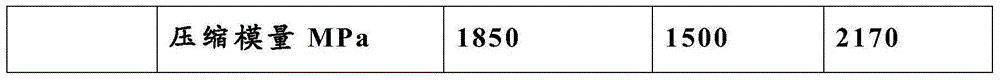

Patents

Literature

48results about How to "Low viscosity requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

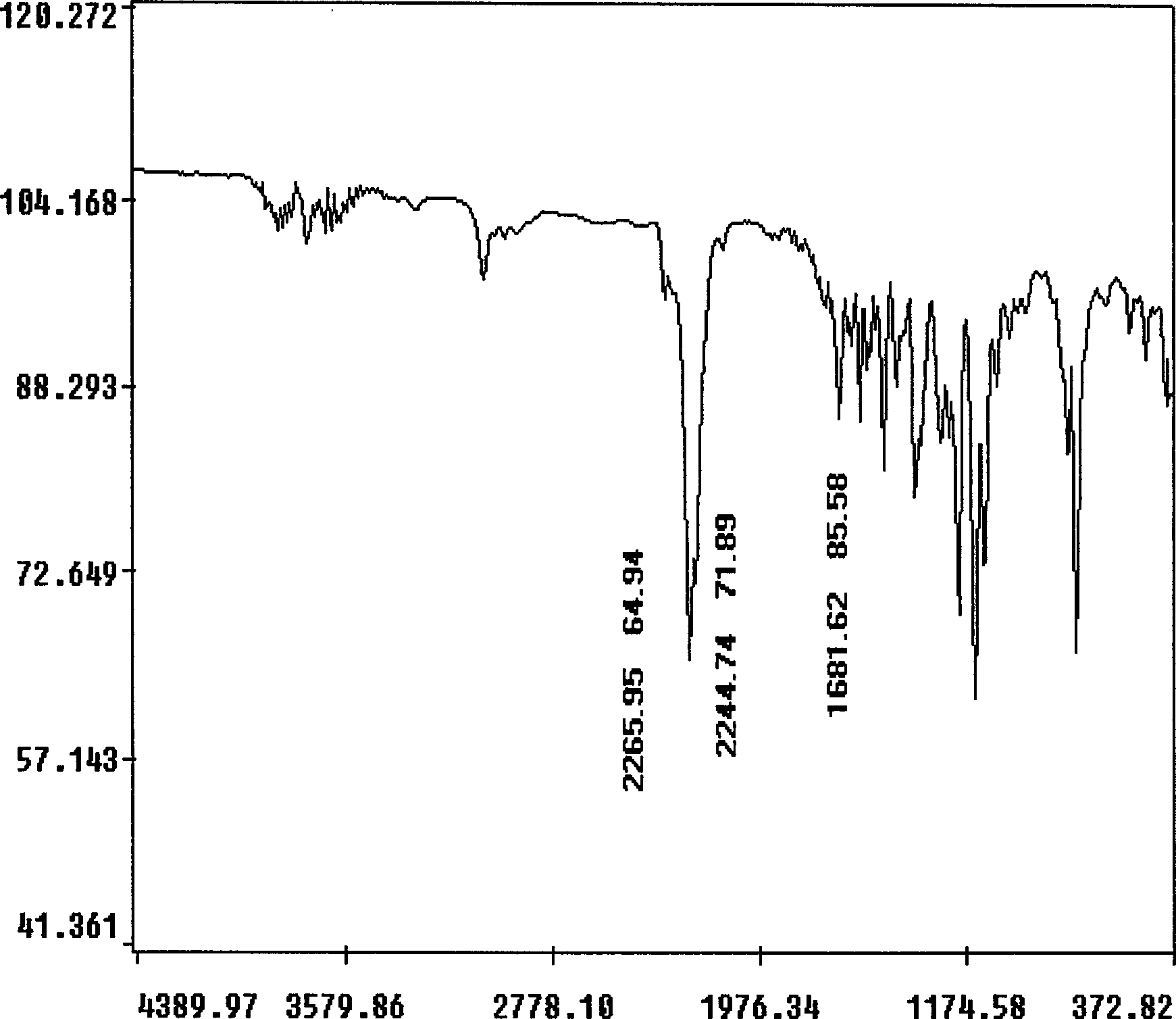

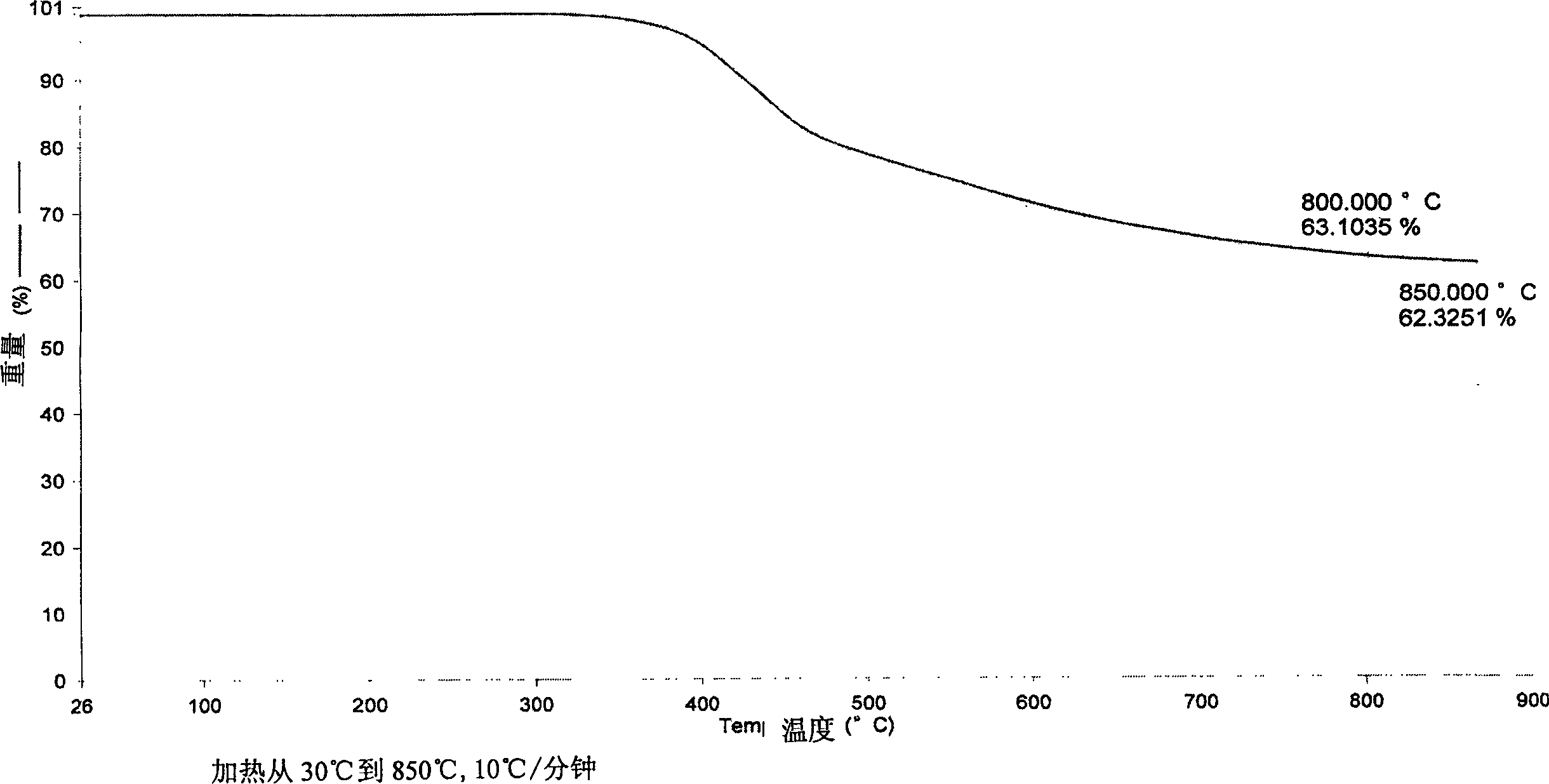

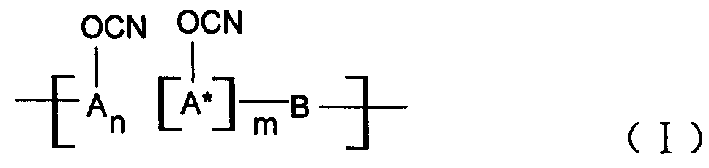

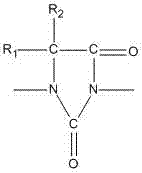

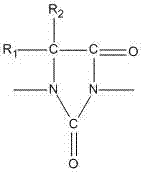

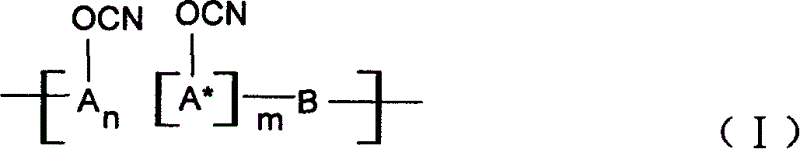

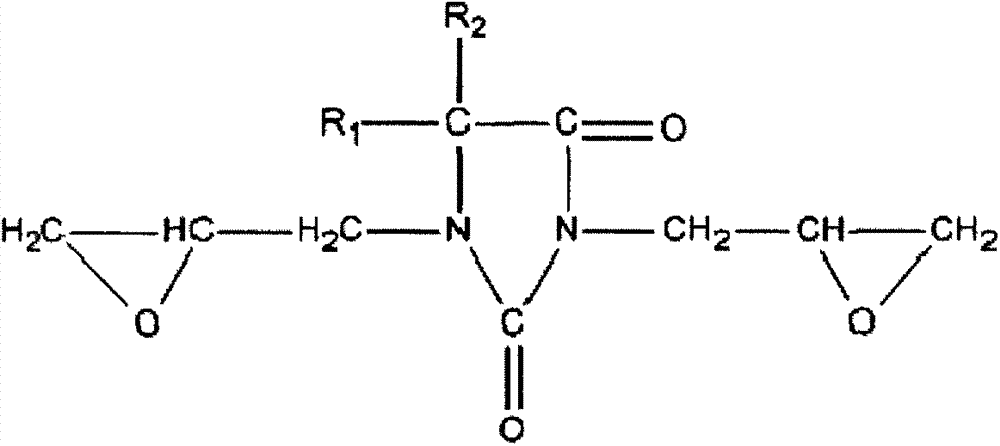

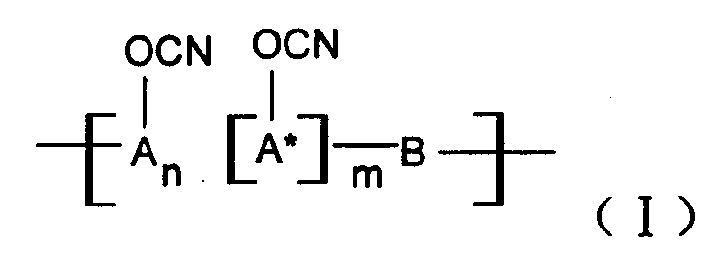

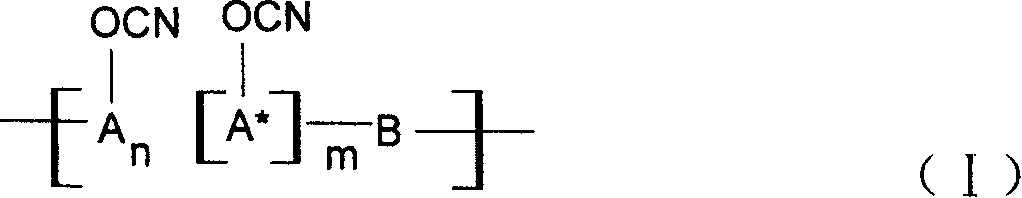

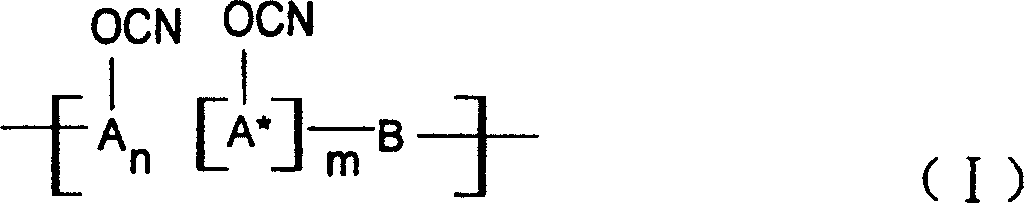

Phenolic cyanate resin and its synthesis method and phenolic cyanate ablative material composite

The present invention discloses a phenol-formaldehyde cyanate resin. It provides its chemical formula and synthesis method, and ablative composite material formed from the the above-mentioned phenol-formaldehyde cyanate resin.

