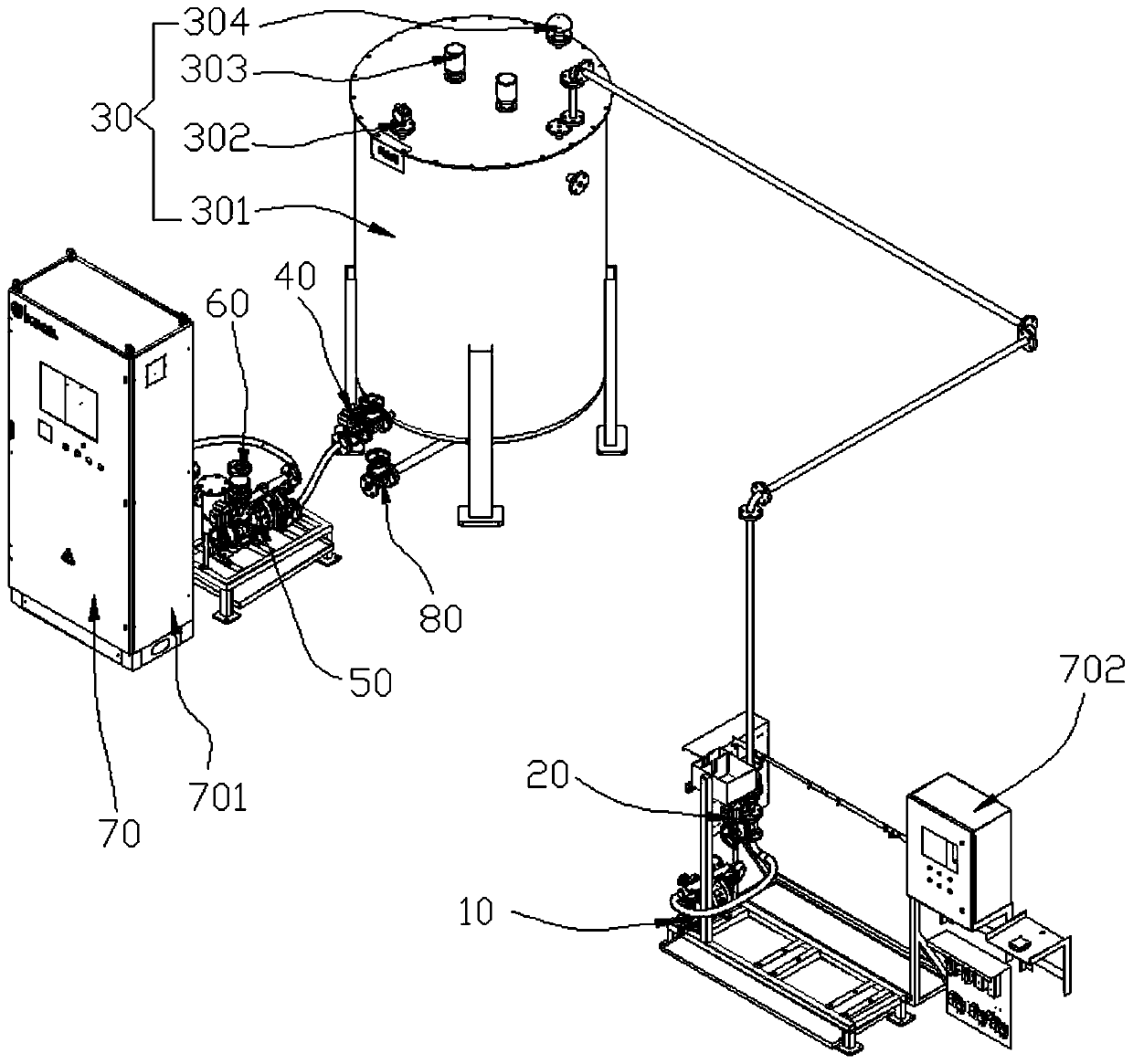

Automatic liquid material conveying system

PendingCN109987566ARealize automatic feeding processAchieve storageLarge containersLiquid transferring devicesEngineeringDelivery system

