Phenolic cyanate resin and its synthesis method and phenolic cyanate ablative material composite

A technology of phenolic cyanate ester and synthesis method, applied in the field of phenolic cyanate ester, can solve the problems of high melt viscosity, high heteroatom content, low carbon content and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

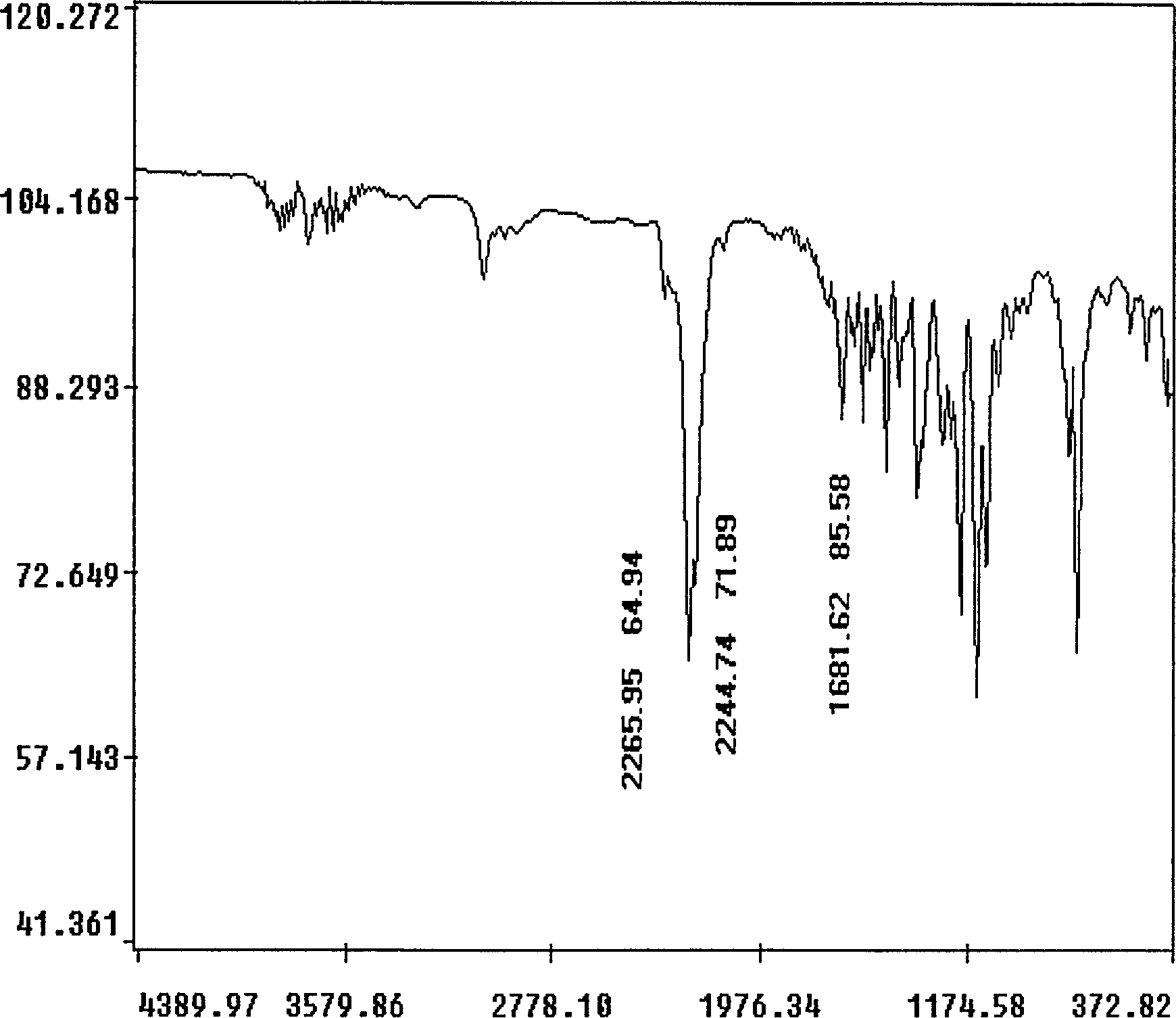

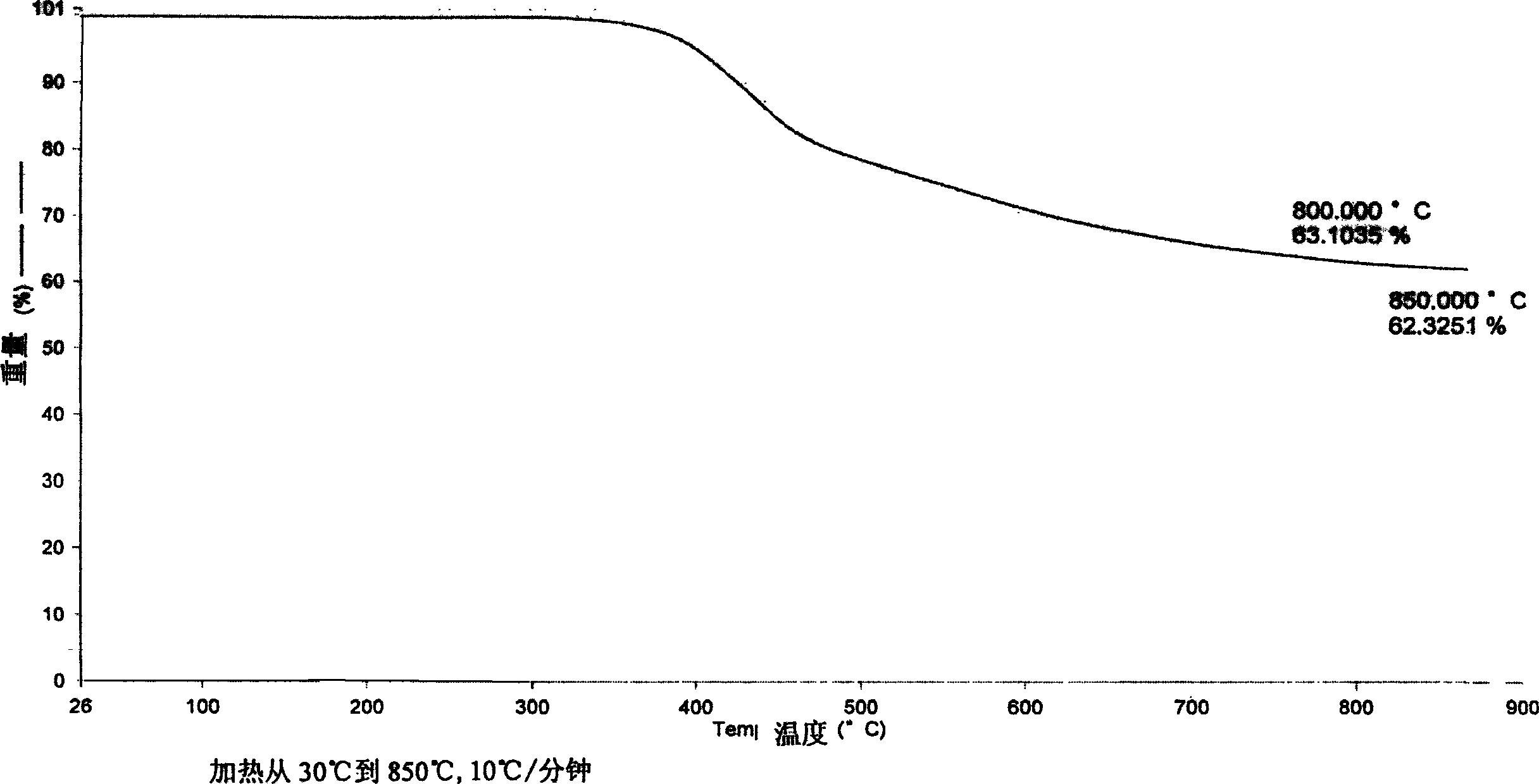

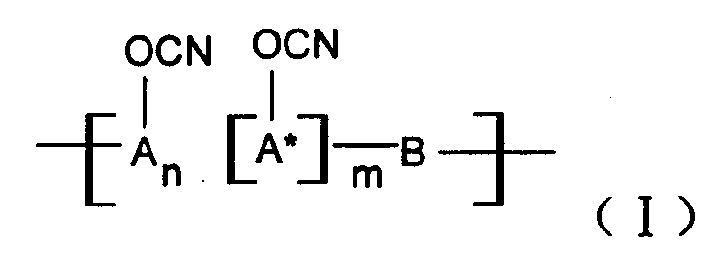

[0030] Embodiment 1: synthetic novolac cyanate

[0031] A 37% aqueous solution of phenol and formaldehyde and oxalic acid in a molar ratio of 1:0.9:0.005 are put into a three-necked flask equipped with a reflux condenser, reacted at 80-100°C for 3-5 hours, washed with water, and vacuumized to obtain the softening point The novolac between 40 and 60°C, the novolac is dissolved in the mixed solvent of dichloromethane and ethyl acetate, put into the four-necked bottle together with BrCN, drop triethylamine, phenolic hydroxyl group and BrCN and triethylamine The molar ratio is 1:1.05:1.10, react at -15°C to -5°C for 5 hours, separate the salt and solvent, and perform purification treatment to obtain novolac cyanate. In this example n=2~5, m=0.