Owner:北京玻钢院复合材料有限公司

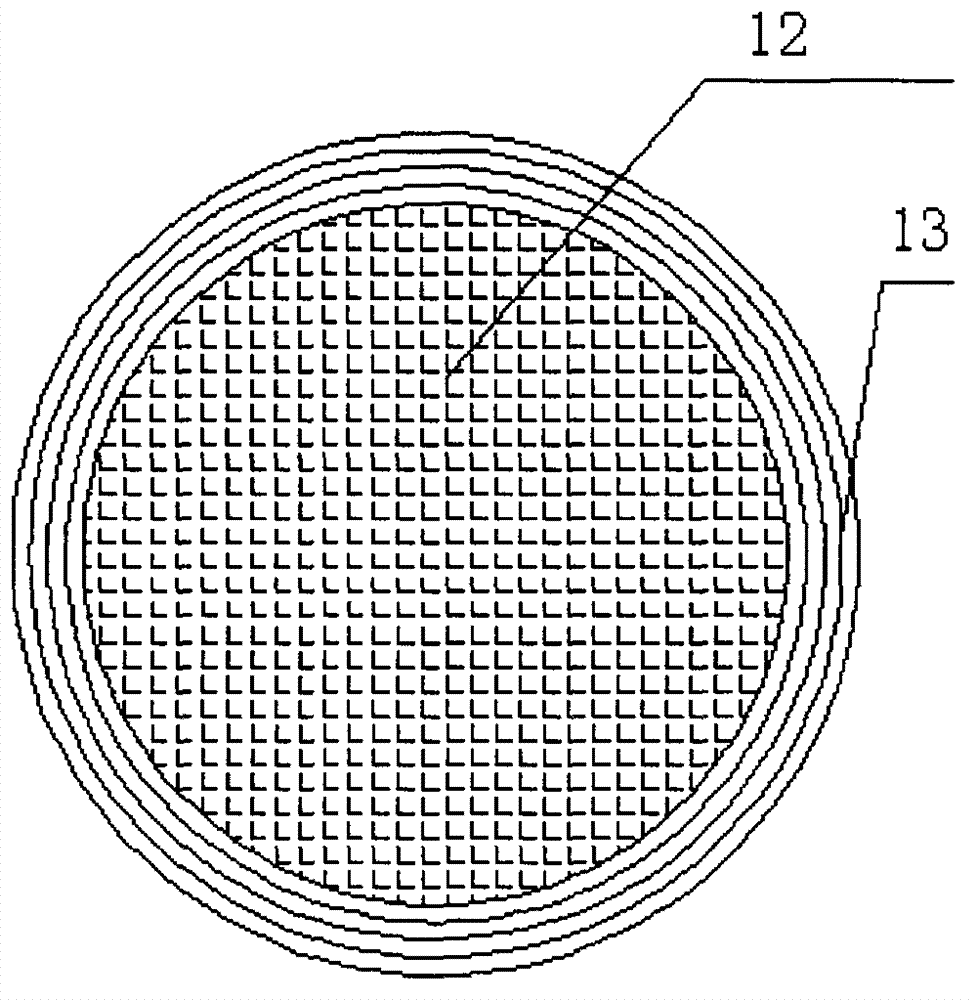

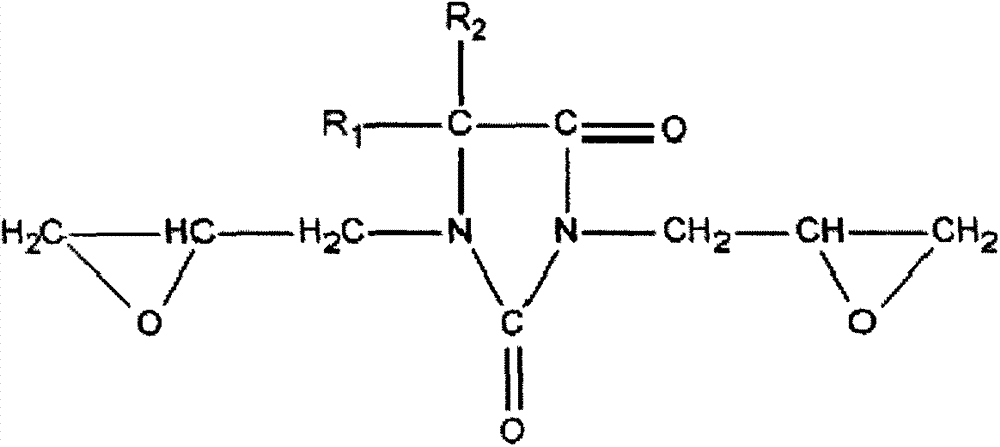

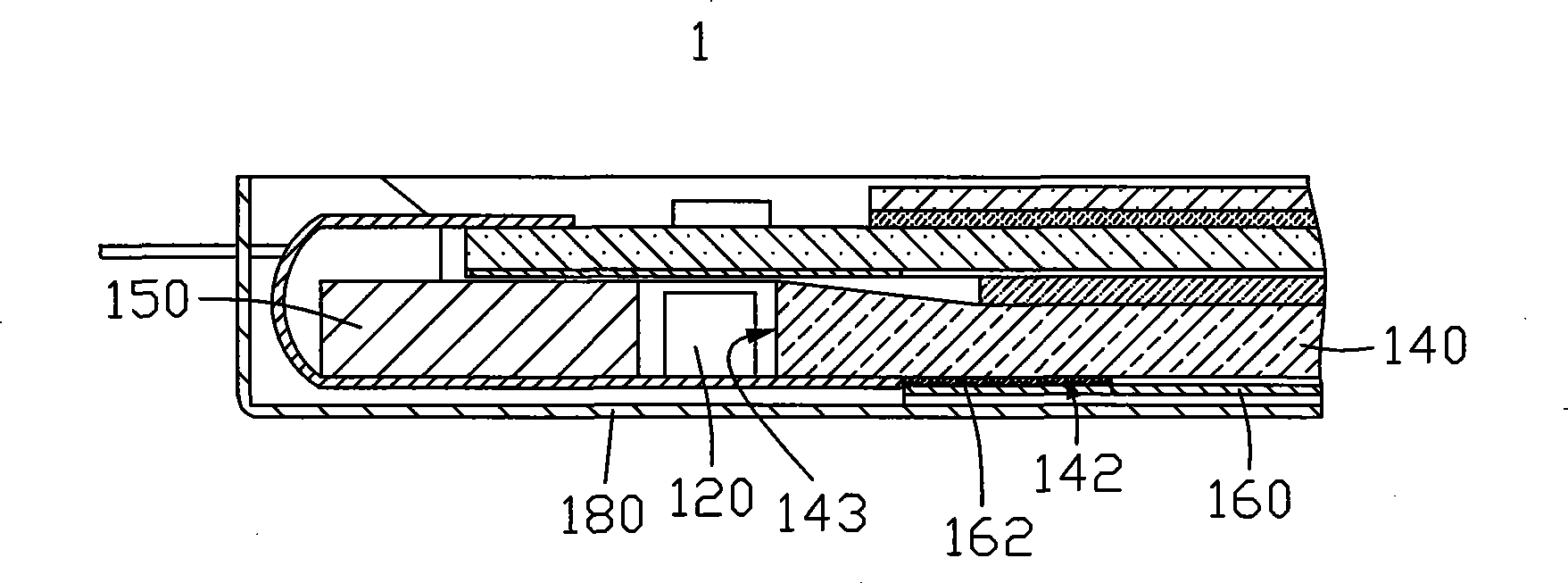

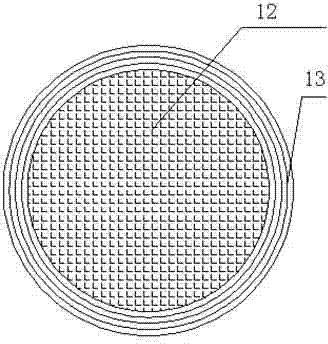

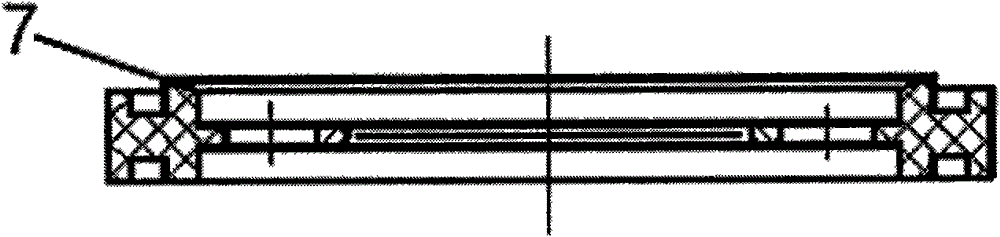

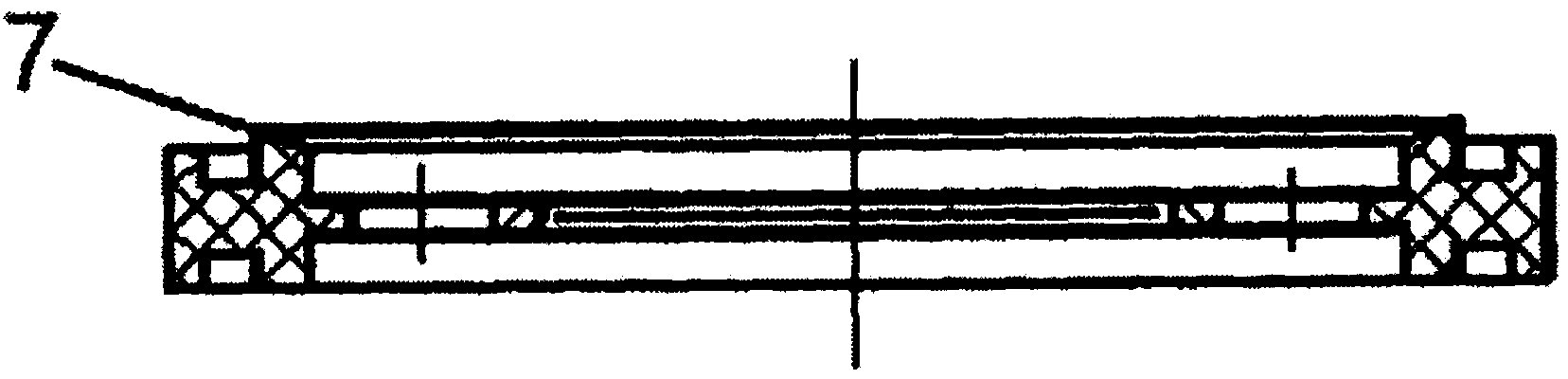

Carbon fiber composite material cable core

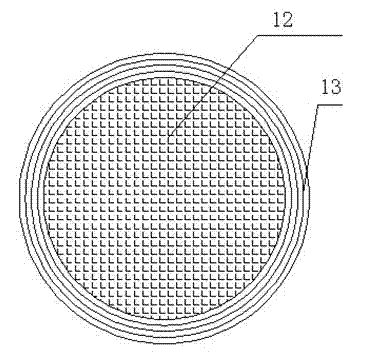

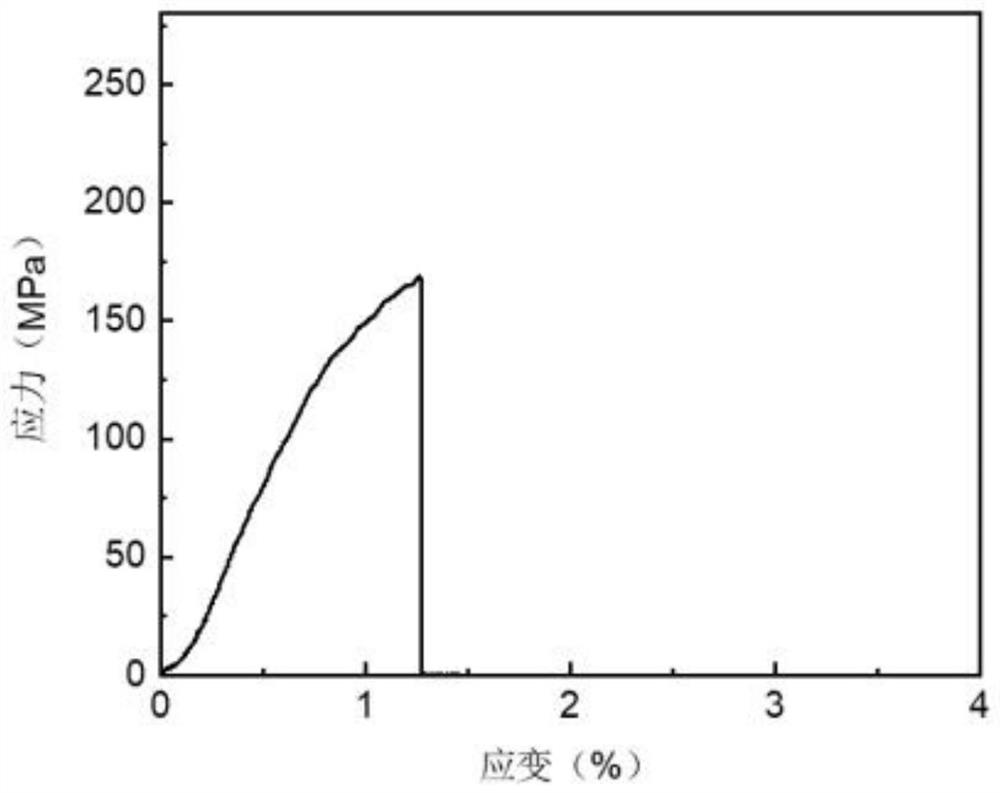

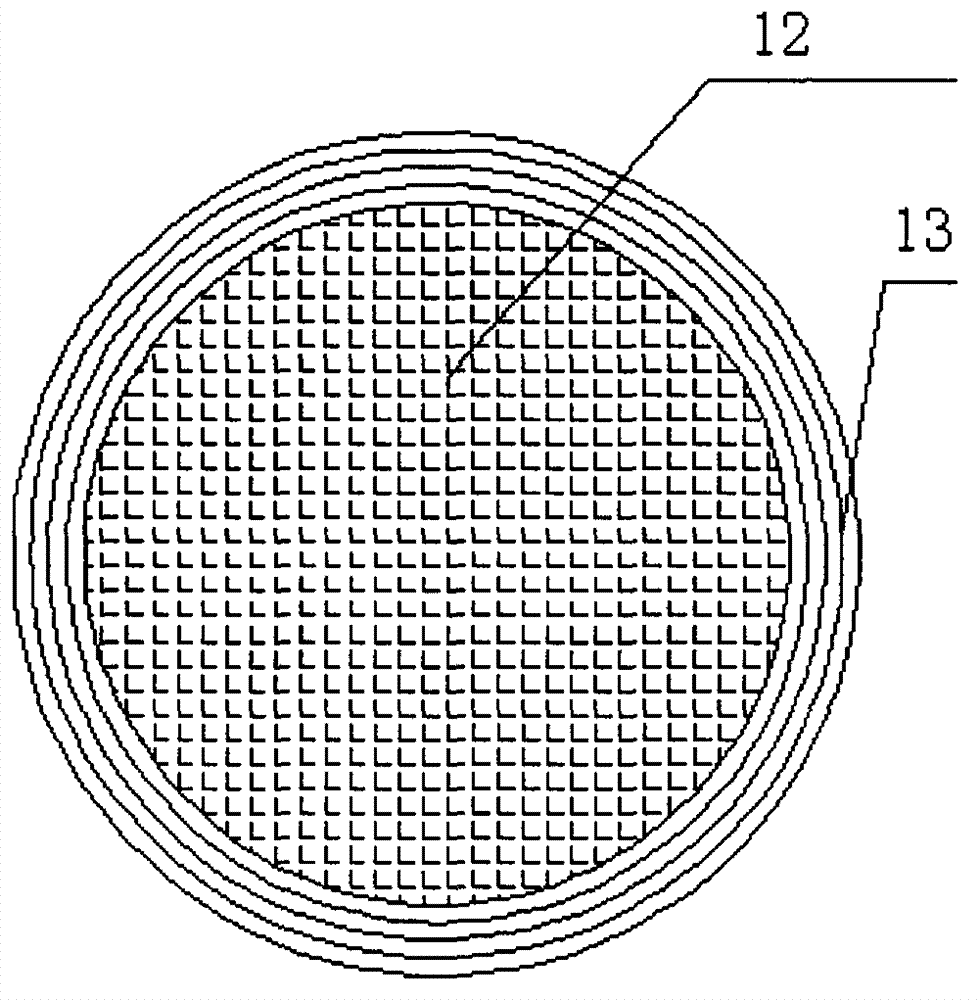

InactiveCN103310878ALow viscosity requirementImprove high temperature resistancePlastic/resin/waxes insulatorsInsulated cablesFiberEpoxy

The invention relates to a carbon fiber composite material cable core, which comprises a load bearing core (12) and a protection layer (13), wherein the protection layer (13) is covered outside the load bearing core (12) through a winding process, the load bearing core (12) is a high-temperature-resistance mechanical property epoxy resin and carbon fiber compound, and the protection layer (13) is a compound of high-temperature-resistance and weather-resistance epoxy resin compositions and glass fibers. The carbon fiber composite material cable core adopts the blending epoxy resin of the hydantoin epoxy resin and low-viscosity epoxy resin as resin substrates, the requirement of glass fibers on the low viscosity of the resin can be met, and the cable core can also have excellent high-temperature-resistance performance.

Owner:喻聪

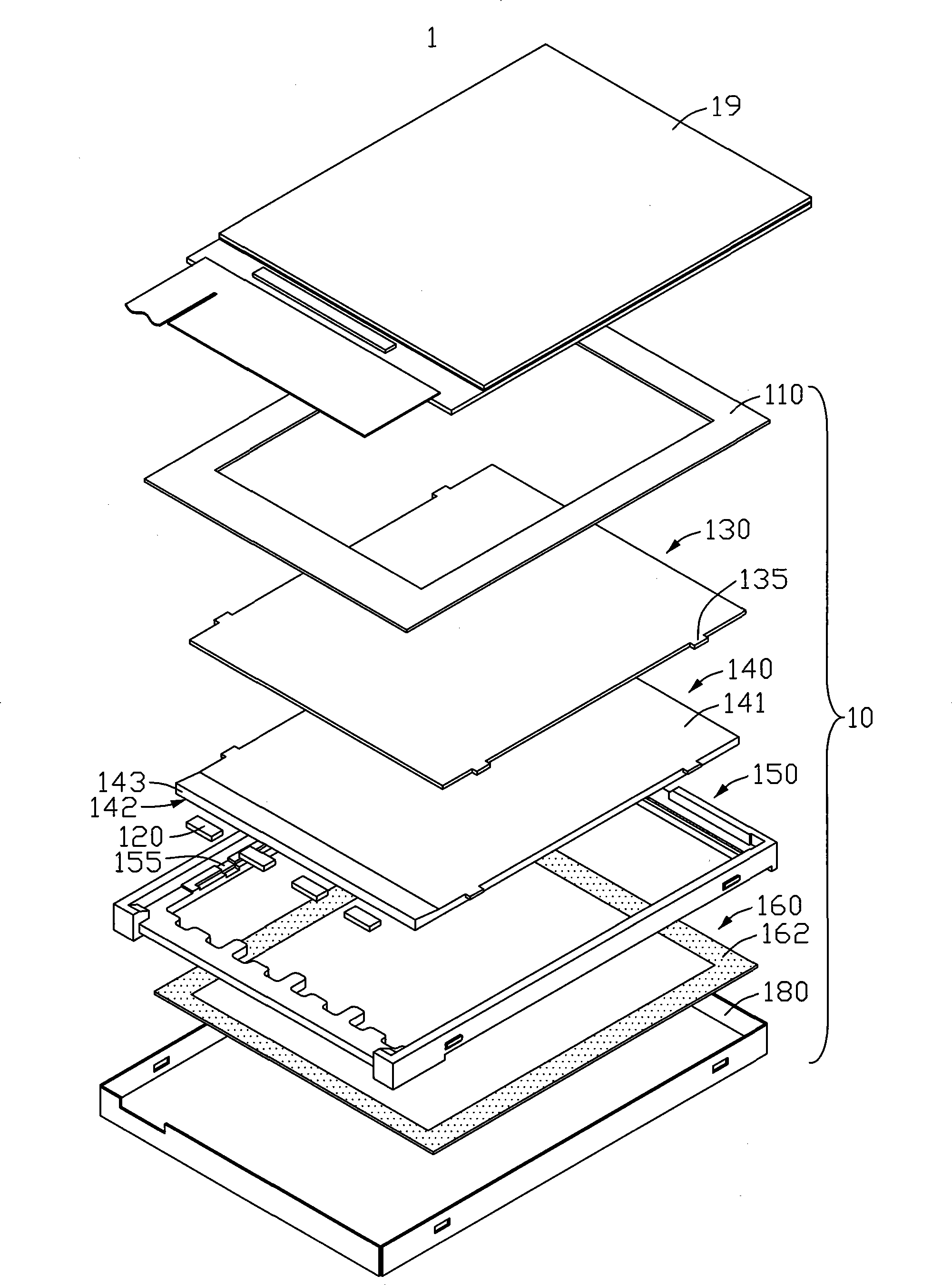

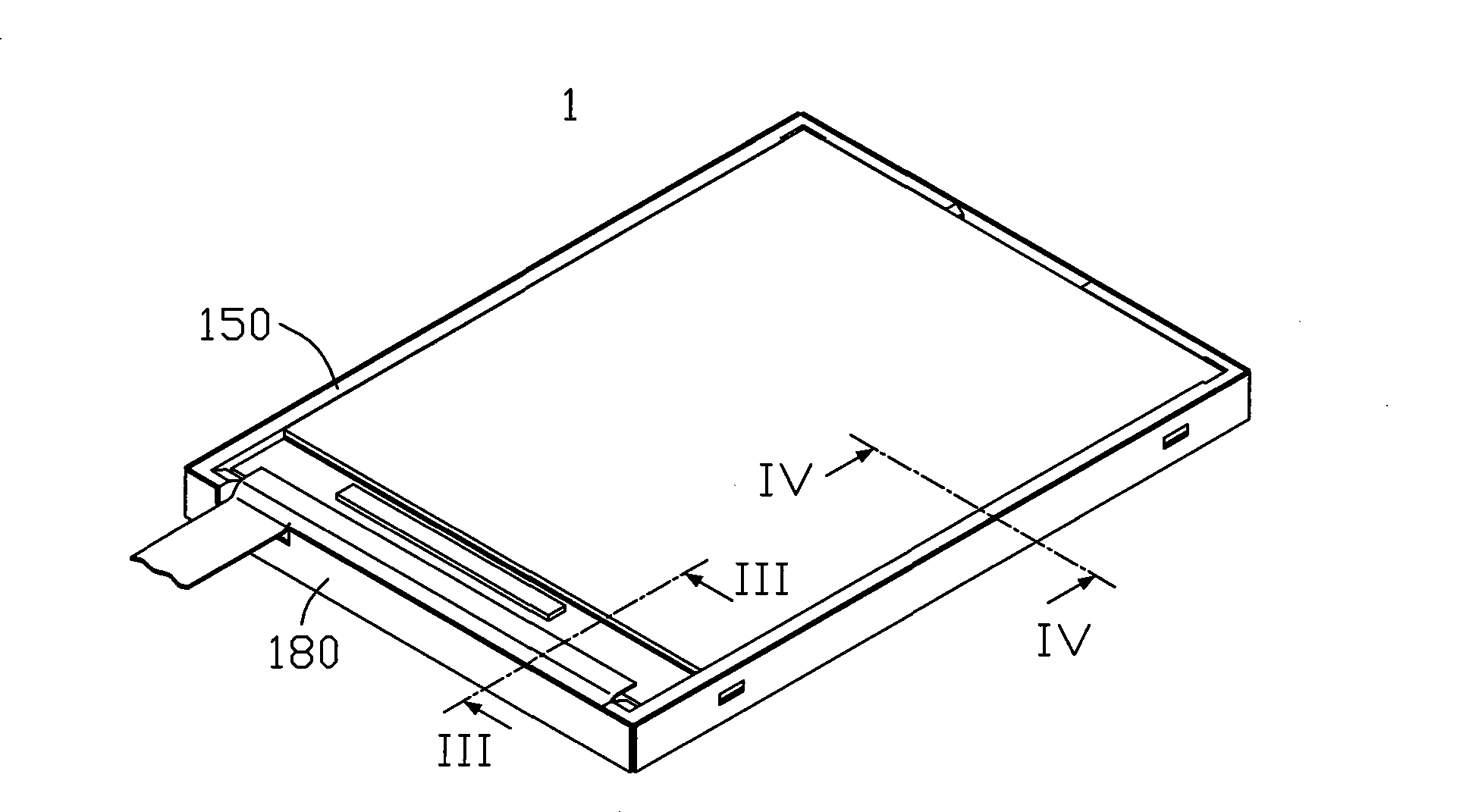

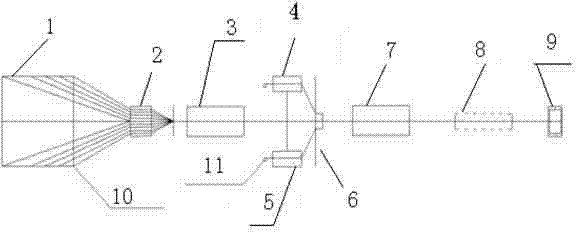

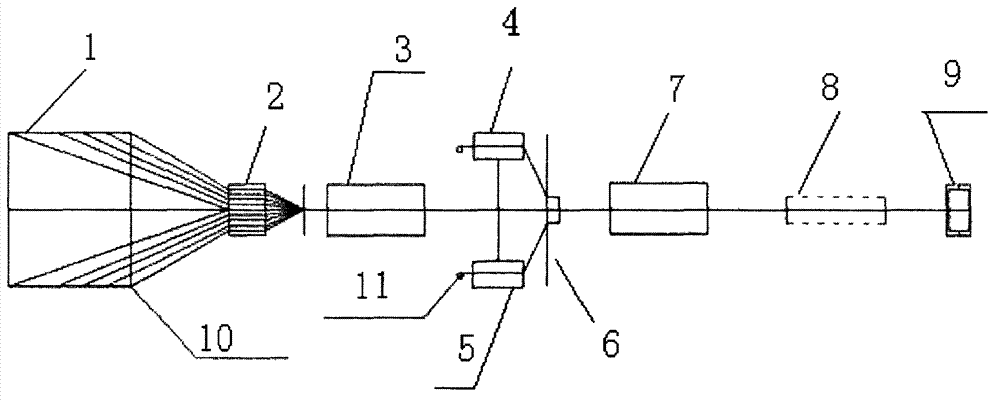

Back light module unit and LCD device

InactiveCN101363996AIncrease lighting brightnessClose contactOptical light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention relates to a backlight module and a liquid crystal display (LCD) adopting the backlight module. The backlight module includes a light guide plate, a reflection plate and a metal back plate for accommodating the light guide plate and the reflection plate. The metal back plate includes a bossed bottom board; the reflection plate is arranged adjacent to the bottom board; and the boss corresponds to the edge of the reflection plate and applies the acting force onto the reflection plate for the contact of the reflection plate and the light guide plate.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

Preparation method of lightweight and high-strength fracturing propping agent

InactiveCN106701055ALow densityNot easy to precipitateFluid removalDrilling compositionHigh densityMicrosphere

The invention discloses a preparation method of a lightweight and high-strength fracturing propping agent, and belongs to the technical field of propping agent preparation. Silicon dioxide generated by calcination is taken as a kernel, hydroxyapatite and aluminum oxide generated by calcination coat the surface, one part of silicon dioxide reacts with carbon in a high-temperature state to generate silicon carbide and the other part of silicon dioxide reacts with sodium carbonate generated by evaporative crystallization at a high temperature to generate sodium silicate, and the sodium silicate is removed through washing and dissolving to form a hollow structure. Hollow microspheres formed by silicon carbide, aluminum oxide and hydroxyapatite are fully utilized to reach the lightweight and high-strength effects; the density of the lightweight and high-strength fracturing propping agent is reduced by over 10% in comparison with a conventional ceramsite fracturing propping agent; the problem that loss of fracturing equipment is easily caused by over-high density of the traditional ceramsite fracturing propping agent is effectively solved.

