Hydrodynamic foaming system and foaming method and closestool comprising foaming system

A foaming system and hydrodynamic technology, applied in the field of sanitary ware, can solve the problems of inaccurate proportioning of foaming agent and water, affecting the number of times of foaming agent use, high foaming agent viscosity, etc., to achieve The effect of improving safety and reliability, convenient operation and simplification of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

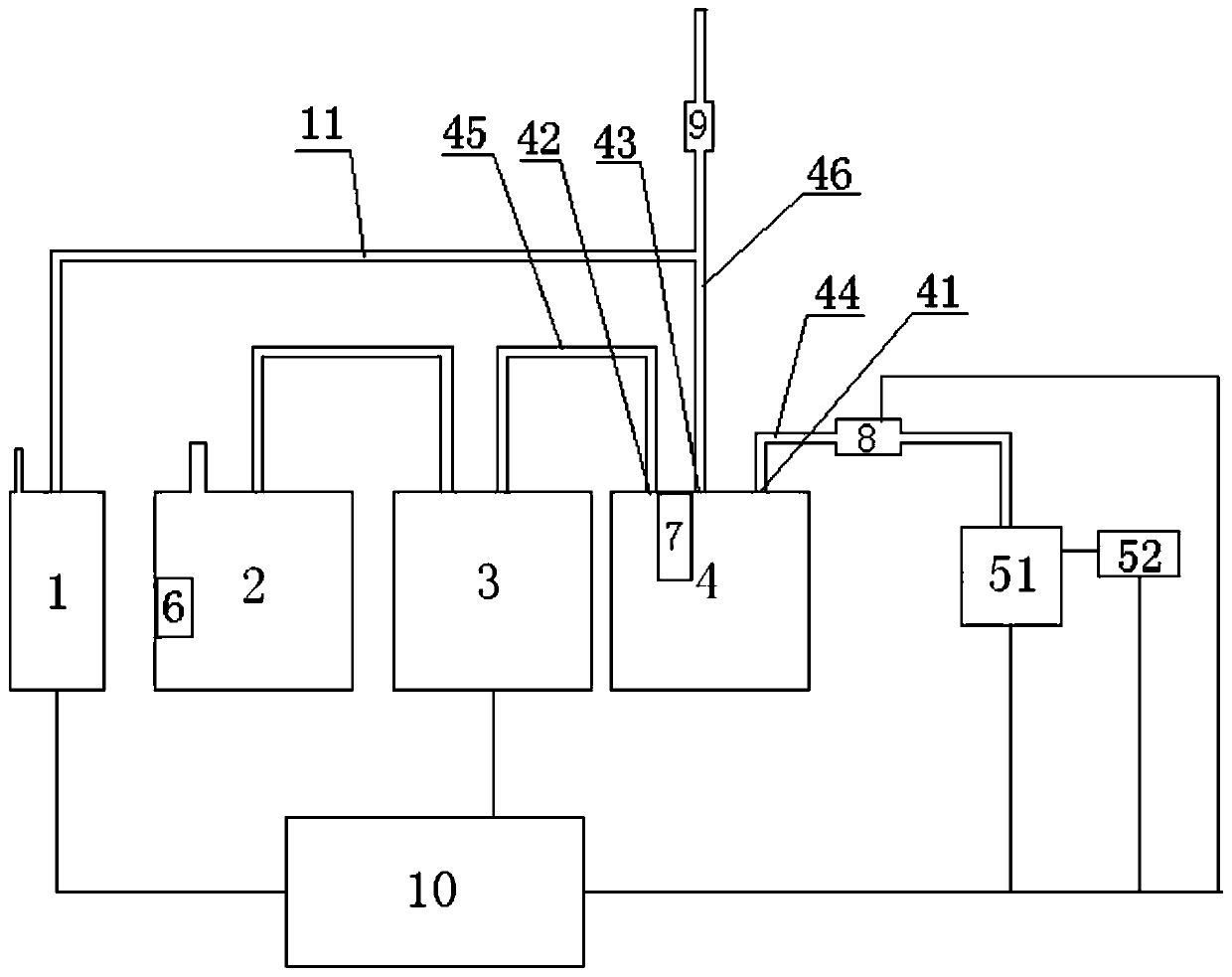

[0037] Reference attached figure 1 As shown, the hydrodynamic foaming system of this embodiment includes a water intake mechanism, a liquid intake mechanism, an air intake mechanism, a hydrodynamic mixing box 4, a foaming tube 9 and a control mechanism 10.

[0038] In this embodiment, the water inlet mechanism adopts a water inlet reversing valve 51 connected with tap water. The water inlet reversing valve 51 is controlled by a solenoid valve 52, and the tap water is directed to the water under the action of the solenoid valve 52 and the water inlet reversing valve 51. The foaming system provides water flow.

