Method for applying membrane oxygen enrichment technology in roller kiln

A roller kiln and oxygen-enriched technology, applied in the field of ceramic production, can solve the problems of prolonged firing cycle, large lateral temperature difference in the kiln, and reduced combustion-supporting air inlet pressure, so as to achieve reduced flue gas emissions and uniform lateral furnace heat, and the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

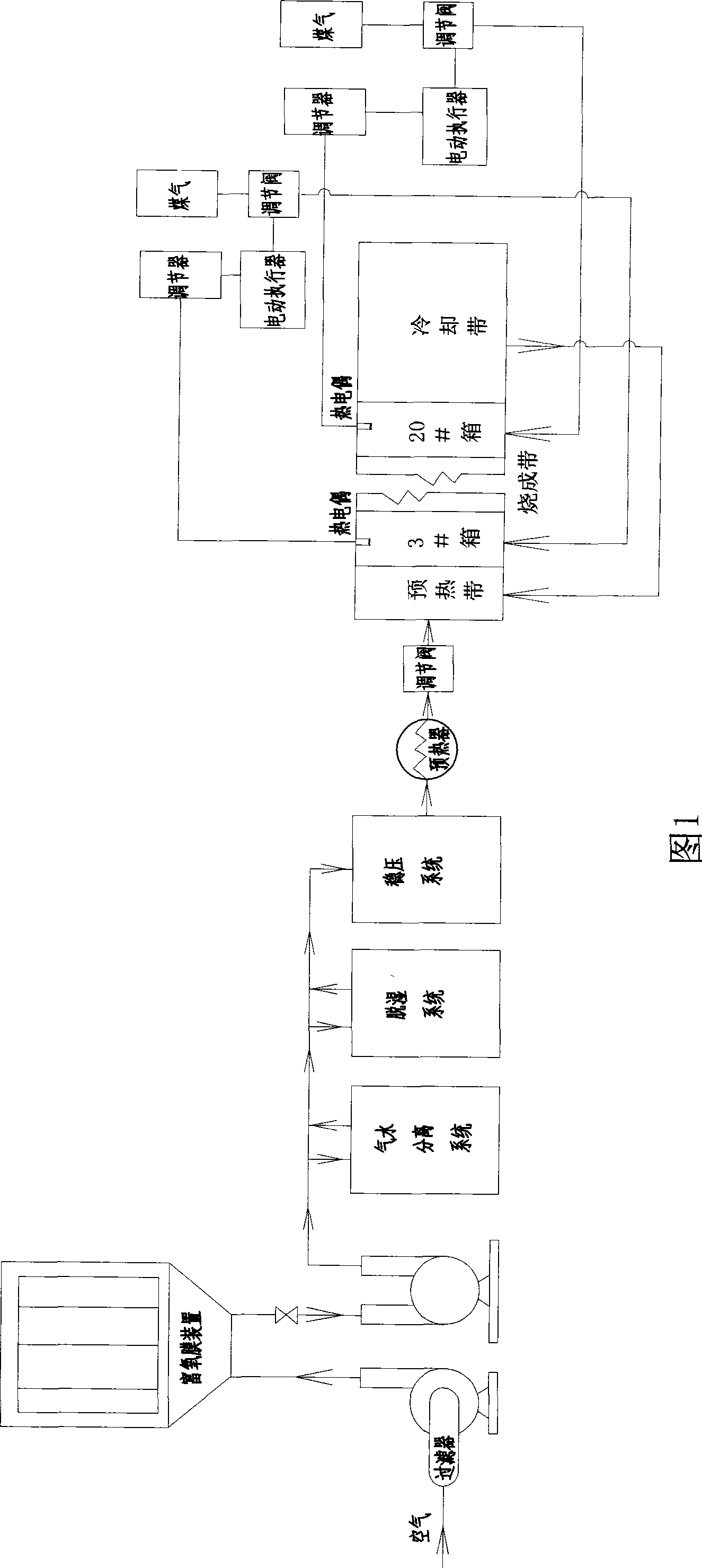

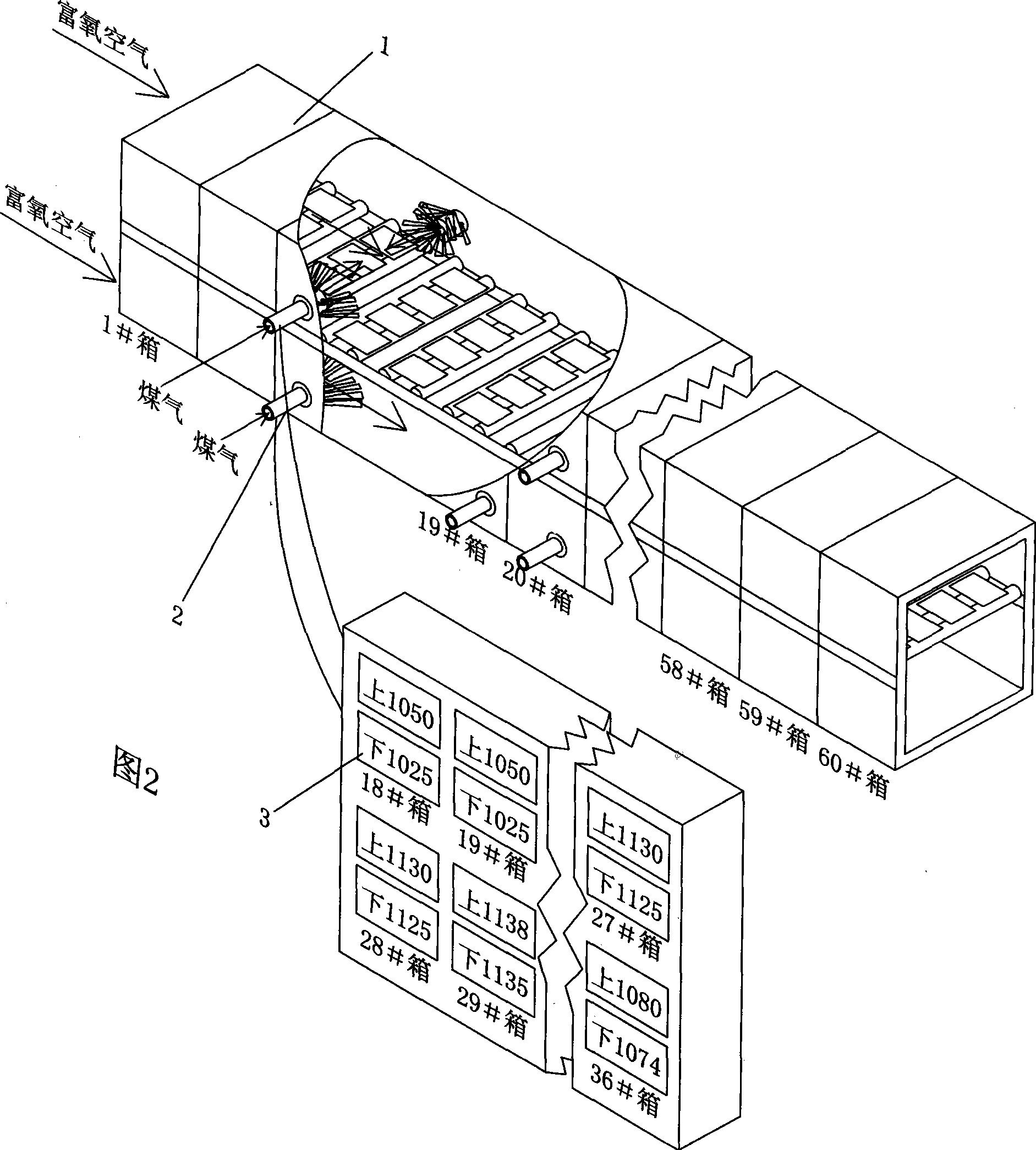

Embodiment 1

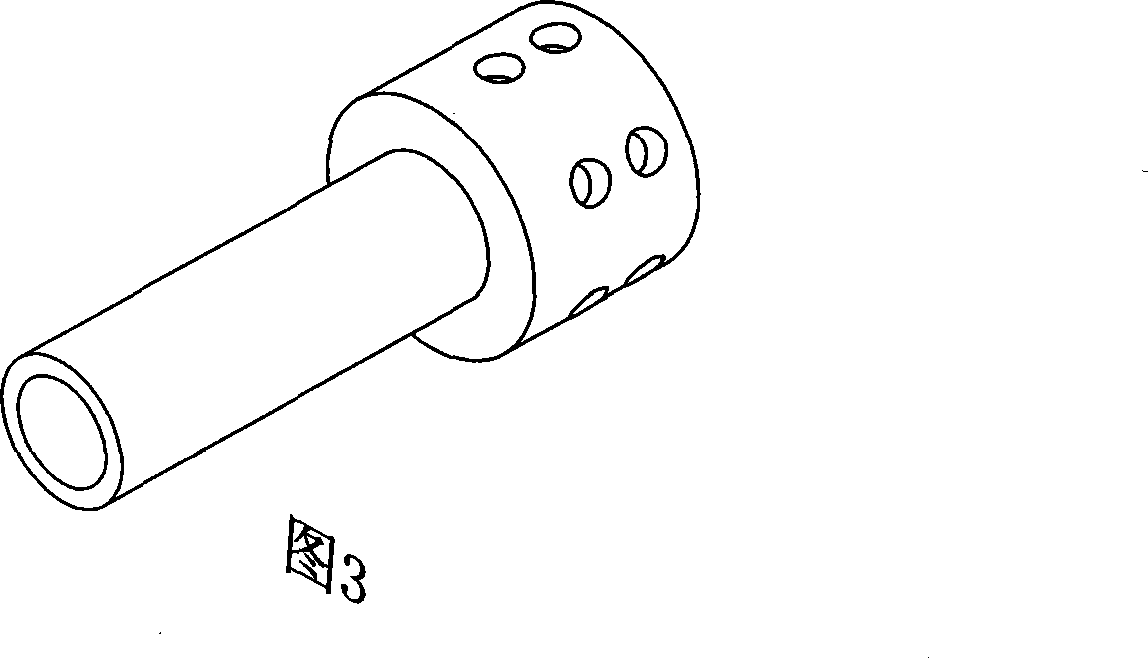

[0018] Take the 130-meter-long roller kiln of Yimen Yida Ceramics Co., Ltd. as an example. The roller kiln is divided into 60 sections, each section is 2.16 meters long. Oxygen-enriched air with an oxygen concentration of 32% is prepared under the action of the air pump, and the