Siliceous modified high-temperature-resistant cyanate resin, and preparation method and application thereof

A technology of cyanate ester resin and high temperature resistance, which is applied in the field of its preparation and silicon-containing modified high temperature resistant cyanate ester resin, which can solve the problems of lower glass transition temperature, lower mechanical and electrical properties, and insufficient toughness, and achieve excellent The effect of high temperature resistance and good cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

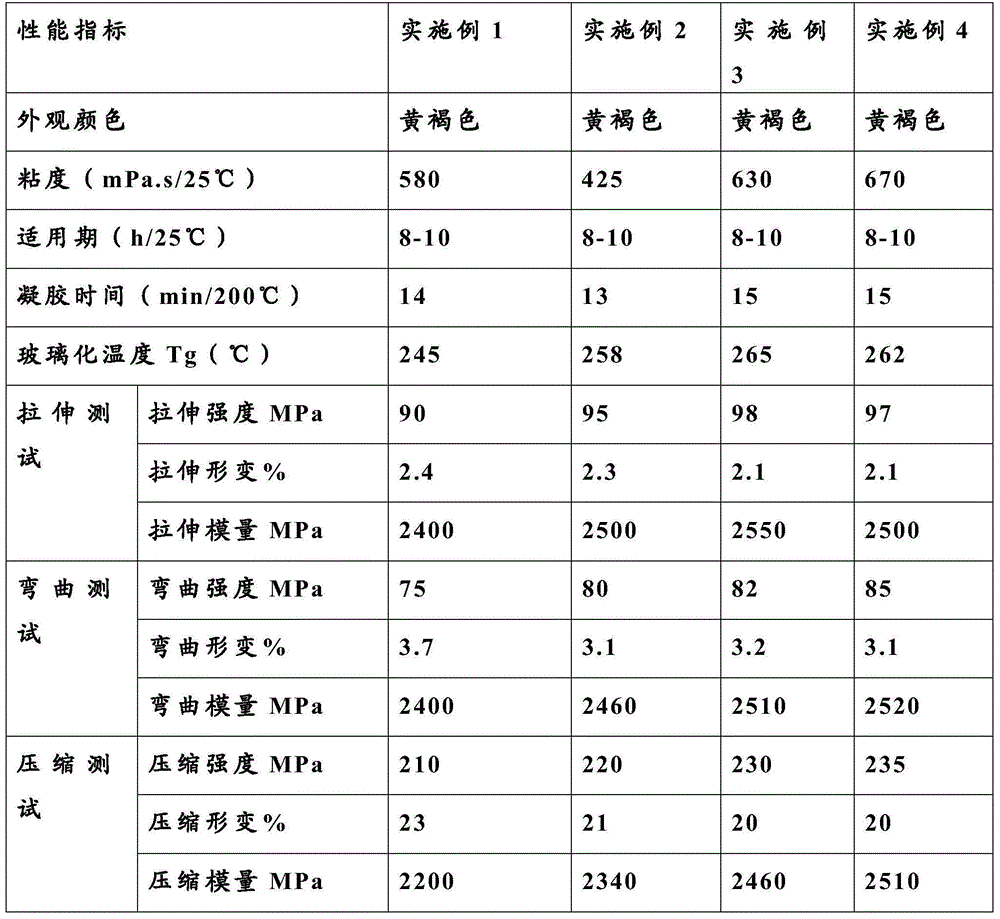

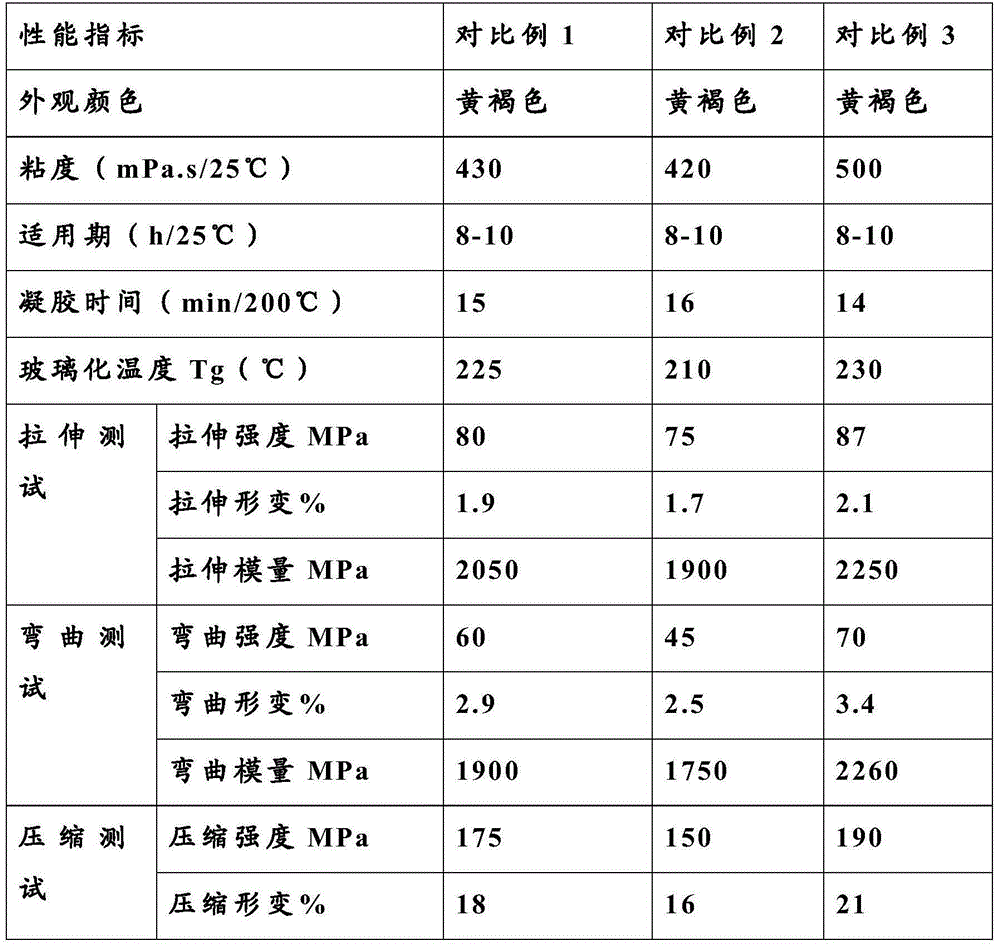

Examples

Embodiment 1

[0032] (a) Add 400g of n-butanol and 20g of tetramethylammonium hydroxide aqueous solution (mass fraction is 10%) in the 1000mL there-necked flask with thermometer and condenser tube, after stirring and mixing evenly, add dropwise 20g of hydroxyl-terminated A mixed solution of polydimethylsiloxane, 120g γ-(2,3-glycidyloxy) propyltrimethoxysilane and 80g ethanol, the drop rate is controlled within 3 hours, the reaction temperature is controlled at 10°C, hydrolysis and polycondensation 6h, after the reaction is completed, use a rotary evaporator to evaporate the solvent and small molecules remaining in the system to obtain a transparent viscous liquid that can flow at room temperature for use, which is epoxy-containing silsesquioxane (G- POSS).

[0033] (b) Pour 30g of the above-mentioned viscous liquid (G-POSS) and 270g of bisphenol A cyanate resin into a 500mL three-necked bottle and stir evenly, prepolymerize at 80-90°C for 2 hours, and cool the modified resin to Stand-by at...

Embodiment 2