[0039] The liquid inlet mechanism includes a liquid storage tank 2 and a liquid pump 3 for pumping out the foaming agent in the liquid storage tank 2. The liquid pump 3 adopts a diaphragm pump, a peristaltic pump, an electromagnetic pump, a centrifugal pump, a gear pump, a vacuum pump, a jet pump, or a stepping motor to accurately extract the amount of foaming agent. In addi...

Embodiment 2

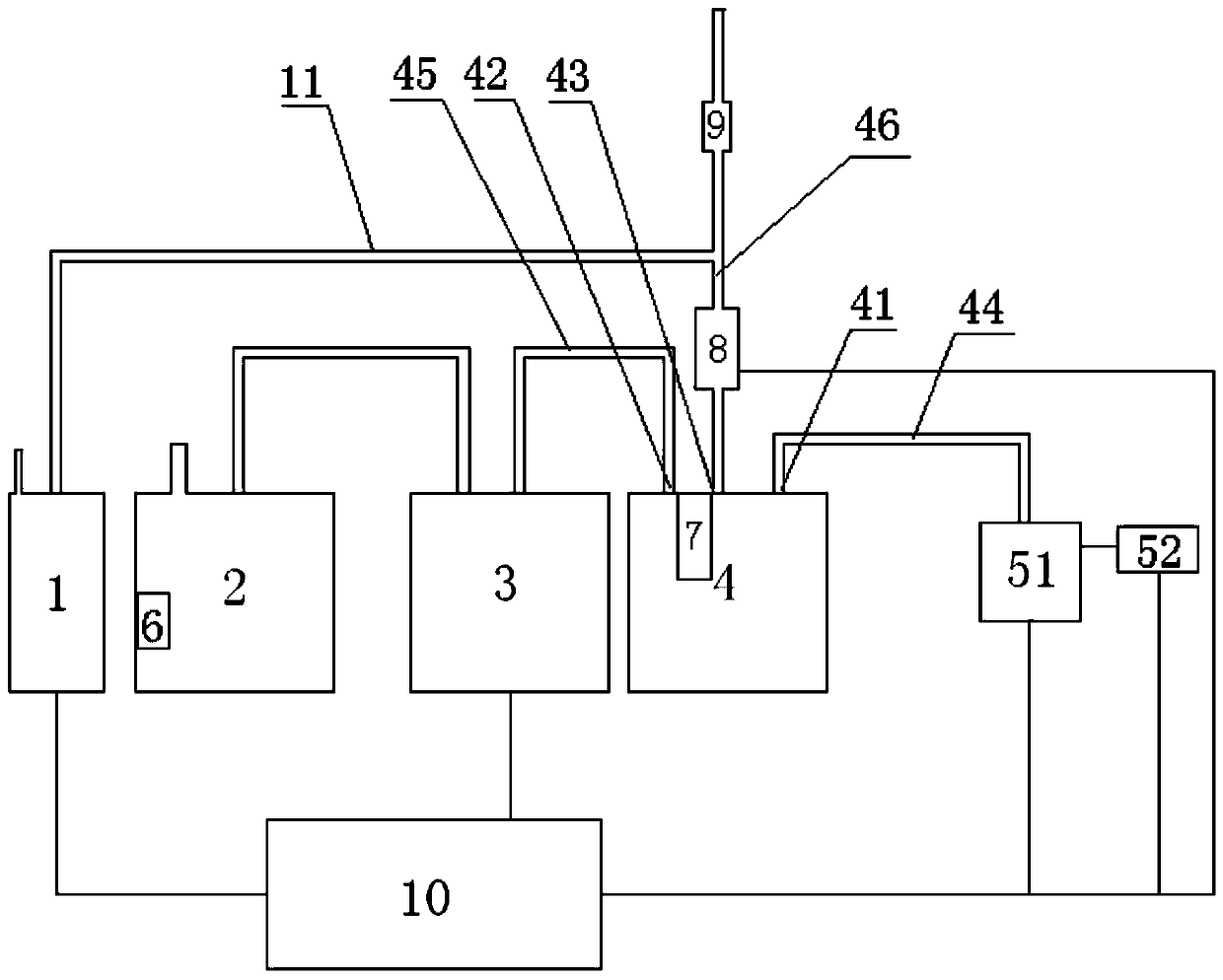

[0052] Reference attached figure 2 As shown, the difference between the hydrodynamic foaming system of this embodiment and the first embodiment is that the vacuum breaker 8 is arranged on the connecting pipe 46 connected to the liquid outlet 43, which also plays a role in avoiding the siphon phenomenon. The remaining parts are the same as the first embodiment, and will not be repeated here.