Owner:CHANGZHOU UNIV

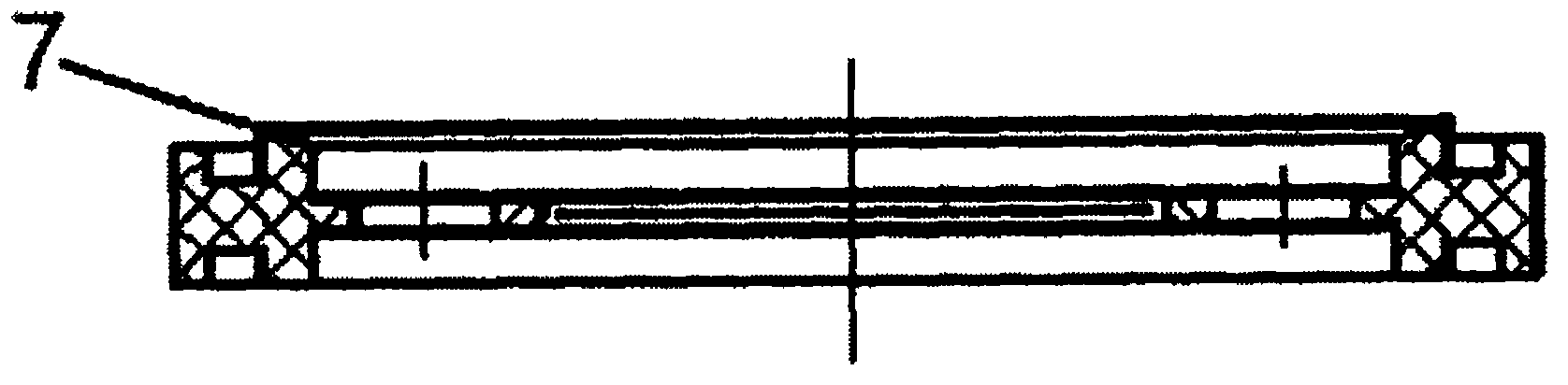

Cable core of carbon fiber composites

ActiveCN103093888AImprove mechanical propertiesExtend working lifeInsulated cablesInsulated conductorsGlass fiberEpoxy

The invention relates to a cable core of carbon fiber composites. The cable core of the carbon fiber composites comprises a bearing core (12) and a protective layer (13), and the protective layer (13) covers the outer portion of the bearing core (12) through a winding process. The cable core is characterized in that the bearing core (12) is the composite of epoxy resin and carbon fibers, wherein the epoxy resin is heat resisting and high in mechanical property, and the protective layer (13) is the composite of epoxy resin and glass fibers, wherein the epoxy resin is high temperature resisting and weather resisting. Due to the fact that the bearing core and the protective layer are chosen to be different epoxy resin systems, the high mechanical property of the epoxy resin system of the bearing core cannot be influenced by the epoxy resin system of the outer protective layer, the good weather resisting property of the outer protective layer protects the bearing core from being damaged by outer environment, and the combination property of the cable core is greatly improved.

Owner:CHANGJI POWER SUPPLY COMPANY STATE GRID XINJIANGELECTRIC POWER +1

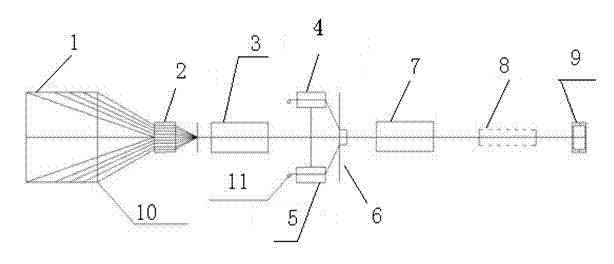

Manufacture method of cable core

InactiveCN103093897AImprove mechanical propertiesExtend working lifeCable/conductor manufactureGlass fiberEpoxy

The invention relates to a manufacture method of a cable core. The manufacture cost of the cable core comprises the following steps: carbon fibers are led out of a creel, gum dipping is carried out to the carbon fibers after entering a first gum dipping area, and used epoxy resin is epoxy resin with heat-resisting high mechanical property; the carbon fibers after gum dipping enter a first curing oven to be precured, carbon fiber composite core are manufactured, the diameter of each carbon fiber composite core is 5mm to 12mm, and a curing degree reaches more than 85% by adjusting temperature; glass fibers on two sides are led out and respectively enter a second gum dipping area and a third gum dipping area, and used epoxy resin is high temperature resistant and weather resistant; the glass fibers after gum dipping pass through a winding area and are wound and cover the outer layers of the carbon fiber cores, the thickness of single side is 0.5mm to 2mm, and winding speed is synchronous with pultrusion speed by being controlled by a servo motor; and the carbon fiber composite cores and the glass fiber protective layers pass through the second curing oven after being compounded, and are fully cured by adjusting temperature. Composite material cable core products pass through a dragger and are wound up on the position of a winding disc.

Owner:STATE GRID CORP OF CHINA +1

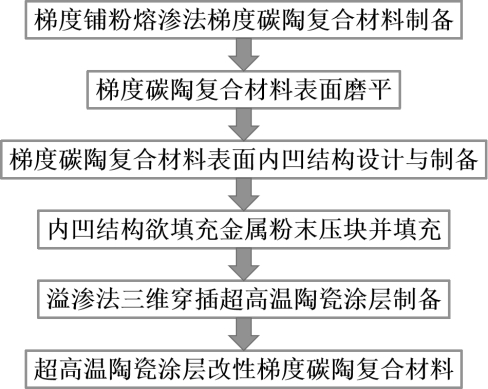

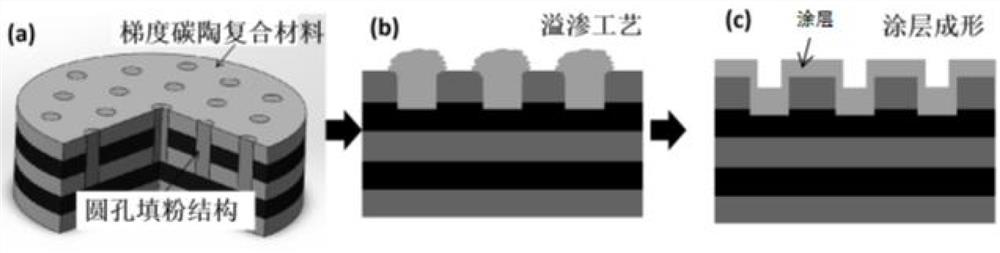

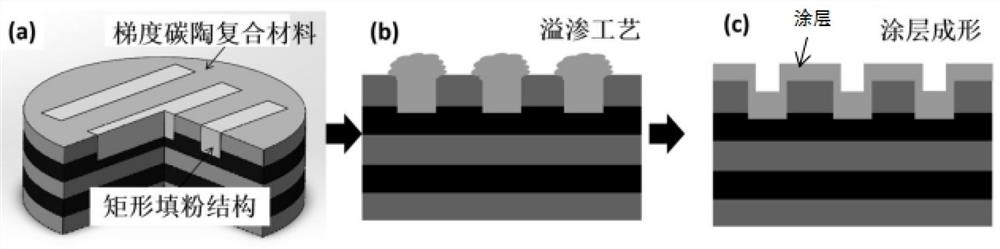

Ceramic coating protection gradient carbon-ceramic composite material and preparation method thereof

ActiveCN113582713AStable high temperature mechanical propertiesImprove high temperature mechanical propertiesCeramic compositeCarbide coating

The invention discloses a ceramic coating protection gradient carbon-ceramic composite material and a preparation method thereof. The ceramic coating protection gradient carbon-ceramic composite material comprises: a gradient carbon-ceramic composite material which is provided with a concave structure on the surface thereof and is a gradient C / C-ZrC-SiC composite material; and an ultrahigh-temperature ceramic coating which is continuously arranged along the surface of the gradient carbon-ceramic composite material and the inner wall surface of the concave structure. The ultrahigh-temperature ceramic coating is an indissolvable metal carbide coating formed by diffusing and infiltrating indissolvable metal along the surface of the gradient carbon-ceramic composite material and reacting the indissolvable metal with the surface of the gradient carbon-ceramic composite material. Therefore, the formed ceramic coating is a three-dimensional jack structure coating, the interfacial strength of the ceramic coating is far higher than that of a two-dimensional plane coating, the surface area of the coating is greatly increased due to the arrangement of the concave structure, meanwhile, the flow resistance of melt on the surface of the composite material can be improved, then the overall temperature resistance of the composite material can be improved, and the risk of coating stripping is reduced.

Owner:CENT SOUTH UNIV

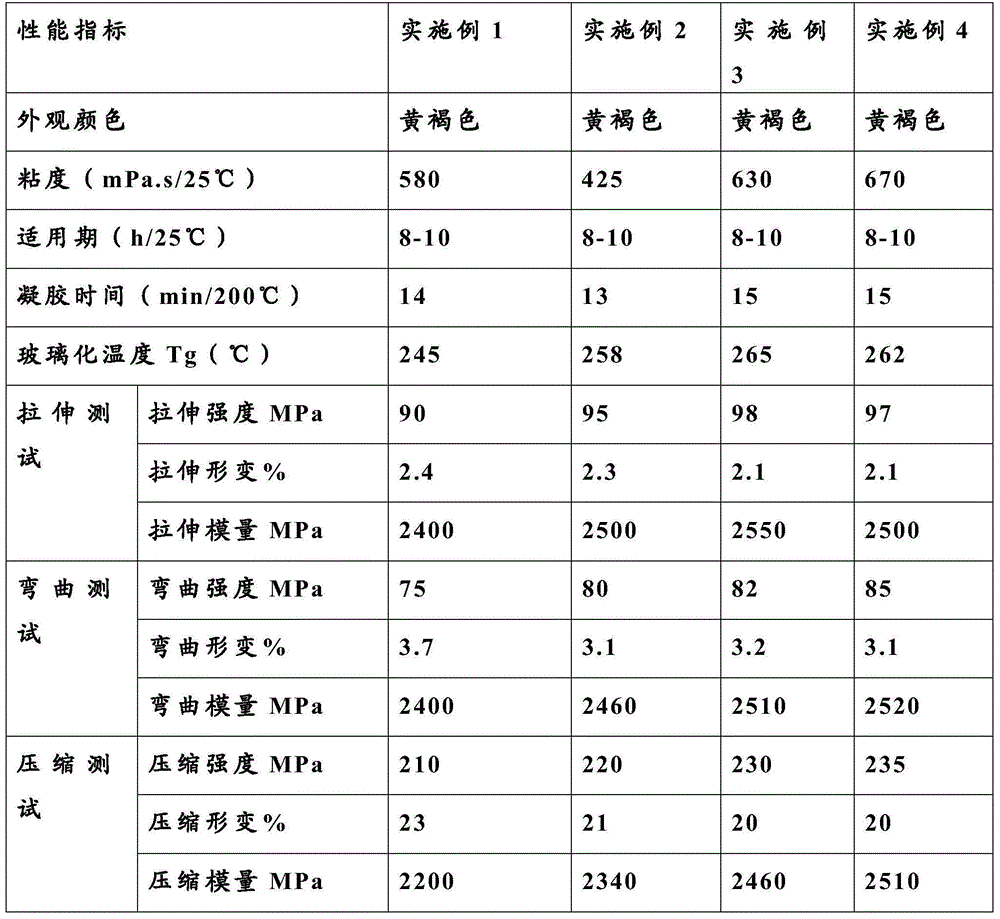

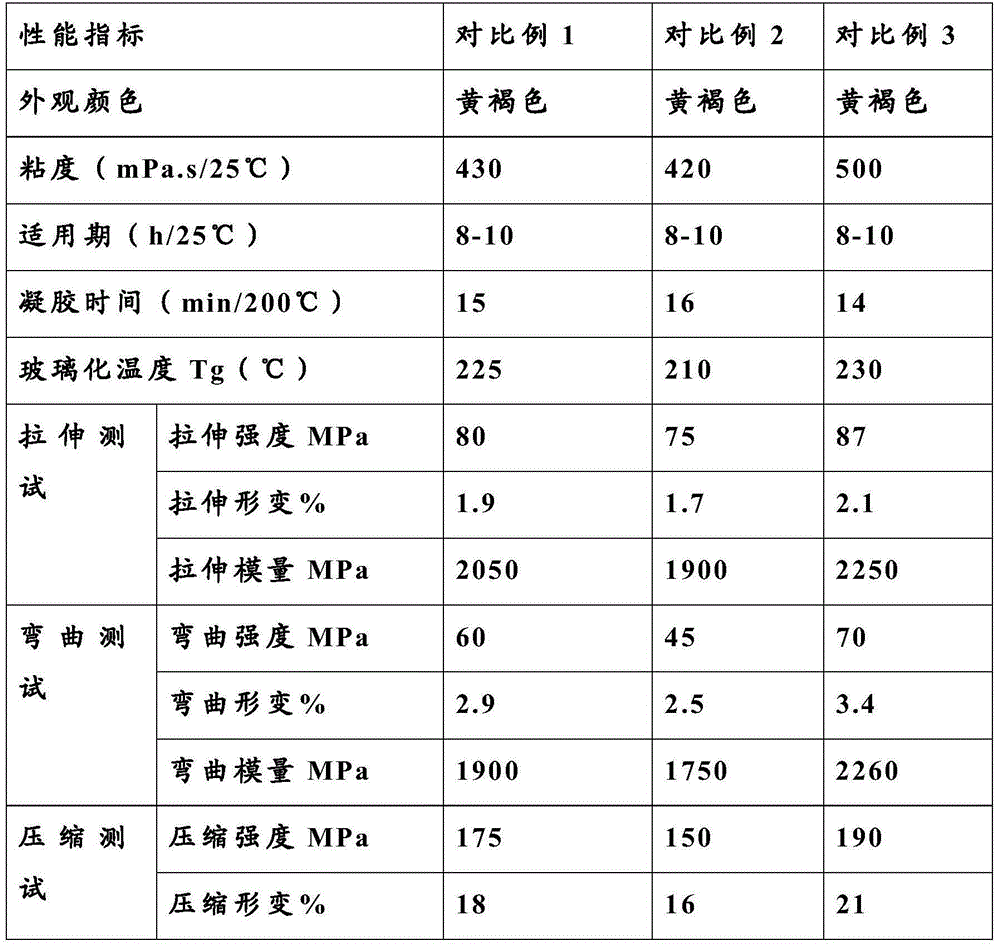

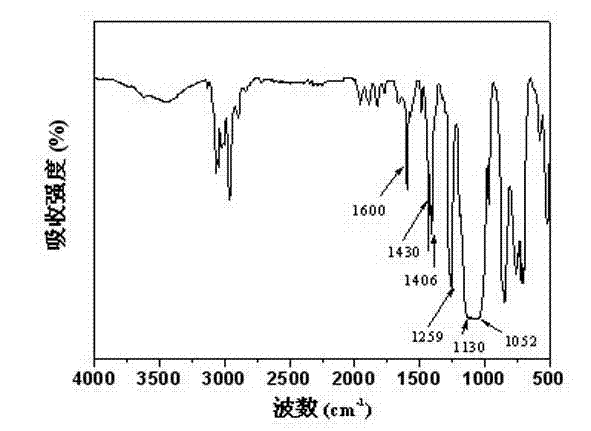

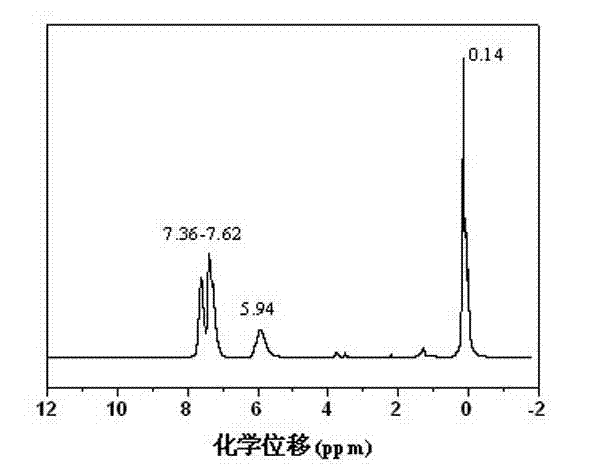

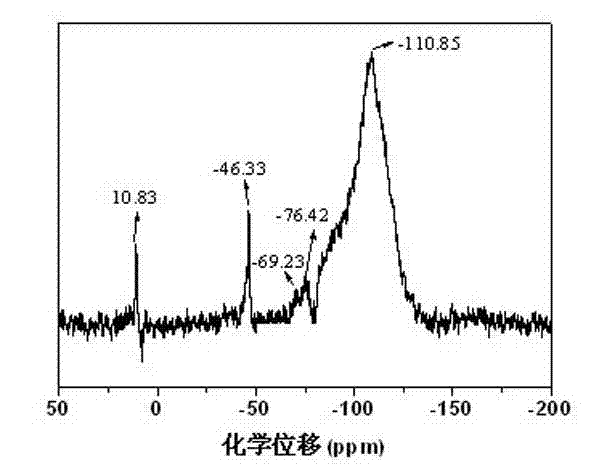

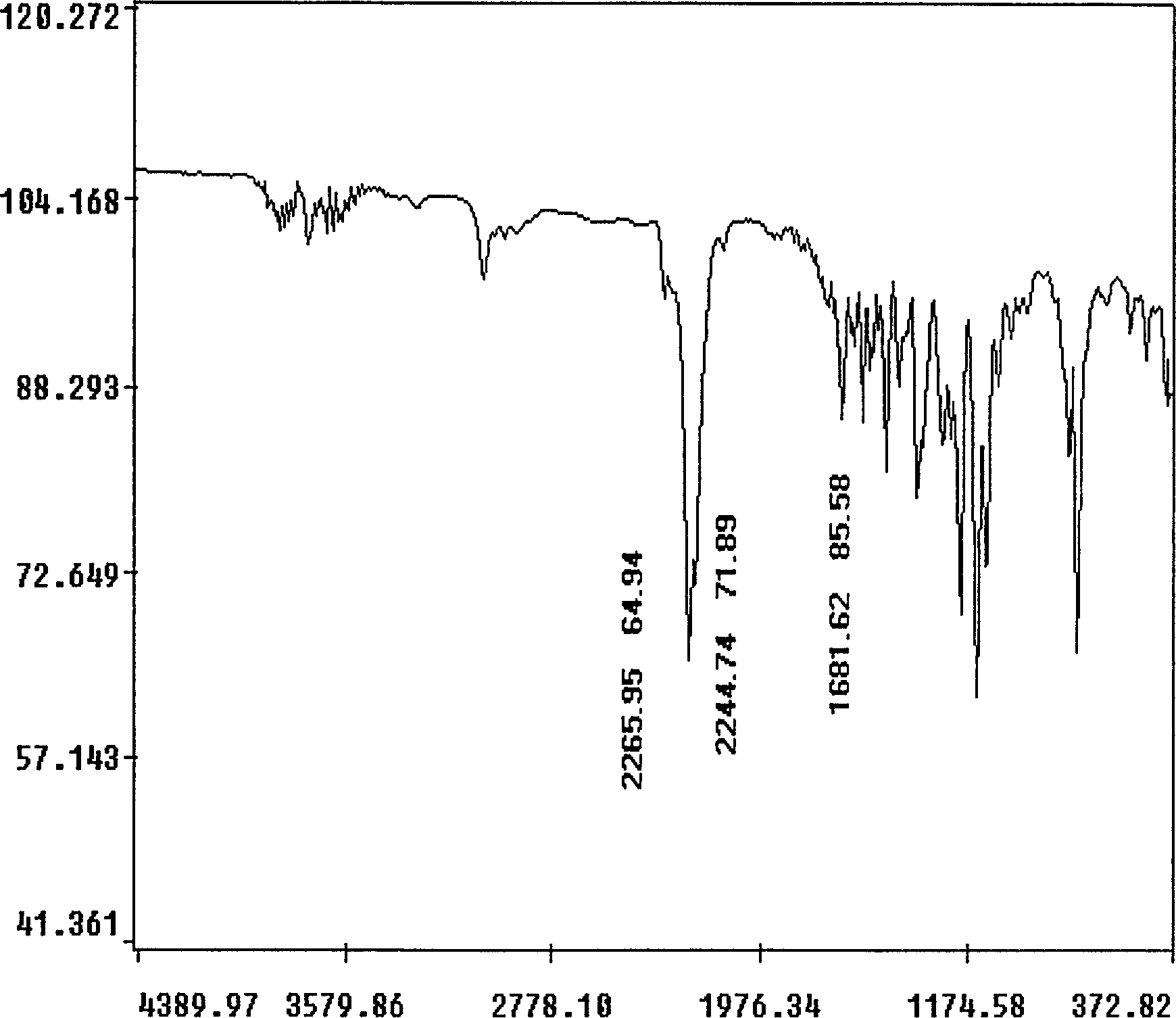

Siliceous modified high-temperature-resistant cyanate resin, and preparation method and application thereof

