Nano-particle ultrasonic atomization and classification device and method

An ultrasonic atomization and nanoparticle technology, which is used in separation methods, chemical instruments and methods, injection devices, etc., can solve the problem that the flow rate of feed liquid and the ultrasonic atomization power of the transducer are not completely matched, and the droplets cannot be fully recovered. , low utilization rate of material and liquid, etc., to achieve the effect of improving the water mist adsorption flow field, improving the water mist collection rate and thorough recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

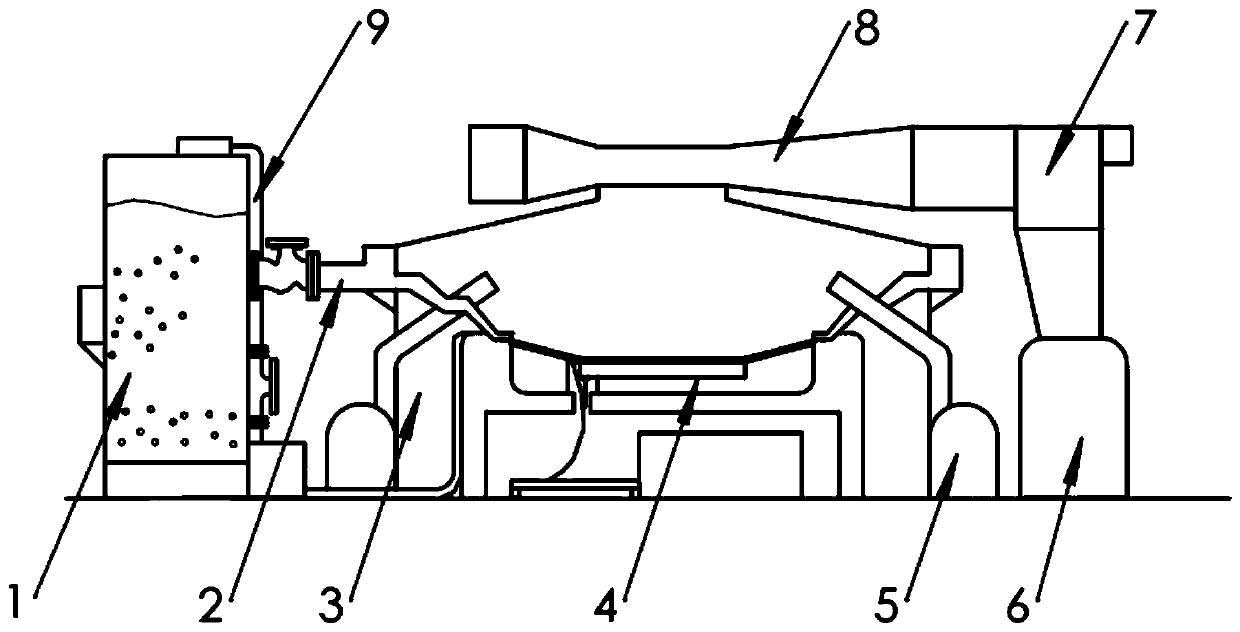

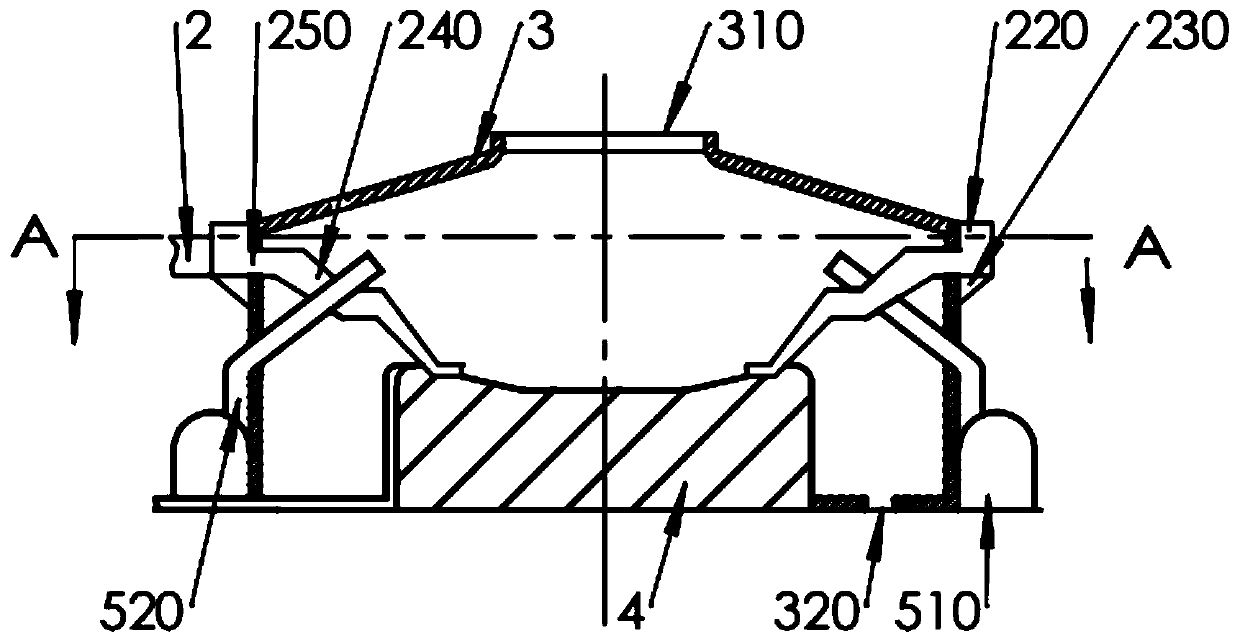

[0050] Such as figure 1 As shown, the present embodiment provides a nanoparticle ultrasonic atomization classification device, the device includes: ultrafine powder solution tank 1, feed pipe 2, ultrasonic atomization reaction tank 3, ultrasonic atomization device 4, blower Device 5, water mist collection tank 6, gas-liquid separation device 7, water mist collection pipe 8 and return pipe 9.

