Waterproof connector support plate

A waterproof connector and support plate technology, applied in the direction of the base/shell, etc., can solve the problems of difficult forming of waterproof glue, low production efficiency, etc., and achieve the effect of solving the difficulty of forming glue filling, beautiful appearance and good size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

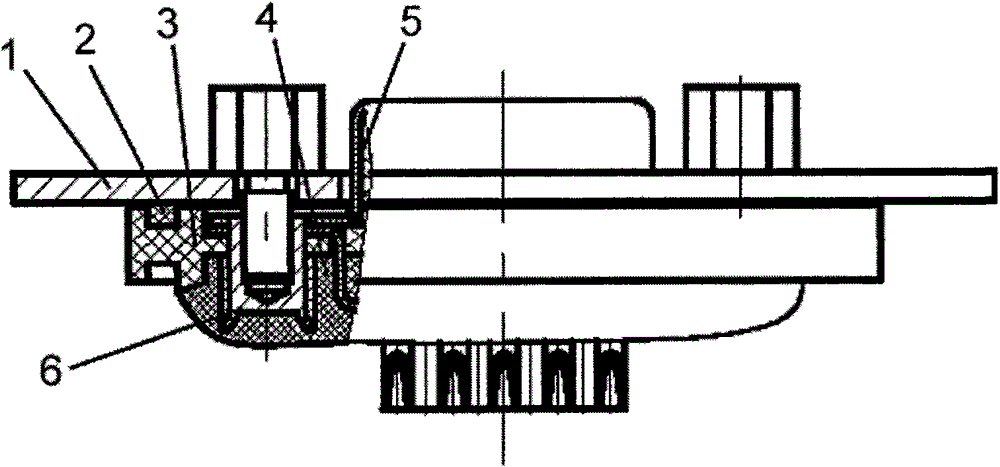

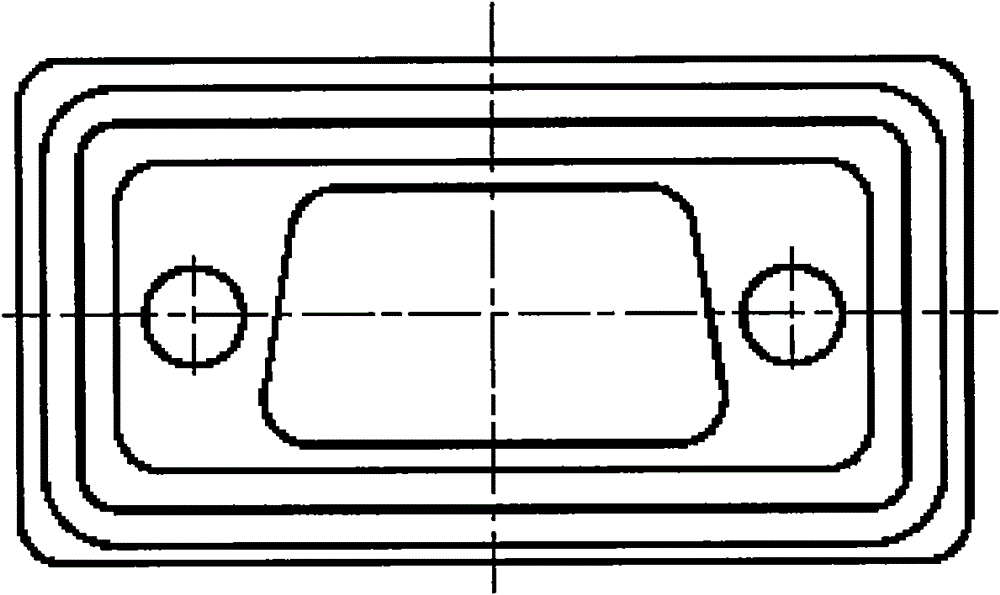

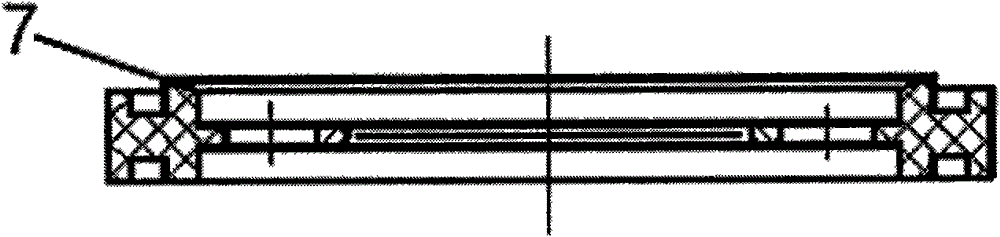

[0017] Example: such as figure 1 , figure 2 , image 3 As shown, a waterproof connector support plate, one side of the support plate 3 is in contact with the installation plate 1, and a sealing ring 2 is installed between the support plate 3 and the installation plate 1; The cavity needs to be filled with a slope-shaped boss 7 around the cavity. The slope-shaped boss 7 is higher than the plane of the support plate 3 and inclined to the side of the glue, similar to the structure of "damming" formed around the waterproof glue 4. , the potting shape of the waterproof glue 4 is controlled by "damming".

[0018] During production and assembly, after the shell assembly 5 is assembled on the support plate 3, the waterproof glue 4 is injected into the mold cavity with an automatic potting device. The waterproof glue 4 relies on its own leveling to fill the cavity along the slope-shaped boss 7 of the support plate 3, and completely covers the nut attachment 6 that needs to be seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com