Insertion-type vortex air compressor

An air compressor, plug-in technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of vibration, high noise, power loss, the overall structure is not compact enough, and achieve low vibration and no power. Loss, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

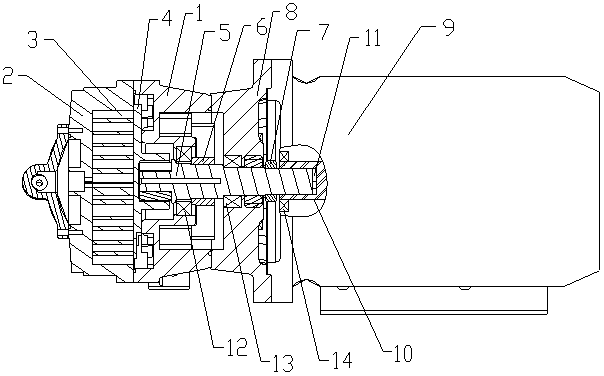

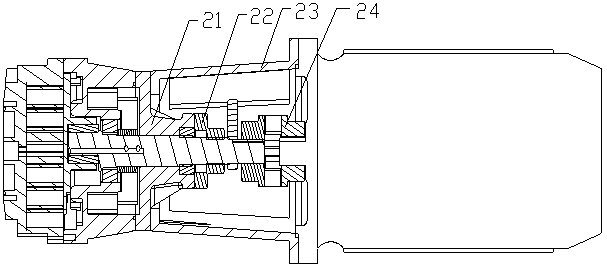

[0013] a kind of like figure 1 The plug-in scroll air compressor shown includes a casing 1 and a static disk 2 installed in the casing 1, a moving disk 3, an Oldham slip ring 4, a crankshaft 5 for driving the moving disk 2, and a moving disk counterweight 6 , balance weight 7, flange 8, motor 9 and motor main shaft 10 connected with flange 8, the connection end of described motor main shaft 10 and crankshaft 5 is hollow to form cavity 11, and the inner diameter of described cavity 11 and crankshaft 5 are matched in size, the crankshaft 5 extends into the motor main shaft 10, the coaxiality error between the crankshaft 5 and the motor main shaft 10 is less than 0.015mm, the size of the flange 8 becomes smaller, the crankshaft 5 is shortened, and the rear cover 21, The end cover 22 and the shaft coupling 24 have a compact structure. Sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com