ActiveCN105199103AHeat resistance without sacrificeImprove brittlenessTetramethylammonium hydroxideSolvent

The invention relates to a siliceous modified high-temperature-resistant cyanate resin, and a preparation method and application thereof. The preparation method comprises the following steps: adding a hydroxy silicone oil-silane coupling agent-organic solvent mixed solution into a tetramethylammonium hydroxide water solution-polar solvent mixed solution, carrying out hydrolytic polycondensation at 5-40 DEG C for 4-8 hours, and distilling to obtain epoxy-containing silsesquioxane; prepolymerizing the epoxy-containing silsesquioxane and a cyanate resin at 50-100 DEG C for 1-8 hours to obtain a modified cyanate resin; and uniformly mixing the modified cyanate resin and modified acid anhydride to obtain the siliceous modified high-temperature-resistant cyanate resin. The intrinsic toughening mode is utilized to improve the brittleness of the cyanate resin without sacrificing the heat resistance of the cyanate resin; and thus, the prepared high-temperature-resistant resin composition for pultrusion, of which Tg is 240-270 DEG C, has the advantages of excellent high temperature resistance and favorable cost.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

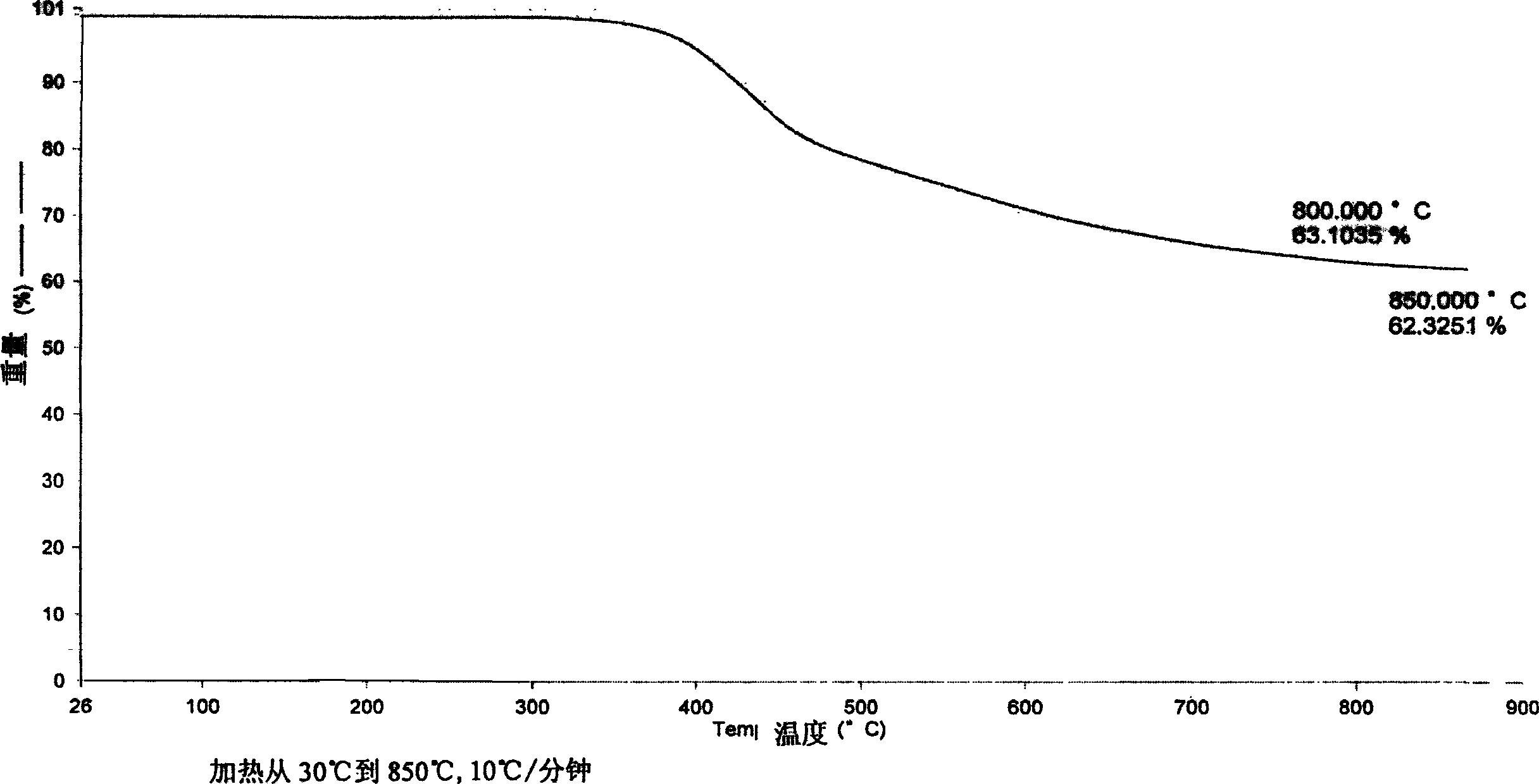

Ablative material of resin of phenolic cyanate

The invention provides a phenolic cyanate resin ablator composed by mixture of alloied linear phenolic cyanate resin and linear fused ring phenolic cyanate resin and strengthen material which can satisfy the demand of high corbon residu ratio (>60 percent), high heat-resistance temp. (>350 deg.C), low fusant viscosity, low solidify agravity ratio and long gel time.

Owner:北京玻钢院复合材料有限公司

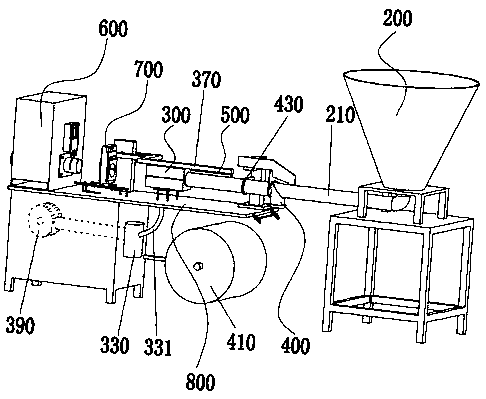

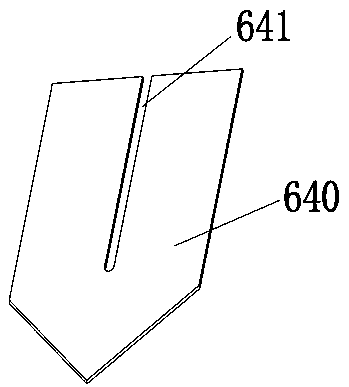

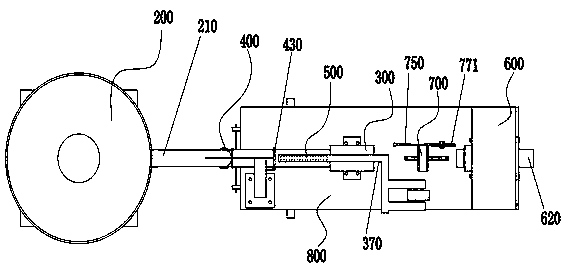

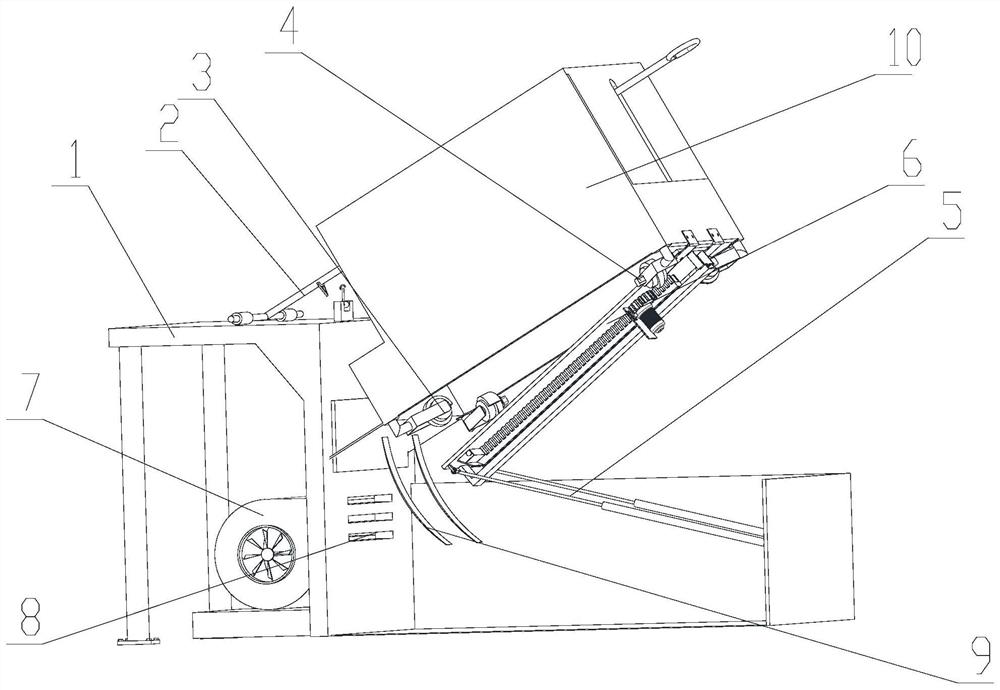

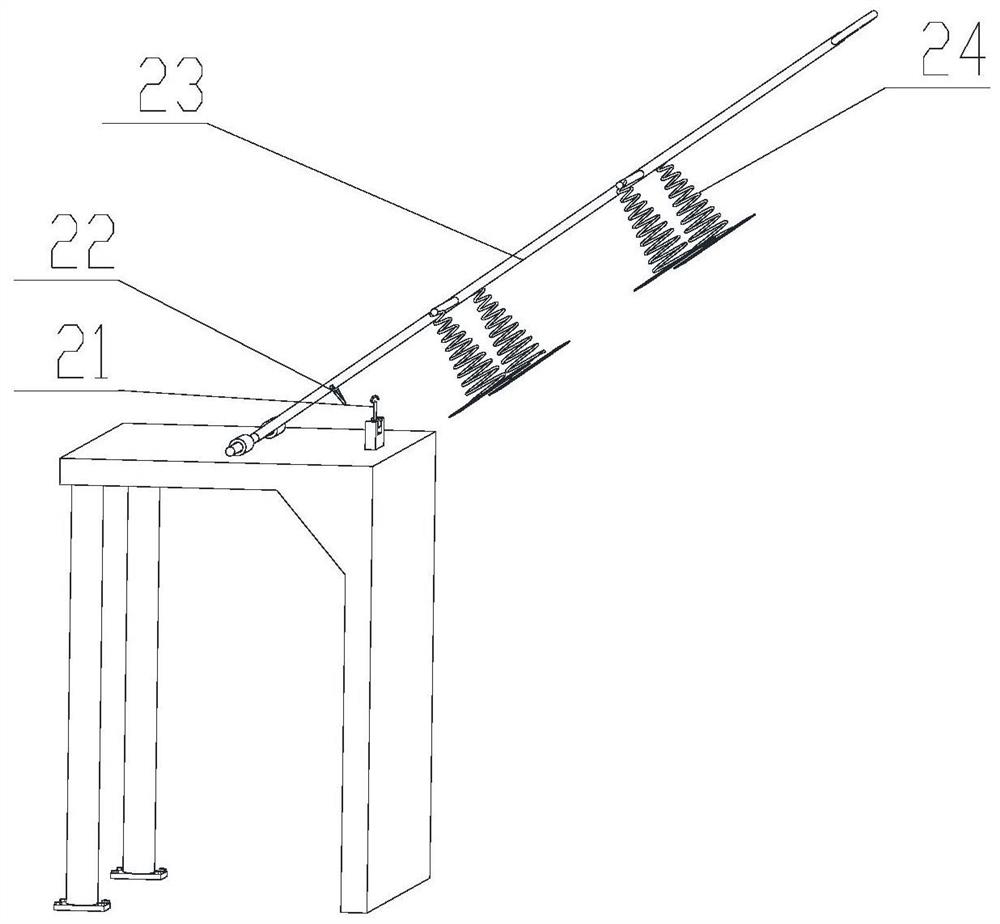

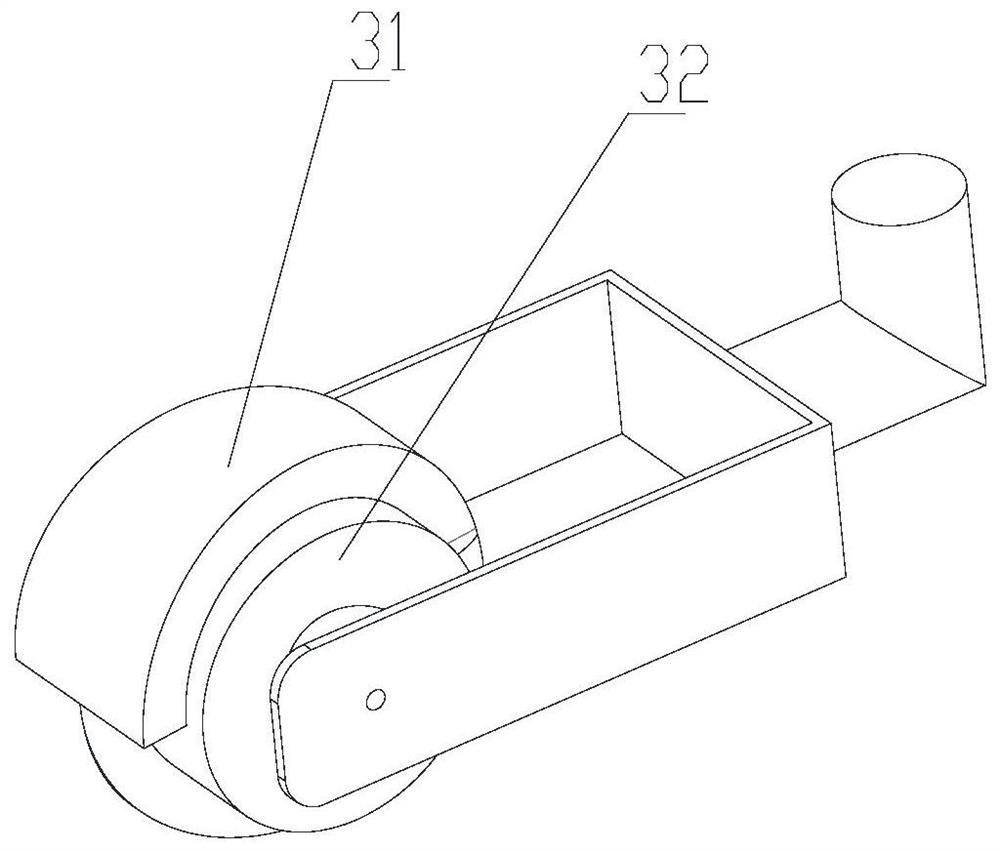

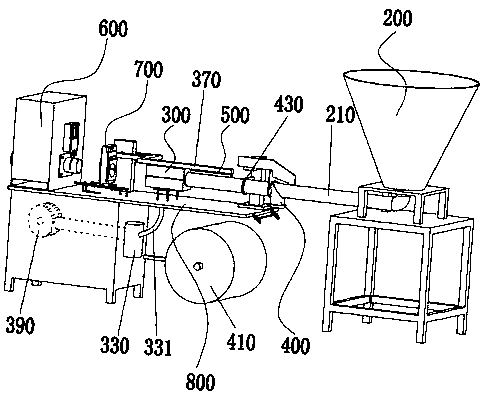

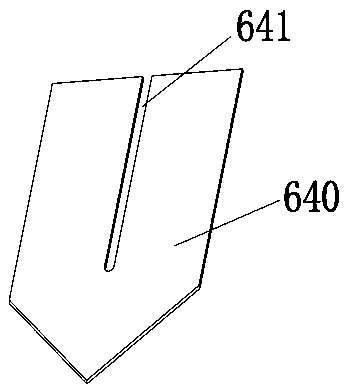

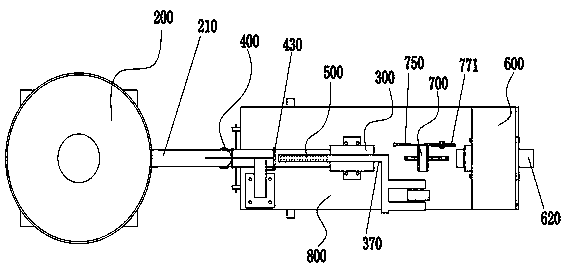

Pneumatic light-substrate net bag fast breeding seedling culture container automatic filling shaping system

PendingCN108849397ALow viscosity requirementMeet the compactness requirementGrowth substratesCulture mediaReciprocating motionEngineering

The invention relates to an automatic filling shaping system, in particular to a pneumatic light-substrate net bag fast breeding seedling culture container automatic filling shaping system, which comprises a material cabin and a vacuum material supply box, wherein the material cabin can be used for accommodating a substrate; the vacuum material supply box is used for sucking and accommodating thesubstrate; the vacuum material supply box is designed again; the vacuum material suction principle is used for sucking the substrate in the material cabin into the vacuum material supply box; on a pushing device, a packaging bag and the substrate are forwards pushed in a clamping reciprocating moving mode; the structure is simple; during the design of a cutting device, a cabinet body structure isspecially made; a sealed structure provides good safety; a cutter uses a 45-degree triangular cutting edge; the inclined direction action force is increased, so that the cutter is sharper after the use; the cutting edge abrasion degree of the cutter is reduced; the characteristics that the cutter blade replacement, the cutter blade edge grinding and the like are convenient are realized; the wholeset of automatic equipment system has the characteristics that the structure is simple; the assembly is easy; the efficiency is improved; the labor cost is reduced, and the like.

Owner:安徽乐林农林科技有限公司

Preparation method of rapid prototyping high-temperature resistant resin system for carbon fiber automobile parts

The invention relates to a preparation method of a rapid prototyping high-temperature resistant resin system for carbon fiber automobile parts, and aims at solving the technical problems that an existing resin system is long in curing time, low in molding efficiency, short in gelation time at an injection temperature, too fast in viscosity increase and relatively poor in wettability on a fiber preform. The method comprises the following steps: stirring and mixing high-activity polyamine and low-activity aromatic amine to form a uniform and stable curing agent component A; heating an anionic initiator and a low molecular epoxide to prepare a modified anionic catalyst; stirring and mixing with a chain transfer agent to obtain a catalyst component B; stirring epoxy resin of different epoxy values evenly to obtain a resin component E; and mixing with the curing agent component A with the catalyst component B evenly to prepare the rapid prototyping high-temperature resistant resin system. The method can be applied to the field of preparation of carbon fiber automobile parts.

