Paint spraying device for wheel hubs

A technology of spraying equipment and wheel hubs, applied in the direction of spraying devices, etc., can solve the problems of uneven surface spraying, inability to accurately control the amount of spraying, and waste of spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

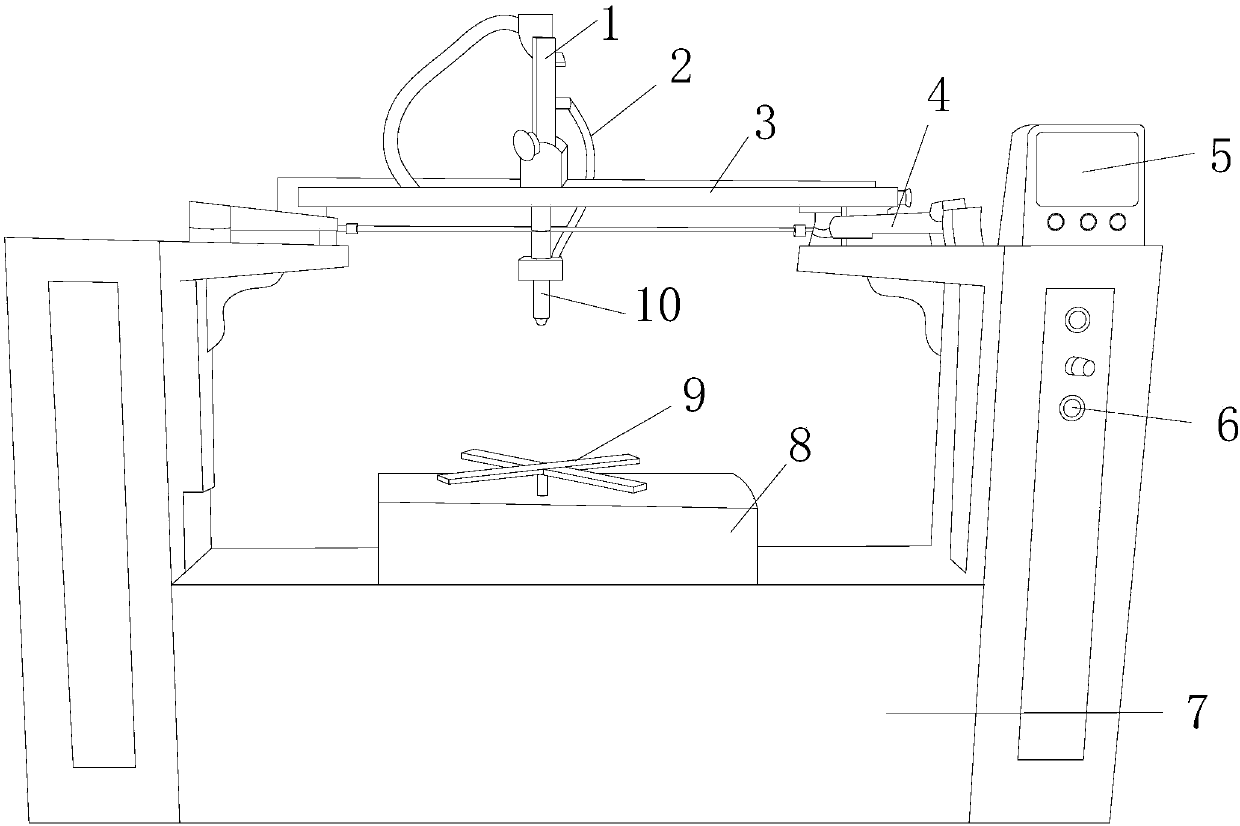

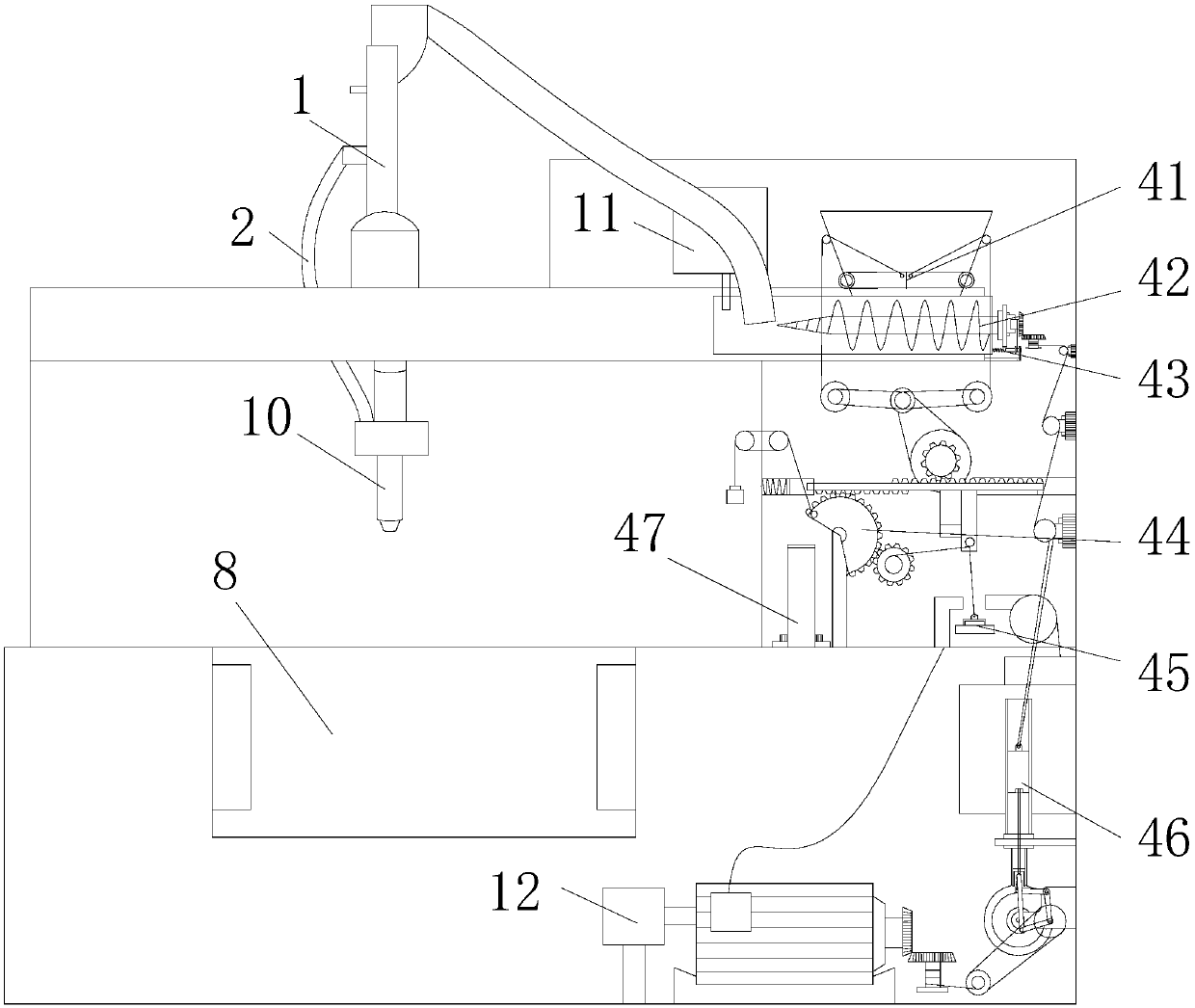

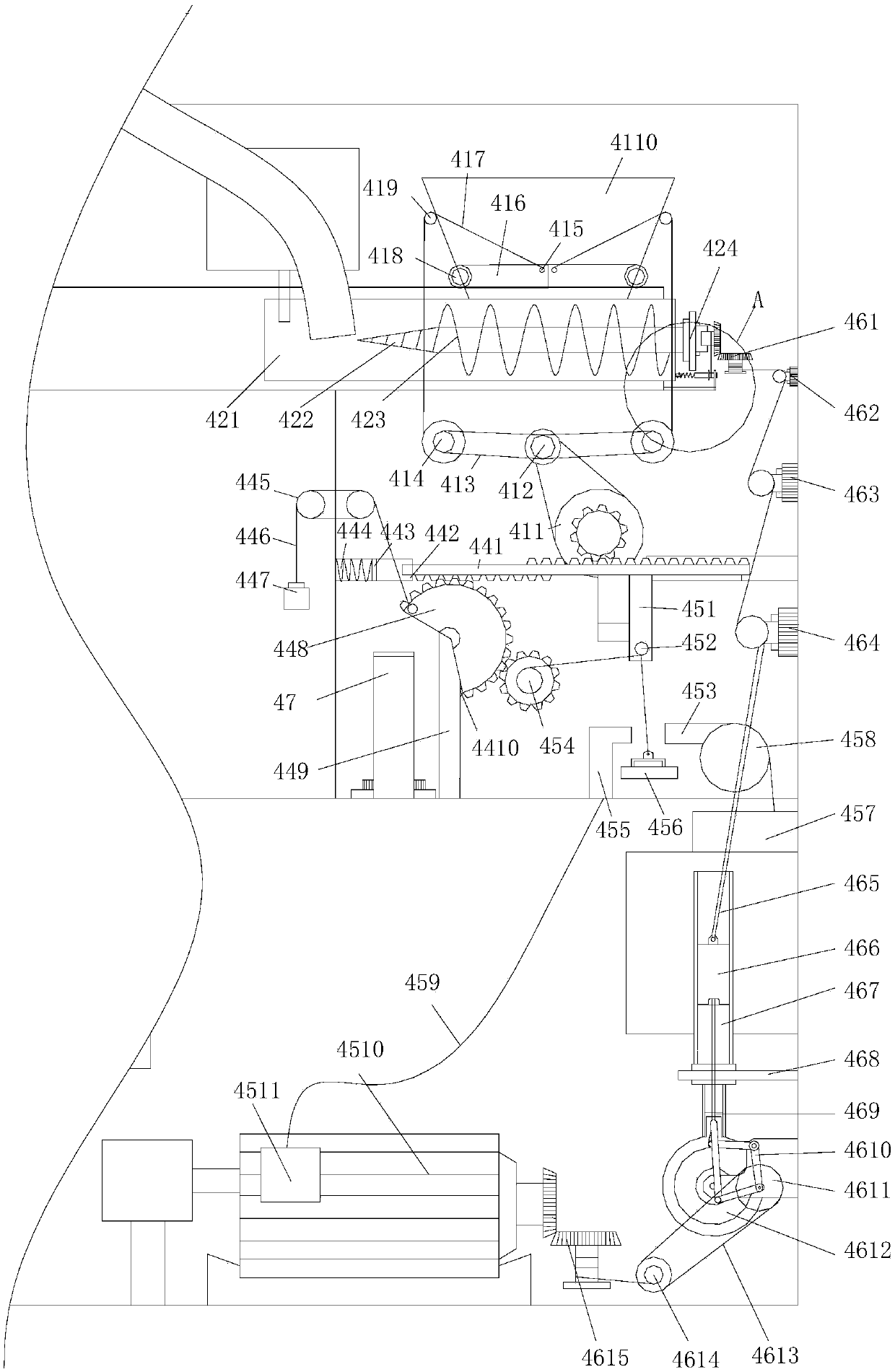

[0031] see Figure 1-Figure 9 , the present invention provides a wheel hub painting equipment, the structure of which includes a nozzle main body 1, a material guide pipe 2, a beam 3, a paint quantitative mechanism 4, a PLC controller 5, a control panel 6, a main body 7, a wheel hub slide seat 8, and a wheel hub placement frame 9. Nozzle 10, flow sensor 11, frequency converter 12, the main body 7 has a U-shaped structure and a hub slide 8 is provided in its U-shaped groove, and a hub is installed in the middle of the hub slide 8 Frame 9, the hub placement frame 9 is facing the nozzle 10, the two ends of the main body 7 are connected by a beam 3, the nozzle body 1 is installed on the beam 3, and the bottom of the nozzle body 1 is installed There is a spray head 10, the spray paint quantitative mechanism 4 and the spray head 10 are communicated with the beam 3, the top of the main body 7 is equipped with a PLC controller 5, and the PLC controller 5 is electrically connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com