The invention belongs to the technical field of industrial liquid material conveying, in particular to an automatic liquid material conveying system. The automatic liquid material conveying system comprises a charging pump, a charging valve group, a liquid material storage device, a feeding valve group, a feeding pump and a filter; the liquid material storage device comprises a liquid material tank, a temperature sensor and material level gauges; a feeding hole and a supplied material discharge hole are correspondingly formed in the upper end and the lower end of the liquid material tank; thecharging pump is connected with the charging valve group; the charging valve group communicates with the feeding hole of the liquid material tank; the supplied material discharge hole of the liquid material tank communicates with the feeding valve group; the feeding valve group is connected with the feeding pump; the feeding pump is connected with the filter; and the filter is connected with a liquid material demand device. The system provided by the invention has the beneficial effects that automatic feeding and storage can be realized, so that manual labor is reduced, and efficiency is increased; conveying capacity and storage capacity can be accurately controlled, so that accurate liquid supply is performed; moreover, the automatic liquid material conveying system can be flexibly buttedwith other devices, and is connected with a needed liquid material device to realize full-automatic intelligent liquid supply; and the automatic liquid material conveying system is capable of realizing pollution-free emission, and is environmentally friendly and energy-saving.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

A device and method for generating gaseous pollutants for air purifier performance detection

ActiveCN103411779BPrecisely control delivery volumeRapid change in concentrationVehicle testingElectricityAir purifiers