oxygen-enriched air is sent to the gas-water separation system, the dehumidification system, and enters the pressure stabilization system, and finally preheated by the heater, and passed through the oxygen-enriched nozzle along the roller The road kiln is sent longitudinally to the upper and lower layers of the fired ceramic bricks; gas is used as fuel, and the gas intake direction is perpendicular to the oxygen-enriched air intake direction, and the gas uses divergent gas burners distributed on both sides of the kiln body (1) Spray into the kiln at high speed, use thermocouples distributed in different boxes to detect the temperature in the kiln at any time, and transmit the signal to the regulator (3)...

Embodiment 2

[0028] Taking the 97-meter-long roller kiln of Yimen Yida Ceramics Co., Ltd. as an example, the specific application method of the membrane method oxygen enrichment technology is the same as that in Example 1. After the method of the present invention is used to realize membrane method oxygen enrichment, the temperature of each place in the kiln is as follows:

[0029]

[0030] The technical indicators and data are as follows:

[0031] Oxygen-enriched air flow: 1200NM 3 / h, output: 5500m 2 / day; the minimum inlet pressure of oxygen-enriched air is reduced to 0.2MPa, and the gas consumption is 5100m 3 / day, the size deviation of fired products is less than 1 silk.

[0032] Before adopting the non-membrane oxygen enrichment technology, the temperature of each place in the kiln is as follows:

[0033]

[0034] The technical indicators and data are as follows:

[0035] Combustion air flow: 4800NM 3 / h, output: 3500m 2 / day; the minimum intake pressure of combustion air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com