[0037] (a) Add 400g of n-butanol and 20g of tetramethylammonium hydroxide aqueous solution (mass fraction is 10%) in the 1000mL there-necked flask with thermometer and condenser tube, after stirring and mixing evenly, add dropwise 20g of hydroxyl-terminated A mixed solution of polydimethylsiloxane, 120g γ-(2,3-glycidyloxy) propyltrimethoxysilane and 80g ethanol, the drop rate is controlled within 3 hours, the reaction temperature is controlled at 10°C, hydrolysis and polycondensation 6h, after the reaction is completed, use a rotary evaporator to evaporate the solvent and small molecules remaining in the system to obtain a transparent viscous liquid that can flow at room temperature for use, which is the final product epoxy-containing silsesquioxane ( G-POSS).

[0038] (b) Pour 30g of the above-mentioned viscous liquid (G-POSS) and 270g of bisphenol F type cyanate resin into a 500mL three-necked bottle and stir evenly, prepolymerize at 80-90°C for 2 hours, and cool the modifie...

Embodiment 3

[0042] (a) Add 400g of n-butanol and 16g of tetramethylammonium hydroxide aqueous solution (mass fraction is 10%) in the 1000mL there-necked flask with thermometer and condenser tube, after stirring and mixing evenly, add dropwise 26g of hydroxyl-terminated A mixed solution of polydimethylsiloxane, 127g γ-(2,3-glycidoxy) propyltrimethoxysilane and 90g ethanol, the drop rate is controlled at 3.5h, the reaction temperature is controlled at 10°C, and the hydrolysis Polycondensation for 5 hours, after the reaction is completed, use a rotary evaporator to evaporate the solvent and small molecules remaining in the system, and obtain a transparent viscous liquid that can flow at room temperature for use, which is the final product of epoxy-containing silsesquioxane (G-POSS).

[0043] (b) Pour 30g of the above viscous liquid (G-POSS) and 270g of bisphenol F type cyanate resin into a 500mL three-necked bottle and stir evenly, prepolymerize at 80-90°C for 2h, and cool the modified resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com