Impinging stream reaction kettle for preparing ultrafine powders

A technology of impinging flow reaction and ultrafine powder, which is applied in the field of reactors, can solve the problems of unsatisfactory impact between the impact surface and the chamber, difficulty in determining the gap between baffle plates, and no entrainment in the surrounding flow field. Achieve the effects of increasing contact and residence time, easy operation, and strengthening interphase transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

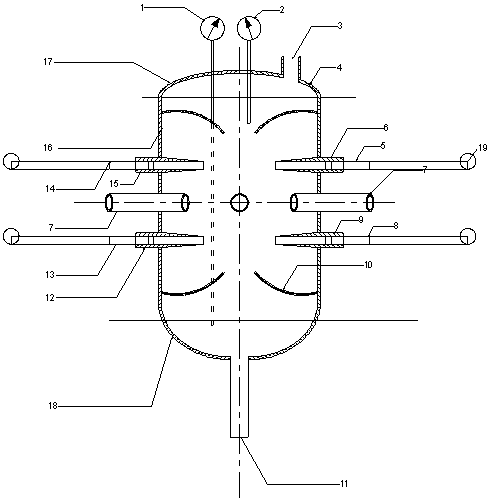

[0018] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0019] In order to improve the mixing degree and mixing rate of two or more liquids, the present invention provides a horizontal double-layer opposed symmetrical baffle to prepare ultra-fine powder impingement flow reactor, including temperature gauge 1, pressure gauge 2, drain Air port 3, heat exchange jacket 4, right feed pipe 5, left feed pipe 14, right feed nozzle 6, left feed nozzle 15, discharge port 7, right circular feed port 8, left circular feed Port 13, right circulation feed nozzle 9, left circulation feed nozzle 12, arc-shaped arc-shaped heat exchange baffle 10, kettle body 16, top cover 17, kettle bottom 18, frequency converter 19. The shape of the kettle body is a vertical straight cylinder, the upper part is an oval top cover, and the lower part is an oval bottom. The cover is equipped with a pressure gauge, a thermometer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com