Owner:BEIJING UNIV OF CHEM TECH

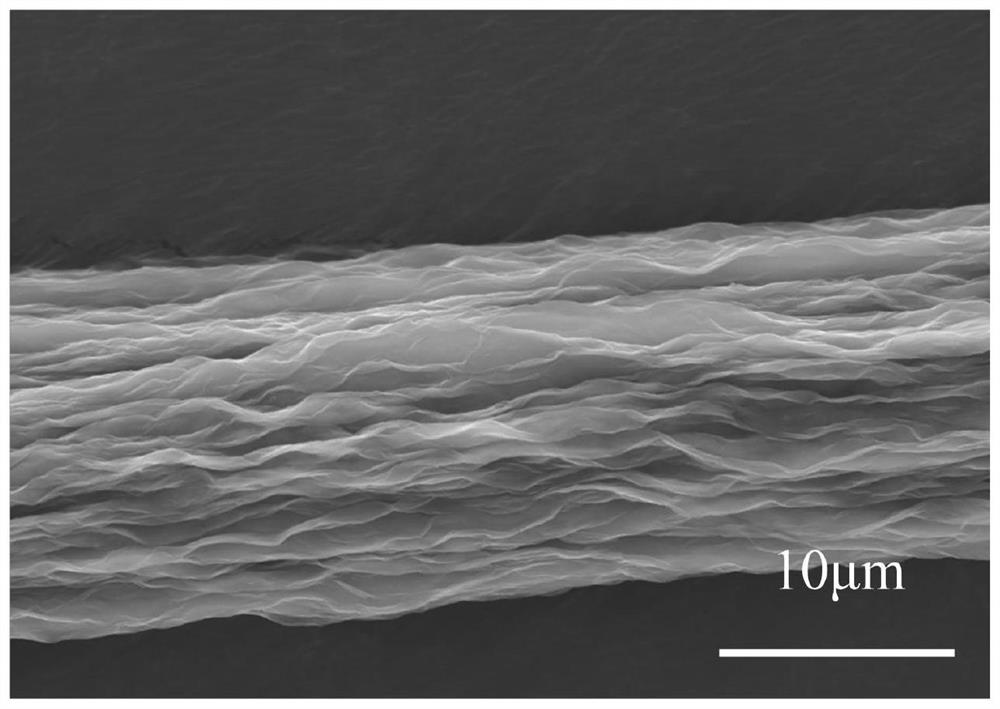

Preparation method of MXene/sodium alginate composite fiber

PendingCN113862831AHigh strengthImprove conductivityElectroconductive/antistatic filament manufactureAlginate artificial filamentsFiberProcess equipment

The invention discloses a preparation method of MXene / sodium alginate composite fiber, and aims to solve the problems of low MXene loading capacity, complex process equipment, incapability of quick preparing in a large scale and the like in an existing preparation method of MXene fiber. The preparation method comprises the following steps of adding SA into an MXene colloidal solution, and magnetically stirring to obtain an MXene / SA composite solution; adding anhydrous CaCl2 into deionized water, magnetically stirring until the anhydrous CaCl2 is completely dissolved, adding isopropanol into the deionized water, and magnetically stirring until the solution is not obviously layered to obtain a coagulating bath; and finally, injecting the MXene / SA composite solution into thread throwing equipment for thread throwing, meanwhile, collecting fiber through a coagulating bath collecting device, and carrying out cleaning and drying to obtain the MXene / SA composite fiber. The surface of the composite fiber has an obvious groove and wrinkle structure, the structure is beneficial to storage and transfer of charge and reflection of electromagnetic waves, and the composite fiber has wide application prospects in the fields of supercapacitors, sensors and electromagnetic shielding.

