A kind of w-ta-mo-nb-c high-temperature high-entropy alloy and its preparation method

A technology of w-ta-mo-nb-c, high-entropy alloy, applied in the field of W-Ta-Mo-Nb-C high-temperature high-entropy alloy and its preparation, to achieve the effect of stable crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of embodiment 1 WTaMoNbC high-temperature high-entropy alloy

[0044] The raw materials used are W elemental powder, TaC carbide powder, Mo elemental particles, and Nb elemental particles, and are formulated according to the atomic ratio of W, Ta, Mo, Nb, and C elements. Put the above raw materials into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, and then carry out vacuum arc melting: vacuumize the vacuum chamber to 5×

[0045] 10 -3 Pa, refill high-purity argon with a purity of 99.999% until the pressure of the vacuum chamber is -0.7MPa, high-purity argon is used as the protective gas and arcing medium, the melting current is 450A, and cooling water is passed during melting to prevent the water-cooled copper plate from overheating and melting , the front and back sides were repeatedly smelted 5 times, each smelting time was 4 minutes, and the alloy was in a liquid state for 20 minutes. After cooling, a WTaMoNbC high-t...

Embodiment 2

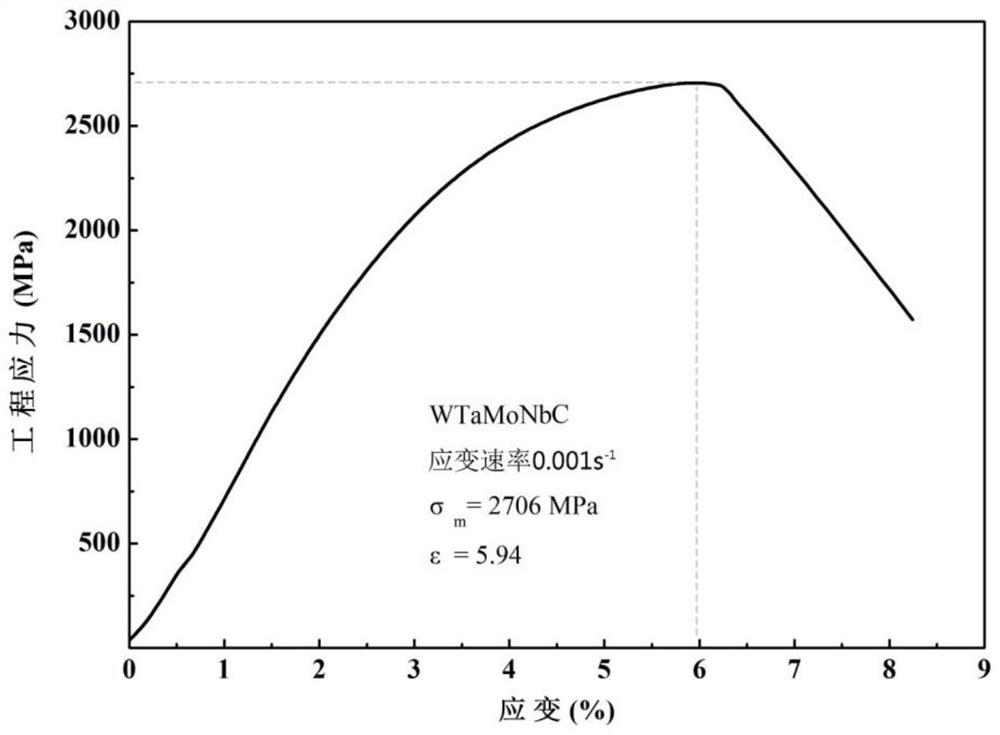

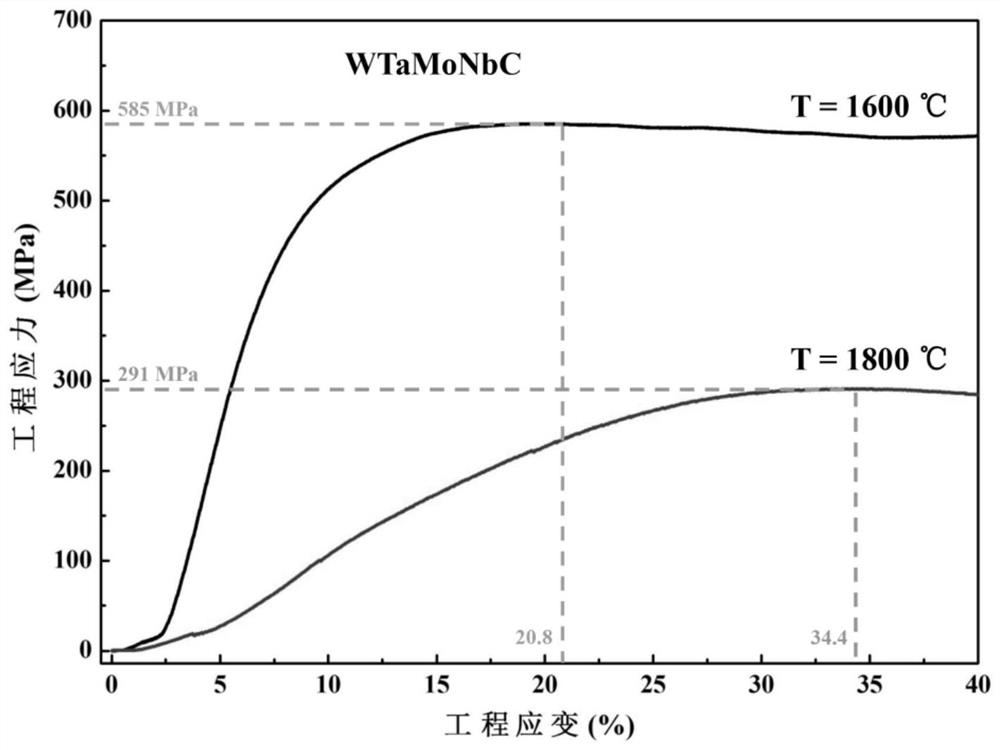

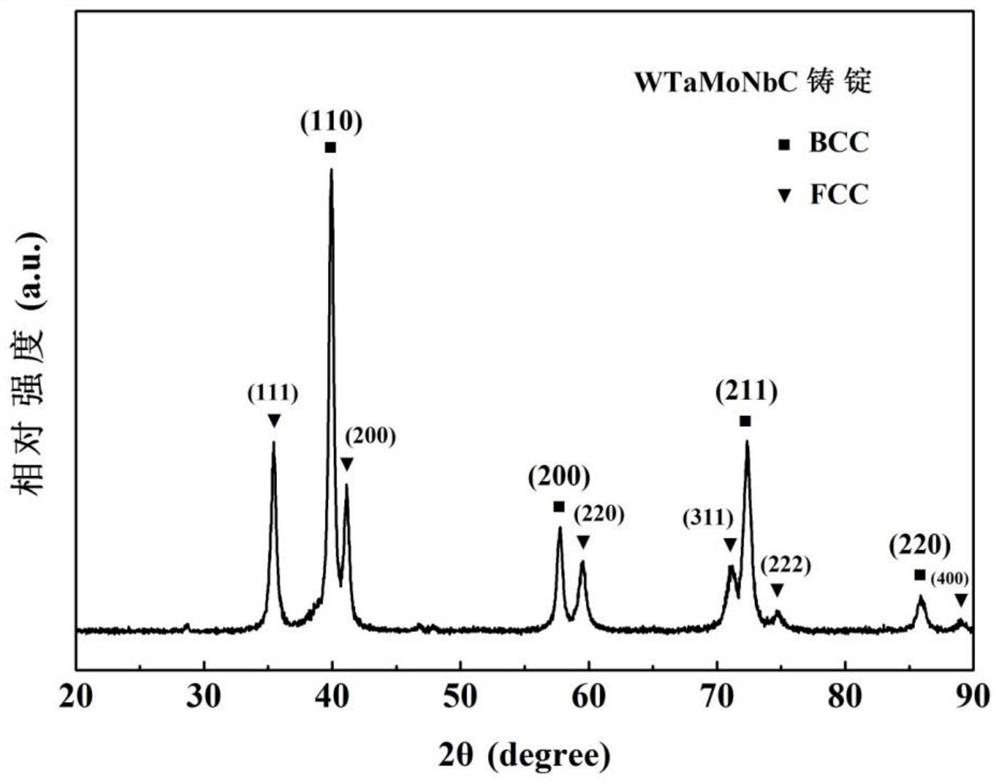

[0046] Performance test and structural characterization of embodiment 2 WTaMoNbC high-temperature high-entropy alloy ingot

[0047] 1. Density determination:

