Ceramic coating protection gradient carbon-ceramic composite material and preparation method thereof

A carbon-ceramic composite material and ceramic coating technology, applied in the field of carbon-ceramic composite materials, can solve problems such as coating protection failure, and achieve the effects of increasing surface area, reducing ablation temperature, and improving interlaminar shear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

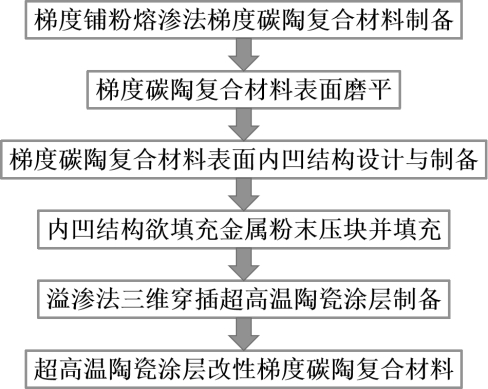

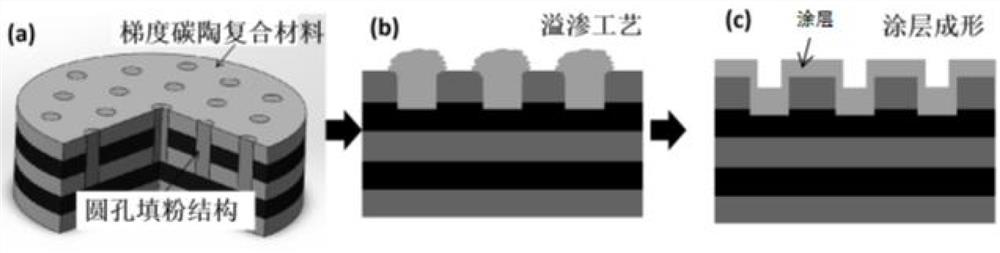

[0081] combine Figure 1-2 , Example 1 relates to a ceramic coating protective gradient carbon-ceramic composite material, which is prepared according to the following steps:

[0082] 1. Preparation of gradient carbon-ceramic composites:

[0083] S1, deposition: 0.9g / cm 3 After the C / C composite material is polished and polished as a whole, it is washed with absolute ethanol, and placed in an oven at 100°C for 12 hours for later use; the chemical vapor deposition method is used to select MTS (methyltrichlorosilane) with a purity of 99.99%. The deposition temperature is 1100°C, the deposition time is 30h, and the deposition atmosphere is vacuum. The density of the SiC modified C / C composite material obtained by the final deposition reaches 1.3g / cm 3 ;

[0084] S2. Powder spreading: the middle of the C / C composite material plate is separated by graphite blocks, the metal powder for infiltration is laid on the left side, and no metal powder is laid on the right side. In this ...

Embodiment 2

[0095] Embodiment 2-3 relates to a kind of ceramic coating protective graded carbon-ceramic composite material, and its difference with embodiment 1 is only that in embodiment 2, in the metal material filled, the mass ratio of Zr powder to V powder is 2:1. Wherein the consumption of Zr is 1.06g, the consumption of V is 0.533g, the consumption of C element is 0.05g, and the consumption of liquid paraffin is 0.08g. In Example 3, in the filled metal material, the mass ratio of Zr powder to V powder is 1:1. Wherein the consumption of Zr is 0.8g, the consumption of V is 0.8g, the consumption of C element is 0.05g, and the consumption of liquid paraffin is 0.08g.

Embodiment 4

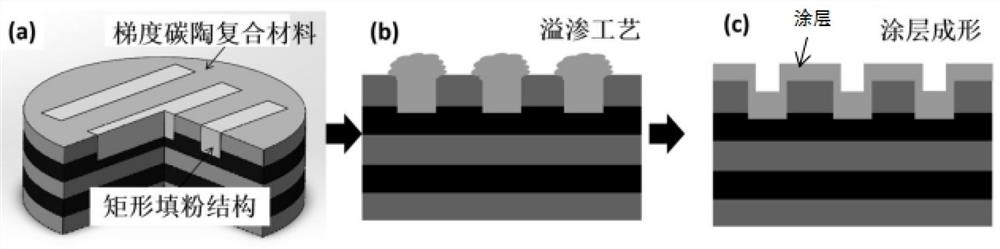

[0097] Such as image 3 As shown, this embodiment relates to a gradient carbon-ceramic composite material with ceramic coating protection, which differs from Embodiment 1 only in the steps of forming a concave structure and filling metal materials.

[0098] Specifically, in this embodiment, the concave structure is formed by processing the gradient C / C-ZrC-SiC composite material with a gradient change in the vertical direction into a round block with a diameter of 30 mm and a thickness of 10 mm, and then on the surface of the round block sample Drill rectangular holes with a spacing of 6 mm, a hole length of 7 mm on a long side, a short side length of 3 mm, and a hole depth of 2 mm.

[0099] The filling metal material is directly selected square ZrV with a size of 7×3×2mm 2 The alloy sintered body (Beijing Xingrongyuan Technology Co., Ltd.) is used as the overflow and infiltration raw material, which is put into the pre-formed rectangular blind hole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com