Owner:HARBIN INST OF TECH

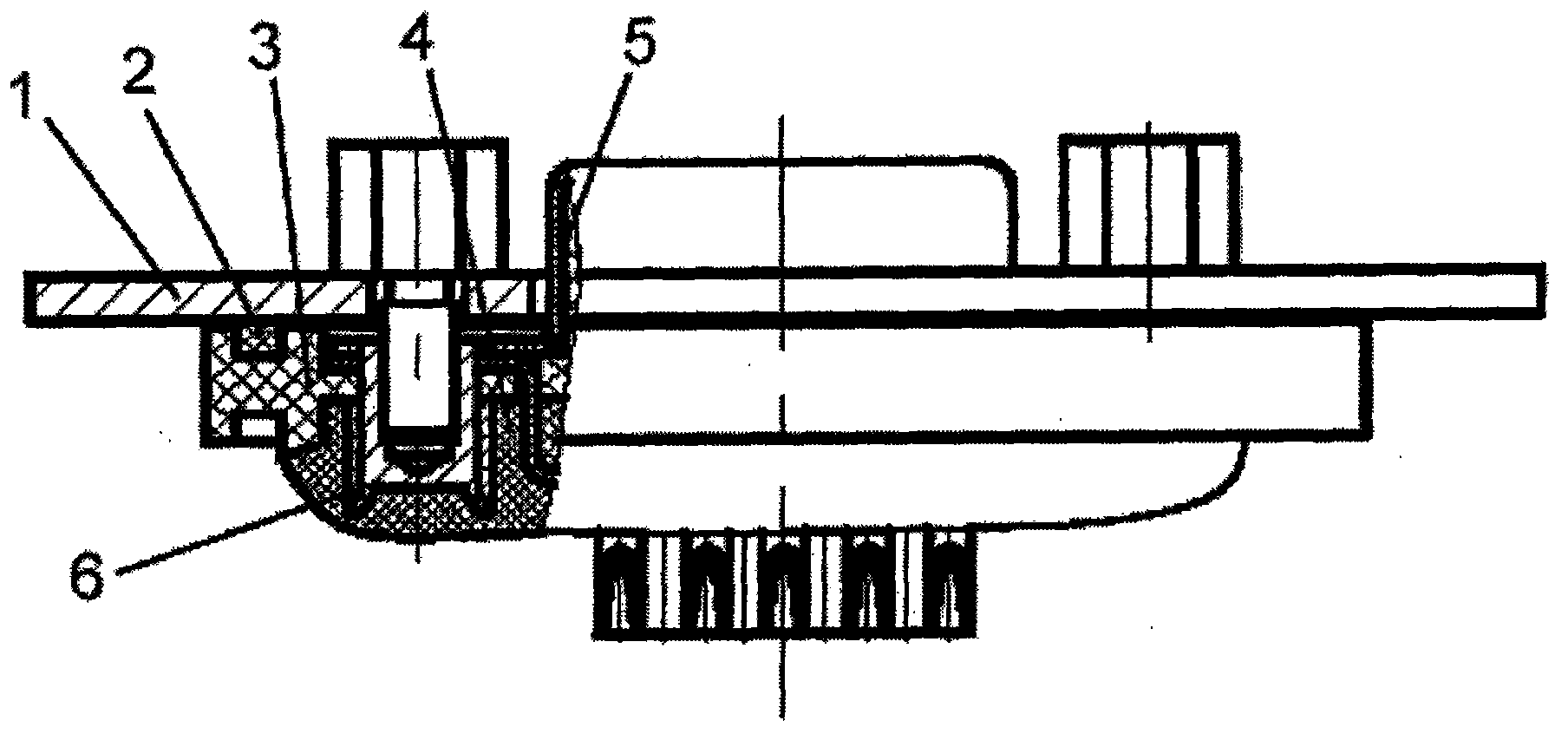

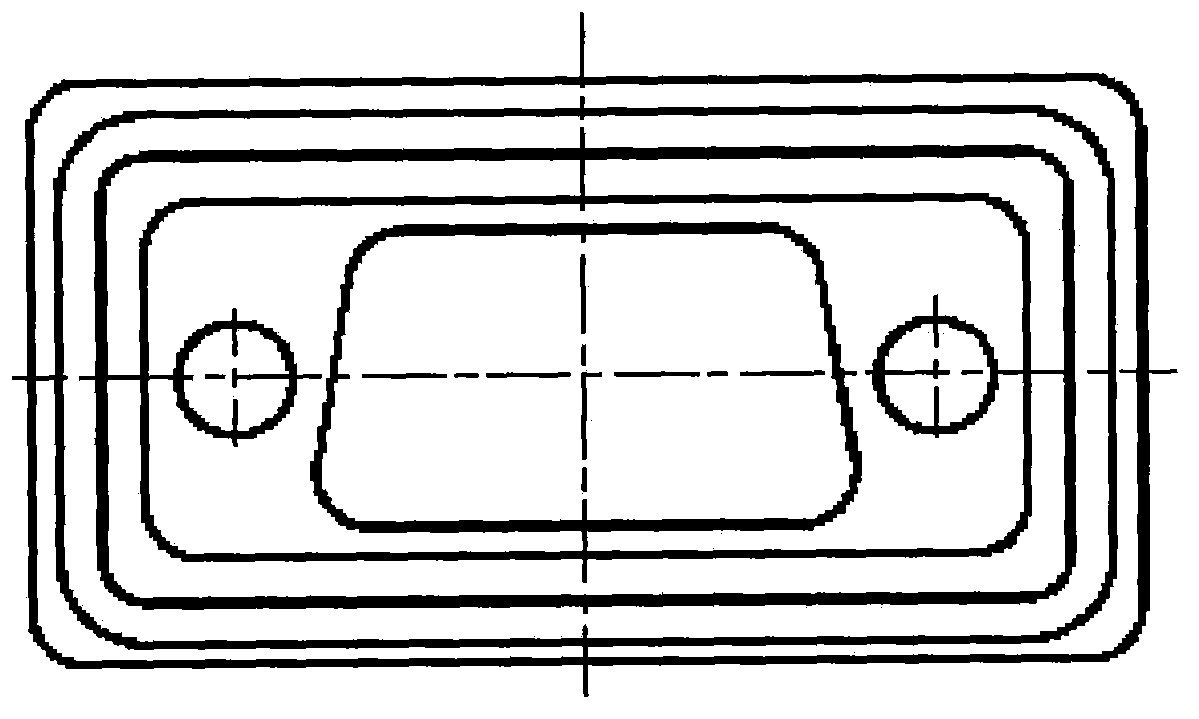

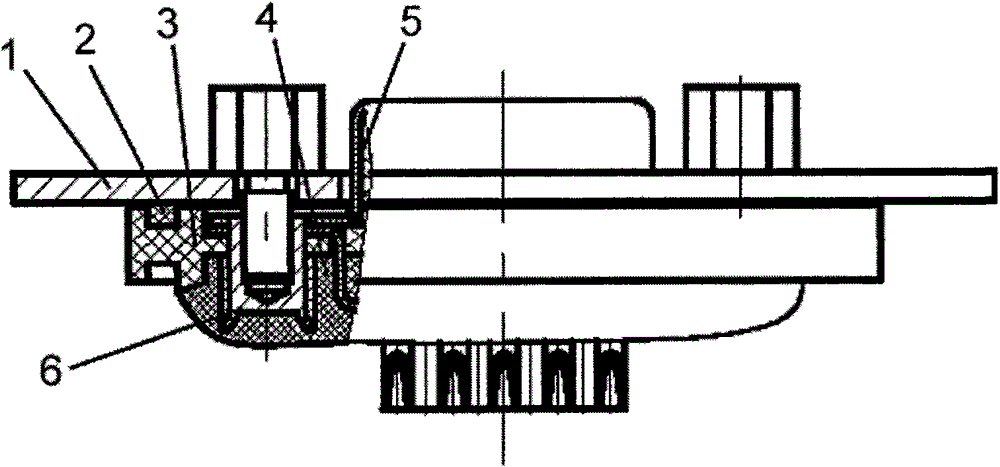

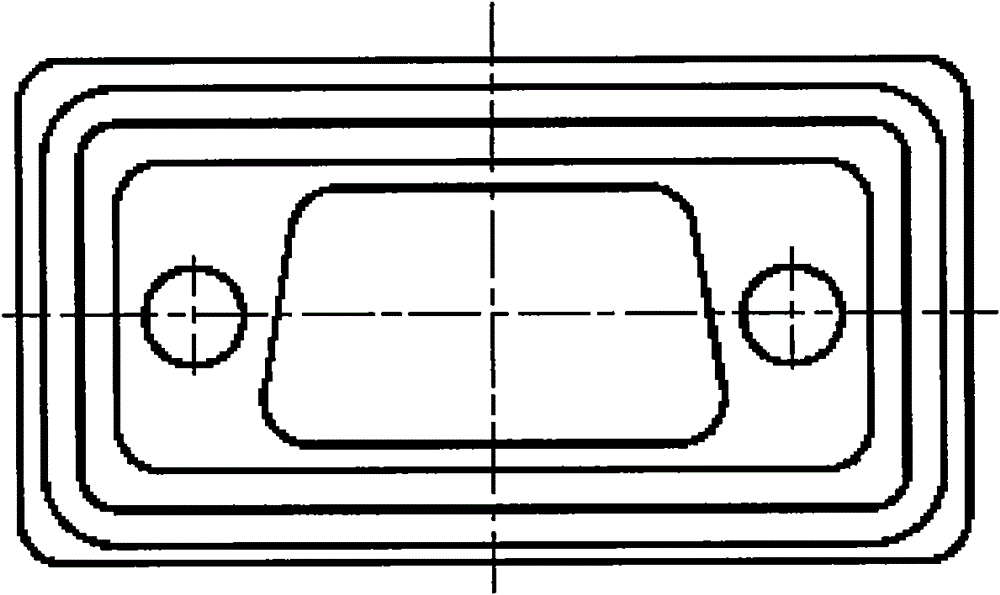

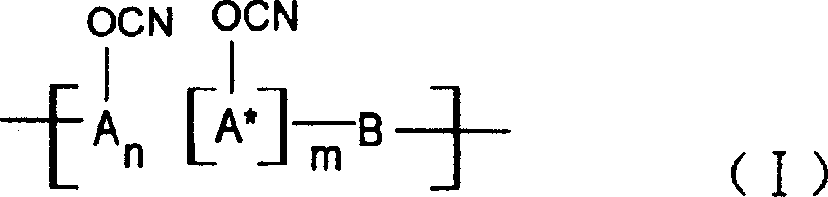

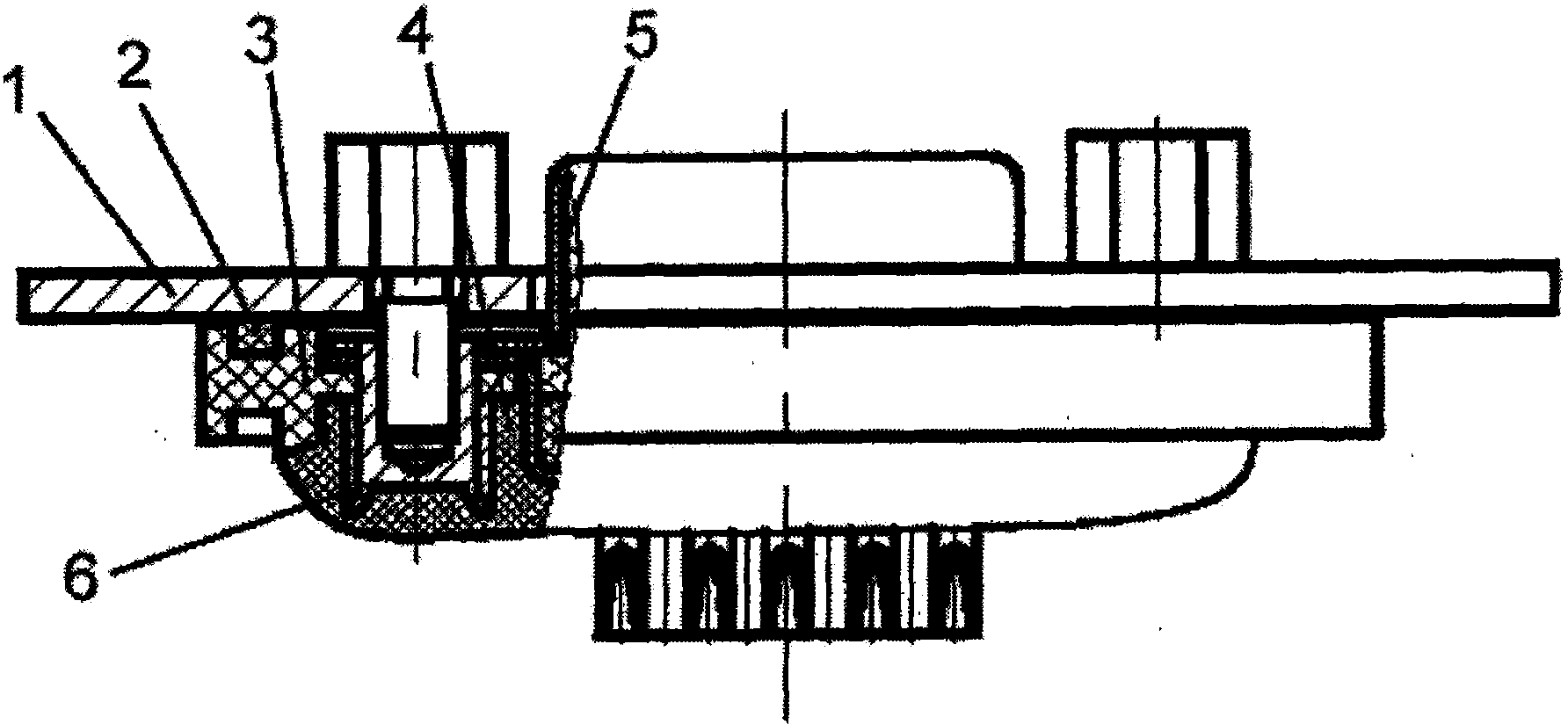

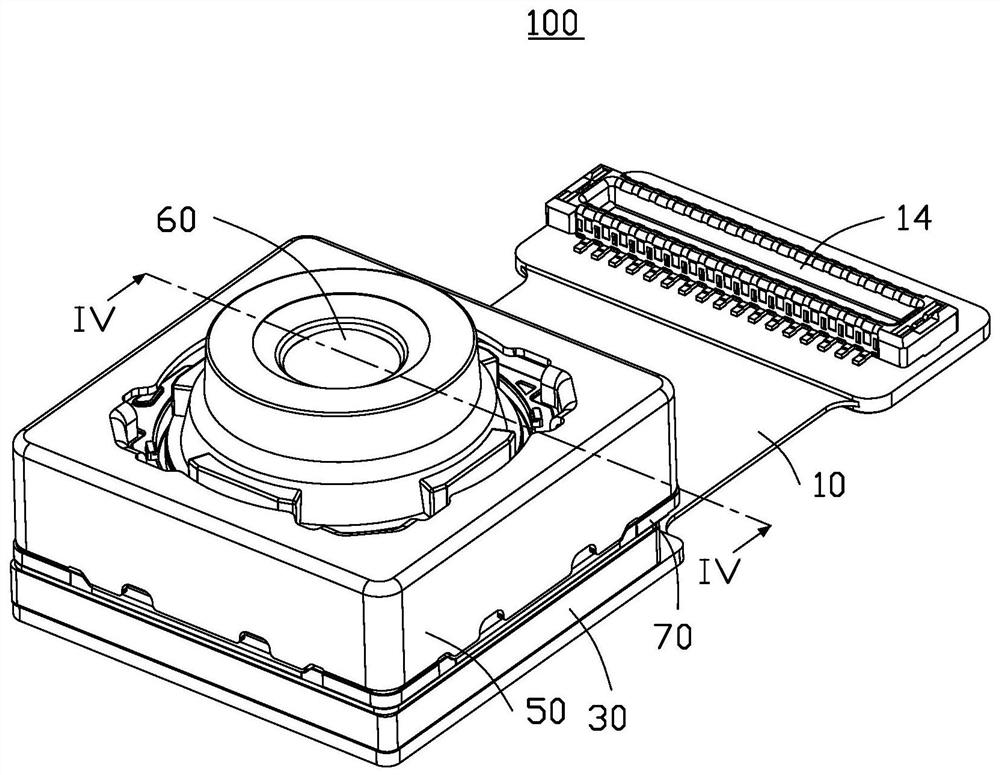

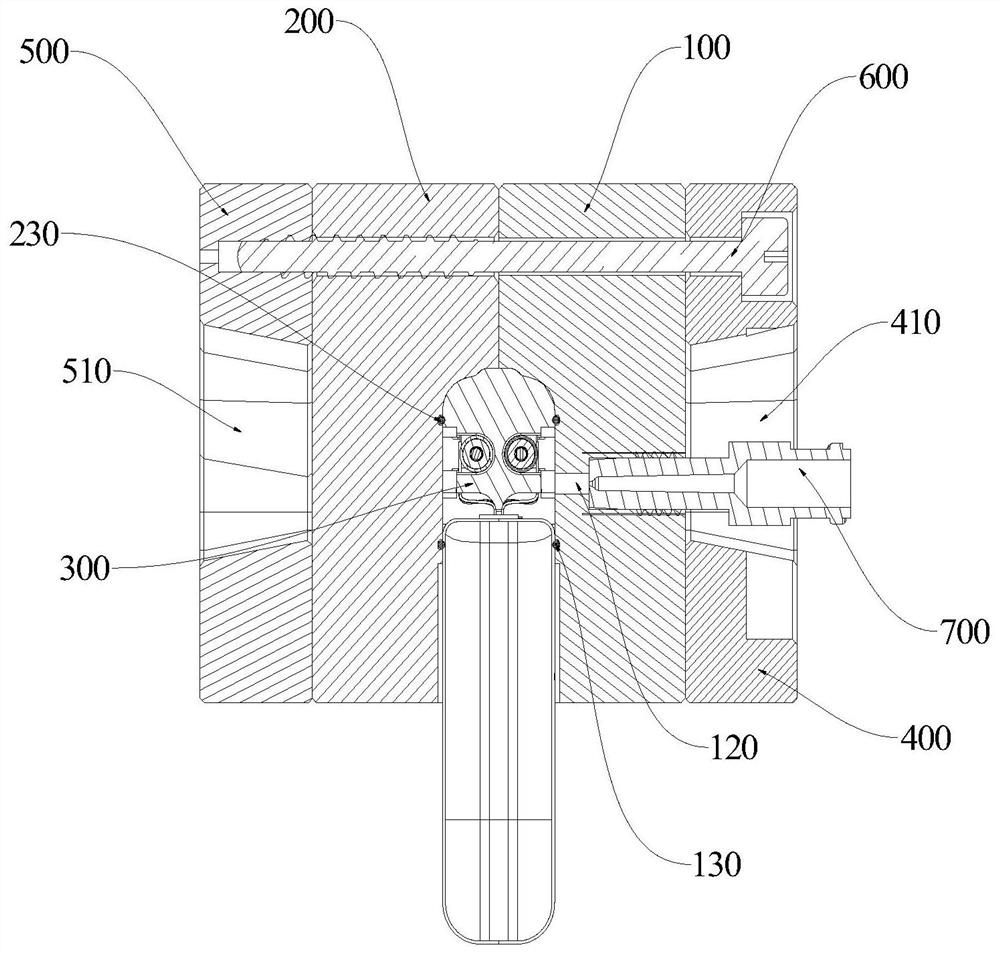

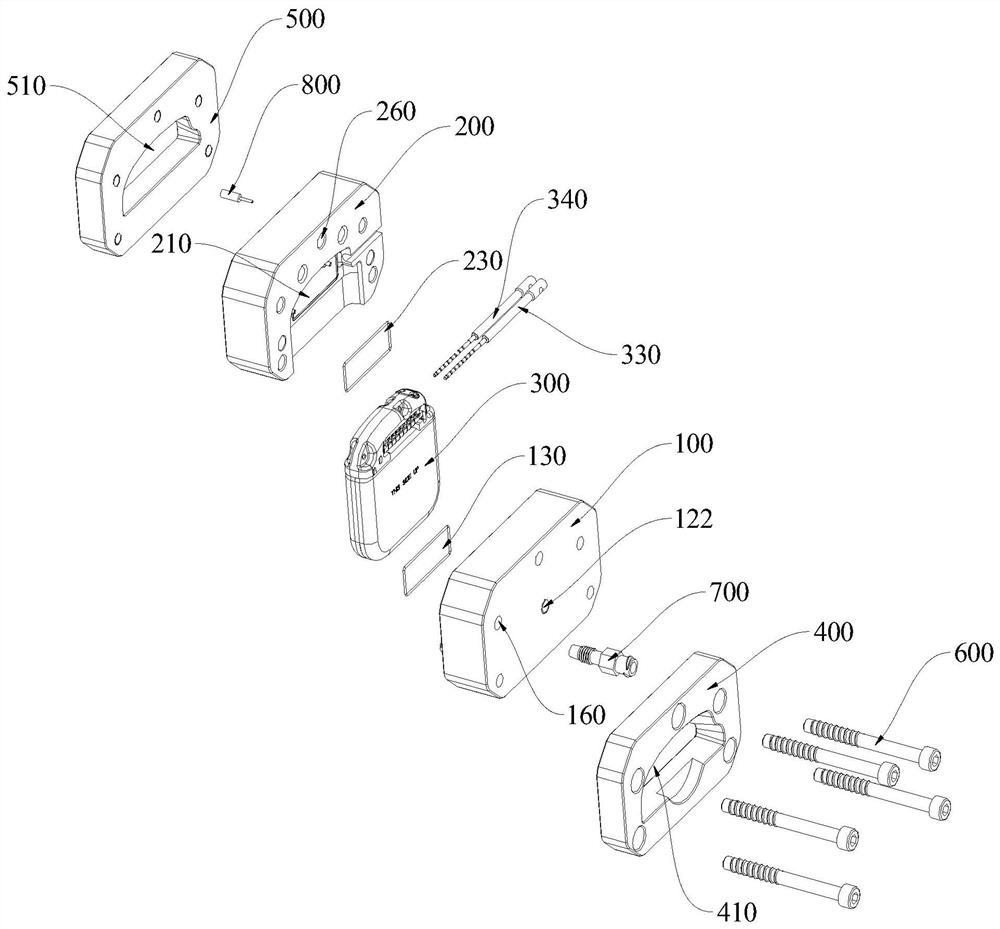

Water-proof connector support plate

ActiveCN103401093ALow viscosity requirementNice appearanceCouplings bases/casesCoupling parts mountingHigh volume manufacturingEngineering

The invention discloses a water-proof connector support plate. The support plate (3) is provided with a side face and an another side face, wherein the side face is provided with a sealing ring (2); the other side of the support plate (3) is provided with a glue pouring die cavity. The water-proof connector support plate is characterized in that a slope-shaped enclosed boss (7) used for controlling the glue pouring shape is arranged around the glue pouring die cavity of the support plate (3); the enclosed boss (7) projects out of a plane on which the support plate (3) is positioned, and tilts towards the glue pouring side. According to the water-proof connector support plate, the problems of difficulty in forming water-proof glue and low production efficiency existing in the conventional product assembling and processing are solved; an automatic glue pouring process can be performed conveniently, the die cavity is filled fully by means of the flowability of the glue, one-time molding is realized, and the glue pouring amount can be controlled accurately without manually repairing the glue pouring shape; and the water-proof connector support plate has the advantages of attractive appearance, high size consistence, high production efficiency and suitability for batch production.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

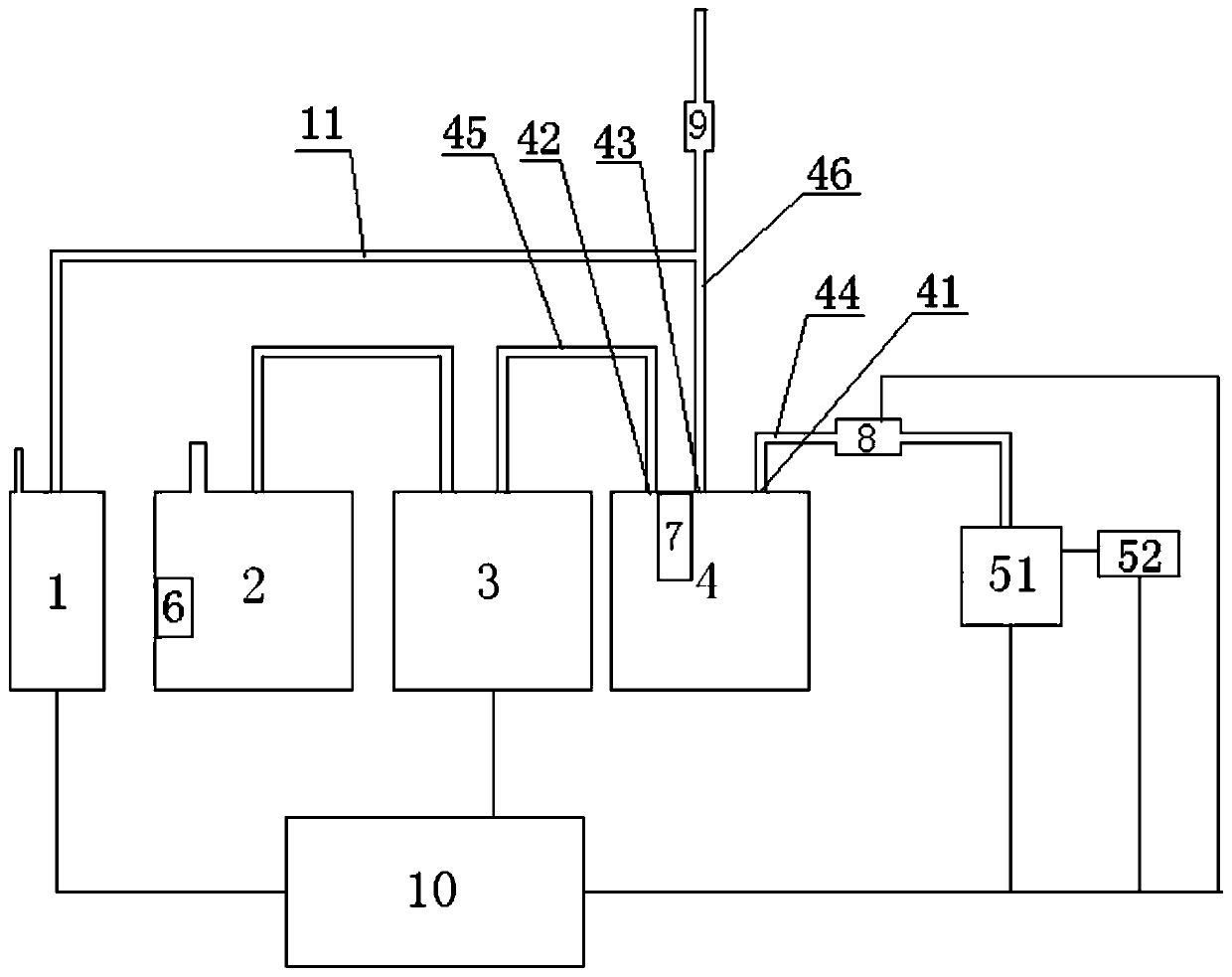

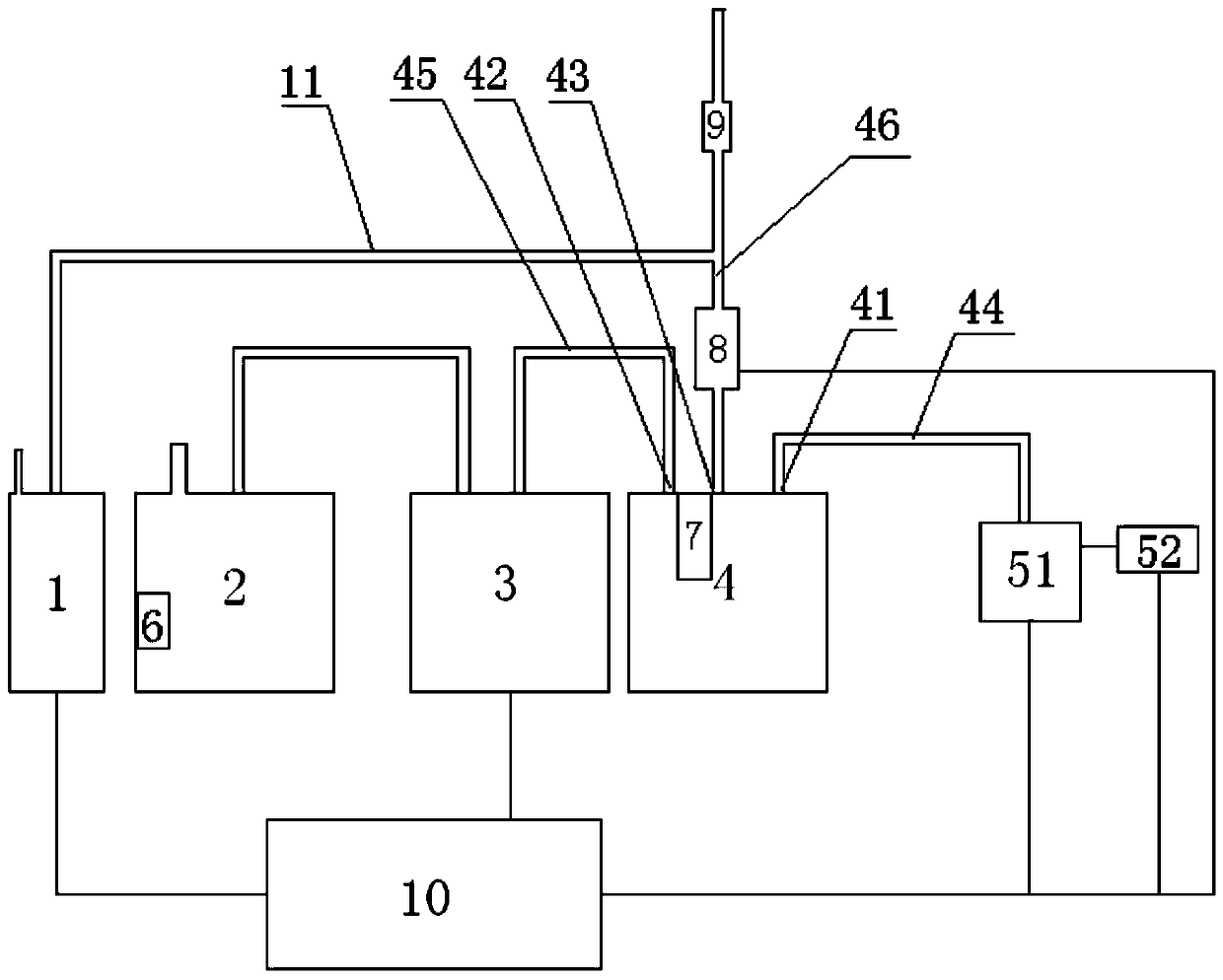

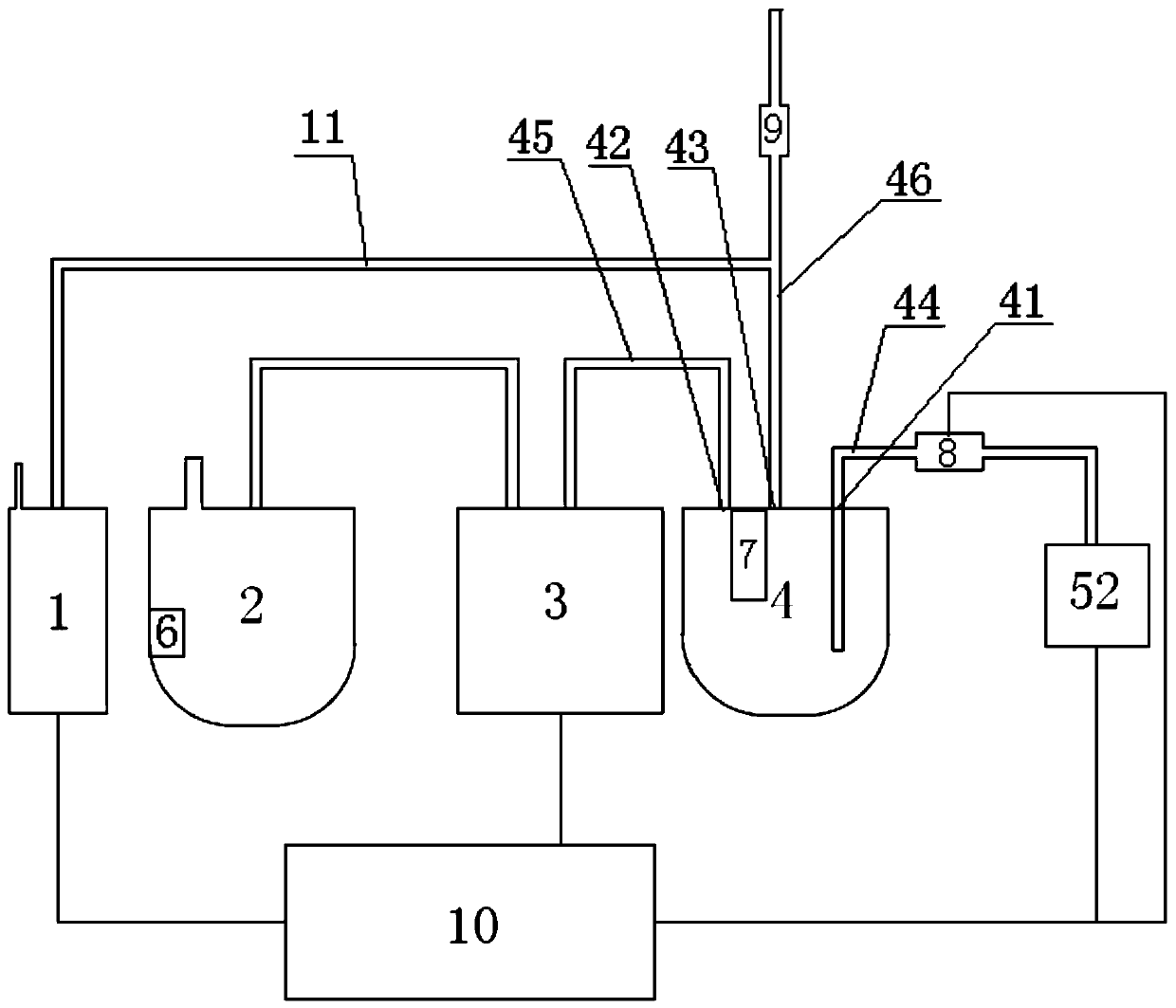

Hydrodynamic foaming system and foaming method and closestool comprising foaming system

PendingCN110093962APrecisely control delivery volumeAccurately control the dosageLavatory sanitoryFoaming agentProduct gas

The invention discloses a hydrodynamic foaming system. The system comprises a water inlet mechanism, a liquid inlet mechanism, an air inlet mechanism, a hydrodynamic mixing box, a foaming pipe and a control mechanism; a water inlet and a liquid inlet are formed in the side wall or the top of the hydrodynamic mixing box; a liquid outlet is formed in the top of the hydrodynamic mixing box, the waterinlet is connected with a water outlet pipe of the water inlet mechanism, the liquid inlet is connected with a liquid outlet pipe of the liquid inlet mechanism, the liquid outlet is connected with aninlet of the foaming pipe through a connecting pipe, the connecting pipe further communicates with an air outlet pipe of the air inlet mechanism, and the control mechanism is connected with the waterinlet mechanism, the liquid inlet mechanism and the air inlet mechanism. A closestool and a foaming method are also disclosed. By adding the hydrodynamic mixing box, a foaming agent is injected in advance, and the use amount of the foaming agent is accurately controlled by logically controlling the working time of a liquid pump. The uniformly mixed foaming liquid is mixed with gas by utilizing the pushing force of water to finally generate foam, so that the application range is wide. The system is simple in structure, low in cost, intelligent in control and capable of rapidly generating foamand better meeting the requirements of customers.

Owner:河北态及环保科技有限公司

Fruit shell high-temperature-resistant resin coated sand and preparation method thereof

The invention relates to fruit shell high-temperature-resistant resin coated sand and a preparation method thereof. The coated sand is prepared from fruit shell particles serving as a kernel propping agent and a resin coating with which the surfaces of the fruit shell particles are coated, wherein fruit shell comprises one or more of walnut shell, apricot pit and peach pit; the resin comprises one or two of a thermosetting phenolic resin and a furan resin. The coated sand is characterized in that the fruit shell (such as the walnut shell, the apricot pit and the peach pit) particles are taken as the kernel propping agent, and the resin coating is taken as a coating layer, so that the coated sand can act effectively at the temperature of 350 DEG C, is low in density, and is easy to prepare; the preparation cost of sand-carrying fluid can be lowered effectively, and the construction success rate is increased effectively.

Owner:PETROCHINA CO LTD

Carton printing device and method

InactiveCN113043722AAvoid Excessive ExudationLow viscosity requirementScreen printersOther printing apparatusCartonPrinting press

The invention discloses a carton printing device and method, and belongs to the technical field of printing. According to the technical scheme, the device comprises a platform and a containing box obliquely arranged on the side wall of the platform, and the bottom of the containing box is open and provided with a facial tissue limiting mechanism and a printing mechanism. The carton printing device provided by the invention has the beneficial effects that facial tissue is obliquely arranged, so that the situation that too much ink leaks when the ink is too thin is avoided. The requirement on the viscosity degree of the ink is low, and the time for preparing the required ink is saved; and besides, the printed facial tissue naturally falls under the action of gravity and is stacked in a collecting area under the action of a facial tissue falling guide mechanism, so that the procedure of manually transferring the facial tissue is omitted, and the printing efficiency is improved.

Owner:高建玲

Transparent organic silicon resin for room temperature resin transfer moulding and preparation method of transparent organic silicon resin

The invention relates to transparent organic silicon resin for room temperature resin transfer moulding and a preparation method of the transparent organic silicon resin. The transparent organic silicon resin is prepared by the reaction of polymethyl phenyl vinyl siloxane, a silicon-containing hydrogen bond, silicon methyl hyperbranched polysiloxane and a platinum catalyst. Si-CH=CH2 content of the polymethyl phenyl vinyl siloxane is (2.02-2.48)*(10-3)mol / g; Si-CH3 content of each of the silicon-containing hydrogen bond and the silicon methyl hyperbranched polysiloxane is (2.97-4.08)*(10-3)mol / g, and Si-H content is (2.45-3.25)*(10-3)mol / g. The organic silicon resin provided by the invention has a viscosity of 200-400mPa.s at room temperature, and the working life is longer than 4 months; when the organic silicon resin is applied to the room temperature resin transfer moulding process, the obtained condensate has excellent light transmission, dielectric performance and heat performance; and according to the preparation method adopted by the invention, the operation is simple, and environmental protection is realized.