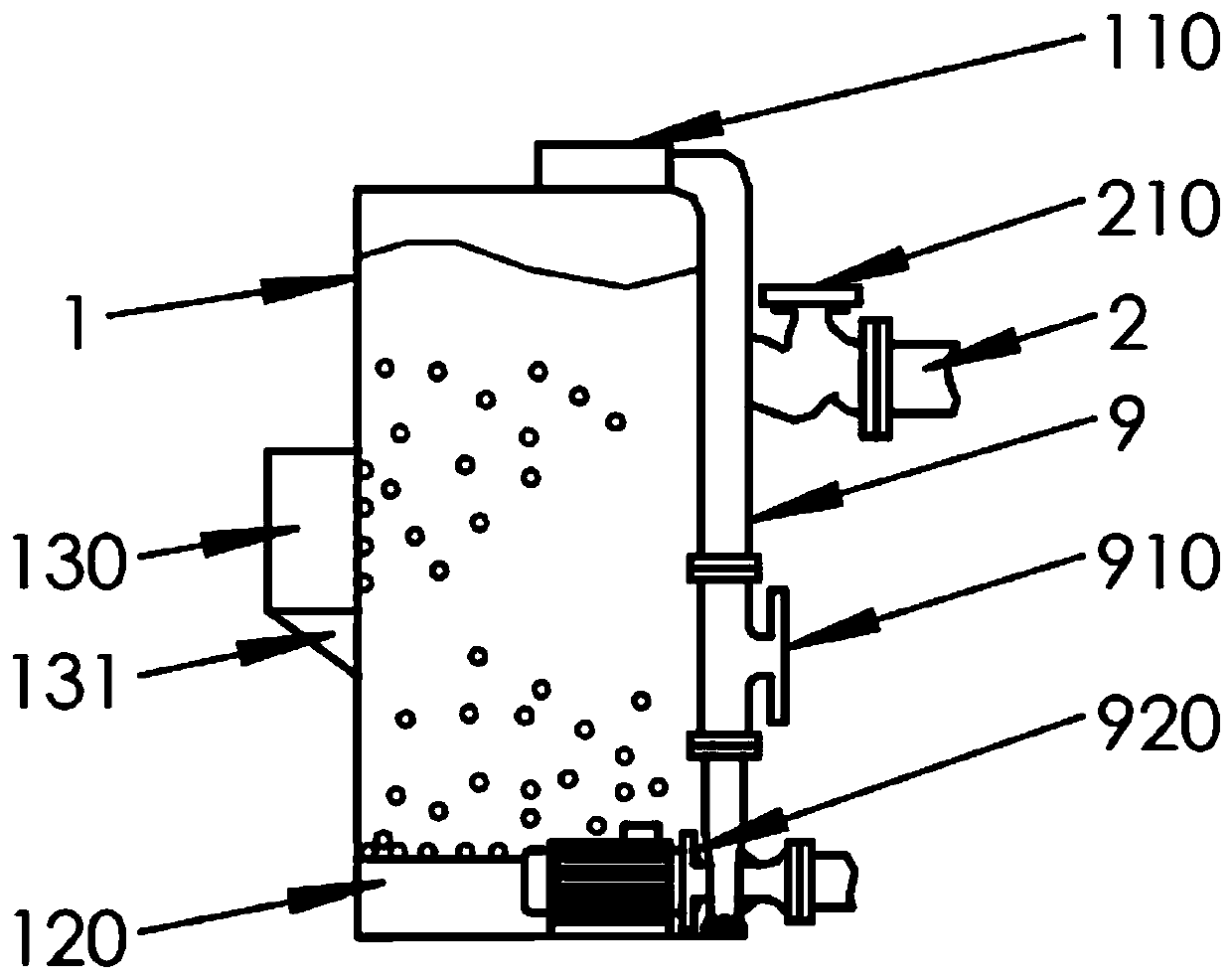

[0051] Such as figure 2 As shown, the top of the ultrafine powder solution tank 1 is provided with an ultrafine powder solution feed port 110, a bottom bubbling generator 120 is installed at the bottom, and a side bubbling generator 130 is installed in the middle through a rib structure 131; The feed pipe 2 is arranged on the side of the ultrafine powder solution tank 1, 20 to 30 cm lower than the top surface of the tank body, and the feed pipe 2 is provided with a feed flow valve 210 for controlling the feed flow rate; the return pipe 9 is installed on the outer wall of the ultrafine...

Embodiment 2

[0061] This embodiment provides a classification method of a nanoparticle ultrasonic atomization classification device, the specific process is as follows:

[0062] Step 1: close the feed flow valve 210, pour a uniformly mixed ultrafine powder suspension into the ultrafine powder solution tank 1, the mass concentration of the ultrafine powder suspension is 0.1% to 1%, and the particle The median particle size range is between 0.5 and 0.6 μm, open the feed flow valve 210 to the maximum flow rate to check whether the pipeline is unblocked and clean the pipeline, open the return flow valve 910 and the return pump 920 after 10 to 15 seconds, and check the return Is it normal;

[0063] Step 2: After confirming that the return material is normal, adjust the flow rate of the feed flow valve 210 to one-half of the maximum flow rate; turn on all the blowers 510 to continuously blow air to the ultrasonic atomization reaction tank 3, and at the same time, ventilate to the water mist deli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com