Preparation method of MXene/sodium alginate composite fiber

A composite fiber, sodium alginate technology, applied in fiber processing, alginate rayon, conductive/antistatic filament manufacturing, etc., can solve the problems of complex process equipment, difficult processing and molding, low MXene loading, etc. , to achieve the effect of simple process equipment, low viscosity requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing MXene / SA composite fibers by immersion spinning method is carried out according to the following steps:

[0030] Step 1. Preparation of MXene / SA composite solution: 6g SA was added to 100ml of MXene solution with a concentration of 20mg / ml, and stirred at 60°C for 6h to obtain MXene / SA composite solution;

[0031] Step 2, the preparation of coagulation bath: the massfraction of 3600ml is 5% CaCl 2 Add the solution into 600ml of isopropanol and stir until there is no obvious layering;

[0032] Step 3. Preparation of MXene / SA composite fiber: Inject the MXene / SA composite solution into the spinning equipment for spinning, and at the same time use the coagulation bath collection device to collect the fibers, use ethanol and deionized water to wash and dry to obtain MXene / SA SA composite fiber.

[0033] The tensile strength of the MXene / SA composite fiber obtained in this example is 192Mpa, which is better than the mechanical strength of the MXene f...

Embodiment 2

[0035] A method for preparing MXene / SA composite fibers by immersion spinning method is carried out according to the following steps:

[0036] Step 1. Preparation of MXene / SA composite solution: 1g SA was added to 200ml of MXene solution with a concentration of 30mg / ml, and stirred at 25°C for 24h to obtain MXene / SA composite solution;

[0037] Step 2, the preparation of coagulation bath: the massfraction of 1200ml is 1% CaCl 2 Add the solution into 1200ml of isopropanol and stir until there is no obvious layering;

[0038] Step 3. Preparation of MXene / SA composite fiber: Inject the MXene / SA composite solution into the spinning equipment for spinning, and at the same time use the coagulation bath collection device to collect the fibers, use ethanol and deionized water to wash and dry to obtain MXene / SA SA composite fiber.

[0039] The tensile strength of the MXene / SA composite fiber obtained in this example is 50Mpa, which is better than the mechanical strength of the MXene ...

Embodiment 3

[0041] A method for preparing MXene / SA composite fibers by immersion spinning method is carried out according to the following steps:

[0042]Step 1. Preparation of MXene / SA composite solution: 2g SA was added to 100ml of MXene solution with a concentration of 20mg / ml, and stirred at 35°C for 18h to obtain MXene / SA composite solution;

[0043] Step 2, the preparation of coagulation bath: the mass fraction of 2400ml is 5% CaCl 2 Add the solution into 600ml of isopropanol and stir until there is no obvious layering;

[0044] Step 3. Preparation of MXene / SA composite fiber: Inject the MXene / SA composite solution into the spinning equipment for spinning, and at the same time use the coagulation bath collection device to collect the fibers, use ethanol and deionized water to wash and dry to obtain MXene / SA SA composite fiber.