Owner:扬州华上新材料有限公司

Honing liquor dedicated for piston ring

The invention discloses a honing liquid of piston, which comprises the following parts: abradant, mechanic oil and additive, wherein the additive is composed of extreme-pressure resistant additive, cleaning additive and rust-proof additive, which improves using efficiency without odor and harm for skin; the invention can be soaked in the kerosene for 0.5min to use, which adopts common water-based abluent or diesel or kerosene or petrol to clean.

Owner:唐玉冰

Manufacturing method of carbon fiber composite material cable wire

ActiveCN103310908ALow viscosity requirementImprove high temperature resistanceCable/conductor manufactureEpoxyFiber

The invention relates to a manufacturing method of a carbon fiber composite material cable wire. The carbon fiber composite material cable wire comprises a load bearing core (12) and a protection layer (13), wherein the protection layer (13) is covered outside the load bearing core (12) through a winding process, the load bearing core (12) is a high-temperature-resistance mechanical property epoxy resin and carbon fiber compound, and the protection layer (13) is a compound of high-temperature-resistance and weather-resistance epoxy resin compositions and glass fibers. The carbon fiber composite material cable wire adopts the blending epoxy resin of the hydantoin epoxy resin and low-viscosity epoxy resin as resin substrates, the requirement of glass fiber on the low viscosity of the resin can be met, and the cable core can also have excellent high-temperature-resistance performance.

Owner:HOHHOT HALLYUEN CARBON FIBER

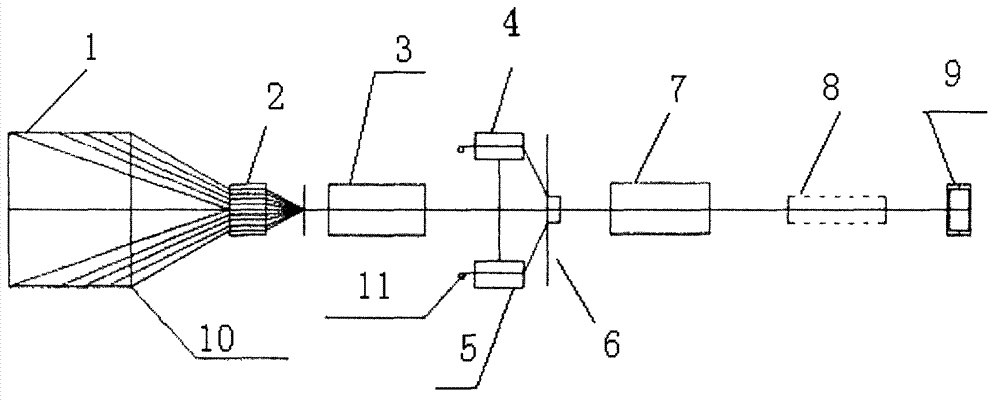

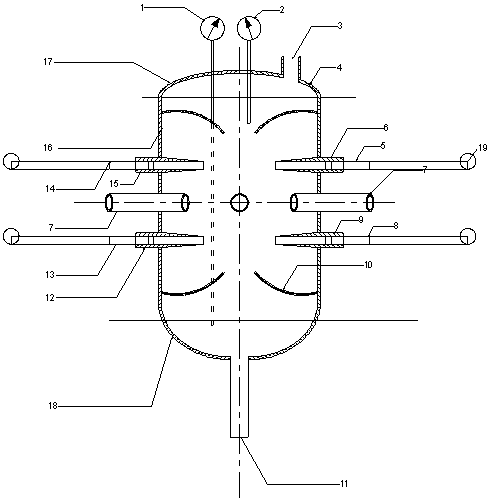

Impinging stream reaction kettle for preparing ultrafine powders

PendingCN109225117ALow viscosity requirementOvercome the shortcomings of mixing to reduce the quality of the final productChemical/physical/physico-chemical nozzle-type rreactorsEngineeringSide reaction

The invention relates to a reaction kettle, and in particular to an impinging stream reaction kettle for preparing ultrafine powders. A heat exchange jacket is arranged outside a kettle body; a pressure gauge and a thermometer are arranged on a head cover; a gas outlet provided with a vent valve is formed in the head cover; a circulating discharge outlet is formed in the lower end of a kettle bottom; an overflow port is formed in the upper part of the kettle body; the circulating outlet in the lower end of the kettle bottom is connected with a lower nozzle; two groups of feed inlets are coaxially and oppositely arranged; three discharge holes are formed among the feed inlets; three center discharge holes are formed between two layers of feed inlets; horizontal discharge holes at an angle of 120 DEG relative to each other are formed between two layers of feed inlets; arc-shaped heat exchange baffles (10) are respectively arranged on the upper layer of the feed inlets and upper and lowerends of the feed inlets; and the spacing and the curvature of the baffles are adjustable; the arc-shaped heat exchanger baffles are divided into two groups: an upper group and a lower group; and flowguiding holes are formed in the lowest parts of the lower group of baffles. The impinging stream reaction kettle structurally comprises the heat exchange plates and the middle discharge holes to inhibit the formation condition of side reactions; recycle mixing can be carried out; the operation is convenient; and therefore, the impinging stream reaction kettle is particularly suitable for preparing a plurality of ultrafine powders.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Automation device for filling substrates into light substrate mesh bag fast seedling breeding container

PendingCN108849075ALow viscosity requirementGood sealingCultivating equipmentsFlower-pot fillingEngineeringPack material

The invention relates to an automation device, in particular to an automation device for filling substrates into a light substrate mesh bag fast seedling breeding container. The automation device comprises a vacuum material supply box, wherein material holes for packing materials and substrates to pass are formed in the two ends of the vacuum material supply box; a cavity communicated with the material holes is arranged in the vacuum material supply box; a vacuum pump for propelling the cavity to form negative pressure is installed; a material suction opening matched with the vacuum pump is arranged in the vacuum material supply box. The vacuum material supply box is redesigned; by using the vacuum material suction principle, substrates in a material cabin are sucked into the vacuum material supply box; the requirements on the substrate viscosity are greatly reduced; through vacuum material suction, the substrate finished package reaches the compactness requirements; the practicabilityis high; an opening sealing device is also arranged on the vacuum material supply box; the opening sealing on a mesh bag is convenient; the automation device also has the characteristics that the structure is simple, and the assembly is easy.

Owner:安徽乐林农林科技有限公司

Phenolic cyanate resin and its synthesis method and phenolic cyanate ablative material composite

Owner:北京玻钢院复合材料有限公司

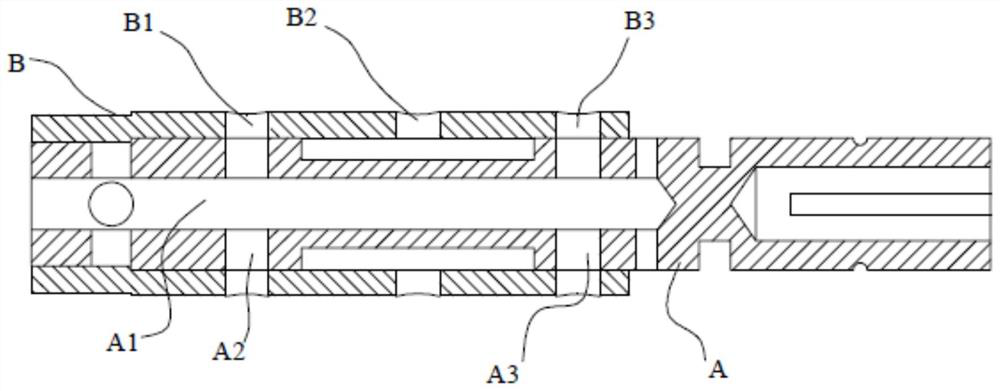

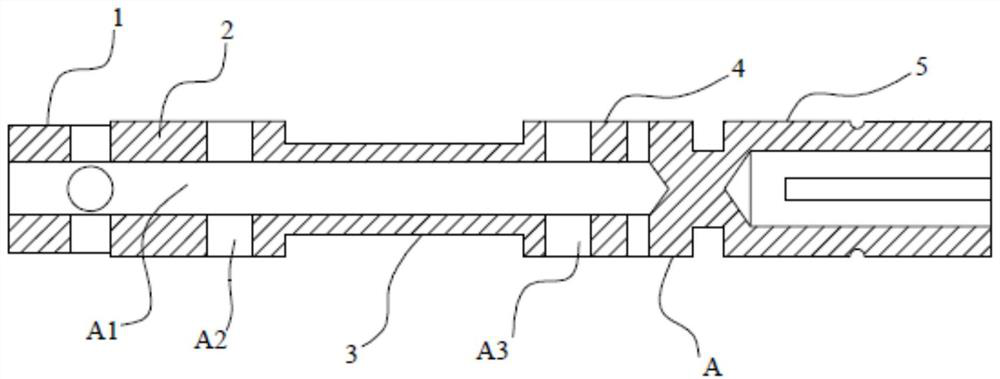

Rotary valve assembly for digital hydraulic oil cylinder and corresponding mechanical feedback digital hydraulic oil cylinder

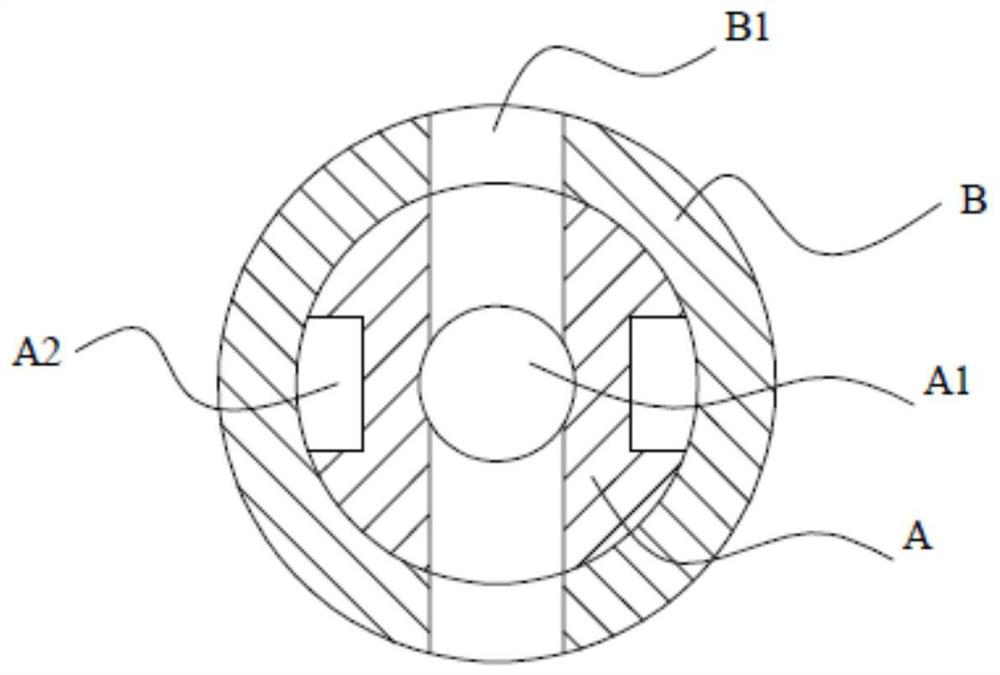

InactiveCN112664500AImprove anti-interference abilityHigh positioning accuracyServomotor componentsThermodynamicsRadial plane

The invention relates to a rotary valve assembly for a digital hydraulic oil cylinder and a corresponding mechanical feedback digital hydraulic oil cylinder. The rotary valve assembly for the digital hydraulic oil cylinder comprises a valve element and a valve sleeve assembled on the outer side of the valve element, and the valve element is a shaft-shaped revolving body; a feedback connecting end, a first oil distribution section, a second oil distribution section, a third oil distribution section and a driving connecting shaft are sequentially arranged from left to right, a first channel is formed in the axial center of the valve element, a second channel is formed in the first oil distribution section in the radial direction, and a third channel is formed in the third oil distribution section in the radial direction; and a fourth channel, a fifth channel and a sixth channel are distributed in the axial direction and are arranged in the radial direction of the valve sleeve, the axis of the fourth channel and the axis of the second channel are located on the same radial plane, the fifth channel is arranged on the outer side of the second oil distribution section, and the axis of the sixth channel and the axis of the third channel are located on the same radial plane. Therefore, the energy consumption loss of the oil cylinder can be reduced, and the requirements of an oil cylinder system on the oil cleanliness and the oil viscosity are reduced.

Owner:苏州宏腾液压机电科技有限公司

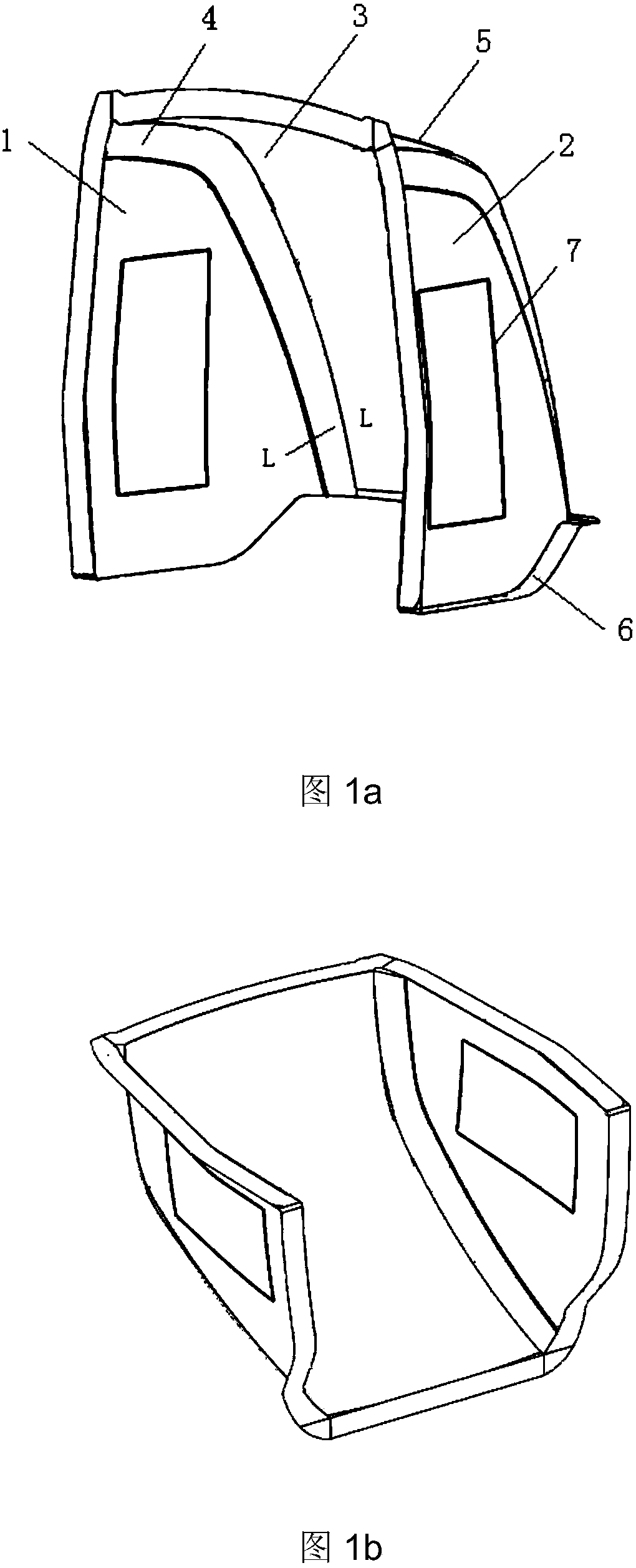

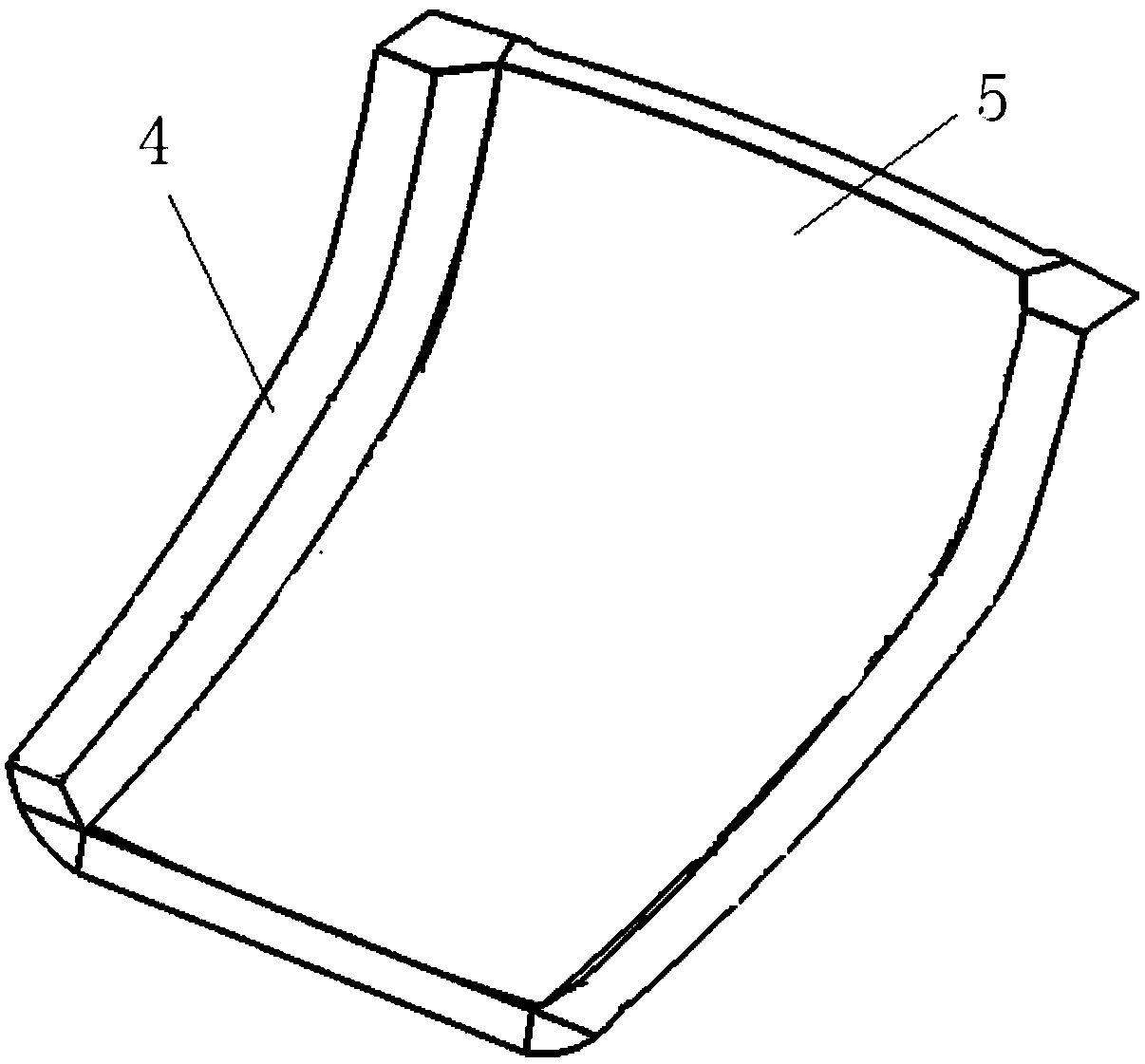

Preparation method of carbon fiber reinforced resin matrix composite rail vehicle head cover

ActiveCN105690799BMeet the use requirementsImprove performanceDomestic articlesPorositySystems design

The invention relates to a forming method of a railway vehicle cowl prepared from a carbon fiber reinforced resin matrix composite material. The forming method comprises the step of forming the vehicle cowl by using a cowl assembling die and specifically comprises the following steps of performing laying and curing forming by adopting a carbon fiber braid; assembling a metal embedded part and carbon fiber composite material reinforcing bars on a cured cowl covering in the cowl assembling die; and then demolding. According to the preparation method disclosed by the invention, by optimizing and innovating the forming die structural design, the laying structural design, the forming process design and the resin formula system design of the railway vehicle cowl, the prepared cowl has excellent integrated properties and has the advantages of low porosity, high specific strength, high specific rigidity, fatigue resistance, good performance stability, light weight and the like; and the integration of the structure and functions is realized, and use requirements of high-speed railway vehicles are met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

