Colored pavement cementing material and preparation method thereof

A cementing material and pavement technology, applied in roads, roads, building insulation materials, etc., can solve the problem of color asphalt high temperature stability, low temperature crack resistance, water stability, color durability is difficult to meet application requirements, color asphalt road performance The durability of color and color is difficult to meet the application requirements, and the cost of color asphalt preparation is high, so as to solve the problems of insufficient road durability, shorten the preparation time, and improve the adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

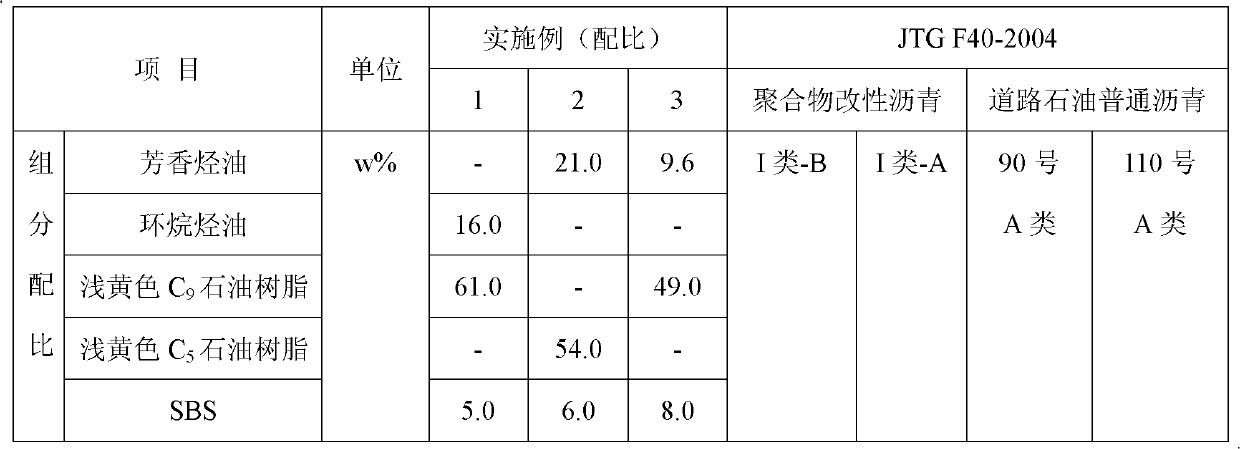

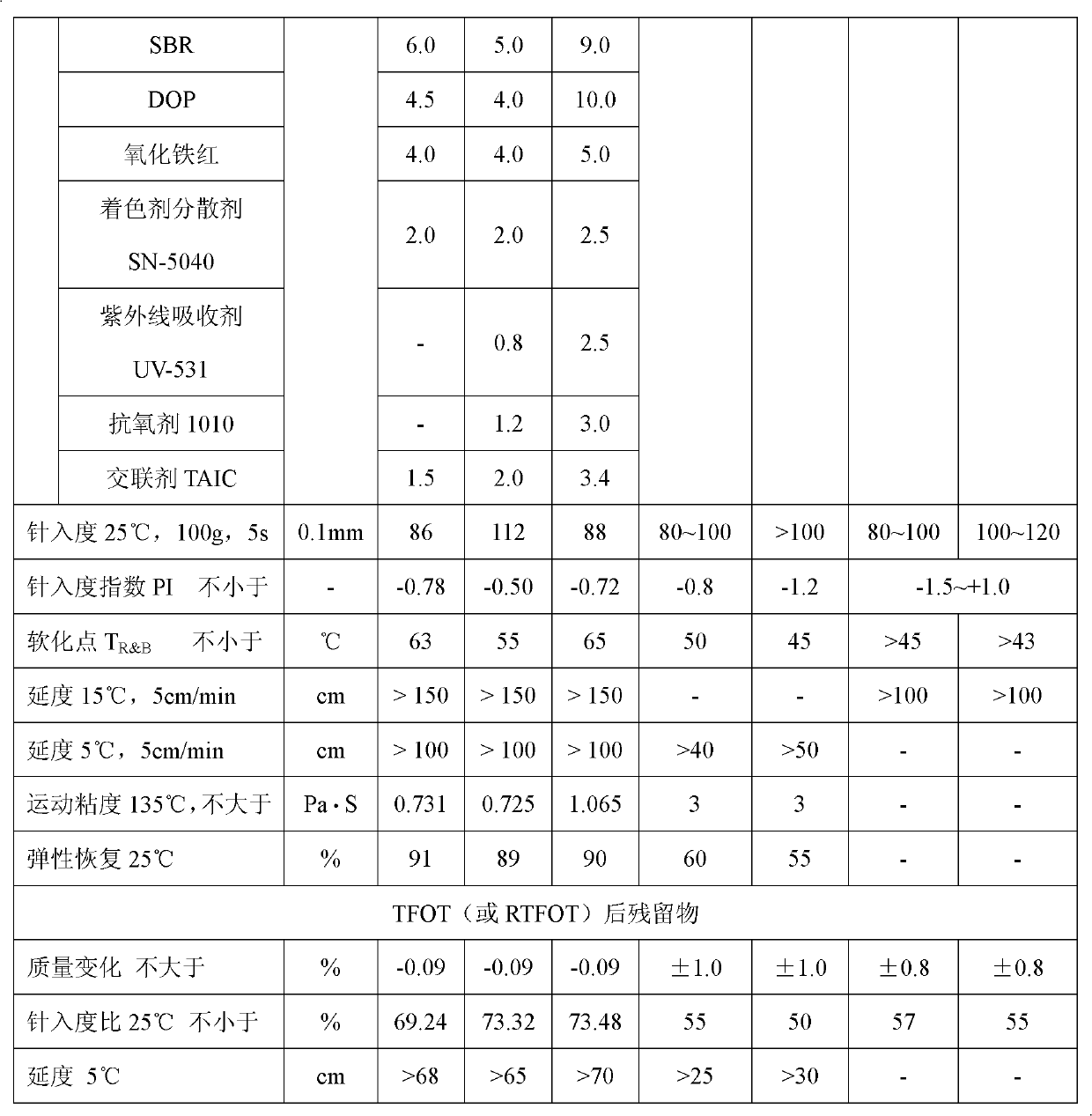

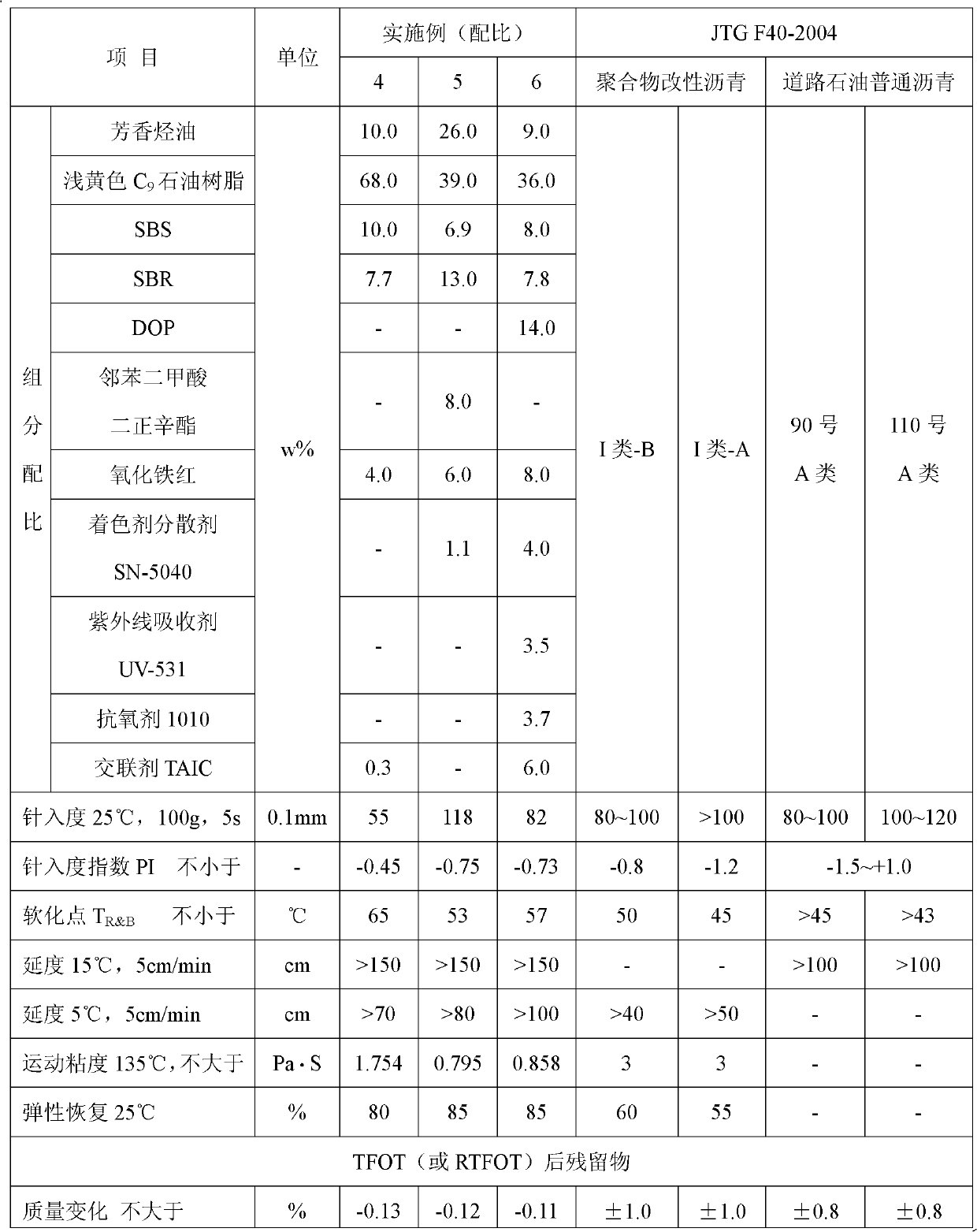

[0031] light yellow C 9 Petroleum resin and naphthenic oil are blended according to the mass ratio of 3.8:1, the modifier SBS and SBR are blended according to the mass ratio of 0.8:1, no ultraviolet absorber UV-531 and antioxidant 1010 are blended; the proportion of each component The specific percentages are shown in Table 1.

Embodiment 2

[0033] light yellow C 5 Petroleum resin and aromatic oil are blended according to the mass ratio of 2.5:1, the modifier SBS and SBR are blended according to the mass ratio of 1.2:1, and the ultraviolet absorber UV-531 and antioxidant 1010 are blended according to the mass ratio of 0.7:1; The specific percentages of each component are shown in Table 1.

Embodiment 3

[0035] light yellow C 9 Petroleum resin and aromatic hydrocarbon oil are blended according to the mass ratio of 5.1:1, the modifier SBS and SBR are blended according to the mass ratio of 0.9:1, and the ultraviolet absorber UV-531 and antioxidant 1010 are blended according to the mass ratio of 0.8:1; The specific percentages of each component are shown in Table 1.

[0036] According to the ratio and dosage proposed in the above-mentioned component blending scheme, the colored asphalt was prepared by the aforementioned preparation process, and the performance test was carried out, as shown in Table 1.

[0037] Table 1 embodiment and technical performance

[0038]

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com