[0048] The Archimedes drainage method is used for measurement, and the specific operation steps are as follows: prepare the WTaMoNbC high-temperature high-entropy alloy prepared in Example 1 into three cylindrical samples of Φ4mm×4mm, and put them into a beaker filled with absolute alcohol before measurement , ultrasonically oscillate and clean for 10 minutes, take it out and blow dry, and then use a DT-100 precision balance (accuracy 0.1mg) to weigh the dry weight of each sample M 1 , weigh each sample 3 times to reduce the measurement error; then, weigh the mass M of each sample in water 2 , each sample was weighed 3 times; finally, the density was calculated according to the following formula,

[0049]

[0050] In the formula, ρ 0 is the density of water, 0.9982g / cm 3 (20°C); ρ l is air density, 0.0012g / cm 3...

Embodiment 3

[0064] Example 3W 20 Ta 20 Mo 21 Nb 19 C 20 Preparation, performance testing and structural characterization of high-temperature high-entropy alloys

[0065] The raw materials used are W elemental powder, TaC carbide powder, Mo elemental particles, and Nb elemental particles, and are formulated according to the atomic ratio of elements W:Ta:Mo:Nb:C=20:20:21:19:20. Put the above raw materials into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, and then carry out vacuum arc melting: vacuumize the vacuum chamber to 5×10 -3 Pa, refill high-purity argon with a purity of 99.999% until the pressure of the vacuum chamber is -0.7MPa, high-purity argon is used as a shielding gas and arcing medium, the melting current is 380A, and cooling water is passed during melting to prevent the water-cooled copper plate from overheating and melting , the front and back sides are repeatedly smelted 4 times, each smelting is 4 minutes, the alloy is in the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com