Pneumatic light-substrate net bag fast breeding seedling culture container automatic filling shaping system

A light-substrate mesh bag and fast-growing seedling technology, which is applied in planting substrates, culture media, gardening, etc., can solve the problems of mechanical loss of hard parts, feeding is greater than output, and high maintenance costs, so as to reduce wear and facilitate The effect of blade sharpening and easy replacement of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

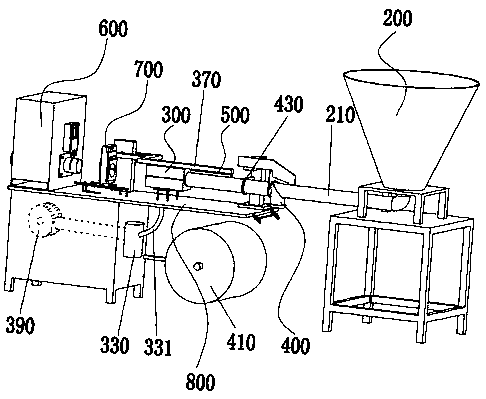

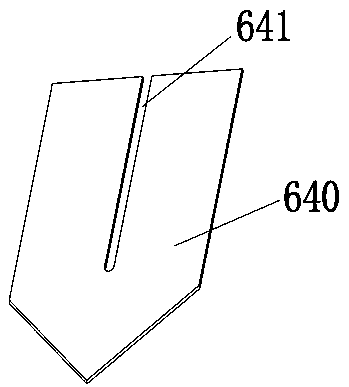

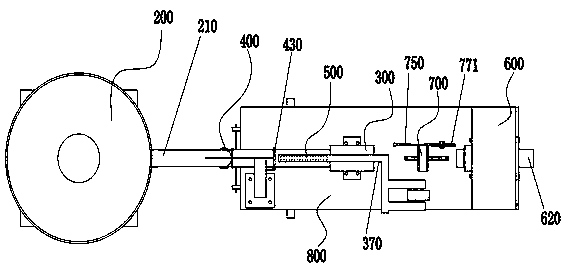

[0030] Such as Figure 1-Figure 10 As shown, a pneumatic light substrate mesh bag fast breeding seedling container automatic filling molding system includes a feed bin 200 that can accommodate the substrate 100 and a vacuum feed box 300 that absorbs the substrate 100, the feed bin 200 and the vacuum feed The boxes 300 are connected by a feed pipe 210, the feed pipe 210 is provided with a wrapping device 400 that wraps the packaging material 420 on the material roller 410 on the outer surface of the feed pipe 210, and the feed pipe 210 is also provided with a The sealing device 500 for sealing the packaging material 420, the other side of the connection between the vacuum feeding box 300 and the feeding pipe 210 is provided with a cutting device 600 for cutting off the packaging material 420 and the matrix 100 coming out of the vacuum feeding box 300, Between the vacuum feeding box 300 and the cutting device 600, there is a pushing device 700 that pushes the packaging material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com