Owner:天津中天环境科技有限公司

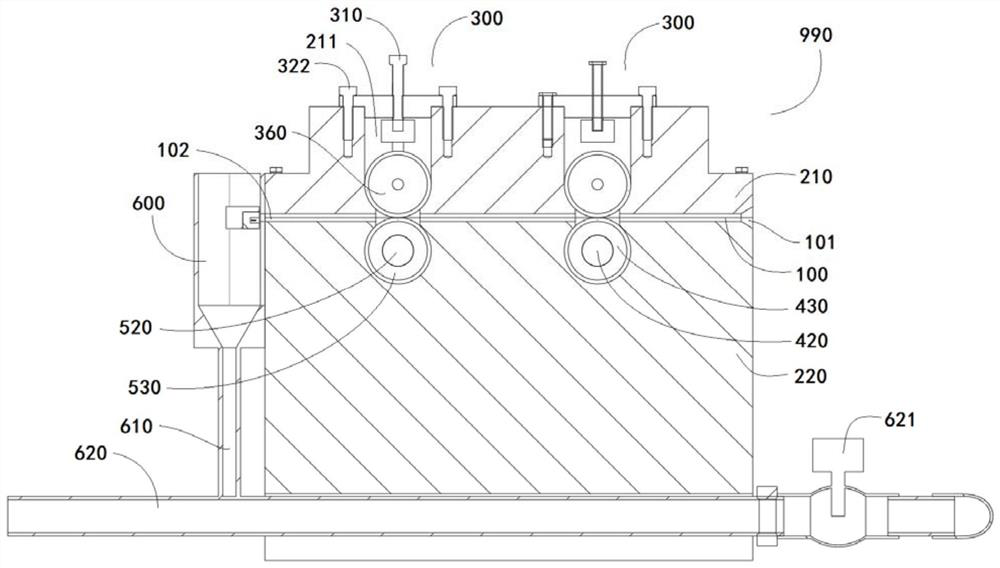

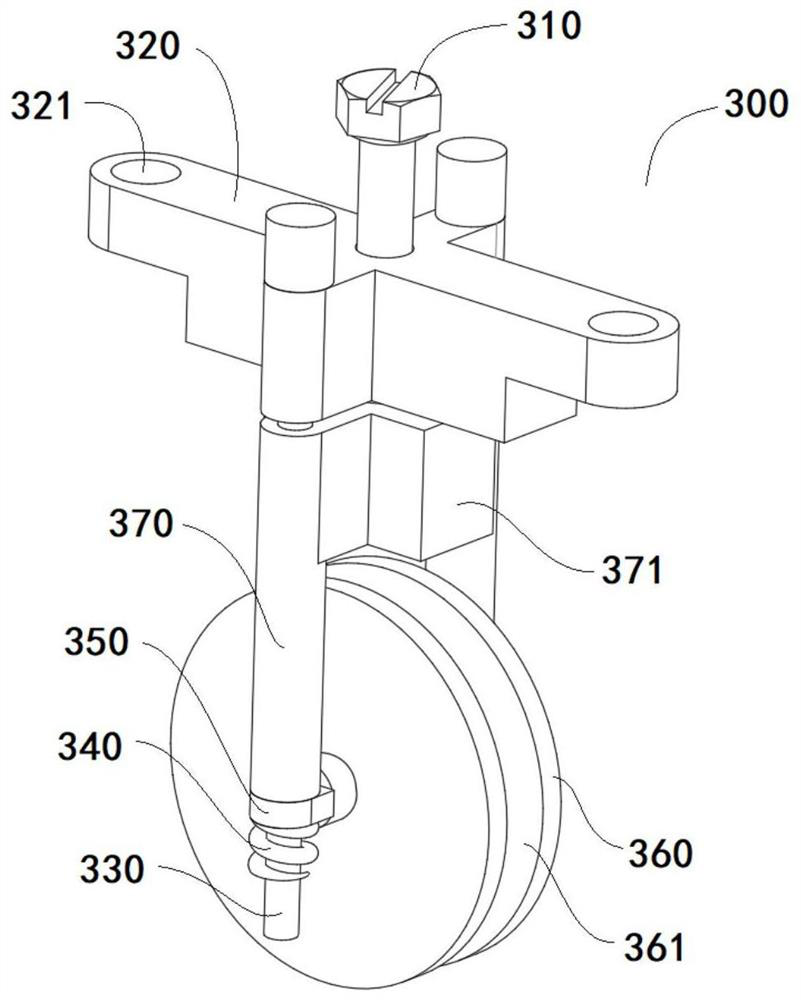

Metal wire feeding device, charging system and charging method

ActiveCN113684370AReduce burning lossStable deliveryFilament handlingIncreasing energy efficiencyDrive wheelMetallurgy

The invention discloses a metal wire feeding device, a charging system and a charging method, and belongs to the technical field of electroslag metallurgy. The metal wire feeding device comprises a feeding channel, a pressing mechanism, a driving mechanism, a driving wheel and a support; the pressing mechanism comprises a guide rod, an elastic piece, a pressing wheel and a sliding sleeve; the guide rod is vertically arranged on the support; the sliding sleeve is arranged outside the guide rod in a sliding mode and connected with the guide rod through the elastic piece, and the pressing wheel is rotationally connected with the sliding sleeve; the driving mechanism is arranged on the support, is connected with the driving wheel and is used for driving the driving wheel to rotate; the driving wheel and the pressing wheel are arranged on the two opposite side portions of the feeding channel respectively, and the rotating plane of the driving wheel and the rotating plane of the pressing wheel and the feeding channel are located in the same plane; and the driving wheel and the pressing wheel can be connected with a metal wire material in the feeding channel in a rolling manner. By means of the metal wire feeding device, stable pressing conveying can be achieved, the conveying amount of metal wire materials can be accurately controlled, the oxygen content of an electroslag remelting system is stably controlled to range from 20 ppm to 30 ppm, and the quality of electroslag ingots is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A forest bird feeder with the function of Internet of Things

ActiveCN111109148BBird Health EffectsControl delivery volumeCharacter and pattern recognitionAvicultureBird feederFishery

Owner:GUANGZHOU CITY CONSTR COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com