Control device of trace addition instrument and trace addition instrument

A control device and additive amount technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as excessive dosage, adverse effects on polishing effect, and inaccurate control of feeding time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

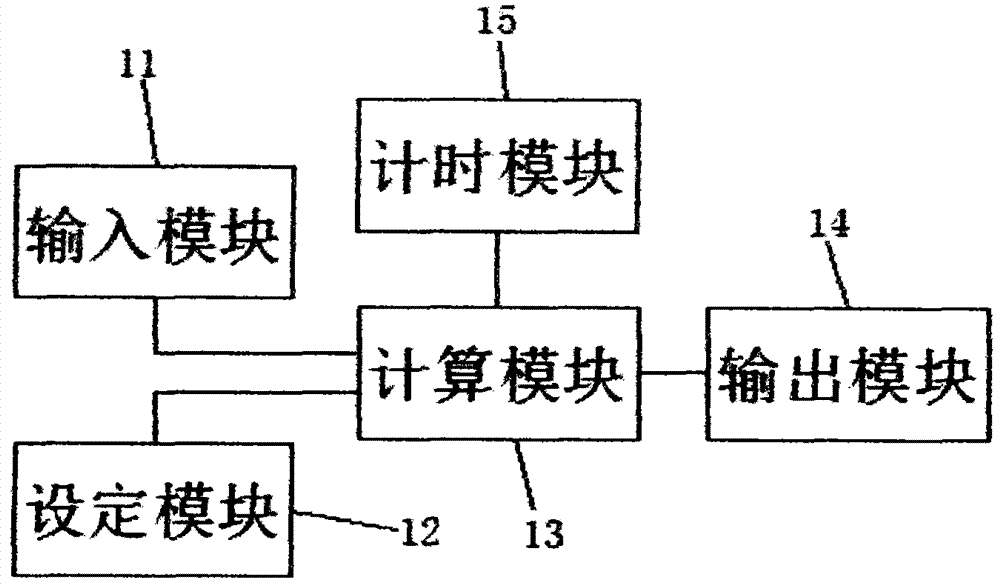

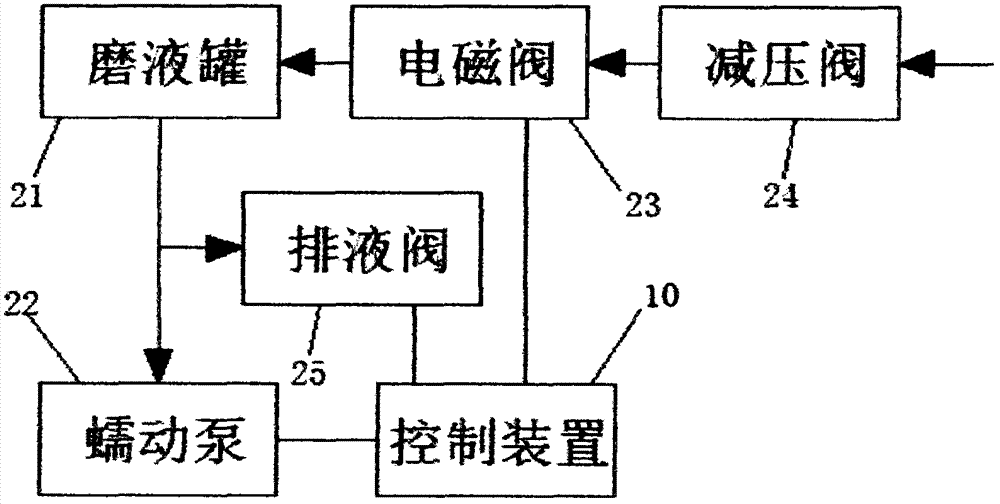

[0029] Such as figure 1 As shown, a kind of trace addition instrument control device described in the present invention, described trace addition instrument comprises grinding liquid tank 21 and the peristaltic pump 22 that is connected on the grinding liquid tank 21, and described control device 10 is connected with peristaltic pump 22 to To control the action of the peristaltic pump 22, the control device 10 includes: an input module 11, connected to the input end of the calculation module 13, for receiving a start signal; a setting module 12, connected to the input end of the calculation module 13, for setting Fixed grinding fluid addition amount information; calculation module 13, used to calculate the number of turns that the peristaltic pump 22 needs to rotate according to the addition amount information after receiving the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com