Processing method of thin aluminum piece

A processing method and technology of aluminum parts, which is applied in the field of processing thin aluminum parts, can solve the problems of low qualified product rate and poor processing stability of piston cover plate, and achieve the effect of high quality stability and improved qualified product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

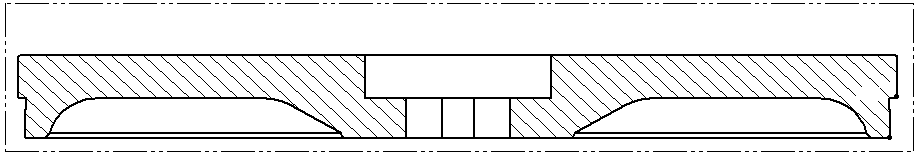

[0018] A processing method for thin aluminum parts, such as figure 1 The thin aluminum part shown has a large cylindrical section and a small cylindrical section connected with the large cylindrical section; the turning process is rough turning the outer circle of the large end, the outer circle of the small end, and the end face of the small end; the semi-finished turning of the outer circle of the large end, the small end End outer circle, which includes the following steps:

[0019] A. Keep the thin aluminum part 1 of the semi-finishing car, which is located at the chuck position on the outer circle side of the big end, and remove the workpiece;

[0020] B, placing the thin aluminum part 1 completed in step A for 3 days;

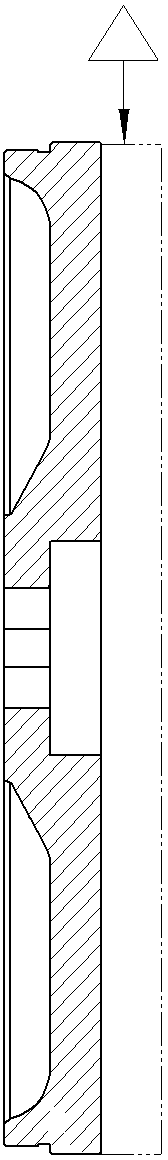

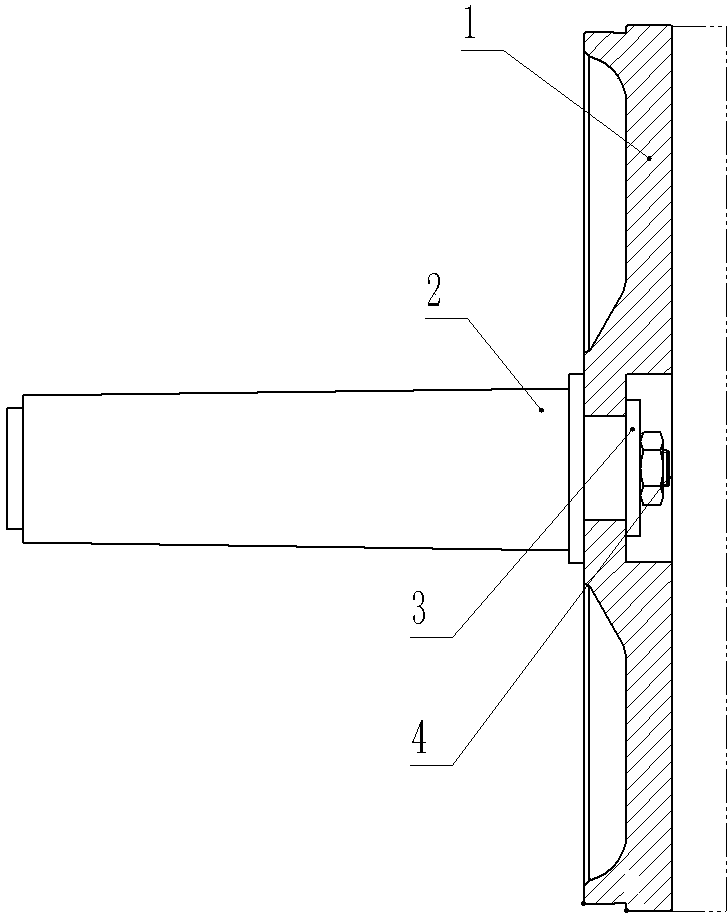

[0021] C. Use the three-jaw chuck to clamp the thin aluminum part 1 at the chuck position on the outer circle side of the big end, such as figure 2 As shown, finish turning the outer circle of the large end, the outer circle of the small end, and the e...

Embodiment 2

[0027] B. Place the thin aluminum part 1 completed in step A for 5 days; other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com