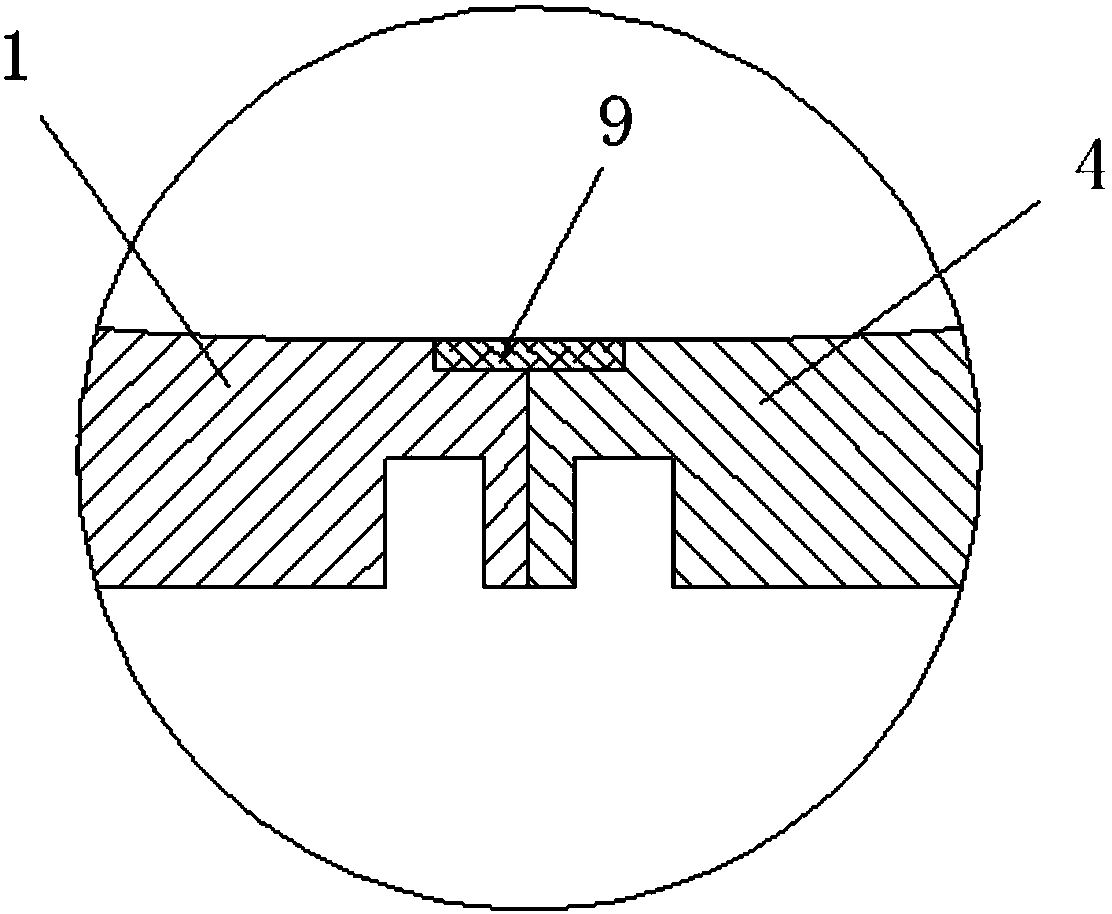

Waterproof connector support plate

ActiveCN102055111BLow viscosity requirementNice appearanceCouplings bases/casesHigh volume manufacturingEngineering

The invention discloses a waterproof connector supporting plate. One side of a supporting plate (3) is contacted with a mounting plate (1), a sealing ring (2) is arranged between the supporting plate (3) and the mounting plate (1) to realize interface waterproofing, and the supporting plate (3) is provided with a groove for accommodating the sealing ring (2); and the other side of the supporting plate (3) is provided with a die cavity for pouring glue to realize waterproofing of a central contactor, the periphery of the die cavity for pouring glue is provided with a lug boss capable of controlling a glue pouring shape, and the lug boss is higher than the plane of the supporting plate (3) and inclines to the glue pouring side to form a slope lug boss (7). The problems of difficult waterproof glue formation and low production efficiency in the conventional product assembly processing are solved; automatic glue pouring process can be conveniently implemented, the die cavity is full of the glue by means of flowability of the glue, the product is formed at one time, the glue pouring amount can be accurately controlled, and manual repair of the glue pouring shape is not needed; and the product has attractive appearance, good size consistency and high production efficiency, and is suitable for large-batch production.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

Ablative material of resin of phenolic cyanate

The invention discloses a phenolic cyanate resin ablation material, which is composed of a blend obtained by blending a linear phenolic cyanate resin and a linear condensed ring phenolic cyanate resin and a reinforcing material. The blended phenolic cyanate can simultaneously meet the characteristics of high carbon residue rate (>60%), high heat resistance temperature (>350°C), low melt viscosity, low curing weight loss rate, long gel time, etc., and can meet Ablation performance requirements for high carbon residue rate and injection process requirements.

Owner:北京玻钢院复合材料有限公司

Water-proof connector support plate

ActiveCN103401093BLow viscosity requirementNice appearanceCouplings bases/casesCoupling parts mountingIndustrial engineeringManufacturing engineering

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

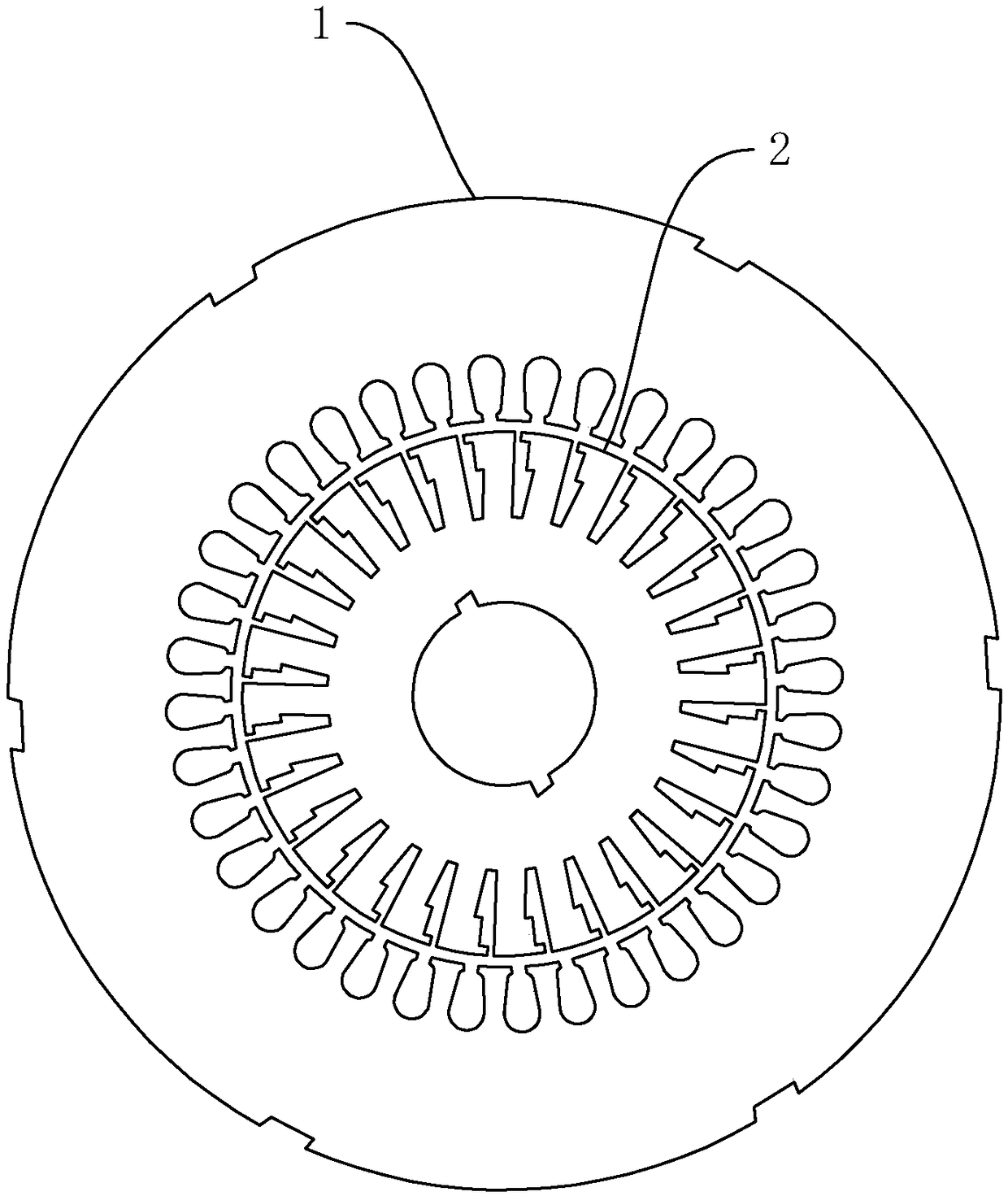

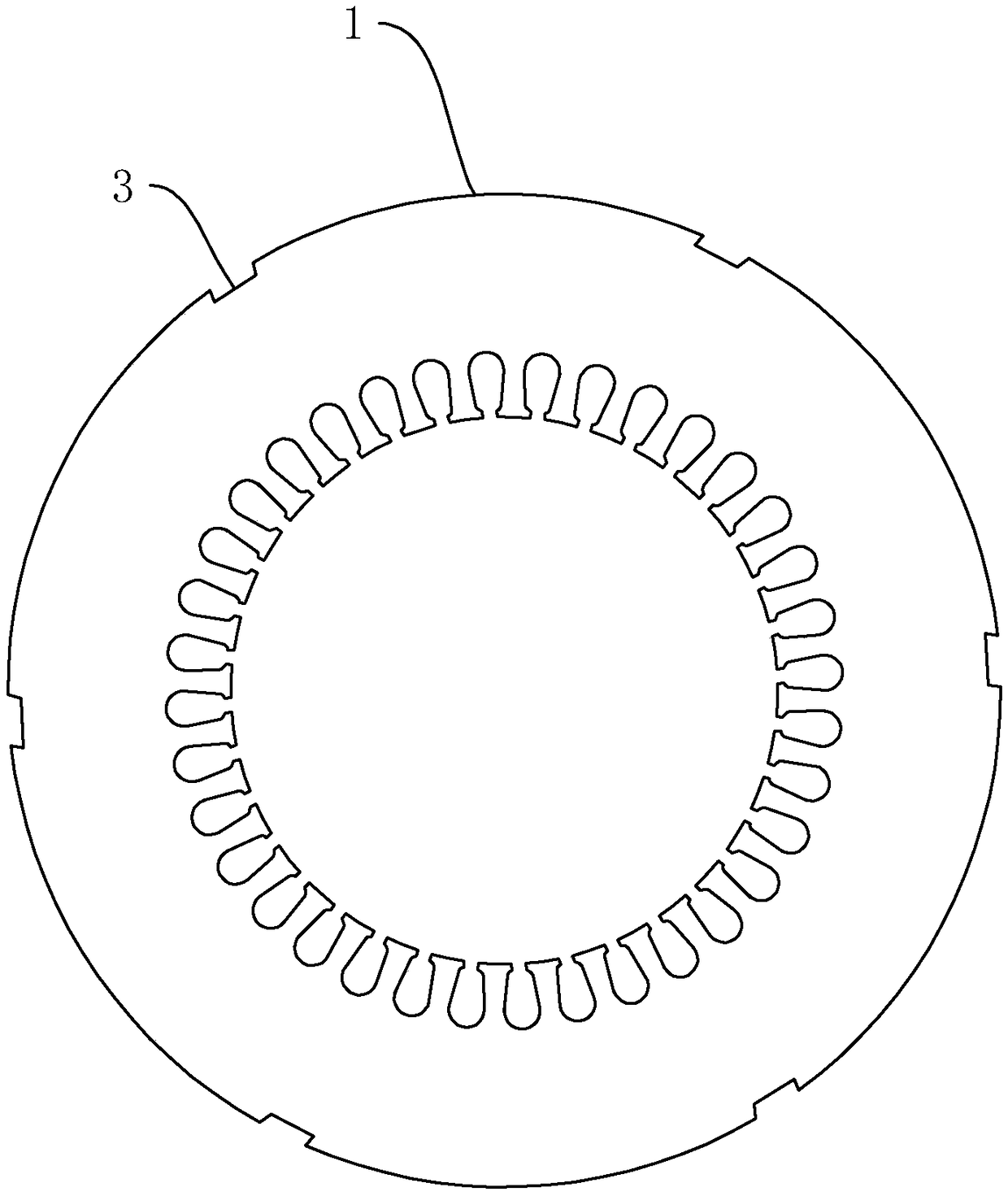

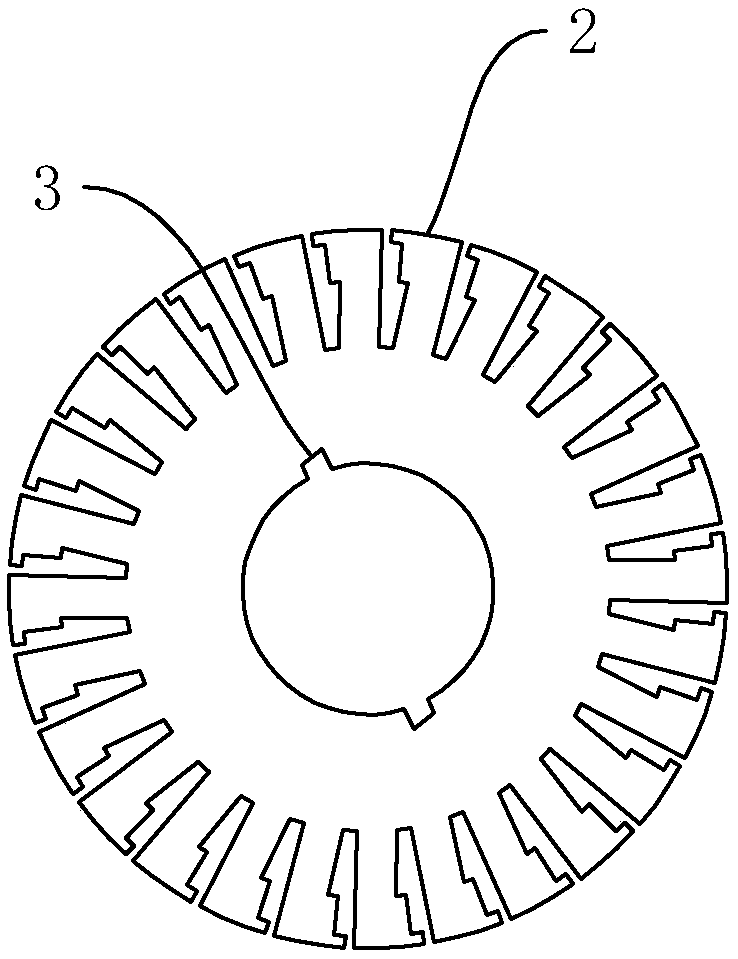

Production process of a motor punching sheet

ActiveCN109256916AReduce punching timesReduce energy consumptionManufacturing stator/rotor bodiesPunch pressEnergy consumption

the invention relates to motor punching sheets and discloses a production process of a motor punching sheet, The invention solves the problem that the blanking times of the prior art are more and theproduction energy consumption is higher, and the technical scheme points out a production process of the electric motor blanking. The blanking of the plate material comprises the following steps: S1,blanking the plate material by a punching machine, blanking to obtain the stator and rotor initial plate material, and simultaneously blanking the stator and rotor initial plate material to determinethe outer edge contour of the sub-blanking preform; 2, punching by a punching machine, punching that stator and rotor initial plate to establish the inner edge contour and the process driving keyway,obtaining the inner edge contours of the stator punching piece and the rotor punching piece preform, obtaining the stator punching piece preform and the second punching piece; S3: punching the inner edge contour and outer edge contour of the rotor blanking preform by the punching machine to obtain the rotor blanking preform, thereby reducing the blanking times necessary and reducing the energy consumption of the equipment.

Owner:温岭市钢锋冲件有限公司

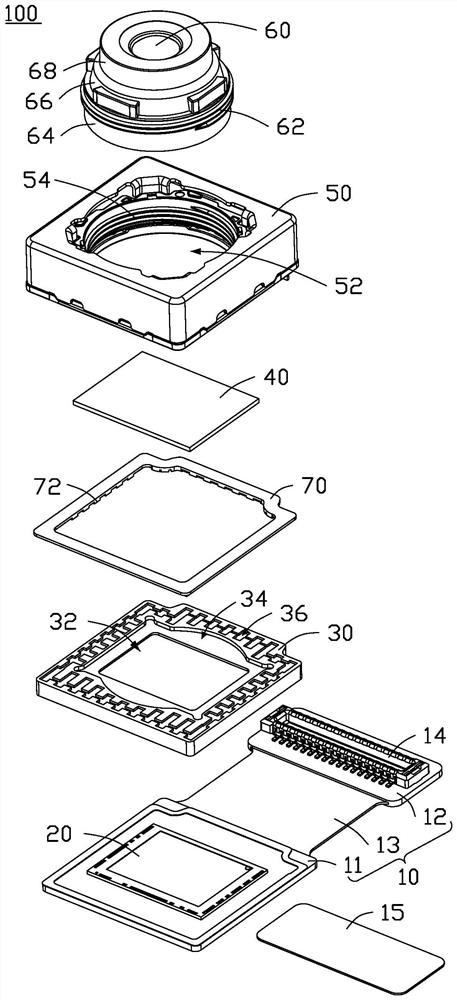

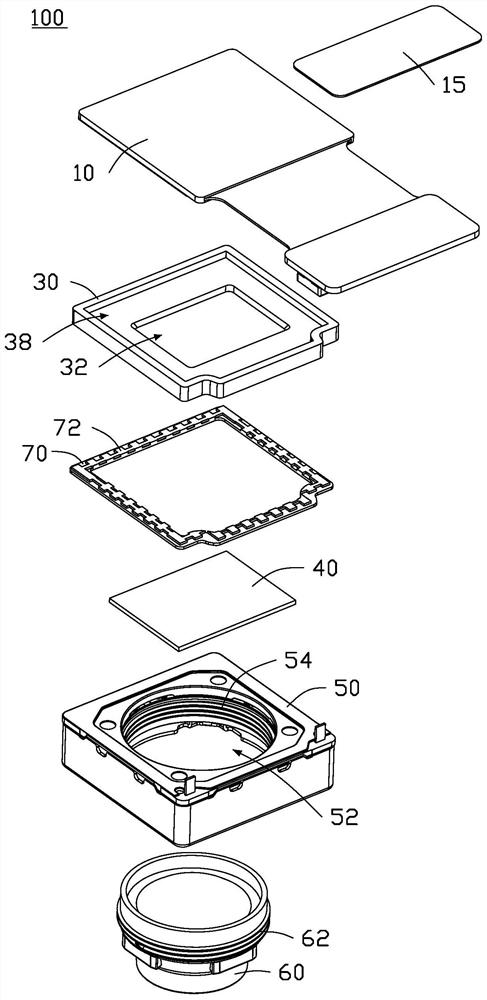

Lens module and electronic device

ActiveCN111669481AImprove reliabilityImprove yieldTelevision system detailsProjectorsMechanical engineeringVoice coil

A lens module comprises a voice coil motor, a bearing seat and a rubber body connected with the voice coil motor and the bearing seat, a groove is formed in the side wall of the bearing seat, the groove is filled with the rubber body, the rubber body is in a cube shape with a protruding part, and the protruding part is meshed with the bearing seat. The invention also provides an electronic deviceusing the lens module.

Owner:TRIPLE WIN TECHSHENZHEN CO LTD

Packaging device, packaging method, pulse generator and implantable medical device

PendingCN114083746AGuaranteed waterproof sealingGuaranteed insulation performanceElectrotherapyArtificial respirationInjection portMechanical engineering

The invention provides a packaging device, a packaging method, a pulse generator and an implantable medical device. The packaging device comprises a first mold and a second mold which are matched with each other; the first mold is provided with a first groove matched with one side of a to-be-packaged piece, the second mold is provided with a second groove matched with the other side of the to-be-packaged piece, and a cavity used for containing the to-be-packaged piece is formed between the first groove and the second groove; one of the first groove and the second groove is provided with a glue injection port, and the other one of the first groove and the second groove is provided with an exhaust port. According to the invention, the front and back surfaces of the to-be-packaged piece can be injected with glue at the same time, and the glue injection efficiency is greatly improved. Besides, the problems of insufficient internal filling during glue injection, generation of bubbles after curing, lack of glue and the like can be avoided, meanwhile, the problems of lack of glue, bubbles and the like caused by expansion or contraction of glue liquid can be prevented, the waterproof sealing performance and the insulating performance of packaged products are guaranteed, and the product yield is increased.

Owner:SHANGHAI NEURAZING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com