Scatheless onion peeling machine

A peeling machine and non-injury technology, which is applied in the fields of application, food processing, food science, etc., can solve the problems of unfavorable onion storage and transportation, leftover knife wounds on onions, easy deterioration and rot, etc., and achieve low maintenance costs, low cost, and reduced maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

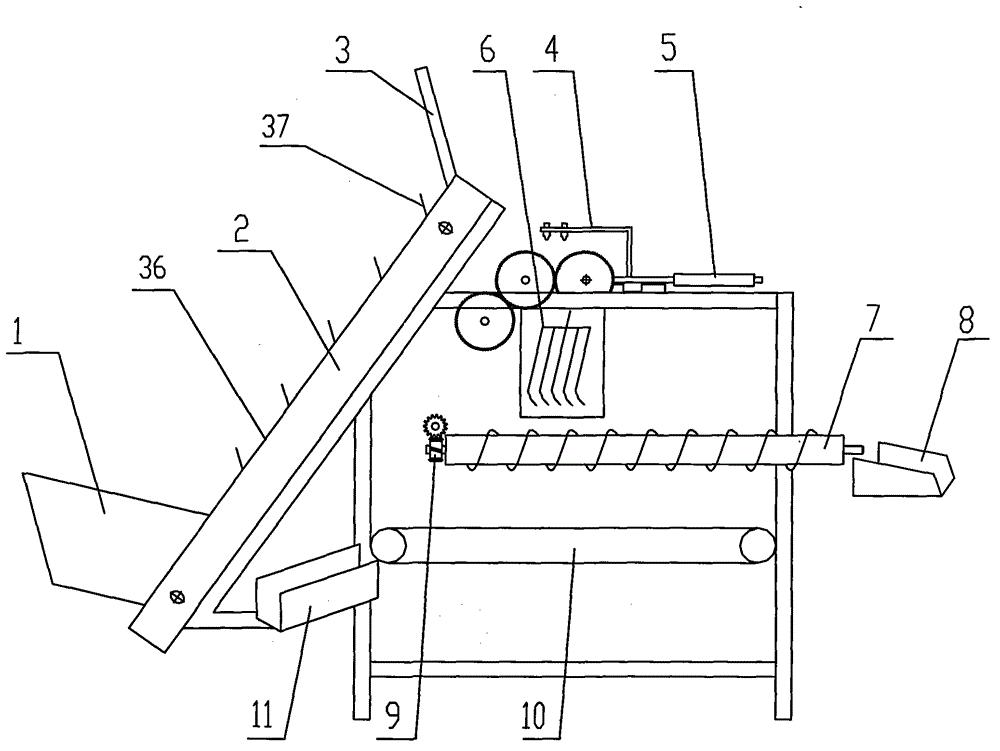

[0016] A kind of non-damaging onion peeling machine, comprises upper hopper 1, feeding device 2, peeling device 3, blowing skin device 5, material receiving device, waste conveyor belt 10 and waste hopper 11, wherein preferred feeding device 2 is to improve Conveyor belt, its bottom end is connected upper hopper 1, and the top is placed on the leather blowing device 5 tops, and wherein, every certain distance is provided with feeding plate 37 on the belt 36.

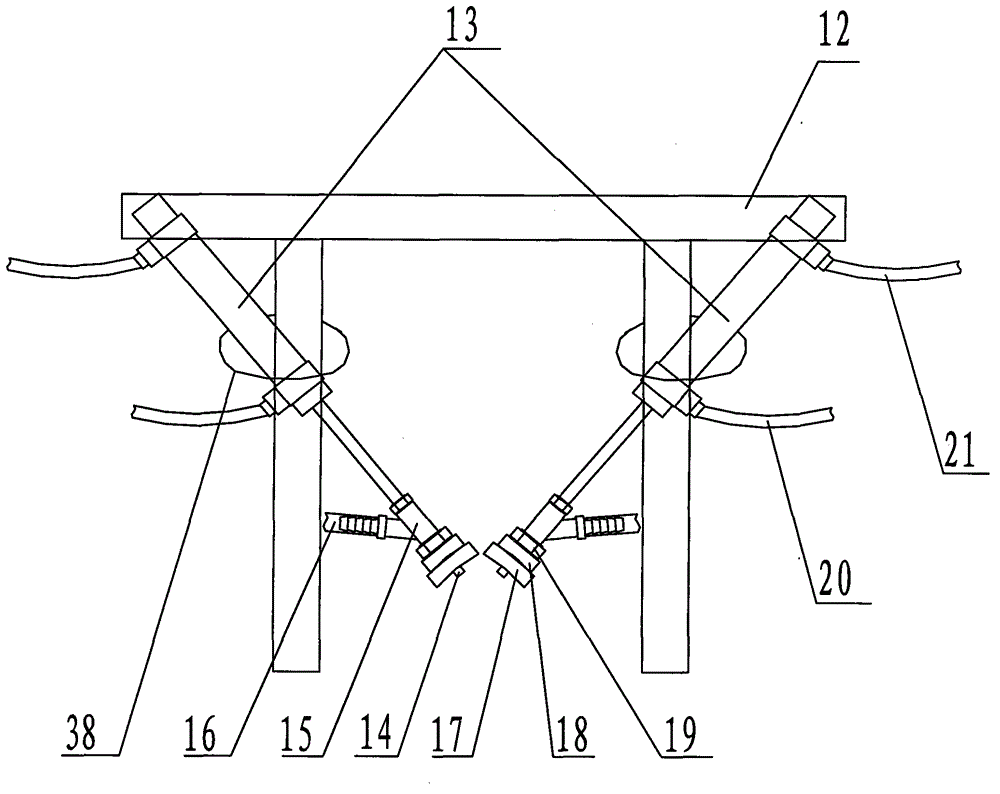

[0017] The skinning device 3 is arranged on the top of the feeding device, and includes a bracket 12, and two skinning guns installed at an angle on the bracket 12. The rear end of the skinning gun is a telescopic cylinder 13, and the front end is a skinning gas Mouth 14, also be provided with the skin trachea 16 on the gas nozzle 14 of chemical skin.

[0018] Among them, the front end of the optimally designed chemical gas nozzle 14 is a needle-shaped gas nozzle 14, and an adjustment nut 17, a rubber pad 18 and a lock n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com