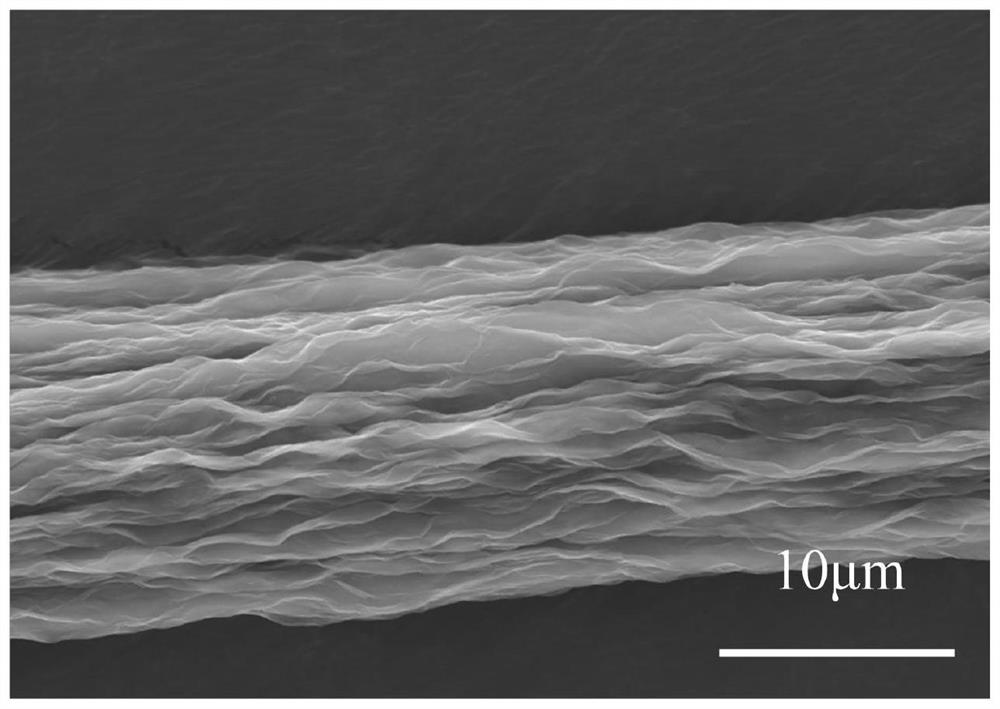

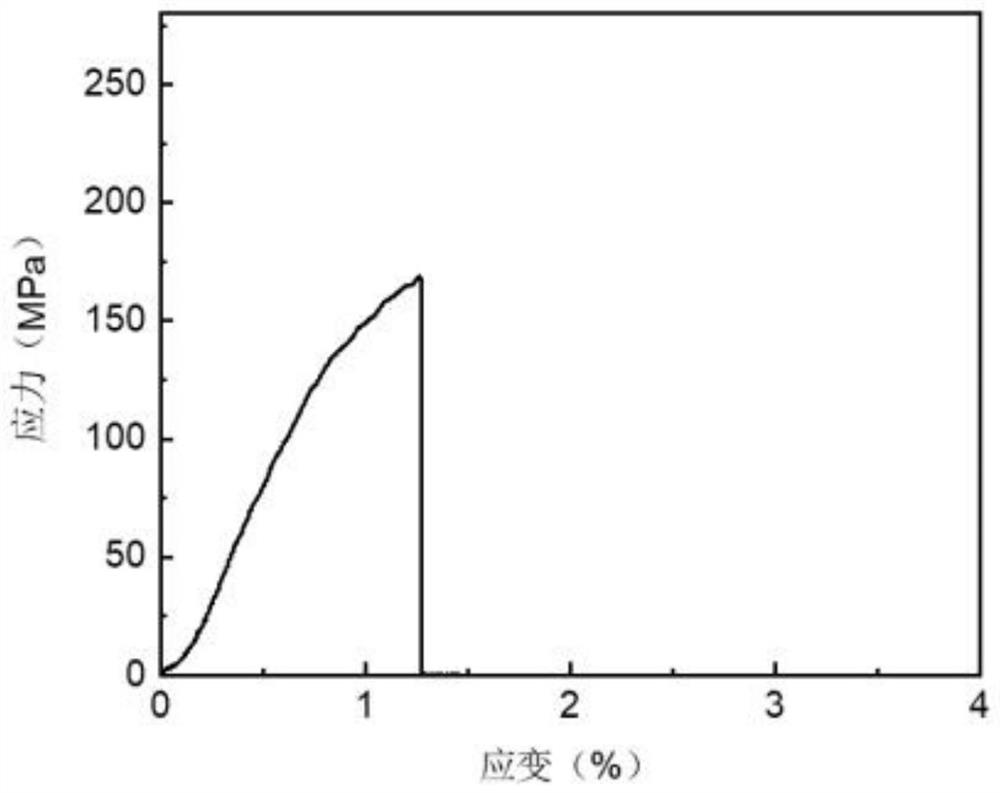

[0045] The tensile strength of the MXene / SA composite fiber obtained in this embodiment is 169Mpa, as shown in the attached figure 2 As shown, this valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com