Embodiment 3

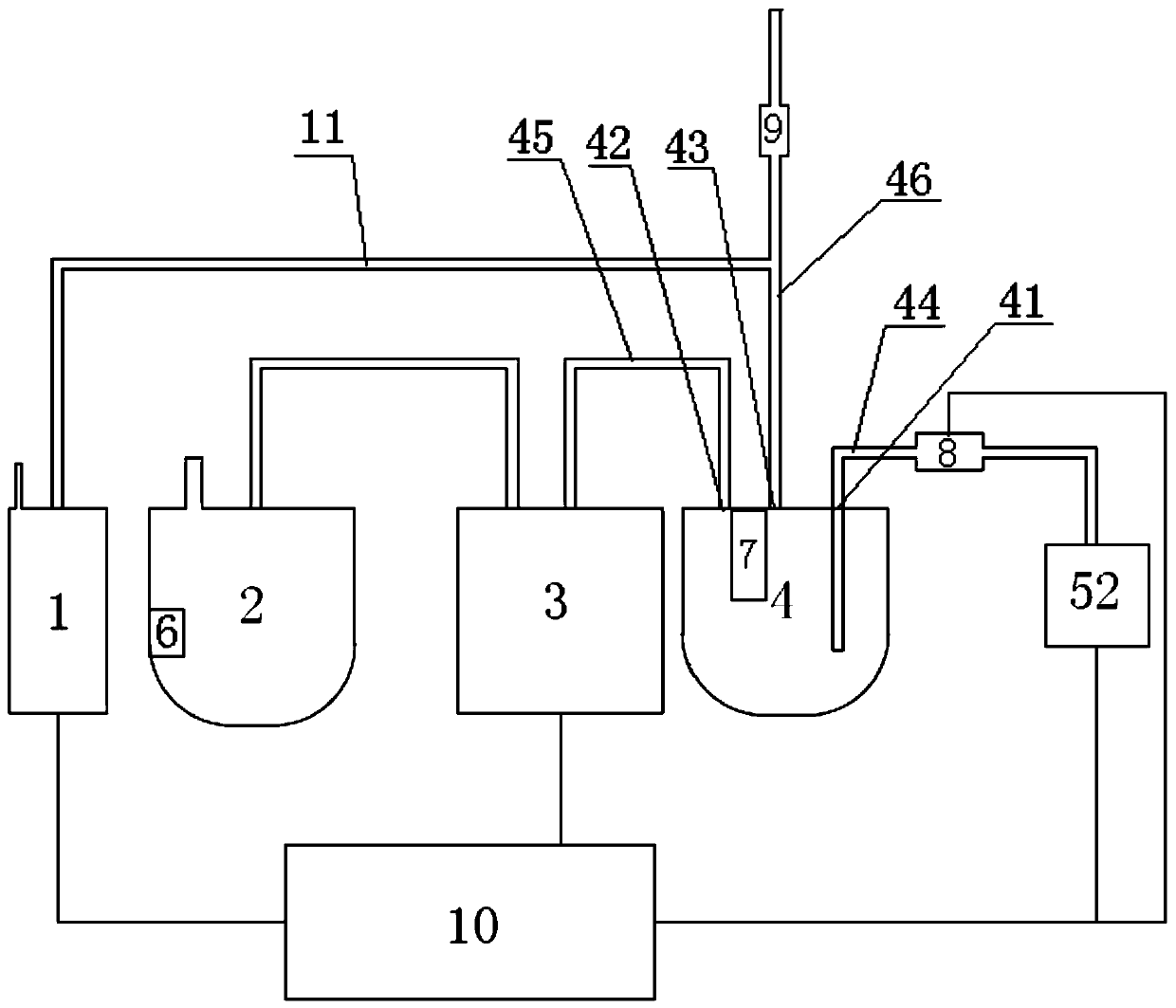

[0054] Reference attached image 3 As shown, the difference between the hydrodynamic foaming system of this embodiment and the first embodiment is that the water inlet mechanism uses a solenoid valve 52 directly connected to tap water, and the control mechanism 10 can directly control the solenoid valve 52 to achieve the The water mechanism transmits the power water flow to the water power mixing box 4, which is simple and reliable.

[0055] In addition, the water outlet end of the water outlet pipe 44 connected to the water inlet 41 of the hydrodynamic mixing tank 4 extends into the lower part of the hydrodynamic mixing tank 4, so that the water with a certain pressure is turned from bottom to top in the tank to reach the power Uniform mixing of foaming agent and water. The liquid outlet end of the liquid outlet pipe 45 connected to the liquid inlet 42 can also be extended into the lower part of the hydrodynamic mixing box 4, which is more conducive to the uniform mixing of foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com