Water-proof connector support plate

A waterproof connector and support plate technology, applied in the installation of connecting components, base/shell, etc., can solve the problems of low production efficiency, difficult forming of waterproof glue, etc., achieve beautiful appearance, solve the difficulty of forming glue filling, and good dimensional consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

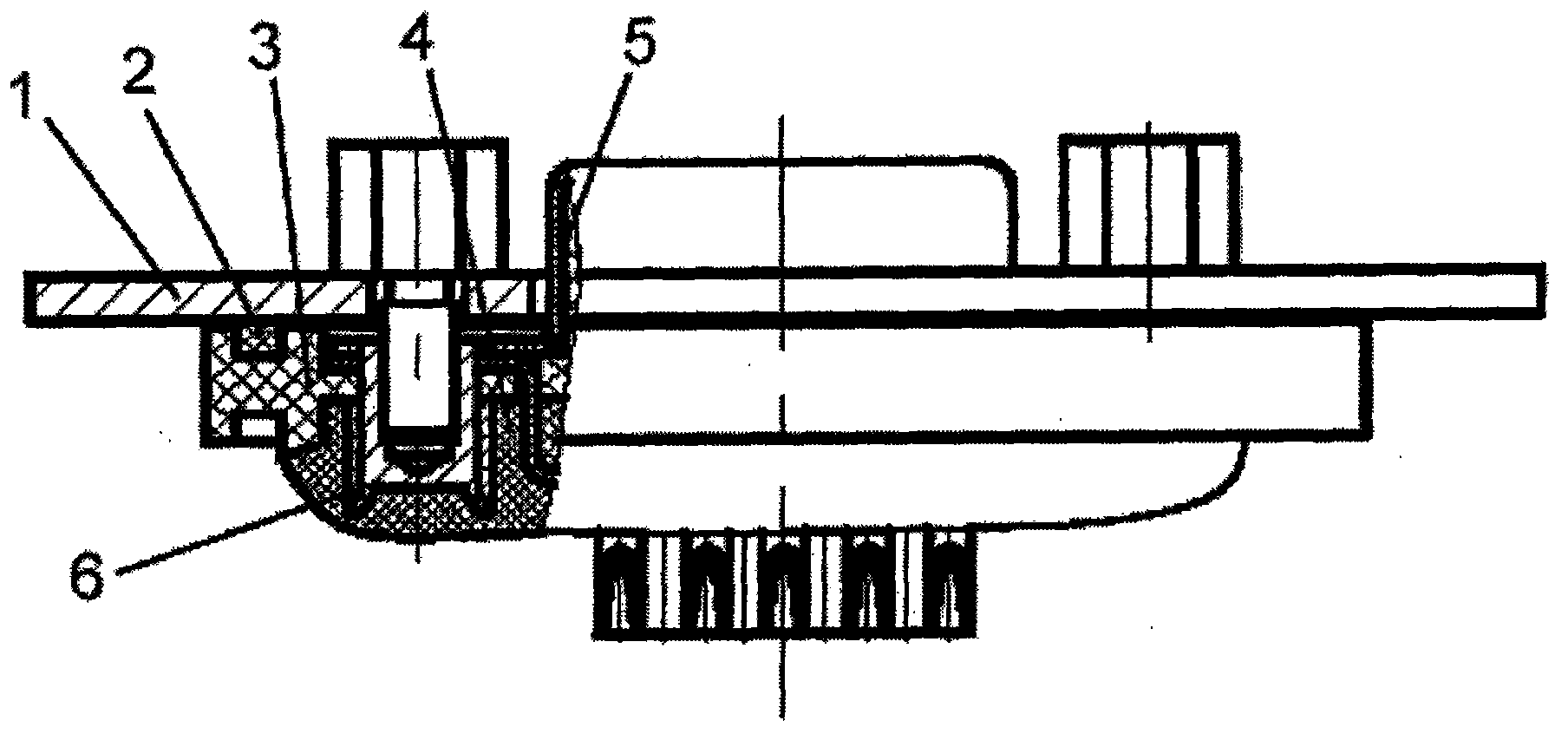

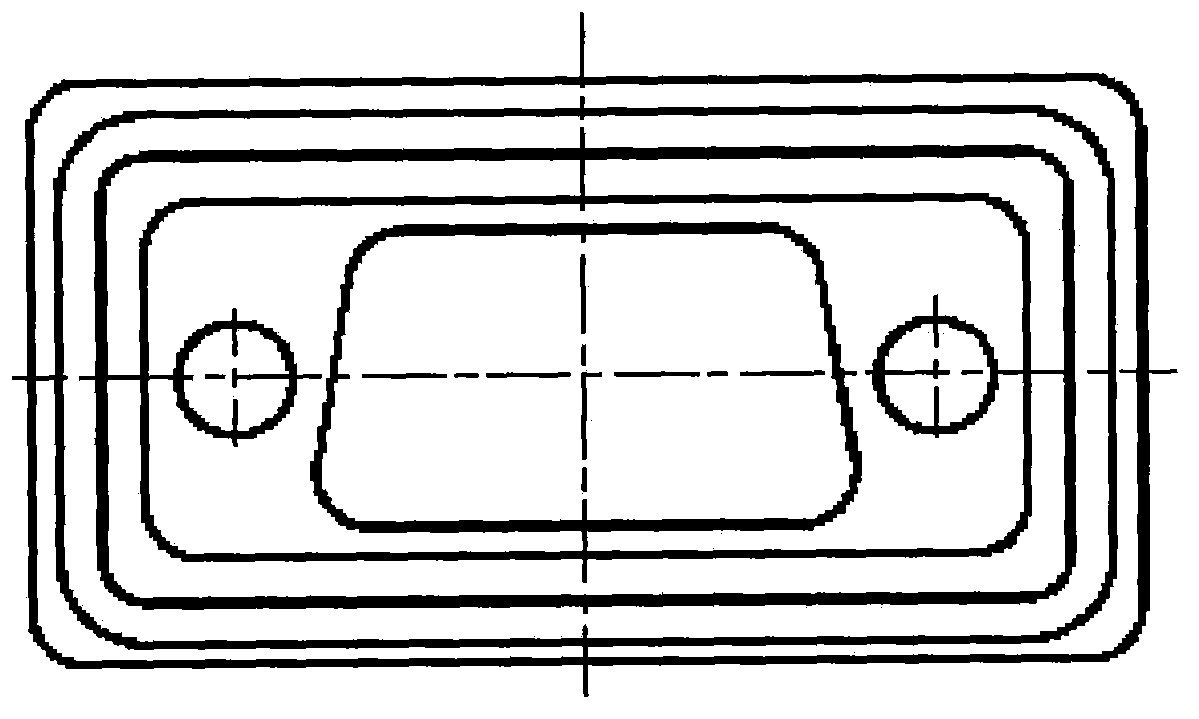

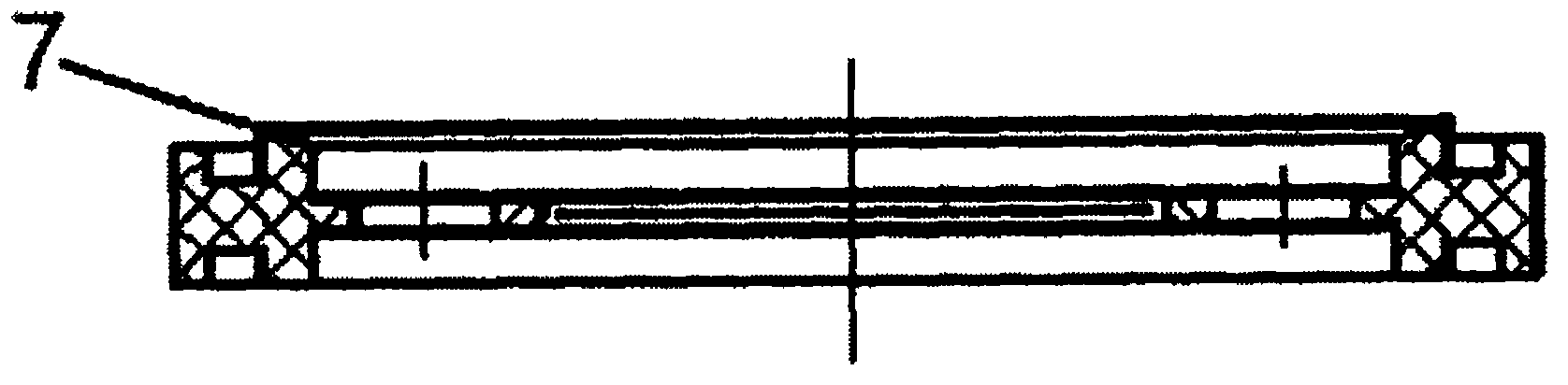

[0019] Example: such as figure 1 , figure 2 , image 3 As shown, a waterproof connector support plate, one side of the support plate 3 is in contact with the installation plate 1, and a sealing ring 2 is installed between the support plate 3 and the installation plate 1; The cavity needs to be filled with a slope-shaped boss 7 around the cavity. The slope-shaped boss 7 is higher than the plane of the support plate 3 and inclined to the side of the glue, similar to the structure of "damming" formed around the waterproof glue 4. , the potting shape of the waterproof glue 4 is controlled by "damming".

[0020] During production and assembly, after the shell assembly 5 is assembled on the support plate 3, the waterproof glue 4 is injected into the mold cavity with an automatic potting device. The waterproof glue 4 relies on its own leveling to fill the cavity along the slope-shaped boss 7 of the support plate 3, and completely covers the nut attachment 6 that needs to be seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com