[0032] 1-2: Using the same method as 1-1, change phenol to p-phenylphenol to obtain novolac cyanate. In this example n=2~5, m=0.

[0033] 1-3: Using the same method as 1-1, change phenol to o-phenylphenol to obtain novolac cyanate. In ...

Embodiment 2

[0035] Embodiment 2: Synthesis of linear fused ring phenol novolac cyanate

[0036] 2-1: A 37% aqueous solution of 1-naphthol and formaldehyde and oxalic acid in a molar ratio of 1:0.80:0.005 are put into a three-necked flask equipped with a reflux condenser, in the presence of a ketone solvent, at 60-100°C React for 3 to 5 hours, wash with water, and vacuumize to obtain linear condensed ring phenol novolac with a softening point between 40 and 60°C. The linear fused-ring phenol novolac was dissolved in dichloromethane solvent, put into a four-necked flask together with BrCN, and triethylamine was added dropwise. React at -5°C for 5 hours, separate the salt and solvent, and perform purification treatment to obtain linear fused ring phenol novolac cyanate. In this example n=0, m=2-5.

[0037] 2-2: Using the same method as 2-1, use 2-naphthol and polyoxymethylene as raw materials to obtain linear fused ring phenol novolac cyanate. In this example n=0, m=2.

[0038] 2-3: Use ...

Embodiment 3

[0039] Embodiment 3: synthetic copolymerization type phenolic cyanate

[0040]3-1: 37% aqueous solution of phenol, naphthol (molar ratio is 1: 1) and formaldehyde and oxalic acid according to phenol, aldehyde, acid molar ratio 1: 0.9: 0.005, drop in the three-necked flask that is equipped with reflux condenser, React at 80-100°C for 3-5 hours, wash with water, and vacuumize to obtain copolymerized phenolic formaldehyde. The copolymerized phenolic formaldehyde is dissolved in acetone solvent, put into a four-necked bottle with BrCN, and triethylamine, phenolic hydroxyl group and BrCN are added dropwise. And the molar ratio of triethylamine is 1:1.05:1.10, react at -15°C to -5°C for 5 hours, separate the salt and solvent, and perform purification treatment to obtain copolymerized phenolic cyanate. In this example n:m=1:1.

[0041] 3-2: Change the molar ratio of phenol and naphthol to 1:2, and obtain the copolymerized phenolic novolac cyanate in the same way as 3-1 with benzalde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com