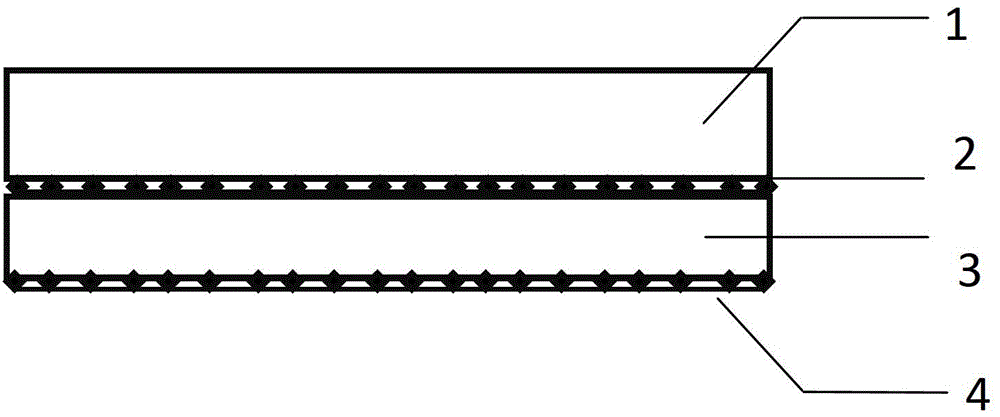

A Composite Rubber Asphalt Concrete Steel Bridge Deck Pavement Structure

An asphalt concrete and compound rubber technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as longitudinal cracking and high temperature shifting, and achieve the effects of extended life, low engineering cost and outstanding durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

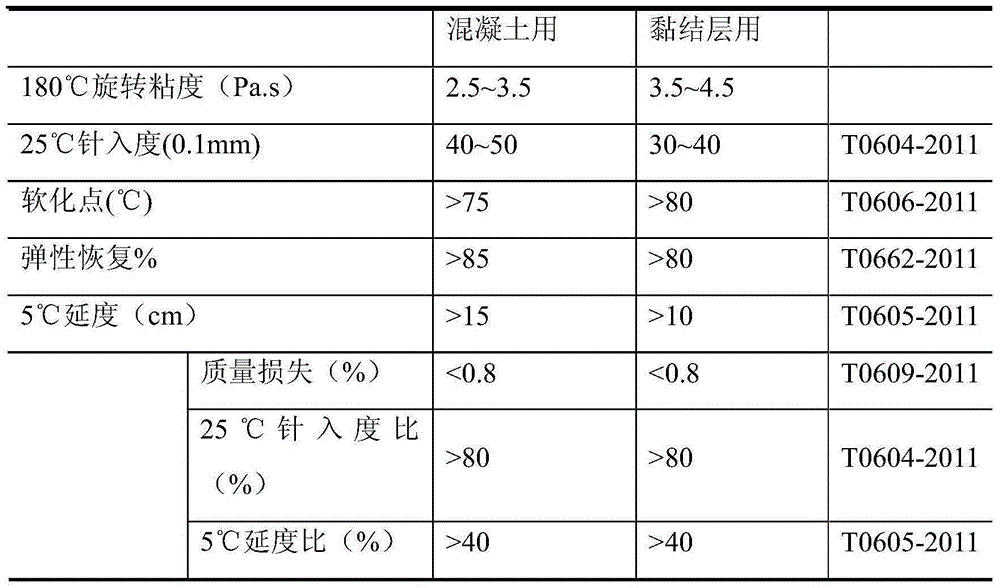

Method used

Image

Examples

Embodiment 1

[0039]A steel box girder bridge deck pavement project in Guangdong Province is an orthotropic steel box girder bridge. It was first built in 1987. The thickness of the orthotropic steel plate is only 12mm. Compared with the newly built steel bridges in recent years, the thickness The thickness of the bridge deck is 4mm thinner, resulting in greater flexibility of the bridge deck, and greater stress unevenness of the asphalt concrete pavement layer on the deck. The project has an average daily natural traffic volume of 45,000, which belongs to the heavy traffic and tropical marine type. The daily average maximum temperature is 30.7 degrees, and the average minimum temperature is 10.8 degrees. The extreme maximum temperature in the past 50 years is 38.7 degrees, and the extreme minimum temperature is -1.0 degrees, the daily maximum The rainfall is 503.3mm, and the relative humidity is about 85%. From the perspective of climatic conditions, the local temperature and humidity are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com