A kind of porous ceramics, light-weight high-strength ceramic plates fired rapidly and preparation method thereof

A technology of porous ceramics and ceramic plates, applied in the field of architectural ceramics, can solve the problems of difficulty in controlling high-temperature foaming, fuel consumption, etc., and achieve the effects of ensuring product flatness, reducing emissions, and shortening the firing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

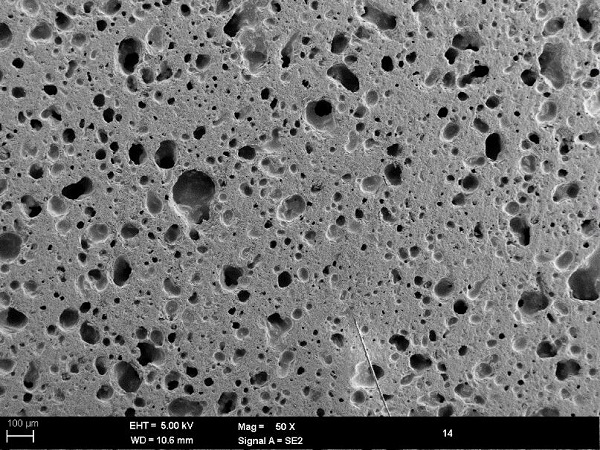

Embodiment 1

[0037] This embodiment is a light-weight and high-strength ceramic plate of rapid firing according to the present invention, and the preparation method of the light-weight and high-strength ceramic plate of rapid firing comprises the following steps:

[0038] (1) According to the formula of porous ceramics, weigh each raw material;

[0039] (2) In the raw material of porous ceramics described in step (1), add silicon carbide foaming agent (addition accounts for 0.1% of the total weight of porous ceramic raw materials) and water glass (addition accounts for 0.7% of the total weight of porous ceramic raw materials) %); after mixing evenly, wet ball milling was carried out with water for 4 hours to obtain ceramic slurry, which was spray-dried at a flow rate of 46 s to obtain a sieve residue of 0.8% on a 250-mesh sieve and a moisture content of 6.4 %ceramic powder;

[0040] (3) Press the ceramic powder obtained in step (2) into a ceramic body, and then sequentially dry, glaze, an...

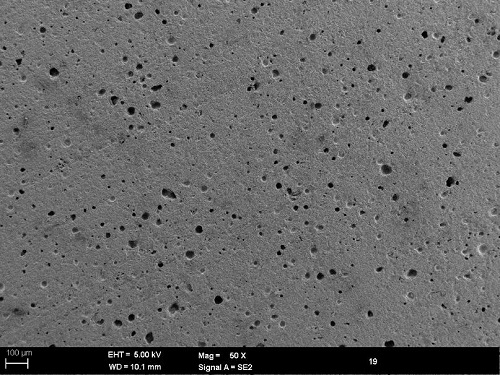

Embodiment 2

[0044] This embodiment is a light-weight and high-strength ceramic plate of rapid firing according to the present invention, and the preparation method of the light-weight and high-strength ceramic plate of rapid firing comprises the following steps:

[0045] (1) According to the formula of porous ceramics, weigh each raw material;

[0046] (2) In the raw material of porous ceramics described in step (1), add high-temperature blowing agent carbon black (addition accounts for 1% of porous ceramic raw material gross weight) and dispersant sodium tripolyphosphate (addition accounts for porous ceramic 1.8% of the total weight of raw materials), after mixing evenly, wet ball milling was carried out with water for 4 hours to obtain ceramic slurry, and the ceramic slurry was spray-dried at a flow rate of 40 seconds to obtain a sieve residue of 250 mesh sieves less than 1.0 %, ceramic powder with a moisture content of 5%;

[0047] (3) Pressing the ceramic powder obtained in step (2) ...

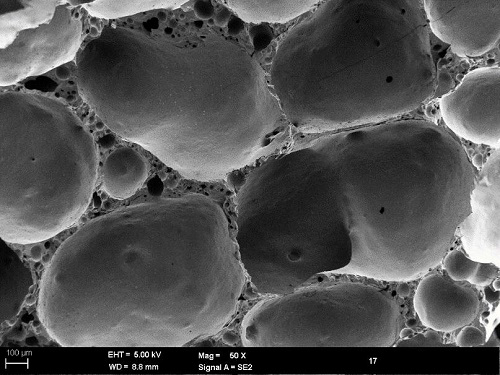

Embodiment 3

[0051] This embodiment is a light-weight and high-strength ceramic plate of rapid firing according to the present invention, and the preparation method of the light-weight and high-strength ceramic plate of rapid firing comprises the following steps:

[0052] (1) According to the formula of porous ceramics, weigh each raw material;

[0053] (2) In the porous ceramic raw material described in step (1), add polishing slag containing silicon carbide (the addition accounts for 10% of the total weight of the porous ceramic raw material) and dispersant sodium tripolyphosphate (the addition accounts for 10% of the porous ceramic raw material). 1% of the total weight of ceramic raw materials), after mixing evenly, wet ball milling was carried out with water for 6 hours to obtain ceramic slurry, and the ceramic slurry was spray-dried at a flow rate of 60 seconds to obtain a sieve residue of 250 mesh sieve less than 1.0%, moisture content 8% ceramic powder;

[0054] (3) Press the ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com